High-carbon steel wire with good fine steel cord drawing machining performance and manufacturing method of high-carbon steel wire

A technology of processing performance and manufacturing method, applied in the field of high carbon steel wire rod and its manufacturing, can solve the problems of reducing material drawing processability, difficulty, affecting the quality of steel wire and production efficiency, etc., so as to reduce intermediate heat treatment and drawing passes, Improve the uniformity of the organization and the effect of excellent microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 200mm×200mm. The chemical composition of the obtained continuous casting slab includes: C: 0.82%, Si: 0.19% , Mn: 0.18%, S≤0.006%, P≤0.008%, Cr: 0.35%, As: 0.003%, Al: 0.0007%, Nb: 0.001%, V: 0.002%, Ni: 0.01%, Ti: 0.0004 %, Cu: 0.01%, Ca: ≤0.0004%, N: ≤0.00206%, Mo: 0.01%, and the balance is Fe and unavoidable impurity elements.

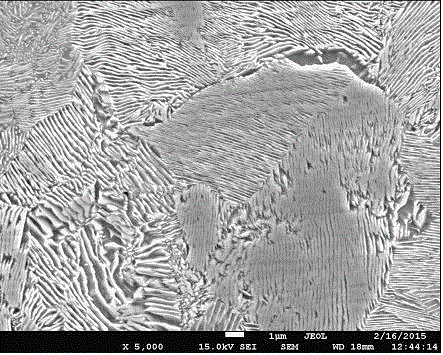

[0050] Heat the continuous casting slab to above 1200°C, control the residual oxygen in the furnace below 5%, heat it for 4 hours, and roll it after descaling with high-pressure water: the rolling start temperature is 1040-1100°C, and the rolling process is divided into 39 passes For the first rolling, the rolling speed is set at 105m / s, and the spinning temperature is controlled at 900±30°C; after rolling, the wire rod is air-cooled through the Stelmo cooling line, in order to achie...

Embodiment 2

[0052] Melt 150 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 200mm×200mm. The chemical composition of the obtained continuous casting slab includes: C: 0.81%, Si: 0.18% , Mn: 0.18%, S≤0.009%, P≤0.009%, Cr: 0.35%, As: 0.003%, Al: 0.0007%, Nb: 0.001%, V: 0.002%, Ni: 0.01%, Ti: 0.0004 %, Cu: 0.01%, Ca: ≤0.0004%, N: ≤0.00207%, Mo: 0.01%, and the balance is Fe and unavoidable impurity elements.

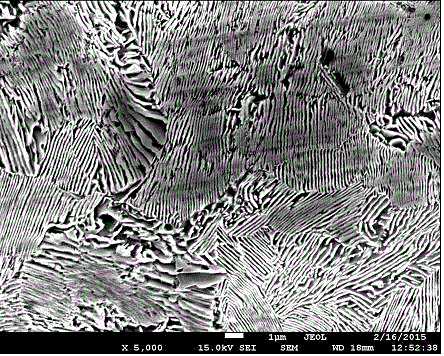

[0053] Heat the continuous casting slab to above 1200°C, control the residual oxygen in the furnace below 6%, heat it for 4 hours, and roll it after descaling with high-pressure water: the rolling start temperature is 1040-1100°C, and the rolling process is divided into 39 passes For the first rolling, the rolling speed is set at 100m / s, and the spinning temperature is controlled at 900±30°C; after rolling, the wire rod is air-cooled through the Stelmo cooling line, in order to achie...

Embodiment 3

[0055] Melt 100 tons of steel with the chemical composition shown below, carry out continuous casting, and make a continuous casting slab with a cross-sectional size of 200mm×200mm. The chemical composition of the obtained continuous casting slab includes: C: 0.82%, Si: 0.21% , Mn: 0.19%, S≤0.004%, P≤0.008%, Cr: 0.34%, As: 0.003%, Al: 0.0008%, Nb: 0.001%, V: 0.002%, Ni: 0.01%, Ti: 0.0003 %, Cu: 0.01%, Ca: ≤0.0004%, N: ≤0.00207%, Mo: 0.01%, and the balance is Fe and unavoidable impurity elements.

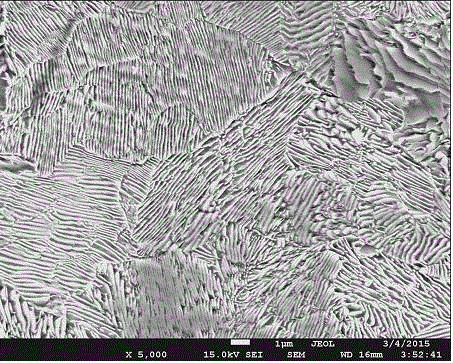

[0056]Heat the continuous casting slab to above 1200°C, control the residual oxygen in the furnace below 6%, heat it for 4 hours, and roll it after descaling with high-pressure water: the rolling start temperature is 1040-1100°C, and the rolling process is divided into 39 passes For the first rolling, the rolling speed is set at 110m / s, and the spinning temperature is controlled at 900±30°C; after rolling, the wire rod is air-cooled through the Stelmo cooling line, in order to achiev...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com