Composite foundry sand material for preventing foundry sand sintering in steel cast casting and preparation method thereof

A composite molding and molding sand technology, which is used in casting molding equipment, casting molds, cores, etc., can solve the problems of local molding sand overheating, not too serious, anti-sticking sand, anti-sintering, low labor productivity of workers, and poor production conditions. The effect of enriching, improving labor productivity and improving the quality of castings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

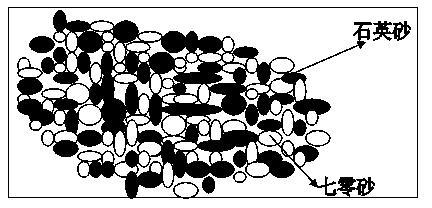

Embodiment 1

[0009] Embodiment 1: A kind of composite molding sand material that can prevent molding sand from sintering in foundry production, its percentage by weight is: quartz sand 40%, seven zero sand 60%, furan resin 1.2%, curing agent accounts for furan resin ratio 30~50% . The curing agent is benzenesulfonic acid; the quartz sand can be replaced by chrome ore sand, zircon ore sand, pearl sand, forsterite sand, and the binder can be replaced by other resin or water glass.

Embodiment 1-1

[0010] Example 1-1: On the basis of Example 1, quartz sand is 45%, Qiling sand is 55%, furan resin is 1.2%, and the curing agent accounts for 50% of the furan resin ratio.

Embodiment 1-2

[0011] Example 1-2: On the basis of Example 1, quartz sand 50%, Qiling sand 50%, furan resin 1.2%, curing agent accounted for 50% of furan resin.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com