Heater for heating network

A heating net heater, filter net technology, applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchanger type, etc., can solve the problem of reducing the effective utilization time of the heater, affecting the efficiency of hot water production, and the inner wall of the tube bundle being easily knotted. Scale and other problems, to achieve the effect of reducing the probability of tube bundle blockage and scaling, reducing the probability of impurities blocking the mesh holes, and reducing the number of cleanings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

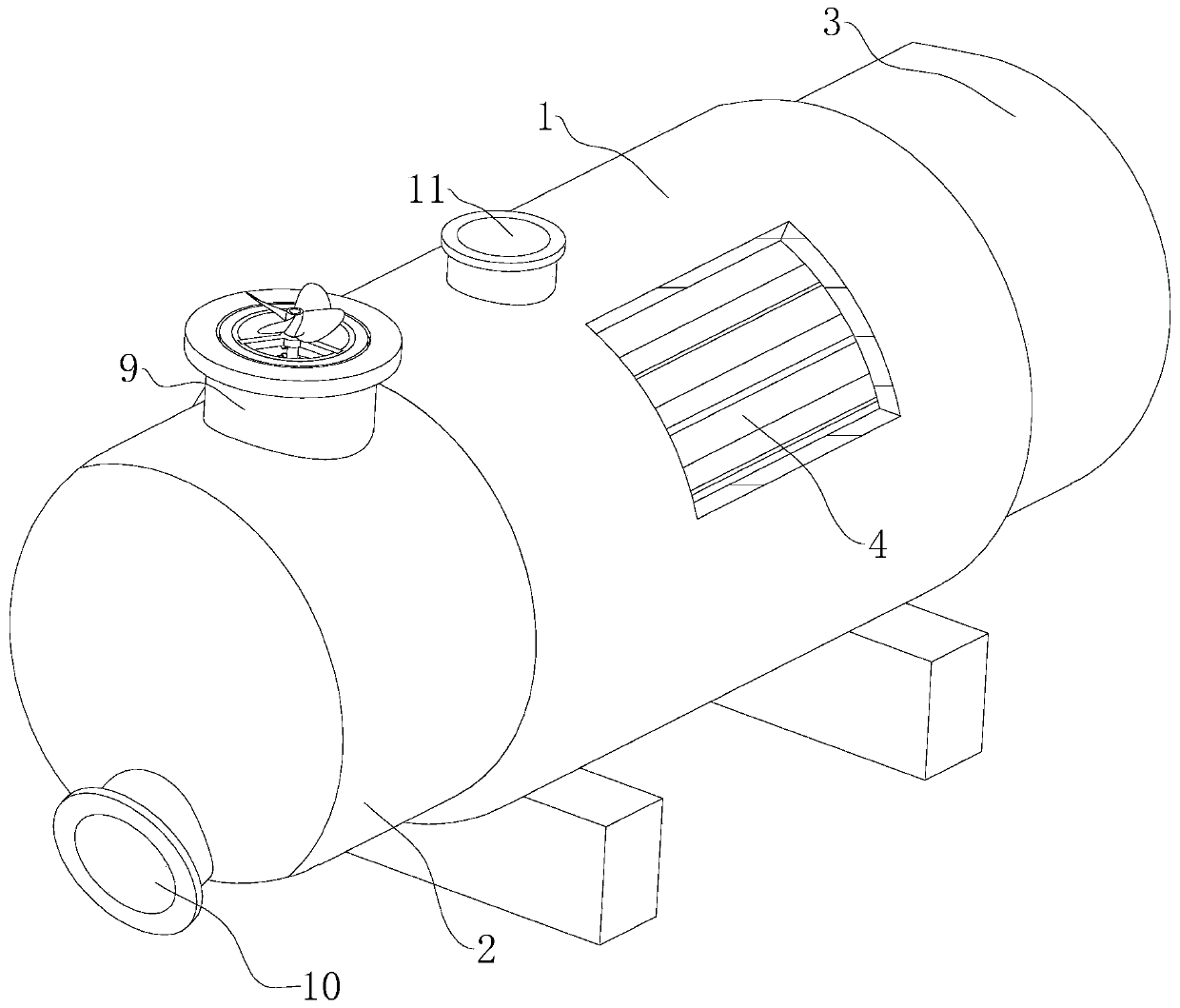

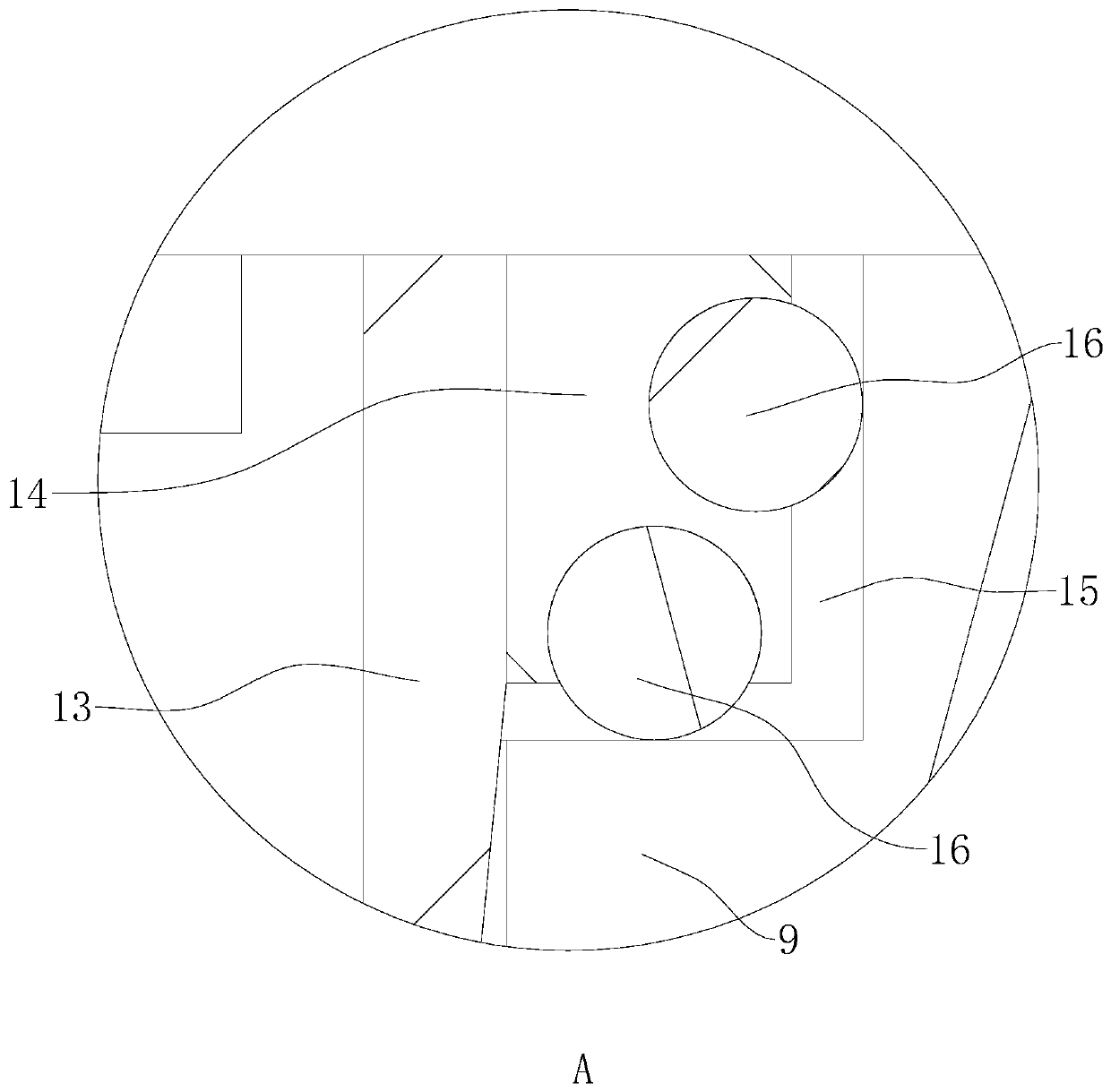

[0040] refer to figure 1 with 2 , is a heating network heater disclosed in the present invention, comprising a hollow housing 1, the housing 1 is cylindrical; the two ends of the housing 1 are respectively fixed with a front pipe box 2 and a rear pipe box 3; Tube plates 5 are respectively fixed at both ends of 1 to isolate the shell 1 from the internal space of the front end tube box 2 and the rear end tube box 3; a tube bundle 4 is also arranged in the shell 1, and the tube bundle 4 is arranged in a U shape, and the Pass through the two tube sheets 5 and be welded and fixed on the two tube sheets 5; wherein, the open ends of the tube bundles 4 are all located in the front end tube box 2. A partition 6 is fixed inside the front end tube box 2 along the axis of the shell 1, and the partition 6 is fixed to the inner wall of the front end tube box 2 and the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com