Short stage preparation technics of overlength copper alloy line staff

A preparation process and copper alloy technology are applied in the field of short-flow preparation technology of ultra-long copper alloy wire rods, and the short-flow preparation technology of ultra-long Cu-Cr-Zr alloy wire rods, which can solve the problem of reduced yield, long production cycle, high problems such as low efficiency, to achieve the effect of reducing production costs and improving yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

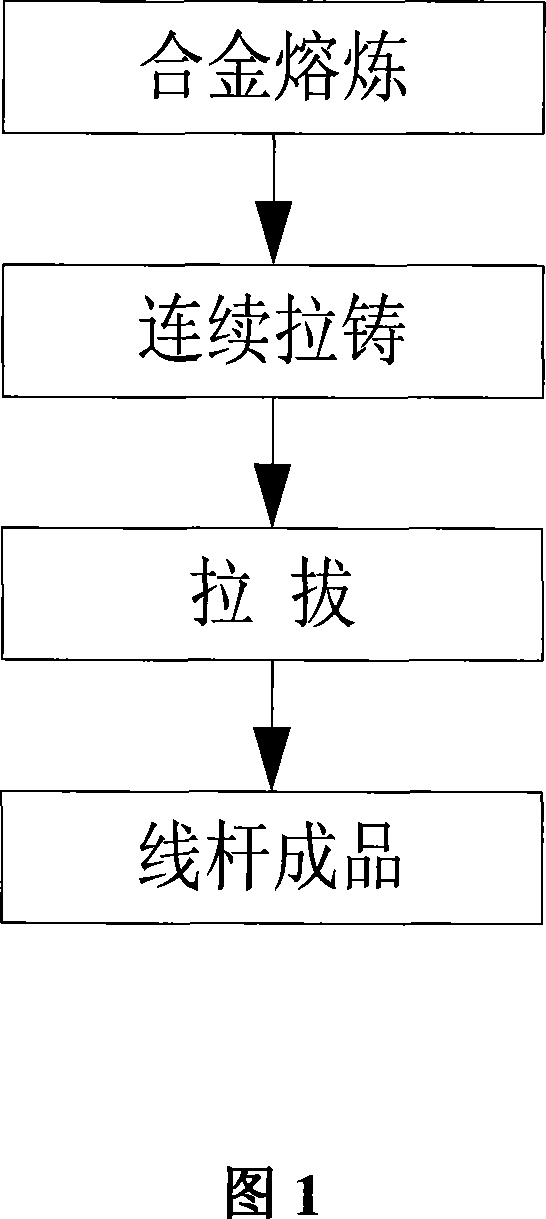

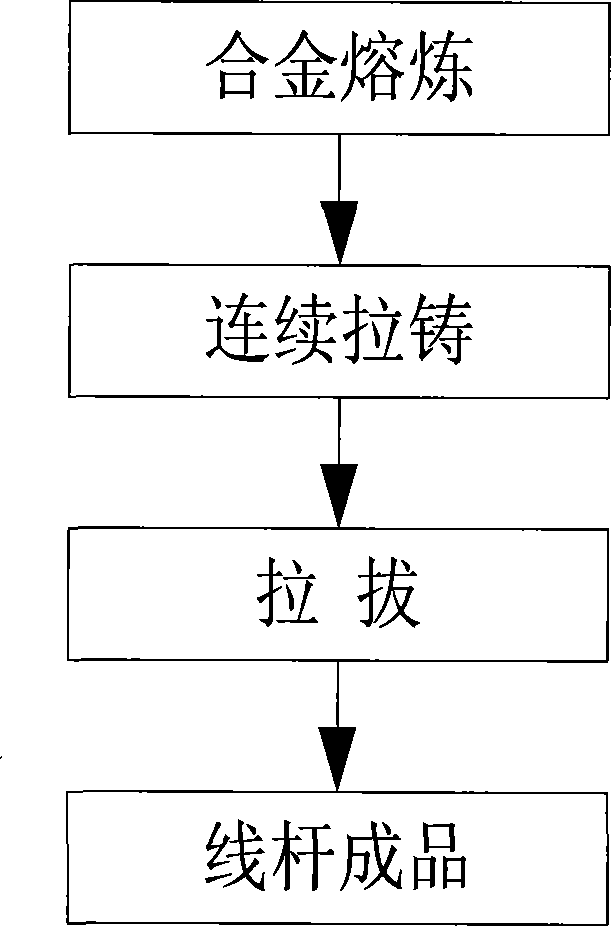

[0021] The process for preparing Cu-Cr-Zr alloy wire rod in the present invention is: alloy smelting-continuous drawing casting-drawing-finished wire rod, the process also includes the drawing process and the necessary annealing treatment for performance adjustment in the finished wire rod . The preparation process is carried out under non-vacuum conditions, and the induction melting furnace with atmosphere protection is used for melting. The induction melting furnace is equipped with different specifications of down-leading, horizontal and up-leading continuous casting crystallizers to continuously draw and cast alloy wire rods for continuous preparation of wire rods. The length extension of the Cu-Cr-Zr alloy wire rod is realized through the continuous drawing casting of down-drawing, horizontal and up-drawing, which satisfies the production of ultra-long Cu-Cr-Zr alloy wire rod. The easily oxidizable elements are protected by a protective atmosphere to obtain Cu-Cr-Zr alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com