Variable-channel mold for improving drawing toughness of steel bar

A technology of changing channels and steel bars, applied in wire drawing dies and other directions, can solve the problems of reducing toughness, high processing cost, complex structure, etc., and achieve the effects of reducing drawing force, reducing toughness damage and improving economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

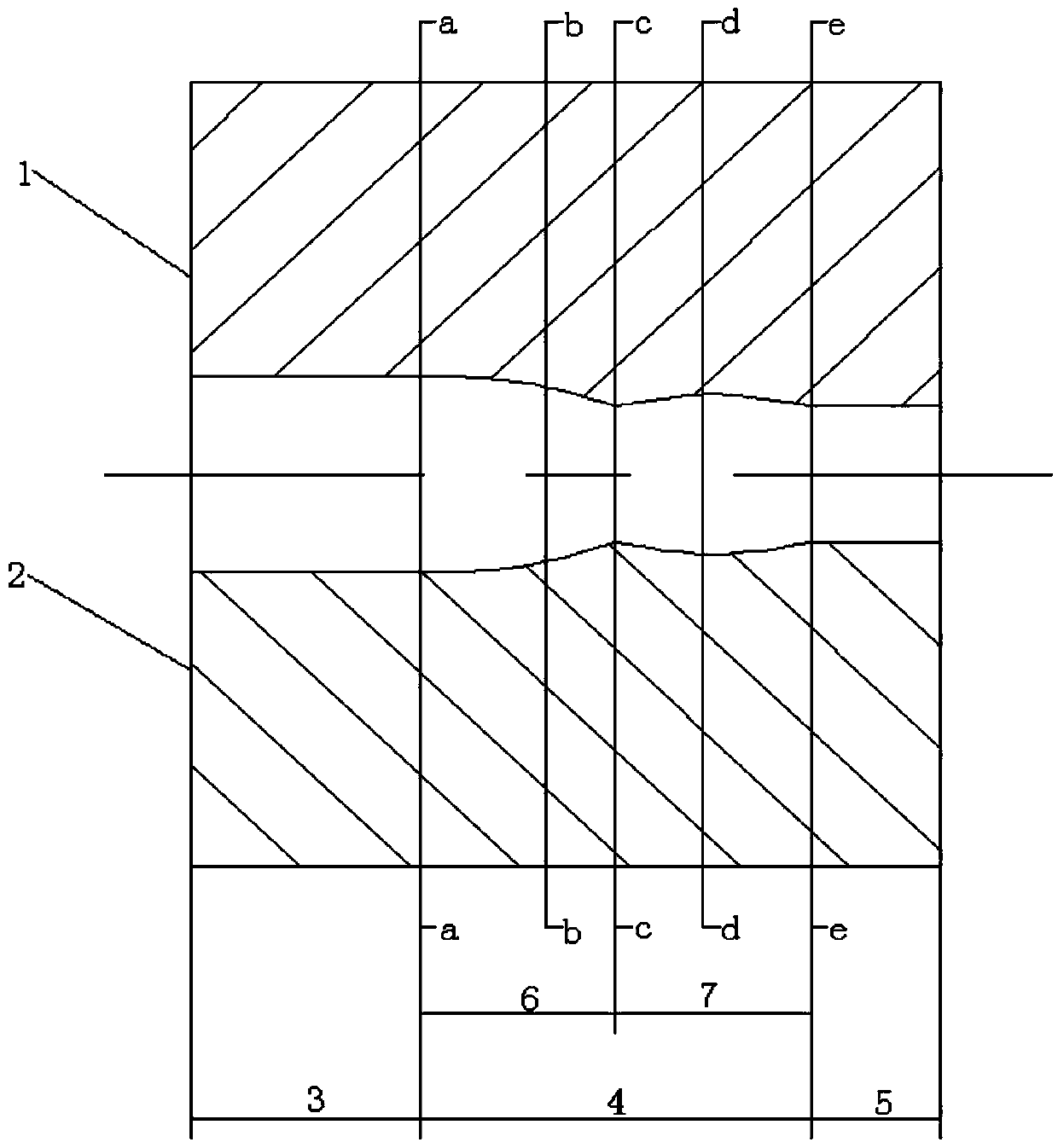

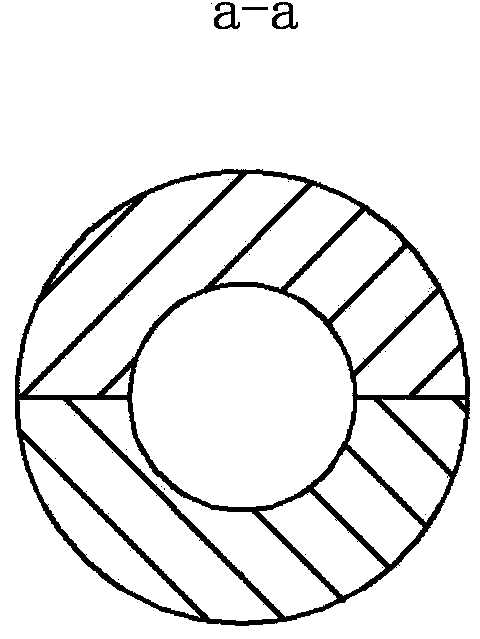

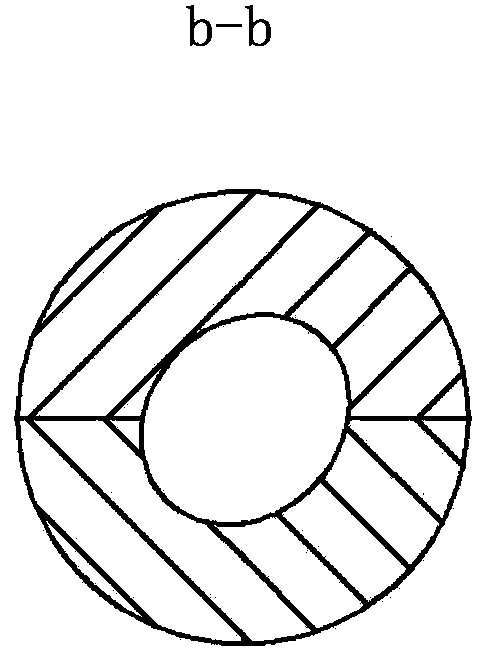

[0018] This embodiment is a variable-channel mold for improving the drawing toughness of steel bars, which is suitable for steel bars with a compression rate of 40%-53% in the drawing forming part.

[0019] When using the variable channel die to draw and form steel bars, one end of the round wire rod blank is first rolled so that it can pass through the drawing die, and then the drawing equipment is driven to make the round wire rod blank pass through the straightening section, the deformation section and the In the fixed-diameter section, the disc rod passes through the deformation section after being straightened, and its cross-sectional shape gradually changes from a large circular cross-section to a twisted oval cross-section, and then gradually changes from a twisted oval cross-section to a small circular cross-section , and finally form the required cold-drawn reinforced steel bars through the sizing section.

[0020] When using the variable channel mold to deform the ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com