A kind of preparation method of 304 wear-resistant stainless steel wire

A technology of 304 stainless steel and stainless steel wire, which is applied in the direction of metal rolling, etc., can solve the problems of not exerting the potential of the material and short life, and achieve the effect of reducing the number of drawing passes, reducing the annealing temperature and shortening the engineering time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

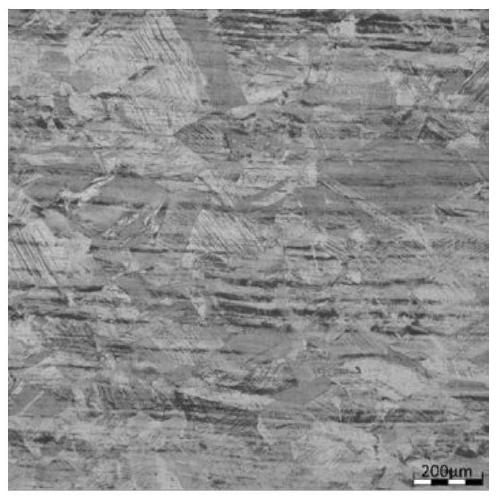

Image

Examples

Embodiment 1

[0041] A preparation method of 304 wear-resistant stainless steel wire, specifically comprising the steps of:

[0042] Step 1, material selection:

[0043] Select 304 stainless steel wire with a raw material diameter of 8mm, and according to the company's wear-resistant steel wire product specifications, the preset finished product diameter is 3.4mm;

[0044] Step 2, annealing:

[0045] The 304 stainless steel wire with a diameter of 8 mm was annealed at a temperature of 800 ° C for 1 h; the principle of annealing temperature selection was to fully soften the wire and at the same time control the structure without recrystallization grain growth.

[0046] Step 3, multi-pass drawing processing:

[0047] Before the drawing treatment, one end of the annealed stainless steel rod is sharpened, and the scale is removed to prepare for drawing.

[0048] First, the annealed stainless steel wire is drawn for the first pass with a wire drawing machine. The diameter of the stainless ste...

Embodiment 2

[0082] A kind of preparation method of 304 wear-resistant stainless steel wire of the present invention specifically comprises the following steps:

[0083] Step 1, material selection:

[0084] Select 304 stainless steel wire with a raw material diameter of 10mm. According to the company's wear-resistant steel wire product specifications, the preset finished product diameter is 8.3mm.

[0085] Step 2, annealing:

[0086] The 304 stainless steel wire with a diameter of 10 mm was annealed at a temperature of 1000 ° C for 2 hours; the principle of annealing temperature selection was to fully soften the wire and control the structure without recrystallization grain growth.

[0087] Step 3, multi-pass drawing processing:

[0088] Before the drawing process, one end of the annealed stainless steel rod is sharpened, and the scale is removed to prepare for the first drawing.

[0089] First, the annealed stainless steel wire is drawn for the first pass with a wire drawing machine. T...

Embodiment 3

[0095] A kind of preparation method of 304 wear-resistant stainless steel wire of the present invention specifically comprises the following steps:

[0096] Step 1, material selection:

[0097] Select 304 stainless steel wire with a raw material diameter of 2.8mm. According to the company's wear-resistant steel wire product specifications, the preset finished product diameter is 2.3mm.

[0098] Step 2, annealing:

[0099] The 304 stainless steel wire with a diameter of 10 mm was annealed at a temperature of 1000 ° C for 30 minutes; the principle of annealing temperature selection was to fully soften the wire and control the structure without recrystallization grain growth.

[0100] Step 3, multi-pass drawing processing:

[0101] Before the drawing process, one end of the annealed stainless steel rod is sharpened, and the scale is removed to prepare for the first drawing.

[0102] First, the annealed stainless steel wire is drawn for the first pass with a wire drawing machin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com