Anti-scaling type trace exhaust valve

A micro-exhaust and anti-scaling technology, which is applied to valve details, valve devices, and valve housing structures, can solve problems that affect the opening and closing of micro-exhaust valves, strong adhesion is difficult to remove, and valve function failures, etc. Small chance of fouling, simple structure, guaranteed normal working effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

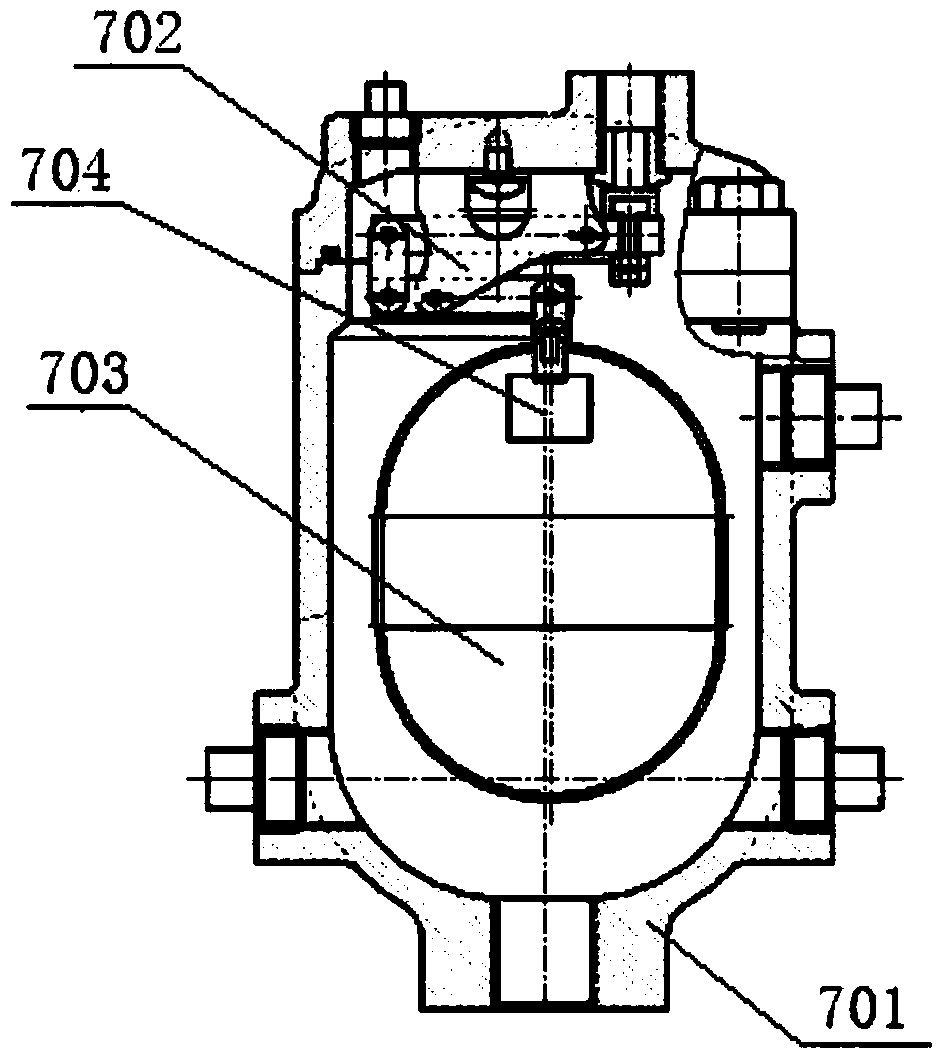

[0022] Embodiment 1: a fixed bracket is provided in the floating ball 703, and a groove is provided on the fixed bracket to fix the permanent magnet 704, and the magnetic field of the permanent magnet 704 is used to protect the surface of the lever assembly 702 from scaling, and the permanent magnet 704 It is fixed on the upper part of the floating ball 703 to further ensure the stability of the magnetic field intensity on the surface of the lever assembly 702 .

Embodiment 2

[0023] Embodiment 2: The outer surface of the floating ball 703 is coated with a magnetic material layer, which is easy to process and has good practicability.

Embodiment 3

[0024] Embodiment 3: The inner surface of the floating ball 703 is coated with a magnetic material layer, the magnetic material of the inner layer is not affected by the water flow, the structure is stable, and the use effect is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com