Novel automatic cold drawing process for colored metal tube and automatic cold drawing machine of colored metal tube

A non-ferrous metal and cold drawing machine technology, which is applied in the direction of wire drawing dies, etc., can solve the problems of difficulty in ensuring the straightness quality of finished pipes, high labor intensity of operators, and difficulty in realizing automatic production, so as to facilitate heat dissipation and improve the quality of lock joints , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. The following description is by way of example, but the protection scope of the present invention should not be limited thereto.

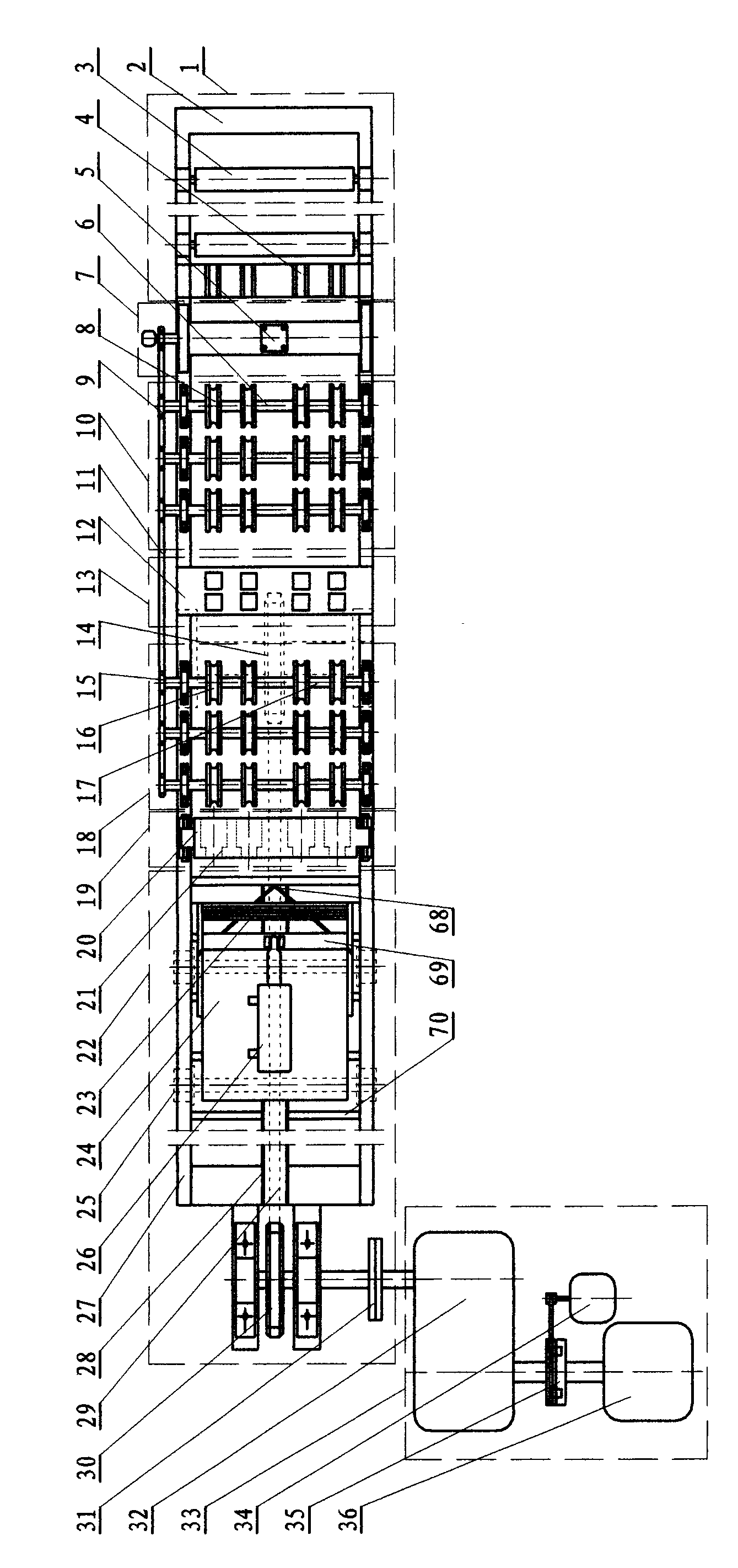

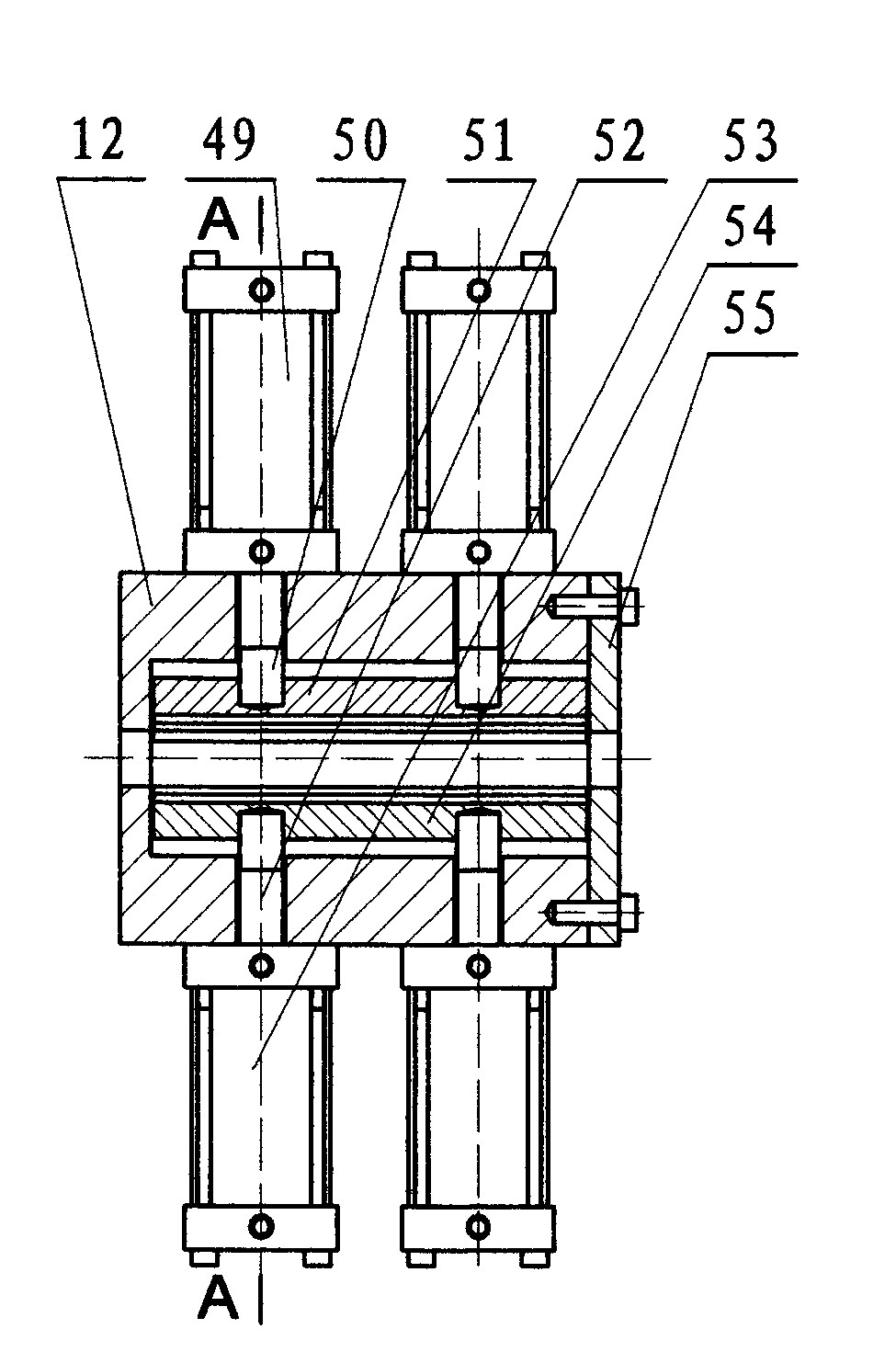

[0035] The automatic pipe drawing machine of the present embodiment is composed of a feeding device 1, a pinch conveying device 7, a first-level auxiliary feeding device 10, a locking device 13, a second-level auxiliary feeding device 18, a die-drawing device 19, Tube pulling device 22 and power unit 33 constitute. The automatic tube drawing machine of the present embodiment is a four-out tube drawing machine, that is, four material tubes are drawn each time (it can also be two or six or eight or more).

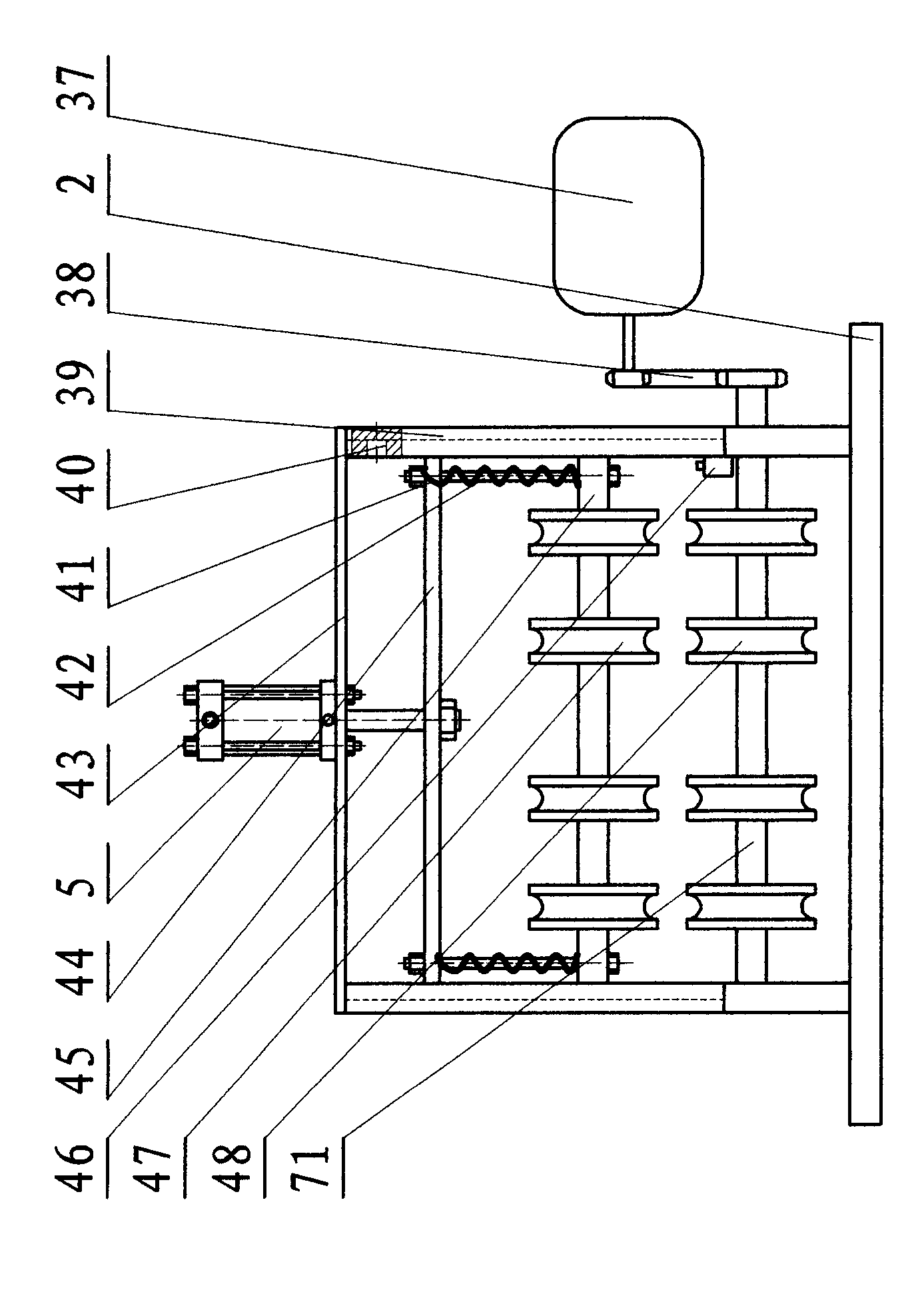

[0036] The feeding device 1 is composed of a frame 2 and several support rollers 3 installed on the frame 2 (the number of support rollers 3 depends on the length of the processed pipe, and the general interval is 500-1000mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com