Oblique Composite High-frequency Vibration Drawing Method for Metal Profiles

A high-frequency vibration, metal profile technology, applied in the direction of fluid using vibration, etc., can solve the problems of many drawing passes, easy mold wear, microscopic surface defects, etc., to reduce drawing passes, improve life and use efficiency. , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

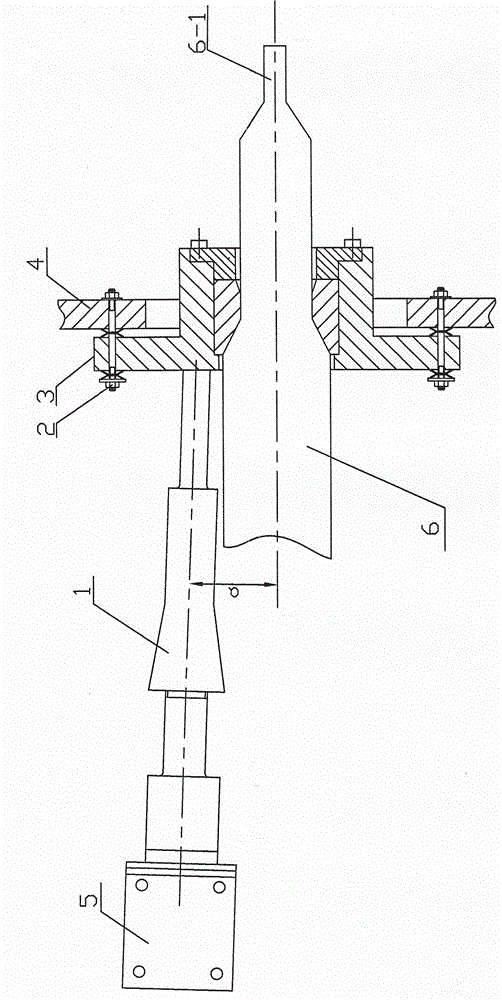

[0019] A method for drawing metal profiles using oblique composite high-frequency vibrations. During the drawing process, composite high-frequency vibrations along the horizontal and vertical directions of the metal profiles 6 are generated by a pair of drawing dies 3 through an oblique composite high-frequency vibration device 1. Vibration reduces the coefficient of friction between the metal profile 6 and the drawing die 3 .

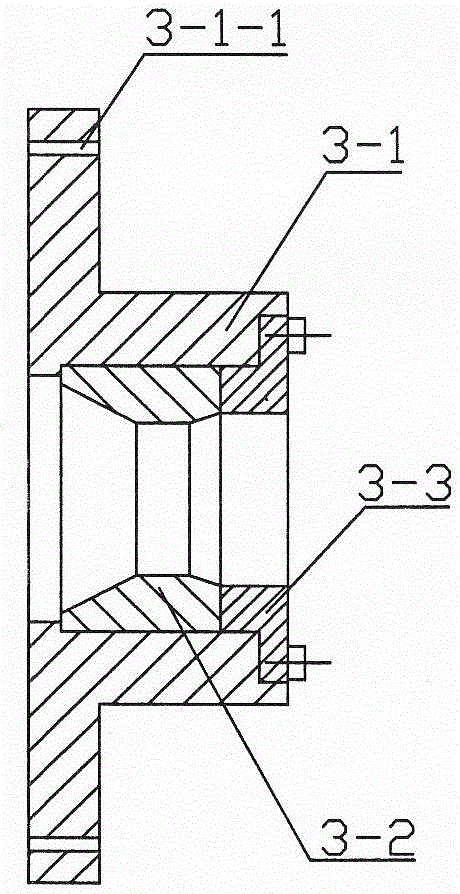

[0020] Elastic connection is adopted between the drawing die 3 and the base die base 4 on the drawing machine, and the drawing die 3 is connected with the base die base 4 on the drawing machine through six elastic connecting devices 2 .

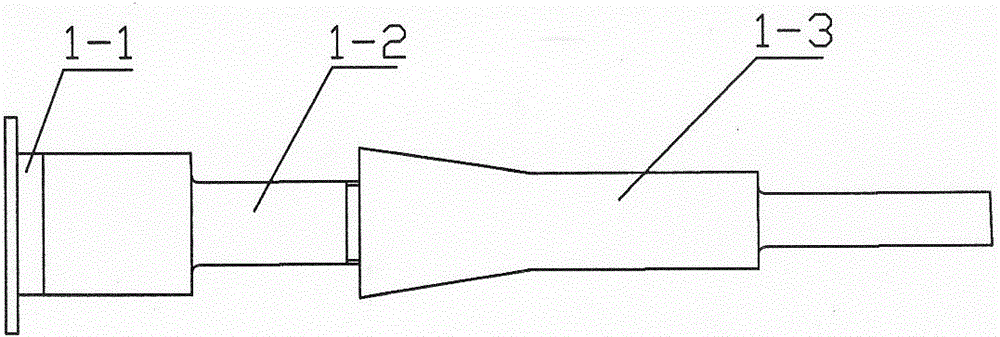

[0021] The oblique composite high-frequency vibration device 1 is fixed on the drawing machine through the mounting plate 5, and the secondary horn 1-3 in the oblique composite high-frequency vibration device 1 and the drawing die base 3- The end faces of 1 are fastened and connected, the angle a between the axis of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com