Double-channel steam injection and oil production sand preventing and scale preventing pump

A dual-channel, steam injection technology, used in pumps, pump components, and production fluids, etc., can solve the problems of easy falling into the pump barrel, the plunger is blocked, and the sand jam is stopped, so as to avoid frequent pump jam accidents and reduce structural damage. The effect of reducing the probability of fouling and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

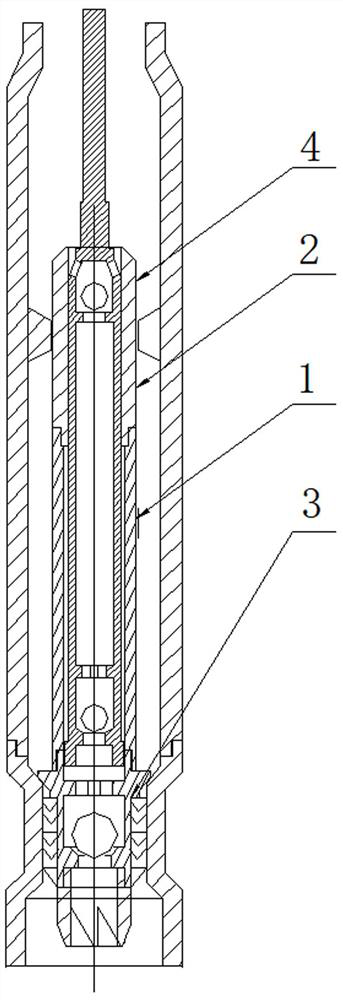

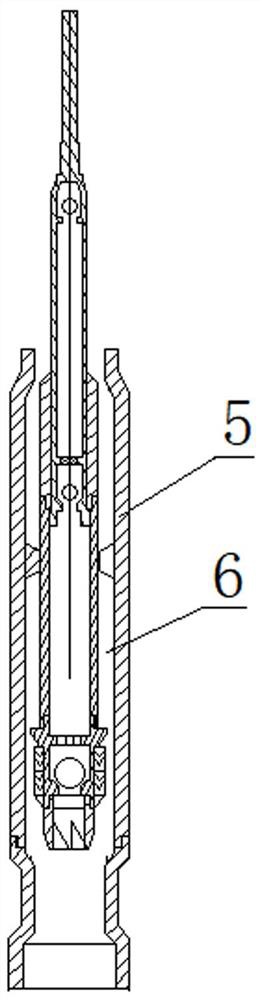

[0031] like Figure 1-11 As shown, a dual-channel steam injection, oil production, sand and scale prevention pump includes a pump body, the pump body is provided with a steam injection outer pipe assembly 1, and the steam injection outer pipe assembly 1 is provided with an oil production assembly, so The oil recovery assembly includes a pump barrel assembly, which is provided with a long plunger assembly 2, and the lower end of the pump barrel assembly is connected with a fixed valve (seal) assembly 3, and the pump barrel assembly The assembly cooperates with the long plunger assembly 2 to form a variable cavity. The long plunger assembly 2 moves upward, and the cavity of the pump barrel assembly changes accordingly. The inside of the fixed valve (seal) assembly 3 A ball valve seat 33 is provided to ensure that the liquid can only flow in one direction. The long plunger assembly 2 is also provided with a ball valve seat to ensure that the liquid can only flow in one direction....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com