A method for producing wear-resistant steel composite coils by hot rolling asymmetric wear-resistant steel composite billets

A wear-resistant steel, asymmetric technology, used in the driving device, roll, metal rolling and other directions of metal rolling mills, can solve the problems of bending and warping, weld cracking, bulging, etc., to improve the yield and overall efficiency. The effect of improving and improving the surface quality of the cladding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Rolling an asymmetric wear-resistant steel composite billet with a size of 7000mm*1200mm*150mm, the composite billet is composed of a piece of 65Mn wear-resistant alloy steel and a piece of Q235 ordinary carbon steel; the size of the 65Mn wear-resistant alloy steel is 7000mm*1200mm*82mm , The size of Q235 plain carbon steel is 7000mm*1200mm*68mm, and the rolling target thickness is 4.5mm.

[0024] A. Send the asymmetric wear-resistant steel composite blank coated with high-temperature anti-oxidation and anti-decarburization coating (the coating thickness is 0.2mm) on the 65Mn surface into the heating furnace, so that the 65Mn wear-resistant alloy steel faces upward;

[0025] B. The temperature of the preheating section of the heating furnace in control step A is 620±20°C, and the residence time of the asymmetric wear-resistant steel composite billet in the preheating section is 90 minutes;

[0026] C. After the asymmetric wear-resistant steel composite billet in step B is...

Embodiment 2

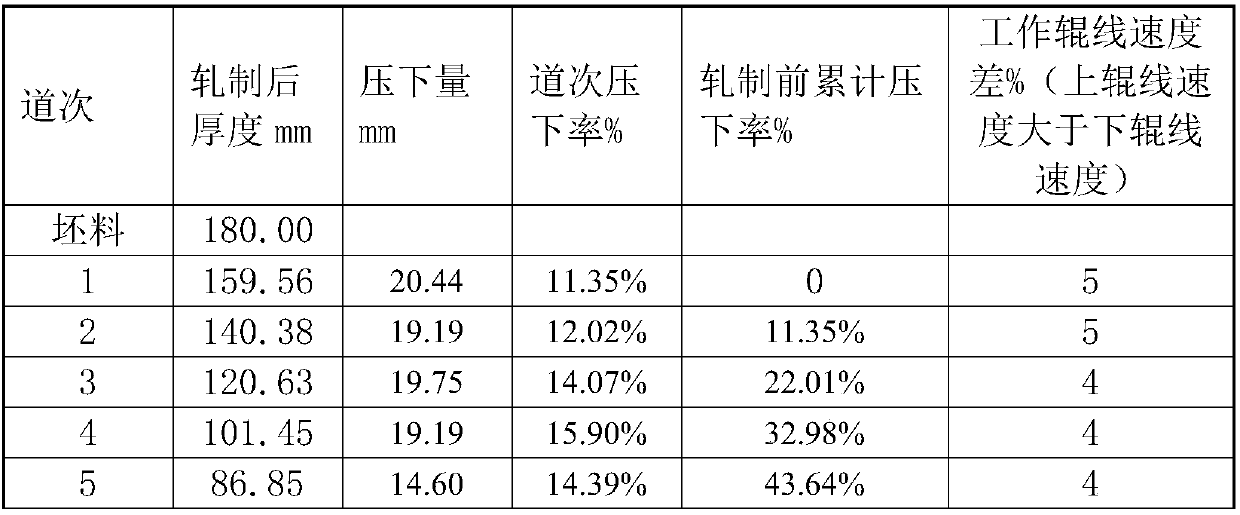

[0032] Rolling asymmetric wear-resistant composite billet with a size of 8000mm*1600mm*180mm, the composite billet is composed of a piece of 45Mn2 wear-resistant alloy steel and a piece of Q345 low-alloy steel; among them, the size of 45Mn2 wear-resistant alloy steel is 8000mm*1600mm*120mm, The size of Q345 low-alloy steel is 8000mm*1600mm*60mm, and the rolling target thickness is 6.0mm.

[0033] A. Send the asymmetric wear-resistant steel composite blank coated with high-temperature anti-oxidation and anti-decarburization coating (the coating thickness is 1mm) on the surface of 45Mn2 wear-resistant alloy steel into the heating furnace, so that the 45Mn2 wear-resistant alloy steel faces upward ;

[0034] B. The temperature of the preheating section of the heating furnace in control step A is 680±20°C, and the residence time of the asymmetric wear-resistant steel composite billet in the preheating section is 60 minutes;

[0035] C. After the asymmetric wear-resistant steel com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com