Purification dispersant and oil slurry scale inhibitor containing purification dispersant

A clean dispersant and antiscalant technology, applied in the petroleum industry, organic chemistry, hydrocarbon oil treatment, etc., can solve the problem that it is difficult to achieve the ideal antiscaling effect by adding dosage of antiscalant, the oil slurry system can not achieve the effect of antiscaling, Increased chance of scaling and other problems, to achieve good cleaning and anti-scaling performance, wide range of use, increase the effect of flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

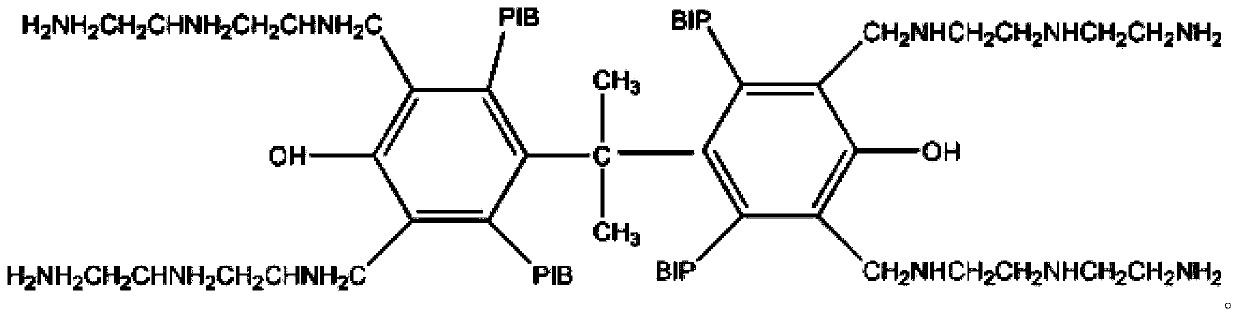

[0036] A kind of brand-new cleansing and dispersing agent bisphenol type Mannich base, its structural formula is as follows:

[0037]

[0038] It uses polyisobutylene as raw material to prepare polyisobutylene bisphenol A intermediate, and then reacts it with diethylenetriamine and paraformaldehyde to obtain it. The specific preparation steps are as follows:

[0039] Add the boron trifluoride (catalyst) of the bisphenol A of 0.1mol, 40mL toluene and 0.015mol in the four-necked flask, agitator, condenser, separatory funnel and thermometer are installed on the four-necked flask; The active polyisobutene was dissolved in toluene, placed in a separatory funnel, fed with nitrogen to maintain normal pressure, and the reaction temperature was controlled at 80°C. The highly active polyisobutene in the separatory funnel was added drop by drop, and the reaction time was 5 hours. After the reaction was completed, statically After the catalyst is completely deposited on the bottom of the...

Embodiment 2

[0045] A kind of oil slurry antiscalant, its raw material composition comprises by weight:

[0046]

[0047] Wherein said cleaning and dispersing agent is bisphenol type Mannich base;

[0048] Described antioxidant is diisooctyl diphenylamine;

[0049] Described polymerization inhibitor is dodecylbenzenesulfonic acid;

[0050] Described viscosity reducer is propylene glycol polyoxyethylene polyoxypropylene ether;

[0051] The carrier dispersant is polypropylene glycol;

[0052] Described solvent oil is the mixture of aliphatic hydrocarbon base benzene such as benzene, toluene, xylene, mesitylene in any ratio;

[0053] Its preparation method is as follows:

[0054] A) adding the cleansing and dispersing agent into the mixed aromatic hydrocarbon solvent oil, and obtaining the mixed solution a after mixing;

[0055] B) adding dodecylbenzenesulfonic acid into the mixed solution a, and mixed to obtain the mixed solution b;

[0056] C) adding diisooctyl diphenylamine to the...

Embodiment 3

[0060] A kind of oil slurry antiscalant, its raw material composition comprises by weight:

[0061]

[0062] Wherein said cleaning and dispersing agent is bisphenol type Mannich base;

[0063] Described antioxidant is N, N'-di-sec-butyl-p-phenylenediamine;

[0064] Described polymerization inhibitor is polyisobutenyl succinimide;

[0065] Described viscosity reducer is fatty alcohol polyoxyethylene polyoxypropylene ether;

[0066] The carrier dispersant is polyethylene glycol;

[0067] The solvent oil is C15-C20 aliphatic hydrocarbon or cycloalkane;

[0068] Its preparation method is as follows:

[0069] A) adding the detergent and dispersant to the alkane solvent oil, and mixing to obtain the mixed liquid a;

[0070] B) Add polyisobutenyl succinimide to mixed solution a, and mix to obtain mixed solution b;

[0071] C) Add N,N'-di-sec-butyl-p-phenylenediamine in mixed solution b, and obtain mixed solution c after mixing;

[0072] D) Add polyethylene glycol to the mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com