Anti-scaling multiple shell pass assembled heat exchanger

A multi-shell-side, assembled technology, applied to indirect heat exchangers, heat exchanger types, heat exchanger shells, etc., can solve problems such as low heat exchange efficiency, increased number of shell passes, and easy fouling of heat exchangers , to achieve the effect of improving heat transfer efficiency, increasing the fluid flow rate in the tube side, and reducing the chance of fouling in the tube side

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

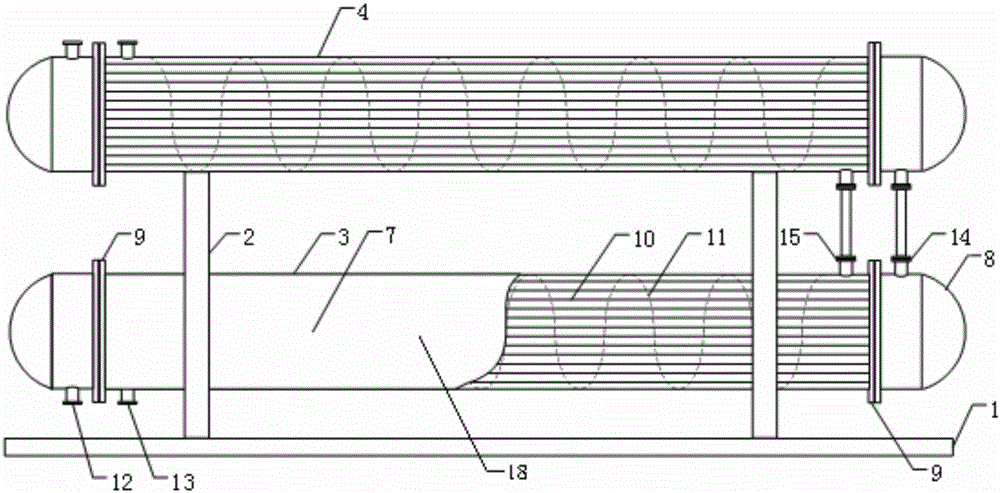

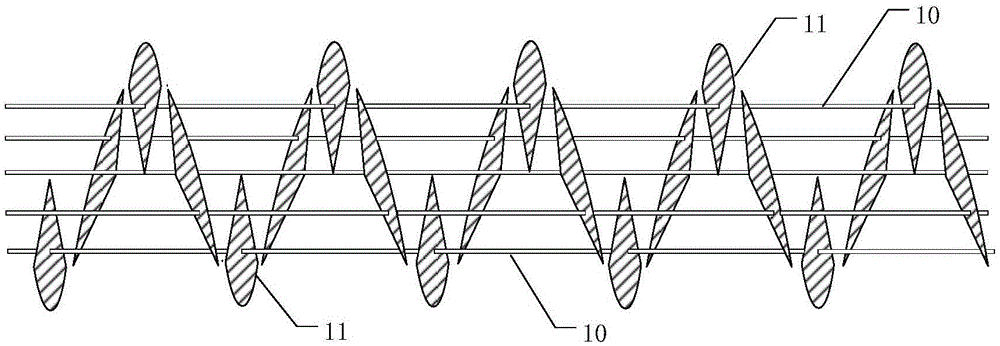

[0026] Such as Figure 1-3 As shown, the anti-fouling multi-shell assembled heat exchanger is customized for the electric desalination device of an oil refinery. The cold side of the heat exchanger is the normal temperature purified water entering the device, and the hot side is the high-temperature saline sewage exiting the device. According to the calculation of the technical parameters of the electric desalination device, the heat exchanger is composed of four heat exchange units connected in series to form an assembled heat exchanger with four tube sides and four shell sides.

[0027] The multi-shell side spiral plate combined anti-scaling heat exchanger includes a base 1, a bracket 2, a 1# heat exchange unit 3, a 2# heat exchange unit 4, a 3# heat exchange unit 5, and a 4# heat exchange unit 6 and internal connecting pipes, the base 1 is fixed on the ground; the bracket 2 is installed on the base 1 to support the heat exchange units 3, 4, 5, 6; the heat exchange units 3, ...

Embodiment 2

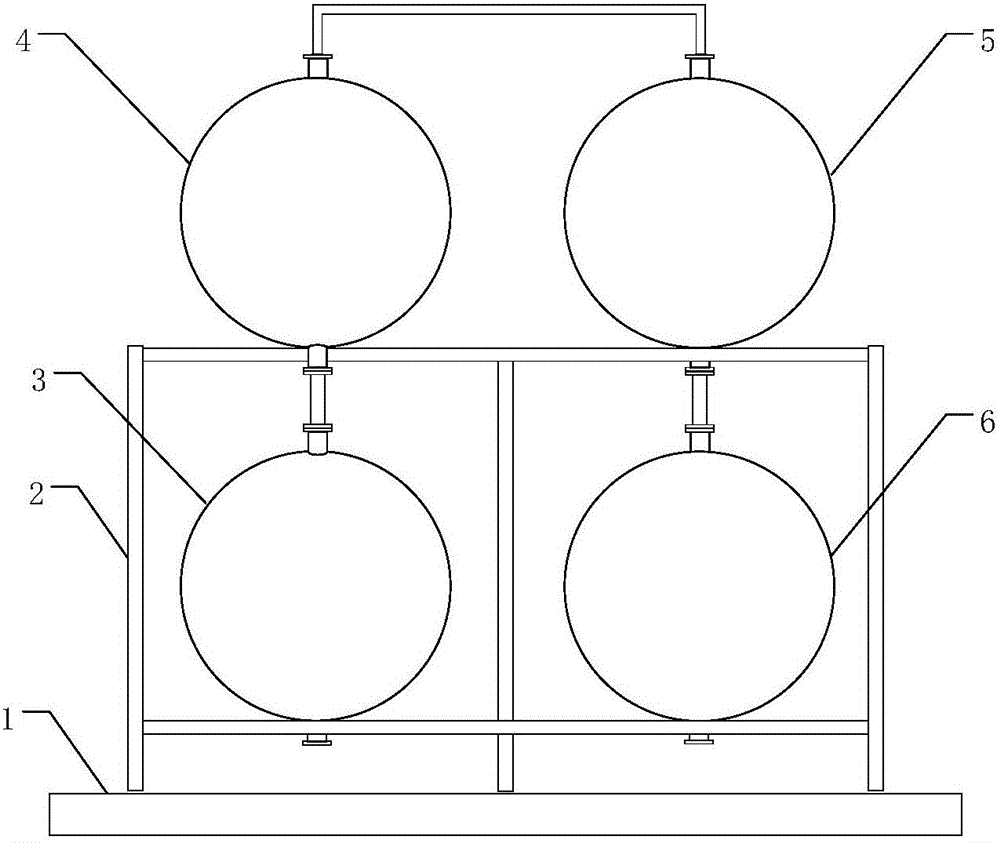

[0031] Such as Figure 4 As shown, the multi-shell-pass spiral plate combined anti-scaling heat exchanger is customized for the sewage stripping unit of an oil refinery. The cold side of the heat exchanger is the raw water, and the hot side is the purified water of the delivery device. According to the calculation of the technical parameters of the sewage stripping device, the heat exchanger is composed of six heat exchange units connected in series to form an assembled heat exchanger with six tube passes and six shell passes.

[0032] The multi-shell side spiral plate combined anti-scaling heat exchanger includes a base 1, a bracket 2, a 1# heat exchange unit 3, a 2# heat exchange unit 4, a 3# heat exchange unit 5, and a 4# heat exchange unit 6 , 5# heat exchange unit 15, 6# heat exchange unit 16, and internal connecting pipes. The base 1 is fixed on the ground; the support 2 is installed on the base 1 , and the heat exchange units 3 , 4 , 5 , 6 , 15 , 16 are fixed on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com