Evaporating crystallizer

A technology of evaporation crystallizer and evaporation chamber, which is applied in the field of wastewater treatment equipment, can solve problems such as blockage and frequency, and achieve the effect of continuous production and extended equipment operation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

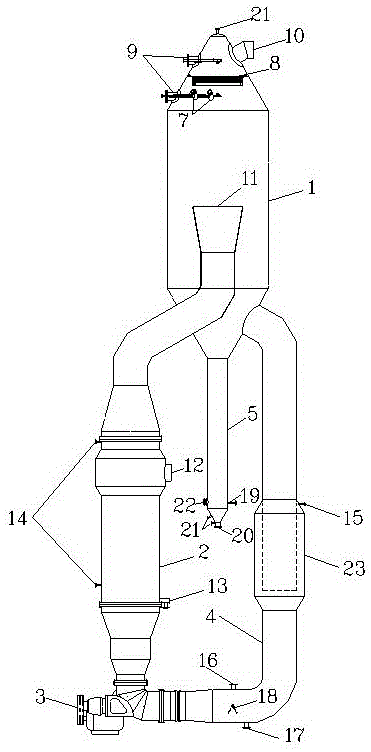

[0010] Such as figure 1 As shown, the evaporation crystallizer includes an evaporation chamber 1, a heating chamber 2, a forced circulation pump 3, a circulation pipe 4, and a salt leg 5. The cone section on the top of the evaporation chamber is provided with an exhaust port 6, an observation mirror 7, a demister 8, Spray device 9, secondary steam outlet 10, exhaust port 6 is provided on the top of evaporation chamber 1, bell mouth 11 is installed inside evaporation chamber 1, and bell mouth 11 is below the liquid surface; steam inlet 12 is arranged on the upper part of the heating chamber, The lower part is provided with a condensed water outlet 13, and the upper and lower ends are provided with a non-condensable gas outlet 14; the forced circulation pump 3 is connected to the heat exchanger through the circulation pipe by means of side entry and ejec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com