Mechanical ventilation forced circulation evaporation device and liquid material evaporation method

A technology of forced circulation of evaporation and liquid materials, which is applied in the direction of evaporation, separation methods, chemical instruments and methods, etc., can solve the problems of poor operation stability of the device and high operation cost of industrial wastewater, and achieve the reduction of operation cost and the improvement of stable operation of the system. Solve the effect of high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028]A project produces 40 tons / hour of saline refractory wastewater per day (chemical oxygen demand 0.5-30%wt, inorganic salt 1.0-30.0%wt, oil content 0.01-1.2%wt), according to the "National Hazardous Waste Catalog", the wastewater belongs to Hazardous Waste. If it is treated as hazardous waste, its treatment cost is as high as 1.72-2.88 million per day, and the direct treatment cost of unit wastewater is 1800-3000 yuan per ton. In order to solve this problem, the project launched a set of three-effect evaporation and concentration equipment for wastewater. The daily treatment cost is 134,000 to 202,000 yuan / day (excluding waste disposal costs), and the direct treatment cost per unit of wastewater is 140 to 210 yuan / ton. However, shortly after the device was started, scaling, blockage of heating pipes, and flooding occurred in the device one after another. The quality of the effluent water fluctuated greatly, which caused a heavy burden on the subsequent biochemical system....

Embodiment 2

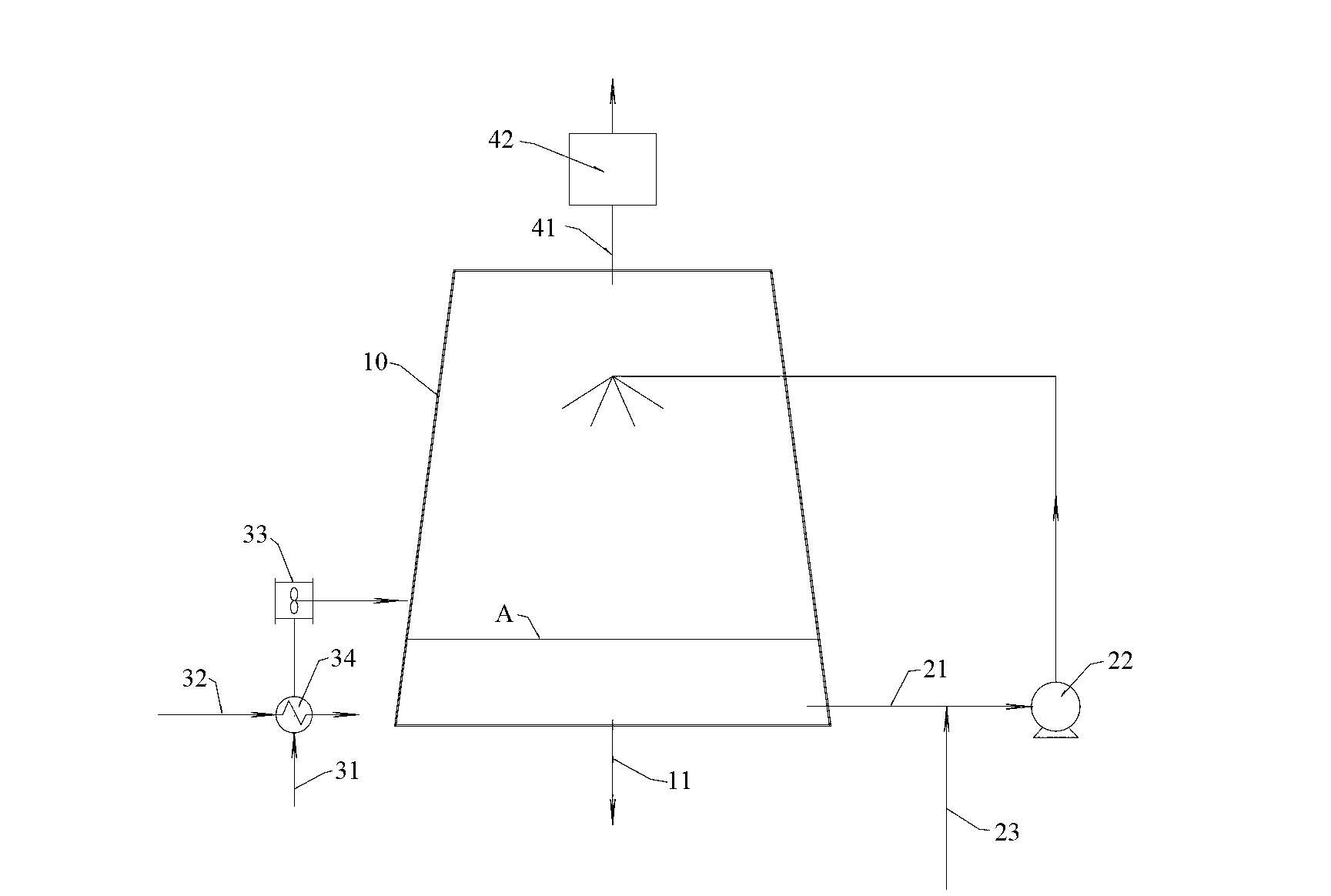

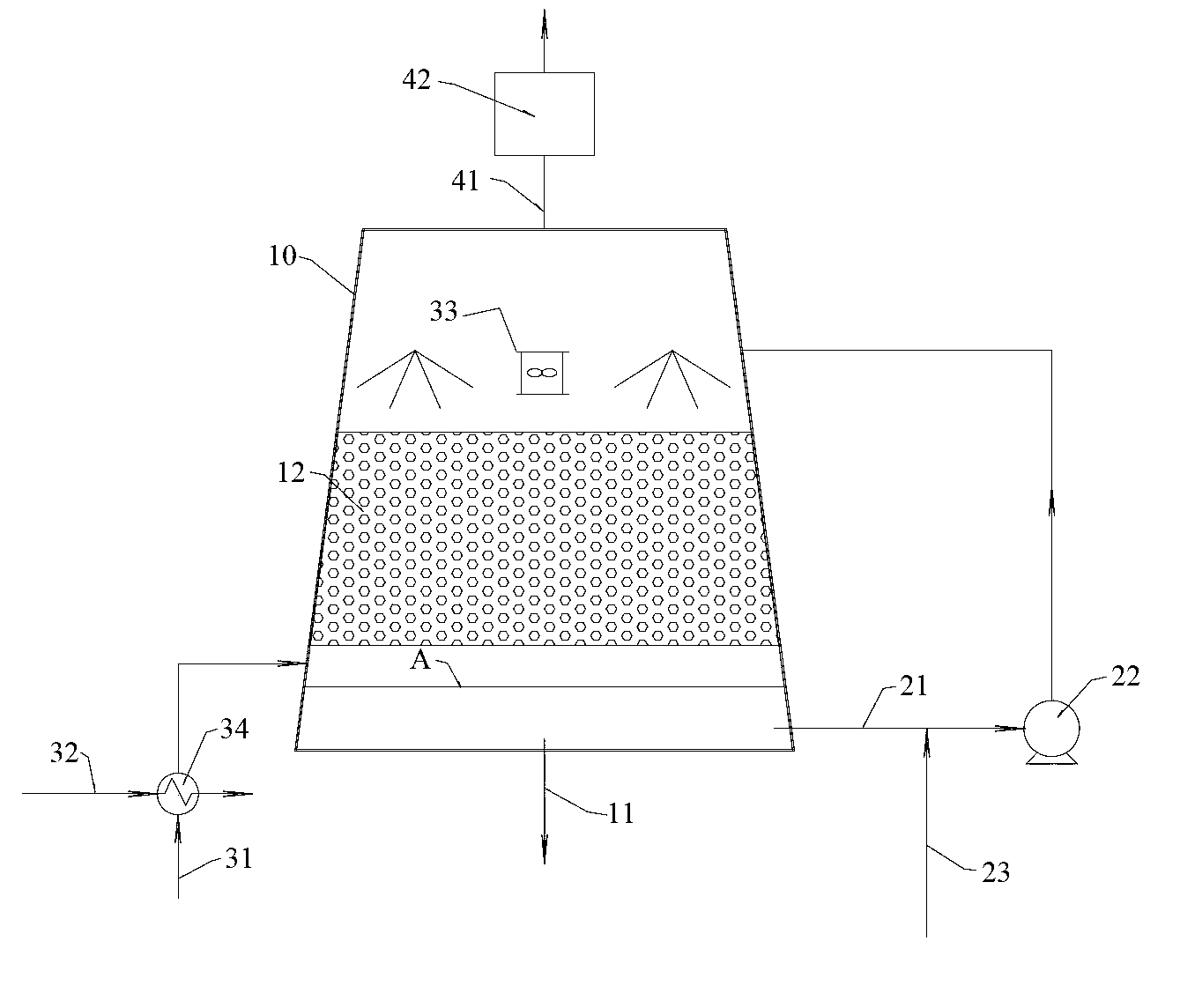

[0032] refer to figure 2 , The wastewater treatment scale is 4 tons / hour, and the water quality is characterized by chemical oxygen demand 0.2-1.0%wt, inorganic salt 1.0-8.0%wt, oil content 0-0.01%wt, ammonia nitrogen content 0.02-1.5%wt. The low-temperature heat source provided by the enterprise is ambient air (the average annual temperature of the ambient air in the current period is 28°C), and the internal circulation volume of the wastewater in the evaporation device is 160-250m 3 / h, the air-water ratio is 800-1200:1, with oblique staggered packing inside (the filling rate is 60%), and the design evaporation chamber temperature is 28±3℃. After being condensed, the tail gas of the device enters the waste water station for further treatment, and the non-condensable gas further enters the subsequent tail gas treatment system. The concentrated waste is in solid state (water content 40-50%), and is regularly transferred out of the evaporation system. Continuous and stable o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com