Sulfuric acid method titanium dioxide waste acid purification process

A technology of titanium white waste acid and sulfuric acid method, which is applied in the direction of iron sulfate, sulfur compounds, sulfur trioxide/sulfuric acid, etc., can solve the problems of expensive equipment, poor effect of crystallization and impurity removal, and increased workload, so as to prolong the use of equipment The effect of life, improvement of heat exchange efficiency, and reduction of the chance of fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

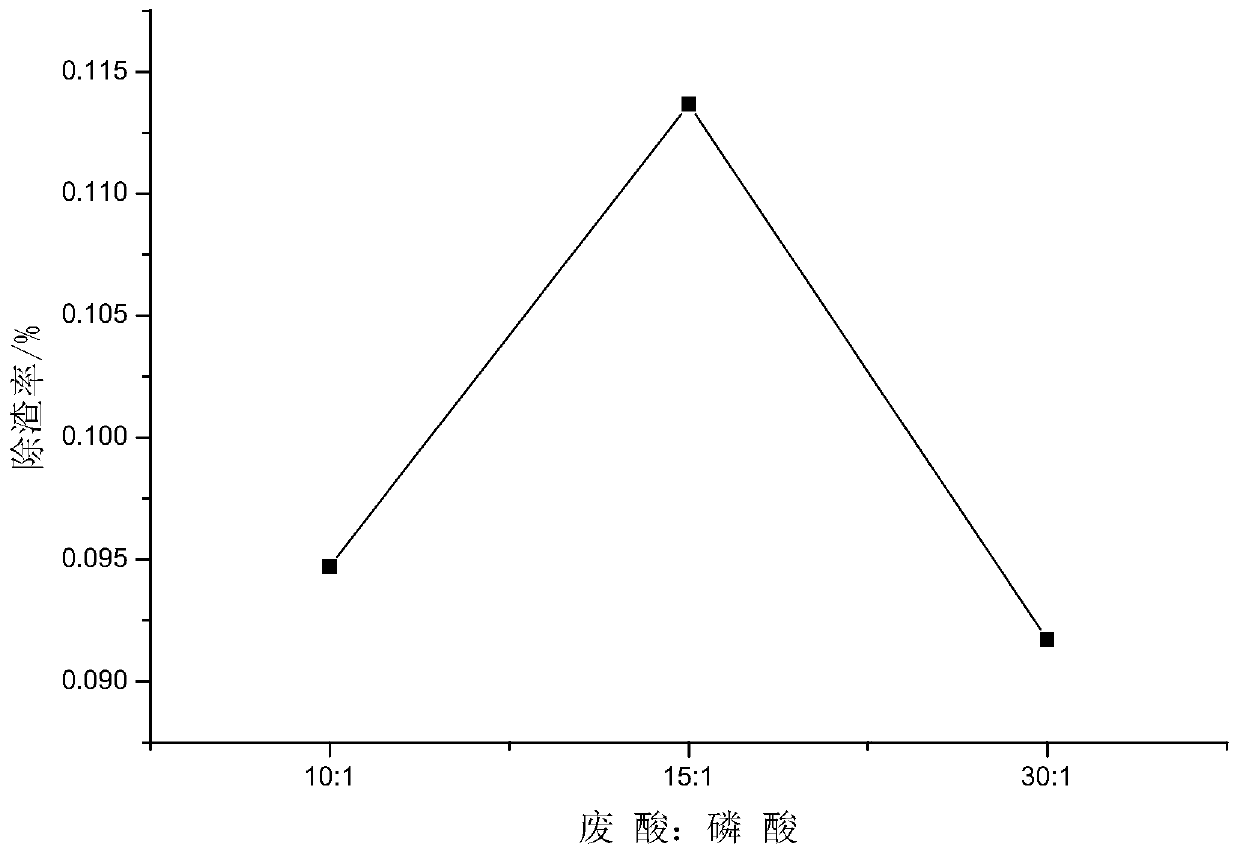

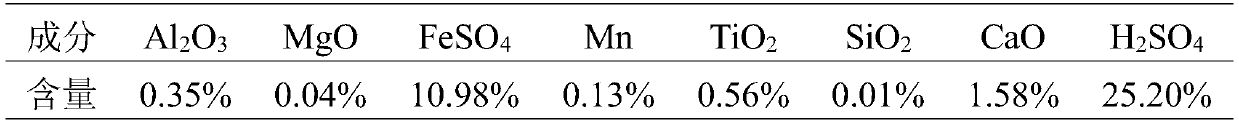

[0048] Embodiment 1 adopts purification process of the present invention to process sulfuric acid process titanium dioxide waste acid

[0049] ①Weigh 60g of titanium dioxide waste acid and 6g of phosphoric acid, stir evenly, and leave the mixed solution at room temperature for 18 hours;

[0050] ② Solid-liquid separation is carried out to obtain the upper clarified solution as primary treatment waste acid, the concentration of sulfuric acid is 36.3% w / w, and the sediment at the bottom of the solution is ferrous phosphate, titanium phosphate and 6.02g of some attachments;

[0051] ③Add 95% ethanol solution to the primary treatment waste acid, the mass ratio of primary treatment waste acid:ethanol is 20:1, stir evenly, and place it at room temperature for 18 hours;

[0052] 4. Carry out solid-liquid separation to obtain the upper clarified solution as secondary waste acid, the concentration of sulfuric acid is 42% w / w, and the precipitate at the bottom of the solution is 5.64 g ...

Embodiment 2

[0055] Embodiment 2 adopts purification process of the present invention to process sulfuric acid process titanium dioxide waste acid

[0056] ①Weigh 60g of titanium white waste acid and 6g of phosphoric acid, stir well, and let the mixed solution stand at a low temperature of -4°C for 12 hours;

[0057] ②Separation of solid and liquid to obtain the upper clarified solution is waste acid for primary treatment, the concentration of sulfuric acid is 74.2% w / w, and the sediment at the bottom of the solution is ferrous phosphate, titanium phosphate and 16.92 g of some attachments;

[0058] ③Add 95% ethanol solution to the primary treatment waste acid, the mass ratio of primary treatment waste acid:ethanol is 20:1, stir evenly, and place it at a low temperature of -4°C for 12 hours;

[0059] 4. Carry out solid-liquid separation to obtain the upper clarified solution as secondary waste acid, the concentration of sulfuric acid is 83%w / w, and the sediment at the bottom of the solution...

Embodiment 3

[0062] Embodiment 3 adopts purification process of the present invention to process sulfuric acid process titanium white waste acid

[0063] ① Weigh 60g of titanium dioxide waste acid and 1.9g of phosphoric acid, stir well, and let the mixed solution stand at room temperature for 18 hours;

[0064] ② Solid-liquid separation is carried out to obtain the upper clarified solution which is waste acid for primary treatment, the concentration of sulfuric acid is 21.32% w / w, and the sediment at the bottom of the solution is ferrous phosphate, titanium phosphate and 4.32 g of some attachments;

[0065] ③Add 95% ethanol solution to the primary treatment waste acid, the mass ratio of primary treatment waste acid:ethanol is 20:1, stir evenly, and place it at room temperature for 18 hours;

[0066] 4. Carry out solid-liquid separation to obtain the upper clarified solution as secondary waste acid, the concentration of sulfuric acid is 28.96% w / w, and the precipitate at the bottom of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com