Method for producing cooking wine with high amino acid nitrogen content by using yellow wine stillage

A technology of rice wine distiller's grains and amino acids, which is applied in the field of fermentation, can solve the problems of low amino acid nitrogen, complex distiller's grains treatment, and long enzymatic hydrolysis time, and achieve the effects of improving product quality, reducing production costs, and reducing waste residues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

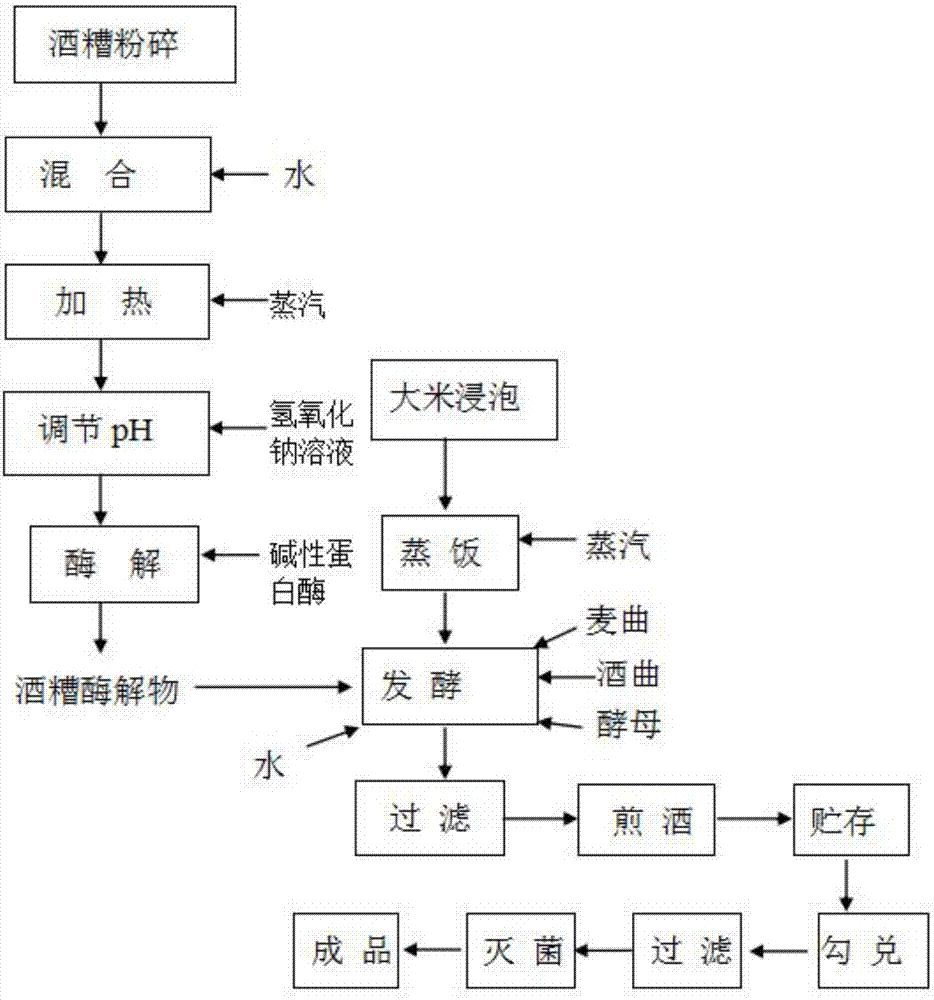

[0024] A method for producing cooking wine with high amino acid nitrogen content by utilizing rice wine distillers grains, such as figure 1 As shown, cooking wine is produced by enzymolyzing rice wine (cooking wine) distiller's grains, and co-fermenting the enzymatic hydrolyzate with rice. The specific production steps are as follows: crush 1Kg of distiller's grains, add 8Kg of distiller's grains to soak in hot water at 50-60°C for 0.5h, and stir slowly , pass through 0.2-0.3MPa steam for 10-15min, cool slightly, add 2Kg tap water, wait until the temperature drops to 45-50°C, slowly add sodium hydroxide solution while stirring, and adjust its pH to 9.5-10.0.

[0025] Join 5.0×10 5 U alkaline protease, incubate at 45-50°C for 0.5h, and keep stirring, this is distiller's grains enzymatic hydrolyzate.

[0026] Weigh 100Kg japonica rice, soak in water (the water surface is not over the rice) for 2 days, drain the water, and steam the rice.

[0027] After steaming the rice, slowl...

Embodiment 2

[0032] Crumble 0.5Kg distiller's grains, add 5Kg hot water at 50-60°C to soak for 0.5h, stir slowly, pass in 0.2-0.3MPa steam for 10-15min, cool slightly, add 5Kg tap water, wait until the temperature drops to 45-50°C, stir while stirring Slowly add sodium hydroxide solution to adjust the pH to 8.5-9.5. Join 4.5×10 4 U alkaline protease, incubate at 40-45°C for 2h, and keep stirring. Weigh 100Kg japonica rice, soak in water (the water surface is not over the rice) for 2 days, drain the water, and steam the rice. After steaming the rice, slowly add 180kg of cold boiled water to the rice, add 10.5Kg of the distiller's grain enzymatic hydrolyzate, add 1kg of wheat koji, 0.1kg of distiller's yeast, 0.05Kg of active dry yeast (distiller's yeast and active dry yeast need to be pre-washed with 2.5% glucose solution Activation 2h), start fermentation after mixing evenly. The temperature is controlled at 28-32°C for 0-6 days, and stirred from time to time, and the temperature is con...

Embodiment 3

[0034] Crumble 5Kg distiller's grains, add 50Kg hot water at 50-60°C to soak for 0.5h, stir slowly, pass in 0.2-0.3MPa steam for 10-15min, cool slightly, add 50Kg tap water, wait until the temperature drops to 30-40°C, stir while stirring Add sodium hydroxide solution slowly to adjust the pH to 8.5-10.0. Join 5.0×10 5U alkaline protease, incubate at 30-35°C for 4.0h, and keep stirring, this is distiller's grains enzymatic hydrolyzate. Weigh 100Kg japonica rice, soak in water (the water surface is not over the rice) for 2 days, drain the water, and steam the rice. After steaming the rice, slowly add 36kg of cold boiled water to the rice, add 105Kg of the distiller's grain enzymatic hydrolyzate, add 3kg of wheat koji, 0.8kg of distiller's yeast, 0.3Kg of active dry yeast (distiller's yeast and active dry yeast need to be activated with 2.5% glucose solution in advance 2h), start fermentation after mixing evenly. The temperature is controlled at 28-32°C for 0-6 days, and stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com