Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Reduce waste rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

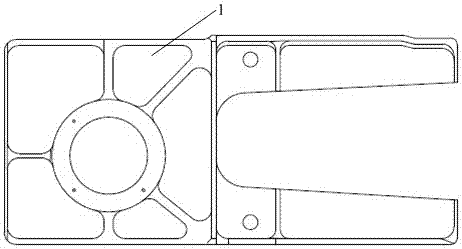

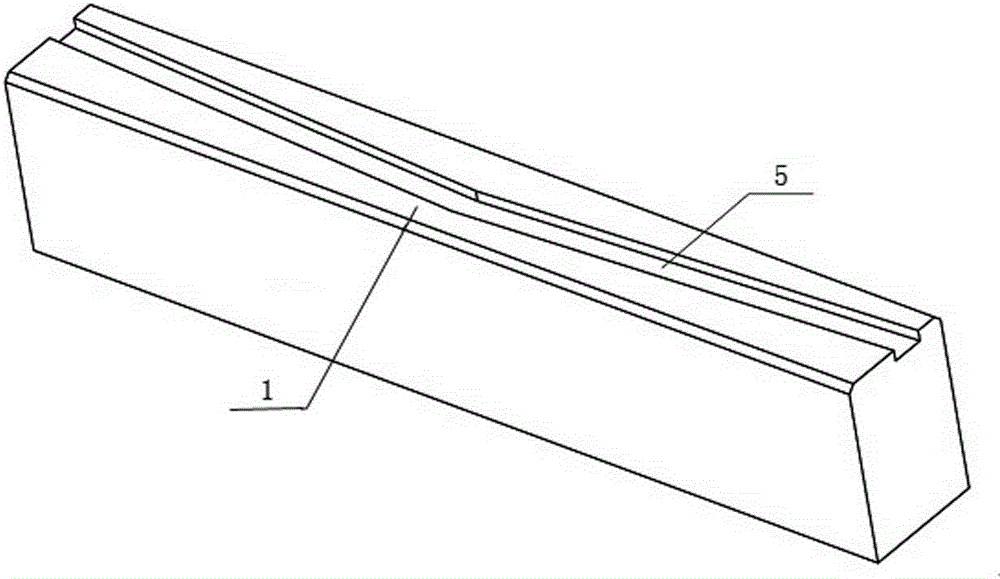

Machining technology of open structure part

The invention discloses a machining technology of an open structure part. The technical problems that open parts are deformed, and surface roughness and the wall thickness size are hard to guarantee can be effectively solved. Technological patches are designed according to the structural feature of the part; the open part of the part is cut open, and threads are tapped in the positions, in an opening, of the technological patches. The machining mode of artificially connecting the open part of the part through the technological patches and a connecting steel plate is adopted, so that the percent of pass and surface machining quality of the part are improved; the reject rate of the part is remarkably reduced; manufacturing cost is saved, and machining efficiency is improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

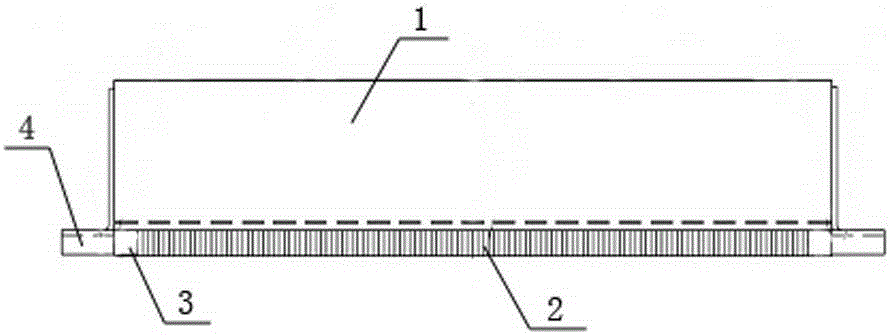

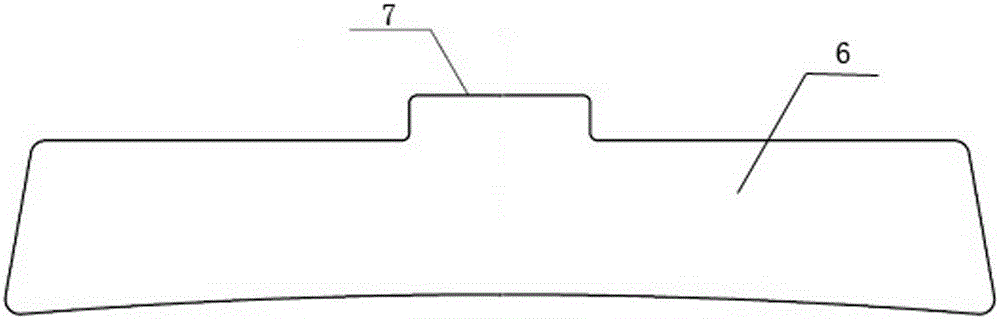

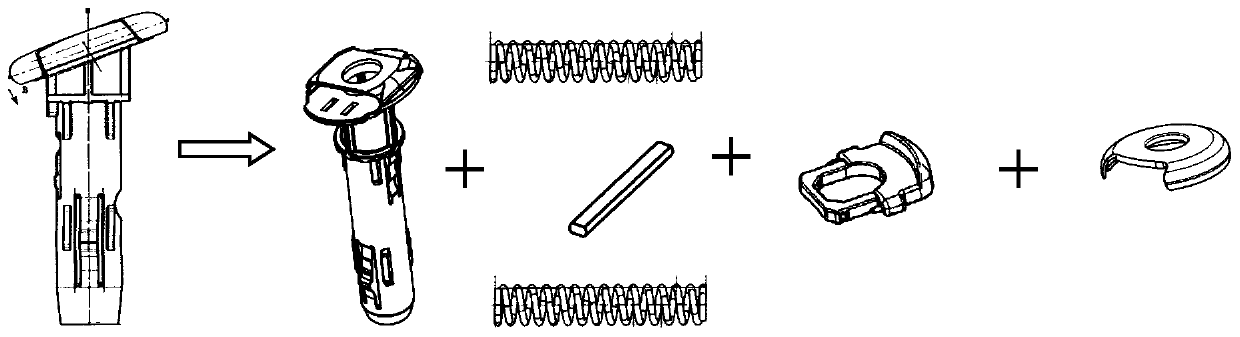

Terminal local shielding method

InactiveCN106329288AIncrease productivityReduce waste rateContact member manufacturingEngineeringElectroplating

The invention relates to a terminal local shielding method, and the method comprises the following steps: S1, preprocessing: enabling a base film for forming a terminal to be placed in a base film groove, dragging the base film forwards through a material dragging mechanism, and carrying out the dust removal of the surface of the base film through a dust removing device; S2, punch forming: leading the base film into a punch forming die, enabling the punch forming fie to carry out the punch forming of the base film, and obtaining the terminal; S3, film pasting: enabling a part, which does not need to be electroplated, of the terminal to be pasted with an insulating film; S4, inspection: detecting the film pasting quality of the terminal; S5, electroplating: enabling the terminal to be placed into an electroplating groove, and carrying out the plating of a conductive film on the surface of the terminal; S6, insulating film removing: peeling off the insulating film on the terminal plated with the conductive film, and obtaining a terminal product. The method is advantageous in that the method is high in production efficiency, and is low in reject percentage.

Owner:CHENGDU HOMIN TECH

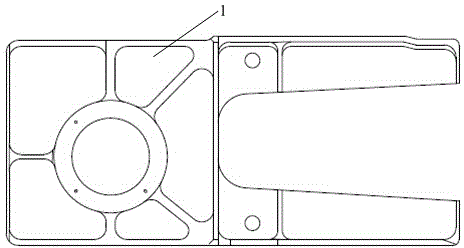

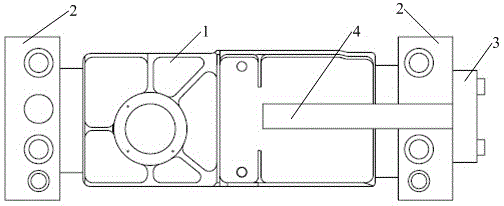

Machining technique for component of open-type structure

InactiveCN108326524AImprove pass rate and surface processing qualityReduce waste rateEngineeringHeat treated

The invention discloses a machining technique for a component of an open-type structure. The machining technique is characterized in that the machining technique comprises the following steps that (1)rough machining is conducted, specifically, the front face and the back face of the component are roughly machined, a main body blank material of the component is removed, the component outline is machined, the technical allowance of the component is reserved by 3 mm after rough machining for material removing during semi-finish machining and finish machining; (2) the roughly-machined component is subjected to heat treatment; and (3) the open-type structure part of the component is cut up, specifically, after heat treatment of the component is completed, the open-type structure part of the component is cut up in order that an area for stress releasing is manufactured, and stress inside the component is guided to be released in the cut-up area. The machining technique has the following advantages that the technical problems that the open part of the component is deformed, and the surface roughness and the wall thickness size are hard to guarantee can be effectively solved, the qualified rate of the component is increased, the surface machining quality of the component is improved, the rejection rate and the defective rate of the component are decreased obviously, the manufacturingcost is saved, and the machining efficiency is improved.

Owner:XUZHOU JINCHENG PLANET TRANSMISSION

Preparation method of sealant 180-degree peel strength sample

InactiveCN107121315AReduce waste rateGuaranteed test cyclePreparing sample for investigationUsing mechanical meansSealantMaterials science

The invention relates to a simple method for preparation of a 180-degree peel strength sample during sealant 180-degree peel strength testing after air aging. By using a diluted sealant as a protective coating, the sealant 180-degree peel strength sample prepared according to HB5249-1993 'Room temperature vulcanization sealant 180-degree peel strength test method' will not be aged or brittle after air aging, and the rate of waste samples is reduced.

Owner:SHAANXI AIRCRAFT CORPORATION

Grifola frondosa three-stage culture production method

InactiveCN104145711AReduce waste rateImprove inoculation efficiencyHorticultureBiotechnologyWheat grain

The invention provides a grifola frondosa three-stage culture production method. The grifola frondosa three-stage culture production method comprises the steps of first-stage culture production, second-stage culture production, third-stage culture production, culture package production, inoculation and cultivation, bud forcing and mushroom cultivation. The third-stage culture production comprises the steps of obtaining of culture medium recipes, production of the culture media, bagging, sterilization, inoculation, cultivation of the culture and raising of the culture. The grifola frondosa three-stage culture production method is characterized in that the culture medium recipes include the wood strip culture medium recipe and the wheat grain culture medium recipe, and the production of the culture media comprises production of a wood strip culture medium and production of a wheat grain culture medium. Compared with a wood chip culture, the culture obtained through the grifola frondosa three-stage culture production method has the advantages that inoculation efficiency is 5-8 percent higher, the maximum culture growth distance is 50-100 percent shorter, the cultivation efficiency is 20-60 percent higher, each culture bag is consistent in mycelial age vertically, so that nutrients are released in a centralized mode, and the first-batch mushroom yield can be increased by 15-30 percent. Compared with liquid culture, the culture obtained through the grifola frondosa three-stage culture production method is applicable to existing culture production and detection, inoculation equipment and technicians in China, and can reduce the cultivation infection rate by 2-5 percent.

Owner:HUNAN RES INST OF EDIBLE FUNGI +1

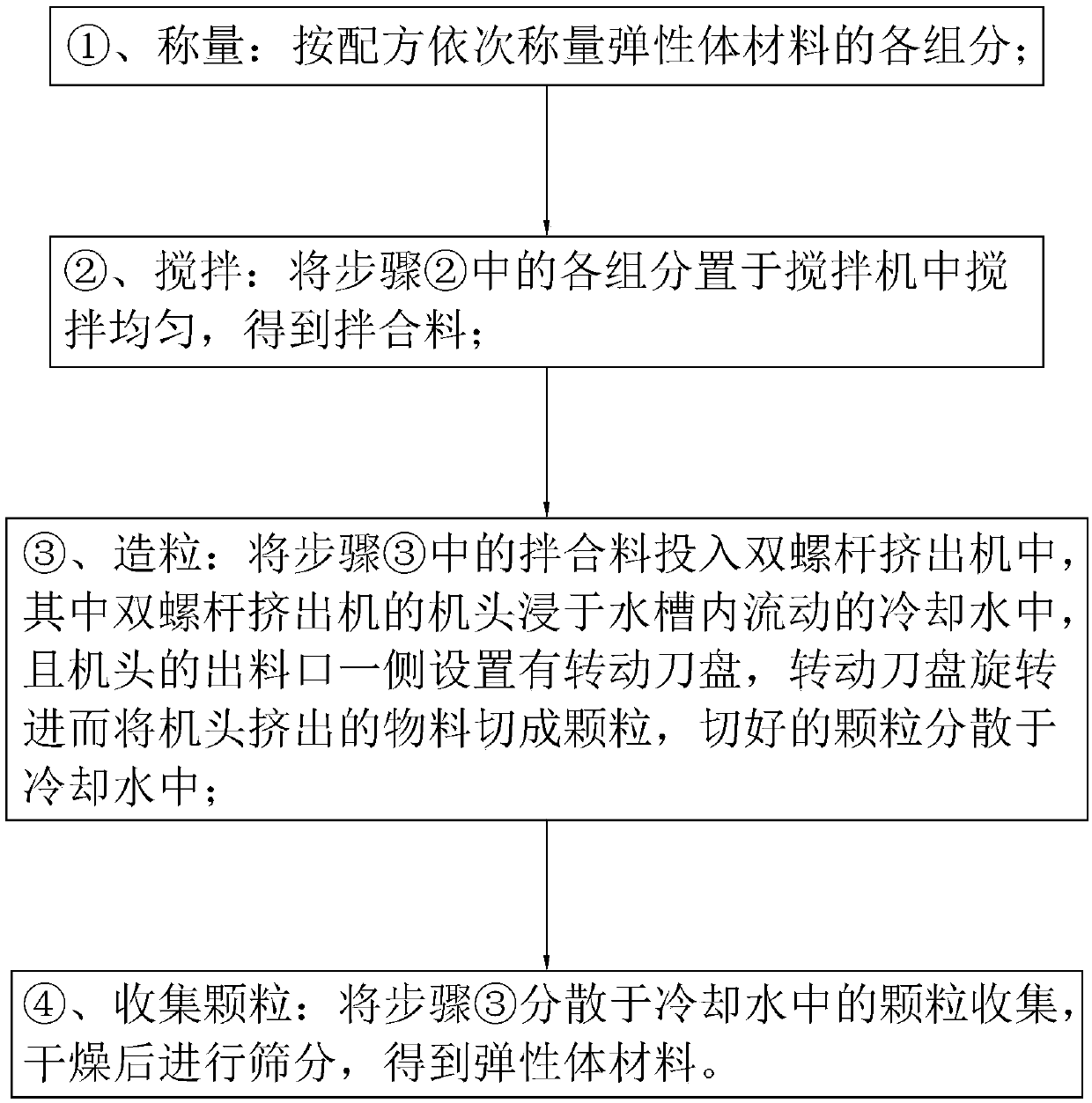

Preparation method of elastomer material for plastic runway

InactiveCN109551656AReduce manufacturing process stepsIncrease productivityElastomerPolymer chemistry

The invention discloses a preparation method of an elastomer material for a plastic runway and relates to the technical field of high polymer materials. The preparation method comprises the followingoperation steps that (1) all components of the elastomer material are sequentially weighed according to a formula; (2) all the components in the step (1) are stirred to obtain a mixture; (3) the mixture in the step (2) is placed in a double-screw extruder, and materials are extruded in cooling water as particle cutting is conducted; and (4) particles in the cooling water are collected, dried and screened, and thus the elastomer material is obtained. Particle cutting can be conducted while the double-screw extruder extrudes the materials, the production efficiency of the elastomer material is improved, and the preparation method has the advantages of easy and convenient operation and low waste residue rate.

Owner:道一高分子聚合物(宁波)有限公司

Manufacture technology of frost shiitake mushroom spawns

InactiveCN107488599AImprove survival rateAvoid reinfectionFungiMicrobiological testing/measurementBiotechnologyManufacturing technology

The invention discloses a production process of velvet mushroom strains, comprising the following steps: making test tube culture medium, transferring test tube species, selecting test tube species, making secondary strains, making plate culture medium, plate transfer, and plate species selection , Three-level strain production, shake flask culture medium preparation, shake flask seed inoculation, shake flask seed cultivation, shake flask seed selection, fermenter production, sterilization, empty barrel sampling, fermenter inoculation, fermenter seed cultivation and observation, Bacteria liquid sampling test, seeding, microscopic examination, inoculation pipeline sterilization, inoculation. The invention can improve the mycelium viability, prevent the infection of miscellaneous bacteria again after inoculation, increase the growth factors such as vitamin C, vitamin D, folic acid, etc., and effectively improve the efficiency of bacteria cultivation, and the peach wood powder with special fragrance can increase the taste of cream mushroom And flavor, improve its food value.

Owner:西充星河生物科技有限公司

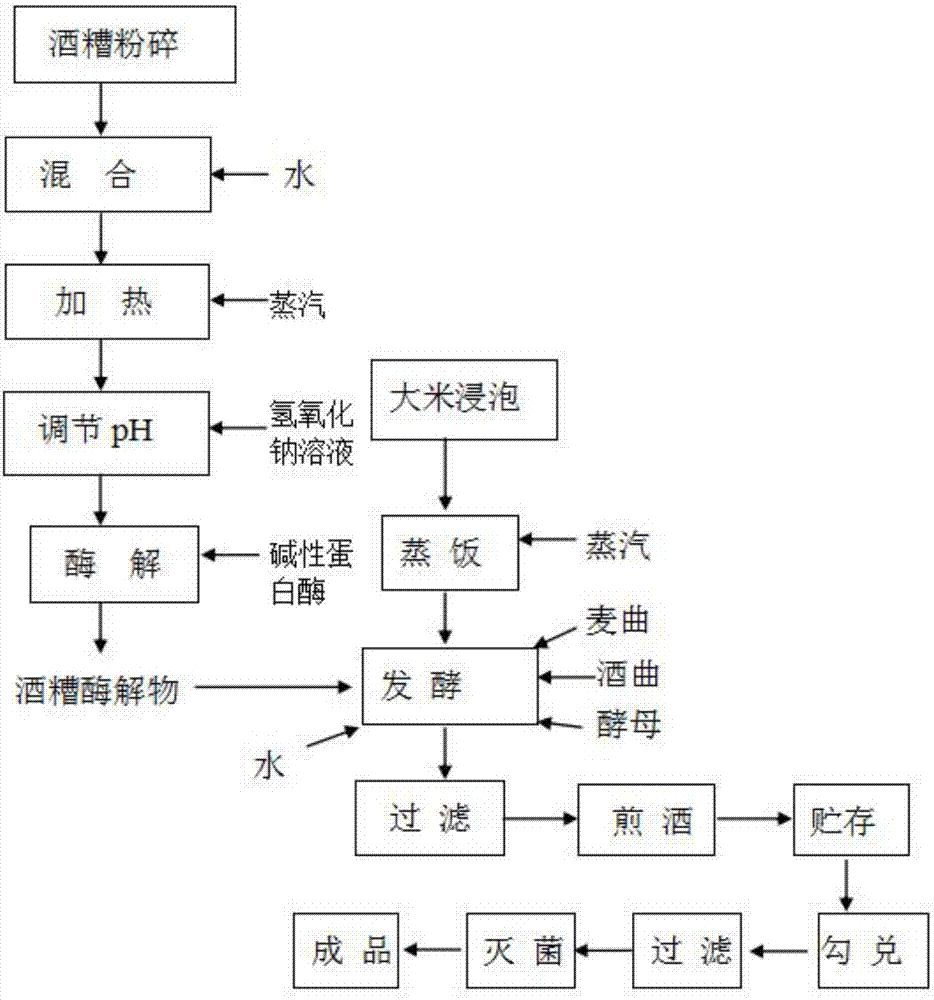

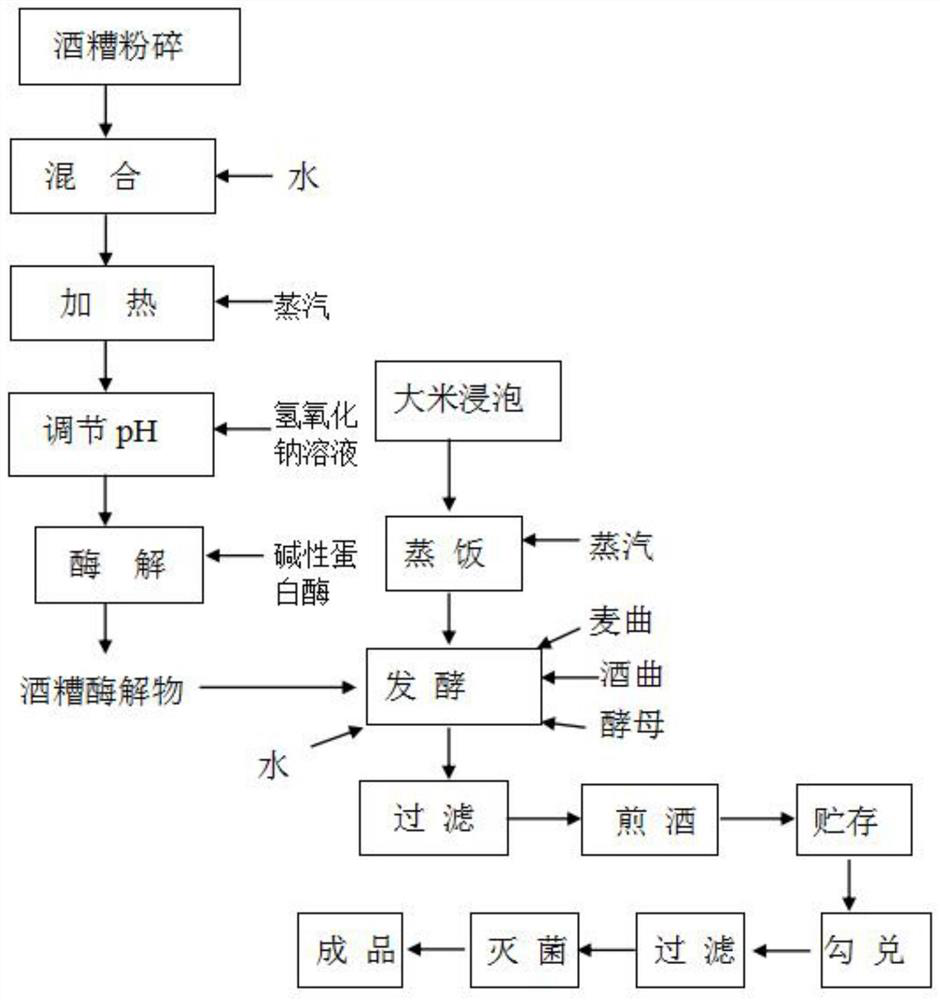

Method for producing cooking wine with high amino acid nitrogen content by using yellow wine stillage

The invention discloses a method for producing cooking wine with high amino acid nitrogen content by using yellow wine stillage. The method at least comprises the following steps of: mixing pretreated stillage with alkaline protease and performing enzymolysis to obtain stillage enzymatic hydrolysate; adding the prepared stillage enzymatic hydrolysate into steamed rice; adding wheat koji, distiller's yeast and active dry yeast; and performing fermentation. According to the method disclosed by the invention, the stillage enzymatic hydrolysate is obtained from the cooking wine stillage by pulverization, heating and protease treatment, the stillage enzymatic hydrolyzate is added into the rice, the fermentation production of the cooking wine is performed, the content of the amino acid nitrogen in the cooking wine is high, and the delicate flavor of the cooking wine is rich; and in addition, when the cooking wine is produced by using the method, resource utilization of the cooking wine stillage can be achieved, the production cost is reduced and the generation of ''waste residues'' in the production process of the cooking wine is reduced.

Owner:安徽海神黄酒集团有限公司

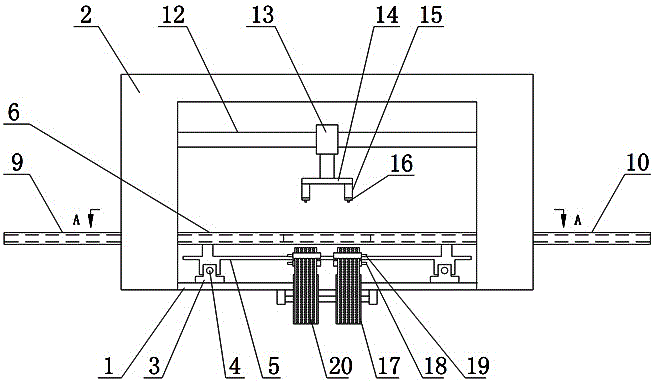

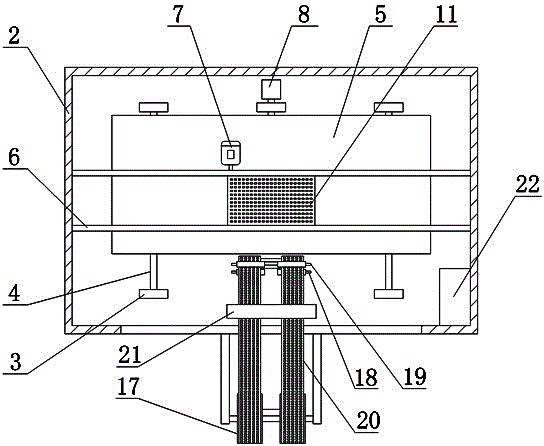

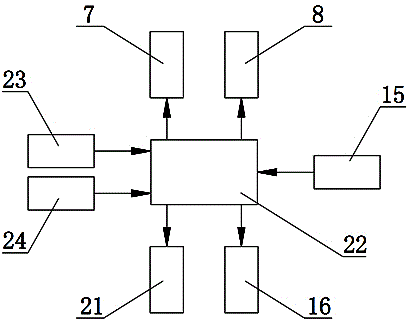

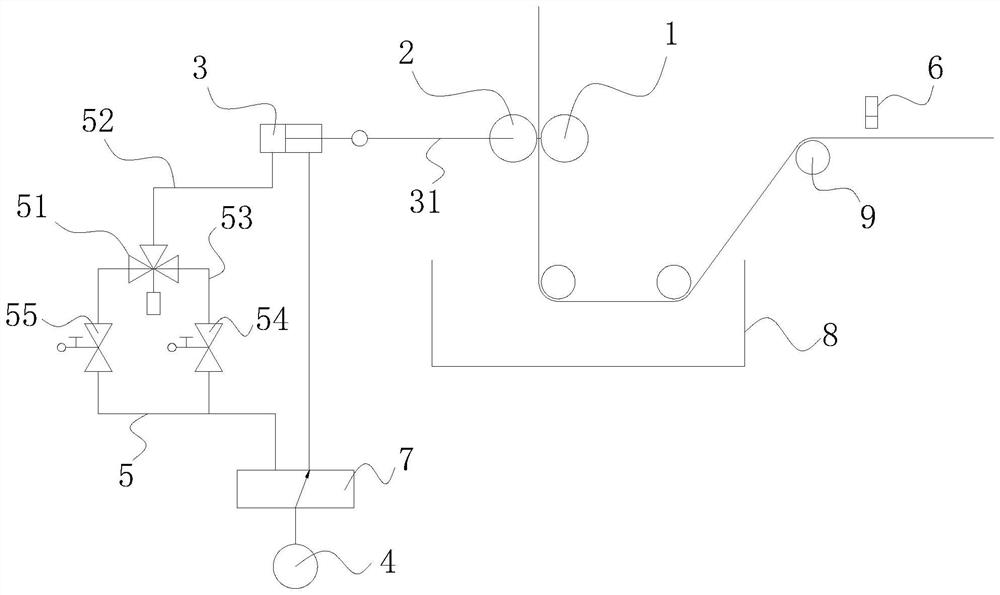

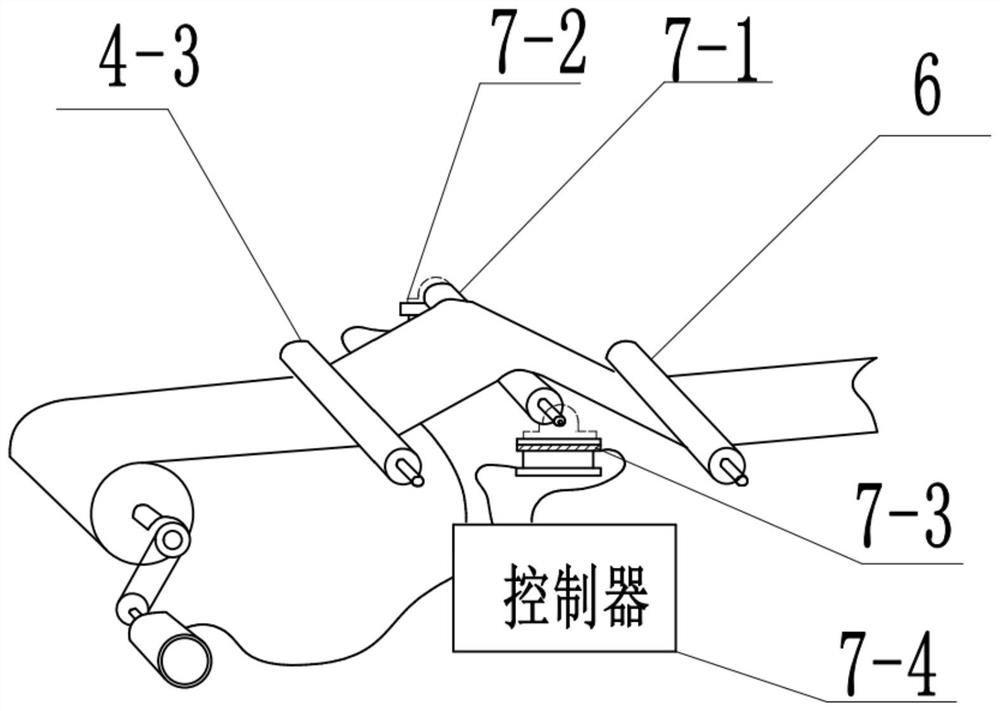

High-speed precision film attaching equipment

ActiveCN106240898AReduce movement distanceShort timeWrapping material feeding apparatusPackaging automatic controlEngineeringCcd camera

The invention relates to high-speed precision film attaching equipment. The high-speed precision film attaching equipment comprises a base, a feeding mechanism, a film delivering mechanism, a film suction mechanism and a controller. The feeding mechanism is arranged in the length direction of the base. The film suction mechanism is mounted on the base and located above the feeding mechanism. The film delivering mechanism is arranged at one side of the base. The feeding mechanism comprises movable supports, a longitudinal movement plate and a transverse movement sliding bracket. The two movable supports are symmetrically fixed to the base. A longitudinal movement guide rail is mounted on each movable support. The longitudinal movement plate is mounted on the longitudinal movement guide rails in a sliding-fit manner. The transverse movement sliding bracket is fixed to the longitudinal movement plate and internally provided with a material containing box in a matched manner. The film delivering mechanism comprises film delivering rollers, film carrying belts and a dragging mechanism. The film suction mechanism comprises a movable support, a slide block, CCD cameras and material suction air cylinders. The controller is connected with a transverse movement servo driving mechanism, a longitudinal movement servo driving mechanism, the CCD cameras, the material suction air cylinders and a material dragging mechanism. The high-speed precision film attaching equipment has the beneficial effects of being high in film attaching efficiency and precision.

Owner:CHENGDU HOMIN TECH

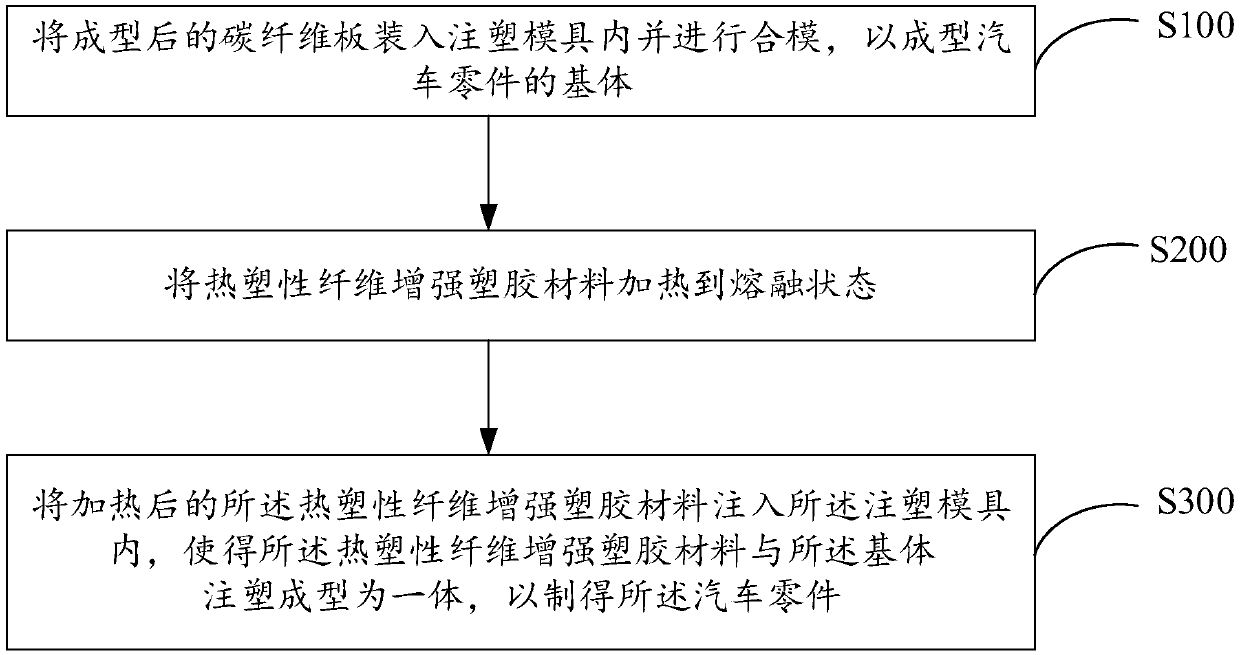

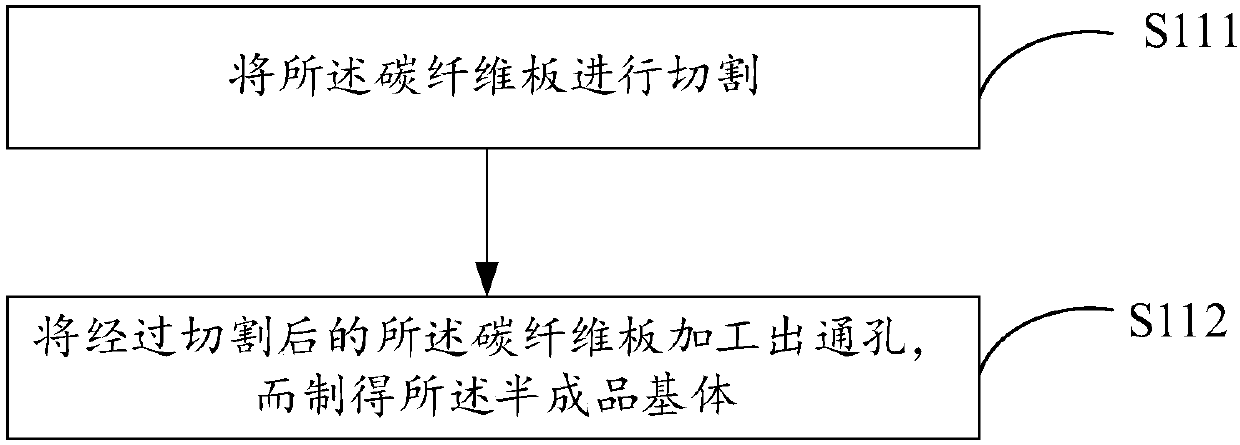

Automobile part and manufacturing method thereof

The invention discloses an automobile part and a manufacturing method thereof. The manufacturing method for the automobile part comprises the following steps: a step S100 of filling a formed carbon fiberboard into an injection mould and performing mould closing, thereby molding a base body of the automobile part; step S200 of heating a thermoplastic fiber reinforced plastic material to a molten state; and step S300 of injecting the heated thermoplastic fiber reinforced plastic material into the injection mould, thereby integrally molding the thermoplastic fiber reinforced plastic material andthe base body to manufacture the automobile part. According to the technical scheme adopted by the invention, when strength of the automobile part is guaranteed, a complex structure is conveniently manufactured.

Owner:SHENZHEN SILVER BASIS TECH

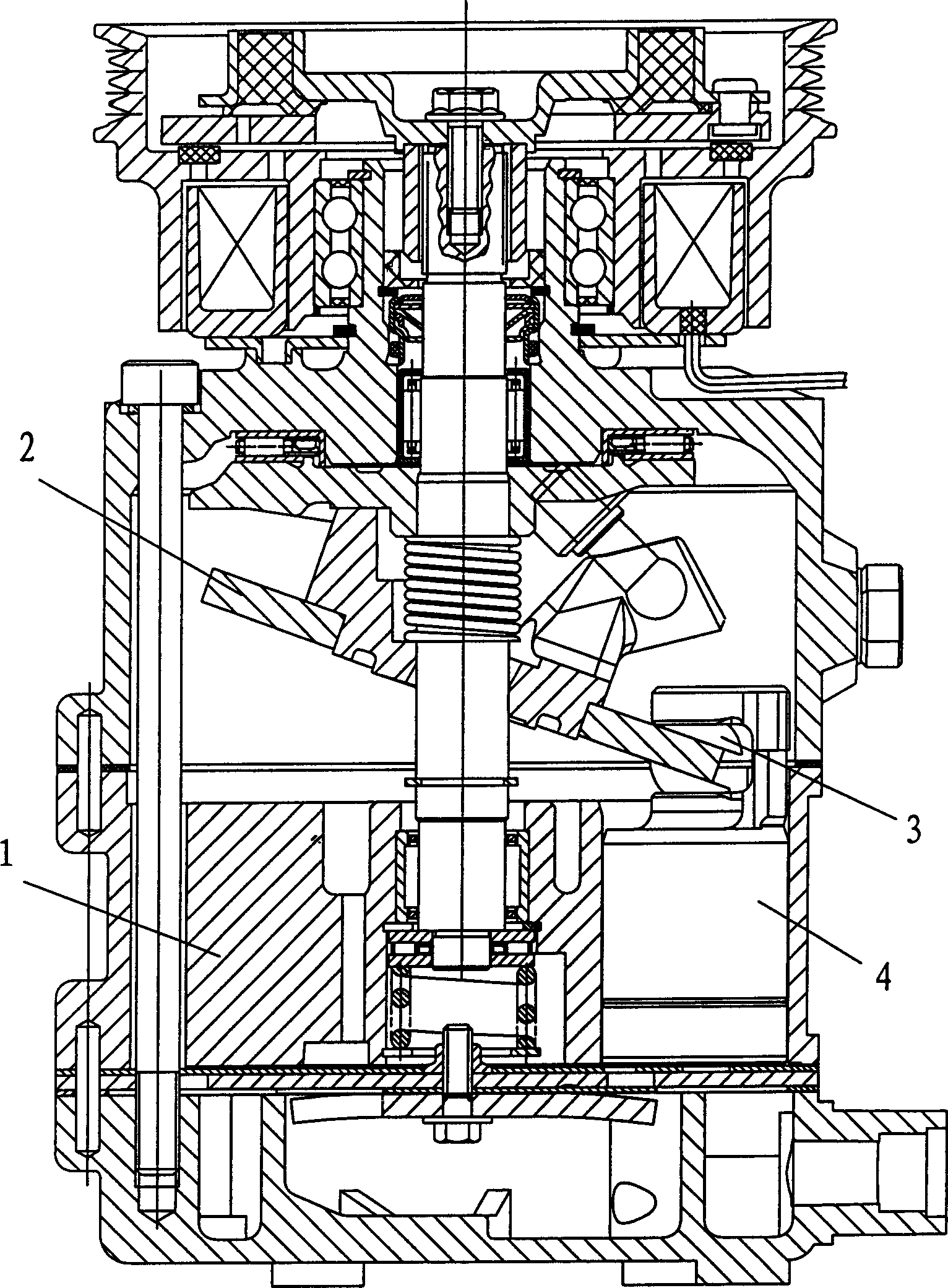

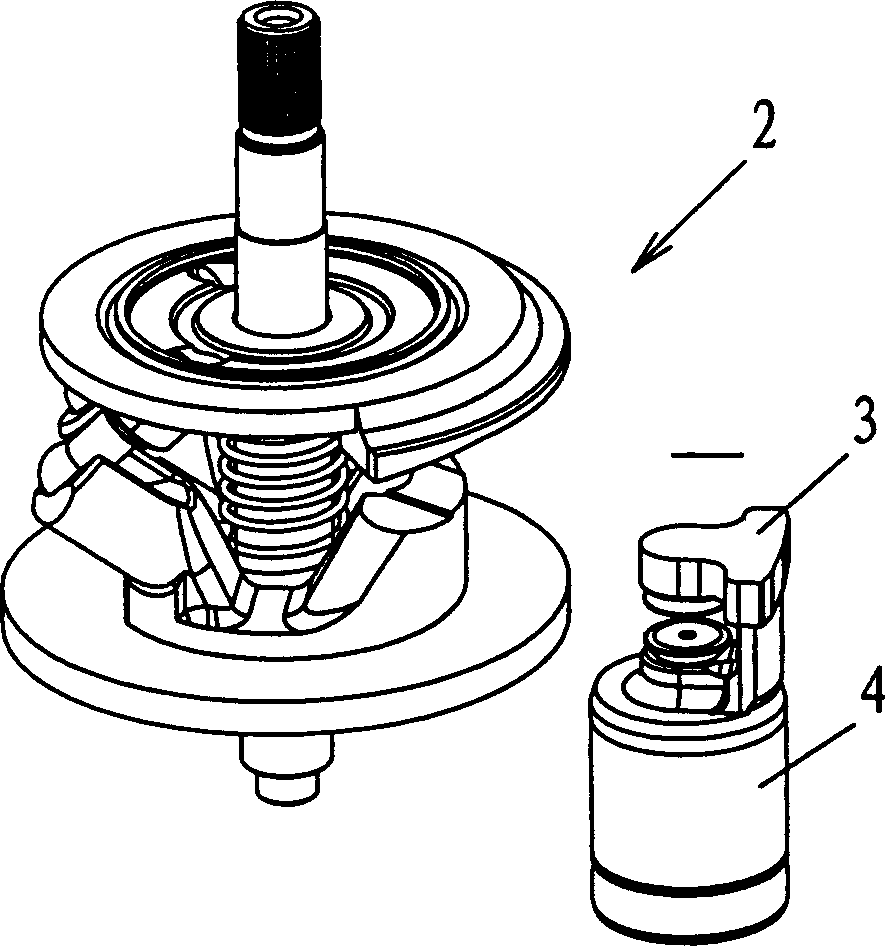

Method for mounting compressor piston and slipper into cylinder

InactiveCN1800641AEasy to assembleReduce labor intensityPositive displacement pump componentsMulti-stage pumpsCylinder blockMechanical engineering

The invention relates to a method for putting the compressor piston and slipper into cylinder, while the traditional method has hard installment and easy abrasion of piston. The inventive method comprises: (1) putting the cylinder on a rotational disc; (2) putting the main axle inclined disc element above the cylinder with a distance between them; (3) rotating the inclined disc of main axle inclined disc element to make the maximum space between the cylinder and the inclined disc be able to contain mounted piston and rotating the cylinder disc to make one piston hole of it aim said maximum space; (4) mounting the piston and slipper on the highest point of inclined disc and loosening the inclined disc to make it recover to horizontal position, and the piston enters relative piston hole; (5) repeating the steps from (2)-(4), putting each piston into relative piston hole; (6) descending the main axle inclined disc element and the piston to be packed in the cylinder. The invention can reduce the mounting hardness and time with improved mounting quality.

Owner:SANDEN HUAYU AUTOMOTIVE AIR CONDITIONING CO LTD

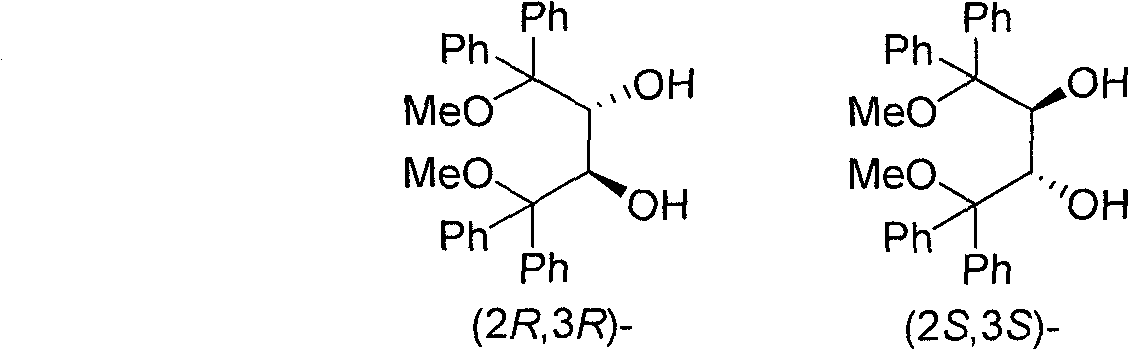

Preparation method of (2R,3R)-1,4-dimethoxyl-1,1,4,4-tetraphenyl-2,3-butanediol and (2S,3S)-1,4-dimethoxyl-1,1,4,4-tetraphenyl-2,3-butanediol

InactiveCN101921181AHigh yieldReduce waste rateOrganic chemistryOrganic compound preparationPolyamine CompoundGrignard reagent

The invention relates to a preparation method of (2R,3R)-1,4-dimethoxyl-1,1,4,4-tetraphenyl-2,3-butanediol and (2S,3S)-1,4-dimethoxyl-1,1,4,4-tetraphenyl-2,3-butanediol, which comprises the steps of preparing chiral 1,1,4,4-tetraphenyl butantetraol by carrying out hydrocarbylation on antipode purity (2R,3R)-tartaric ester and (2S,3S)-tartaric ester with a phenyl Grignard reagent; and then reacting with a boron compound in the presence of a metal compound or an amino compound to generate chiral spiral borate to obtain the (2R,3R)-1,4-dimethoxyl-1,1,4,4-tetraphenyl-2,3-butanediol and (2S,3S)-1,4-dimethoxyl-1,1,4,4-tetraphenyl-2,3-butanediol with high yield. The method has the remarkable characteristics of easy obtaining of raw materials (no need of special reagents or expensive reagents), simple process, convenient and simple operation, good reaction selectivity, high yield of products, and the like.

Owner:WUHAN UNIV

Prewelding method of thin-wall longitudinal submerged-arc welded (LSAW) pipes with small bore diameter

InactiveCN105171208AImprove one-shot molding rateReduce welding flashArc welding apparatusWelding/cutting media/materialsPower flowEngineering

The invention discloses a prewelding method of thin-wall longitudinal submerged-arc welded (LSAW) pipes with a small bore diameter, and relates to the technical field of steel products welding. The prewelding method lies in that prewelding is carried out by adopting CO2 and Ar mixed gas protective automatic welding, and further comprises the following steps: firstly, determining welding technological parameters, determining the diameter of a welding wire as 2.0 mm and the welding speed as 1.8-2.9 m / min, and determining the proportion and flow of mixed gas, then carrying out preparation before welding, preparing a groove, determining the grade of the welding wire and the welding parameters. During the process of producing thin-wall steel pipes with a small bore diameter, prewelding is carried out by utilizing a shielding welding wire with the diameter of 2.0 mm, welding is carried out by adopting low current, the prewelding seam is plump, the overlaps of an internal groove are greatly reduced, the occurrence probability of defects like burning through and weld misalignment is reduced, and at the same time, the prewelding failure discharge regulation times is reduced, the prewelding once-shaping ratio is increased, and the production efficiency is improved.

Owner:CNPC BOHAI EQUIP MFG +1

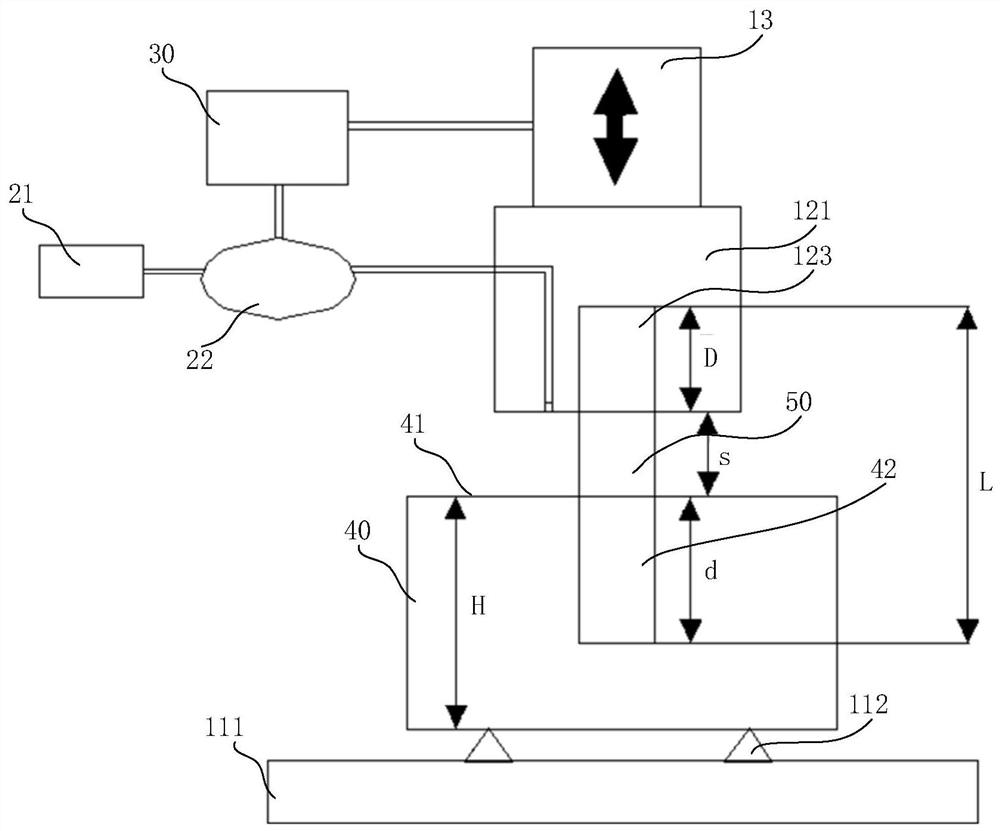

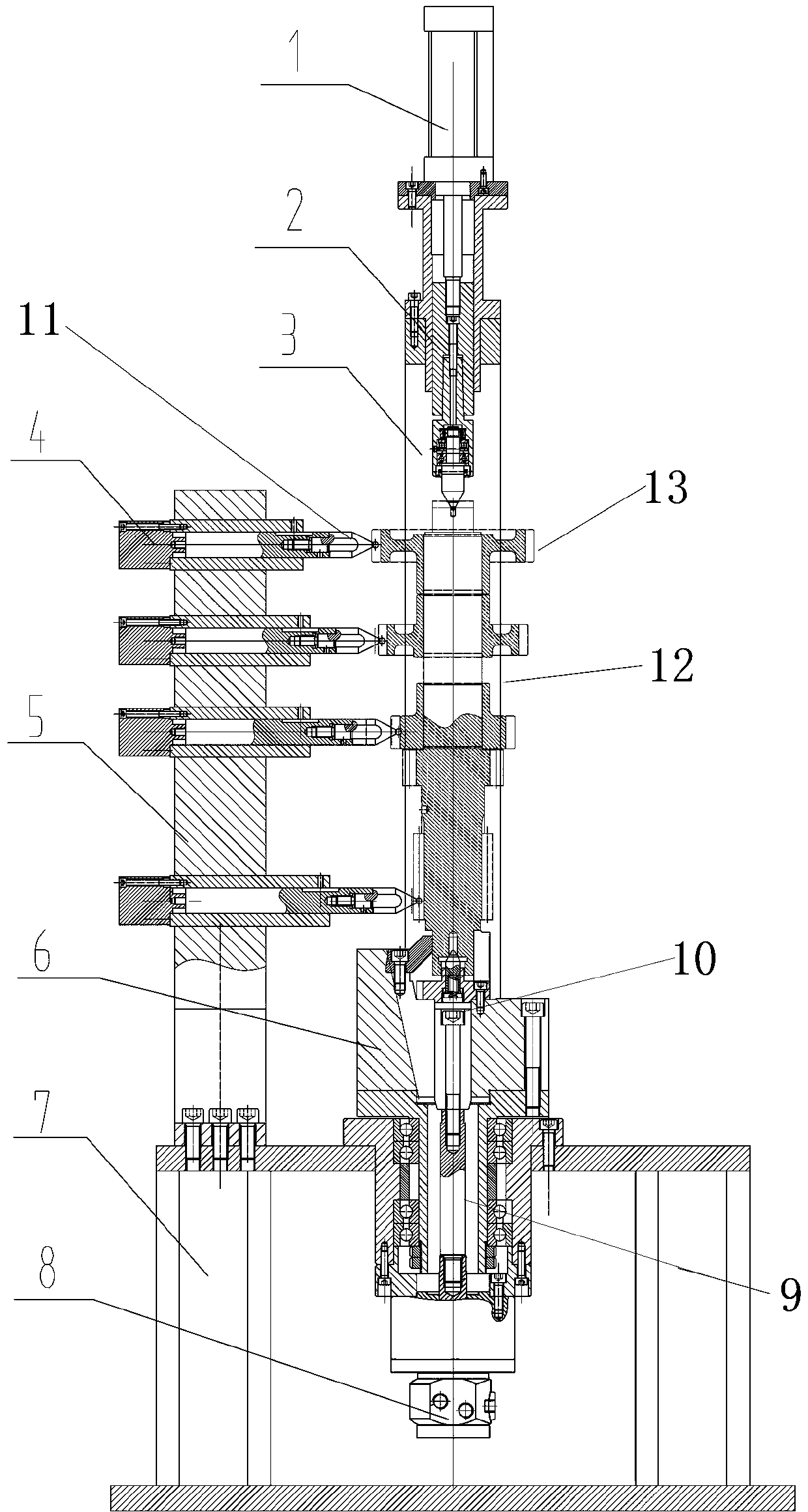

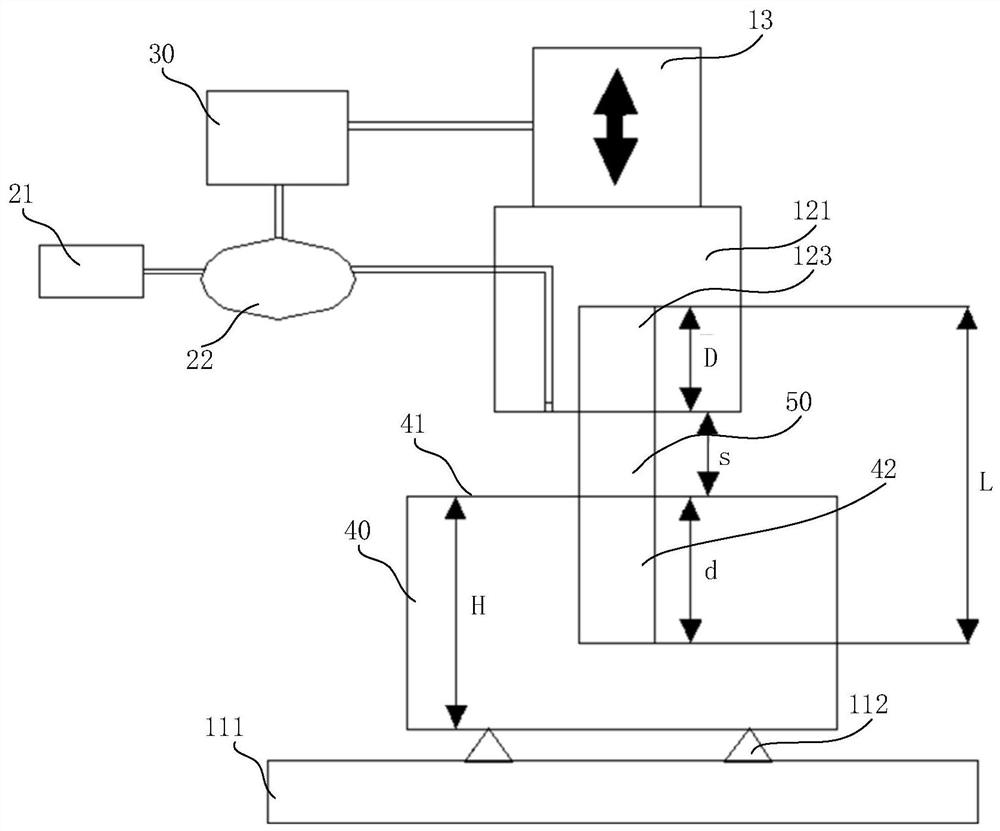

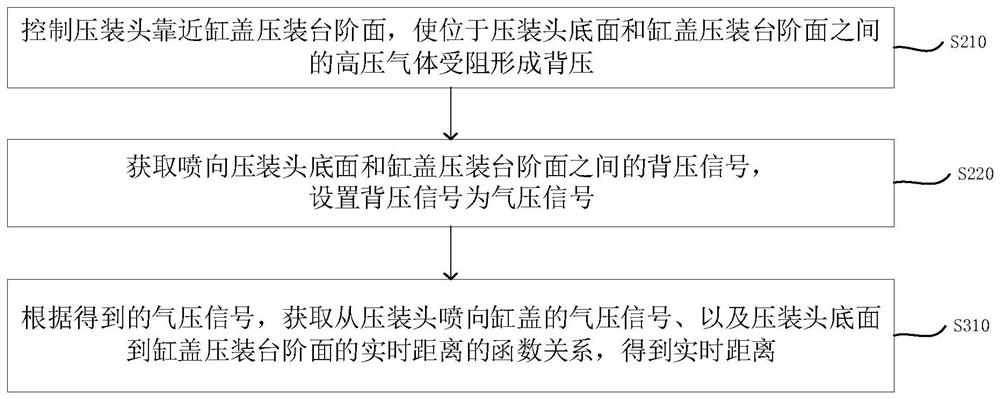

Cylinder cover guide pipe pressing method, system and device with self-adaptive characteristic

ActiveCN113070669AIncrease productivityReduce waste rateUsing fluid meansMetal working apparatusStructural engineeringSelf adaptive

The invention discloses a cylinder cover guide pipe pressing method, system and device with a self-adaptive characteristic. The pressing method comprises the following steps that a signal of air pressure sprayed to a position between the bottom face of a pressing head and the pressing step face of a cylinder cover is obtained; according to the obtained air pressure signal, the real-time distance from the bottom face of the pressing head to the pressing step face of the cylinder cover is obtained; according to the obtained real-time distance, the value of pressing depth by which a to-be-press guide pipe is pressed into a guide pipe hole in the cylinder cover is obtained, and the numerical value range of the pressing depth value is judged; and when it is detected that the pressing depth value does not reach the preset numerical value range, the pressing head is controlled and driven to move downwards till the pressing depth value reaches the preset numerical value range. According to the cylinder cover guide pipe pressing method with the self-adaptive characteristic, the pressing head is controlled and driven to conduct self-adaptive adjustment till the pressing depth value reaches the preset numerical value range, so that poor pressing is avoided, the production efficiency of pressing the guide pipe into the cylinder cover is improved, and the waste rate is reduced.

Owner:DONGFENG MOTOR GRP

Wheat seedling barley green composition and preparation technology thereof

InactiveCN107212403AImprove stabilityNot easy to absorb moistureFood shapingNatural extract food ingredientsAdditive ingredientTableting

The present invention provides a wheat seedling barley green composition and a preparation technology thereof. The wheat seedling barley green composition is obtained by combining a wheat seedling young leaf extract and natural xylooligosaccharides and prepared by suing the advanced preparation technology. The wheat seedling barley green composition is specifically prepared by accessory material weighing, dry method material mixing granulating (using an one-step granulator with an even material mixing function), tableting, sterilizing, sampling and sealed packaging. The wheat seedling barley green tablet product is processed by a formula and the preparation technology. Due to abandons of falling-behind technologies of the traditional wet method granulating and oven drying, losses of active nutritional ingredients of the barley green are reduced, waste rates of the raw materials are also significantly reduced, and the wheat seedling barley green composition is high in purity, good in taste and suitable for consumptions of patients with diabetes.

Owner:浙江禾蓓生物科技有限公司 +1

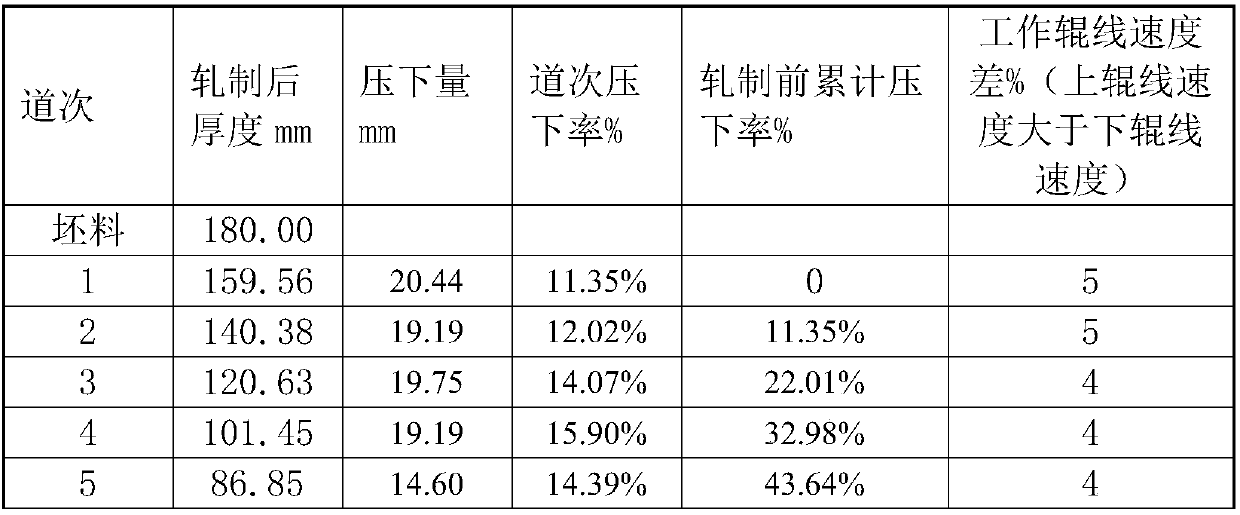

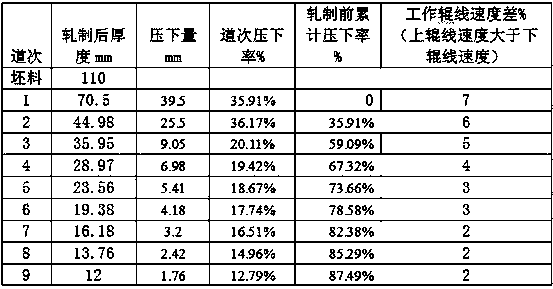

A method for producing wear-resistant steel composite coils by hot rolling asymmetric wear-resistant steel composite billets

ActiveCN105855292BReduce the amount of weldingAvoid sticking inRollsWork cooling devicesLaminar coolingWear resistant

The invention discloses a hot-rolling production method of an asymmetrical abrasion-resistant steel composite blank. The method comprises the following steps: putting the asymmetrical abrasion-resistant steel composite blank in a heating furnace in a manner of enabling the abrasion-resistant steel surface to face upwards; controlling the temperature of a preheating stage and the furnace staying time of the heating furnace in the step A and heating in an uniform heating stage conventionally after the preheating stage is ended; conventionally dephosphorizing the asymmetrical abrasion-resistant steel composite blank, then conveying the asymmetrical abrasion-resistant steel composite blank into a hot rolling machine for conventionally rolling to obtain a composite plate, wherein the diameter of an upper roller is smaller than that of a lower roller of a working roller, and the linear speed of the upper roller is greater than that of the lower roller; starting laminar cooling behind a part in a distance of 2-5cm away from the heat of a plate belt of the rolled composite plate, then conventionally rolling to obtain an asymmetrical abrasion-resistant steel composite roll. The hot-rolling production method of the asymmetrical abrasion-resistant steel composite blank is small in welding quantity; the overall efficiency is improved; the asymmetrical abrasion-resistant steel composite blank is stable to roll, low in damage rate, free of problems of bulges, serious warp and damaged heads and high in yield; the prepared asymmetrical abrasion-resistant steel composite roll is high in composite layer surface quality and low in equipment damage rate.

Owner:云南昆钢新型复合材料开发有限公司

A Processing Technology of Open Structural Parts

The invention discloses a machining technology of an open structure part. The technical problems that open parts are deformed, and surface roughness and the wall thickness size are hard to guarantee can be effectively solved. Technological patches are designed according to the structural feature of the part; the open part of the part is cut open, and threads are tapped in the positions, in an opening, of the technological patches. The machining mode of artificially connecting the open part of the part through the technological patches and a connecting steel plate is adopted, so that the percent of pass and surface machining quality of the part are improved; the reject rate of the part is remarkably reduced; manufacturing cost is saved, and machining efficiency is improved.

Owner:JIANGXI HONGDU AVIATION IND GRP

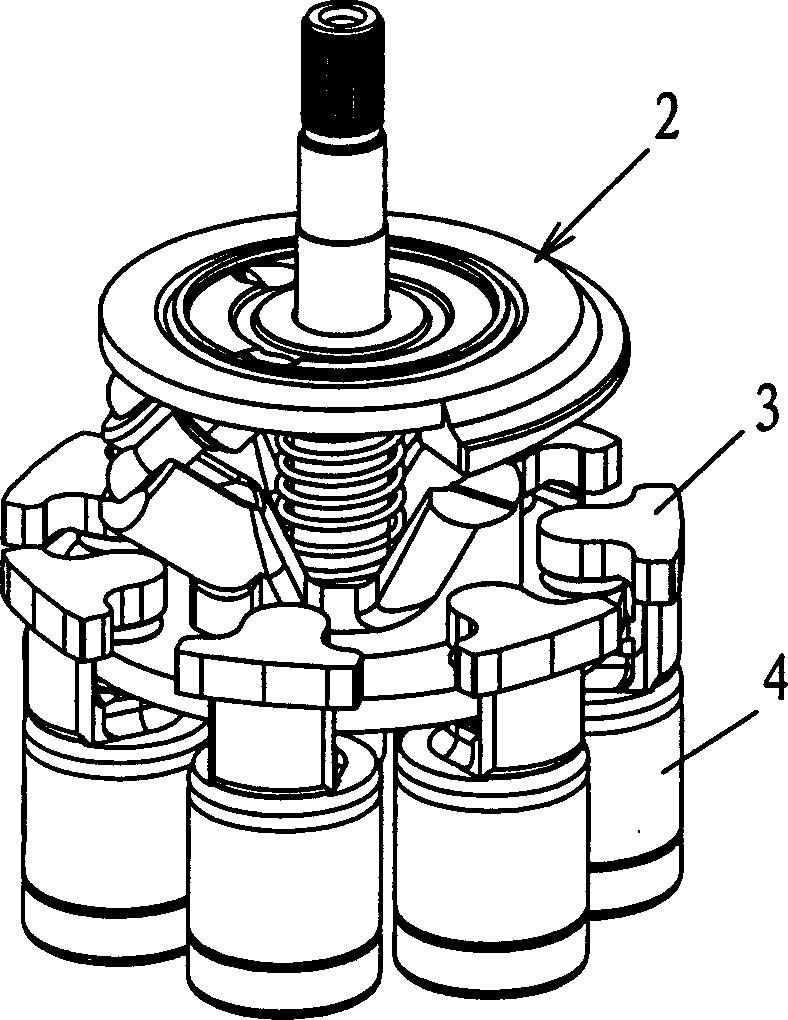

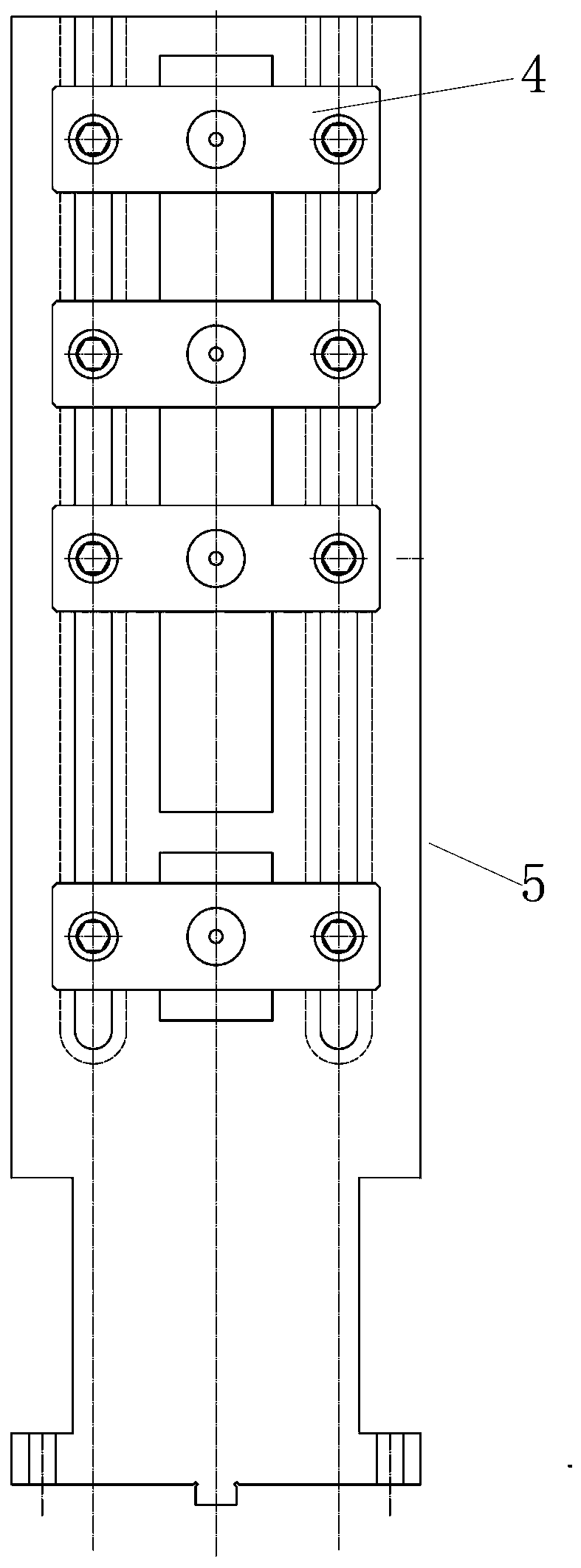

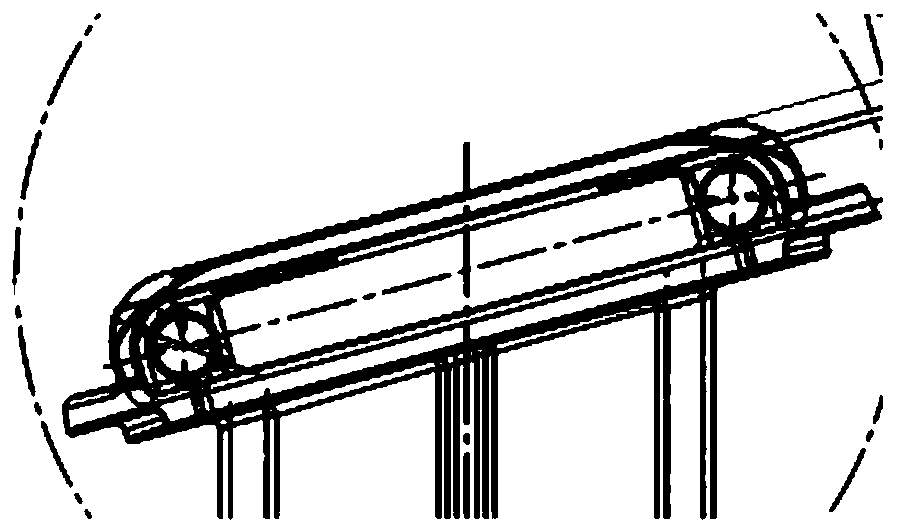

Gear alignment jig for auxiliary shaft assembly

ActiveCN108000404BReduce parts wasteReduce waste rateWork holdersMetal working apparatusEngineeringHeavy duty

The invention relates to clamp design in shaft type part machining and assembly technologies in the field of machining field, in particular to a tooth alignment clamp for countershaft assembly shrinkage fit. The tooth alignment clamp for countershaft assembly shrinkage fit solves the technical problem that after shrinkage fit of a bevel gear countershaft of an existing heavy-duty vehicle gearbox,the tooth alignment position degree requirement is difficult to meet. The tooth alignment clamp for countershaft assembly shrinkage fit comprises a tool platform. The tool platform is provided with acenter hole. A clamping device is installed at the center hole. The upper side of the tool platform is provided with an upper air cylinder through a back supporting plate. The moving end of the upperair cylinder is downward and provided with an upper center corresponding to the center of the clamping device. The center of the clamping device is provided with a lower air cylinder. The moving end of the lower air cylinder is upward and provided with a lower center corresponding to the upper center. The tool platform is further vertically provided with a locating pin supporting plate. The locating pin supporting plate is movably sleeved with multiple pneumatic locating pin assemblies. Each pneumatic locating pin assembly is provided with a tooth alignment column.

Owner:CHINA NAT HEAVY DUTY TRUCK GROUP DATONG GEARCO

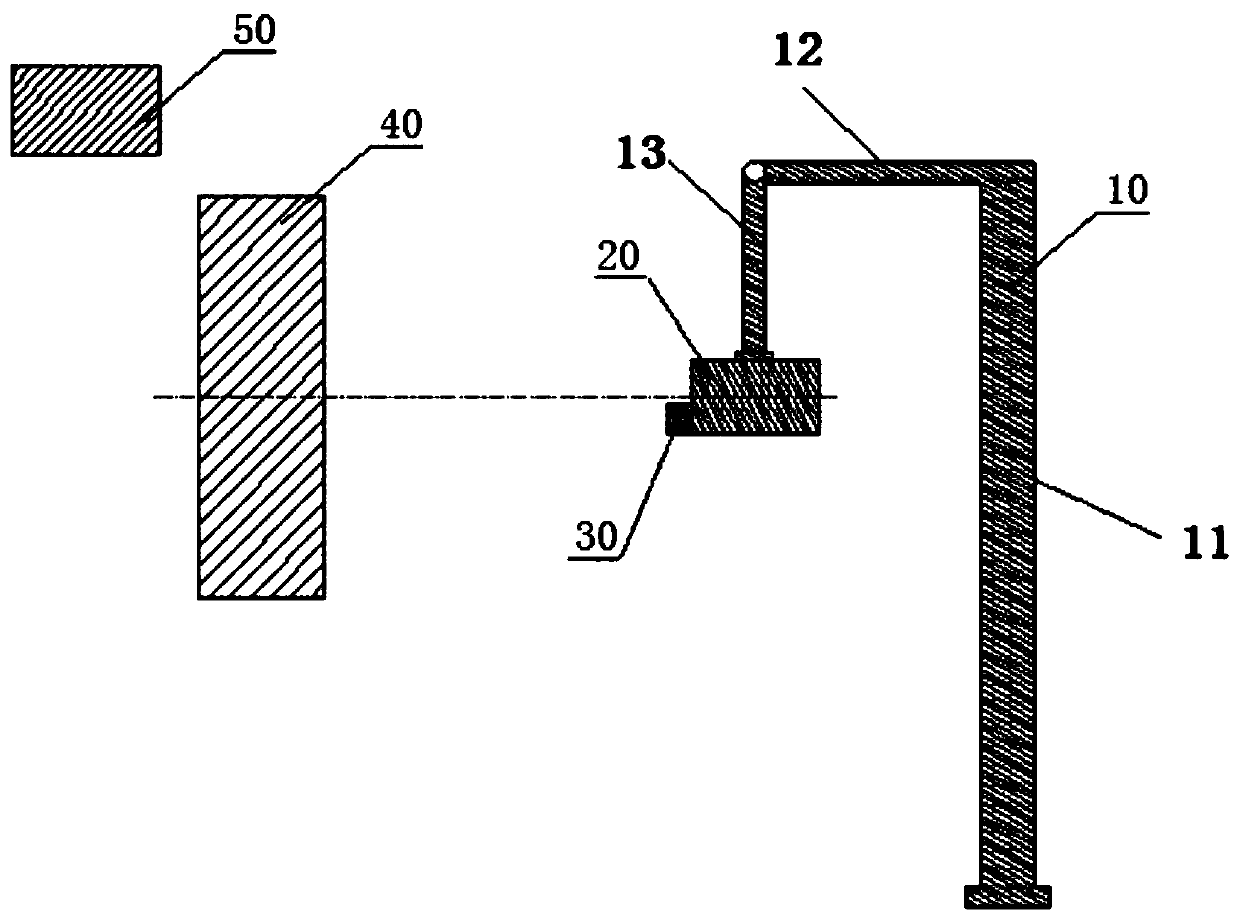

Deviation adjusting device and deviation adjusting method for insulating sheath mold

The invention relates to the technical field of wire and cable insulation sheath production, in particular to a deviation adjusting device and deviation adjusting method for an insulating sheath mold.A machine head of the mold comprises a mold sleeve and a mold core in the mold sleeve. The deviation adjusting device comprises a support, the support is provided with an image collecting device, thecenter line of the image collecting device coincides with the center line in the machine head; and the auxiliary device further comprises a display device used for displaying images of the image collecting device. The machine head is provided with a deviation adjusting screw used for adjusting the relative position between the mold sleeve and the mold core of the machine head. A deviation adjusting screw comprises a nut and a bolt, a dial is fixed between the nut and the bolt, rotating scales are indicated on the dial, and the thread displacement on the bolt is in direct proportion to the rotating scales on the dial. The product quality can be effectively improved, the defective rate can be reduced, and the uniform thickness of the insulation and sheath can be ensured.

Owner:BAOSHENG SCI & TECH INNOVATION

Cylinder head conduit press-fitting method, system and device with self-adaptive characteristics

ActiveCN113070669BIncrease productivityReduce waste rateUsing fluid meansMetal working apparatusCylinder headEngineering

The invention discloses a cylinder head duct press-fitting method, system and device with self-adaptive characteristics. The press-fitting method includes the following steps: obtaining the air pressure signal sprayed between the bottom surface of the press-fitting head and the cylinder head press-fitting step surface; according to the obtained air pressure signal to obtain the real-time distance from the bottom surface of the press-fit head to the press-fit step surface of the cylinder head; according to the obtained real-time distance, obtain the press-fit depth value of the conduit to be pressed into the conduit hole of the cylinder head, and judge the numerical range of the press-fit depth value ; When it is detected that the press-fit depth value does not reach the preset value range, the control drives the press-fit head to move down until the press-fit depth value reaches the preset value range. The cylinder head conduit press-fitting method with self-adaptive characteristics provided by the present invention controls and drives the press-fitting head to adjust adaptively until the press-fit depth value reaches a preset value range, avoiding the occurrence of bad press-fitting phenomena; improving the efficiency of cylinder head press-fit conduit Increase production efficiency and reduce waste rate.

Owner:DONGFENG MOTOR GRP

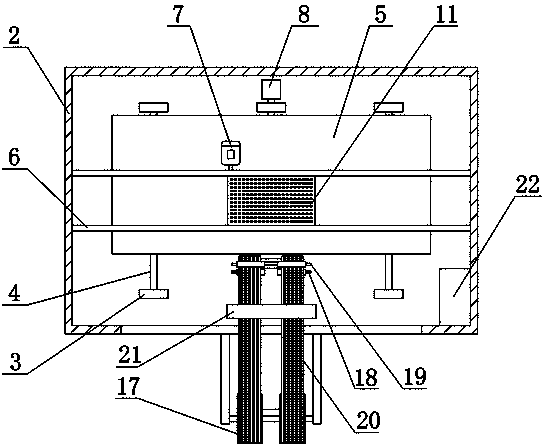

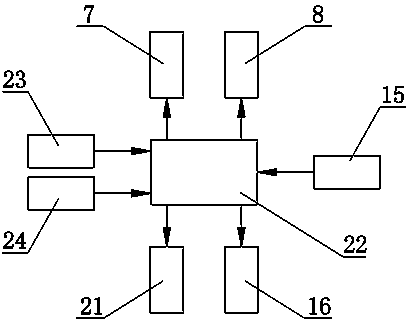

High-speed precision film lamination equipment

ActiveCN106240898BReduce movement distanceShort timeWrapping material feeding apparatusLaminationEngineeringCcd camera

The invention relates to high-speed precision film attaching equipment. The high-speed precision film attaching equipment comprises a base, a feeding mechanism, a film delivering mechanism, a film suction mechanism and a controller. The feeding mechanism is arranged in the length direction of the base. The film suction mechanism is mounted on the base and located above the feeding mechanism. The film delivering mechanism is arranged at one side of the base. The feeding mechanism comprises movable supports, a longitudinal movement plate and a transverse movement sliding bracket. The two movable supports are symmetrically fixed to the base. A longitudinal movement guide rail is mounted on each movable support. The longitudinal movement plate is mounted on the longitudinal movement guide rails in a sliding-fit manner. The transverse movement sliding bracket is fixed to the longitudinal movement plate and internally provided with a material containing box in a matched manner. The film delivering mechanism comprises film delivering rollers, film carrying belts and a dragging mechanism. The film suction mechanism comprises a movable support, a slide block, CCD cameras and material suction air cylinders. The controller is connected with a transverse movement servo driving mechanism, a longitudinal movement servo driving mechanism, the CCD cameras, the material suction air cylinders and a material dragging mechanism. The high-speed precision film attaching equipment has the beneficial effects of being high in film attaching efficiency and precision.

Owner:CHENGDU HOMIN TECH

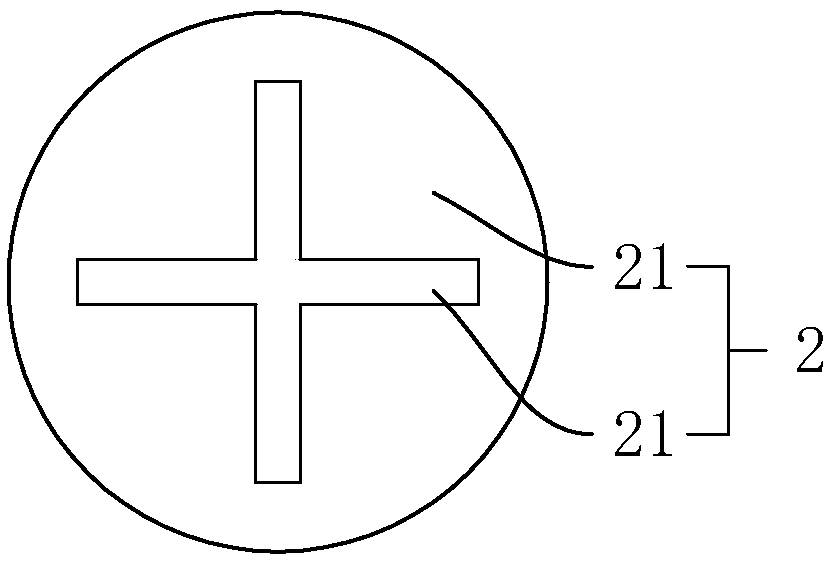

pole core

ActiveCN102938590BSignificant progressSimple structureMagnetic circuit shape/form/constructionPunchingMagnetic poles

Owner:CRRC YONGJI ELECTRIC CO LTD

Novel extrusion roller pressure regulating device

PendingCN114277530AAvoid formingReduced service lifeLiquid surface applicatorsLiquid/gas/vapor removal by squeezing rollersFiberAdhesive glue

The invention is applicable to the technical field of chemical fiber production, and provides a novel squeeze roller pressure regulating device which comprises a roller press, a conveying mechanism, a pushing air cylinder, a first pressure roller, a second pressure roller, a second pressure roller, a pressure regulating device, a pressure regulating device and a pressure regulating device, and the first pressure roller and the second pressure roller are oppositely arranged, and a gap for cloth to penetrate through is reserved between the first pressure roller and the second pressure roller. The output end of the air source is fixedly connected with the first pressure roller, the air source is communicated with the propelling air cylinder, the pressure values of a first manual adjusting valve and a second manual adjusting valve need to be manually adjusted in advance, and compressed air output by the air source passes through a low-pressure path of the first manual adjusting valve during normal work and then flows into the second manual adjusting valve through a low-pressure path of the second manual adjusting valve. When the joint detecting device detects joint cloth, the pressure switching valve switches the air source channel to the second manual regulating valve, the air channel passes through the high-pressure path of the second manual regulating valve, and the pressure switching valve controls the propelling air cylinder to automatically increase the pressure between the first pressure roller and the second pressure roller, so that redundant glue is squeezed away.

Owner:JUNMA TIRE CORD

SBS modified asphalt high-self-adhesive waterproof coiled material and its preparing process

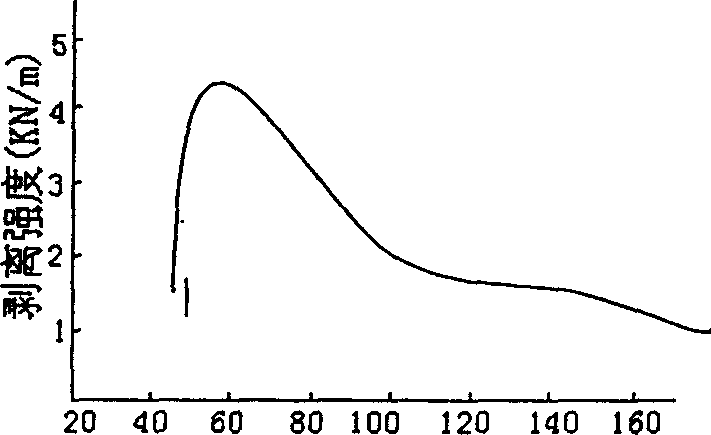

InactiveCN1264926CHigh peel strengthShorten production timeOther chemical processesBuilding insulationsBenzenePlasticizer

The adhesive waterproof coil material consists of alkyl asphalt, adhesive SBS, plasticizer naphthene base oil, stuffing calcium carbonate and composite tackifier of coumarone resin and terpene resin. It has the composition of: alkyl asphalt 35-40 wt%, adhesive SBS 10-13 wt%, naphthene base oil 3-5 wt%, stuffing 39-42 wt% and composite tackifier 5-13 wt%. It has high adhesion strength, and the production process has low power consumption, short time and low cost.

Owner:余建国

A centerless grinder discharge machine

ActiveCN105215799BAvoid shaft jammingAvoid receiving materialsRevolution surface grinding machinesGrinding drivesDrive shaftEngineering

The invention relates to the technical field of centerless grinding machines and discloses a discharging machine of a centerless grinding machine. The discharging device comprises a drive device, a material guide slot and a material receiving frame, wherein one end of the material guide slot is provided with a transmission shaft; the other end of the material guide slot is provided with a driven shaft; belt wheels are arranged on the transmission shaft and the driven shaft; a conveyor belt is arranged between the two belt wheels, and is used for receiving and conveying workpieces from the centerless grinding machine; the drive device is connected with the transmission shaft and used for driving the transmission shaft to rotate; and the material receiving frame is positioned at one end of the material guide slot and used for receiving workpieces conveyed by the conveyor belt. The discharging machine of the centerless grinding machine provided by the invention can automatically receive materials while the centerless grinding machine discharges, so that phenomena of shaft blocking, delayed material receiving and the like of manual operation are avoided, thereby reducing an industrial waste rate, improving production efficiency and reducing labor intensity.

Owner:JIHUA 3534 CLOTHING

Production method of ABS composite powder additive

The invention discloses a production method of an ABS composite powder additive. The production method comprises the process steps of vacuum powder feeding, powder weightlessness flow metering and powder conveying, mixing and extrusion, air cooling, pelletizing and screening, air conveying, storage and packaging. The dispersion uniformity of the obtained additive in an ABS product is relatively better, the defective rate of an ABS device is reduced, the ABS device can realize automatic vacuum feeding of the powder additive, , and various properties of the ABS product prepared by mixing the composite additive with ABS powder and SAN for granulation are greatly improved.

Owner:无锡弘润森化工科技有限公司

A method for producing cooking wine with high amino acid nitrogen content by using rice wine distiller's grains

ActiveCN107455723BHigh amino acid nitrogen contentStrong umamiYeast food ingredientsBiotechnologyLees

Owner:安徽海神黄酒集团有限公司

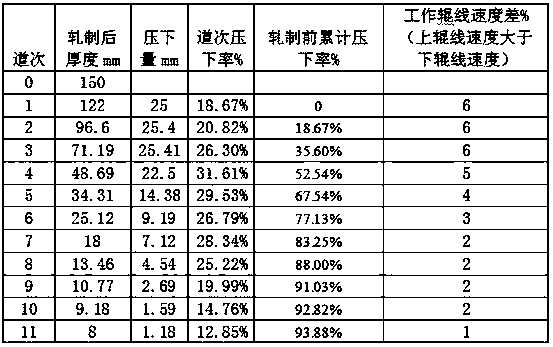

A method for producing stainless steel clad coils by hot rolling of asymmetric stainless steel clad billets

ActiveCN105750330BReduce the amount of weldingAvoid sticking inRoll force/gap control deviceTemperature control deviceLaminar coolingSS - Stainless steel

The invention discloses a method for producing composite plates from asymmetric stainless steel composite blanks by means of hot-rolling. The method includes arranging the asymmetric stainless steel composite blanks with upward stainless steel surfaces in a heating furnace; controlling the temperatures of the heating furnace in preheating stages at a step A and the furnace staying time, and conventionally heating the asymmetric stainless steel composite blanks at soak stages after the preheating stages are completed; conventionally removing phosphorus on the asymmetric stainless steel composite blanks, then feeding the asymmetric stainless steel composite blanks into a hot-rolling mill and conventionally rolling the asymmetric stainless steel composite blanks to obtain the composite plates; carrying out laminar cooling the rolled composite plates from certain portions behind the heads of plate strips of the rolled composite rolls, and conventionally reeling the composite plates to obtain asymmetric stainless steel composite rolls. The diameters of upper rollers of work rollers of the hot-rolling mill are smaller than those of lower rollers of the work rollers, and the linear speeds of the upper rollers are higher than the linear speeds of the lower rollers. The certain portions are separated from the heads of the plate strips by distances of 2-5 m. The method has the advantages that the method is low in weld load and damage rate and high in yield, the integral efficiency can be improved, the asymmetric stainless steel composite blanks can be stably rolled, and problems of bulging, severe bending, warping, buckling and the like can be solved; composite layers of the asymmetric stainless steel composite rolls produced by the aid of the method are high in surface quality, and the method is low in equipment wear rate.

Owner:云南昆钢新型复合材料开发有限公司

Spring feeding control device in automatic tool

PendingCN110653596AReduce the number of failuresAvoid wrong loadingMetal working apparatusCar seatEngineering

The invention discloses a spring feeding control device in an automatic tool. The device is characterized by comprising a vibration disc used for placing springs, the vibration disc communicates withone end of a spring feeding hose, the other end of the spring feeding hose communicates with the upper end of a metal pipe, a spring baffle used for blocking springs is arranged below the lower end ofthe metal pipe, the middle of the metal pipe is provided with a first hole allowing a spring limiting needle to pass through, the spring limiting needle and the spring baffle are connected with a telescopic end of a left and right sliding air cylinder, one side of the lower end of the metal pipe is provided with a second hole allowing a spring clamp to clamp the springs, and the spring clamp is fixed to the telescopic end of an up and down sliding air cylinder. The device is mainly used for operation of spring feeding in the car seat guide sleeve automatic tool, the air cylinder work principle is used for controlling the running track of the soft springs, it is ensured that the springs are precisely mounted in corresponding part holes, wrong arranging and missed arranging are avoided, thefailure frequency in tool running can be reduced, the waste damage rate is reduced, and the cost reducing and efficiency increasing of a factory are achieved.

Owner:上海飞尔汽车零部件股份有限公司

Automatic rubber sheet winding process for clutch facing

PendingCN113247656AAvoid stickingWidth controllable and adjustableFriction clutchesWebs handlingEngineeringRubber sheet

The invention discloses an automatic rubber sheet winding process for a clutch facing, and relates to the technical field of clutches. According to the automatic rubber sheet winding process for the clutch facing, a rubber sheet feeding mechanism, an automatic powder adding mechanism, a powder brushing mechanism, a rubber sheet winding mechanism and a rubber sheet are included, the rubber sheet feeding mechanism, the automatic powder adding mechanism, the powder brushing mechanism and the rubber sheet winding mechanism are sequentially arranged from right to left, and the upper portion of the rubber sheet feeding mechanism is provided with a front traction wheel and a rear traction wheel through a belt assembly in a connected manner. The automatic powder adding mechanism comprises a powder adding shaft device, a powder box and a power transmission device, wherein the powder box is located above the powder adding shaft device, and isolation powder is arranged in the powder box. With the automatic rubber sheet winding process for the clutch facing, a separant can be automatically added to prevent the rubber sheet from bonding, the rubber sheet can be automatically slit and winded, and the width of the rubber sheet is controllable and adjustable; the production efficiency can be improved, transfer frames are not needed, and the loss of leftover materials and the rate of defective products are reduced; less space is needed without using the transfer frames; and the number of workers and the labor intensity of workers are reduced, and the stability of product quality is good.

Owner:福建冠良汽车配件工业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com