A kind of niti nano wire and preparation method thereof

A technology of nanowires and alloy ingots, applied in metal processing equipment, transportation and packaging, etc., can solve the problems of inability to obtain NiTi nanowires, low electrode potential, etc., achieving low cost, less drawing passes, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation process of this embodiment is as follows:

[0030] 1. Preparation of Ni 37 Ti 37 V 26 Alloy wire

[0031] (11) Smelting Ni 37 Ti 37 V 26 Alloy: Mix according to the atomic percentage of each element to obtain 1kg of mixed metal raw material, and obtain Ni by arc melting 37 Ti 37 V 26 alloy ingot;

[0032] (12) Forging and drawing: forging the ingot at 750°C, and thermally deforming the ingot into a rod shape with a diameter of about φ5mm; and then hot drawing at 550°C to obtain a wire of φ1mm.

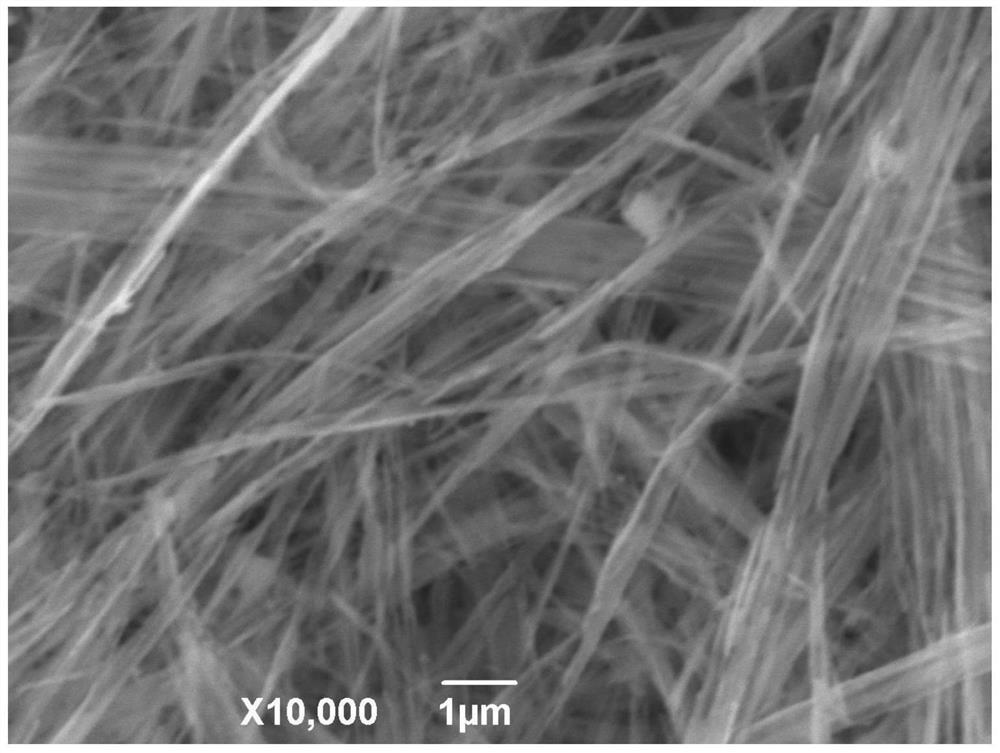

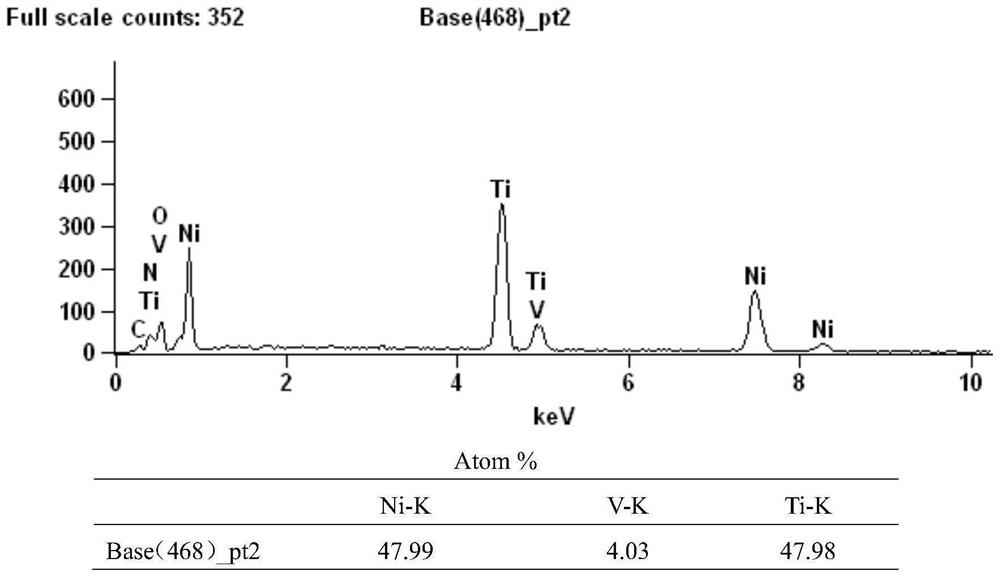

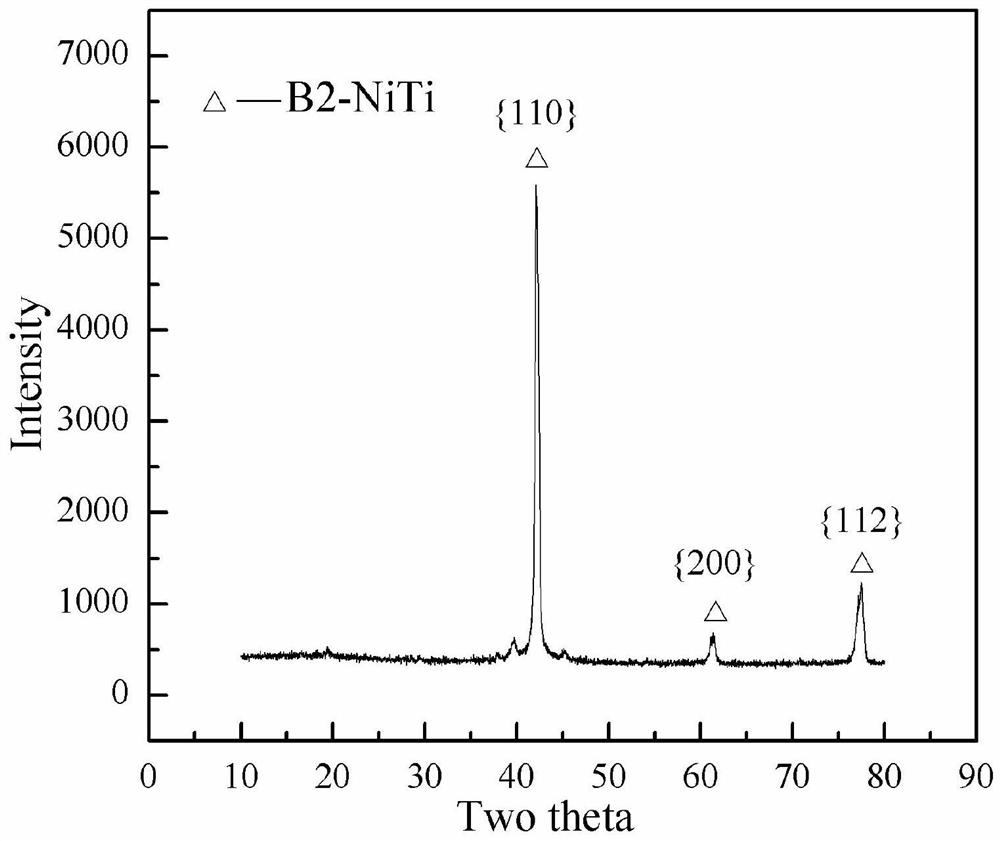

[0033] 2. Preparation of NiTi nanowires by electrolysis of Ni37Ti37V26 alloy wire

[0034] (21) Under normal temperature and pressure, the volume ratio of 65% nitric acid to 99.5% methanol is 1:5 to configure 600ml of electrolyte, evenly mixed and transferred to the electrolytic cell;

[0035] (22) from Ni with a diameter of 1mm 37 Ti 38 V 25 Select 20cm from the composite material wire, after grinding and cleaning, the electrolysis anode is made, a...

Embodiment 2

[0040] The preparation process of this embodiment is as follows:

[0041] 1. Preparation of Ni 31 Ti 29 V 40 Composite wire

[0042] (11) Smelting Ni 31 Ti 29 V 40 Alloy: Mix according to the atomic percentage of each element to obtain 1kg of mixed metal raw material, and obtain Ni by arc melting 31 Ti 29 V 40 alloy ingot;

[0043] (12) Forging and drawing: forging the ingot at 750°C, and thermally deforming the ingot into a rod shape with a diameter of about φ5mm; and then hot drawing at 550°C to obtain a wire of φ1mm.

[0044] 2. To you 31 Ti 29 V 40 Preparation of NiTi nanowires by electrolysis of composite filaments

[0045] (21) Under normal temperature and pressure, the volume ratio of 65% nitric acid to 99.5% methanol is 1:5 to configure 600ml of electrolyte, uniformly mixed and transferred to the electrolytic cell;

[0046] (22) from Ni with a diameter of 1mm 31 Ti 29 V 40 Select 20cm from the composite material wire, after grinding and cleaning, the e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com