High-strength iron-nickel-molybdenum alloy wire and low-cost preparation method thereof

A technology of iron-nickel-molybdenum and alloy wire, which is applied in the field of metallurgy, can solve the problems of reducing the plasticity, toughness and torsion performance of the final wire, reducing production continuity, and prolonging the production cycle, so as to shorten the production cycle and reduce the number of drawing passes , reduce the effect of drawing passes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

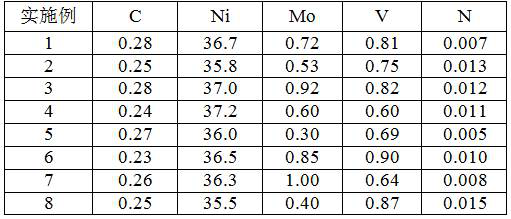

[0020] The chemical composition and mass percentage of the high-strength iron-nickel-molybdenum alloy wire in this example are shown in Table 1. Its production method includes vacuum smelting, electroslag remelting, forging, high temperature solution treatment, low temperature rolling, aging heat treatment, peeling and cold drawing process. Concrete process steps are as follows:

[0021] The electroslag ingot obtained by vacuum smelting and electroslag remelting is forged into a 140mm×140mm billet, and after a high-temperature solution treatment at 1250°C for 3 hours in a nitrogen-protected environment, it is cooled to 920°C in a heating furnace, and then moved to the furnace Cooling with external water to room temperature; rolling the billet into a φ5.5mm wire rod after high-temperature solution treatment, the starting rolling temperature is 900°C, the final rolling temperature is 670°C, water cooling to room temperature immediately after rolling; the wire rod is aged at 620°...

Embodiment 2

[0023] The chemical composition and mass percentage of the high-strength iron-nickel-molybdenum alloy wire in this example are shown in Table 1. Its production method includes vacuum smelting, electroslag remelting, forging, high temperature solution treatment, low temperature rolling, aging heat treatment, peeling and cold drawing process. Concrete process steps are as follows:

[0024] The electroslag ingot obtained by vacuum smelting and electroslag remelting is forged into a 135mm×135mm billet, and after a high-temperature solution treatment at 1210°C for 3.5 hours in a nitrogen-protected environment, it is cooled to 900°C in a heating furnace, and then moved to Water cooling outside the furnace to room temperature; rolling billet into φ5.0mm wire rod after high-temperature solution treatment, starting rolling temperature is 890°C, finishing rolling temperature is 700°C, water cooling to room temperature immediately after rolling; wire rod aging heat treatment at 550°C Af...

Embodiment 3

[0026] The chemical composition and mass percentage of the high-strength iron-nickel-molybdenum alloy wire in this example are shown in Table 1. Its production method includes vacuum smelting, electroslag remelting, forging, high temperature solution treatment, low temperature rolling, aging heat treatment, peeling and cold drawing process. Concrete process steps are as follows:

[0027] The electroslag ingot obtained by vacuum smelting and electroslag remelting is forged into a 145mm×145mm billet, and after a high-temperature solution treatment at 1230°C for 4 hours in a nitrogen-protected environment, it is cooled to 870°C in a heating furnace, and then moved to the furnace The external water is cooled to room temperature; the high-temperature solution-treated billet is rolled into a φ4.5mm wire rod, the rolling temperature is 920°C, the final rolling temperature is 700°C, and water is cooled to room temperature immediately after rolling; the wire rod is aged at 580°C for 2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com