Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

59results about How to "Reduce the chance of fouling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

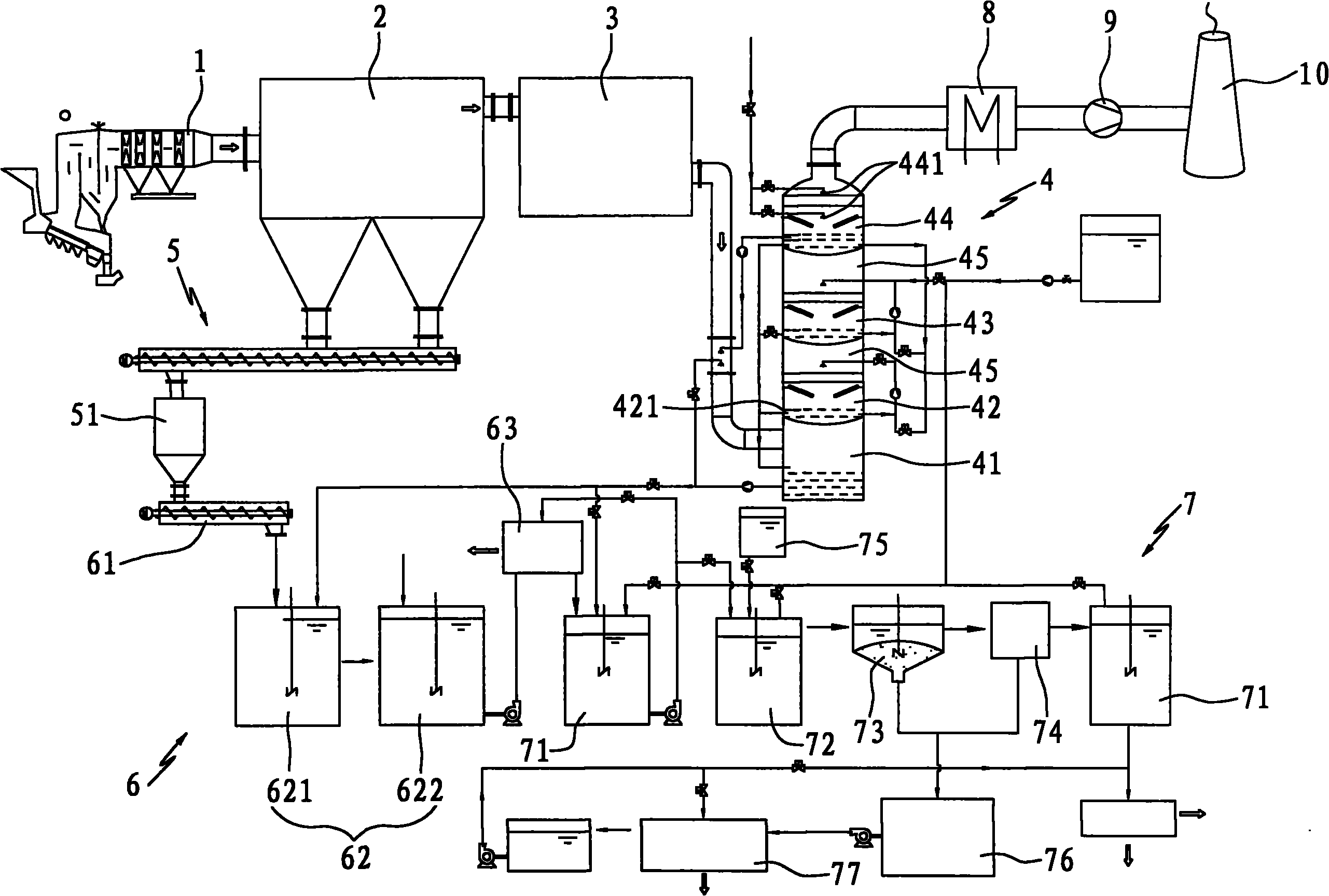

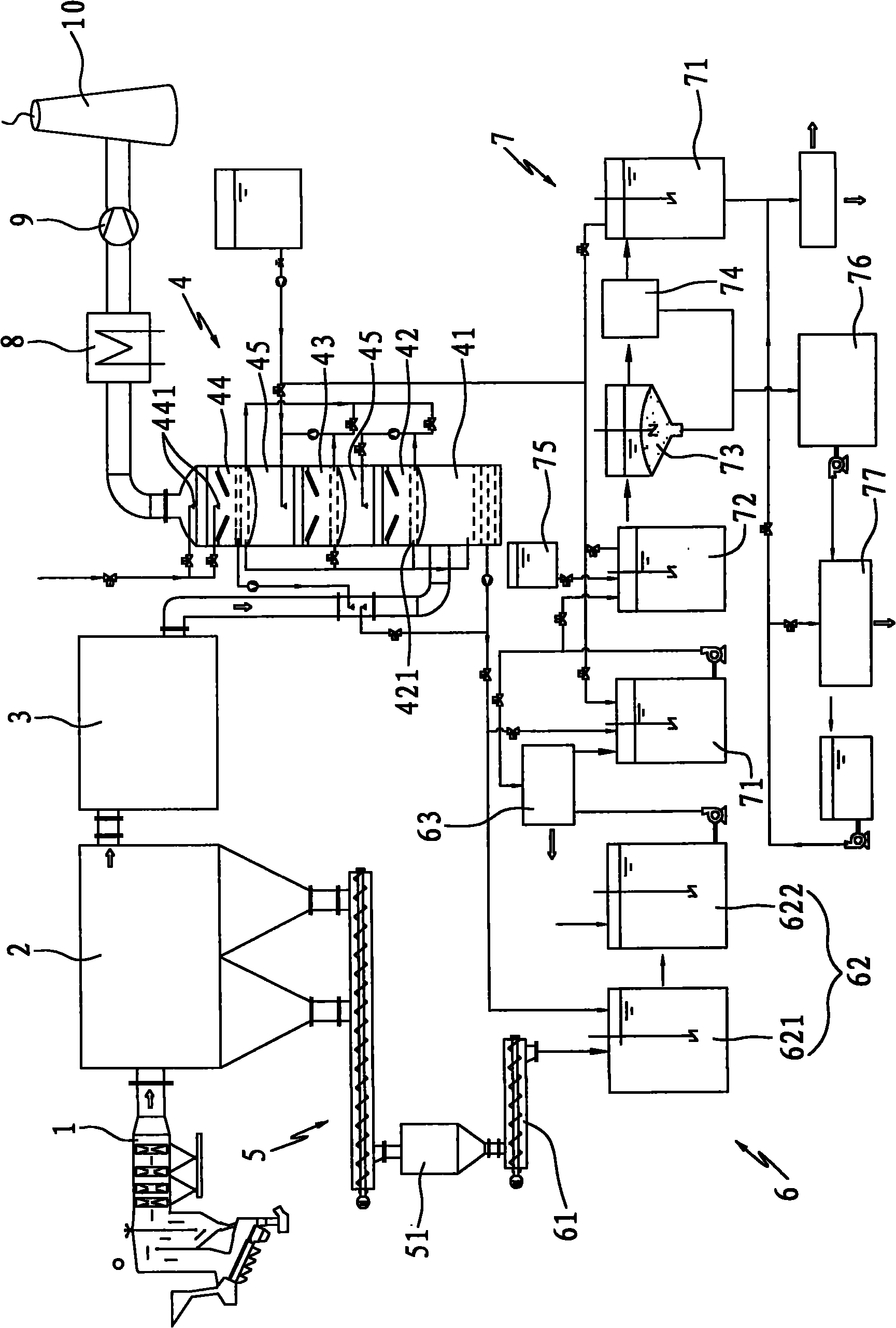

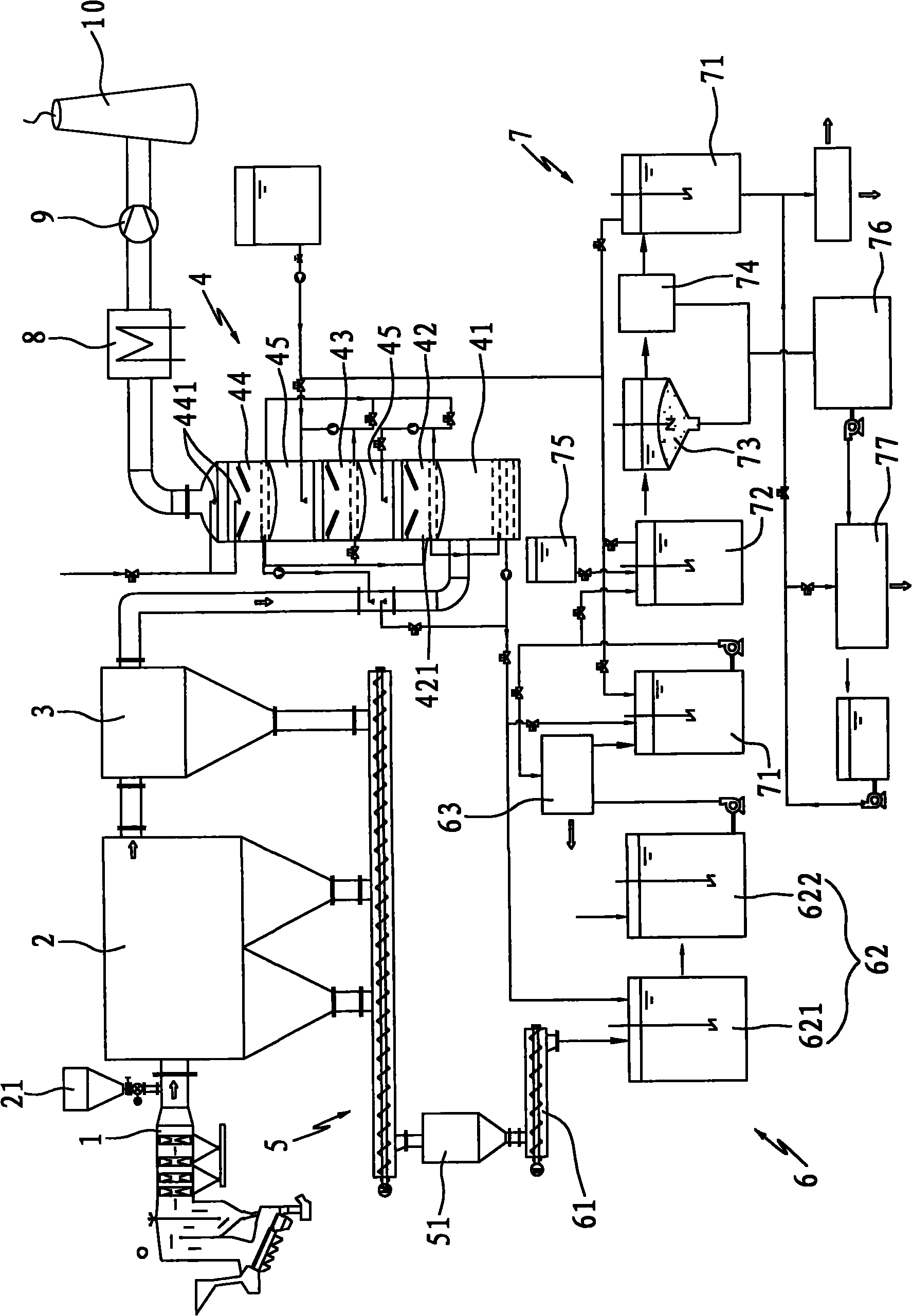

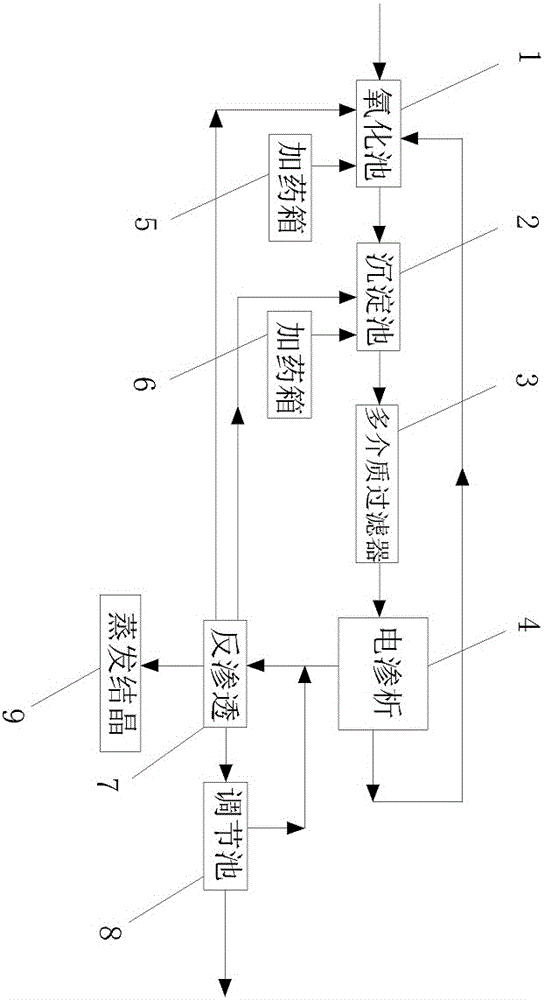

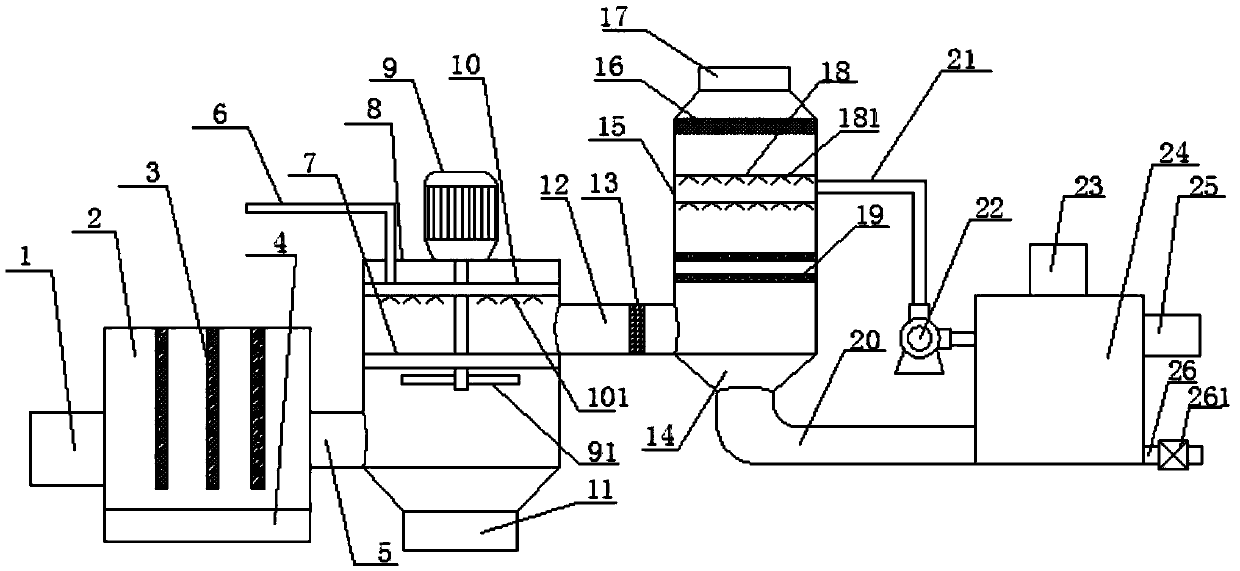

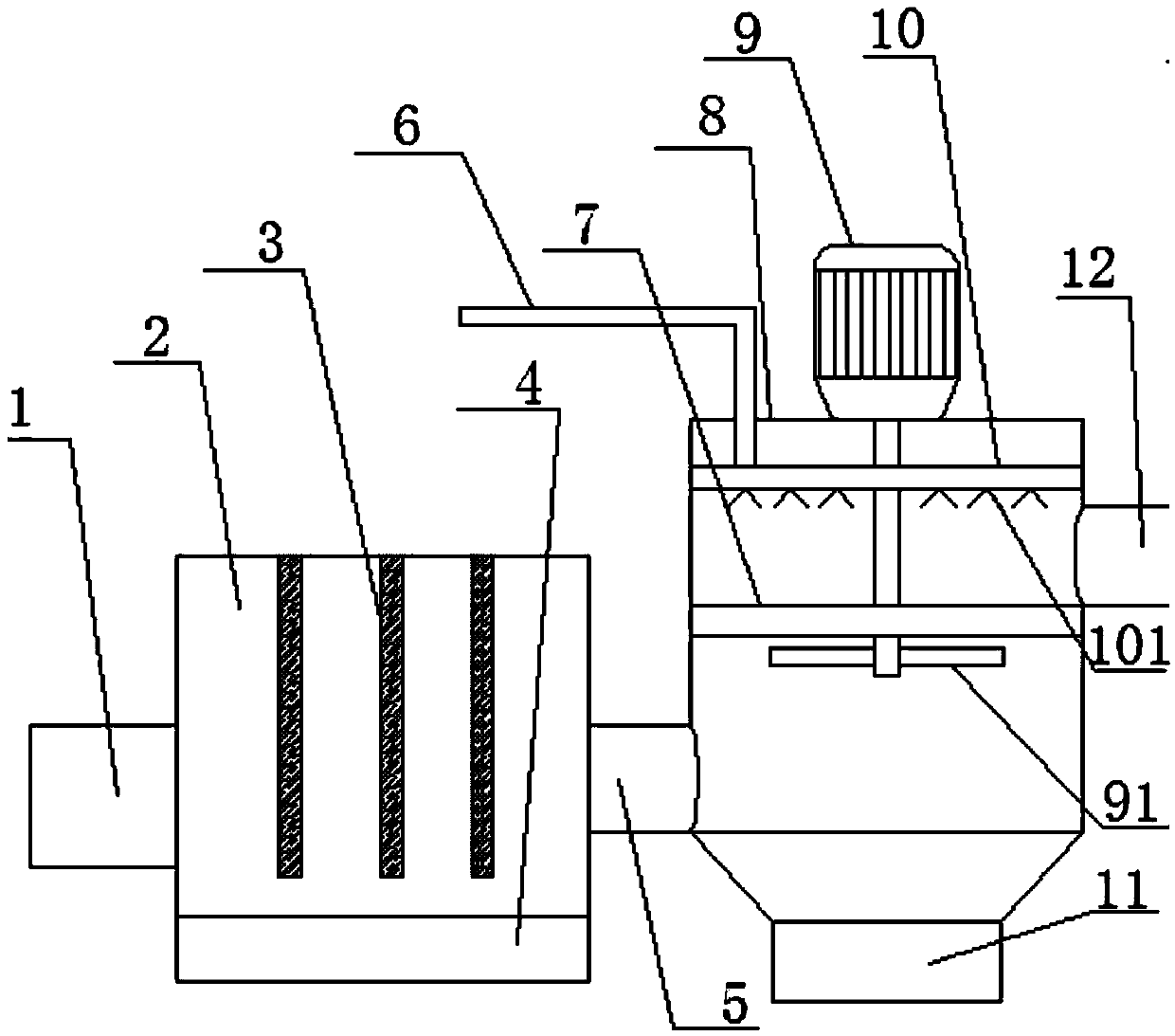

Purification system for flue gas generated by burning wastes and purification process thereof

InactiveCN101810992ASimple purification processEfficient purification processCombination devicesFlue gasSewage

The invention discloses a purification system for flue gas generated by burning wastes and a purification process thereof. The purification system comprises a flue of a refuge incinerator, a dust remover, a device for decomposing and removing dioxins, a flue gas washing tower, a fly ash collecting device, a fly ash washing and dehydrating system, a sewage treatment system, a flue gas heating device and a draught fan; one side of an inlet of the dust remover is connected with the flue, and the other side of the inlet of the dust remover is connected with the device for decomposing and removing dioxins; the fly ash collecting device is connected under the dust remover and the fly ash washing and dehydrating system; the device for decomposing and removing dioxins is connected with the lower part of the flue gas washing tower through a pipeline; an outlet of the flue gas washing tower is connected with the flue gas heating device; meanwhile, a water drain of the flue gas heating device is respectively connected with the fly ash washing and dehydrating system and the sewage treatment system; and purified flue gas is exhausted through the draught fan by using the flue gas heating device. The flue gas can meet the stricter exhaust standard by the purification treatment processes of removing dust, decomposing the dioxins, absorbing and neutralizing acid gases, removing heavy metals, deeply removing dust and the like.

Owner:瀚蓝(厦门)固废处理有限公司 +2

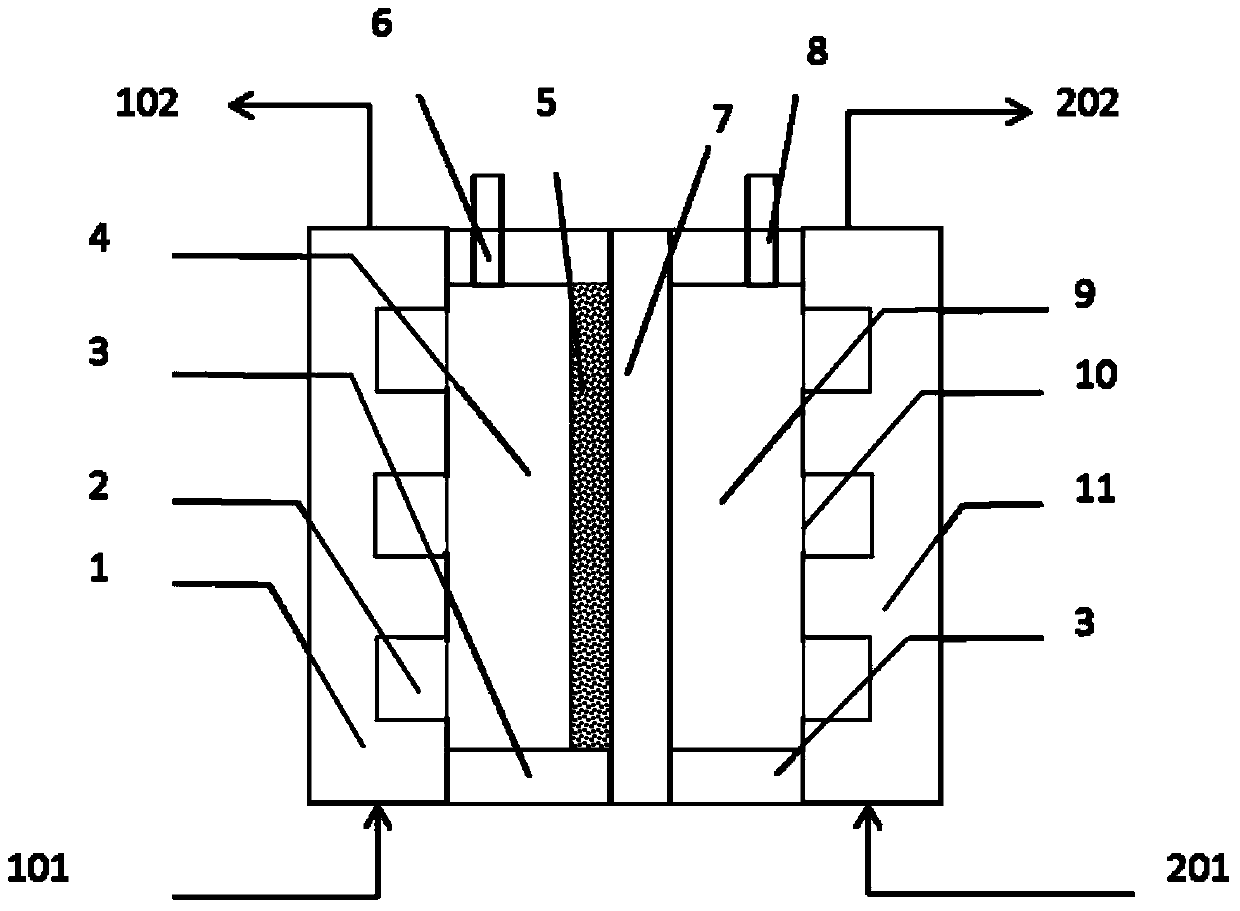

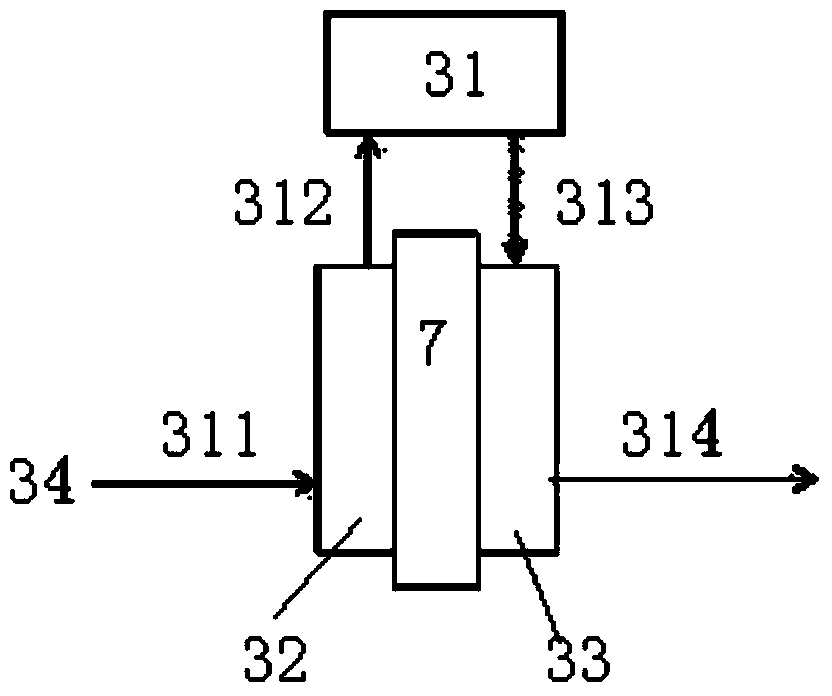

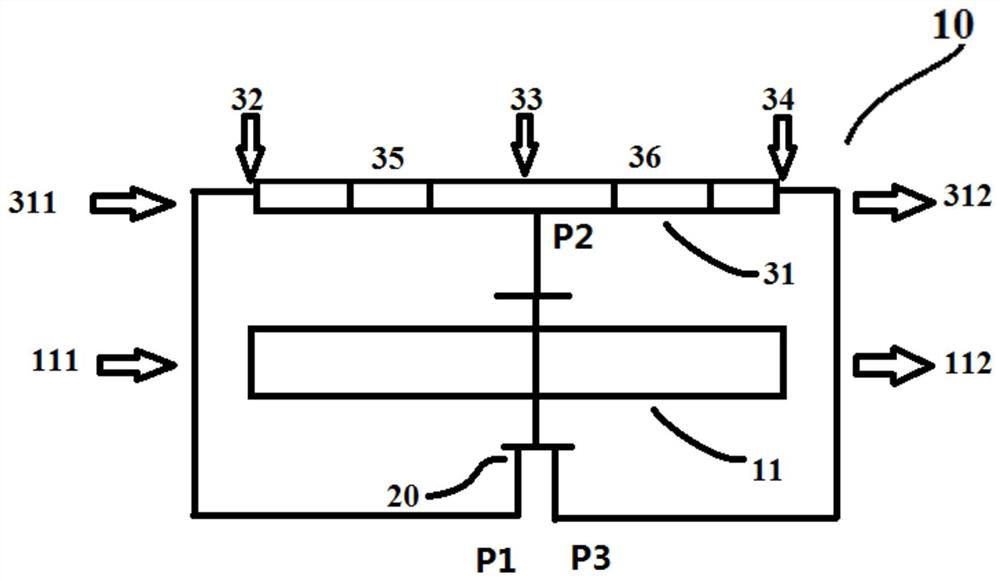

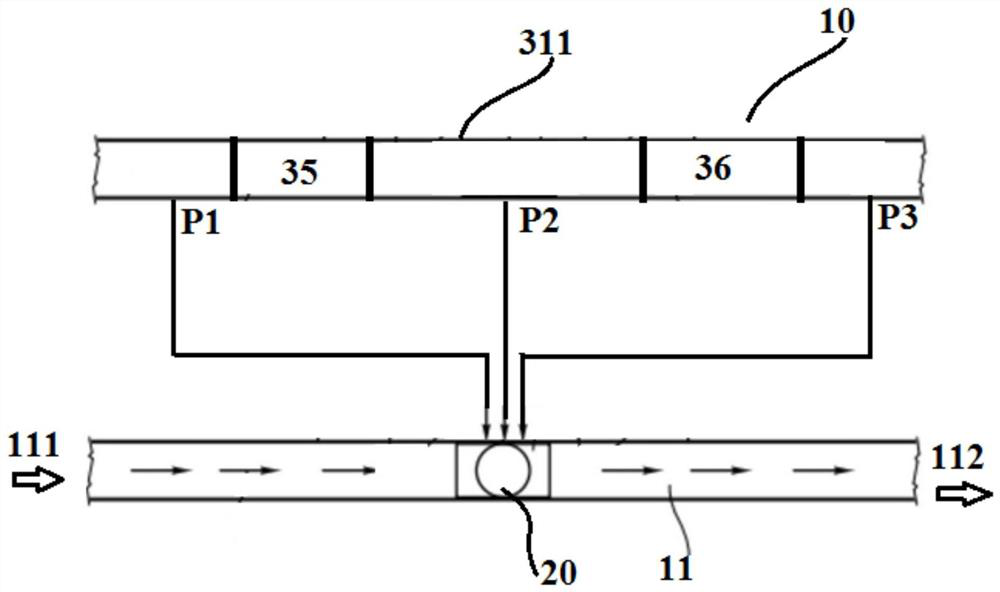

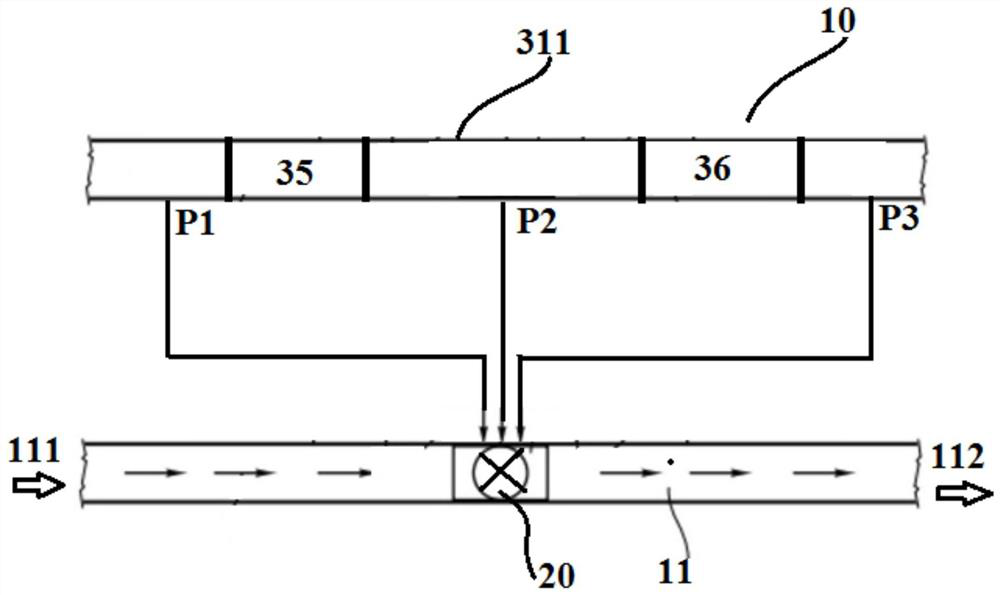

Water distribution structure and water distribution method of SPE (Solid Phase Extraction) electrolytic tank

ActiveCN104211141AHigh pHReduce the chance of foulingWater/sewage treatmentDistribution methodWater source

The invention relates to a water distribution structure and a water distribution method of an SPE (Solid Phase Extraction) electrolytic tank. The water distribution structure comprises a water collecting tank, an ion exchange membrane, an anode chamber and a cathode chamber, wherein the anode chamber and the cathode chamber are positioned on two sides of the ion exchange membrane; an ion exchange membrane material is an anion exchange membrane or a cation exchange membrane; the anode chamber is provided with an anode water inlet and an anode water outlet; the cathode chamber is provided with a cathode water inlet and a cathode water outlet; the water collecting tank is provided with a water collecting tank water inlet and a water collecting tank water outlet; a waste water source to be treated is connected to the anode water inlet, the anode water outlet is connected to the water collecting tank water inlet, the water collecting tank water outlet is connected to the cathode water inlet, and the cathode water outlet is connected to treated treating water. According to the water distribution structure, a water distribution mode is simple, and tap water is unnecessary to add as catholyte; anode effluent water is low in pH, and the anode effluent water greatly reduces the pH of a cathode and reduces the pH concentration difference between a cathode and an anode after entering the cathode, so that the pressure of the electrolytic tank is greatly reduced; because the pH of the cathode is reduced, the cathode is reduced in scaling and blocking probability; final effluent water is in proximity to neutrality.

Owner:BEIJING JINDAYU ENVIRONMENT TECH CO LTD

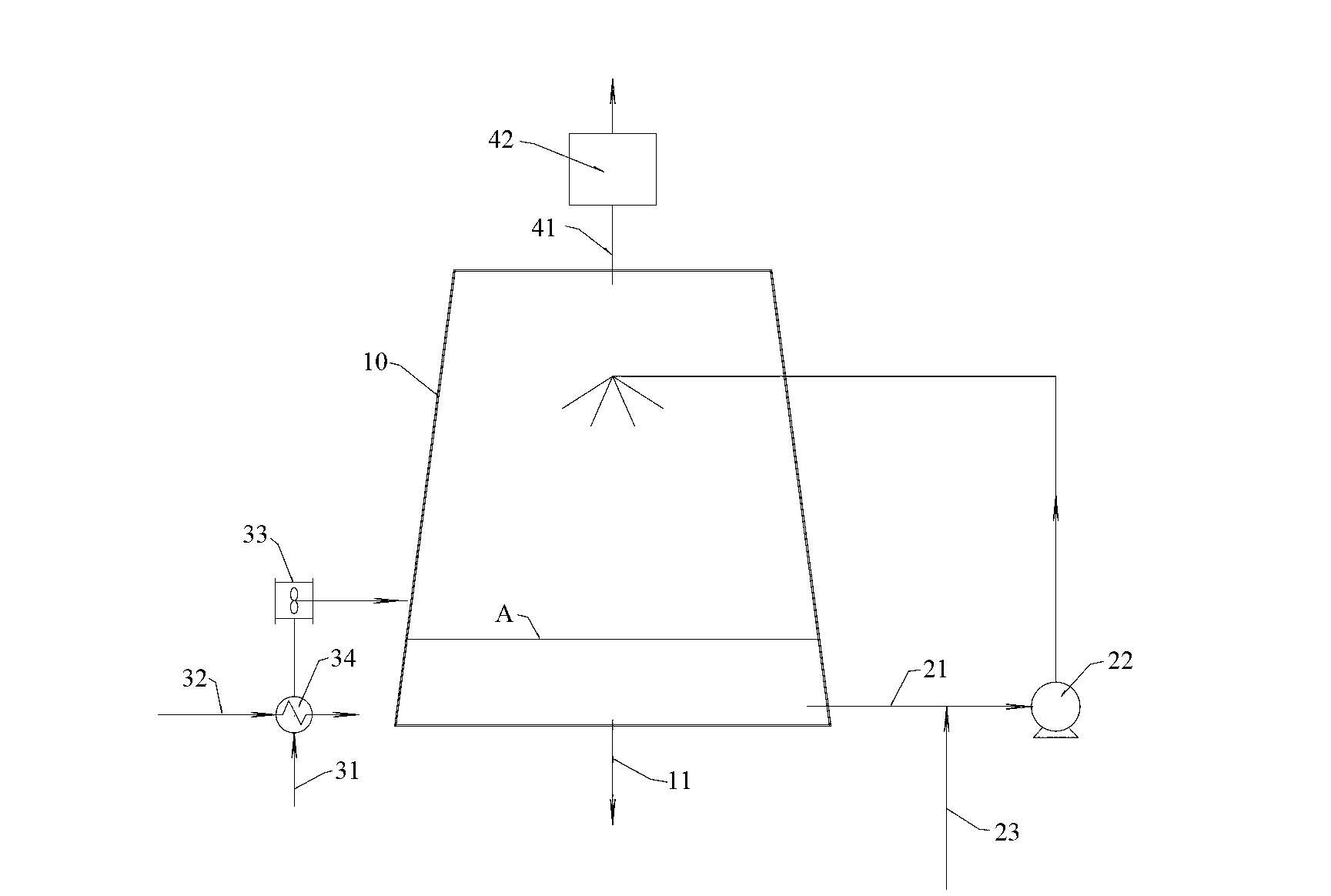

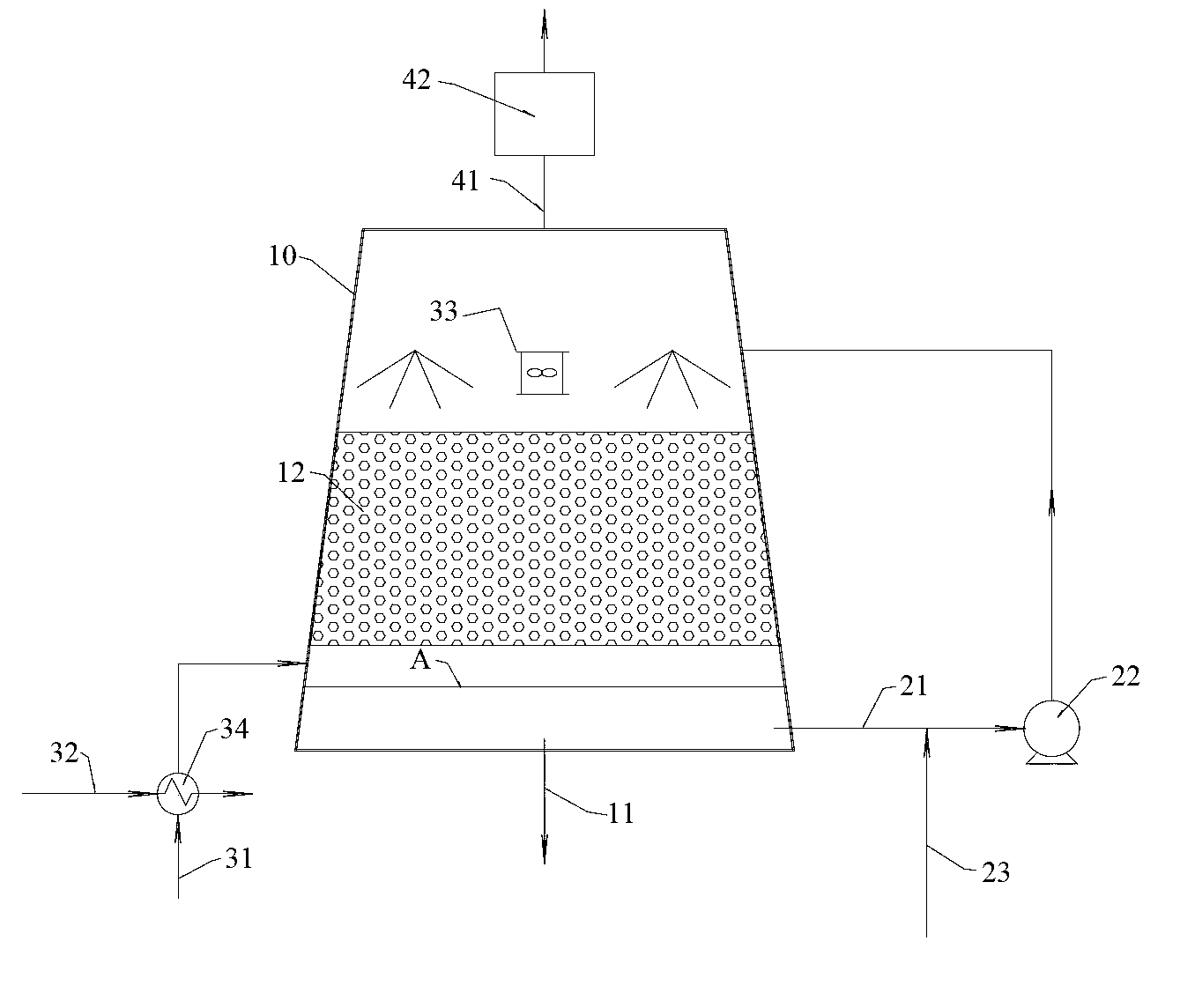

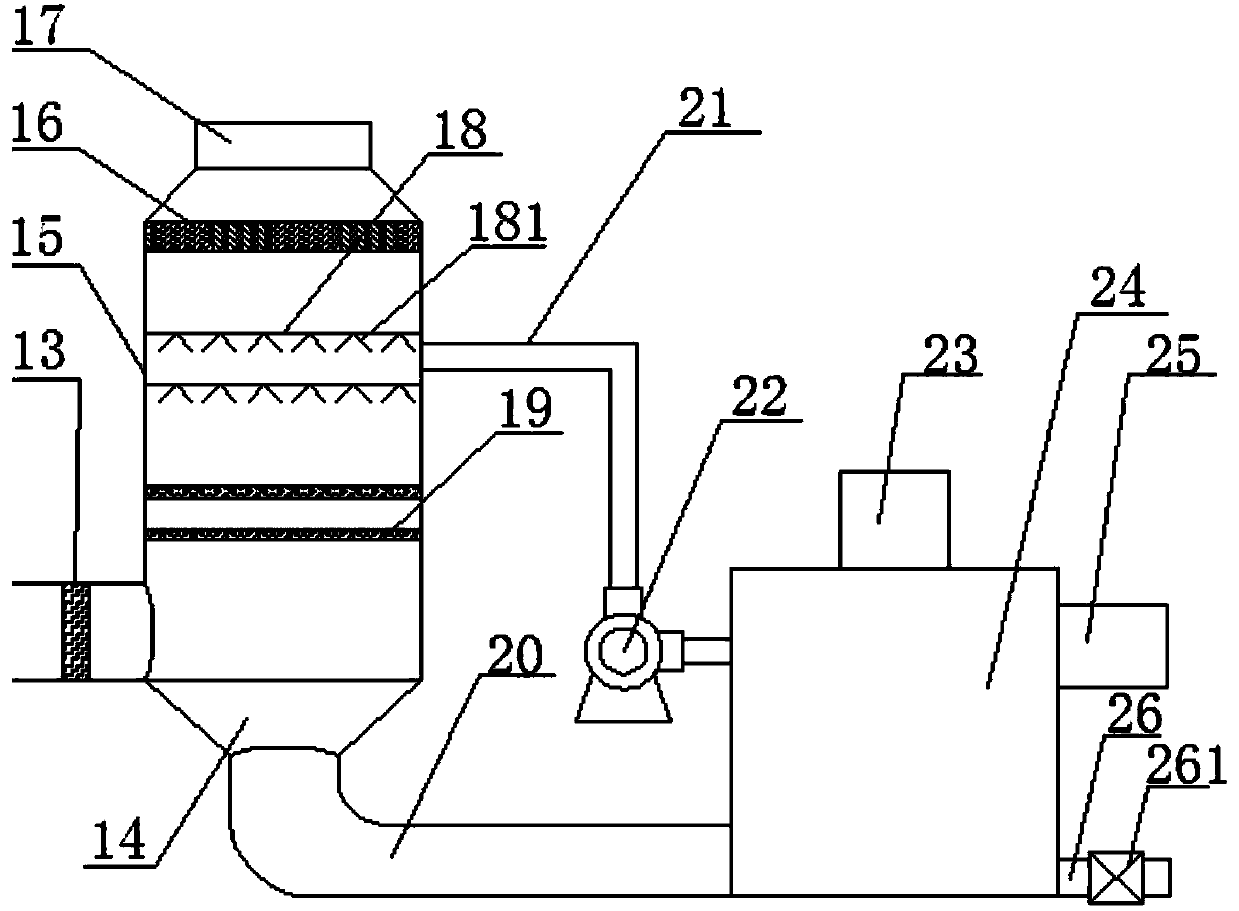

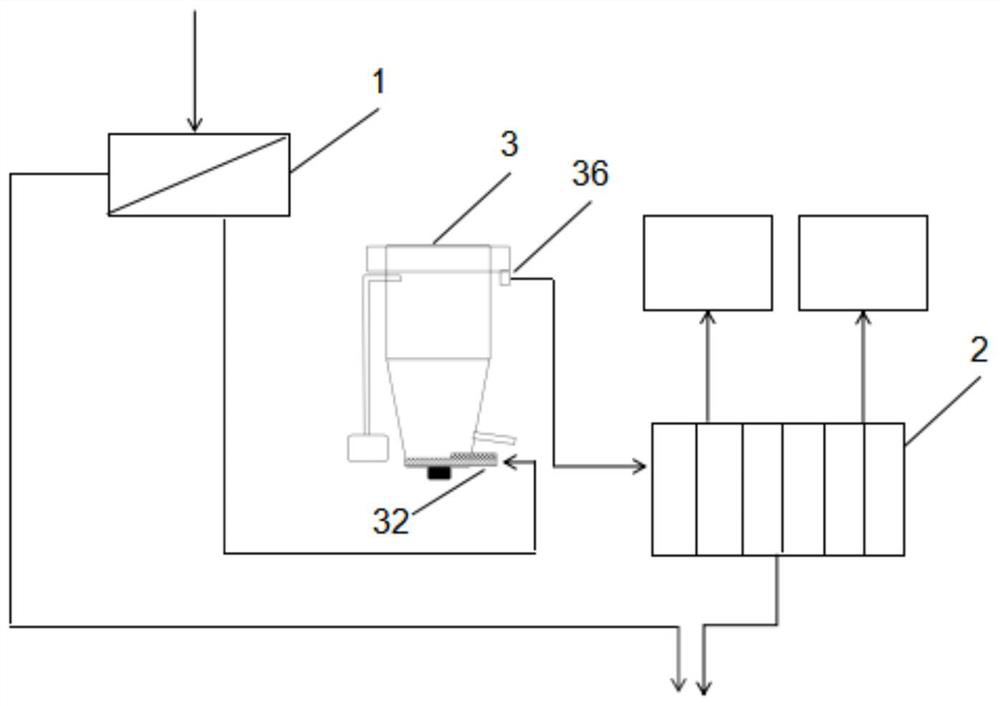

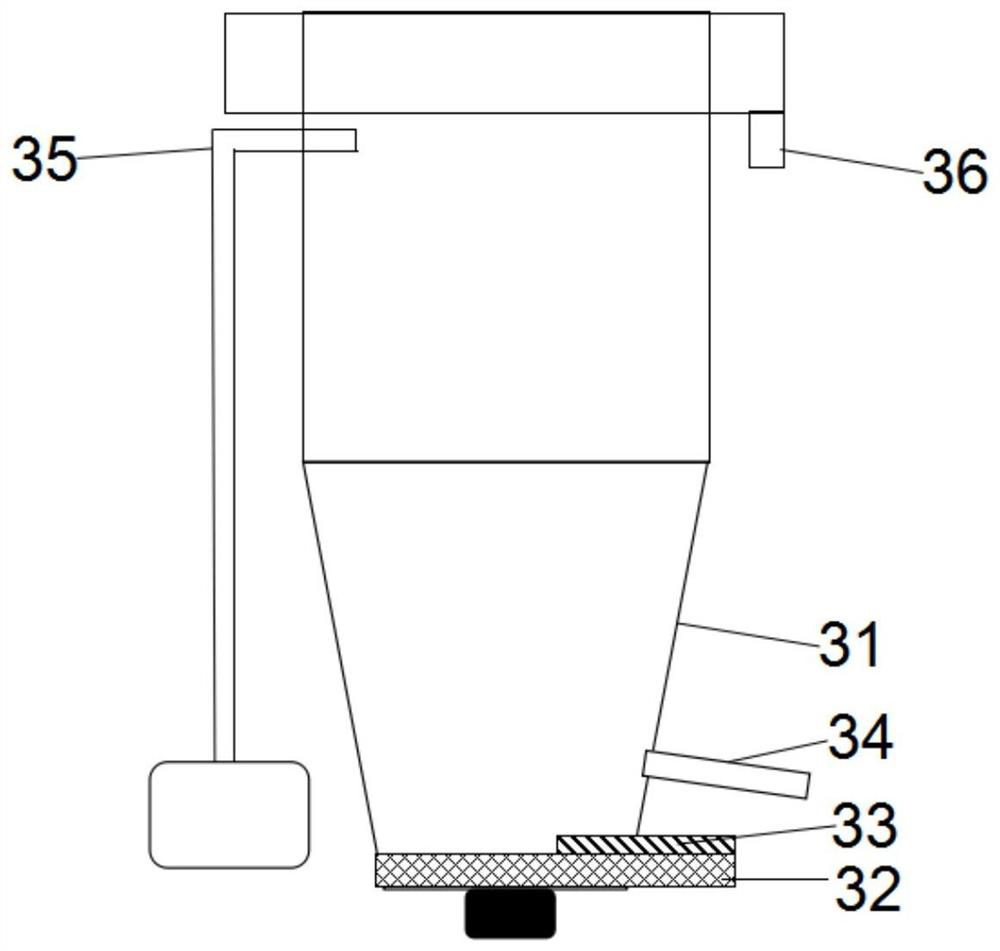

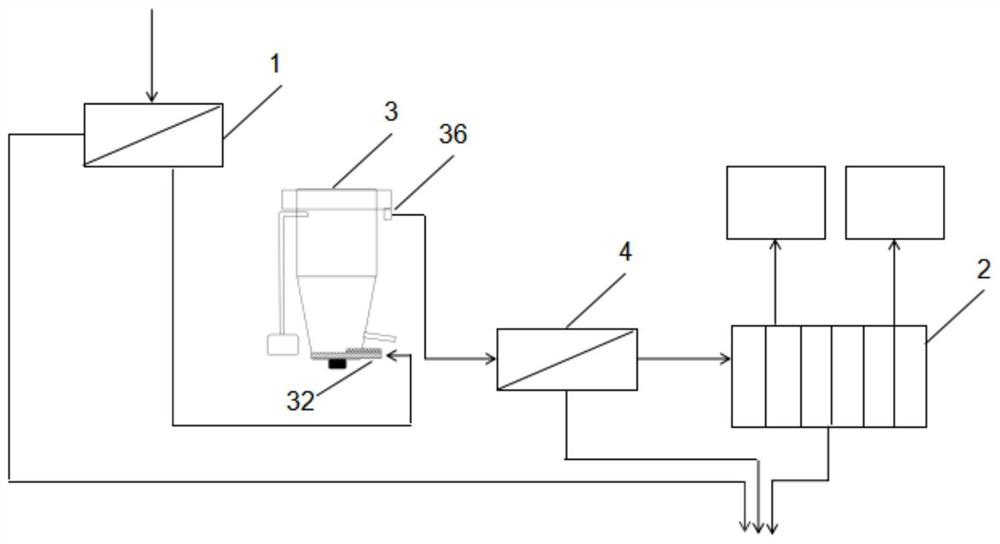

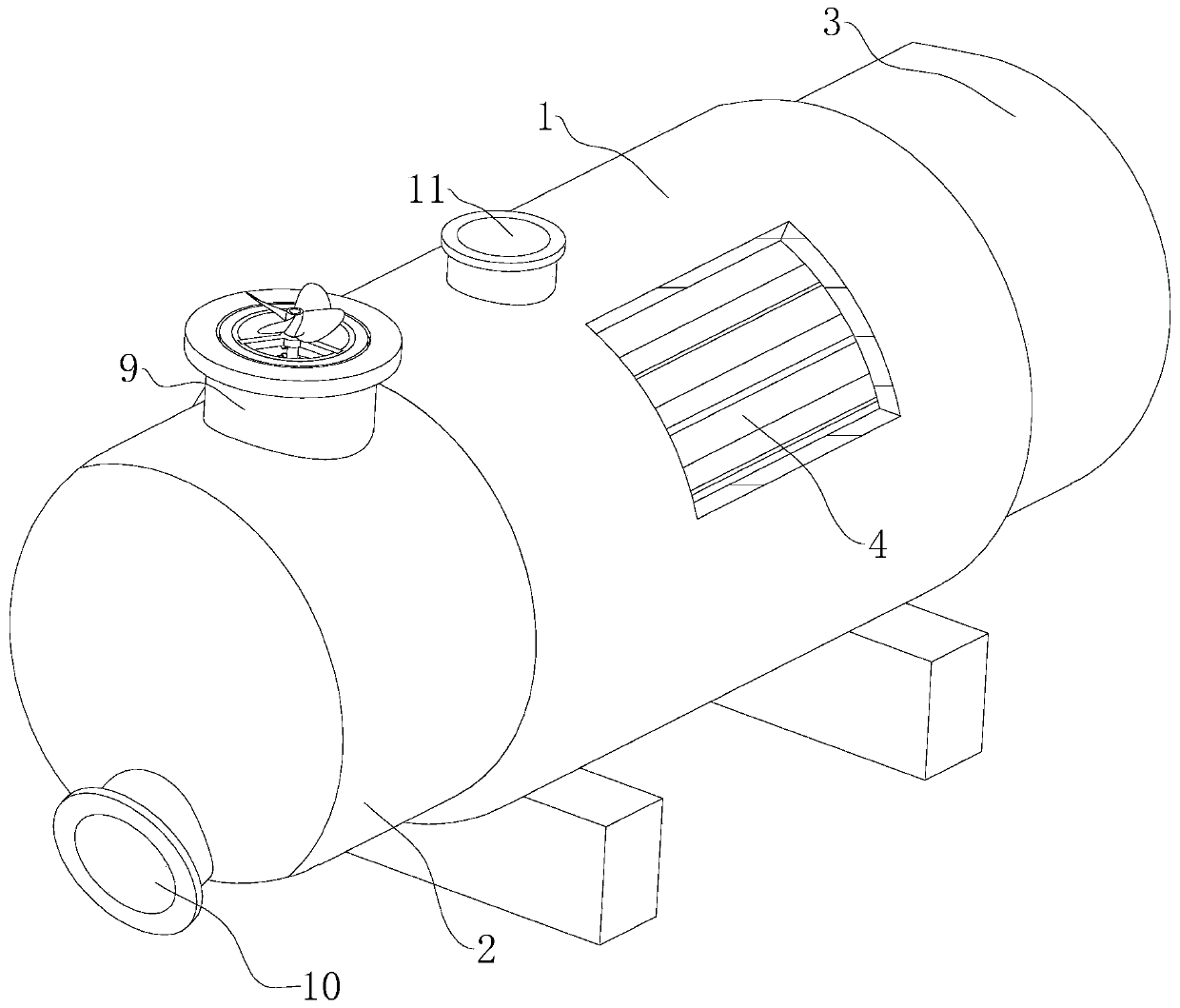

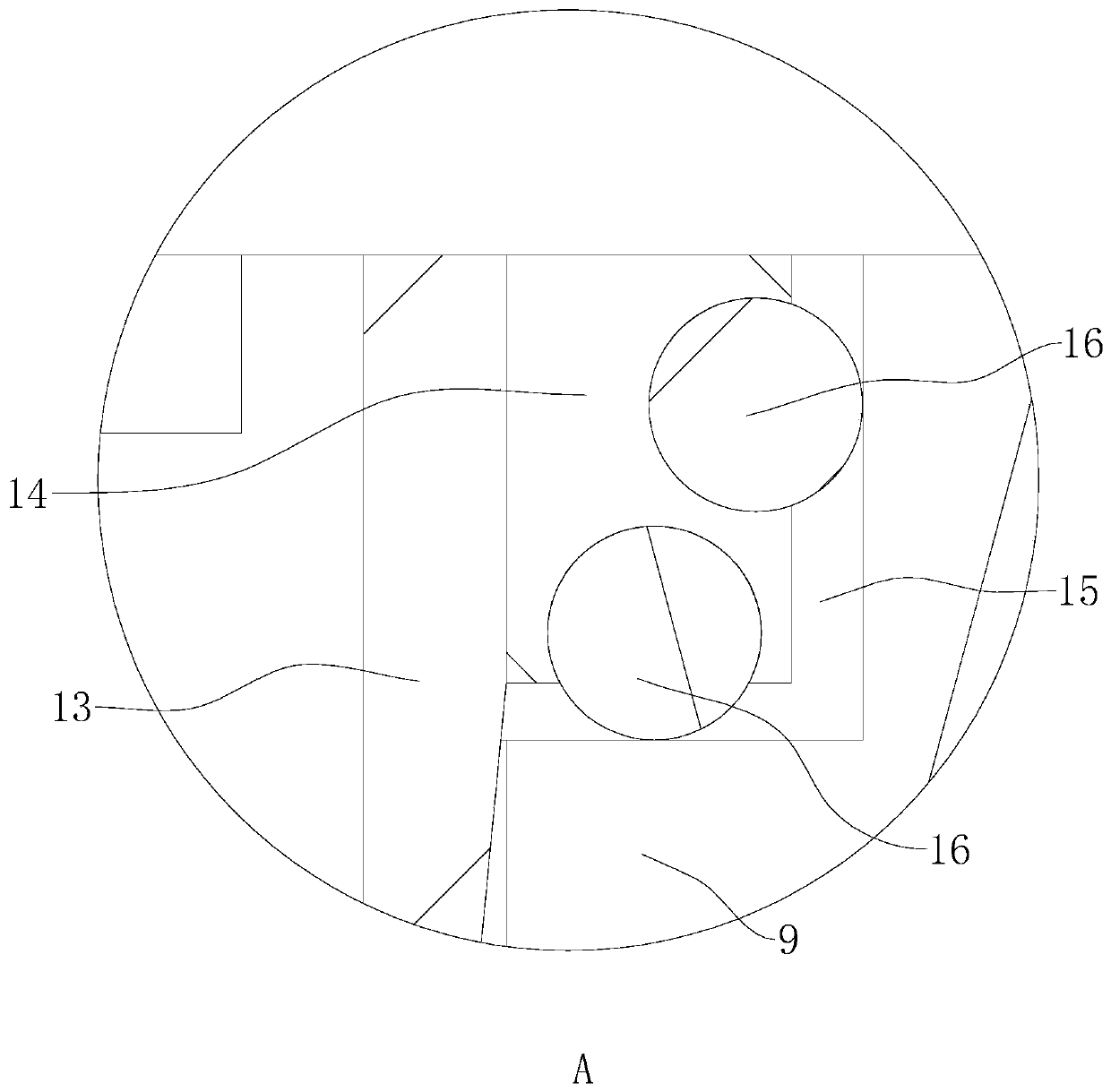

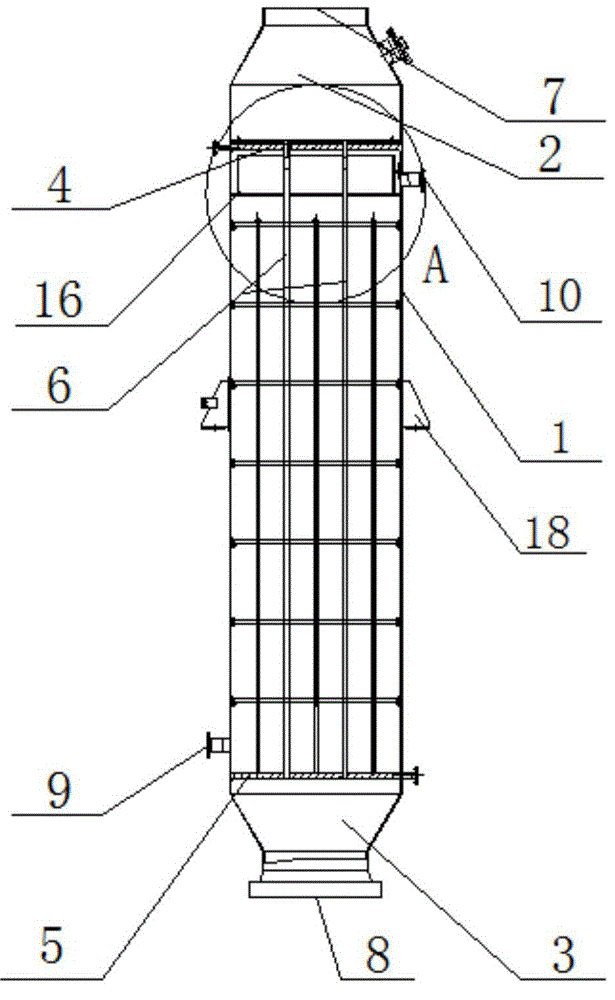

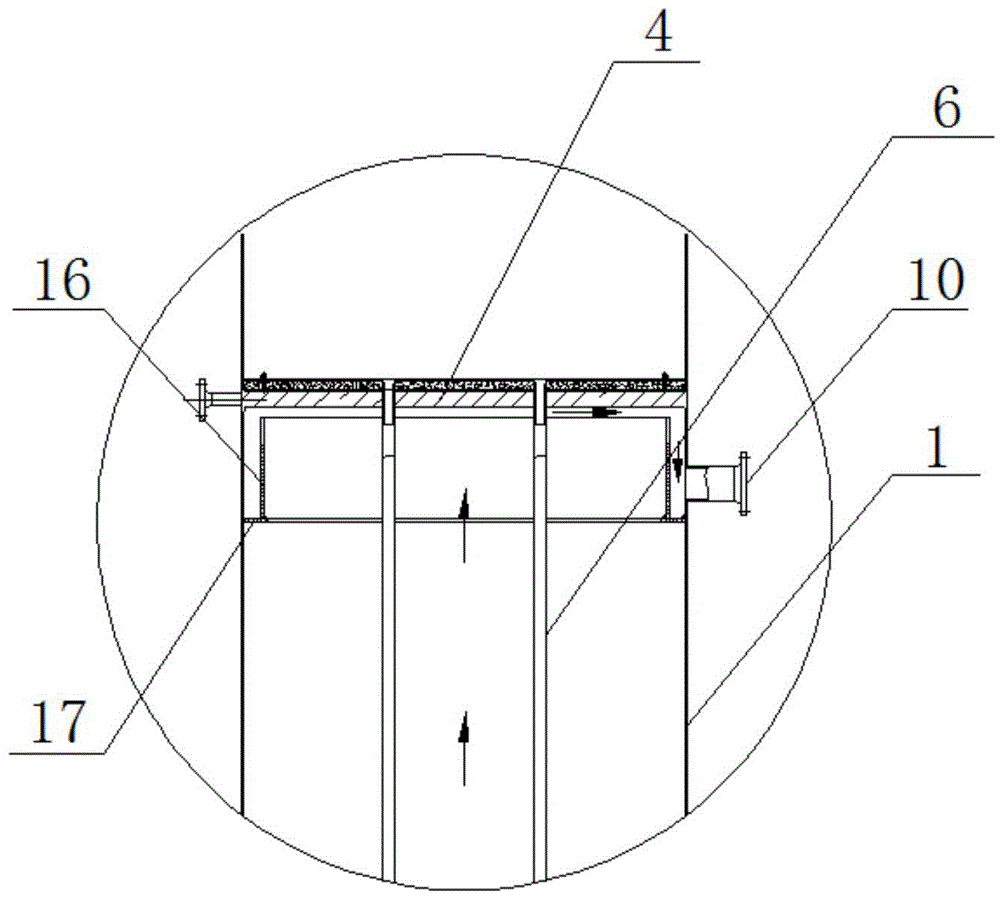

Mechanical ventilation forced circulation evaporation device and liquid material evaporation method

InactiveCN103265091AReduce the chance of foulingLow chance of floodingWater/sewage treatmentEvaporationEvaporationEnergy consumption

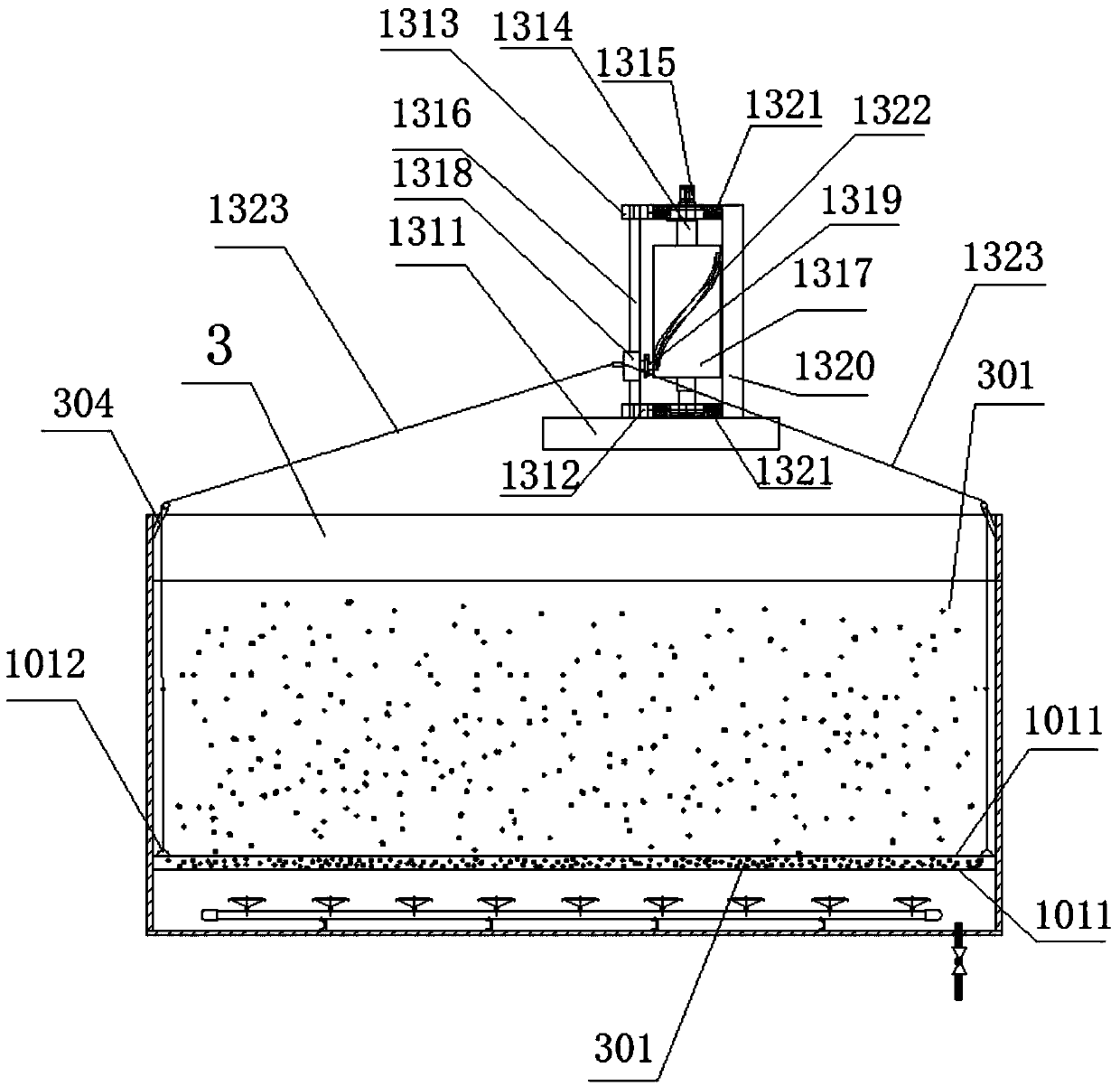

The invention provides a mechanical ventilation forced circulation evaporation device and a liquid material evaporation method which are used for improving the operation reliability of an evaporation system and reducing the energy consumption and the operation cost. The mechanical ventilation forced circulation evaporation device comprises an evaporation container (10), a liquid material circulation system, a hot air conveying system and a tail gas collecting discharging system, wherein the evaporation container (10) is sealed, and a discharging pipe (11) is arranged at the bottom of the evaporation container (10); the initialing end and the terminal end of the liquid material circulation system are respectively positioned below and above a liquid level (A) inside the evaporation container (10); the terminal end of the air conveying system is communicated with a cavity of the evaporation container (10); and the initialing end of the tail gas collecting discharging system is communicated with a cavity above the liquid level (A) in the evaporation container (10).

Owner:魏华

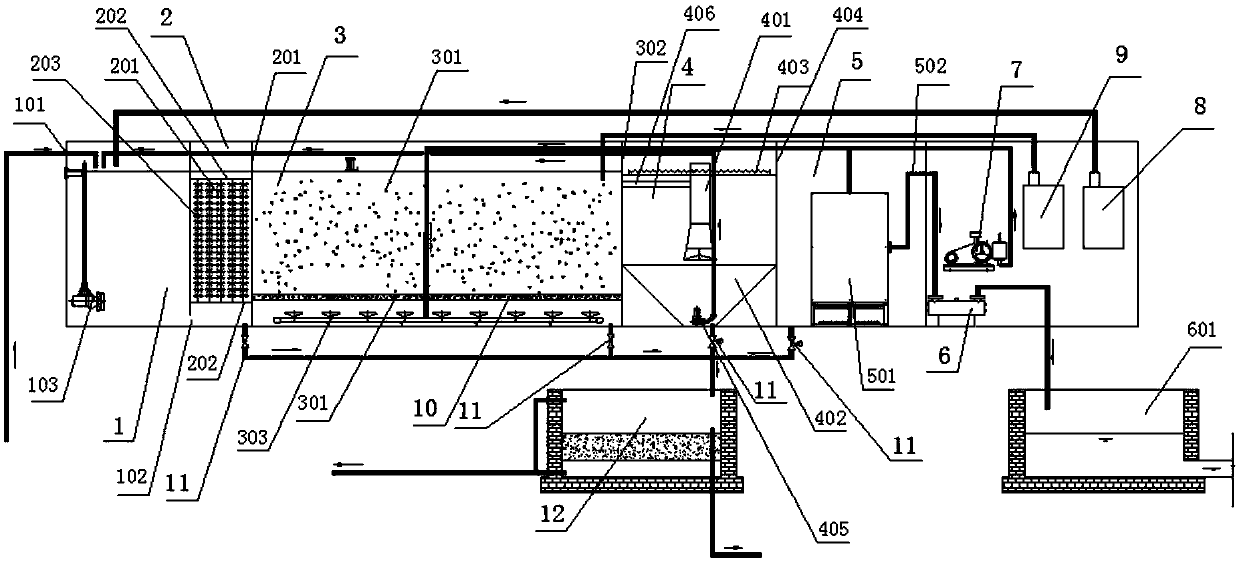

Integrated sewage treatment equipment

InactiveCN109665681AImprove the efficiency of phosphorus uptake reactionGuaranteed anaerobic stateWater/sewage treatment by irradiationSpecific water treatment objectivesSludgeUv disinfection

The invention provides integrated sewage treatment equipment, which comprises an anoxic tank, an anaerobic tank, an aerobic tank, a sedimentation tank and a membrane reaction tank communicated sequentially from front to back, wherein an MBR membrane is arranged in the membrane reaction tank and communicated with an ultraviolet disinfector; aeration equipment is communicated with both the aerobic tank and the MBR membrane; an elastic filler is uniformly distributed in the anaerobic tank and an MBBR filler is arranged in the aerobic tank; a mixer is arranged in the anoxic pool, a carbon source adding device is communicated with the anoxic pool, and a medicine dosing barrel is communicated with the aerobic tank. Compared with the traditional sewage treatment device, the continuous aeration ofthe integrated sewage treatment equipment enables a moving bed in a flowing state and react more fully with the sewage, which greatly improves the treatment efficiency. The sedimentation tank is designed in front of the membrane reaction tank to separate the mud and water and remove the floating sludge, so that most of the mud is precipitated before entering the membrane area, thereby reducing the operating load of the MBR membrane, reducing the probability of fouling, delaying the service life of the membrane, also prolonging the backwashing cycle of the membrane and further ensuring the quality of the effluent.

Owner:重庆尚泽源环保科技有限公司

Desulfurization wastewater reverse osmosis reconcentration device

InactiveCN106242145APrevent complete oxidationReduce workloadWater treatment parameter controlSpecific water treatment objectivesElectricityEvaporation

The invention relates to an industrial wastewater treatment technology and device, and in particular, relates to a desulfurization wastewater reverse osmosis reconcentration device; an inlet of a precipitation pool communicates with an outlet of an oxidation pool and an inlet of a multi-medium filter; an outlet of the multi-medium filter communicates with an inlet of an electrodialysis device; a concentrated water outlet of the electrodialysis device communicates with an inlet of the oxidation pool; a fresh water outlet of the electrodialysis device communicates with an inlet of a reverse osmosis device; a fresh water outlet of the reverse osmosis device communicates with the inlet of the precipitation pool and the inlet of the oxidation pool; a concentrated water outlet of the reverse osmosis device communicates with an inlet of an evaporation crystallizer; an outlet of a first drug feeding box communicates with the inlet of the oxidation pool; an outlet of a second drug feeding box communicates with an inlet of the precipitation pool. Salts and other components in desulfurization waste water of a thermal power plant can be effectively removed, and the components can also be recycled in a useful form.

Owner:刘永锋

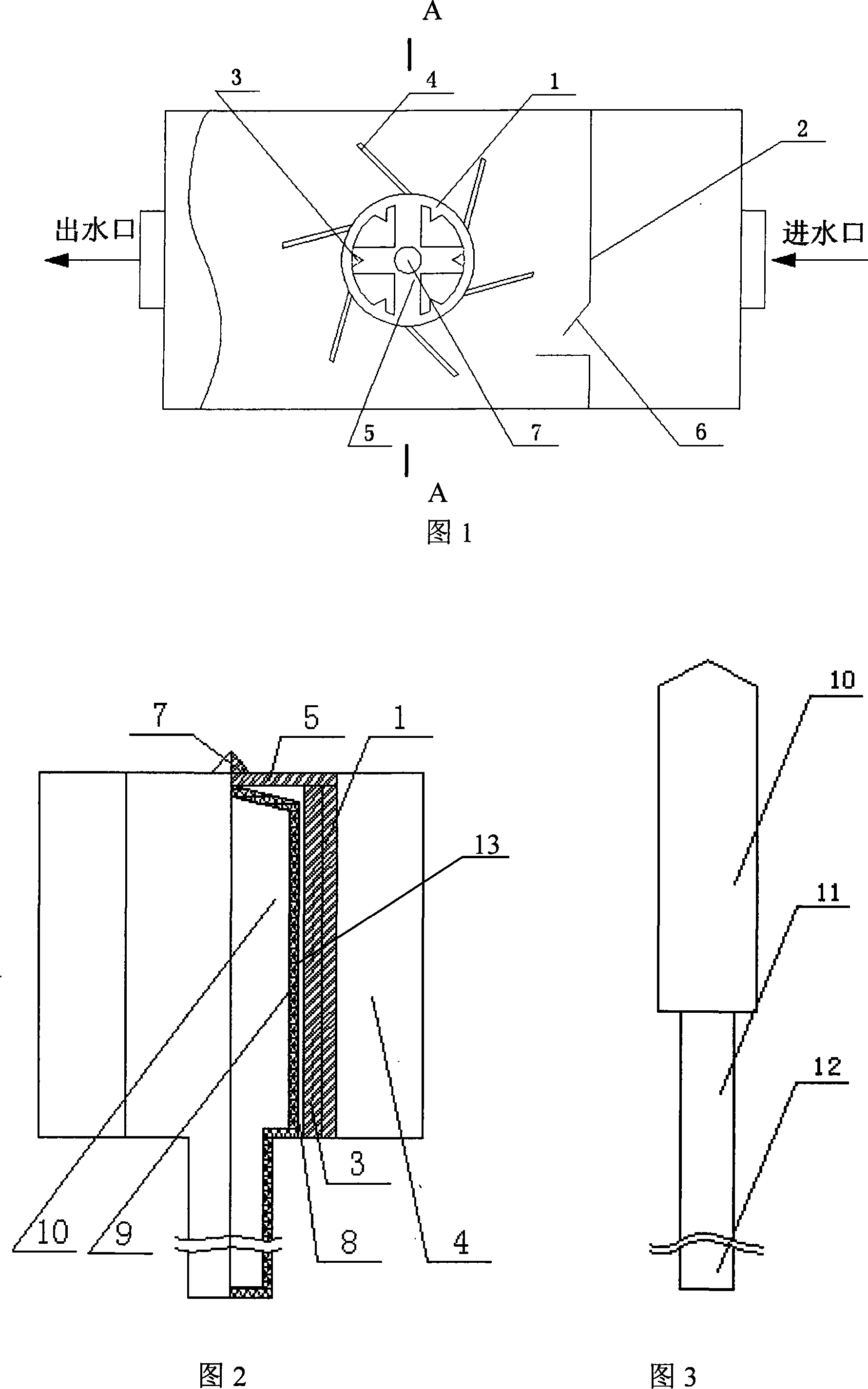

Antiscaling and descaling device of solar water heater hot pipe condensation terminal

InactiveCN101182978AAvoid wastingReduce volumeCorrosion preventionHeat exchange apparatusSolar waterEngineering

The invention discloses an antiscale and descale device on the condensation end of a heat pipe of a solar water heater and comprises a heat exchange water jacket; the heat exchange water jacket is provided with a water inlet and a water outlet and the condensation end of the heat pipe in the heat exchange water jacket is sleeved with an antiscale wheel component; a water baffle is respectively arranged between the water inlet of the heat exchange water jacket and the antiscale wheel component in the heat exchange water jacket; the antiscale wheel component consists of a plurality of blades on the wheel body of the antiscale wheel and the internal wall of the wheel body of the antiscale wheel is uniformly provided with a plurality of V-shaped antiscale teeth; one end of the wheel body of the antiscale wheel is provided with the end baffle sheet of the condensation end of the heat pipe; the water baffle is respectively provided with a drainage hole. The antiscale and descale device of the invention is designed according to the principle of hydrodynamics and effectively takes circulation water pressure as the power of antscale and de-scale while avoiding resources waste due to adopting other antiscale and descale ways, moreover, the invention has small volume and simple structure and is suitable for mass production.

Owner:TIANJIN UNIV

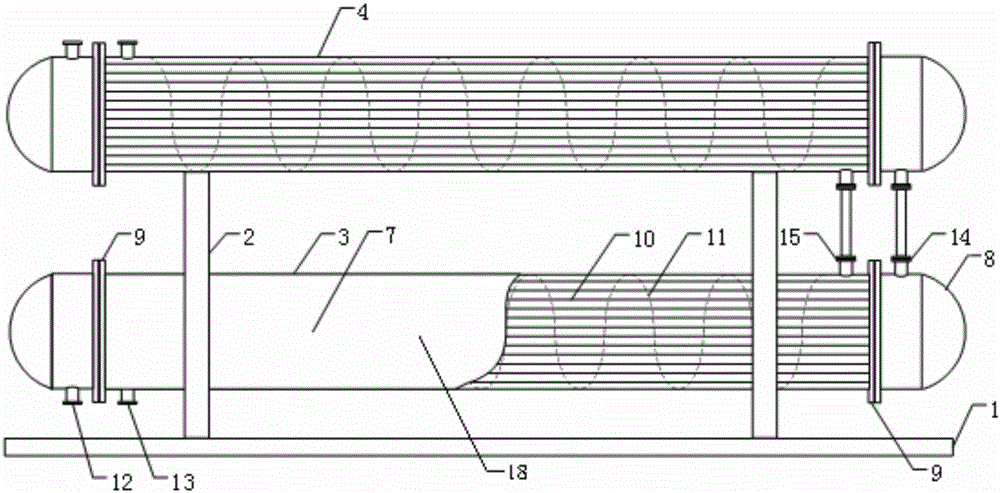

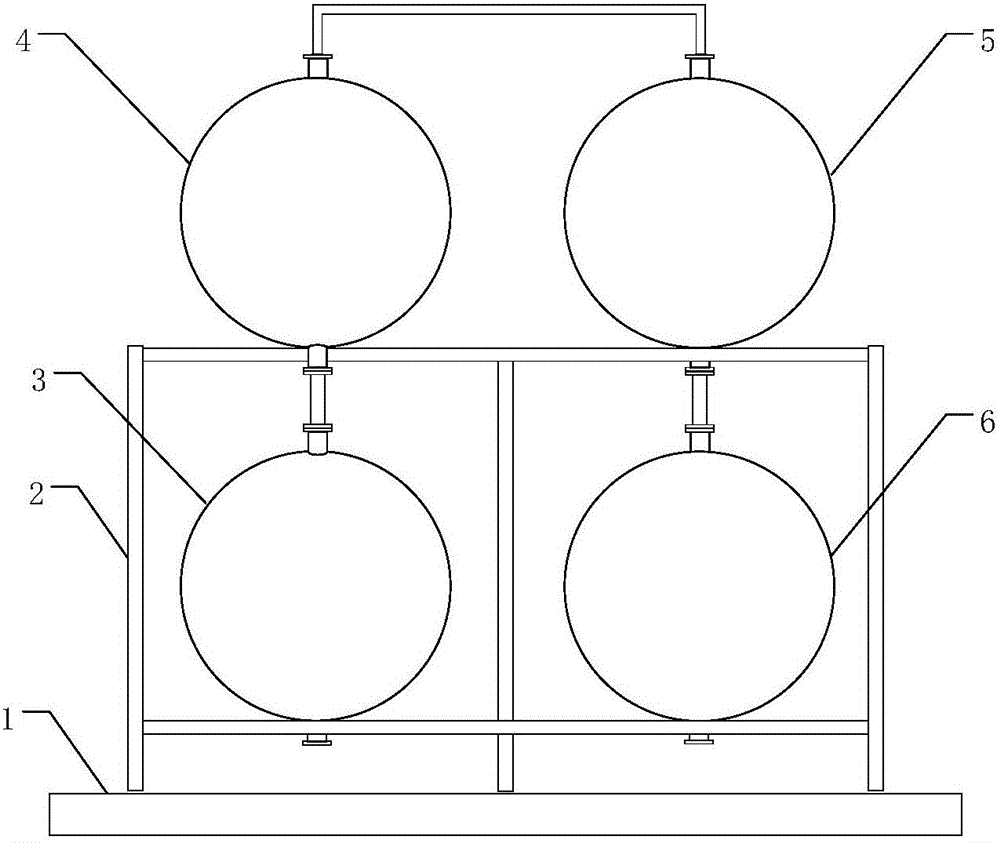

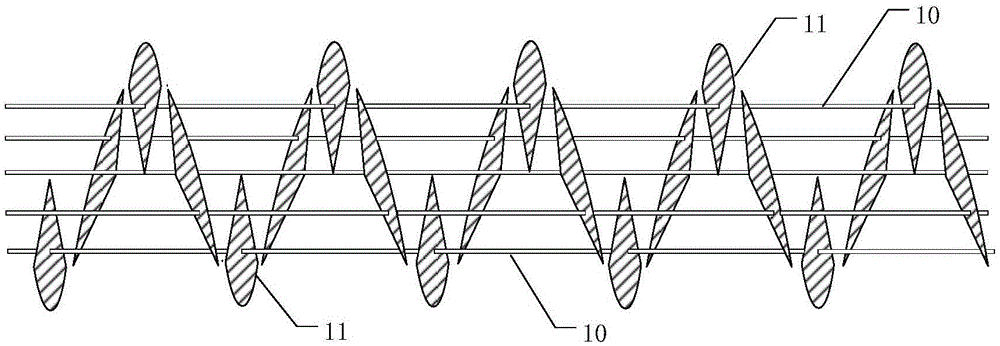

Anti-scaling multiple shell pass assembled heat exchanger

InactiveCN106705711AIncrease the lengthReduce the chance of foulingCorrosion preventionHeat exchanger casingsPlate heat exchangerShell and tube heat exchanger

The invention relates to an anti-scaling multiple shell pass assembled heat exchanger. The anti-scaling multiple shell pas assembled heat exchanger comprises a base, a bracket and a plurality of heat exchange units, wherein the base is fixed on the ground, the bracket is mounted at the upper end of the base, the plurality of the heat exchange units are mounted on the bracket, each of the heat exchange units is an independent single tube pass and single shell pass shell-and-tube heat exchanger and the heat exchange units are connected in pairs; each of the heat exchange units comprises a housing, tube boxes, tube plates, a tube bundle, a spiral baffle plate, a tube pass inlet, a shell pass inlet, a tube pass outlet and a shell pass outlet; the tube boxes are arranged at two ends of the housing, the tube bundle and the spiral baffle plate are arranged in the housing, the tube bundle is composed of a plurality of heat transfer tubes, the tube plates are welded at two ends of the tube bundle, and the spiral baffle plate is continuously welded by fan-shaped surface plates to form a spiral surface structure and is mounted on the tube bundle. By lengthening the lengths of the tube passes of the heat exchangers, the sections of the tube passes are reduced and the fluid flow rate of the tube passes is improved, so that the scaling probability of the tube passes is greatly reduced.

Owner:张炳辰

Dedusting and desulfurization integrated machine

InactiveCN104190190AImprove solubilityReduce the chance of foulingCombination devicesFlue gasEngineering

The invention discloses a dedusting and desulfurization integrated machine. The machine comprises an inlet flue, a filter chamber, a dust chamber, a desulfurizing tower, an outlet flue and a circulating pool, wherein the inlet flue is communicated with the filter chamber; the filter chamber is communicated with the dust chamber through a first flue gas passage; the dust chamber is communicated with the desulfurizing tower through a second flue gas passage; a uniformly distributing board is arranged in the second flue gas passage; the outlet flue is formed in the top of the desulfurizing tower; a circulating hole is formed in the bottom of the desulfurizing tower and communicated with the circulating pool through a circulating pipeline; the circulating pool is connected with a circulating pump; and the circulating pump is connected with the desulfurizing tower through a liquid inlet pipe. The machine disclosed by the invention has the advantages that the dedusting and the desulfurization can be integrally completed; the dedusting effect is good; a bag dedusting method is not adopted, so that the operating cost is saved; the flue gas is stable and uniform; the desulphurization efficiency is high; scale cannot be easily formed in the desulfurizing tower and the pipeline; the machine is simple and convenient to operate; and the system can be stably operated in a long term.

Owner:浙江润洁环境科技股份有限公司

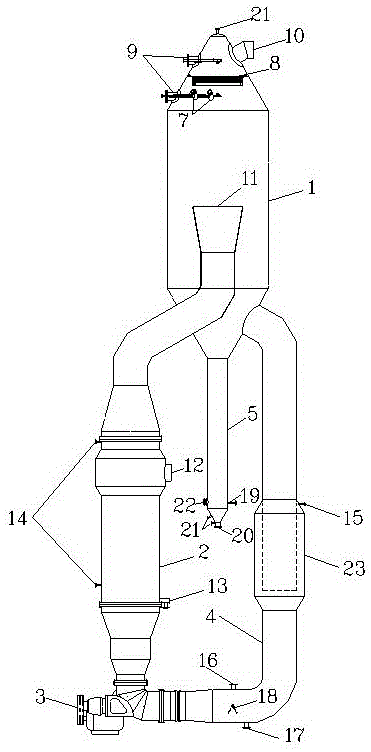

Evaporating crystallizer

InactiveCN105129890AReduce easy cloggingReduce the chance of foulingWater/sewage treatment by heatingPlate heat exchangerWastewater

An evaporating crystallizer comprises an evaporating chamber, a heat exchanger, a forced circulating pump, a circulating pipe clamp sleeve and a salt leg. A foam remover is arranged in the evaporating chamber. Spraying devices are arranged in front of and behind the foam remover. A horn mouth is formed in the center of the foam remover and is located below the liquid level. The forced circulating pump is connected with the heat exchanger through a circulating pipe in a side-inlet and top-outlet mode. A material liquid inlet is formed in the horizontal section of the circulating pipe. A clamp sleeve connector is arranged on the perpendicular section of the circulating pipe. By means of forced circulating heat exchange, the possibility that salt-bearing wastewater is prone to blocking the heat exchanger and producing scales in the heat exchanger in a conventional process is lowered; meanwhile, by means of the built-in foam remover and the spraying devices, secondary steam carries little liquid foam; due to the tank type, the evaporating crystallizer is suitable for various salt-bearing wastewater concentration working conditions, is particularly suitable for an MVR process device, can achieve continuous production, and is long in running cycle, stable in operation and convenient to control.

Owner:CHINA CEC ENG

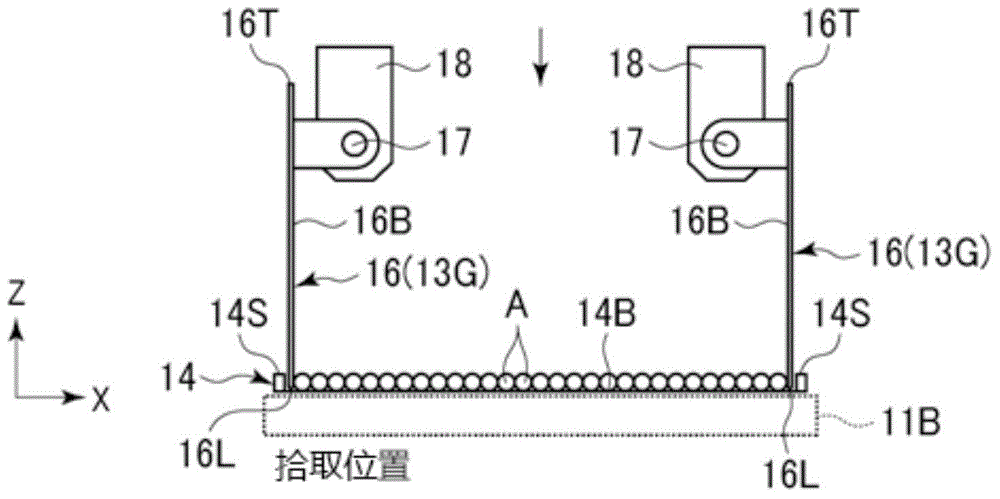

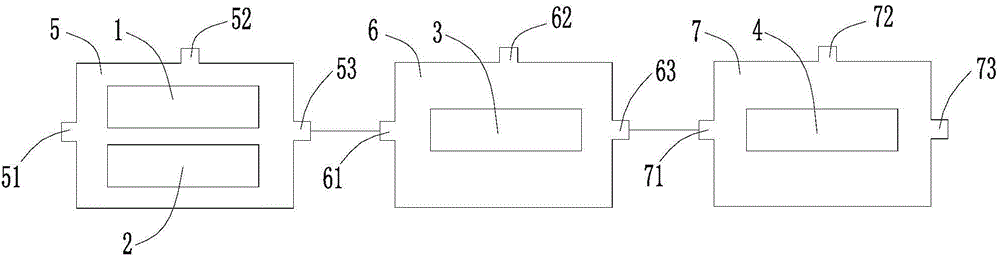

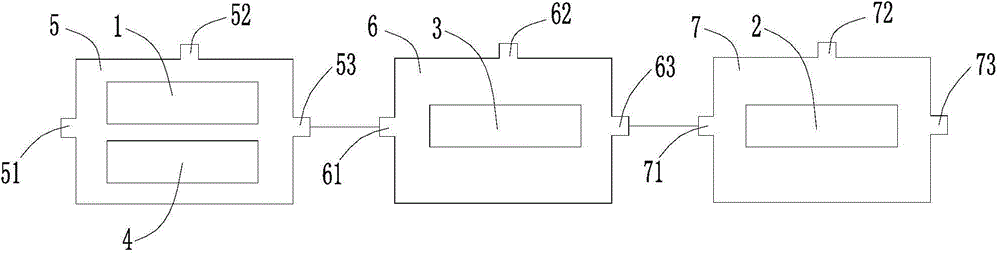

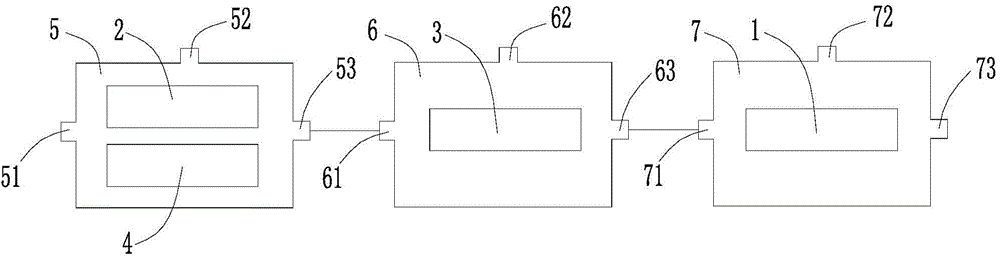

Article transfer device

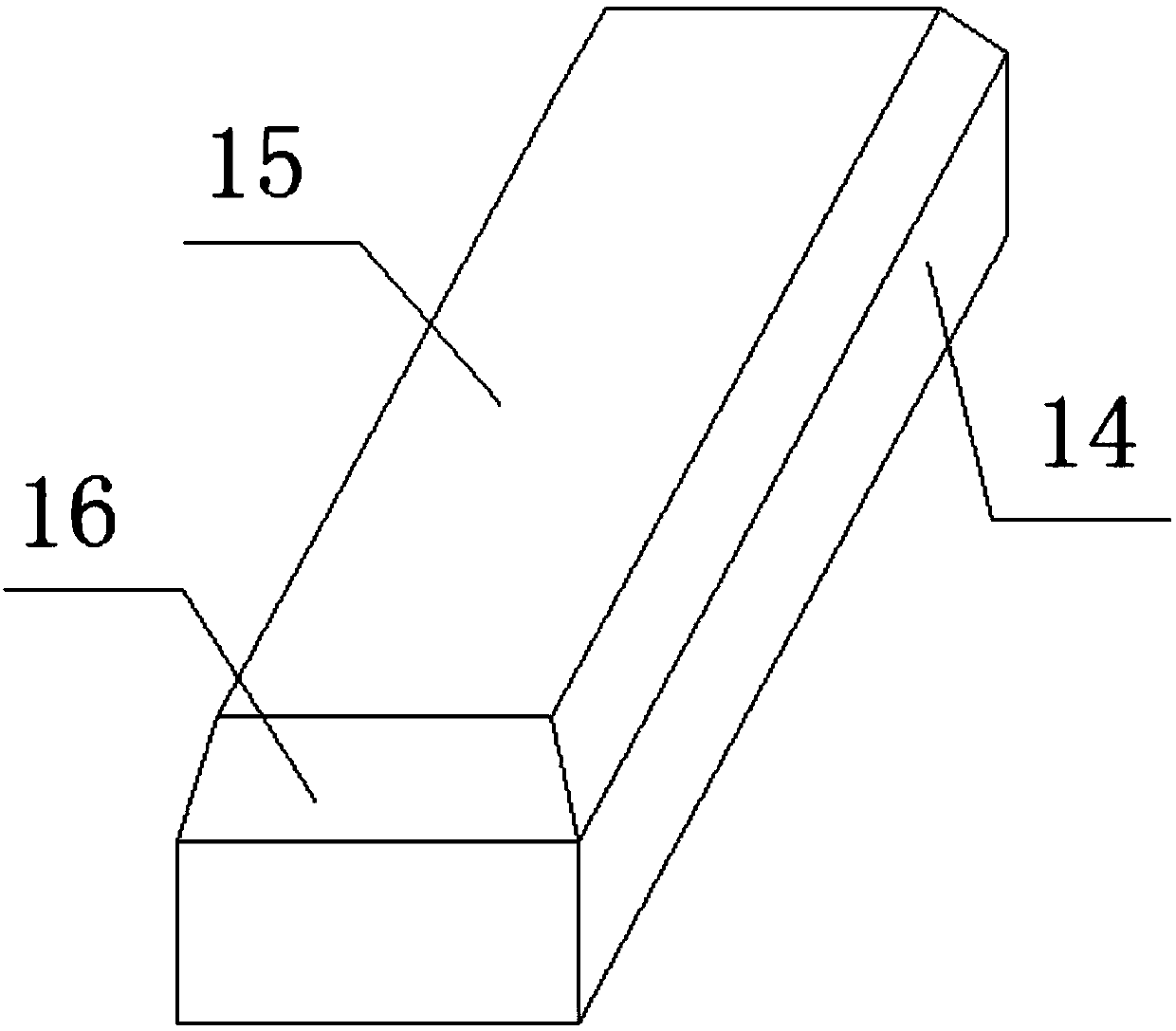

ActiveCN105314380ALow chance of being fouledReduce the chance of foulingConveyor partsEngineeringMechanical engineering

The invention provides an article transfer device which can transfer a plurality of articles at each batch without dispersing the articles and reduces the possibility of contaminating and polluting the articles as well as the costs of maintenance and operation. An elevator (15) is utilized to transport loading trays on the first delivering machine (11A) and a second delivering machine (12B) and the second delivering machine (11B) to the pickup device right below a shifting device (13); a pair of scooping-up-and-guiding parts (13G) are inserted into the two sides of the rod-shaped article (A) in order to scoop up the article (A); the empty-loaded trays (14) and the second delivering machine (11B) are descended to the transportation position through the elevator (15); the product discharging delivering machine (15) is extended to the reception position below the shifting position (13) from the avoiding position so as to enable the scoop-up-guiding part (13G) to perform backward driving relative to the scooping up action, and the scooped up product is discharged to the product discharging delivering machine (12). The product discharging delivering machine (12) is driven to discharge the product along the Y axis.

Owner:FAB TOYAMA

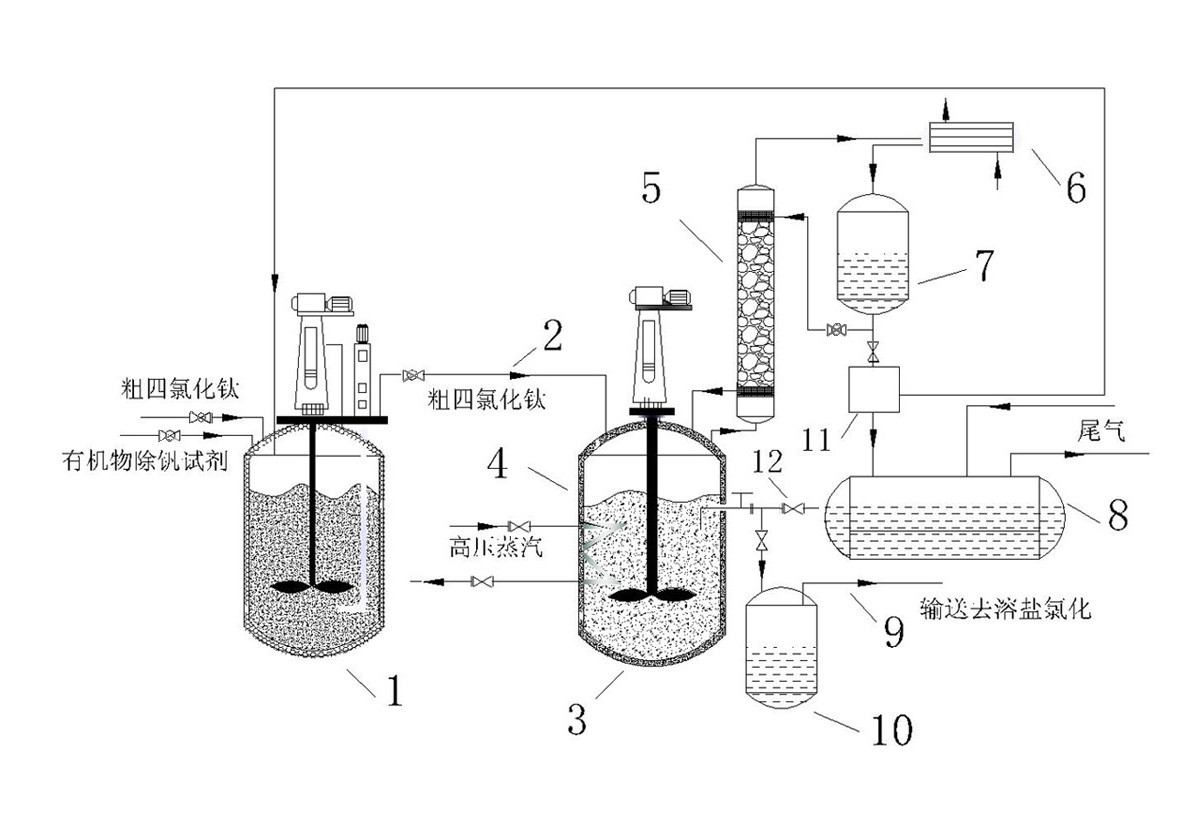

Process used for refining crude titanium tetrachloride and capable of prolonging production cycle

ActiveCN102040244AIncrease productionExtend the production cycleTitanium halidesMolten saltOrganic matter

The invention discloses a process used for refining crude titanium tetrachloride and capable of prolonging the production cycle. The process comprises the following steps: crude titanium tetrachloride and a vanadium-removing reagent as an organic matter are fed into a mixed-material feed system, then the obtained mixed materials is fed into a reactor and heated in the reactor by a heat source provided by a heating coil so as to complete the vanadium-removing process in the reactor; pure titanium tetrachloride steam is fed into a condenser, and after the pure titanium tetrachloride steam exchanges heat with circulating cooling water, the obtained steam enters a reflux accumulator, then part of the obtained steam as refluxed liquid is returned to a packed tower and then transported back to a reaction system, and the other part of the obtained steam is fed into an intermediate tank to detect, after passing the detection, this part of the obtained steam is fed into a finished-product storage tank, wherein in the process of refluxing, the reflux ratio is controlled at one second to one third; mud samples are taken out from the reactor every 6 to 8 hours so as to keep the solid-liquid ratio in the range of 30 to 60 percent; and the mud discharged from the reactor is transported to a molten salt chlorination system every 6 to 8 hours so as to recycle the titanium tetrachloride in themud. The process provided by the invention has the advantages that a production system can continuously and stably operate more than 24 months, thereby improving the production efficiency; and the titanium tetrachloride in the mud discharged from the reactor can be recycled, thereby reducing the production cost and reducing the environmental pollution.

Owner:中信钛业股份有限公司

Thermal power plant desulfurization wastewater electrodialysis reconcentrator

InactiveCN106348510APlay a protective effectPrevent complete oxidationTreatment involving filtrationMultistage water/sewage treatmentFresh waterMedia filter

The invention relates to an industrial wastewater treatment technique and device, particularly a thermal power plant desulfurization wastewater electrodialysis reconcentrator. An inlet of a precipitation tank communicates with an outlet of an oxidation tank and an inlet of a multimedia filter; an outlet of the multimedia filter communicates with an inlet of a regulating tank; a first outlet of the regulating tank communicates with an inlet of the oxidation tank; a second outlet of the regulating tank communicates with an inlet of an electrodialysis plant; a cathode water outlet of the electrodialysis plant communicates with the inlet of the precipitation tank; an anode water outlet of the electrodialysis plant communicates with the inlet of the oxidation tank; an electrodialysis concentrated water outlet of the electrodialysis plant communicates with an inlet of an evaporative crystallizer; an electrodialysis fresh water outlet of the electrodialysis plant communicates with an inlet of an reverse osmosis unit; an outlet of a first dosing tank communicates with the inlet of the oxidation tank; and an outlet of a second dosing tank communicates with the inlet of the precipitation tank. The thermal power plant desulfurization wastewater electrodialysis reconcentrator has high electrodialysis weight concentration, reduces the subsequent evaporative crystallization load, and lowers the investment and operating cost.

Owner:刘永锋

High-strength and corrosion-resisting novel building exterior wall paint with worm expelling function and preparation process thereof

InactiveCN106675406AHigh strengthGood corrosion resistanceWax coatingsAntifouling/underwater paintsWaxChitin

The invention discloses high-strength and corrosion-resisting novel building exterior wall paint with a worm expelling function. The high-strength and corrosion-resisting novel building exterior wall paint is prepared from the following components in parts by weight: 8 to 15 parts of pearl powder, 10 to 15 parts of nano titanium dioxide powder, 3 to 10 parts of cyclodextrin, 3 to 8 parts of acrylic resin, 0.2 to 0.4 part of chitin, 1 to 5 parts of fibrous wollastonite powder, 7 to 15 parts of glass fibers, 0.1 to 0.8 part of fluorescent powder, 1 to 3 parts of Chinese herbal medicine dry powder with the worm expelling function, 0.2 to 2 parts of carbon nanotubes, 1 to 3 parts of ceramic powder, 5 to 7 parts of wax and the balance of water. The exterior wall paint disclosed by the invention has high strength and good corrosion-resisting performance. The herbal medicine dry powder with the worm expelling function is arranged so that mosquitoes can be expelled and the mosquitoes are prevented from getting close to a building, so that the probability that the mosquitos, such as the mosquitos and flies, enter a room is reduced; and furthermore, the probability that the flies attach on an exterior wall is also reduced, so that the probability that the exterior wall is polluted by the flies is reduced.

Owner:广州艺砼科技有限公司

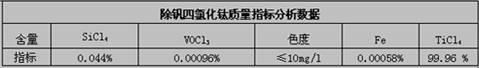

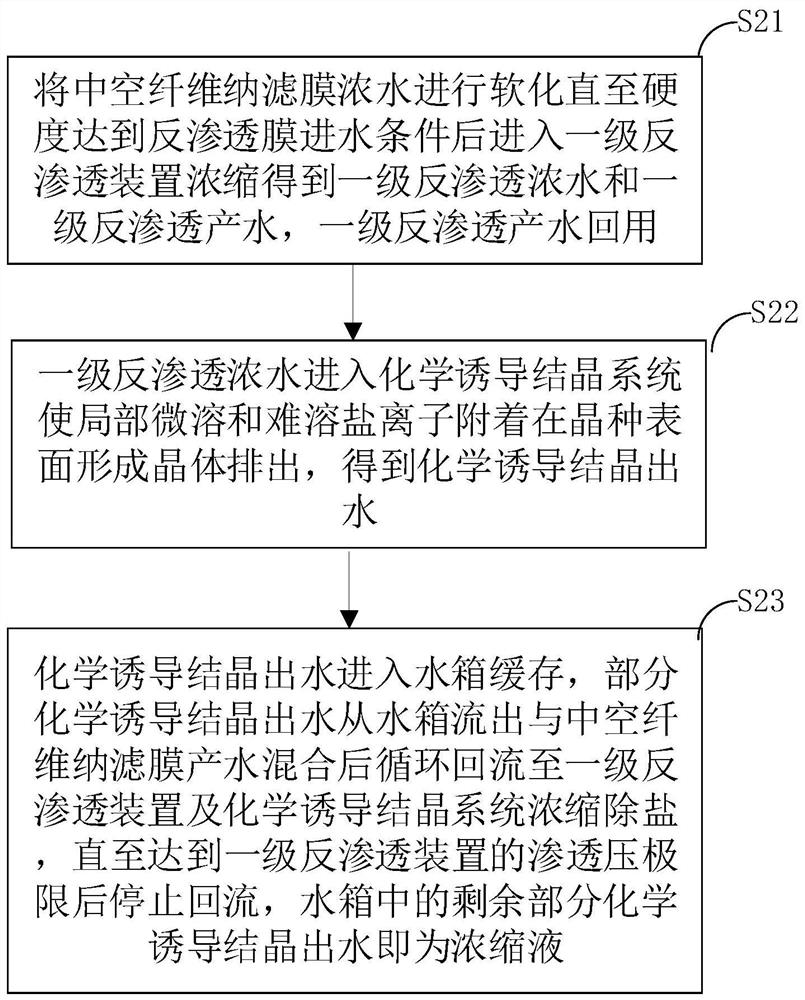

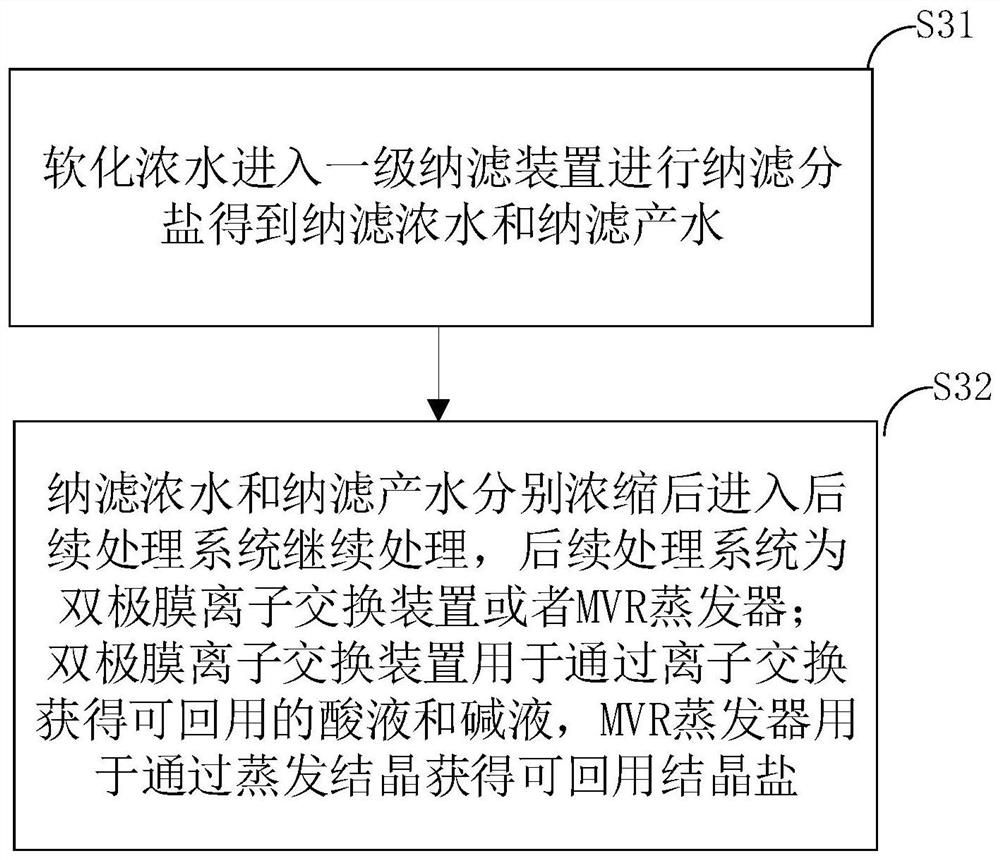

Resourceful treatment system and method for efficient reuse of salt-containing mine water

PendingCN113526760AAchieving zero emissionsReduce operating pressureWaste water treatment from quariesGeneral water supply conservationHollow fibreFiber

The invention provides a resourceful treatment system and method for efficient reuse of salt-containing mine water. According to the invention, the salt-containing mine water enters a hollow fiber nanofiltration membrane device, soluble salts such as MgSO4, Na2SO4, MgCl2 and NaCl are intercepted under the pressure of 0.1 MPa-5MPa, produced water can be directly reused, concentrated water is softened and then subjected to hardness removal through reverse osmosis concentration coupled with chemical induced crystallization, and reflux circulation is performed until the osmotic pressure of a reverse osmosis concentration device is reached; then obtained concentrated water is subjected to nanofiltration salt separation and further concentration; and then obtained concentrated water enters a bipolar membrane ion exchange device to obtain recyclable acid liquor and alkali liquor, or the concentrated water is subjected to concentration and evaporative crystallization to obtain crystallized salt. In order to improve the reuse rate of mine water resources, salt ions in the mine water are partially removed under low pressure by adopting a hollow fiber nanofiltration membrane technology, and meanwhile, the water production rate of first-stage RO is improved to 90% or above by using RO coupled with chemical induced crystallization; and concentrated strong brine can be treated by using a bipolar ion exchange membrane technology, and an acid-base solution which can be recycled for a water treatment system is obtained at the same time, so real zero discharge of wastewater is realized.

Owner:国能朗新明环保科技有限公司

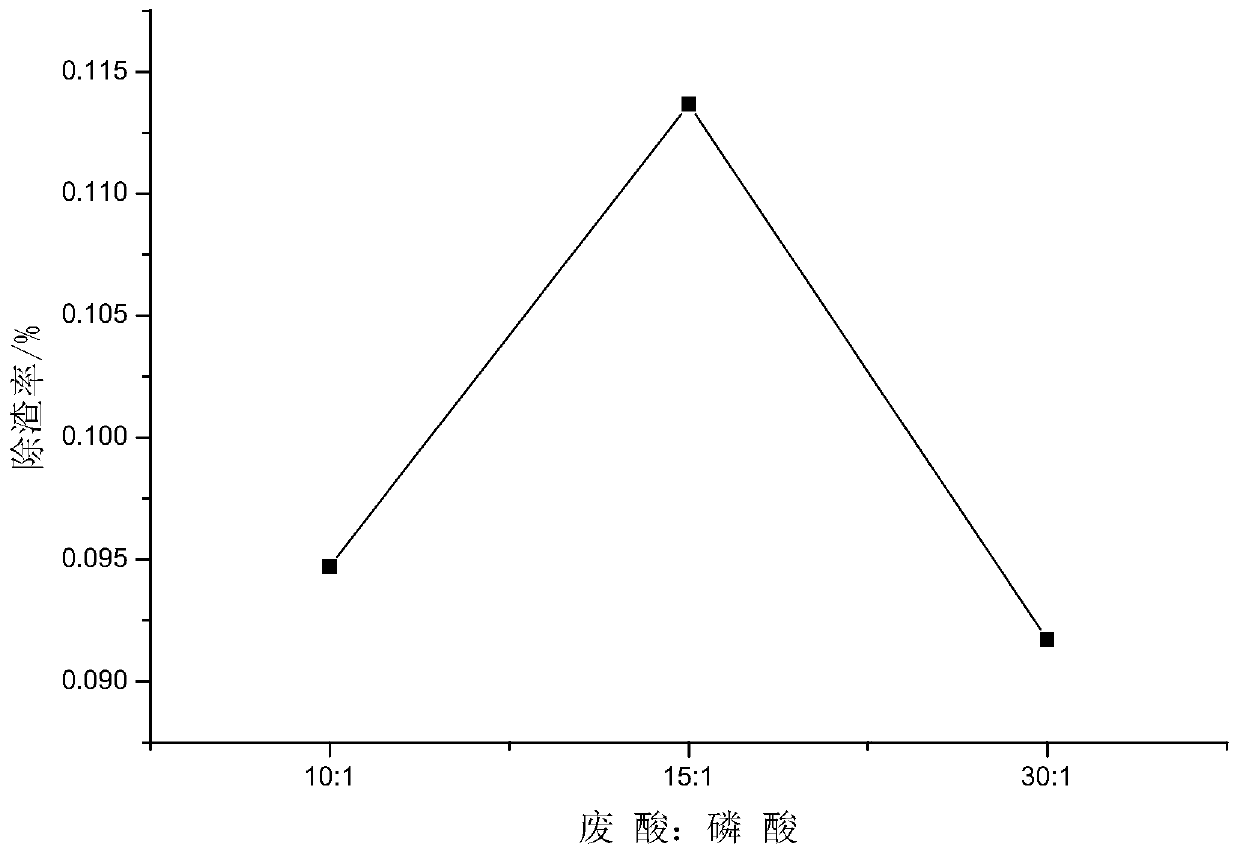

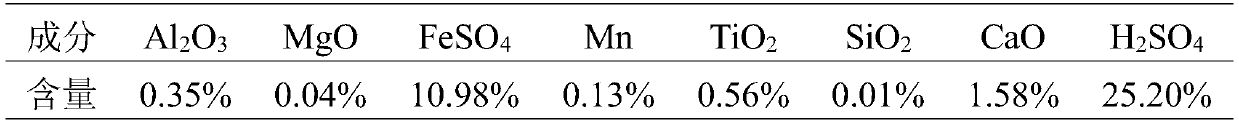

Sulfuric acid method titanium dioxide waste acid purification process

InactiveCN110436420AEfficient removalReduce contentSulfur-trioxide/sulfuric-acidIron sulfatesChemical industryEthylenediamine

The invention relates to a sulfuric acid method titanium dioxide waste acid purification process, belongs to the field of chemical industry waste acid recycling, and provides a sulfuric acid method titanium dioxide waste acid purification process, which comprises: a, adding phosphoric acid to sulfuric acid method titanium dioxide waste acid, stirring uniformly, carrying out solid-liquid separationafter precipitating, and collecting the liquid to obtain first treatment waste acid; and b, adding at least an organic solvent selected from ethanol, acetone, tetrahydrofuran, ethylamine, ethylenediamine, ethylene glycol and glycerin to the first treatment waste acid, stirring uniformly, carrying out solid-liquid separation after precipitating, and collecting the liquid to obtain a purified acid.According to the present invention, with the purification process, only cheap reagents such as phosphoric acid, ethanol and the like are used, and are consumed less, and organic solvents such as ethanol and the like can be recovered so as to achieve recycling, such that the economic cost of waste acid treatment is significantly reduced.

Owner:PANZHIHUA UNIV

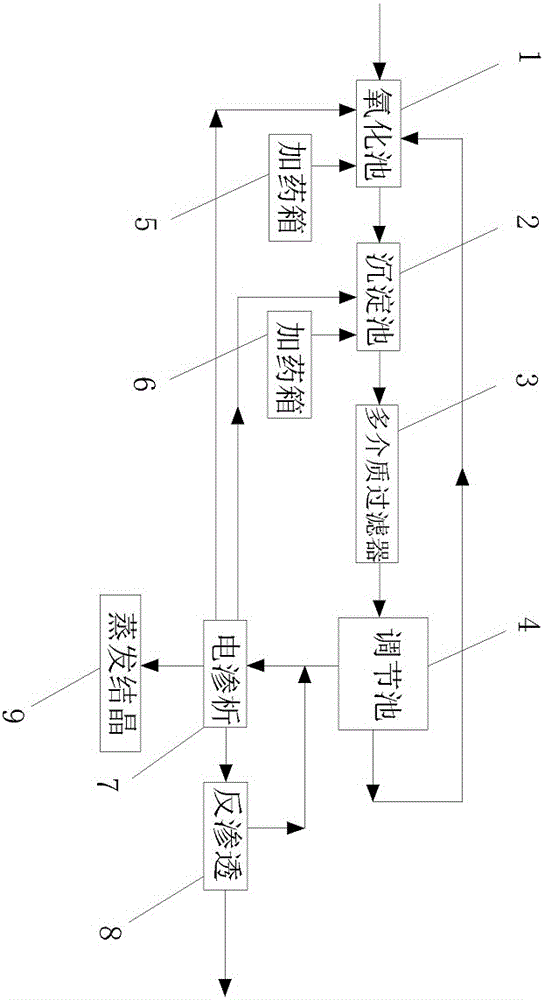

High-salt industrial wastewater resource recovery treatment system and method

PendingCN111675394ASolve the problem of low value and limited market demandReduced alkali regeneration performanceWater contaminantsWater softeningIndustrial waste waterResource recovery

The invention provides a high-salt industrial wastewater resource recovery treatment system and method. The high-salt industrial wastewater resource recovery treatment system comprises a reverse osmosis device and a bipolar membrane electrodialysis device, and an induced crystallization device is arranged between the reverse osmosis device and the bipolar membrane electrodialysis device; and the reverse osmosis device is used for concentrating incoming water, the bipolar membrane electrodialysis device is used for hydrolyzing and ionizing water molecules to form recyclable acid and alkali, andthe induced crystallization device is used for removing heavy metal ions and / or Ca<2+> in the concentrated incoming water so as to meet the liquid inlet requirement of the bipolar membrane electrodialysis device. The invention aims to solve the problem of discharge of industrial wastewater containing high-concentration salt and heavy metals. The reverse osmosis device and the bipolar membrane electrodialysis device are combined, and the induced crystallization device is arranged between the two, so that high water yield can be obtained, water resources are saved, hard ions and heavy metal ions in the wastewater can be removed, the risk of membrane blockage is reduced, high-value acid and alkali byproducts are generated, and the problems of low value of byproduct crystalline salt and limited market demand are solved.

Owner:国能朗新明环保科技有限公司

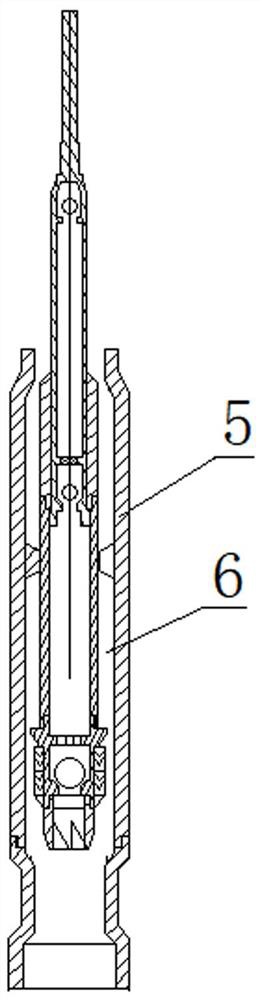

Double-channel steam injection and oil production sand preventing and scale preventing pump

PendingCN111677657AReduce the chance of foulingReduce the labor intensity of frequent workoverPositive displacement pump componentsFlexible member pumpsThermodynamicsOil production

The invention discloses a double-channel steam injection and oil production sand preventing and scale preventing pump which comprises a pump body. A steam injection outer pipe assembly is arranged onthe pump body. An oil production assembly is arranged in the steam injection outer pipe assembly. The oil production assembly comprises a pump cylinder assembly, and a long plunger assembly is arranged in the pump cylinder assembly. The lower end portion of the pump cylinder assembly is connected with a fixing valve assembly, and the pump cylinder assembly is matched with the long plunger assemblyto form a variable containing cavity. Valve ball valve seats are arranged in the fixing valve assembly and the long plunger assembly correspondingly. The fixing valve assembly comprises a core shaftpart and a lining part arranged at the outer portion of the core shaft part. The double-channel steam injection and oil production sand preventing and scale preventing pump has the beneficial effectsthat the labor intensity of frequent well repairing is lowered, the service life is prolonged, and the production cost is reduced.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

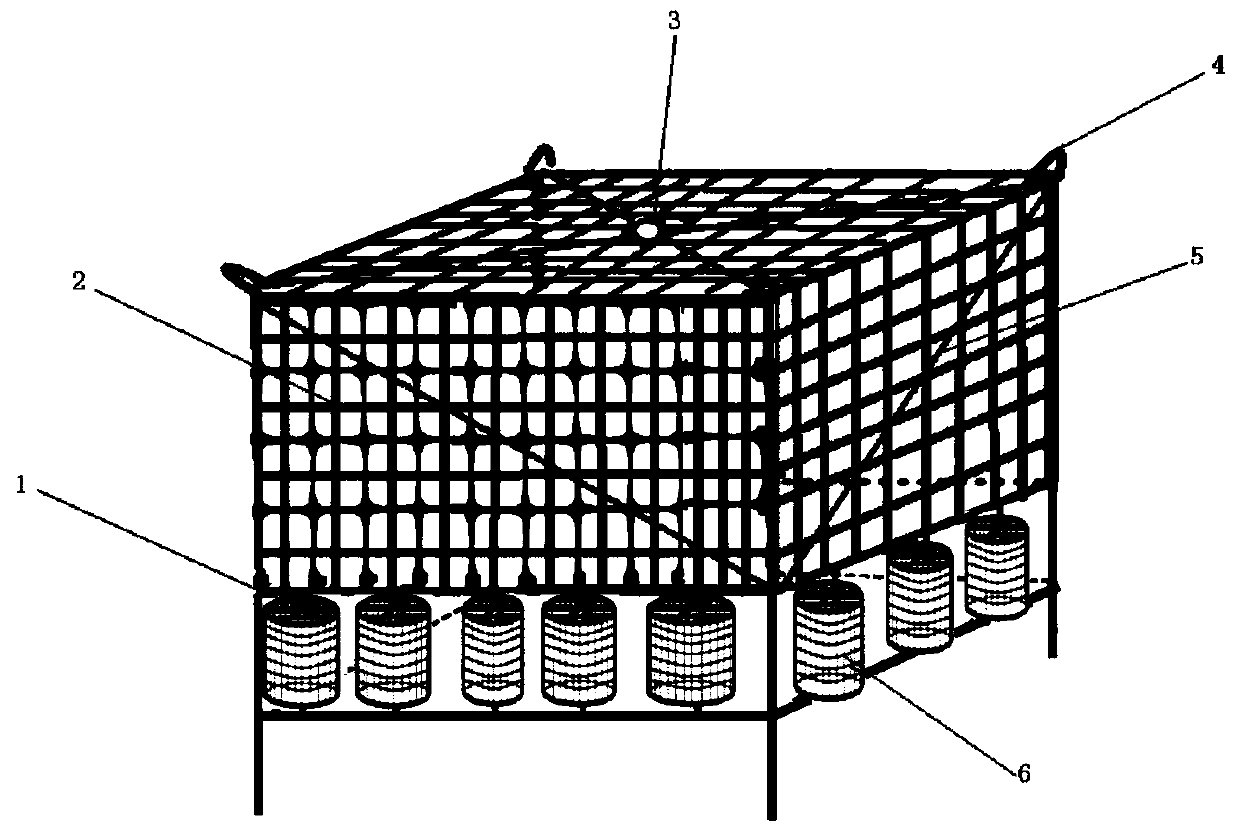

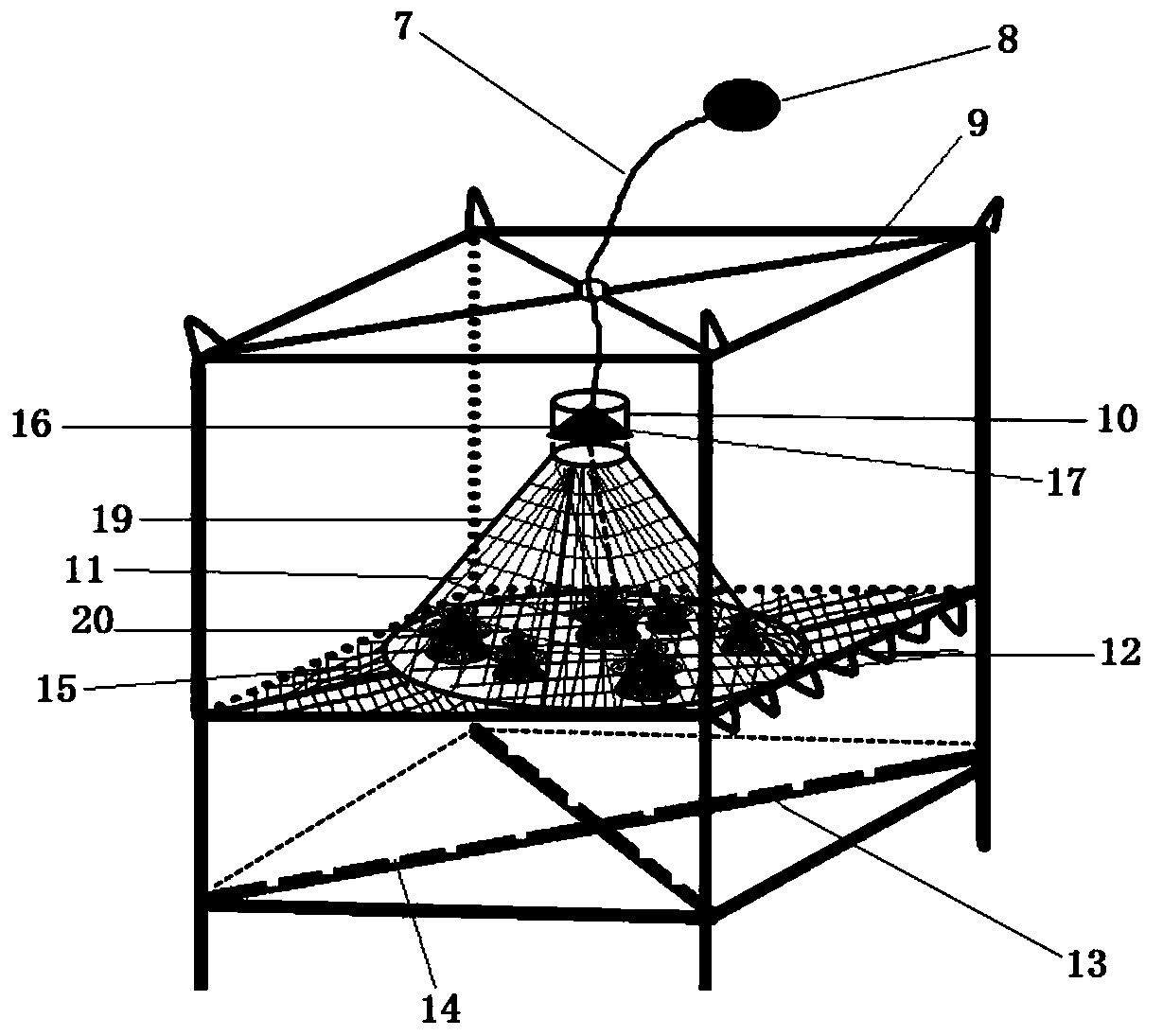

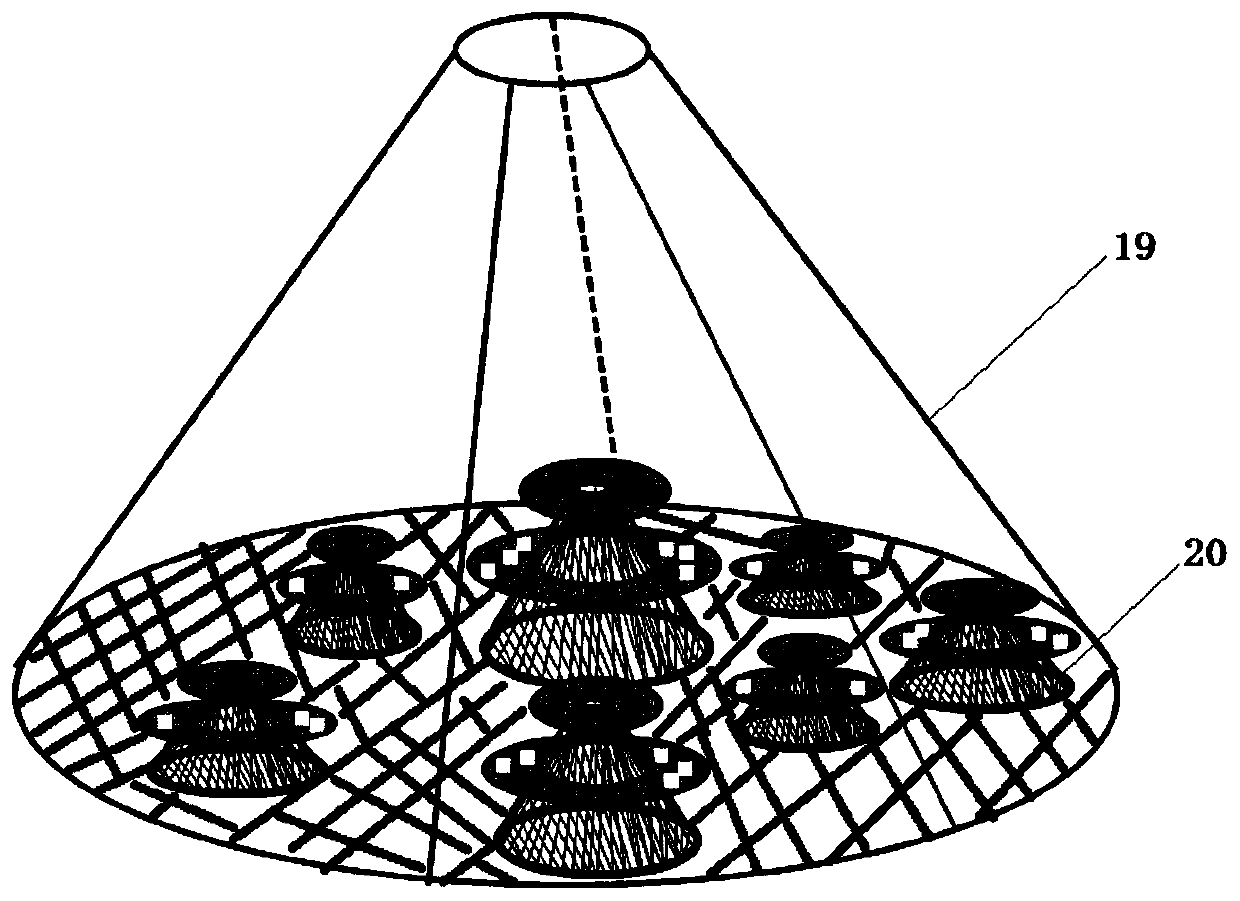

Fish attracting type culture and proliferation fish shelter and use method thereof

PendingCN110521657AConducive to habitatTo achieve the purpose of selective fishingClimate change adaptationPisciculture and aquariaRed mulletFishing

The invention discloses a fish attracting type culture and proliferation fish shelter and a use method thereof, and belongs to the technical field of fish culture and proliferation. The fish attracting type culture and proliferation fish shelter is composed of a cuboid frame divided into an upper layer and a lower layer, wherein a cone frame is arranged in the upper layer, a tapered iron cover isarranged at the top end of the cone frame, the tapered iron cover is connected with a floating ball outside the frame through a hinge rope, the inner portion of the cone frame is provided with a plurality of small cone passages, the side face of the lower layer is provided with a plurality of waste cages, and the bottom of the lower layer is provided with a bracket. The fish attracting type culture and proliferation fish shelter can provide an excellent habitat for fishes and has an attracting effect. The fish shelter can not only provide a survival habitat environment for the fishes, but alsocan achieve the purpose of selective fishing of the attracted fishes, and can also rise and fall through lifting equipment to facilitate movement.

Owner:大连市水产研究所 +1

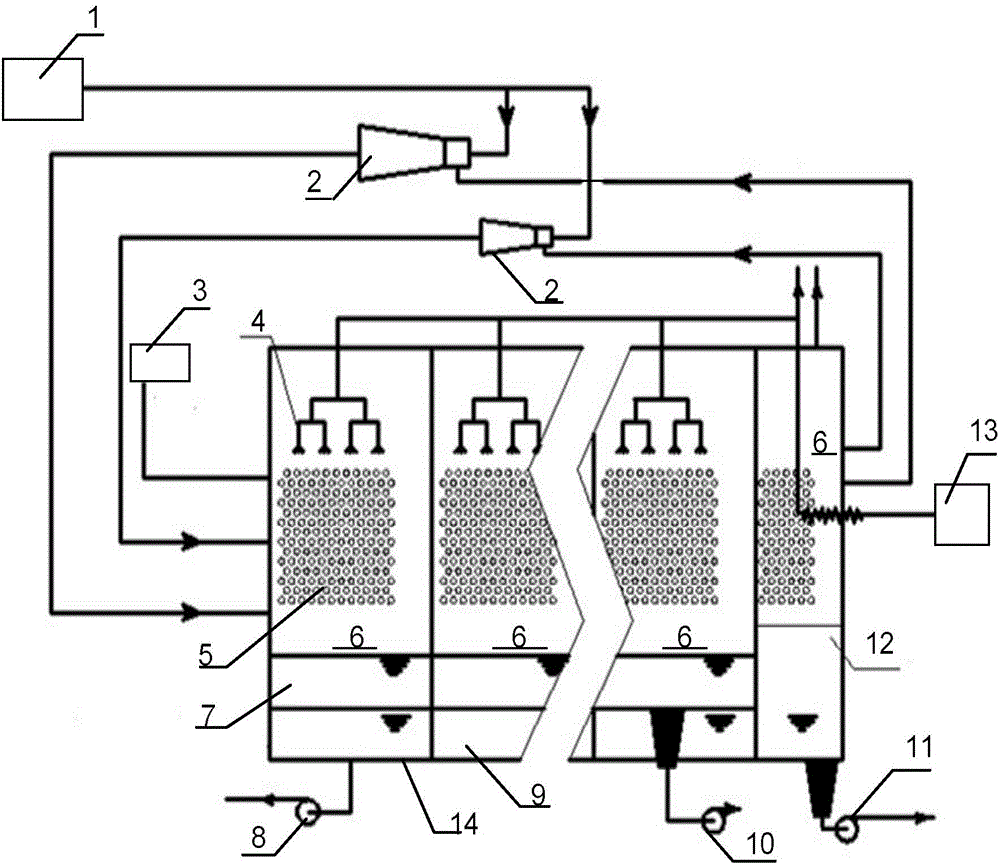

Water purification process

InactiveCN104961195AReduce the chance of foulingReduce chemical cleaning costsWater/sewage treatment bu osmosis/dialysisEnvironmental engineeringChemical cleaning

The invention discloses a water purification process, which purifies water through purification devices. Each purification device comprises a water inlet, a purification membrane group for water purification, a water producing port for discharging purified water, and a water outlet for discharging concentrated water. According to the process, a plurality of the purification devices are distributed and combined to form a front part purification device group and a back part purification device group, and the front part purification device group and the back part purification device group compose a purification system. Through different collocation and combination of the purification devices in the front part purification device group and the purification devices in the back part purification device group, the purification system has multiple operation states, and according to needs, the purification devices in the back part purification device group and the purification devices in the front part purification device group can be interchanged in terms of the connection position. With the process, the pollution and plugging probability of the purification membrane group is lowered, the chemical cleaning expense caused by pollution and plugging of the purification membrane group is reduced, and the service life of the purification membrane group is prolonged.

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

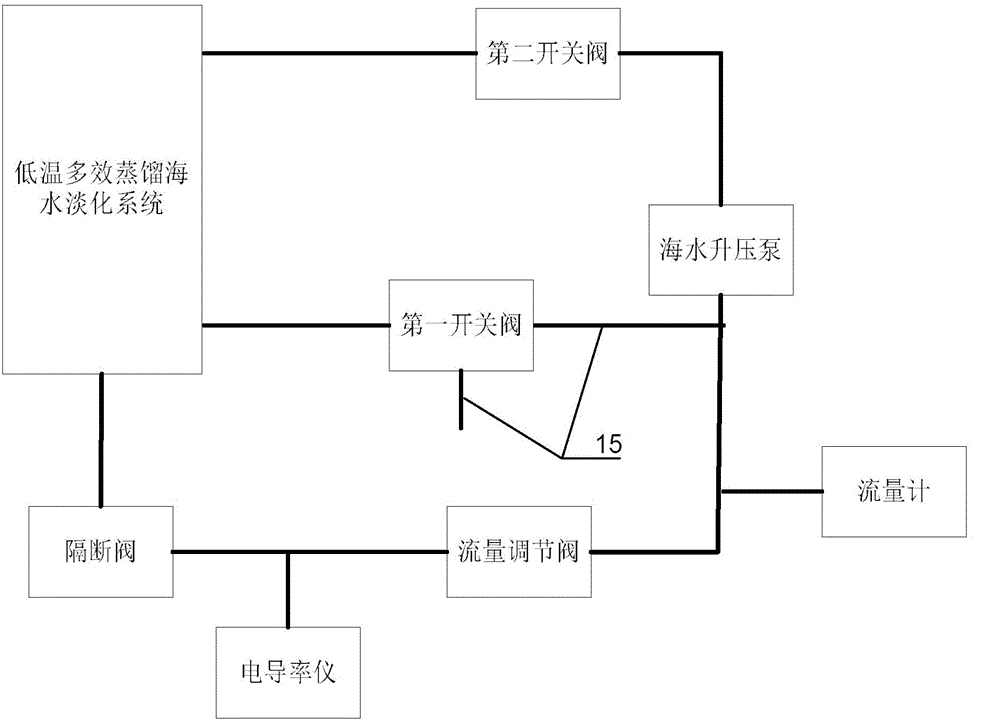

Recondensation apparatus of concentrated seawater

ActiveCN103910397AEasy to reconcentrateReduce the chance of foulingGeneral water supply conservationSeawater treatmentSaline waterEngineering

The invention relates to the technical field of seawater desalination, and especially relates to a recondensation apparatus of concentrated seawater. The recondensation apparatus of concentrated seawater comprises a low temperature multiple-effect distillation seawater desalination system, an isolating valve, a seawater booster pump, a conductivity instrument and a flowmeter. The inlet of the isolating valve is connected to a concentrated seawater pump of the low temperature multiple-effect distillation seawater desalination system, the outlet of the isolating valve is connected to the inlet of the concentrated seawater pump through a pipeline; the outlet of the concentrated seawater pump is connected to a spray apparatus of the low temperature multiple-effect distillation seawater desalination through the pipeline; and the conductivity instrument and the flowmeter are respectively connected on the pipeline between the isolating valve and the concentrated seawater pump. The recondensation apparatus of concentrated seawater conveniently makes the concentration of seawater to reach a requirement of a salt chemical enterprise.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

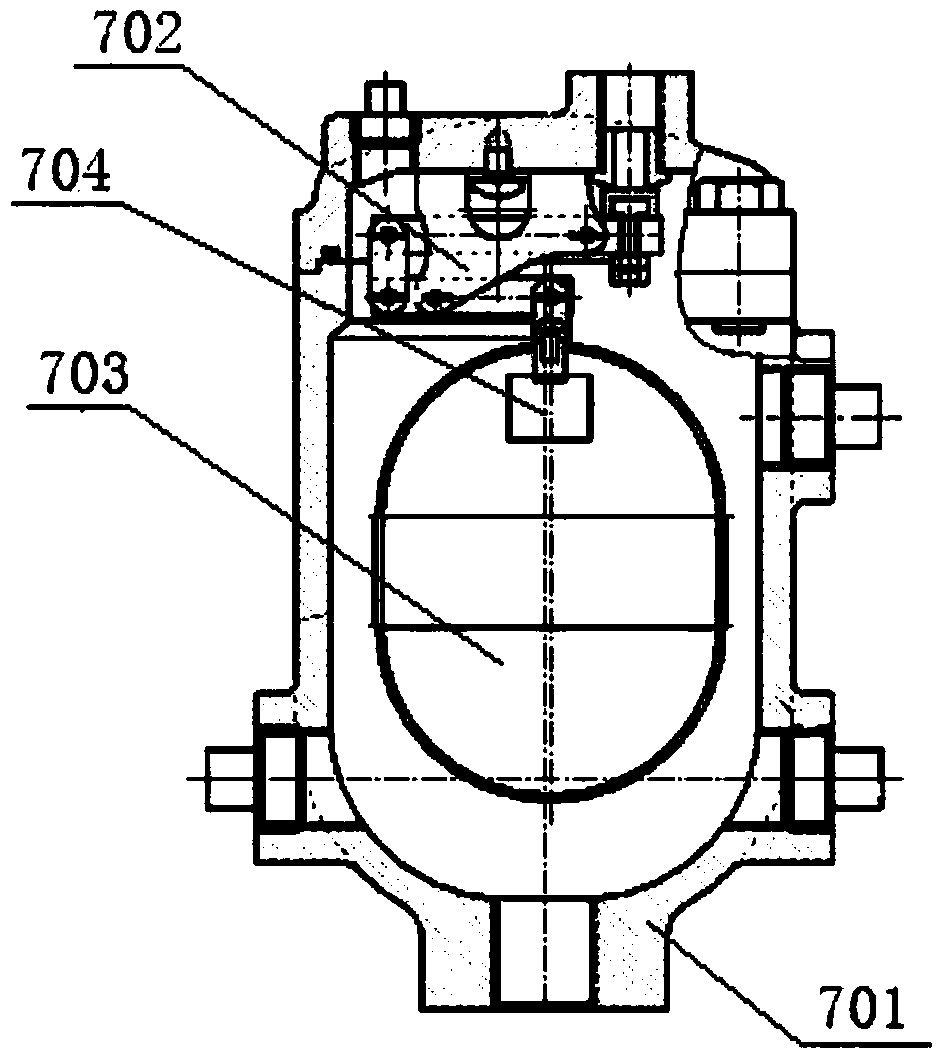

Anti-scaling type trace exhaust valve

ActiveCN103470837AGuaranteed to workImprove stabilityValve housingsFloats for valve actuationExhaust valveEngineering

The invention discloses an anti-scaling type trace exhaust valve. The anti-scaling type trace exhaust valve comprises a valve body, wherein the valve body is internally provided with a lever assembly, the lever assembly is connected with a floating ball, and the valve body is also internally provided with a magnetic material of which the magnetic field range acts on the surface of the lever assembly. According to the anti-scaling type trace exhaust valve disclosed by the invention, the magnetic material is arranged in the anti-scaling type trace exhaust valve, a magnetic field of the magnetic material covers the surface of the lever assembly, thus the polarity is changed when ions pass through the surface of the lever assembly, the nucleation rate is increased, a large number of micro-crystals can be generated, the stability of the micro-crystals is better, the generation of macro-crystals is restrained, the scaling probability on the surface of the lever assembly is greatly reduced, the normal work of the lever assembly is ensured, the phenomena of clamping and blocking cannot happen, the structure is simple, the consumption of electric energy is not needed, and the practical performance is better.

Owner:WUHAN DAYU VALVE

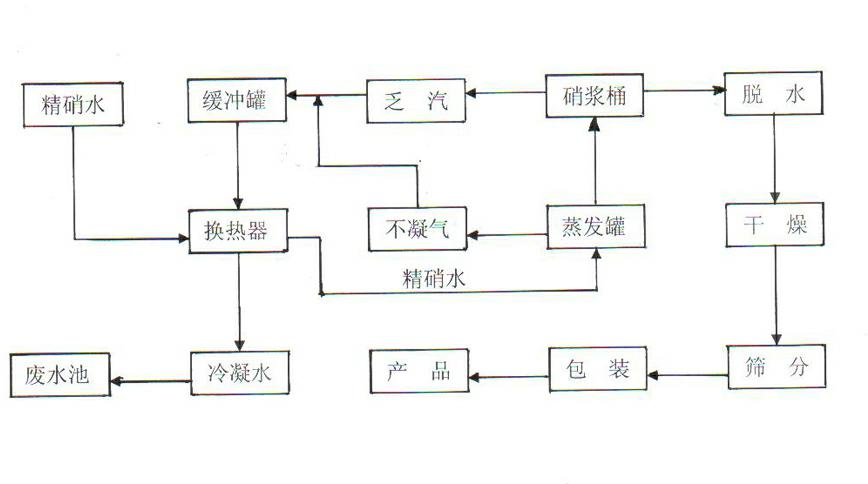

Method for recycling saltpeter-production dead steam

InactiveCN102180487ASignificant progressCutting costsEnergy inputAlkali metal sulfite/sulfate dehydrationEvaporationSlurry

The invention discloses a method for recycling saltpeter-production dead steam, which comprises the following steps of: 1, collecting the dead steam from a saltpeter slurry barrel and waste incondensable gases discharged from I and II effect evaporating pot heating chambers in a closed buffer tank; 2, performing heat exchange on fine saltpeter water by a heat exchanger to preheat the fine saltpeter water to the temperature of between 50 and 60 DEG C; 3, discharging condensed water after the heat exchange of the dead steam into a wastewater tank, and then returning the condensed water in the wastewater tank into a mine to re-dissolve sodium sulfate mineral substances; and 4, conveying the preheated fine saltpeter water into an evaporating pot through a centrifugal pump to perform evaporation, concentration and crystallization, and then dehydrating, separating, drying, screening and packaging to obtain an industrial anhydrous sodium sulfate finished product. Because a waste dead steam heat source is used, the heat exchanger performs heat exchange on the fine saltpeter water to ensure that the fine saltpeter water is heated to be 6 DEG C, and then the fine saltpeter water is evaporated in the evaporating pot, the waste saltpeter-production dead steam heat energy is fully used, the energy expense is greatly saved, the zero discharge of the waste gasses is basically realized, and thus, the aim of energy conservation and environmental protection is fulfilled and the noise pollution is relieved.

Owner:HUNAN XINLI CHEM

Method for removing impurities in recycled acetic acid

PendingCN113968782ASmall particle size distributionIncrease the difficultyOrganic compound preparationCarboxylic compound separation/purificationSodium acetateCellulose acetate

The invention belongs to the field of chemistry and chemical engineering, and relates to a method for removing impurities in recycled acetic acid and application thereof. The method for changing the distribution of the polymer in the mixed system comprises the following steps: adding concentrated sulfuric acid into the mixed system for hydrolysis and / or degradation; and adding magnesium acetate or sodium acetate for reaction, then carrying out extraction reaction, and collecting an organic phase to finally obtain pure acetic acid. The method disclosed by the invention is suitable for recycling acetic acid in a mixed system related to cellulose acetate production and removing intermediate products and wastes. The method is simple and easy to operate, no expensive equipment is added, the impurity removal effect is good, the energy consumption and material consumption of the acetic acid recovery process are remarkably reduced, the overhaul frequency of a heat exchanger is reduced, the productivity is improved, and the economic benefit is obvious.

Owner:NANTONG CELLULOSE FIBERS CO LTD +2

High-strength nanometer reinforced steel capable of inhibiting marine organism fouling and preparation method thereof

ActiveCN110205545AGood structural mechanical propertiesMarine Biofouling Inhibition PerformanceMechanical properties of carbon nanotubesPrecipitation

The invention belongs to the field of high-strength steel materials, and particularly relates to a high-strength nanometer reinforced steel capable of inhibiting marine organism fouling and a preparation method thereof. The steel comprises the following chemical components of, by weight, 0.03%-0.06% of C, less than or equal to 0.5% of Si, 0.7%-1.2% of Mn, 1.0%-3.0% of Cu, 2.0%-4.0% of Ni, 0.5%-1.5% of Al, 0.5%-1.0% of Cr, 0.2%-0.4% of Mo, 0.04%-0.06% of Nb, 0.03%-0.06% of V, 0.01%-0.03% of Ti, 0.001%-0.01% of N, less than or equal to 0.0050% of S, less than or equal to 0.0050% of P and the balance Fe. According to the steel, through a nano precipitation phase synergistic reinforcement technology and a grading aging heat treatment process, high-strength and high-plasticity mechanical property in which the yield strength is not lower than 1200 MPa, the tensile strength is not lower than 1300 MPa and the elongation percentage is not lower than 15% is achieved; meanwhile, the steel also has the unique performance for inhibiting marine organism fouling, so that the dual purposes of excellent mechanical property and the organism fouling inhibition performance are achieved, and the steelcan be applied to the important fields, such as naval construction, marine platforms and bridge construction, facing marine organism fouling environments.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

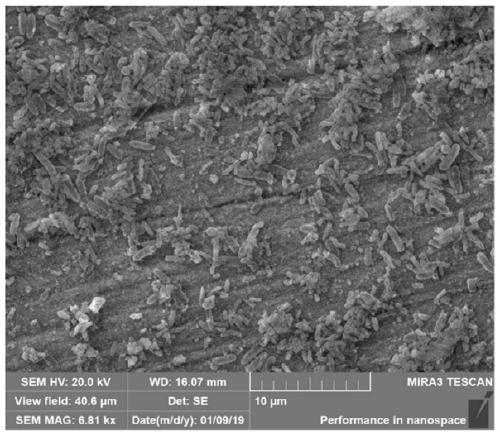

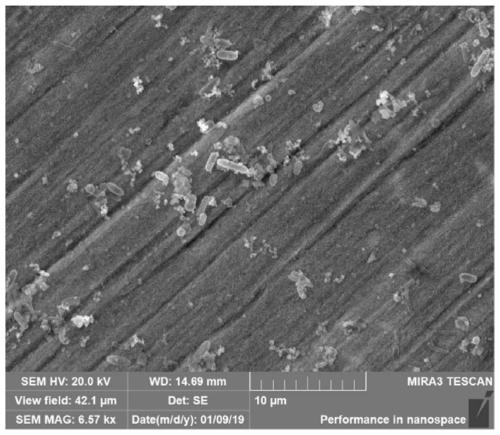

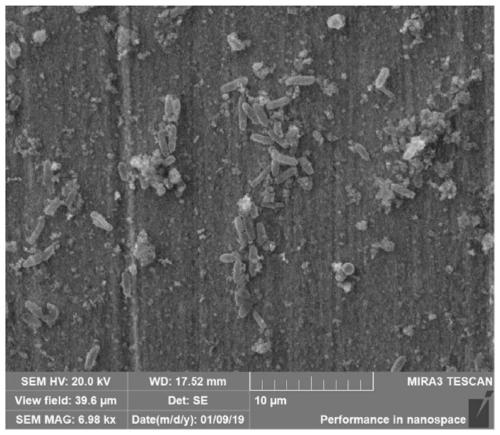

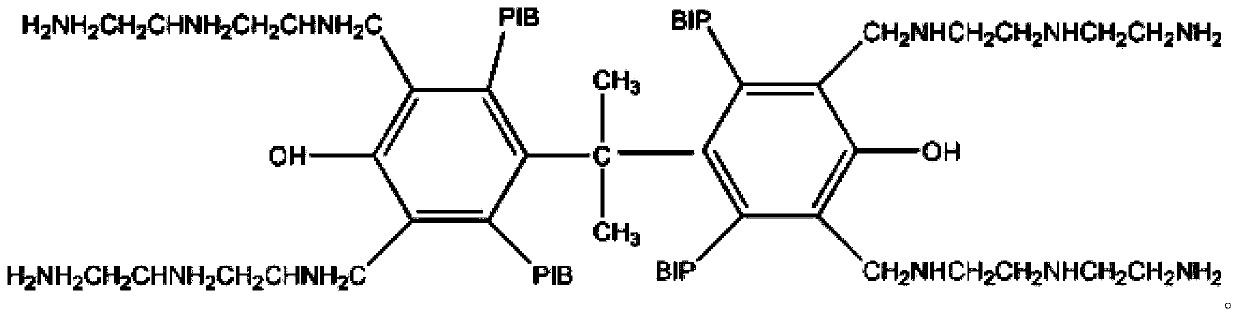

Purification dispersant and oil slurry scale inhibitor containing purification dispersant

ActiveCN110627662ASlow down the fouling rateLow viscosityOrganic chemistryTreatment apparatus corrosion/fouling inhibitionAntioxidantDecomposition

The invention provides a purification dispersant, and an oil slurry scale inhibitor containing the purification dispersant and a preparation method thereof. The purification dispersant is a newly synthesized bisphenol type Mannich base. A polymerization inhibitor, an antioxidant, a carrier dispersant, a viscosity reducer and solvent oil are added to the purification dispersant so as to form the brand-new oil slurry scale inhibitor. The scale inhibitor is suitable for different types of raw oil, and especially has good scale inhibition effect on raw oil with poor properties, high solid content,high asphaltene content, high aromatic hydrocarbon content and high olefin content. The scale inhibitor is high in decomposition temperature and applicable in a wide temperature range, and maintainsgood scale inhibition effect when a tower bottom temperature is high; the scale inhibitor can reduce the viscosity of raw materials, increase the flow rate of system and decrease coking probability; and the addition amount of the scale inhibitor is small, and the addition amount of a normal product in the market is 30-200 ppm while the addition amount of the scale inhibitor is 10-20 ppm, so addition cost is reduced.

Owner:山东京博众诚清洁能源有限公司

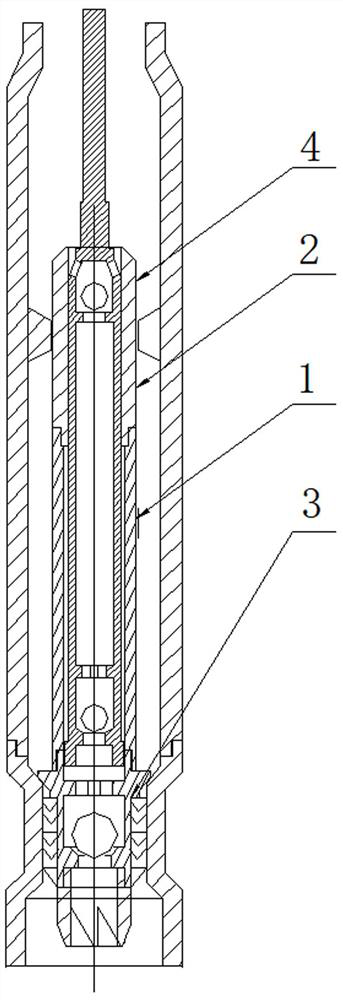

Downhole automatic fluid control device

PendingCN113027394AReduce wearReduce the chance of foulingSurveyFluid removalFluid controlControl switch

The invention provides a downhole automatic fluid control device. The device comprises a fluid control module, a switch module and a sensing module. Fluid enters from an inlet of a sensing flow channel and leaves from an outlet of the sensing flow channel, pressure detection is respectively carried out on an upstream sensing point, a midstream sensing point and a downstream sensing point in the flowing process of the fluid, a first flow resistor and a second flow resistor have sensitivity to the viscosity change of the fluid, and the viscosity sensitivity of the first flow resistor is higher than that of the second flow resistor. According to the viscosity of the fluid, the flowing state of the fluid flowing through the first flow resistor is switched between laminar flow and turbulent flow, so that a corresponding pressure value is generated at the downstream sensing point, and the switch module is controlled to be switched between a first position and a second position according to the pressure difference between the upstream sensing point and the downstream sensing point.

Owner:SUZHOU FLOWAY TECH CO LTD

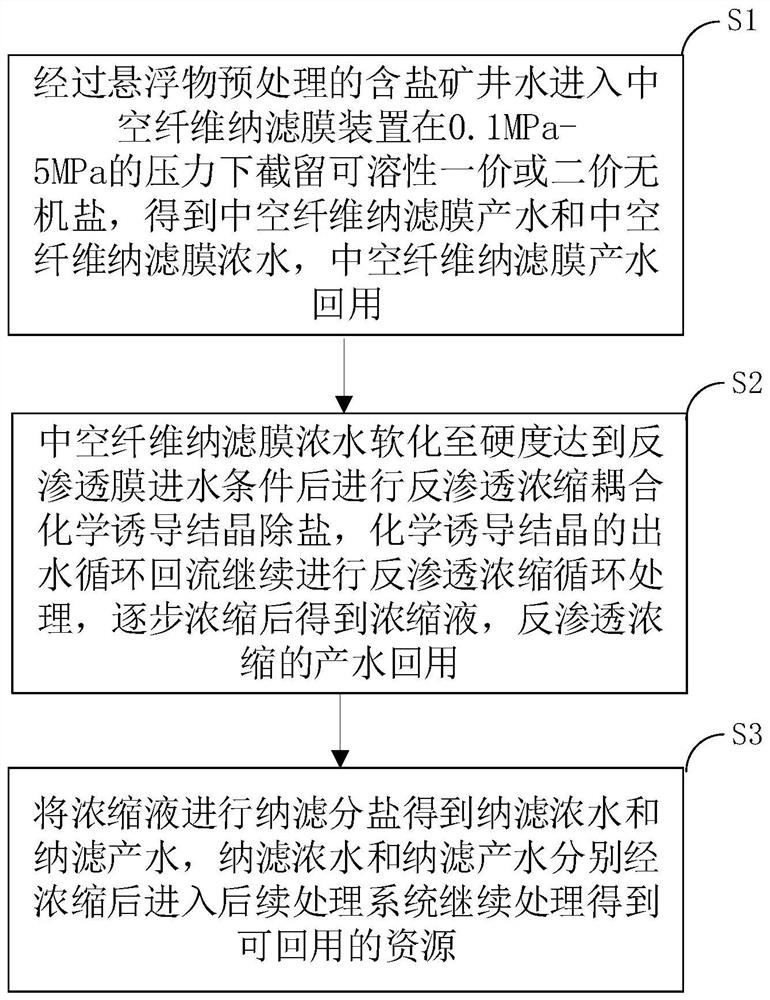

High-salt-content wastewater circulation treatment process

PendingCN114772821AAchieving zero emissionsReduce operating pressureWaste water treatment from quariesMultistage water/sewage treatmentHollow fibreFiber

The invention discloses a high-salt-content wastewater circulating treatment process which comprises the following steps: desalting by a hollow fiber nanofiltration membrane; concentrating: softening the concentrated water of the hollow fiber nanofiltration membrane until the hardness reaches the water inlet condition of a reverse osmosis membrane, then carrying out reverse osmosis concentration coupled chemical induced crystallization desalination, continuously carrying out reverse osmosis concentration circular treatment on the chemically induced crystallization effluent, gradually concentrating to obtain a concentrated solution, and recycling the reverse osmosis concentrated water; and performing nanofiltration. The hollow fiber nanofiltration membrane technology is adopted to partially remove salt ions in the mine water under low pressure, RO < + > chemical induced crystallization is used to improve the water production rate of the first-stage RO, the bipolar ion exchange membrane technology is used to treat the high-salt concentrated solution and obtain a recyclable acid-base solution, real zero discharge of wastewater is realized, and the method is suitable for industrial production. And the water production rate of RO is improved to 90% or above.

Owner:SUZHOU JOYFA ENVIRONMENTAL TECH CORP LTD

Production method of high-content and low-trimethyl ester spermine

InactiveCN103724371ASimplified material compositionAvoid security issuesGroup 5/15 element organic compoundsDesolvationVacuum pump

The invention discloses a production method of high-content and low-trimethyl ester spermine, which comprises the following steps of: coarse amine water washing: washing a coarse amine compound with water in advance, and obtaining the coarse amine compound after water washing and lamination, and (2) high vacuum unit desolvation: conveying the coarse amine compound after the water washing and the lamination into a coarse amine compound head tank through a stock pump and then conveying the coarse amine compound into an evaporator for desolvation. According to the method, with the adoption of the coarse amine water washing, substance components in the coarse amine compound are simplified, the safety problem caused by pipeline blocking due to salt in a desolvation procedure is basically solved at the same time, the scaling probability due to concentration of ammonium chloride and ammonia scale in a vacuum pump in a desolvation process is greatly reduced, the product quality after desolvation can be ensured, furthermore, the production energy consumption is greatly reduced, and the maintenance expense is also greatly lowered.

Owner:荆州沙隆达控股有限公司

Heater for heating network

The invention relates to a heater for heating network. The heater for heating network comprises a shell and a front end pipe box and a rear end pipe box; the front end pipe box and the rear end pipe box are arranged at the two ends of the shell; pipe bundles are arranged in the shell; a partition plate is arranged in the front end pipe box along the axis of the shell and the front end pipe box isdivided into an upper water inlet cavity and a lower water outlet cavity; the upper end of the water inlet cavity communicates with a water inlet pipe connecting pipe; the lower end of the water outlet cavity communicates with a water outlet pipe connecting pipe; the upper end of the shell is provided a steam inlet connecting pipe; the lower end of the shell is provided with a drain outlet connecting pipe; a filter screen is arranged in the water inlet pipe connecting pipe; the filter screen is cylindrical with an opening arranging at the upper end; the upper end of the filter screen is rotationally connected in the water inlet pipe connecting pipe and the lower end of the filter screen extends into the water inlet cavity; and a driving part for driving the filter screen to rotate is arranged in the water inlet pipe connecting pipe. The heater for heating network has the effects that the water medium is filtered, impurities are reduced from entering the pipe bundles, the probability ofblockage and scaling of the pipe bundles is reduced so that the cleaning times are further reduced, the utilization efficiency of the heater is guaranteed to the greatest extent, and the production efficiency is improved.

Owner:SHANDONG GUOSHUN PRESSURE VESSEL

Low-pressure steam generator

InactiveCN104930486AEffective heat insulationAvoid erosionSteam generation using hot heat carriersThermal insulationEngineering

The invention provides a low-pressure steam generator. The steam generator comprises a housing provided with openings at the upper and lower ends, a shell side inlet, a shell side outlet, an upper tube plate arranged at the opening at the upper end of the housing, and a lower tube plate arranged at the opening at the lower end of the housing. An upper head is arranged above the upper tube plate, and a lower head is arranged below the lower tube plate. A heat exchange tube set is arranged between the upper and lower tube plates and is vertically disposed inside the chamber of the housing. The steam generator also comprises a tube side inlet and a tube side outlet. A tube plate thermal insulation layer is arranged on the upper surface of the upper tube plate. The inner tube wall at the upper end of each heat exchange tube is provided with a heat exchange tube thermal insulation layer, the heat exchange tube thermal insulation layer is internally provided with a sleeving, and the upper end of the sleeving protrudes from the heat exchange tube and is disposed inside a through hole in the tube plate thermal insulation layer in a penetrating manner. The steam generator is provided with the tube plate thermal insulation layer and the heat exchange tube thermal insulation layers, so that the tube plates and heat exchange tube materials can be effectively prevented from being thermally eroded by tube side high-temperature mediums, the temperature of the tube plates and the heat exchange tubes is reduced, and the temperature of the tube plates and the heat exchange tubes can be controlled within the using temperature range of the used materials.

Owner:北京广厦环能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com