Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36results about How to "Reduce the number of drawing passes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-carbon steel wire with good fine steel cord drawing machining performance and manufacturing method of high-carbon steel wire

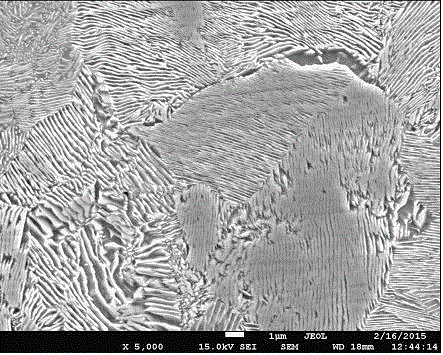

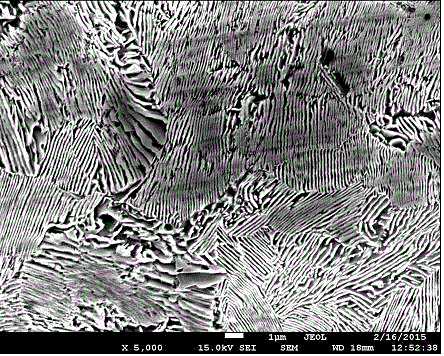

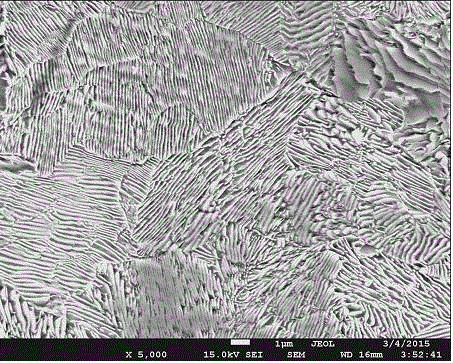

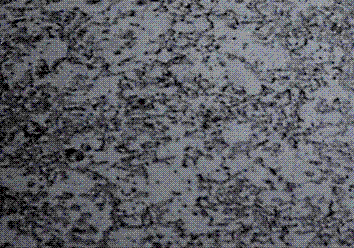

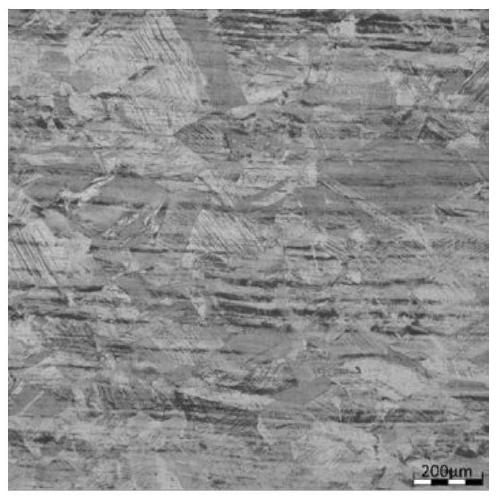

The invention relates to a high-carbon steel wire with good fine steel cord drawing machining performance. Chemical components of the steel wire include, by mass percentage, 0.60-1.00% of C, 0.10-0.60% of Si, 0.10-0.20% of Mn, 0.20-0.50% of Cr, smaller than or equal to 0.01% of S, smaller than or equal to 0.013% of P, smaller than or equal to 0.05% of Cu, smaller than or equal to 0.0010% of Ca, smaller than or equal to 0.005% of V, 0.0010-0.0040% of N, smaller than 0.0010% of solid dissolved N, smaller than or equal to 0.0030% of Al, smaller than or equal to 0.02% of Mo, smaller than or equal to 0.02% of Ni, smaller than or equal to 0.0005% of B and the balance Fe. Due to the fact that the key elements in the steel wire are optimized, the steel wire which has the good mechanical performance, a specific pearlite microstructure and more simple components is obtained, and the requirement for the good steel cord drawing machining performance is met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

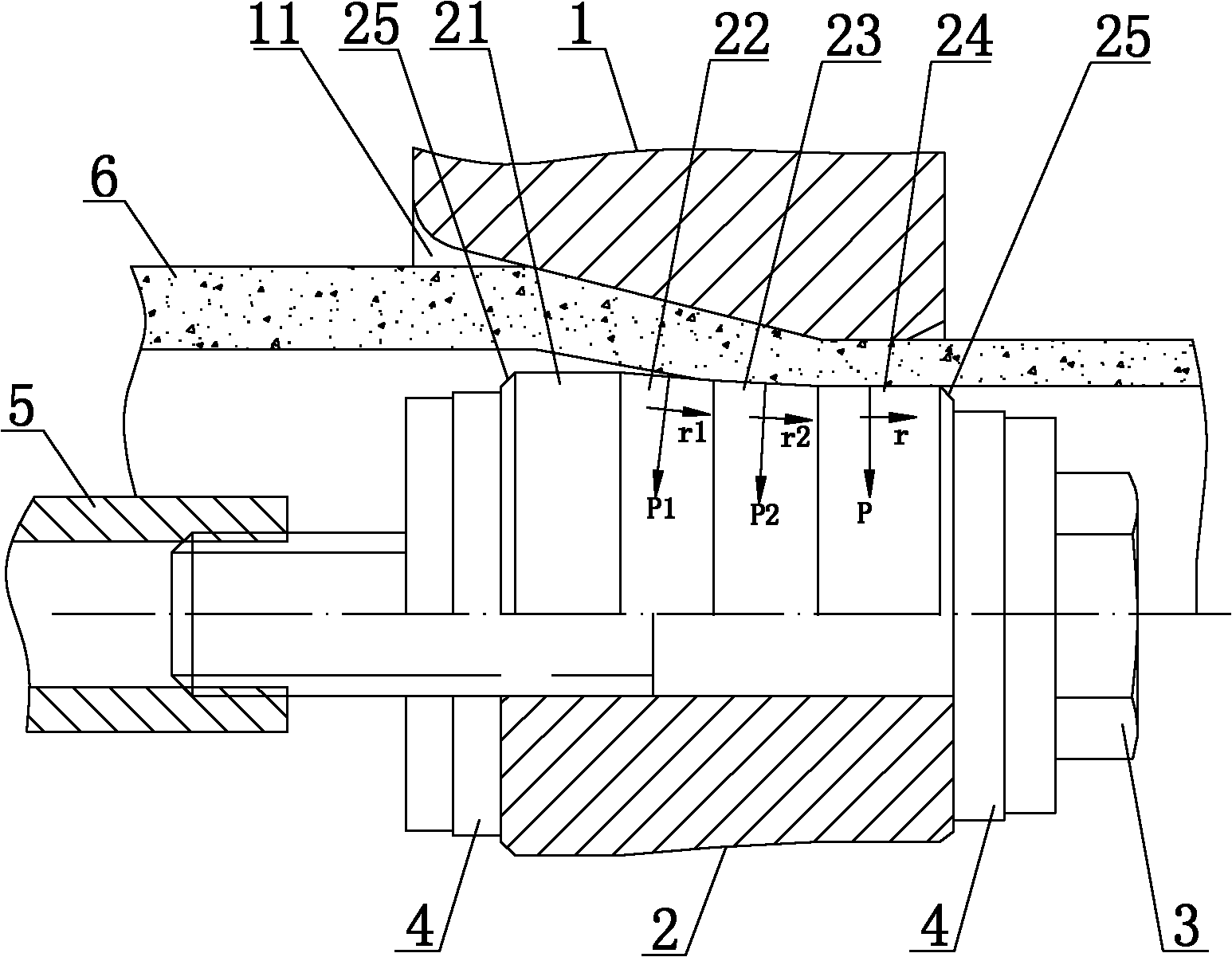

Improved cold drawing mould of seamless steel pipe and cold drawing process thereof

InactiveCN102120227AReduce stressAvoid breakingDrawing diesGreek letter sigmaUltimate tensile strength

Owner:ZHEJIANG JIANLI CO LTD

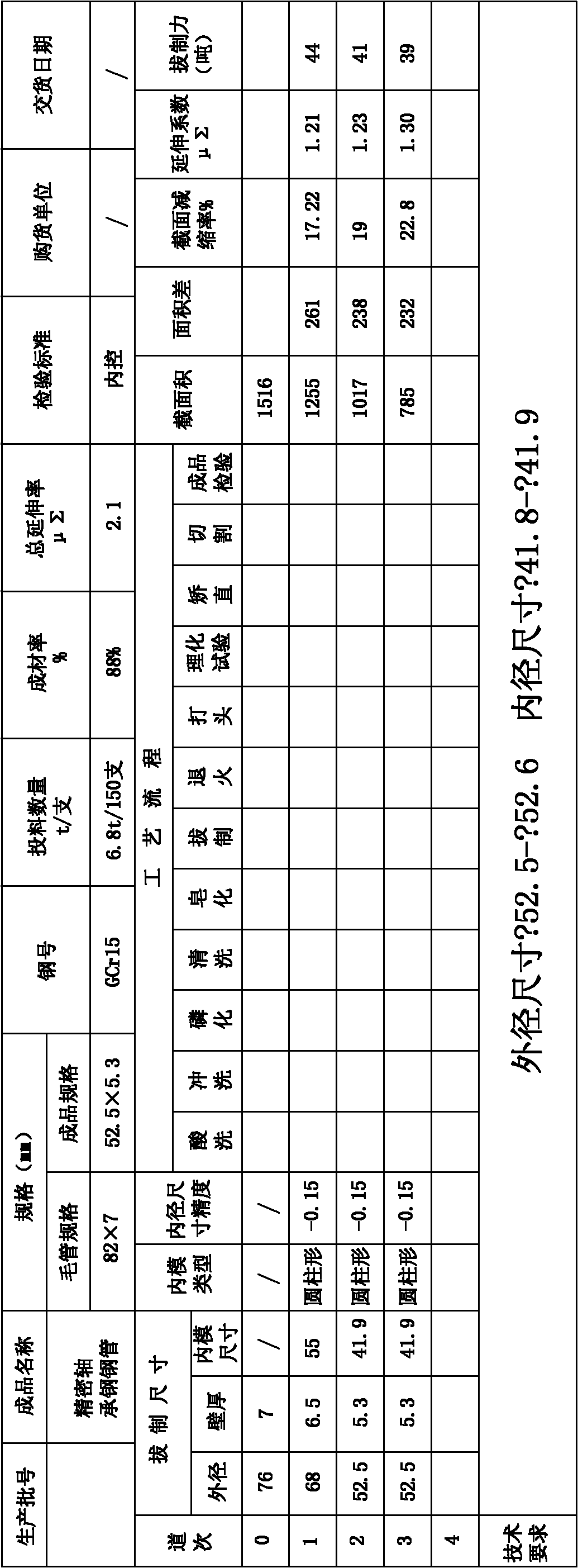

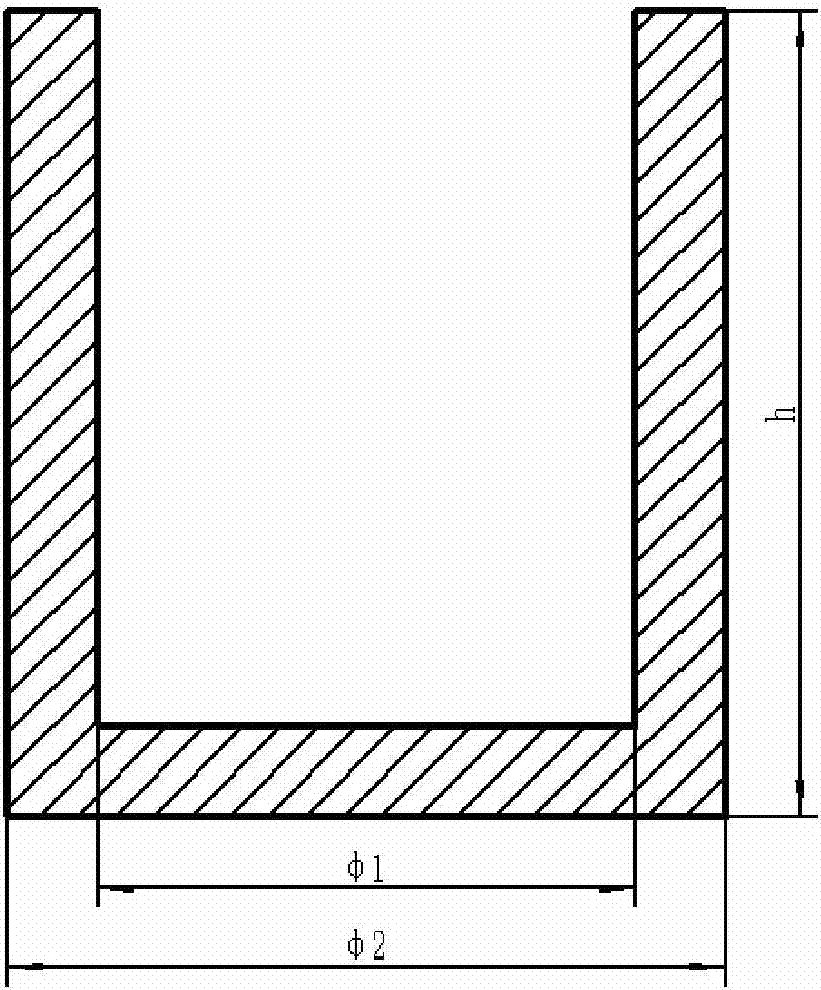

Large-diameter thin-wall cupronickel tube short process production method

The invention discloses a large-diameter thin-wall cupronickel tube short process production method and belongs to the technical field of metal materials. Specific to the problems that large-scale extrusion equipment up to 5000 tons is needed to produce large-diameter thin-wall cupronickel tubes through a traditional technique of semi-continuous casting solid ingot casting, punching, extruding, acid pickling, drawing and annealing, the finished product rate is low and the cost is high, the invention provides a method for producing the large-diameter thin-wall cupronickel tubes. Hot and cold combination casting horizontal continuous casting is adopted to producing large-size cupronickel tube blanks, and then a hole enlargement or / and hole shrinkage drawing is adopted to machining and forming the large-diameter thin-wall cupronickel tubes. The method has the advantages of being small in equipment investment, short in technical process, free of acid pickling and the like. The outer diameter of horizontal continuous casting tube blanks is 110-350 mm, the wall thickness is 5-30 mm, the elongation coefficient of hole enlargement drawing pass is 0.80-1.0, and the elongation coefficient of hole shrinkage drawing pass is 1.1-1.5; the outer diameter of machined products is 100-320 mm, and the wall thickness is 3-20 mm.

Owner:UNIV OF SCI & TECH BEIJING

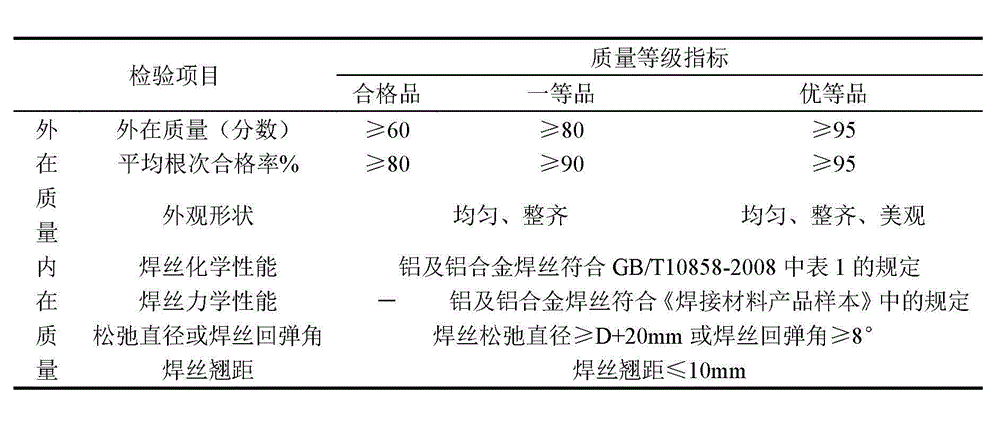

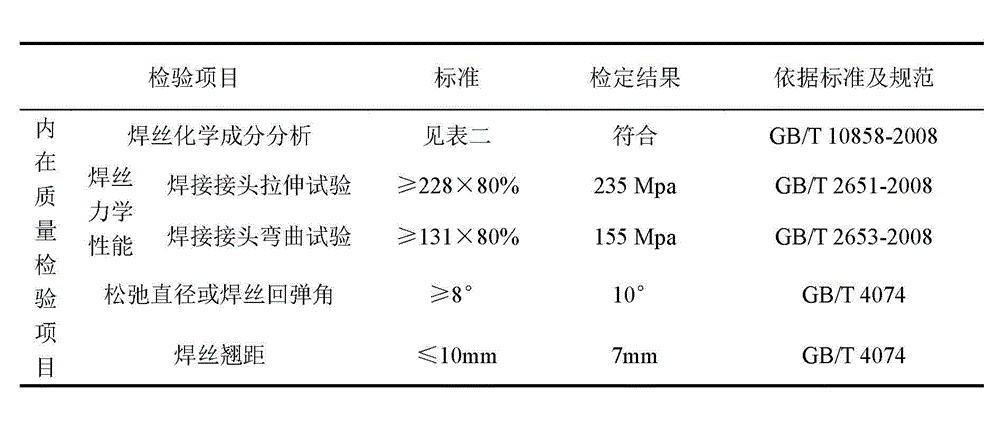

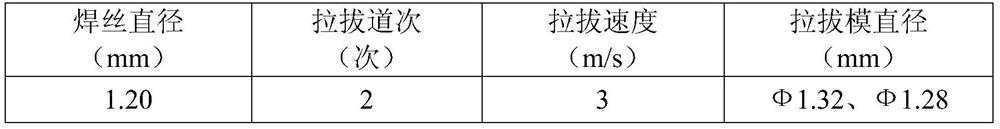

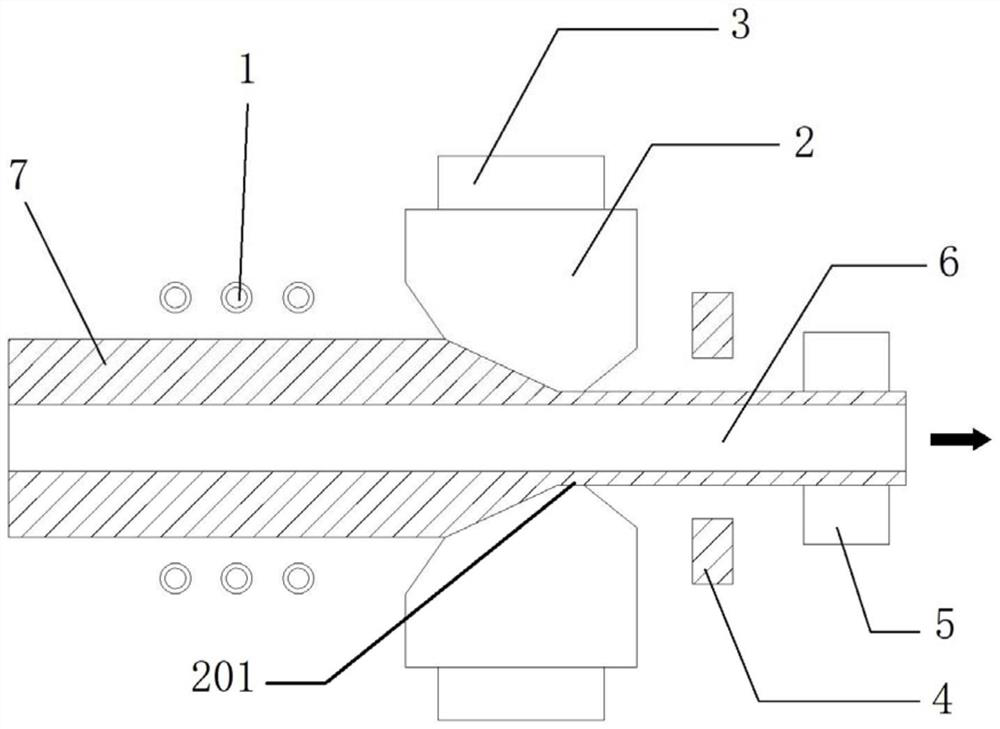

Preparation method of aluminum alloy welding wire

InactiveCN102941423AReduce problemsGrain refinementWelding/cutting media/materialsSoldering mediaWire rodLight treatment

The invention discloses a preparation method of an aluminum alloy welding wire, and belongs to the technical field of aluminum alloy. The preparation method of a high-performance aluminum alloy welding wire comprises the following steps of: (1) coldly and continuously rolling; (2) drawing; (3) shaving; (4) drawing a water tank; (5) carrying out light treatment; (6) cleaning by an ultrasonic wave, and (7) drying by hot air. The preparation method has the characteristics that a partial drawing procedure is replaced by a cold continuous rolling manner, and an aluminum alloy steel wire rod is subsequently processed after being rolled to have specific wire diameter once. Therefore, the drawing passes are reduced; the annealing passes are also reduced; the automation capability of the production process is improved; the utilization rate of the material is greatly improved; the production loss and the labor intensity are reduced; personnel quota is reduced; the production cost is reduced; the shaving procedure is carried out after the traditional water tank is drawn; the procedure is adjusted into the process of firstly shaving and then drawing the water tank; the welding wire is shaved when the wire diameter is large; an oxide skin at the surface of the welding wire is removed early; the welding wire is not easily broken due to high strength when the wire diameter is large; and the quality of the surface of the welding wire and the stability of the quality are greatly improved.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

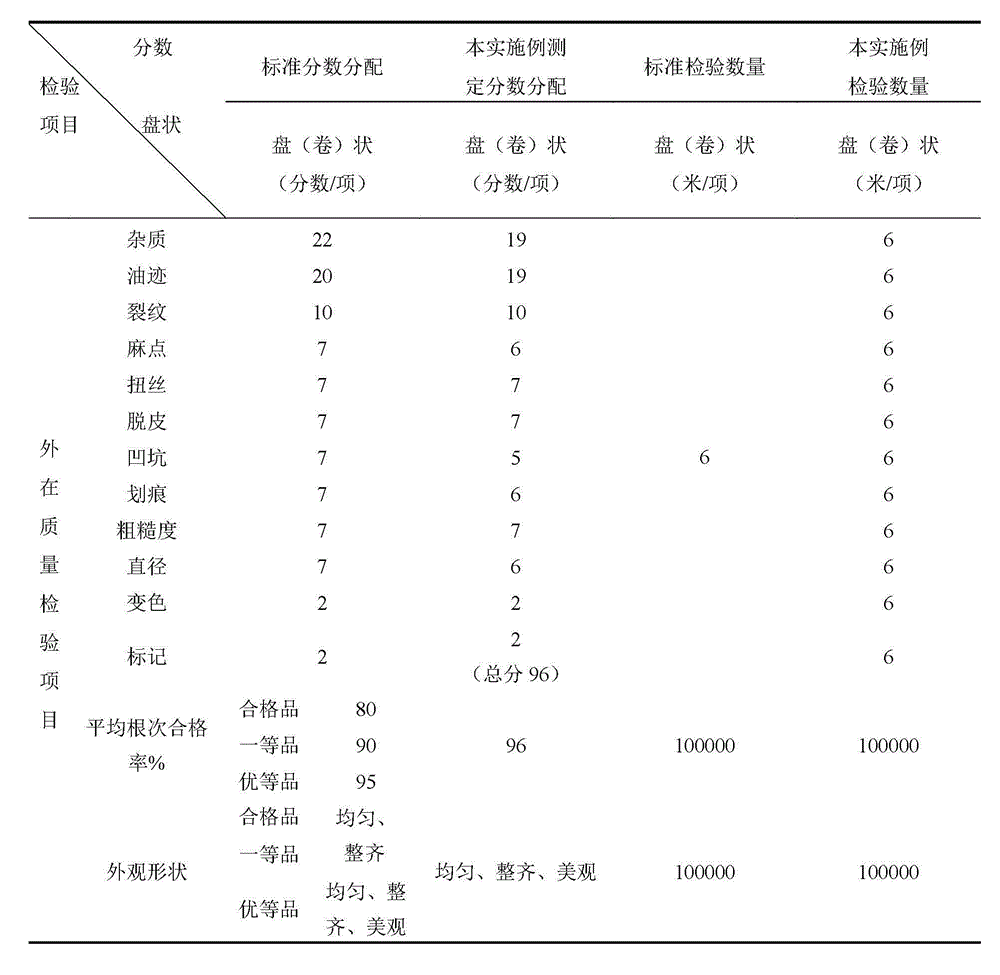

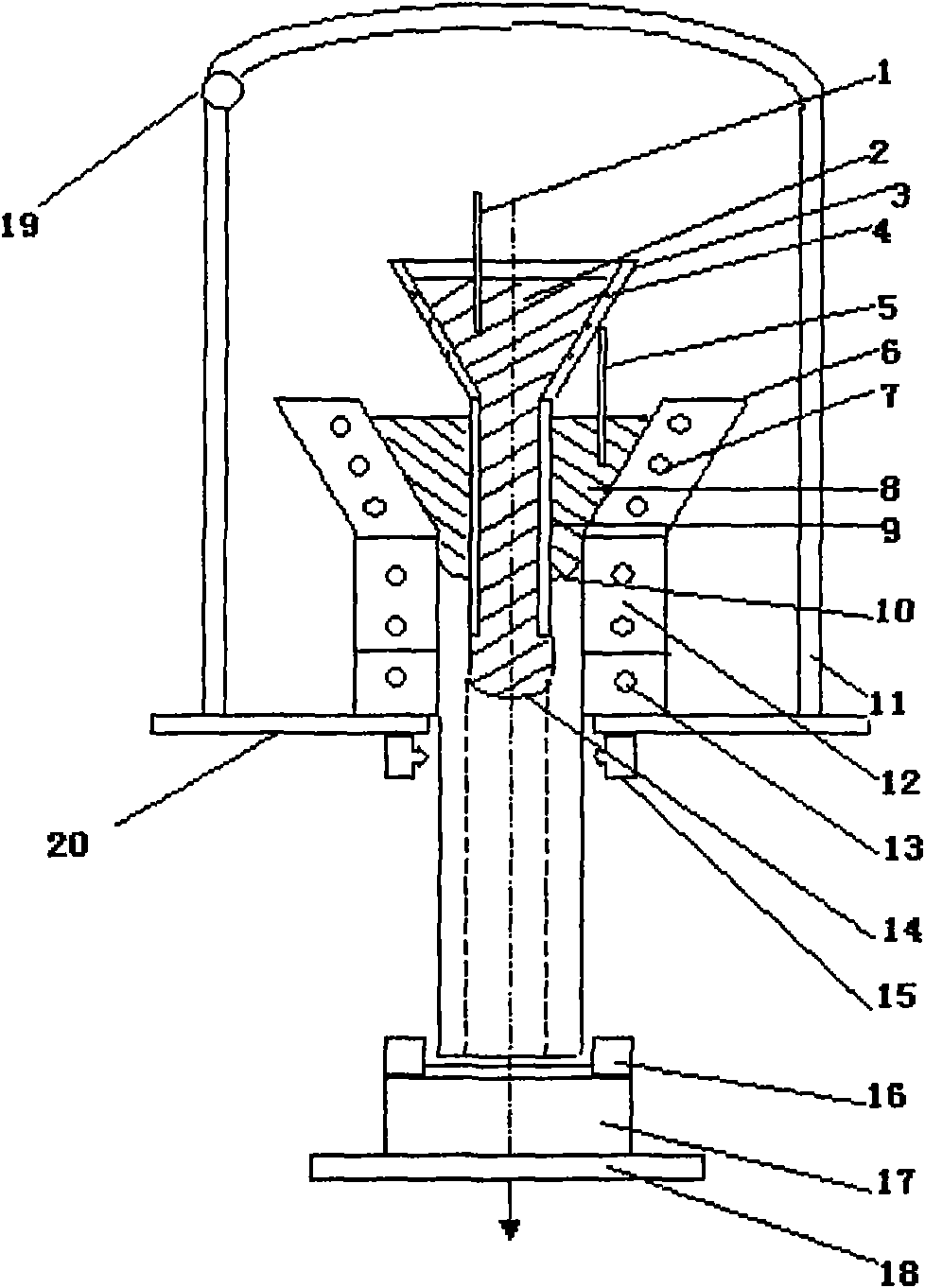

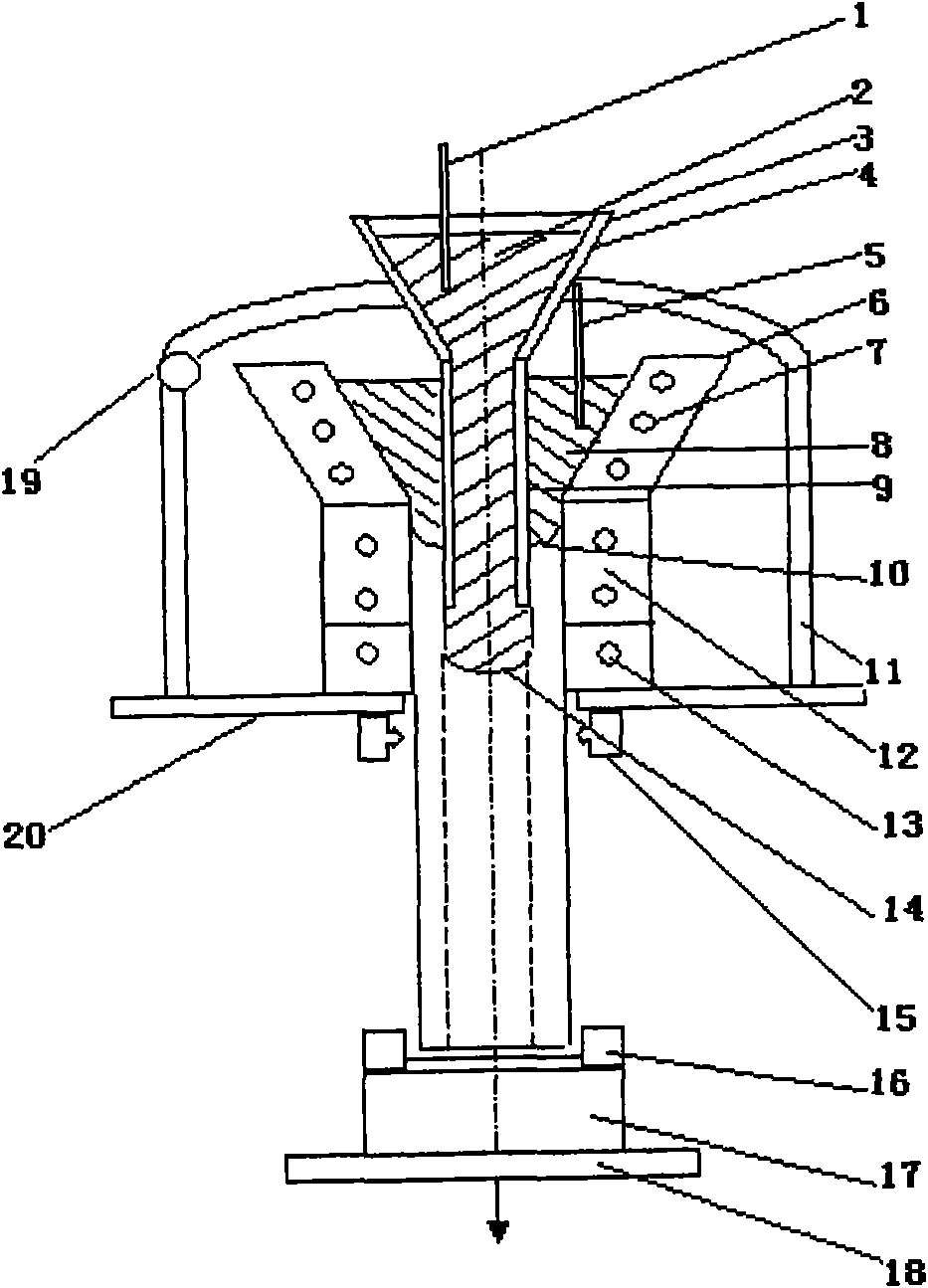

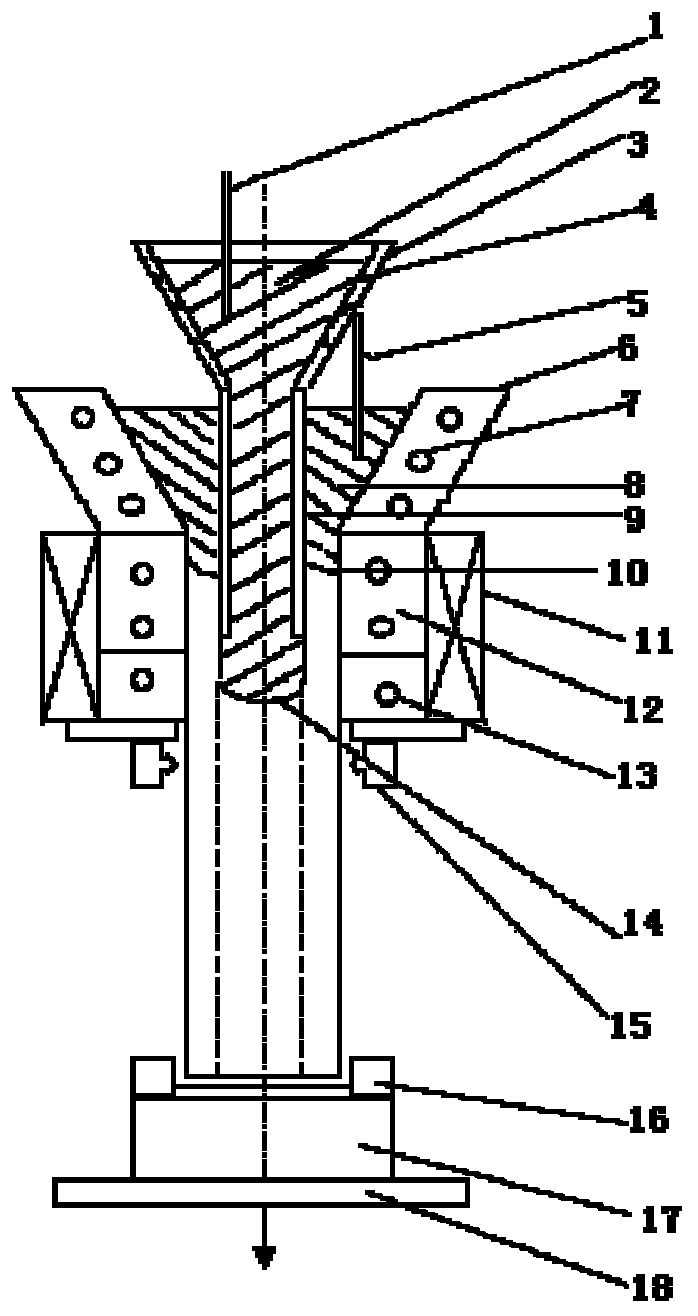

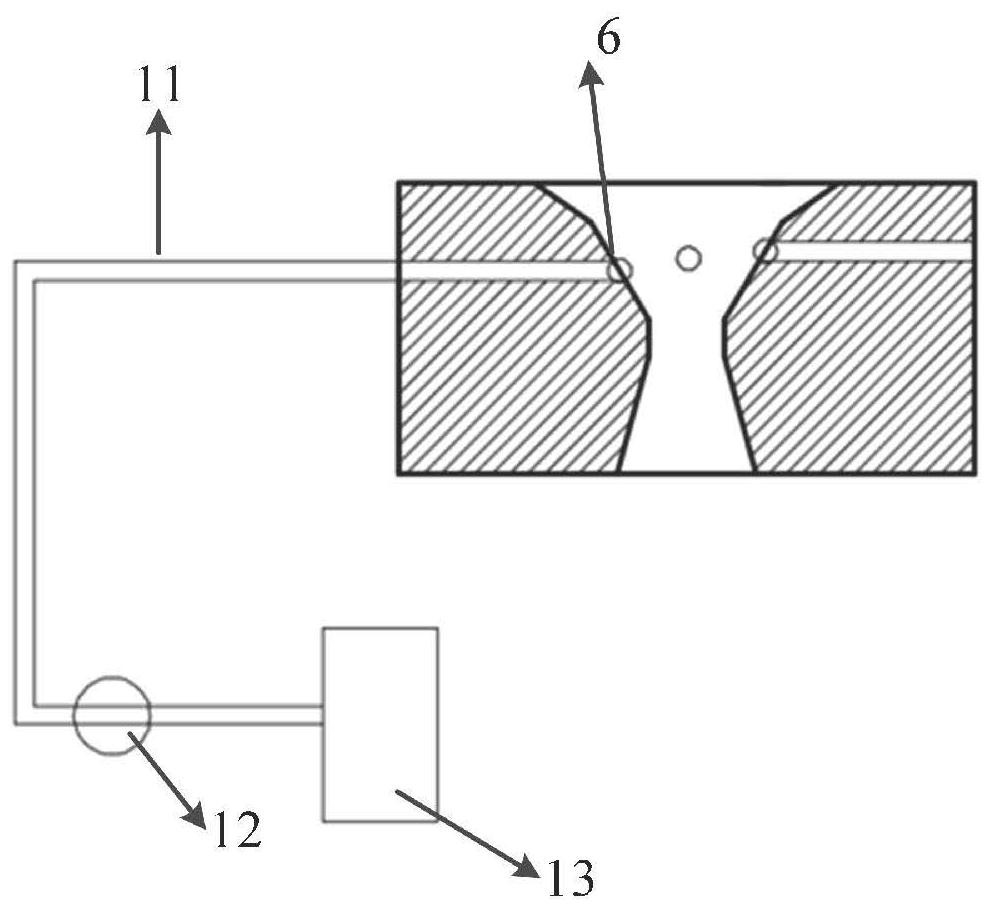

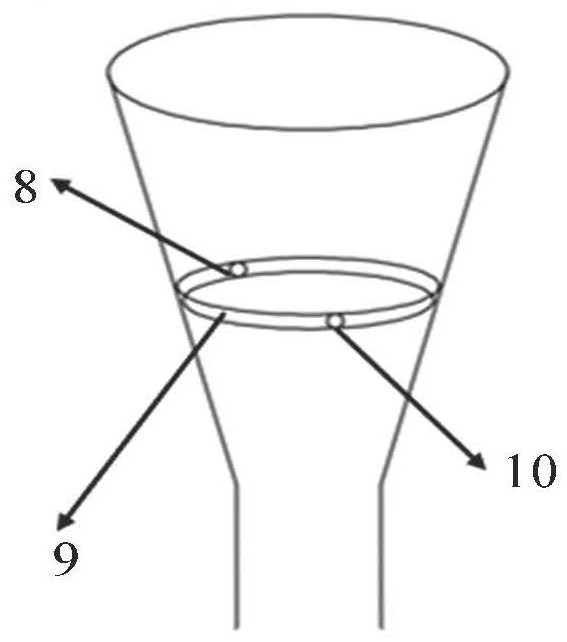

Fine forming equipment of coating material which is pressed, ejected, core-filled and continuously casted and technique

The invention relates to a fine forming equipment of a coating material which is pressed, ejected, core-filled and continuously casted and a technique, belonging to the pressure processing field in metal materials. The equipment consists of an upper crystallizer, a lower crystallizer, a temperature measuring instrument, a core metal temperature control furnace, an outer metal temperature control furnace, a core-filling tube, a pressure cover, a supporting plate, a secondary cooling device, a limiting device, a pressure sensor and a conceding device, wherein an outer metal crystallizer and a core metal liquid core-filling tube are arranged on a same axis along the continuous casting direction; the upper end of the core metal liquid core-filling tube is connected with a core metal temperature control crucible and the lower end thereof penetrates deeply in the outer metal liquid; the core metal liquid core-filling tube is used for isolating the outer layer and the core metal liquid to form an outer layer metal mold core; and the core metal liquid is casted. The pressure cover is connected with the edge end of the supporting plate and the inner side of the supporting plate is connected with a lower temperature crystallizer; an outer metal casting blank is ejected by applying pressure through the gas in the pressure cover. The invention eliminates cracks and oscillation marks which occur in common continuous casting blanks easily, can continuously cast the coating material by one time, and obtain a high-quality composite interface; and the follow-up processing production has low cost and high efficiency.

Owner:UNIV OF SCI & TECH BEIJING

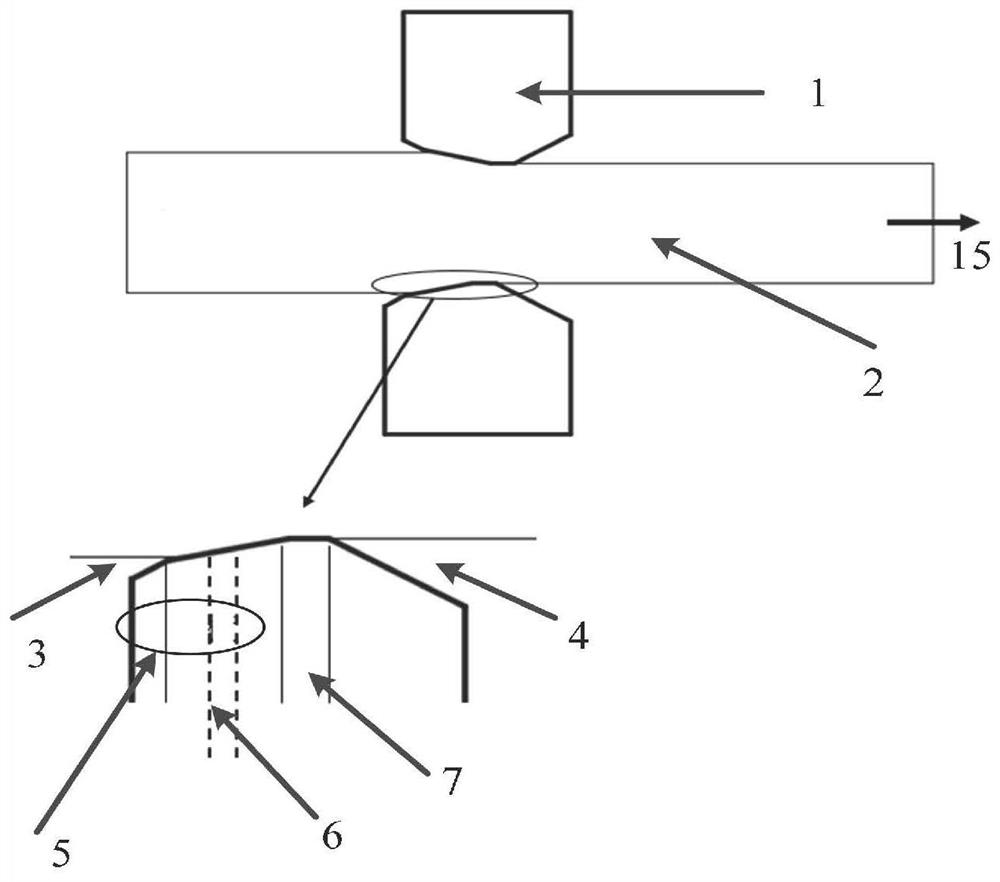

Apparatus for preparing easy-oxidizing hard-distortion alloy wire staff

InactiveCN101157119AAvoid various problems of vacuum production processShort processWire rodProduct demand

The invention relates to equipment for preparing an alloyed wire rod which is easy to be oxidated and difficult to be distorted. A smelting furnace adopts a non-vacuum induction smelting furnace protected by the atmosphere, holes are arranged on the side of the smelting furnace body, horizontal continuous casting crystallizers with different cross sections and specifications are installed at the side hole positions, the sprues of the horizontal continuous casting crystallizers are communicated with the smelting furnace body, draughting mechanisms are arranged at the outlet openings of the horizontal continuous casting crystallizers, and curling mechanisms are connected with the draughting mechanisms end to end. The horizontal continuous casting alloyed wire rod is realized through installing the horizontal continuous casting crystallizers with different cross sections and specifications at the side hole positions, for the sizes of the horizontal continuous casting crystallizers, different specifications and different cross sections are determined according to product demand, the draughting mechanisms realize that the wire rod advances at the specified casting draughting speed, the curling mechanisms realize to collect the alloyed wire rod, so that the length of the wire rod can be expanded, the invention is widely suitable for production equipment of the wire rod of easily oxidable alloys of Cu-Cr-Zr, Cu-Ti, etc., and difficultly distorted alloys of Cu-Ti, etc.

Owner:苏州有色金属研究院有限公司

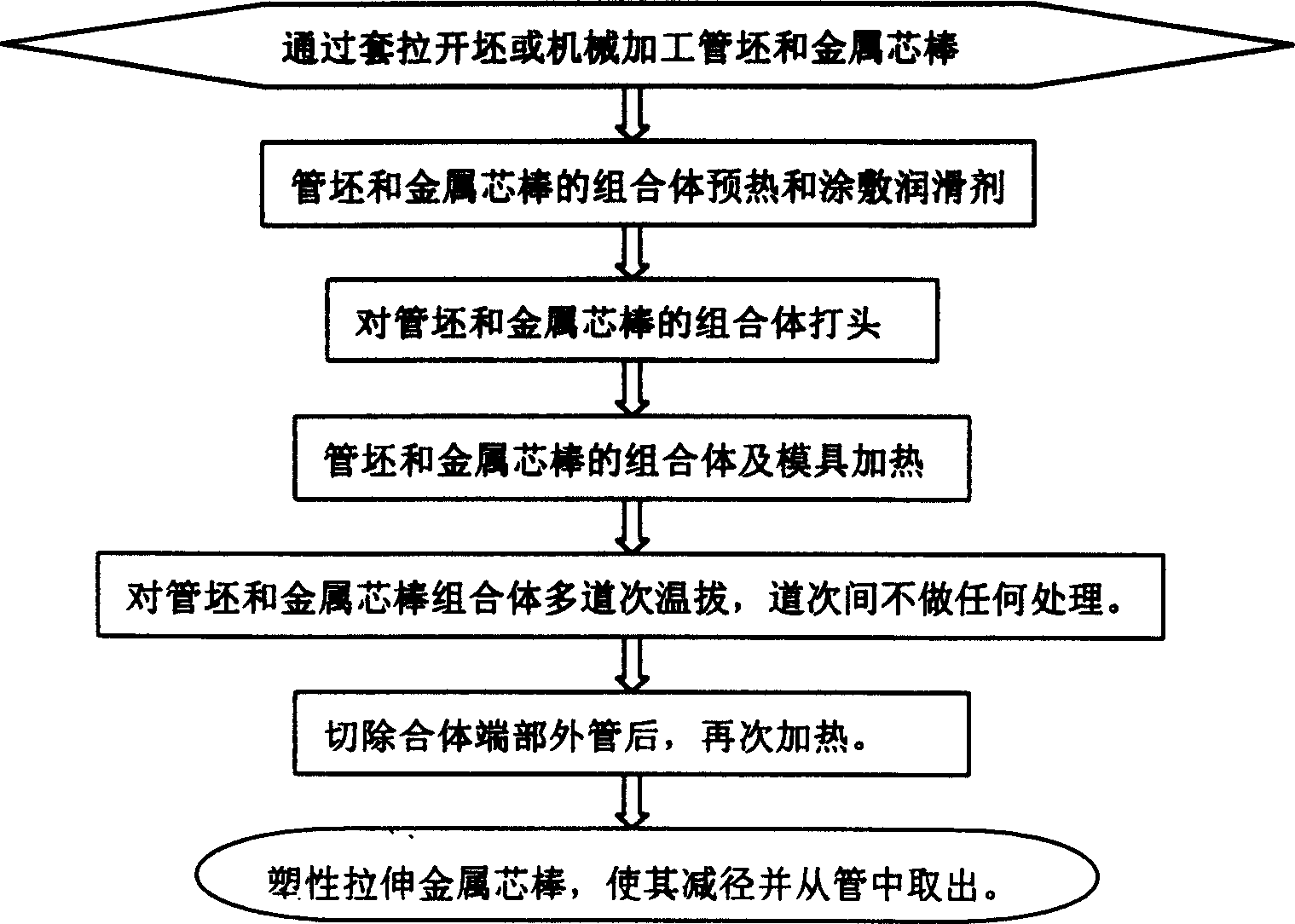

Sleeve pulling shaping method of nickel titanium base marmem pipe material

A sleeving-pulling technology for manufacturing the NiTi-based marmem pipe includes machining NiTi-based marmem pipe blank and mandrel, heating them and die to 200+ / -10 deg.C, spraying lubricant,inserting the mandrel in the pipe blank, reducing the diameter of both ends, heating it to 700+ / -20 deg.C and die to 350+ / -10 deg.C, drawing more times while spraying lubricant, cutting out both ends, heating to 800-850 deg.C, and pulling the mandrel out of the pipe.

Owner:JIANGSU FASTEN TECH DEV CENT

Variable-channel mold for improving drawing toughness of steel bar

The invention discloses a variable-channel mold for improving the drawing toughness of a steel bar. An upper mold and a lower mold are buckled, and the mold forms a mold cavity with variable channel and variable section. The mold cavity comprises a straightening section, a deforming section and a sizing section sequentially, wherein the straightening section is a steel bar drawing front section, and the cross section of the mold cavity is a large circular section; the sizing section is a steel bar drawing rear section, and the cross section of the mold cavity is a small circular section. The mold cavity of the deforming section is partitioned to be a large circle to ellipse traditional twist section and an ellipse to small circle traditional twist section. The section of each section gradually deforms from a large circular section to a twisted elliptic section, and then gradually deforms from the twisted elliptic section to a small circular section, finally a required cold-drawing reinforced steel bar is molded from the sizing section. When the variable-channel variable-section mold is used in a steel bar cold machining, the toughness damage of the mold to the materials is low, the metal grains can be thinned under the condition of multi-section deformation, consequently, a preferable toughness is obtained while the strength of the cold-drawing steel bar is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Continuous casting forming equipment and process method for electromagnetic ejection filling core of cladding material

The invention relates to continuous casting forming equipment and a process for an electromagnetic ejection filling core of a cladding material, belonging to the field of the continuous casting processing in metal material. The equipment provided by the invention comprises upper and lower temperature control crystallizers, a temperature measuring instrument, a metal temperature control furnace of the core, an outer metal temperature control furnace, a filling core tube, an electromagnetic pump, a secondary cooling device, a limiting device, a pressure sensor and a recession device, wherein the upper and lower temperature control crystallizers and a metal liquid filling core tube of the core are arranged on the same axis along the continuous casting direction; the electromagnetic pump is installed outside the upper and lower temperature control crystallizers and assembled on the same axis with the upper and lower temperature control crystallizers; the upper end of the metal liquid filling core tube of the core is connected with a metal temperature control crucible of the core, and the lower end is inserted into outer metal liquid; the outer metal liquid and the metal liquid of the core are isolated through the metal liquid filling core tube of the core; the outer metal liquid is cooled to form an outer metal tube; the metal liquid of the core is poured into the outer metal tube through the metal liquid filing core tube of the core; and a composite blank is ejected out by exerting the pressure through the electromagnetic pump. The invention eliminates cracks and vibration marks which are easy to occur in a common continuous casting blank, can continuously cast the cladding material once, obtains a composite interface of high quality and has the advantages of low production cost and high efficiency of subsequent processing.

Owner:UNIV OF SCI & TECH BEIJING

A short-process production method for large-diameter thin-walled copper-nickel pipes

The invention discloses a short-process production method of a large-diameter thin-walled white copper pipe, which belongs to the technical field of metal materials. Aiming at the traditional "semi-continuous casting solid ingot-piercing extrusion-pickling-drawing-annealing" process to produce large-diameter thin-walled copper-nickel pipes requires more than 5,000 tons of large-scale extrusion equipment, and the yield is low and the cost is high. The present invention proposes a method of horizontal continuous casting of large-sized white copper pipe blanks using hot and cold combined molds, and then adopts diameter expansion or / and diameter reduction drawing to process and form large-diameter thin-walled white copper pipes, which has the advantages of small equipment investment, short process flow, No pickling and other advantages. The outer diameter of the horizontal continuous casting tube blank is 110~350mm, the wall thickness is 5~30mm, the extension coefficient of the drawing pass for expanding diameter is 0.80~1.0, the extension coefficient for drawing pass for reducing diameter is 1.1~1.5, and the outer diameter of the processed product is 100~ 320mm, wall thickness 3~20mm.

Owner:UNIV OF SCI & TECH BEIJING

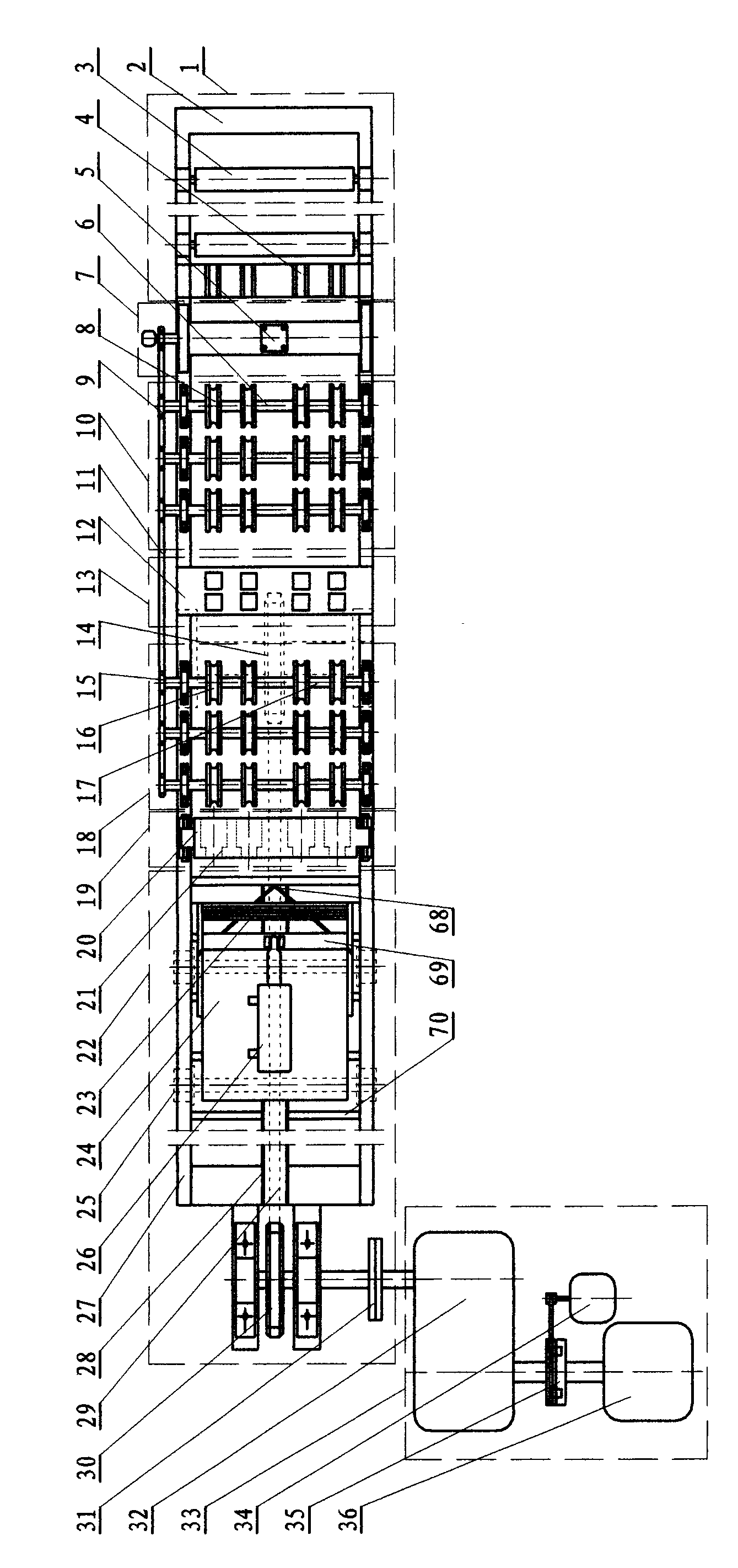

Novel automatic cold drawing process for colored metal tube and automatic cold drawing machine of colored metal tube

ActiveCN102240686AReduce labor intensityIncrease lock speedDrawing diesEngineeringUltimate tensile strength

The invention discloses a automatic cold drawing process for a colored metal tube, and relates to the technical field of colored metal tube processing. The process comprises the following steps of: feeding material tube, conveying the material tube at the first time, locking the opening of the material tube, conveying the material tube at the second time, clamping the material tube, drawing the material tube and resetting the material tube. The automatic cold drawing machine has the characteristics of reducing the labor intensity, improving the production efficiency, reducing the energy consumption, improving the product quality, realizing automatic and continuous production and the like, and is suitable for all types of colored metal tubes, such as a cold drawing aluminum tube, a cold drawing copper tube and the like.

Owner:QIYANG HONGTAI ALUMINUM IND

Manufacturing method of 304 wear-resistant stainless steel wire

ActiveCN108465699AHigh hardnessImprove performanceMetal rolling arrangementsWear resistantRoom temperature

The invention discloses a manufacturing method of a 304 wear-resistant stainless steel wire. The manufacturing method comprises the following steps that 1) a raw material 304 stainless steel wire material with the diameter of 1.3 times larger than the preset diameter of a finished product is selected; 2) annealing is carried out on the 304 stainless steel wire material; 3) multi-pass drawing treatment is carried out on the annealed stainless steel wire material, if the size of the finished product is reached, the finished product is obtained, if the size is not the size of the finished product, annealing is carried out again, air cooling is carried out on the annealed stainless steel wire material until the temperature of the steel wire material reaches the room temperature, and the stainless steel wire material subjected to drawing and annealing is obtained; 4) the diameter of the stainless steel wire material subjected to drawing and annealing is 1.3 times larger than the preset diameter of the finished product, the step 3 is repeated until the diameter of the stainless steel wire subjected to drawing and annealing is 1.3 times less than or equal to the preset diameter of the finished product, and then the step 5 is carried out; and 5) drawing treatment is carried out on the stainless steel wire material subjected to drawing annealing to reach the size of the finished product, and the 304 wear-resistant stainless steel wire finished product is manufactured. According to the 304 wear-resistant stainless steel wire finished product manufactured by the method, the tensile strength is improved by 1-3 times, the micro vickers hardness is improved by 2-3 times, and the wear performance is improved by 5-30%.

Owner:NORTHEASTERN UNIV +1

A kind of preparation method of magnesium alloy welding wire

ActiveCN109570826BSave energySolve the "bottleneckWelding/cutting media/materialsSoldering mediaLaser-hybrid weldingFusion welding

A preparation method of magnesium alloy welding wire, the steps are: ingot extrusion; wire billet cleaning; preheating; continuous extrusion: continuous feeding into the extruder, through the control of the extrusion speed and the adjustment of the temperature control system, to maintain The continuous extrusion temperature is between 380°C and 450°C; drawing; scraping; surface treatment. The preparation method of the present invention is not only simple in process and easy to operate, but also efficient in processing and low in economic cost, adopts continuous extrusion, greatly improves the processing performance of magnesium alloys, effectively solves the problem of joint connection of magnesium alloy welding wires, and can produce high-quality magnesium Alloy jointless welding wire can meet the quality requirements of fusion welding such as automatic MIG welding, TIG welding and laser hybrid welding, and is suitable for industrial production of high-quality magnesium alloy welding wire.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

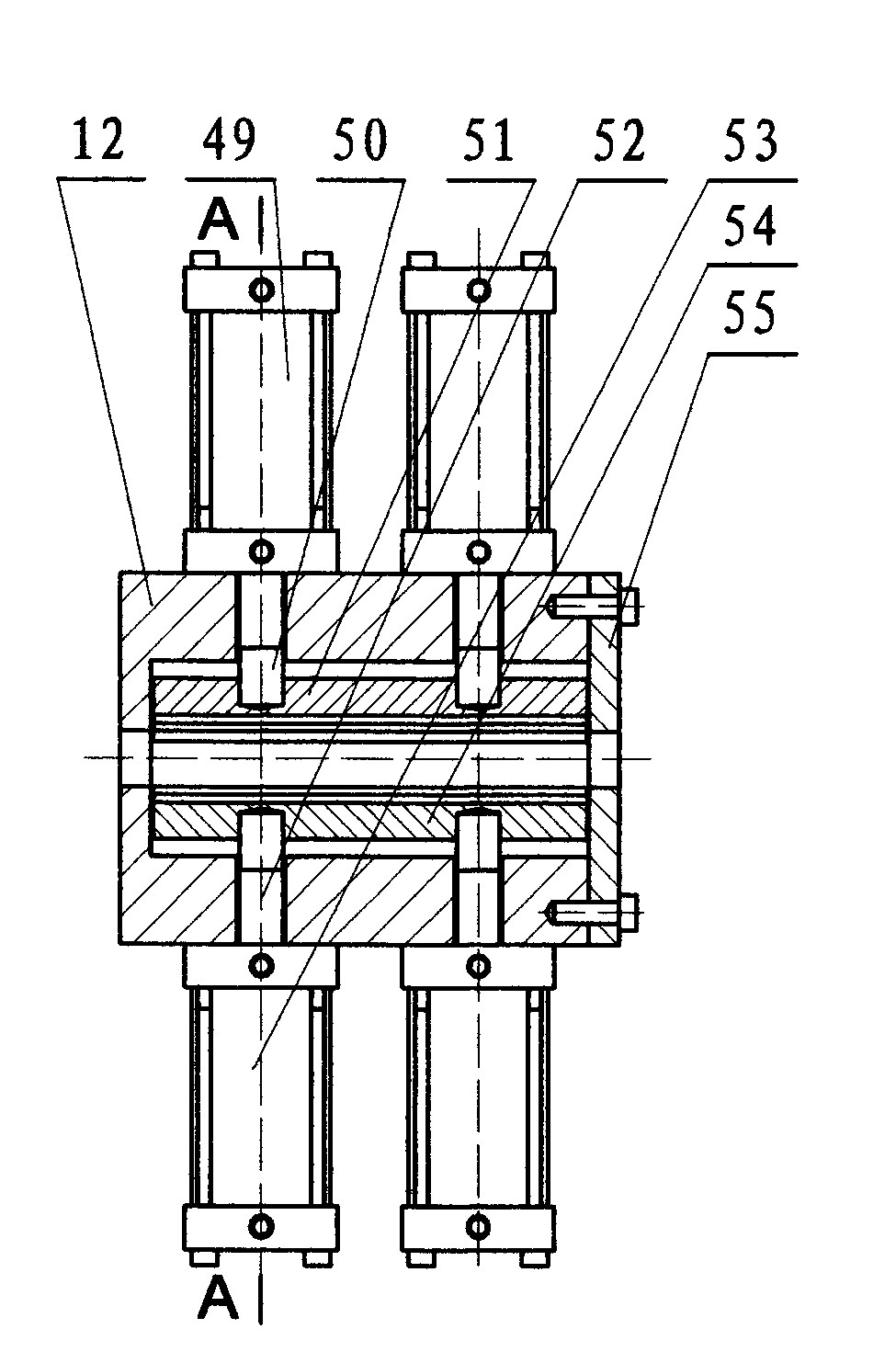

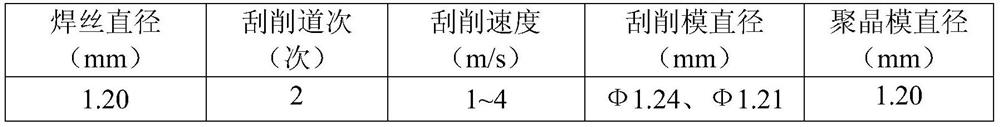

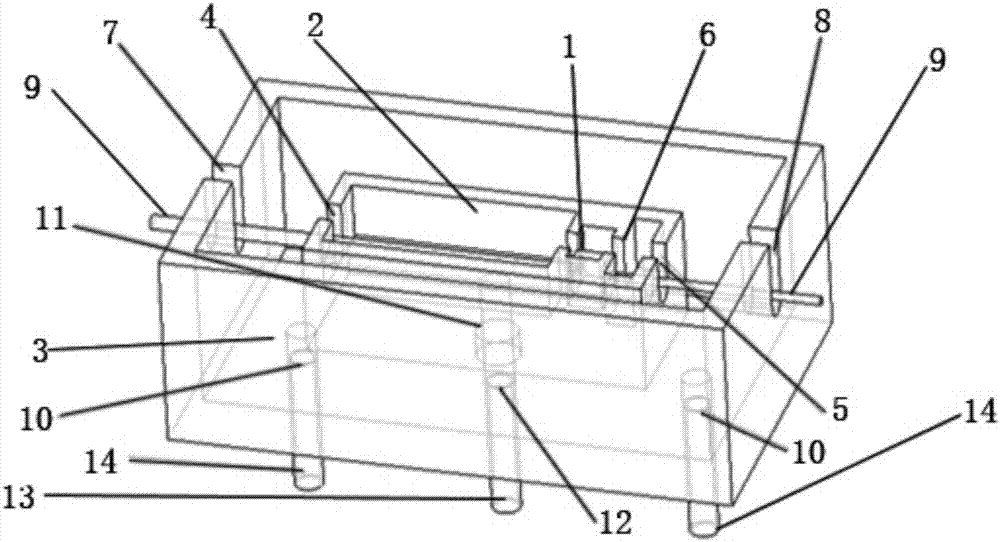

Induction heating auxiliary drawing device for preparing capillary tube

PendingCN113083922ARaise the deformation temperatureImprove plasticityDrawing diesCapillary TubingEngineering

The invention discloses an induction heating auxiliary drawing device for preparing a capillary tube. The induction heating auxiliary drawing device comprises an induction heating device, a drawing mold, a vibration generator and a cooler. The drawing mold is provided with a shaft hole for the capillary tube to pass through before drawing. The induction heating device is arranged on one side of the shaft hole, and the vibration generator is installed on the outer surface of the drawing mold. The cooler is arranged on the other side of the shaft hole relative to the induction heating device, and the induction heating device, the drawing mold and the cooler are coaxially and oppositely arranged. The deformation temperature of the tube is increased through the induction heating device, and the plasticity of the tube is improved, so that the pass deformation is finally increased and the drawing pass is reduced; meanwhile, an ultrasonic vibration device enables the mold to vibrate, improves the friction condition and reduces the drawing force, finally, the pass deformation can be increased, the drawing pass can be reduced, and large-deformation drawing of the capillary tube is achieved through the multi-energy-field combined auxiliary drawing device.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Heat treatment method of zinc-aluminum rolled strip

ActiveCN103924179AImprove plasticityIncrease the deformation of a single drawingSolution treatmentRoom temperature

The invention discloses a heat treatment method of a zinc-aluminum rolled strip. The heat treatment method is used for improving the plasticity and the stability of the zinc-aluminum rolled strip and comprises the following steps: (1), placing the zinc-aluminum rolled strip in a heating furnace for performing solution treatment at a temperature of 360 DEG C for 4-10 hours; (2), reducing the furnace temperature of the heating furnace to 250 DEG C, and preserving heat of the zinc-aluminum rolled strip at the temperature of 250 DEG C for 2-3 hours; and (3), after heat preservation, continuously reducing the furnace temperature of the heating furnace to 170 DEG C, and then taking the zinc-aluminum rolled strip out to ensure that the zinc-aluminum rolled strip is cooled to a room temperature in air. The zinc-aluminum rolled strip subjected to heat treatment by adopting the heat treatment method disclosed by the invention is subjected to repeated bending tests; the repeated bending times of the zinc-aluminum rolled strip subjected to heat treatment by adopting the heat treatment method disclosed by the invention is increased by 61 percent in comparison with that of an original rolled strip, a stable structure is obtained, and the mouldability is greatly improved. The heat treatment method disclosed by the invention is simple to operate, and strong in practicability; the obtained material is good in plasticity, stable in performance and difficult in aging.

Owner:SHANGHAI LONGSHUO WELDING MATERIAL

Short flow-path production of copper and copper alloy precise pipe

ActiveCN100496808CExcellent cold working elongation and deformation abilityReduce consumptionDirectional solidificationCopper alloy

A short-path technology for preparing the precise copper or copper-alloy tube by precise conticasting includes such steps as smelting copper or copper alloy at 1150-1300 deg.C, continuous pulling while continuous directional solidifying to obtain the copper or copper alloy tube with 15-50 mm for external diameter and 1-5 mm for wall thickness, and drawing by 5-12 passes.

Owner:LUOYANG COPPER PROCESSING GROUP +1

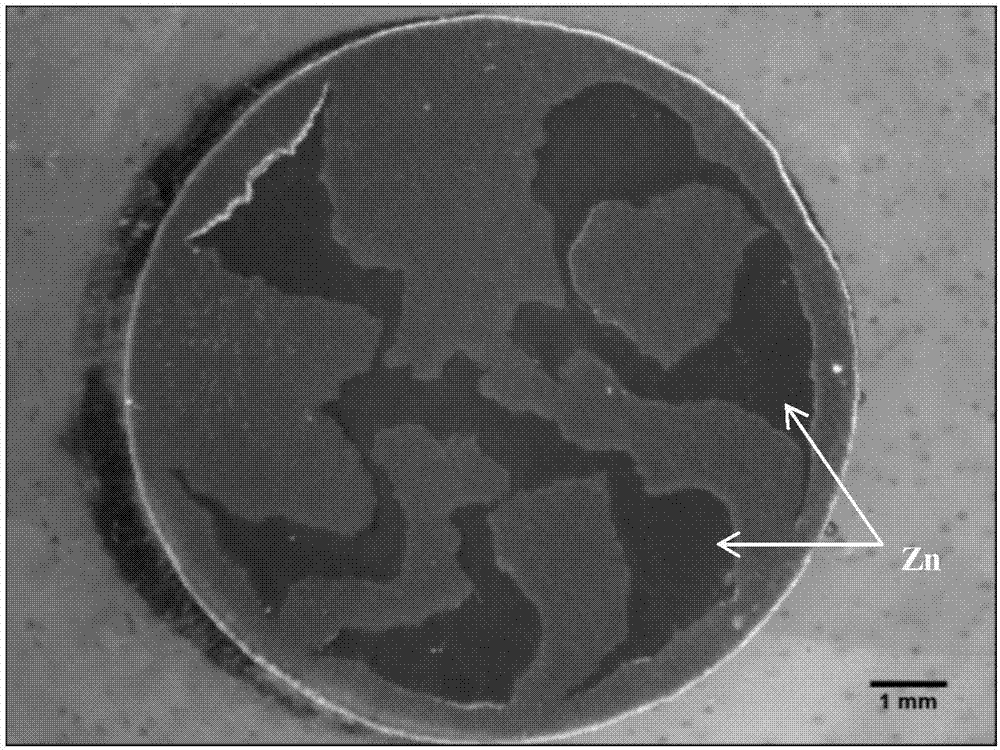

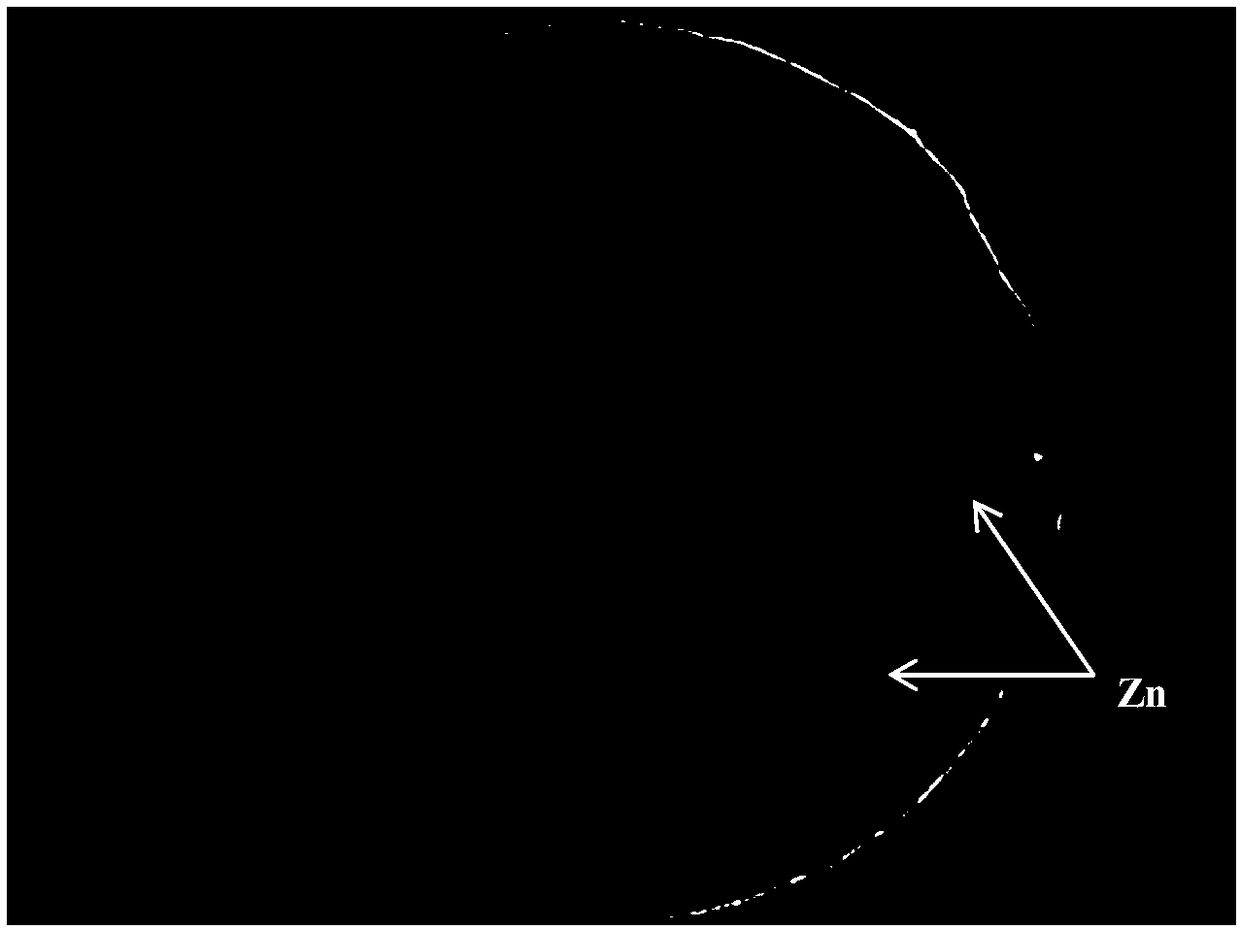

Preparation method of high aluminum zinc-aluminum pseudo-alloy rod materials and wire materials

The invention discloses a preparation method of high aluminum zinc-aluminum pseudo-alloy rod materials and wire materials. The preparation method comprises the following steps that a pure aluminum rod or an aluminum alloy rod and a pure zinc rod are put into a package of pure aluminum or aluminum alloy materials in a certain order, so that composite billet materials are formed; after heating the composite billet materials and extrusion dies of an extrusion machine, then the composite billet materials are put into the extrusion dies, the billet materials are extruded, and composite pseudo-alloy rod materials are prepared; and the obtained composite pseudo-alloy rod materials are drawn and diameter-reduced for multiple passes, and the wire materials are manufactured. According to the preparation method of high aluminum zinc-aluminum pseudo-alloy rod materials and wire materials, the aluminum rod and the zinc rod arranged in the package are extruded, so that the pseudo-alloy rod materials are formed by deformation and mixing, and then the rod materials are drawn and diameter-reduced to obtain the high aluminum zinc-aluminum pseudo-alloy wire materials. In the above process, the zinc and the aluminum are only deformed, the diameter is reduced, alloying does not happen between the zinc and the aluminum, the eutectic structure and the hard brittle phase are not produced, the deformation ability of the obtained rod materials is good, and a high aluminum zinc-aluminum coating layer is formed in heat spraying preparation of an anticorrosive coating after the pseudo-alloy wire materials are prepared by drawing and diameter reduction.

Owner:BEIHANG UNIV

Preparation method of aluminum alloy welding wire

InactiveCN102941423BReduce problemsGrain refinementWelding/cutting media/materialsSoldering mediaWire rodLight treatment

The invention discloses a preparation method of an aluminum alloy welding wire, and belongs to the technical field of aluminum alloy. The preparation method of a high-performance aluminum alloy welding wire comprises the following steps of: (1) coldly and continuously rolling; (2) drawing; (3) shaving; (4) drawing a water tank; (5) carrying out light treatment; (6) cleaning by an ultrasonic wave, and (7) drying by hot air. The preparation method has the characteristics that a partial drawing procedure is replaced by a cold continuous rolling manner, and an aluminum alloy steel wire rod is subsequently processed after being rolled to have specific wire diameter once. Therefore, the drawing passes are reduced; the annealing passes are also reduced; the automation capability of the production process is improved; the utilization rate of the material is greatly improved; the production loss and the labor intensity are reduced; personnel quota is reduced; the production cost is reduced; the shaving procedure is carried out after the traditional water tank is drawn; the procedure is adjusted into the process of firstly shaving and then drawing the water tank; the welding wire is shaved when the wire diameter is large; an oxide skin at the surface of the welding wire is removed early; the welding wire is not easily broken due to high strength when the wire diameter is large; and the quality of the surface of the welding wire and the stability of the quality are greatly improved.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

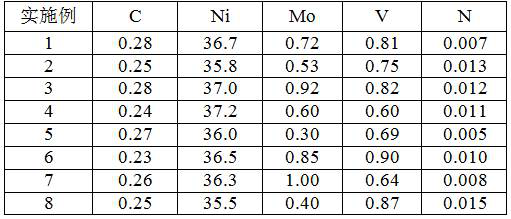

High-strength iron-nickel-molybdenum alloy wire and low-cost preparation method thereof

The invention discloses a high-strength iron-nickel-molybdenum alloy wire and a low-cost preparation method thereof, and belongs to the technical field of metallurgy, and the wire comprises the following chemical components in percentage by mass: 0.23-0.28% of C, 35.5-37.2% of Ni, 0.30-1.00% of Mo, 0.60-0.90% of V, 0.005-0.015% of N and the balance of Fe and inevitable impurities. The preparation method comprises the working procedures of vacuum melting, electroslag remelting, forging, high-temperature solution treatment, low-temperature rolling, aging heat treatment, peeling and cold drawing. And in the high-temperature solution treatment process, the temperature of solution treatment is 1200-1250 DEG C, and the time is 3-5 hours. The prepared iron-nickel-molybdenum alloy wire has the properties of high strength, low expansion coefficient, high torsion and the like, and is short in production period and low in production cost.

Owner:HEBEI IRON AND STEEL +2

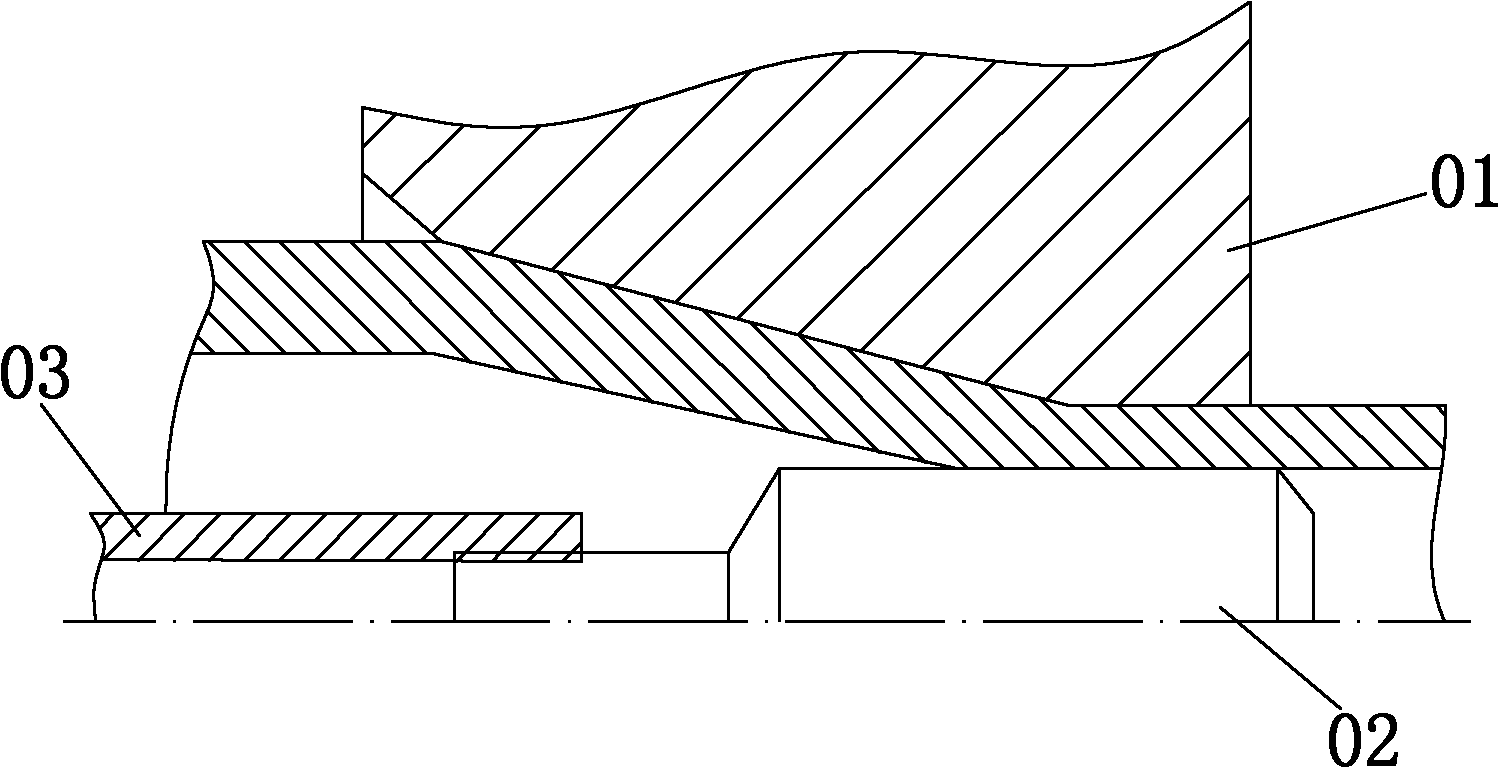

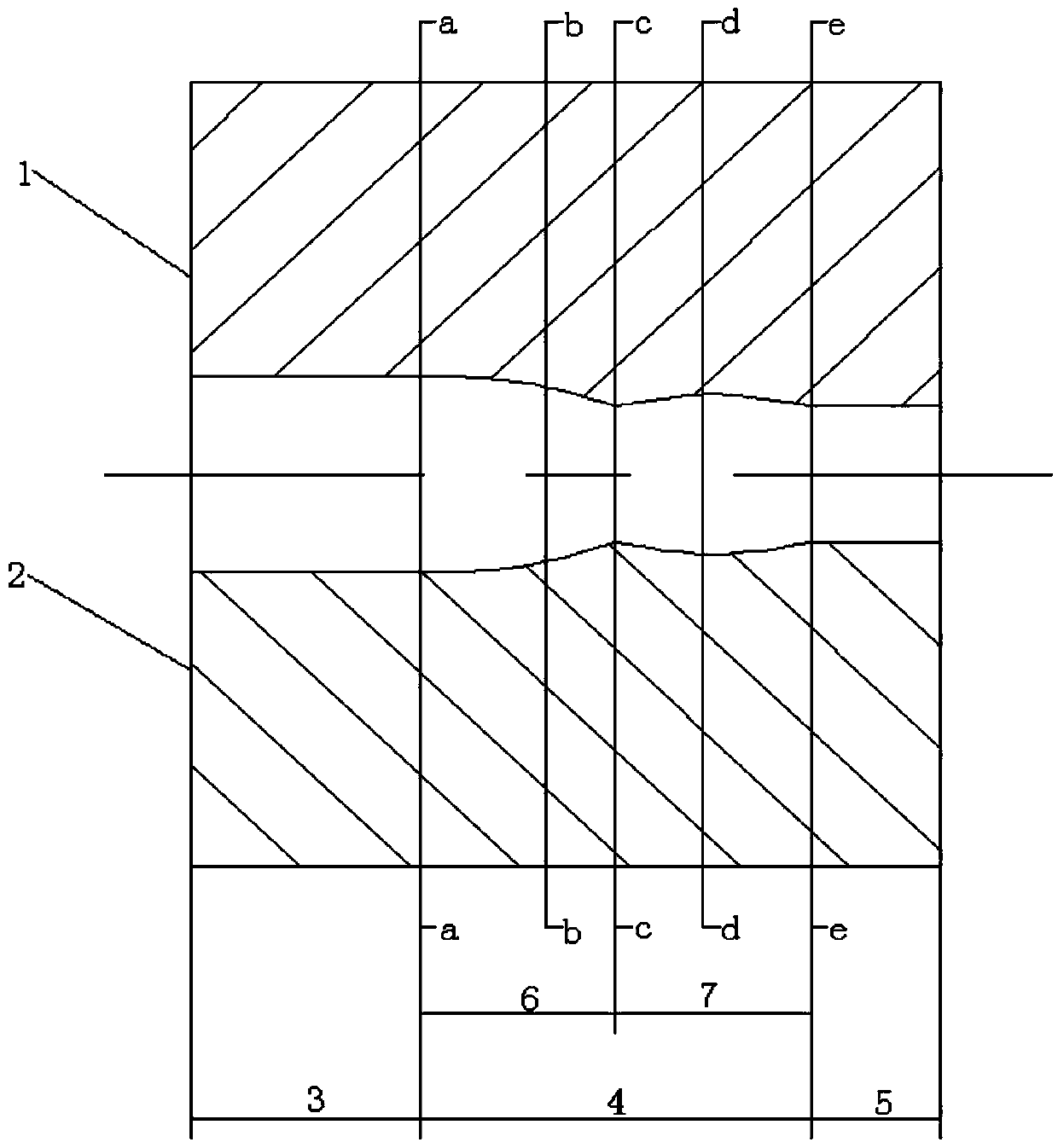

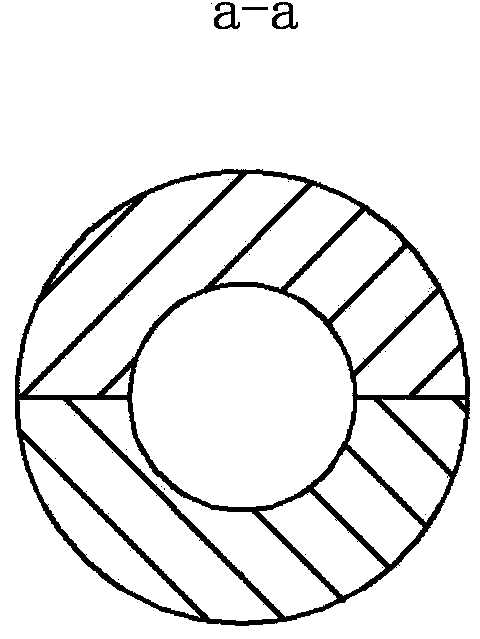

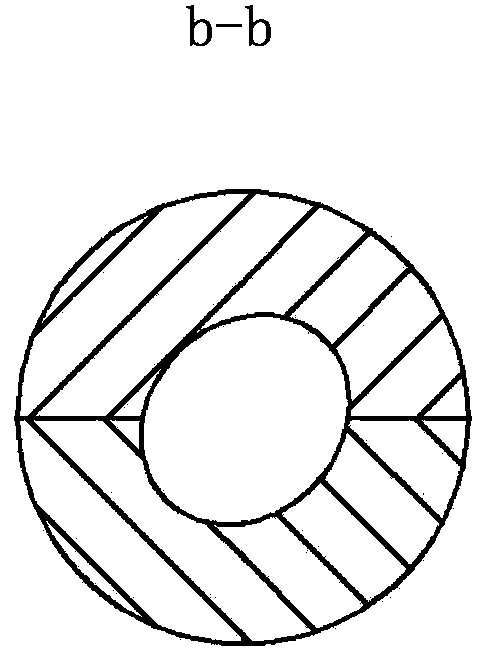

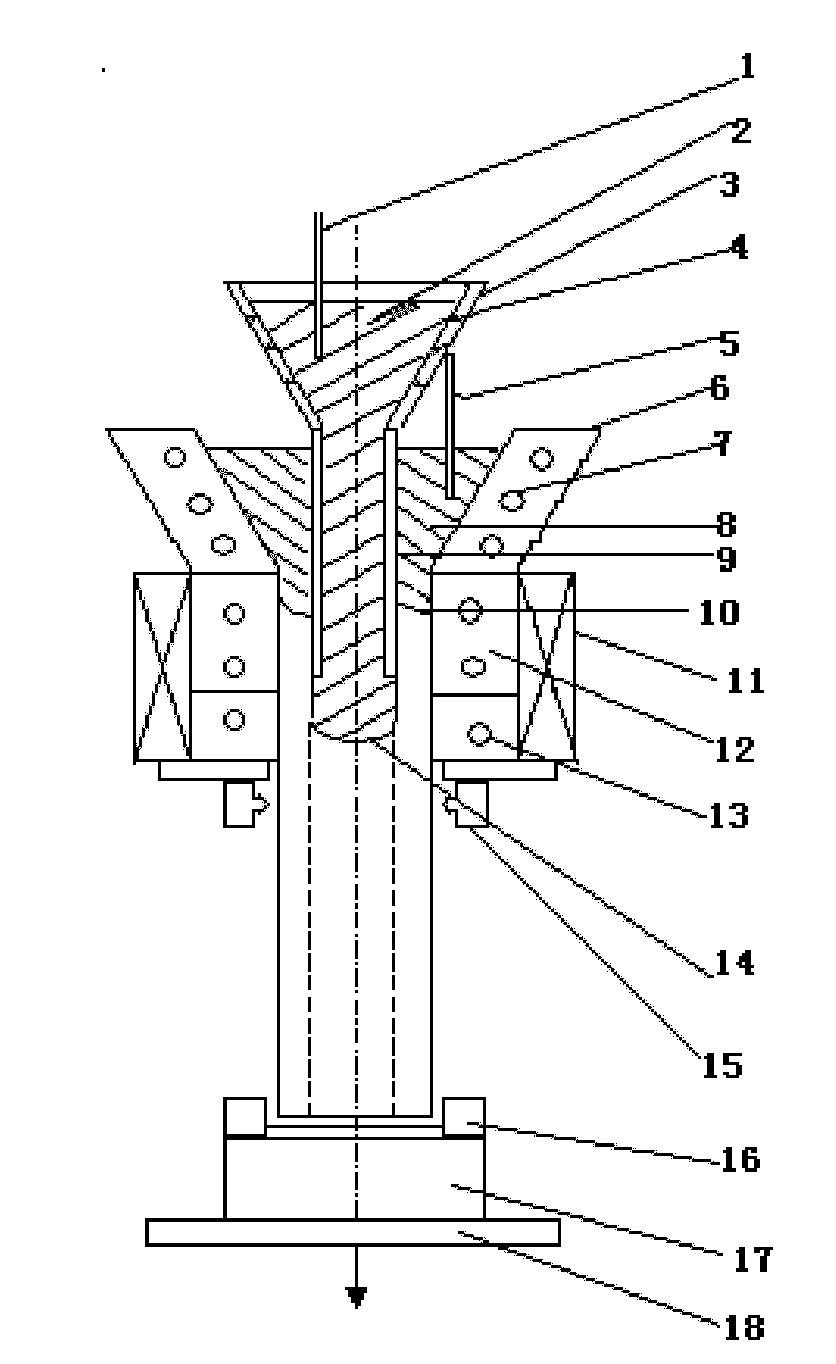

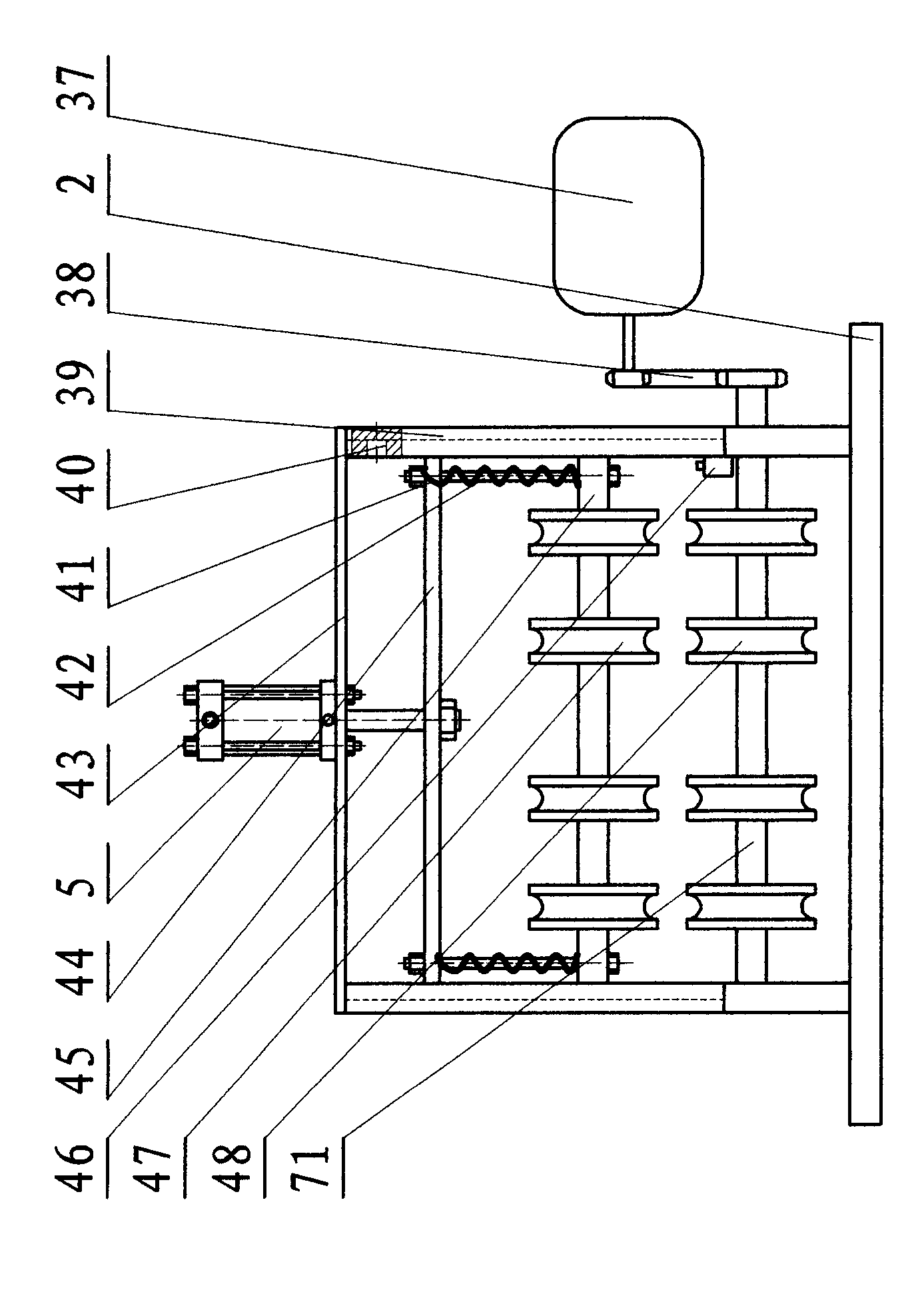

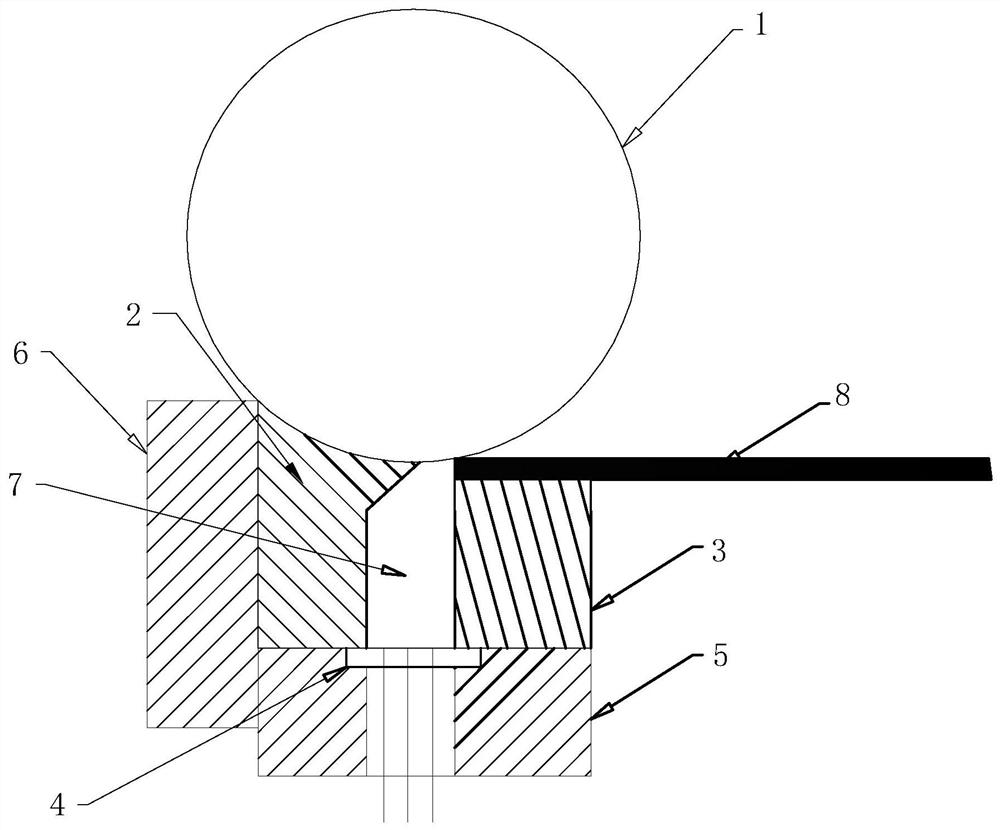

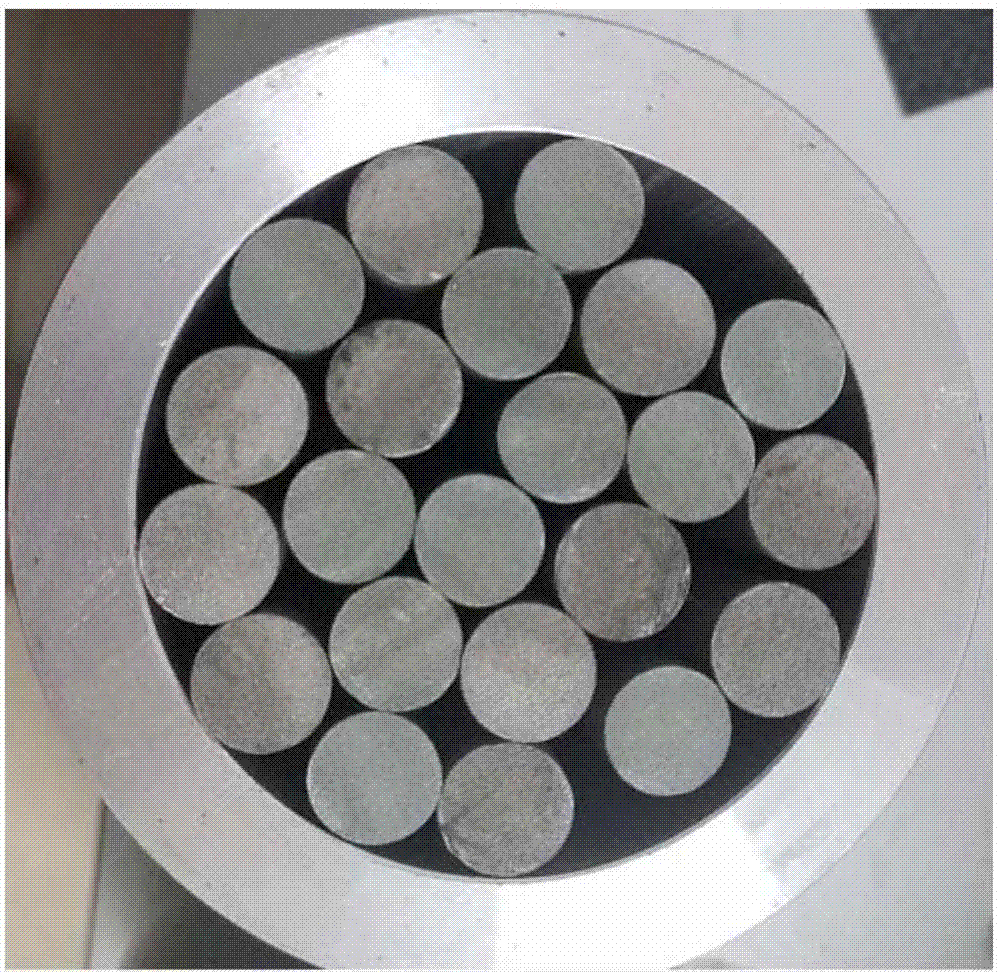

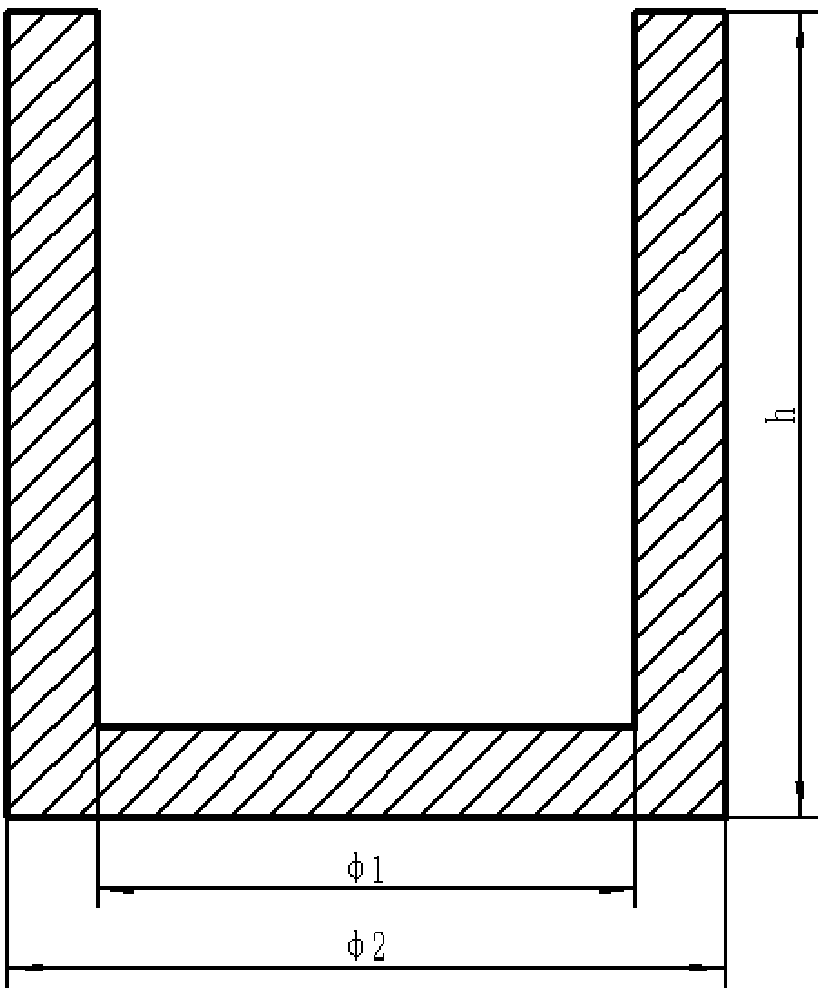

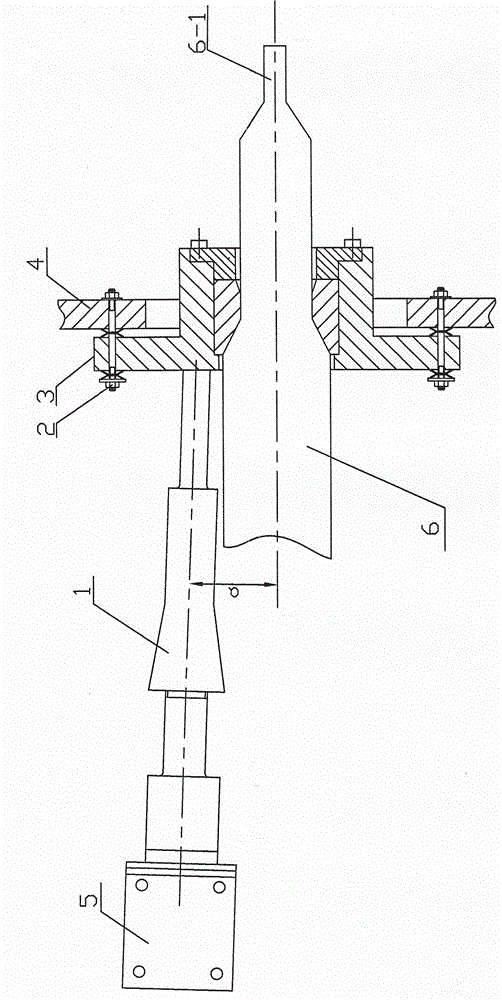

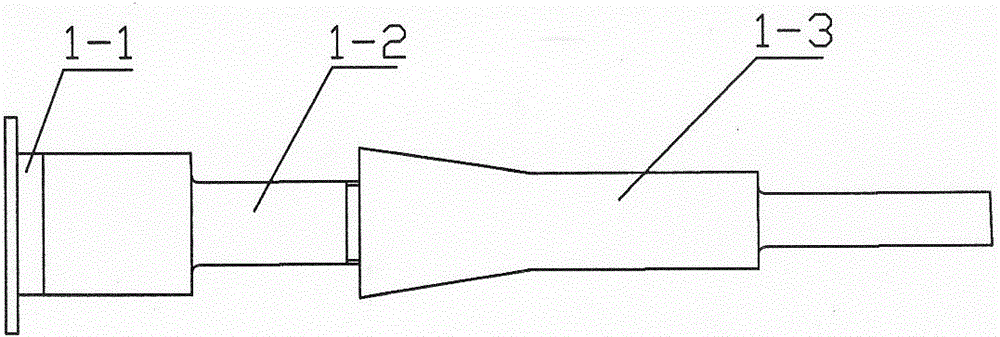

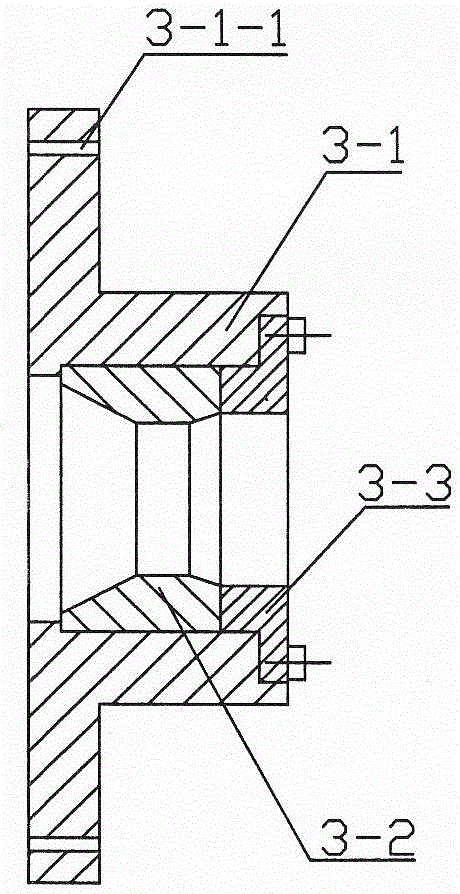

Stack mold drawing process for nickel-based superalloy thin-wall seamless tube with small diameter

InactiveCN113172106AReduce the number of drawing passesHigh yieldDrawing diesSuperalloyLarge deformation

The invention provides a stack mold drawing process for a nickel-based superalloy thin-wall seamless tube with a small diameter. Through matching between two drawing molds which are in different sizes and are arranged tightly front and back, the drawing passes of the superalloy thin-wall seamless tube with the small diameter are reduced, the production efficiency is improved, and the production cost is reduced; meanwhile, the defects of surface scratches caused by shaking and deviation due to small contact area between the tube and the mold surface in the single-mold drawing process, and stacking, creases, uneven wall thickness and the like caused by single-pass large deformation are avoided, and therefore the yield of the tube is improved.

Owner:天津冶金集团天材科技发展有限公司

Drawing die and drawing method for micro tube

PendingCN113578990AReduce frictionIncrease the amount of deformationExtrusion diesIndustrial engineeringConical surface

The invention provides a drawing die and a drawing method for a micro tube, and the drawing die comprises a drawing die main body, one end of the drawing die main body is provided with a tube feeding port, and a tube discharging port is formed symmetrically with the tube feeding port; the drawing die further comprises a drawing channel communicating with the feeding port and the discharging port, and a conical surface area close to the feeding port is arranged on the drawing channel; an annular oil groove or N oil injection holes are formed in the conical surface area, and N is larger than or equal to 1; and a tube is extruded and lubricated by injecting oil into the annular oil groove or the oil injection holes. According to the drawing device and the drawing method provided by the invention, the single-pass deformation of the tube can be improved, the drawing passes are reduced, and the drawing efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

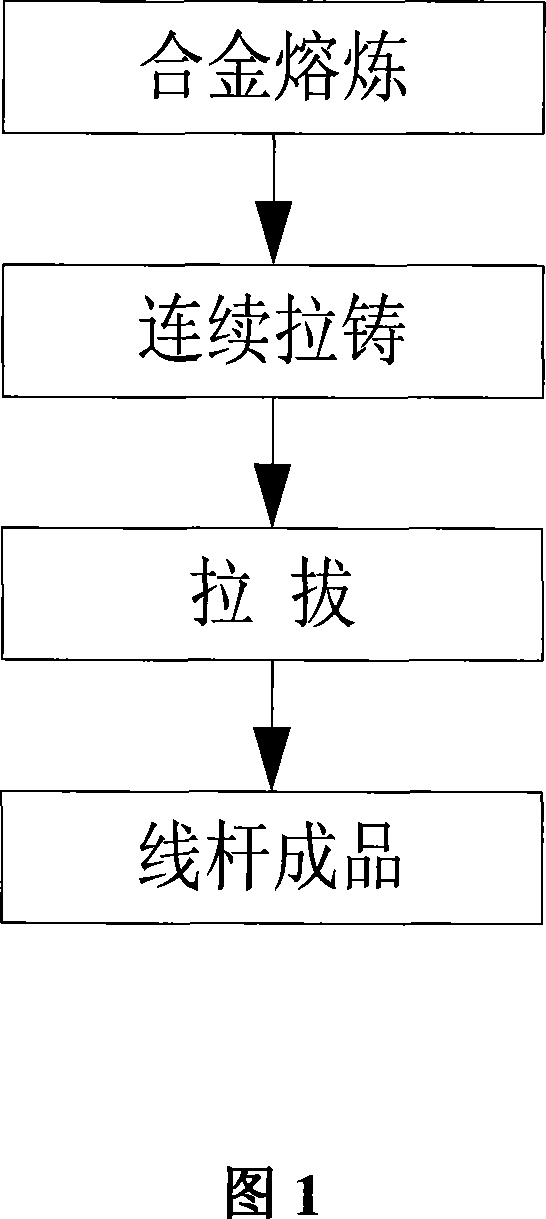

Short stage preparation technics of overlength copper alloy line staff

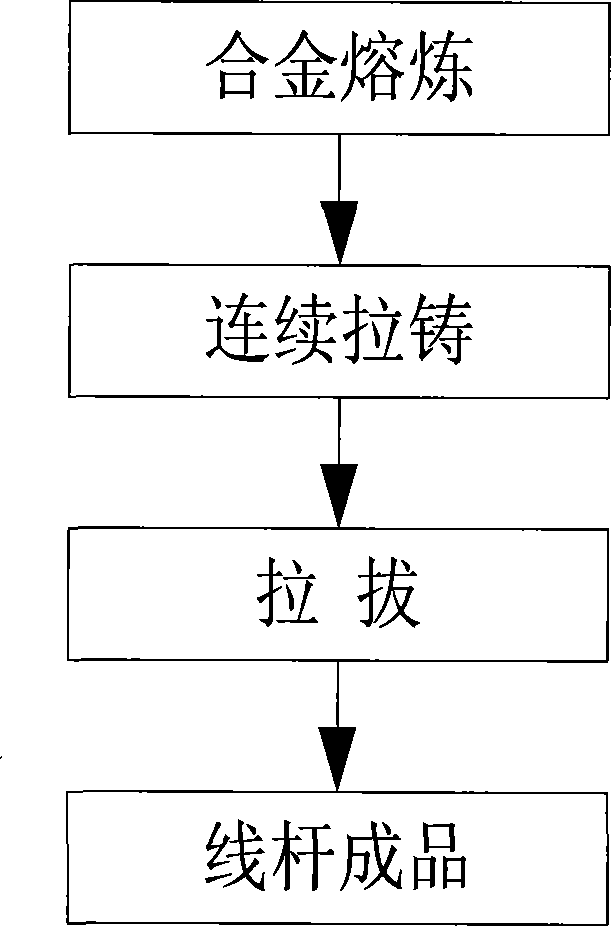

The invention provides a preparation process for the short flow of an ultra-long copper alloy wire rod. The process includes the following steps: alloy melting, continuous casting, pulling, and a wire rod finished product, an atmosphere protective induction melting furnace is adopted to melt under the non-vacuum condition, the induction melting furnace is provided with a down-drawing, a horizontal, and an up-drawing continuous casting crystallizers which have different specifications, and the preparation is formed through continuously casting the wire rod. The invention can realize the expansion of a Cu-Cr-Zr alloy wire rod on the length through the down-drawing, horizontal, and up-drawing continuous casting, to meet the production requirement of the ultra-long Cu-Cr-Zr alloy wire rod; the protective atmosphere can protect oxidable elements, thereby obtaining Cu-Cr-Zr alloy wire rod materials which meet the requirement of alloying components, and produced wire rods uniformly are bright rods, the surface is not required to perform the scalping treatment. In addition, through changing the down-drawing, the horizontal, and the up-drawing continuous casting crystallizersw, continuous casting wire rods with various cross sections can be produced, and the rod material organization is better, thereby having the excellent plastic processing performance.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

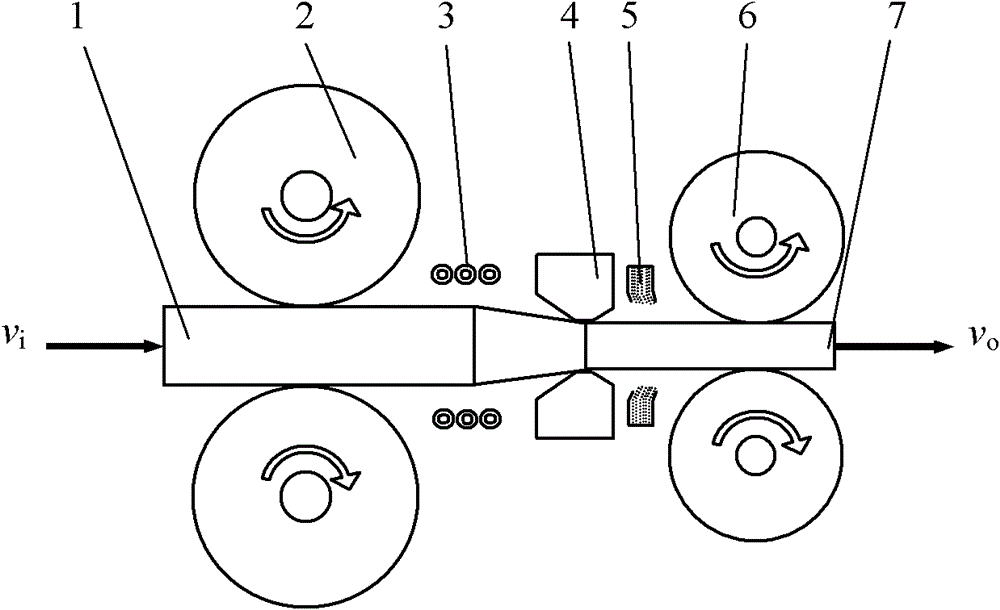

Mold/non-mode combined pulling process and device

InactiveCN102133582BImproving the process conditions of drawing formingReduce consumptionDrawing profiling toolsPull forceEngineering

The invention belongs to the technical field of metal plastic processing, and particularly provides a mold / non-mold combined pulling process and a device. The device is characterized in that a pulling mold is directly installed between a heater and a cooling machine of a non-mold pulling device, the waste heat of non-mold pulling is utilized fully, so that the mold puling and sizing with temperature can be completed before the non-mold pulling is molded, and the surface quality is improved. In the invention, the pulling force is reduced greatly, the intermediate heat treatment or heating process of the traditional process is saved, the mold consumption is reduced, the energy resource is saved, the production cost is lowered, a high-quality metal product can be pulled and molded in short flow range, and the advantages that the deformation amount of the non-mold pulling is large, the precise of the mold pulling size is high and the like can be realized.

Owner:UNIV OF SCI & TECH BEIJING

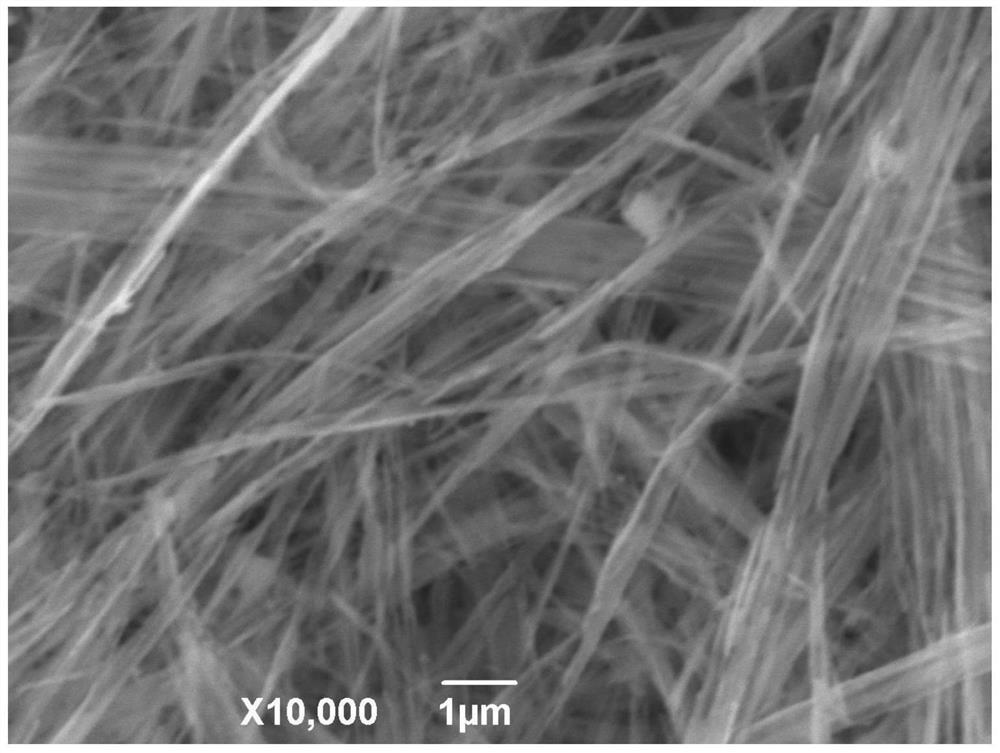

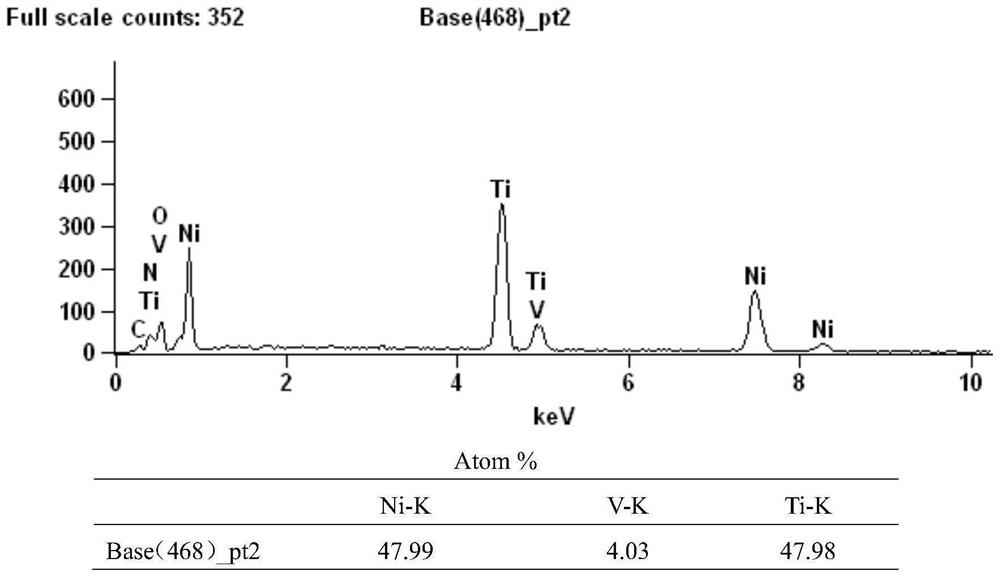

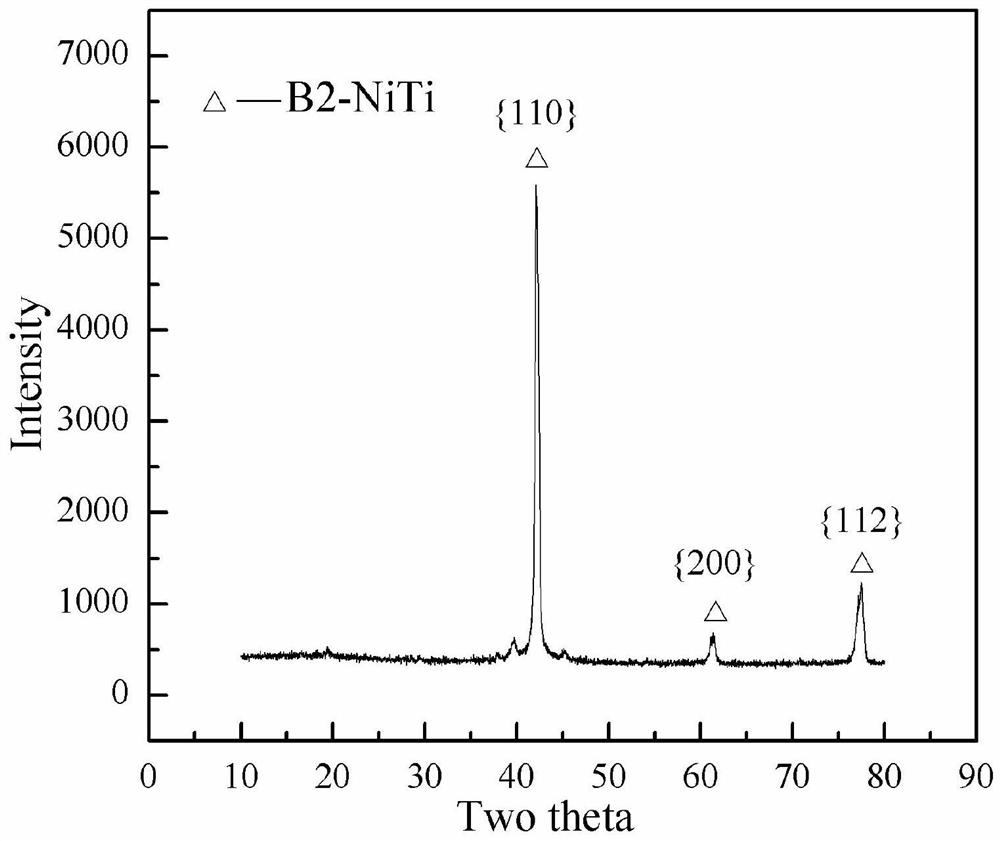

A kind of niti nano wire and preparation method thereof

ActiveCN110216281BSmall diameterEasy to prepareTransportation and packagingMetal-working apparatusElectrolytic agentNanowire

The invention discloses a NiTi nanowire and a preparation method thereof. Ni, Ti and V elements are mixed according to the atomic percentage Ni:Ti:V=31-37:29-37:26-40, and the alloy is obtained by arc melting Ingot casting; alloy ingots are forged and drawn to obtain wires; under normal temperature and pressure, nitric acid and methanol are prepared with an electrolyte solution at a volume ratio of 1:1 to 10; electrolytic anodes are made with wires, and stainless steel electrodes are used as electrolytic Cathode, put the electrolysis anode and the electrolysis cathode into the electrolytic cell with the electrolyte; use the constant voltage DC power supply as the electrolysis power supply, the output voltage is 2-9V, stop the electrolysis until the current density drops to zero; take out the electrolysis anode , NiTi nanowires were obtained after washing and drying. The present invention adopts the electrolytic method to prepare the electrolytically prepared NiTi nanowires, the diameter of which can be smaller than 100nm, and the length can reach more than 15 μm; the whole preparation method is simple, only needs to be drawn to 1-2mm, and the number of drawing passes is less, and the process is simple , low cost, low energy consumption.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Drawing production method for aluminum cladding optical unit and tool device corresponding to same

InactiveCN106914500AExtended service lifeInternal dimensionally stableDrawing diesMaterials scienceAluminium

The invention provides a drawing production method for an aluminum cladding optical unit. No drawing oil residues are generated through water drawing in the drawing process, the field environment is improved, and the expenditure and cost are reduced. A drawing position of a drawing die is put into an environment filled with water. An aluminum tube to be drawn passes through the drawing position of the drawing die in the environment where water surrounds the aluminum tube to be drawn to form the aluminum cladding optical unit with the corresponding diameter at a time after drawing. Drawing and direct take-up are completed under the action of rear take-up drawing. The invention further provides a tool device adopted in the drawing production method for the aluminum cladding optical unit.

Owner:FUJIKURA HENGTONG AERIAL CABLE SYST

A kind of preparation method of high-aluminum zinc-aluminum pseudo-alloy rod and wire

The invention discloses a preparation method of high aluminum zinc-aluminum pseudo-alloy rod materials and wire materials. The preparation method comprises the following steps that a pure aluminum rod or an aluminum alloy rod and a pure zinc rod are put into a package of pure aluminum or aluminum alloy materials in a certain order, so that composite billet materials are formed; after heating the composite billet materials and extrusion dies of an extrusion machine, then the composite billet materials are put into the extrusion dies, the billet materials are extruded, and composite pseudo-alloy rod materials are prepared; and the obtained composite pseudo-alloy rod materials are drawn and diameter-reduced for multiple passes, and the wire materials are manufactured. According to the preparation method of high aluminum zinc-aluminum pseudo-alloy rod materials and wire materials, the aluminum rod and the zinc rod arranged in the package are extruded, so that the pseudo-alloy rod materials are formed by deformation and mixing, and then the rod materials are drawn and diameter-reduced to obtain the high aluminum zinc-aluminum pseudo-alloy wire materials. In the above process, the zinc and the aluminum are only deformed, the diameter is reduced, alloying does not happen between the zinc and the aluminum, the eutectic structure and the hard brittle phase are not produced, the deformation ability of the obtained rod materials is good, and a high aluminum zinc-aluminum coating layer is formed in heat spraying preparation of an anticorrosive coating after the pseudo-alloy wire materials are prepared by drawing and diameter reduction.

Owner:BEIHANG UNIV

A kind of preparation method of 304 wear-resistant stainless steel wire

ActiveCN108465699BHigh hardnessReduce manufacturing costMetal rolling arrangementsWear resistantRoom temperature

Owner:NORTHEASTERN UNIV LIAONING +1

Oblique Composite High-frequency Vibration Drawing Method for Metal Profiles

InactiveCN104772354BExtend your lifeImprove efficiencyMechanical vibrations separationTransducerEngineering

The invention relates to a method for drawing metal section in an inclined composite high-frequency vibration manner. An inclined composite high-frequency vibration device is used for generating composite high-frequency vibration in a horizontal direction and a vertical direction of the metal section to act on a drawing die in a drawing process, thus, the friction coefficient between the metal section and the drawing die is reduced; the drawing die is elastically connected with a die holder of the machine base of a drawing machine, the composite high-frequency vibration device is fixed on a drawing machine tool by a mounting plate, a secondary amplitude-change pole in the composite high-frequency vibration device is fastened on and connected with the end surface of a drawing die holder, an included angle alpha between the axis of the composite high-frequency vibration device and the axis of the drawing die is 5-15 degrees, a piezoelectric ceramic transducer in the composite high-frequency vibration device generates high-frequency excitation frequency to drive a primary amplitude-change pole to vibrate at high frequency, and then the secondary amplitude-change pole vibrates at high frequency under the driving action of the primary amplitude-change pole; therefore, the drawing die is driven to do composite high-frequency vibration in the horizontal direction and the vertical direction.

Owner:NANHUA UNIV

A heat treatment method for zinc-aluminum rolled strip

ActiveCN103924179BImprove plasticityIncrease the deformation of a single drawingSolution treatmentRoom temperature

The invention discloses a heat treatment method of a zinc-aluminum rolled strip. The heat treatment method is used for improving the plasticity and the stability of the zinc-aluminum rolled strip and comprises the following steps: (1), placing the zinc-aluminum rolled strip in a heating furnace for performing solution treatment at a temperature of 360 DEG C for 4-10 hours; (2), reducing the furnace temperature of the heating furnace to 250 DEG C, and preserving heat of the zinc-aluminum rolled strip at the temperature of 250 DEG C for 2-3 hours; and (3), after heat preservation, continuously reducing the furnace temperature of the heating furnace to 170 DEG C, and then taking the zinc-aluminum rolled strip out to ensure that the zinc-aluminum rolled strip is cooled to a room temperature in air. The zinc-aluminum rolled strip subjected to heat treatment by adopting the heat treatment method disclosed by the invention is subjected to repeated bending tests; the repeated bending times of the zinc-aluminum rolled strip subjected to heat treatment by adopting the heat treatment method disclosed by the invention is increased by 61 percent in comparison with that of an original rolled strip, a stable structure is obtained, and the mouldability is greatly improved. The heat treatment method disclosed by the invention is simple to operate, and strong in practicability; the obtained material is good in plasticity, stable in performance and difficult in aging.

Owner:SHANGHAI LONGSHUO WELDING MATERIAL

Erbium-containing aluminum magnesium alloy wire and production method thereof

The invention provides an erbium-containing aluminum magnesium alloy wire and a production method thereof, and belongs to the technical field of alloy production. The erbium-containing aluminum magnesium alloy wire comprises the following components, in percentage by weight, of 1.3% to 2.5% of Mg, 0.4% to 0.8% of Er, 0.01% to 0.1% of Cr, 0.01% to 0.15% of Mn, 0.1% to 0.3% of Fe, 0.03% to 0.15% of Si and the balance Al, a total content of other impurities does not exceed 0.25%, and a content of a single impurity component does not exceed 0.1%. A manufacturing method of the erbium-containing aluminum magnesium alloy wire comprises the manufacturing steps of burdening, melting, refining, liquid discharging, horizontal traction casting, cast rod drawing, intermediate annealing, thick wire drawing, intermediate annealing, thin wire drawing and finished product annealing. The production efficiency is improved, the production cost is reduced, and the properties such as product strength and ductility can be improved.

Owner:百色市广百金属材料有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com