Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "Reduce the amount of splatter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Steel wire for carbon dioxide shielded arc welding and welding process asing the same

InactiveCN1533315AAchieve Jet TransitionGood effectArc welding apparatusWelding/cutting media/materialsRare-earth elementBead shape

In carbon dioxide arc welding by use of shielding gas comprised of carbon dioxide as main component, a welding wire that enables spray transfer of globules, and provides an excellent bead shape in addition to reduction of amount of spatters even in a high-speed welding, and a welding method using the welding wire are proposed. As the specific means, a welding steel wire for use in carbon dioxide arc welding in DC-electrode negative, comprising a bar steel having a composition that contains 0.003 to 0.20% by mass of C, 0.05 to 2.5% by mass of Si, 0.25 to 3.5% by mass of Mn, 0.015 to 0.100% by mass of REM (rare-earth elements), 0.001 to 0.05% by mass of P, and 0.001 to 0.05% by mass of S, or further contains 0.0100% by mass or less of O, or further contains one or two or more of 0.02 to 0.50% by mass of Ti, 0.02 to 0.50% by mass of Zr, and 0.02 to 3.00% by mass of Al, or further contains 0.0001 to 0.0150% by mass of K, or further contains 3.0% by mass or less of Cr, 3.0% by mass or less of Ni, 1.5% by mass or less of Mo, 3.0% by mass or less of Cu, 0.015% by mass or less of B, 0.20% by mass or less of Mg, 0.5% by mass or less of Nb, 0.5% by mass or less of V, and 0.020% by mass or less of N, and contains Fe and unavoidable impurities as residue is used.

Owner:JFE STEEL CORP

Process method for welding aluminum and aluminum alloy material by laser

InactiveCN101850472ASmall sizeEasy to closeGrinding machinesWelding/soldering/cutting articlesOrganic solventHigh energy

The invention relates to laser welding and discloses a process method for welding aluminum and aluminum alloy material by laser. The process method comprises steps of: (1) selecting an Nd:YAG laser with high beam quality and high energy density; (2) adopting double-beam laser to weld aluminum and aluminum alloy material, wherein the distance between the two beams is 0.6-1.0 mm, and the energy ratio of the two beams is larger than 1:1; (3) surface treatment of a material to be welded: removing greasy dirt and dust with an organic solvent and removing an oxidation film by mechanical cleaning and / or chemical cleaning; and (4) utilizing the two-beam laser to weld the aluminum and the aluminum alloy material. A needle body, a sleeve and a lead of the invention are manufactured into a whole; therefore, the invention solves adaptability of the laser welding to assembly precision, enhances the stability of welding process and improves welding line quality.

Owner:武汉楚天激光(集团)股份有限公司

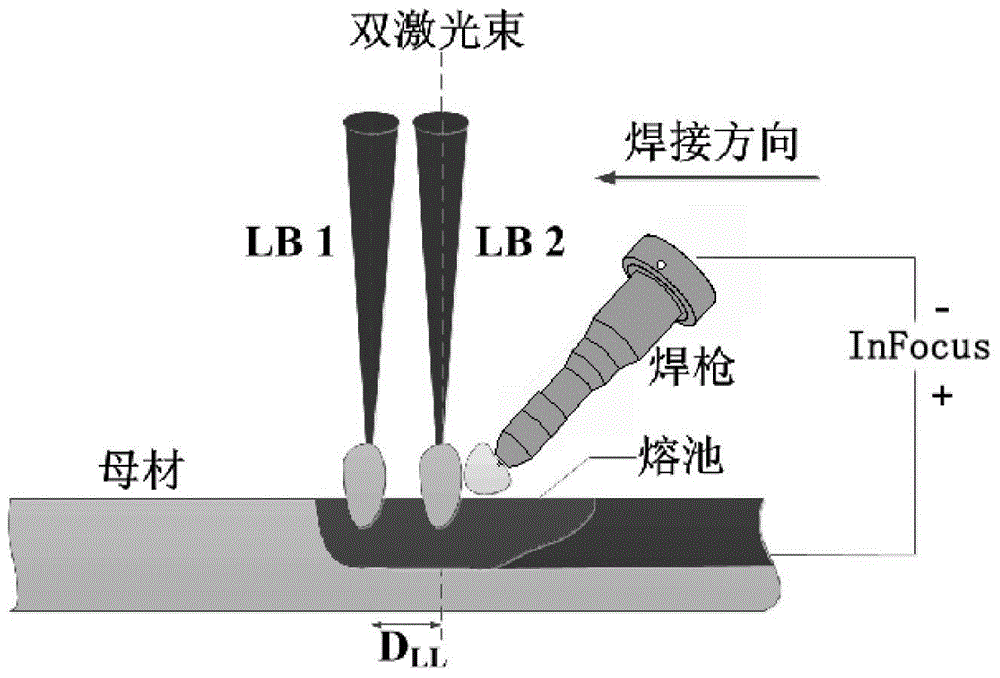

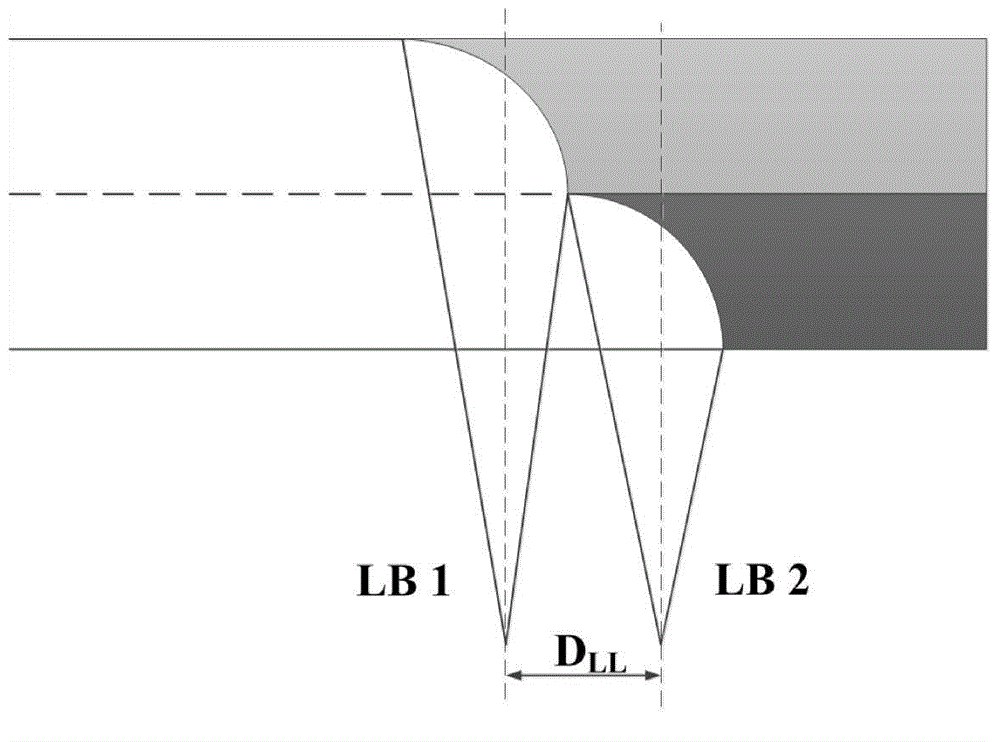

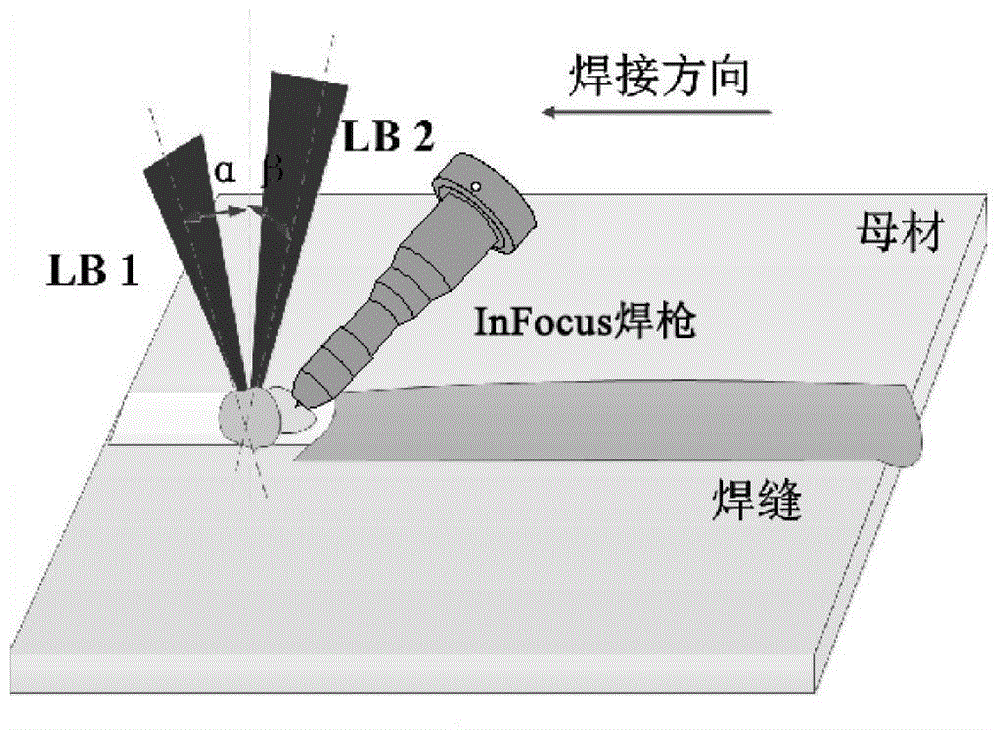

Bifocus laser and InFocus arc hybrid welding method

InactiveCN104985327AImprove energy utilizationIncrease weld penetrationLaser beam welding apparatusElectric arcEngineering

The invention discloses a bifocus laser and InFocus arc hybrid welding method, and relates to a welding method. The method includes the steps that (1) a to-be-welded workpiece is polished or washed; (2) the spot diameter is set to range from 0.1 mm to 0.5 mm, and the defocusing amount ranges from -3 mm to +3 mm; (3) welding parameters are set, wherein the arc current ranges from 50 A to 900 A, an included angle formed between a welding gun and the vertical direction ranges from 25 degrees to 55 degrees, the welding speed ranges from 100 mm / min to 1000 mm / min, the wire feeding speed ranges from 100 mm / min to 600 mm / min, the protection gas is inert gas, and the flow of the protection gas ranges from 15 L / min to 30 L / min; and (4) a switch is started, and laser-InFocus arc welding is carried out. According to bifocus lasers and InFocus, as the InFocus arc fusion depth is larger, and a key hole can be formed through welding, when a medium-thickness plate is welded, the lasers can directly act on the bottom of the key hole generated by the InFocus arc, and the fusion depth is continuously increased.

Owner:HARBIN INST OF TECH

Method for decreasing laser welding pores

InactiveCN107186339AStable working conditionGood effectLaser beam welding apparatusPorosityButt joint

The invention provides a method for decreasing laser welding pores, and relates to the technical field of laser welding. The method for decreasing the laser welding pores comprises the steps of (1) placing two metal to-be-welded parts in a horizontal butt joint manner to form a to-be-welded workpiece; (2) clamping and fixing the two ends of the metal to-be-welded workpiece; (3) preheating the metal to-be-welded workpiece through laser beams; and (4) starting a control switch, introducing a protective gas, igniting electric arcs for 1 s to 2 s, emitting laser, combining laser emitted by a laser A and a laser B into one laser beam, and moving a high pressure air rifle which injects acetone together with the laser A and the laser B. According to the method, a device utilized in the method comprises the two lasers, firstly, the material surface is subjected to preheating treatment, an oxide film generated on the surface is scrubbed through acetone, and then, the two lasers emit the two laser beams to melt the material for welding, so that metal weld joint porosity is obviously decreased, and porosity of 8% to 10% during laser welding is decreased to zero.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

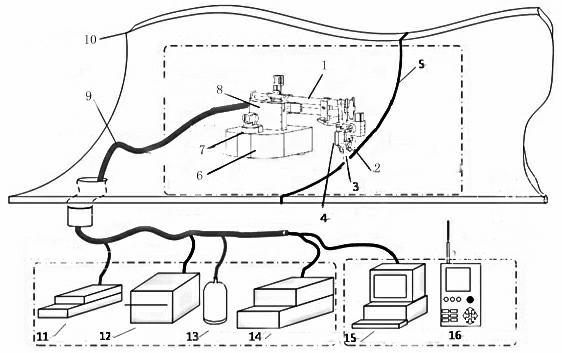

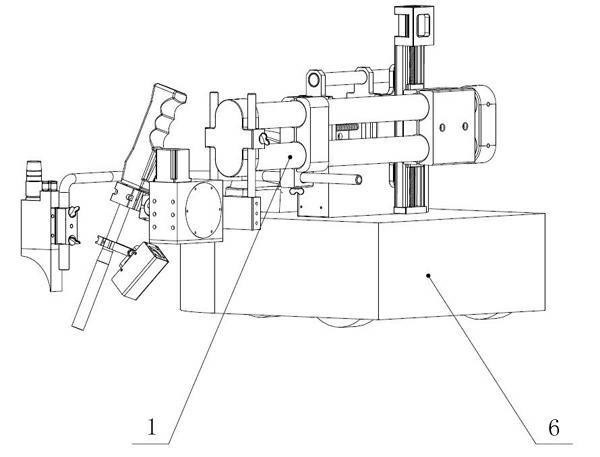

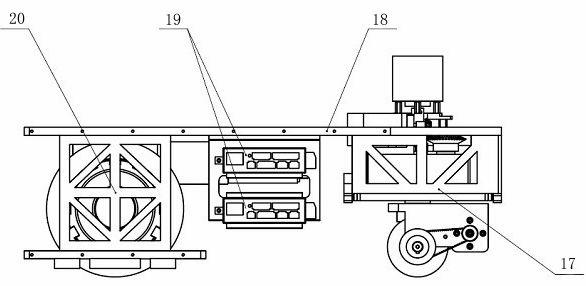

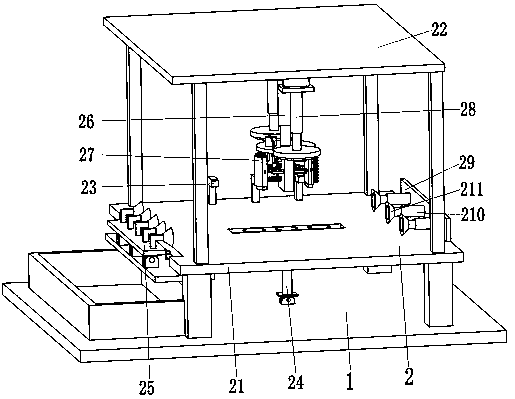

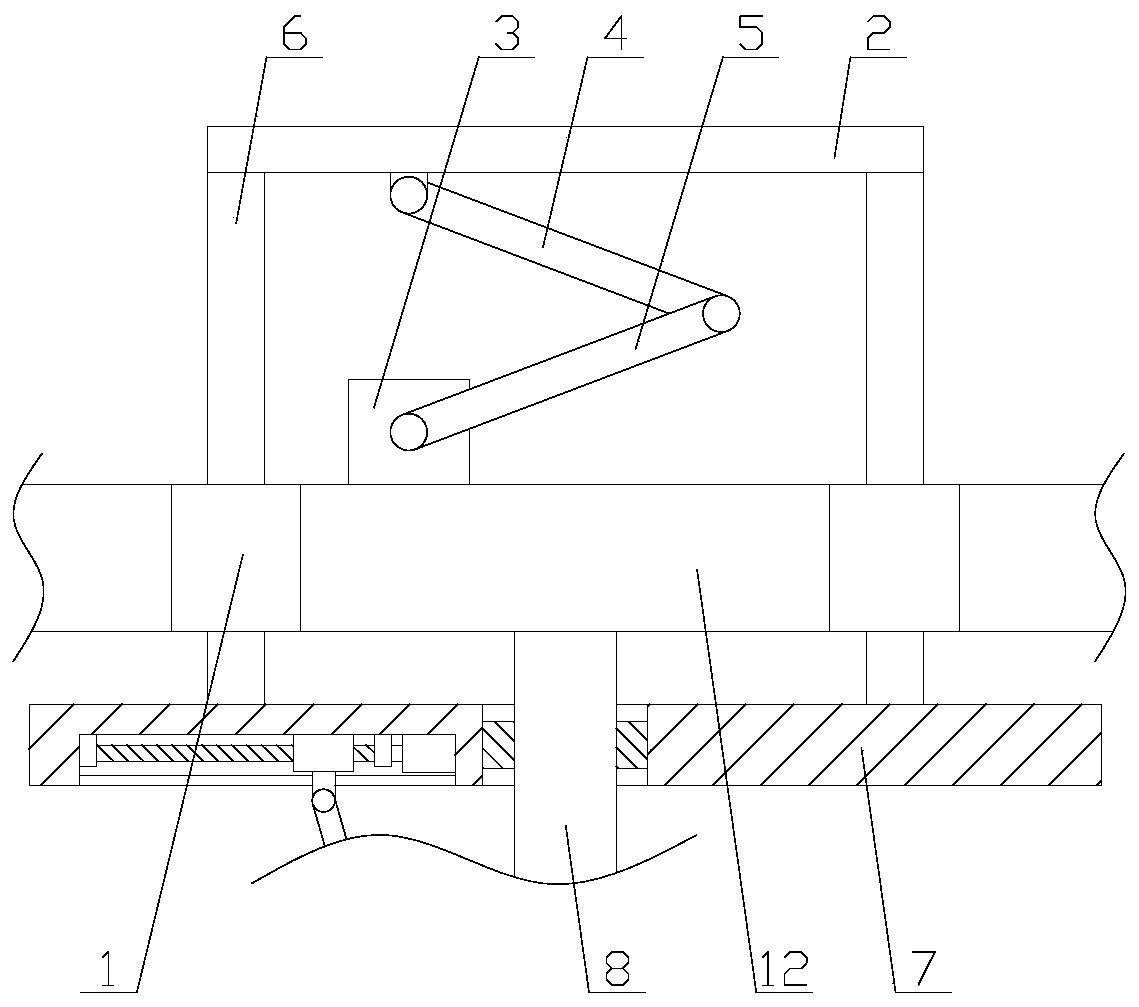

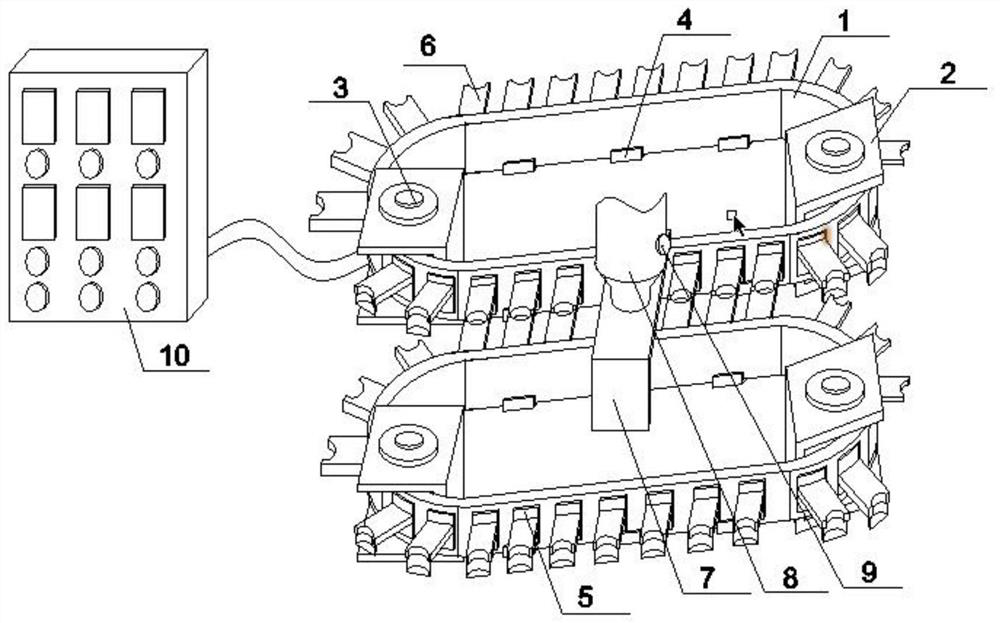

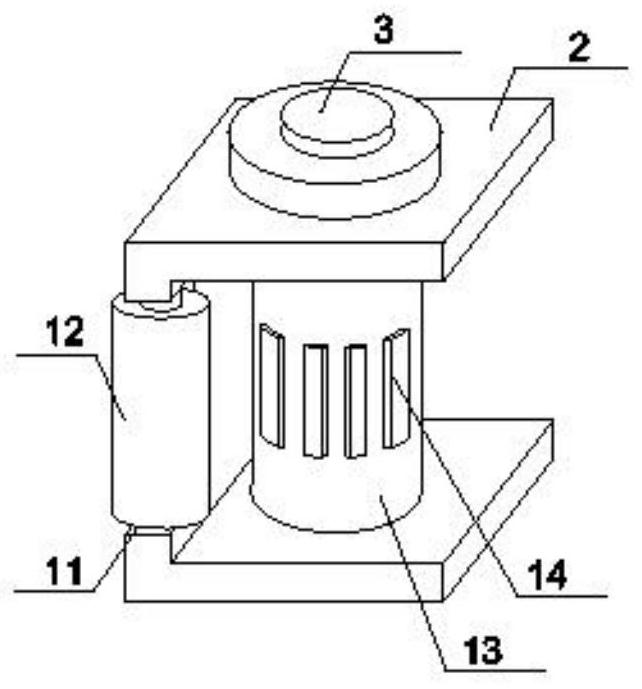

Autonomous mobile robot system for metal-inert-gas (MIG)/metal-active-gas (MAG) multilayer multipass welding of large thick plate

ActiveCN102689083AImprove performanceWith environmental monitoringElectrode supporting devicesDrive wheelShielding gas

The invention belongs to the technical field of welding of robots, and in particular relates to an autonomous mobile robot system for metal-inert-gas (MIG) / metal-active-gas (MAG) multilayer multipass welding of a large thick plate. The system comprises a robot body, a control system and an MIG / MAG welding system, wherein the robot body comprises a crawling mechanism and an operating mechanism; the control system comprises a sensing system, a robot body control box and a robot master control system; the MIG / MAG welding system comprises an MIG / MAG welding gun, an MIG / MAG welding power supply, a wire feeding machine, shielding gas and a weld cooling system; and the robot body, the control system and the MIG / MAG welding system are connected with one another through cables. The system has the advantages that a contact type magnet-wheel adsorption and non-contact type clearance adsorption composite mode and a three-wheel full-drive wheel type movement mode are used by the crawling mechanism, so that a robot can autonomously and flexibly move at all positions on the surface of an operating object, can be reliably adsorbed and can perform all-position welding operation, and the system is high in comprehensive performance.

Owner:DONGFANG ELECTRIC CORP LTD

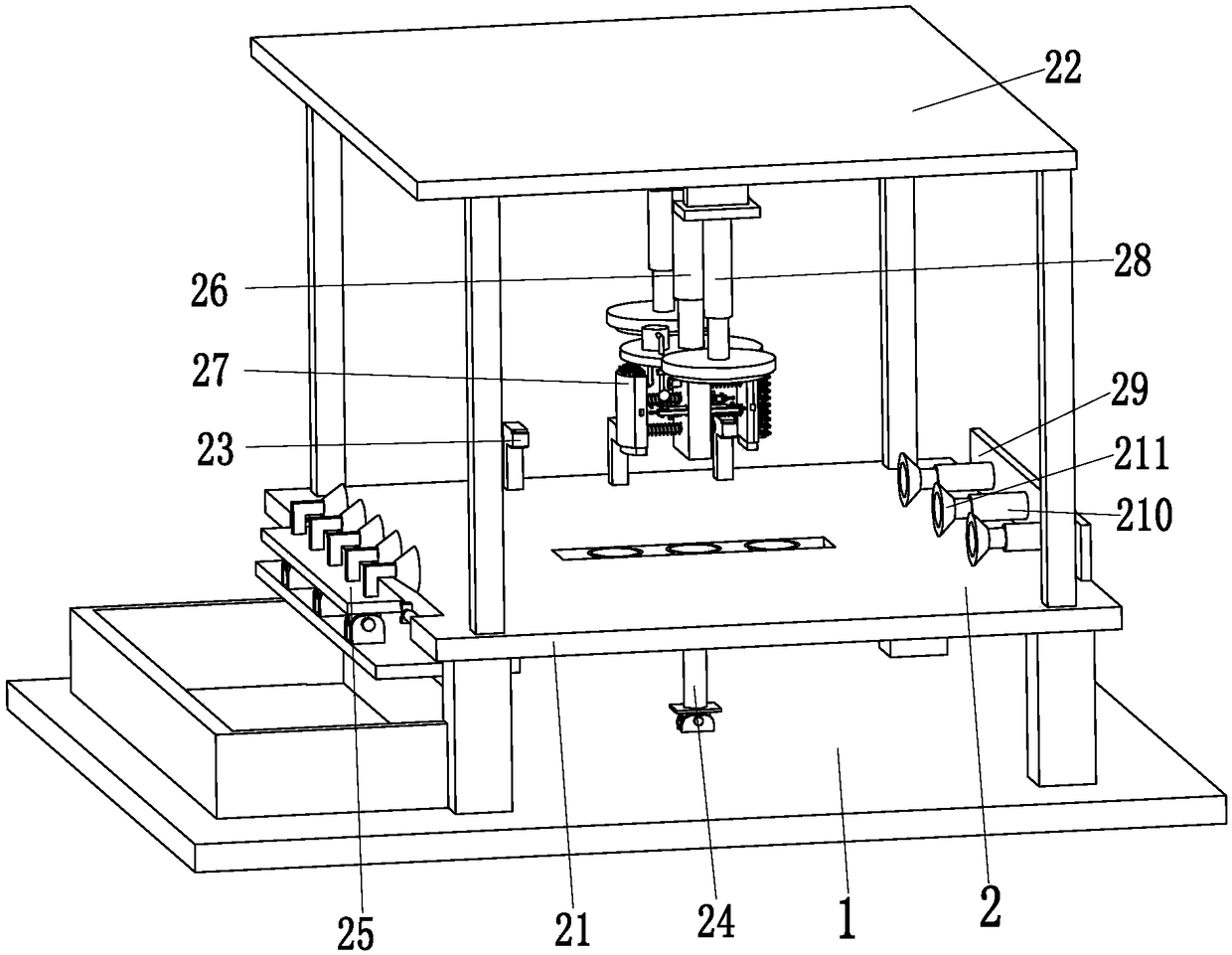

Medical tray disinfecting instrument for hospital nursing department

InactiveCN108580368AEasy to scrubImprove scrubbing effectCleaning using toolsCleaning using liquidsSewageSlide plate

The invention discloses a medical tray disinfecting instrument for a hospital nursing department. The instrument comprises a supporting bottom plate, a brushing and cleaning device and a drying device, wherein a sewage frame is placed on the upper end surface of the left side of the supporting bottom plate, and the top of the right end of the supporting bottom plate is provided with the brushing and cleaning device; the drying device is installed on the top of the left end of the supporting bottom plate; and the drying device comprises a drying side plate, a drying sliding column, a sliding push column rod, a drying sliding plate, a drying electric sliding block, a drying push rod and a drying machine. According to the instrument, the problems that in the prior art, when a medical tray isbrushed, the workload is large, the medical tray is difficult to wash, the tray is poor in brushing and cleaning effect, the tray cannot be effectively fixed when the tray is brushed and cleaned, a brushing and cleaning solution is seriously splashed when the tray is brushed and cleaned, manual turnover and water pouring is carried out on the brushed and cleaned tray, the trays are manually driedare solved, and the functions of all-directional locking of the medical tray, comprehensive brushing and cleaning of the tray, and turnover and drying of the tray are achieved.

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

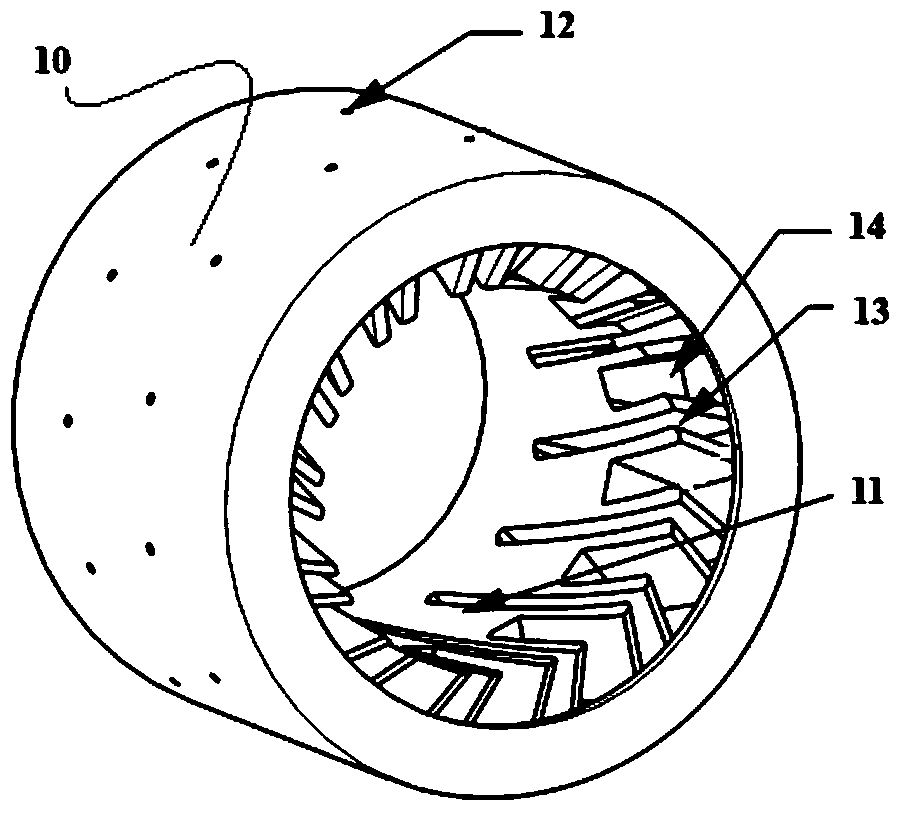

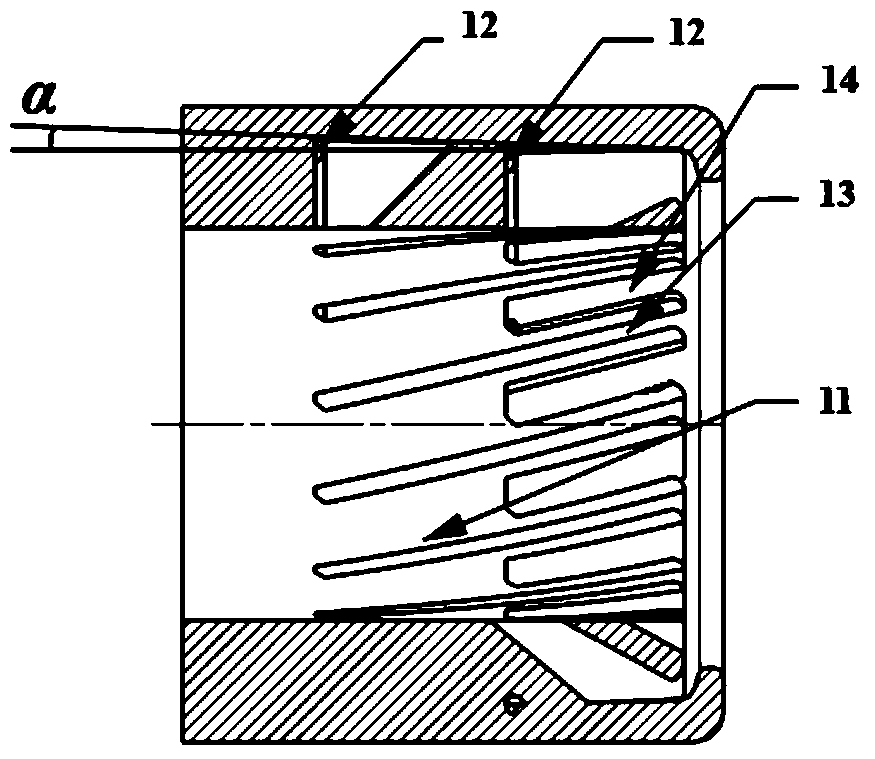

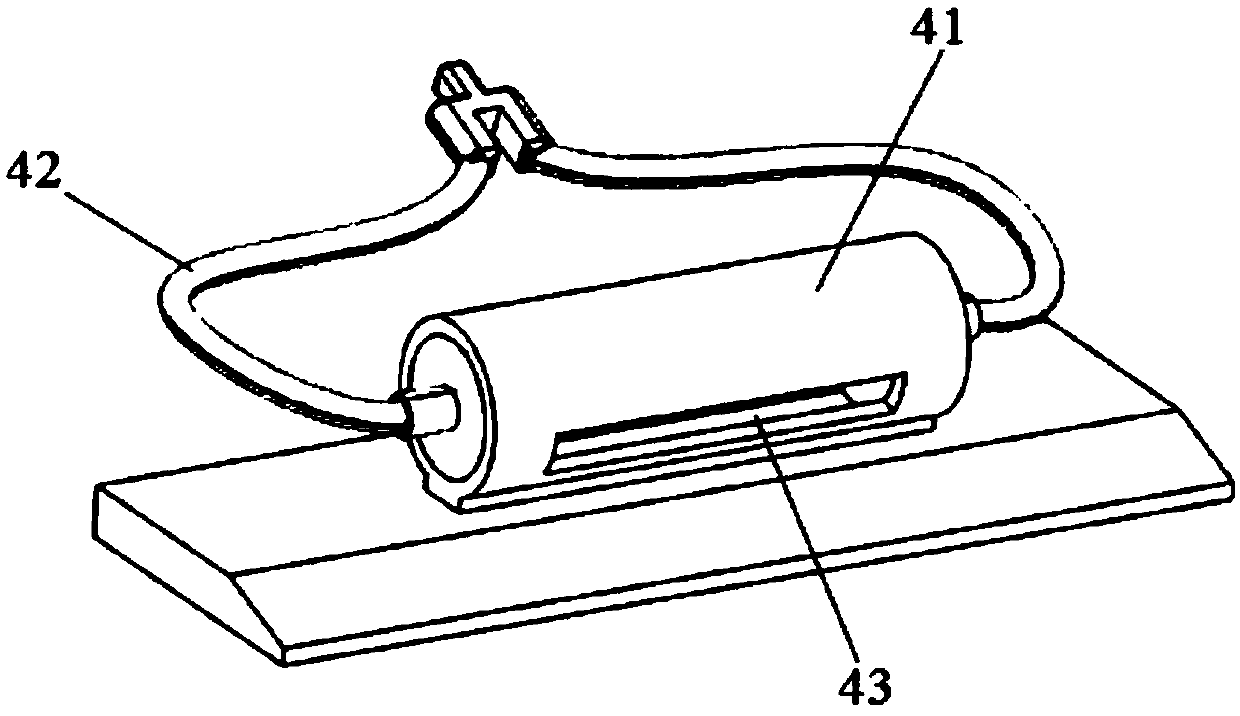

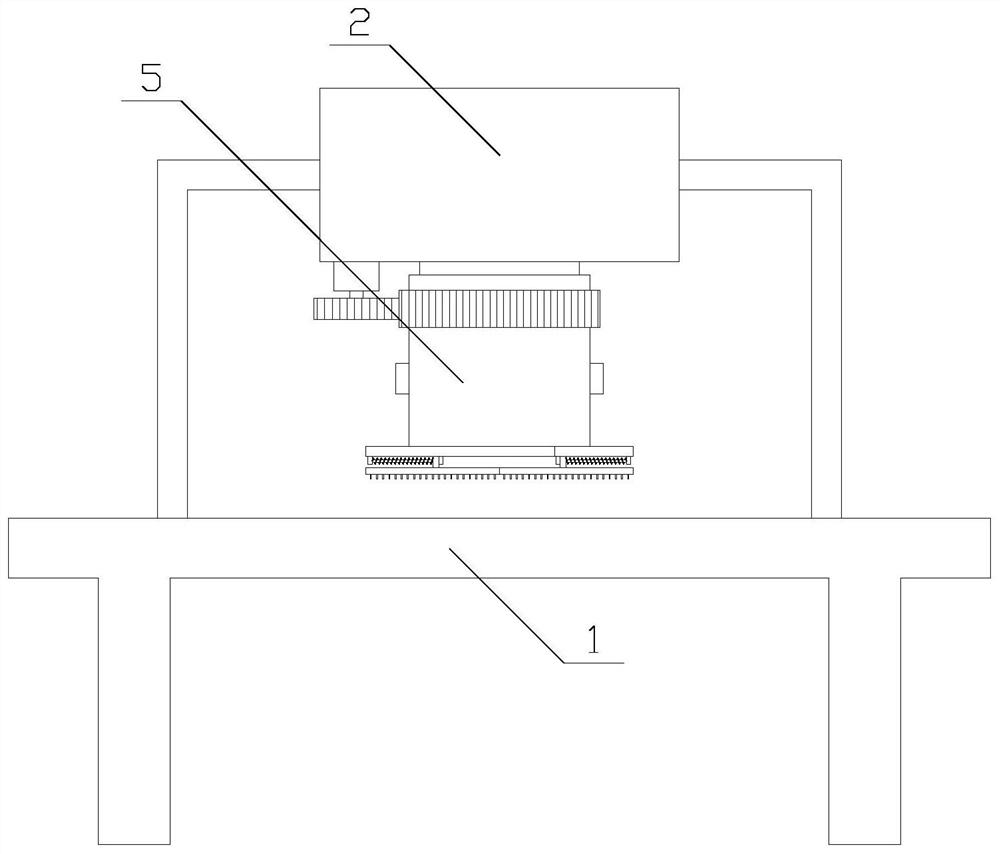

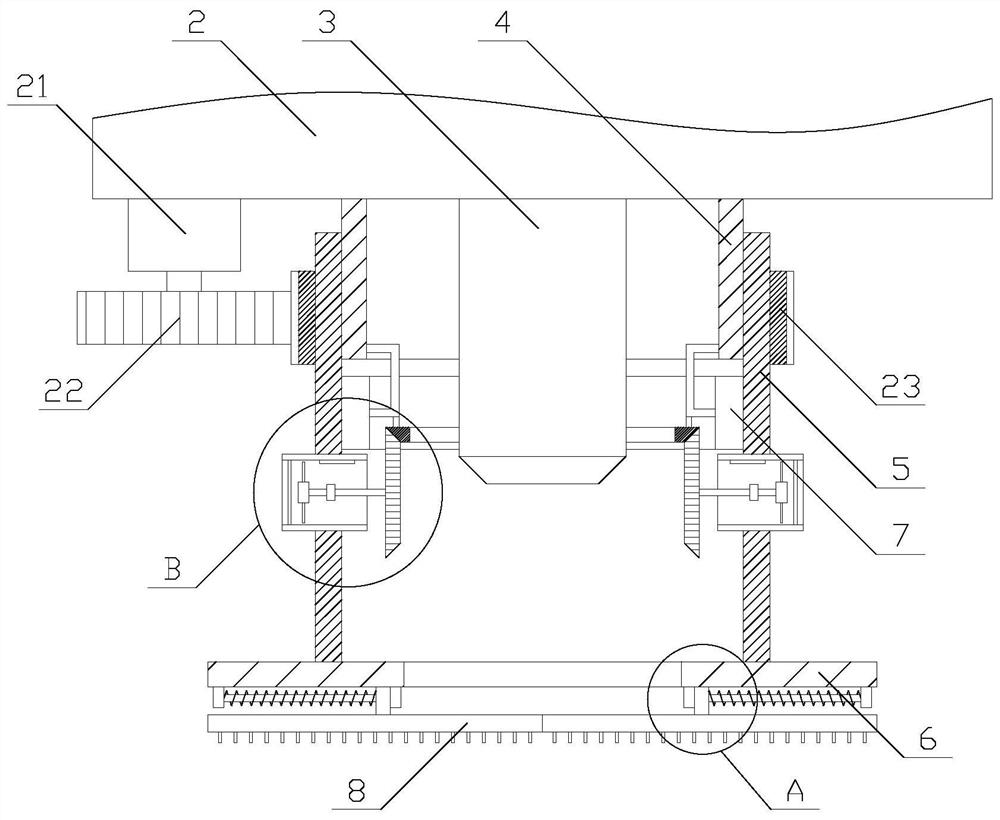

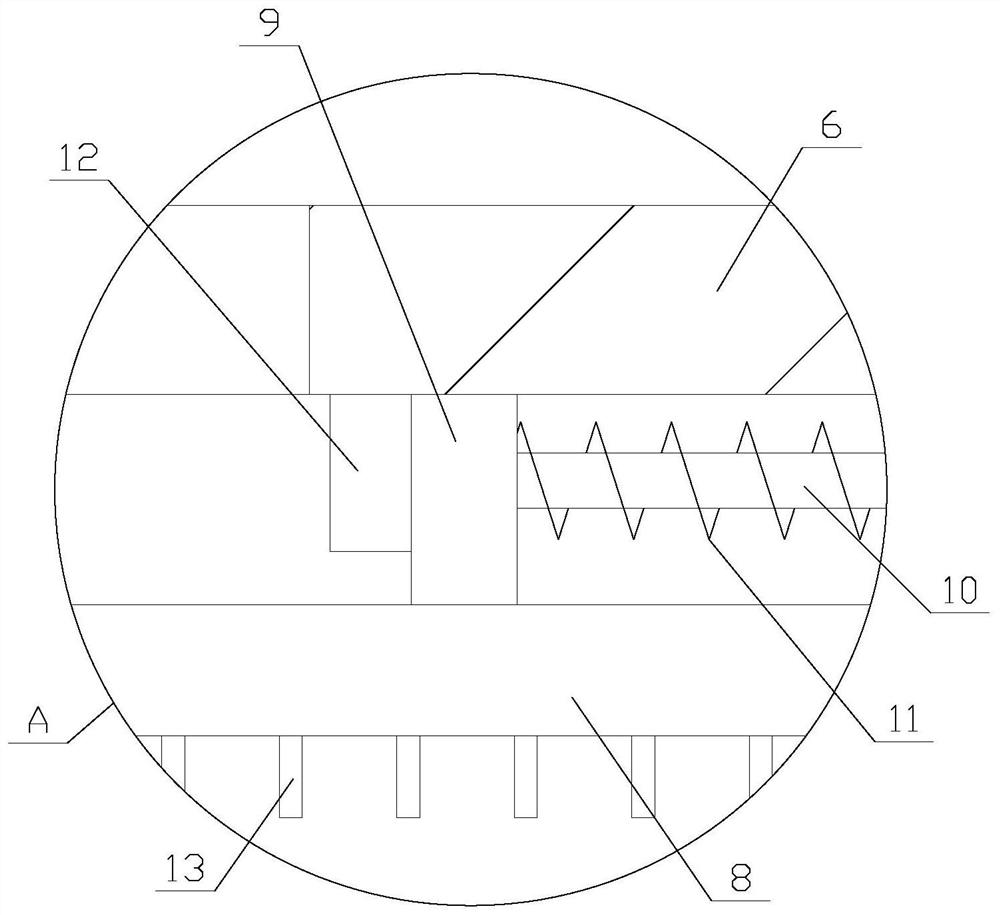

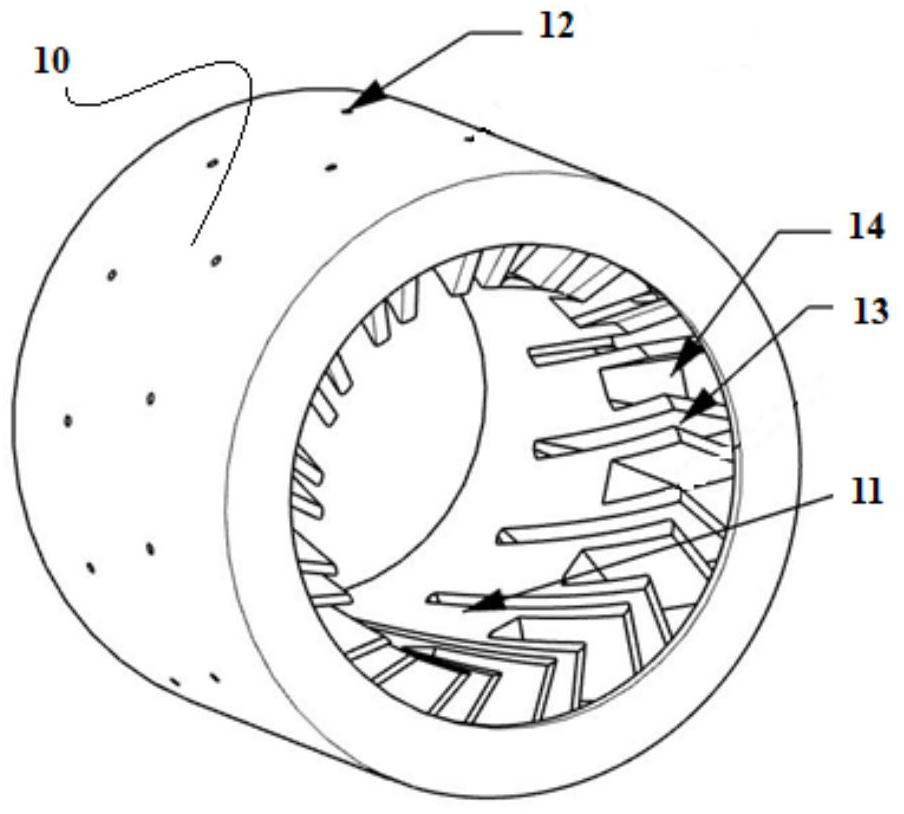

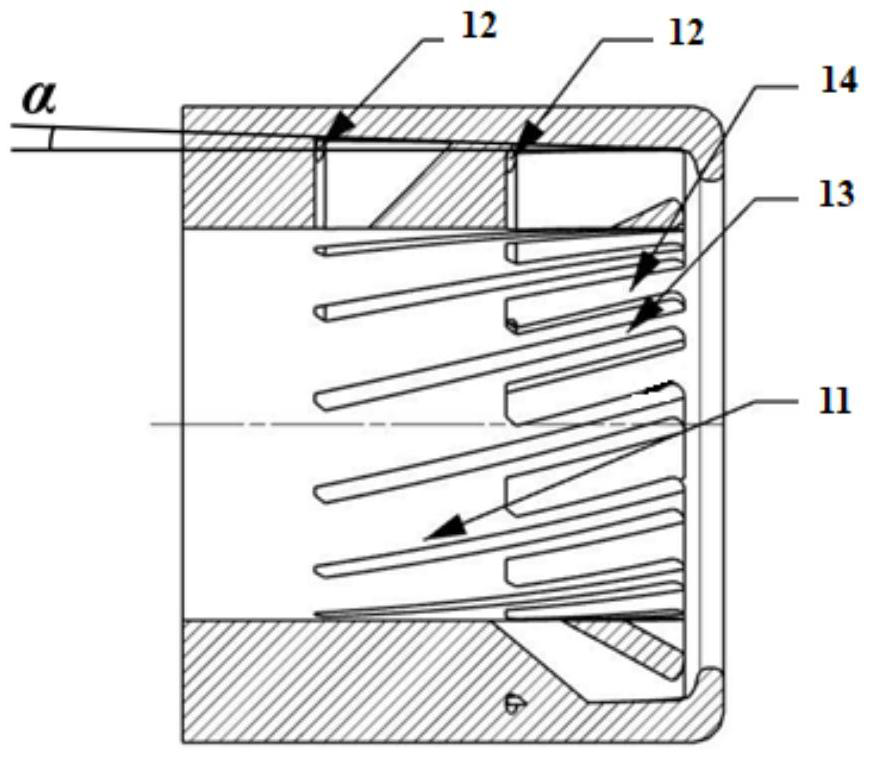

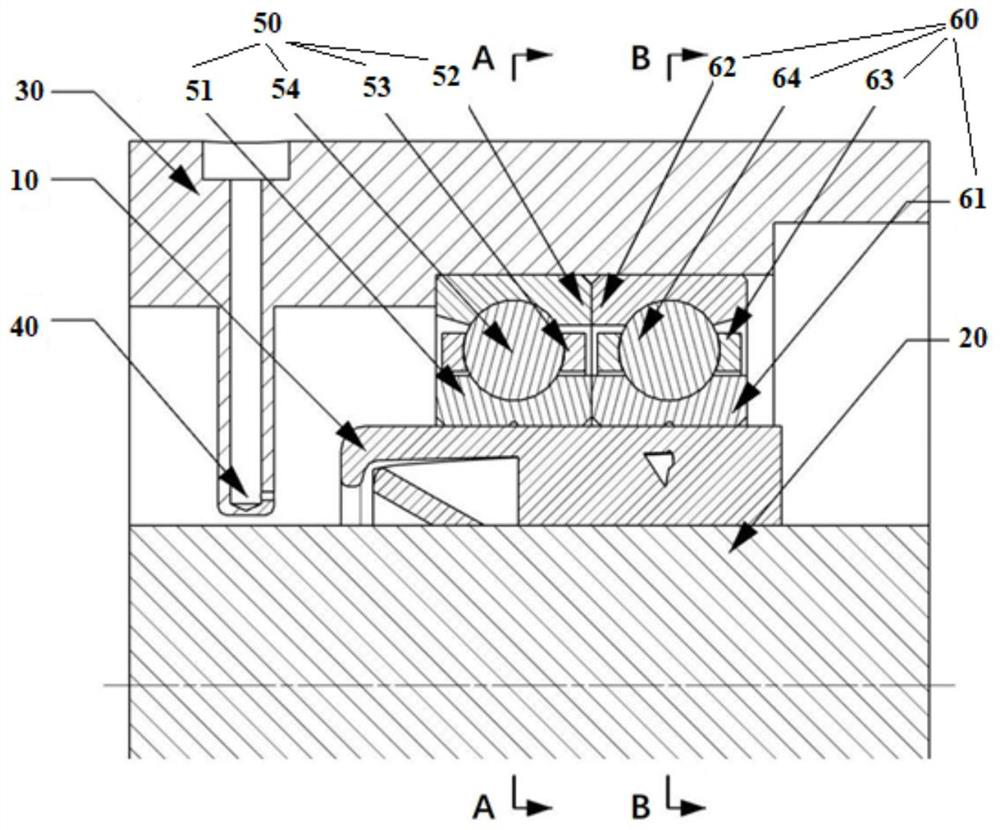

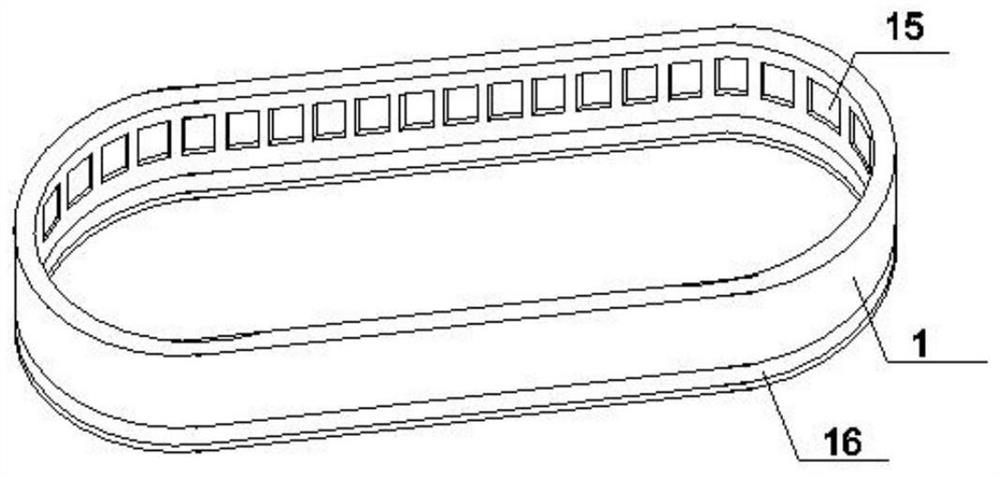

Axial oil collecting ring and inner-ring lubricating device and method of aviation engine main bearing

ActiveCN110748419AReduce the amount of splatterImprove oil recovery efficiencyTurbine/propulsion engine coolingTurbine/propulsion lubricationOil canAviation

The invention provides an axial oil collecting ring and an inner-ring lubricating device and method of an aviation engine main bearing. The axial oil collecting ring comprises a cylindrical oil collecting ring body, a plurality of oil collecting grooves arranged in the circumferential direction are formed in the inner wall of the oil collecting ring body, one end of each oil collecting groove penetrates to the opening of the oil inlet end of the oil collecting ring body to form an oil collecting inlet, and the other end of each oil collecting groove does not penetrate to form an oil collectingbaffle wall; an oil conveying hole penetrating through the wall surface of the oil collecting ring body is formed in the position, near the corresponding oil collecting baffle wall, of each oil collecting groove; the inner-ring lubricating device comprises the axial oil collecting ring, a main shaft, a bearing, a bearing seat sleeving the bearing and an oil supply nozzle which is arranged on thebearing seat and connected with an oil supply path and penetrates into the bearing seat; the axial oil collecting ring sleeves the main shaft, the bearing sleeves the axial oil collecting ring, and both the axial oil collecting ring and the bearing can rotate synchronously along with the main shaft. According to the axial oil collecting ring and the inner-ring lubricating device and method of theaviation engine main bearing, quantitative distribution of lubricating oil can be realized under high oil collection efficiency, lubrication and cooling requirements of high-speed rolling bearings aremet, and safety and reliability of the bearings are improved.

Owner:西安瑞谱捷特动力技术有限公司

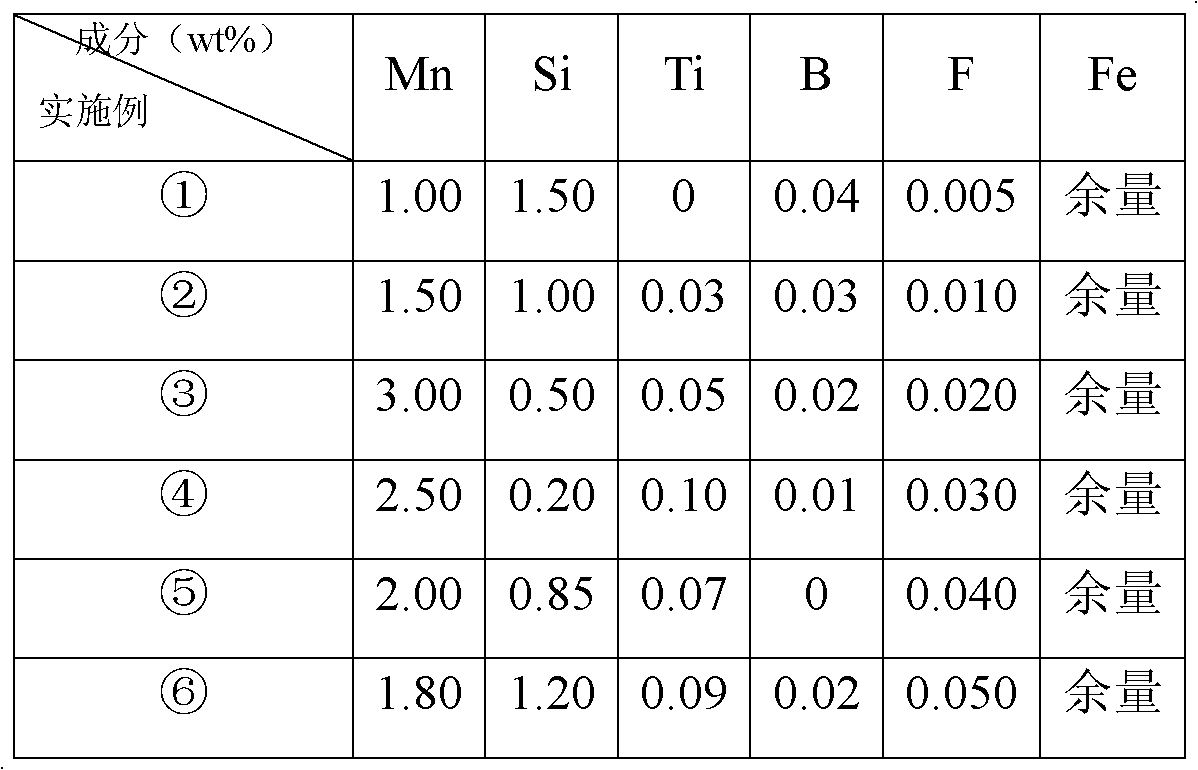

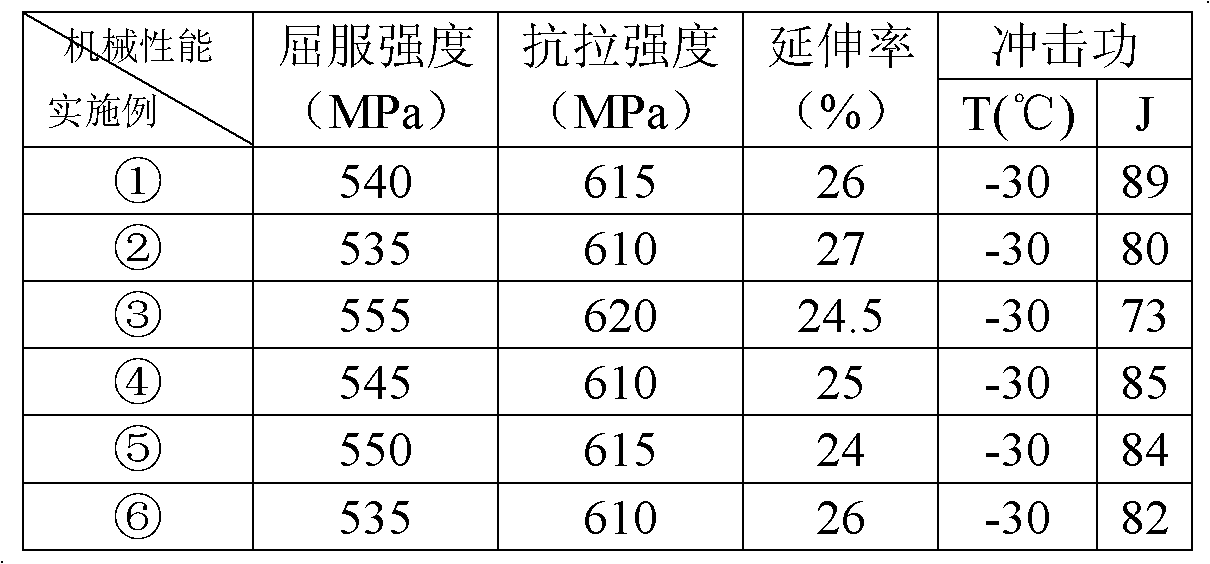

Metal powder flux-cored wire for high-strength steel

InactiveCN102554496AImprove purityImprove thermal cracking resistanceWelding/cutting media/materialsSoldering mediaSlagManganese

The invention discloses a metal powder flux-cored wire for high-strength steel, which comprises carbon steel sheath and a flux core with the filling ratio of 10-20%. The metal powder flux-cored wire is characterized in that in the overall weight percent of the wire, components in the flux core include 1.00-3.00% of Mn (manganese), 0.20-1.50% of Si (silicon), 0.005-0.050% of F (fluorine), 0-0.1% of Ti (titanium) and 0-0.004% of B (boron). The flux-cored wire is applicable to backing weld of the high-strength steel of an X80 pipeline, and when in welding, deposition efficiency is high, speed is high, arc is stable, splash is little, a welding bead is smooth and beautiful in appearance, and post-welding slag is little.

Owner:KUSN GINTUNE WELDING

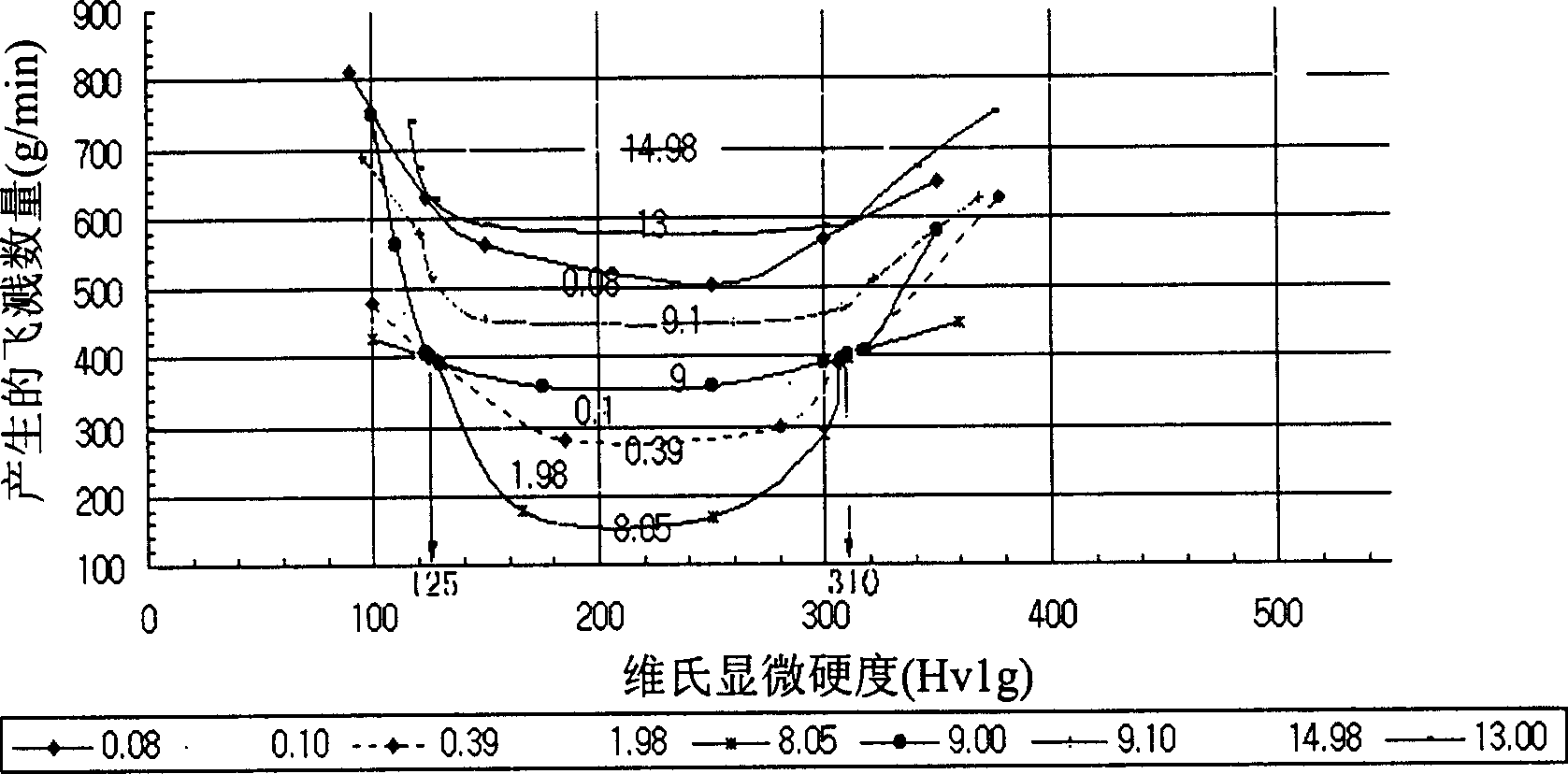

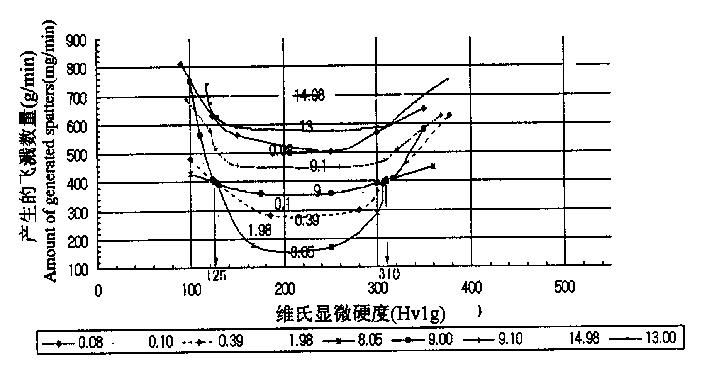

Copper-free wires for gas-shielded arc welding

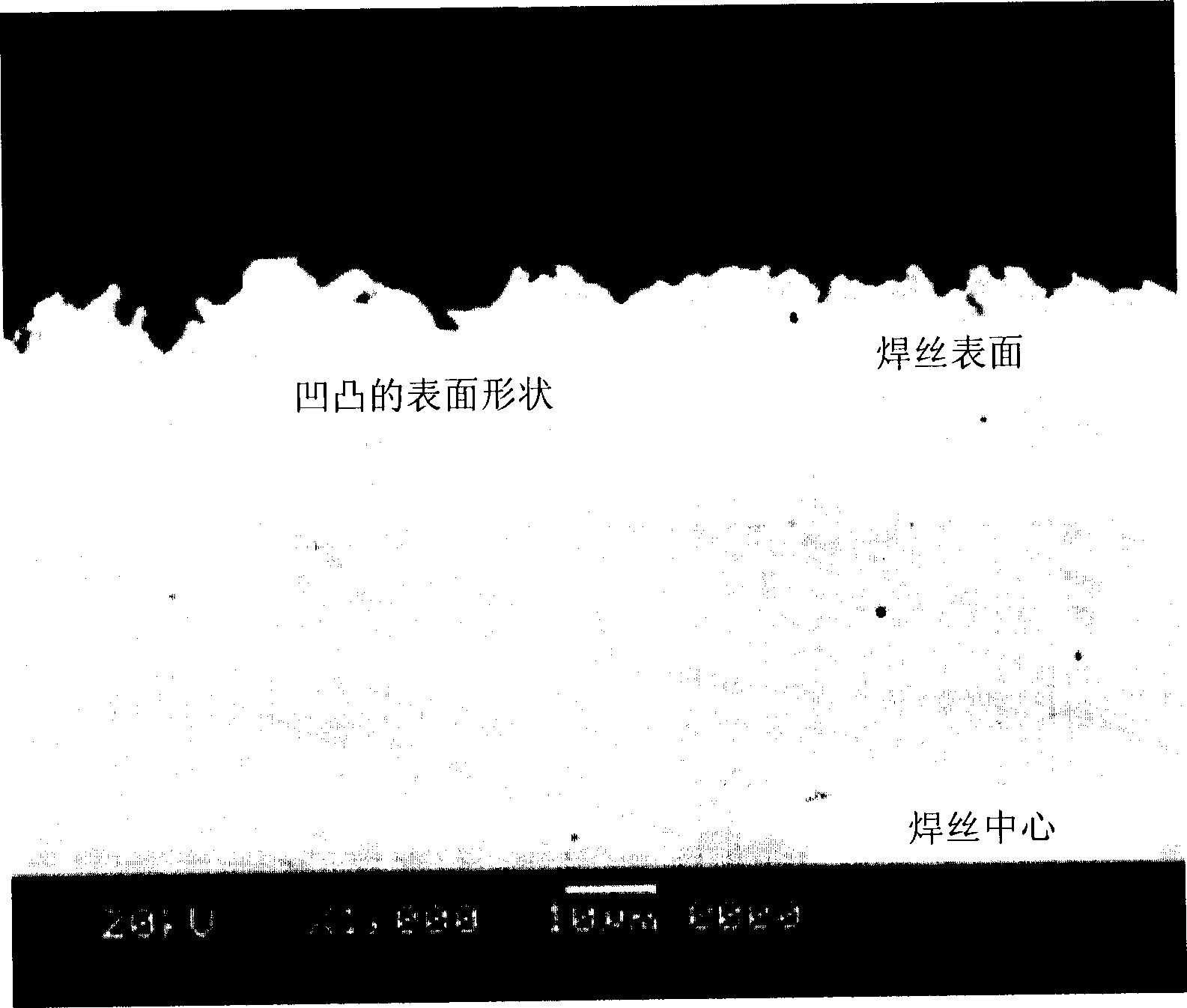

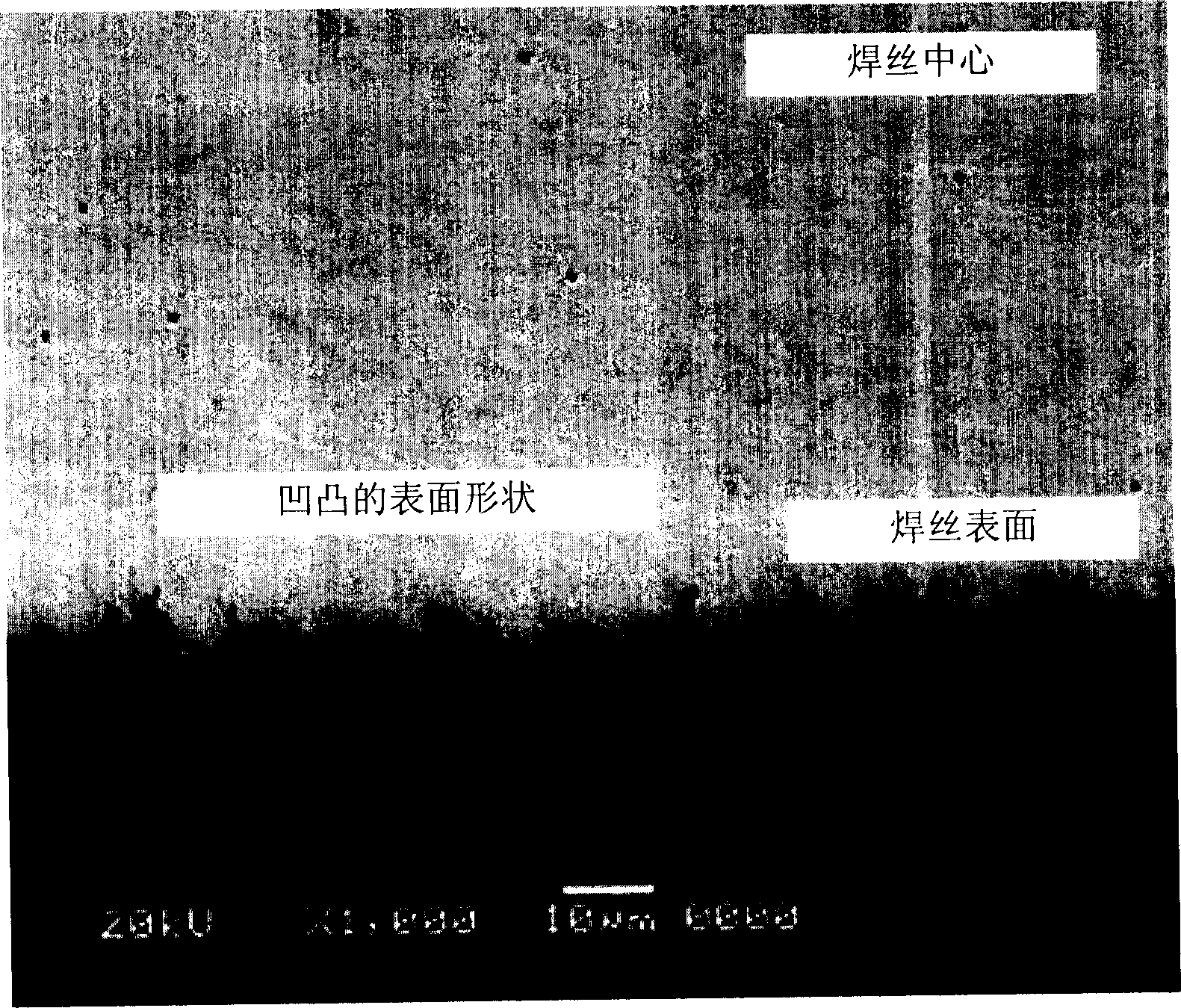

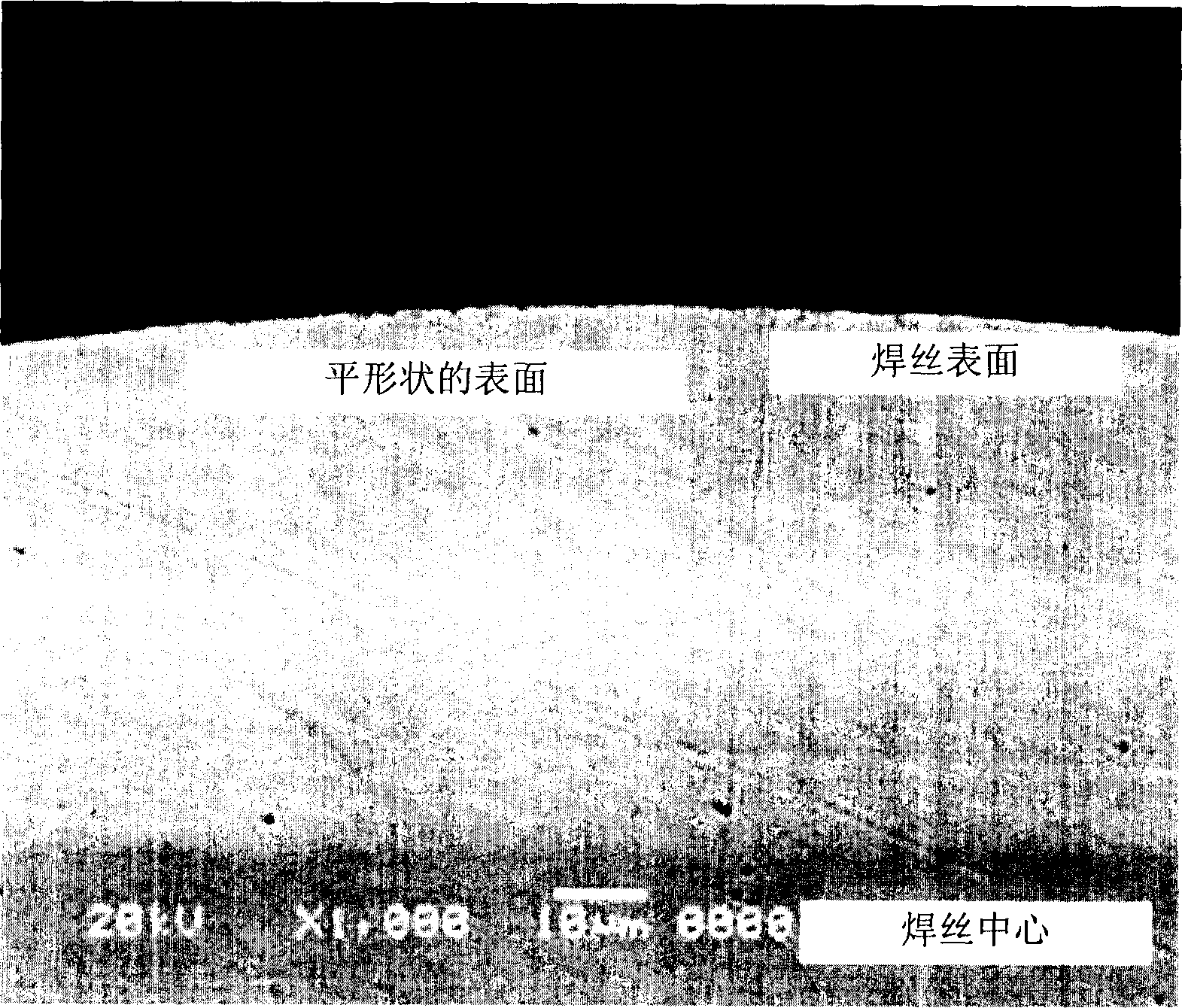

ActiveCN1781651AContact stabilityGuaranteed arc stabilityArc welding apparatusWelding/cutting media/materialsCopper platingArc stability

The invention relates to a copper-free welding wire for gas shielded arc welding. The copper-free wire for gas shielded arc welding includes a flat processed surface; and depressions formed circumferentially in a negative direction (toward the center of the wire) with respect to the processed surface reference. The ratio (dr / di) of the actual length (dr) of the arc to the apparent length (di) of the arc is within the range of 1.015-1.515. The lubricant residue on the wire surface is equal to or less than 0.50g / W.kg. The coating agent of the welding wire on the surface of the welding wire is 0.03-0.70g / W.kg. The coating agent includes at least one selected from the group consisting of liquid animal oil, vegetable oil, mineral oil, mixed oil and synthetic oil. The wire is in constant contact with the contact tip during welding, thus providing good arc stability and wire feedability while reducing the amount of spatter.

Owner:KISWEL LTD

Calcium silicon iron core-spun yarn core layer composition

The invention relates to a Si-Ca-Fe cored-wire sandwich layer combination, the combination is composed of calcium powder whose percentage by weight is 10%-60%, refining slag 40%-90% and ferrous powder 0-30%, wherein the refining slag can lower the vapor tension which is produced by calcium in the reaction process, lower the spraying amount of molten steel, and increase the utilization ratio, the refining slag adopts a calcium oxide and aluminum oxide slag system, which can exist in the molten steel in molten state, the concentration is smaller than that of the molten steel, inclusions are absorbed along the refining slag floats upward, which is very beneficial for purifying the molten steel, the ferrous powder not only can enlarge the specific weight of the cored-wire, which is beneficial for sinking the cored-wire, but also can play the role which is same with that of the refining slag, and the availability ratio of the calcium is further increased.

Owner:马长慧

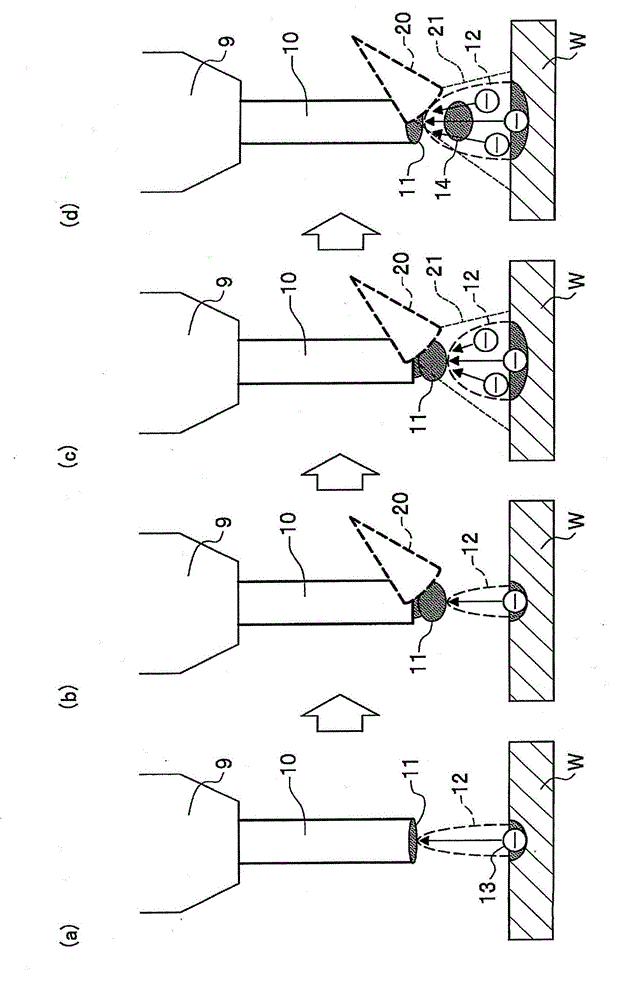

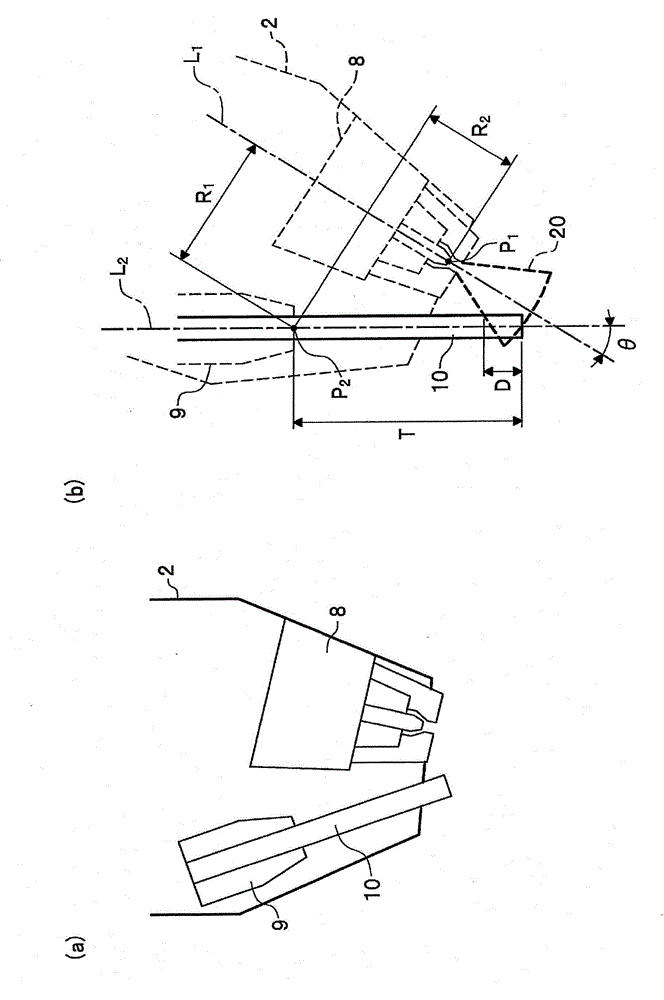

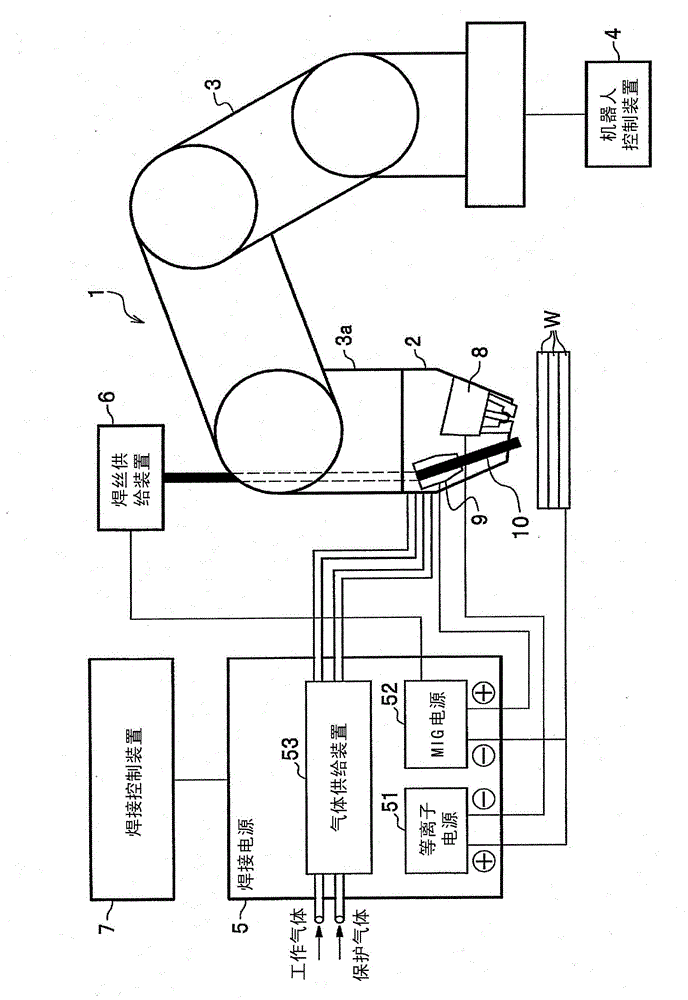

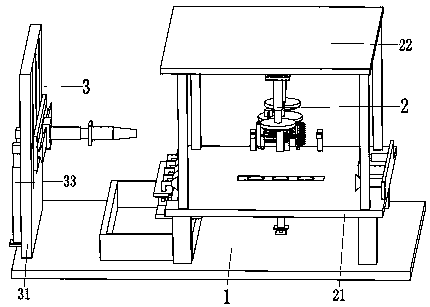

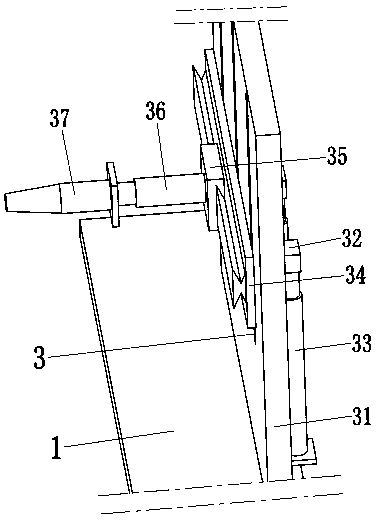

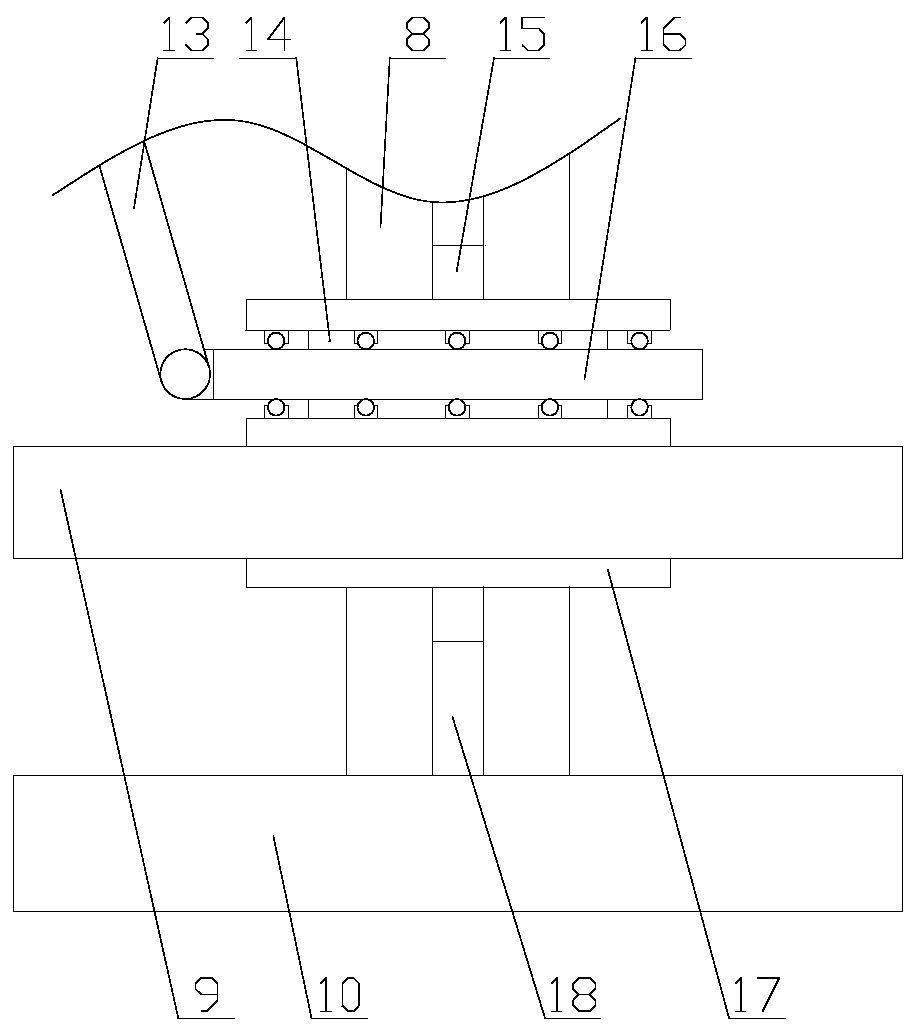

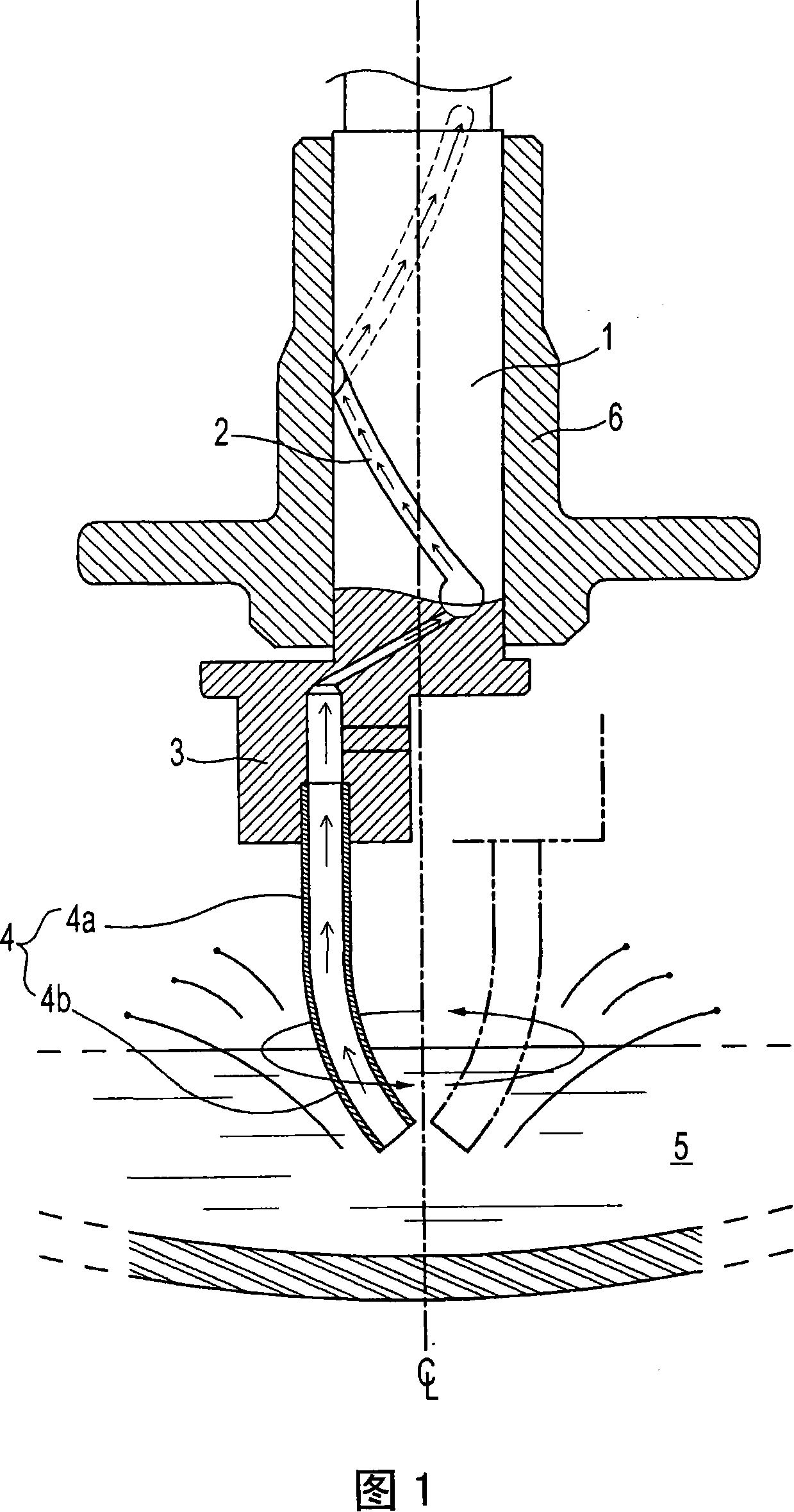

Plasma-mig welding method and welding torch

InactiveCN104136161AReduce the amount of splatterArc welding apparatusPlasma welding apparatusWelding power supplyEngineering

Provided are a plasma-MIG welding method and a welding torch that are capable of reducing spatter amount without relying on control of the MIG welding power supply. The plasma-MIG welding method employs a plasma-MIG welding device configured from: a plasma torch section that includes a plasma nozzle and a plasma electrode; and an MIG torch (9) that includes an MIG tip and a welding wire (10). The plasma torch section and the MIG torch (9) are arranged so as to face in different directions at a predetermined distance from one another. The plasma-MIG welding method is characterized in that a plasma arc (21) is made to overlap locally with the tip portion of the welding wire (10) in order to carry out heating, and in a state in which melting of the welding wire (10) has been promoted, MIG welding is carried out without short-circuiting between a workpiece (W) and the tip (11) of the welding wire (10), said welding wire (10) being a consumable electrode.

Owner:HONDA MOTOR CO LTD

Non copper plating solid welding wire used for carbon dioxide gas protective arc welding

InactiveCN1442270AReduce the amount of splatterImprove feedabilityWelding/cutting media/materialsSoldering mediaCopper platingCarbon dioxide

Owner:KISWEL LTD

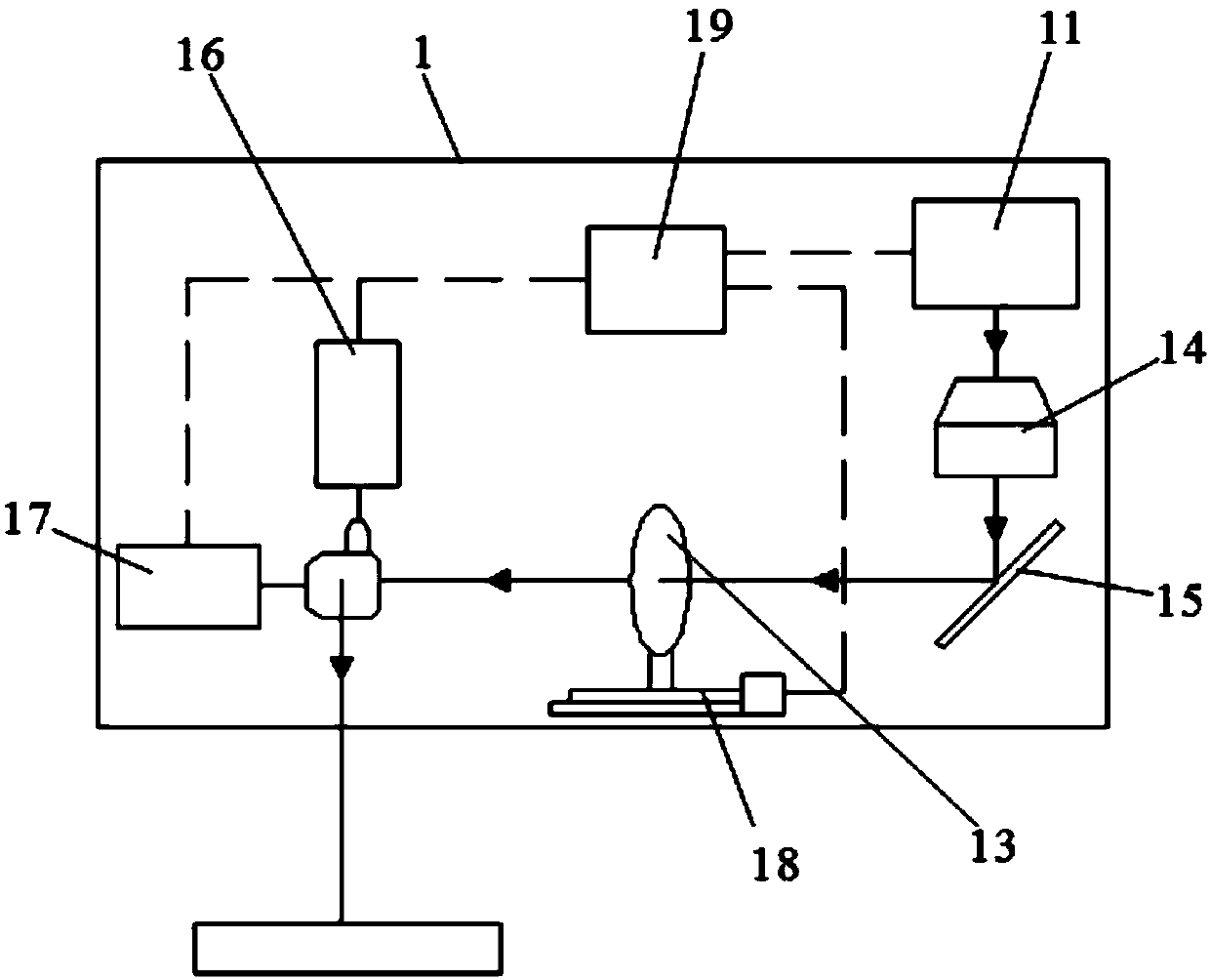

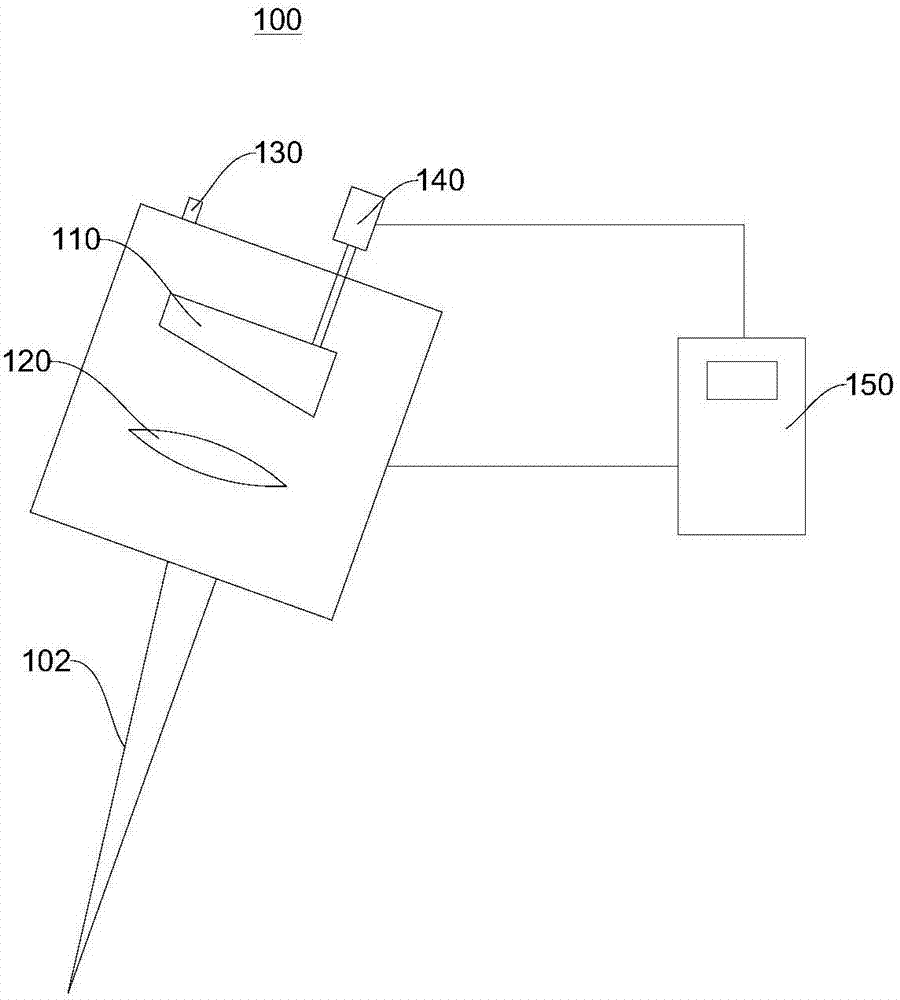

High-power laser welding system and method based on high-speed scanning galvanometer

PendingCN107584211AUniform shapeNo crackLaser beam welding apparatusHigh power lasersTransmitted power

The invention discloses a high-power laser welding system and method based on a high-speed scanning galvanometer. The system comprises a mechanical hand, a laser welding mechanism fixed to the movableend of the mechanical hand, a high-order shielding gas cutter located below the laser welding mechanism, a low-order shielding gas cutter located below the high-order shielding gas cutter and above the to-be-welded position, and a gas shielding device for blowing gas to the two sides of the to-be-welded position, and the laser welding mechanism comprises a laser with the transmitting power being5 KW or more, a collimating mirror, a 45-degree holophote, a focus lens moving in the laser beam direction, an X-axis scanning galvanometer, a Y-axis scanning galvanometer, a Z-axis driving mechanismfor driving the focus lens to move and a control device; the control device is electrically connected with the laser, the X-axis scanning galvanometer, the Y-axis scanning galvanometer and the Z-axisdriving mechanism, and the focal length of the focus lens is 300 mm or larger. The problems of aluminum alloy welding burst points, air holes, welding cracks and the like can be solved, and aluminum alloy welding lines with the high strength, deep welding penetration and stable welding width are obtained.

Owner:SUZHOU QUICK LASER TECH

Cored wire core compound and its manufacture method

InactiveCN101060022ALow vapor pressureIncrease profitConductive materialCable/conductor manufactureYarnAluminate

The related core compound of core-spun yarn comprises calcium powder, calloy powder and calcium aluminate, wherein the preparation method including: mixing the lime powder and aluminum particle, and vacuum refining. The elemental calcium and calcium-aluminum alloy have high melting point and density fit to reduce the vapor pressure and decrease the molten steel splash. Specially, the calcium aluminate exists in molten steel as molten state, and has less density than the molten steel to adsorb the impurity for cleaning the molten steel.

Owner:马长慧

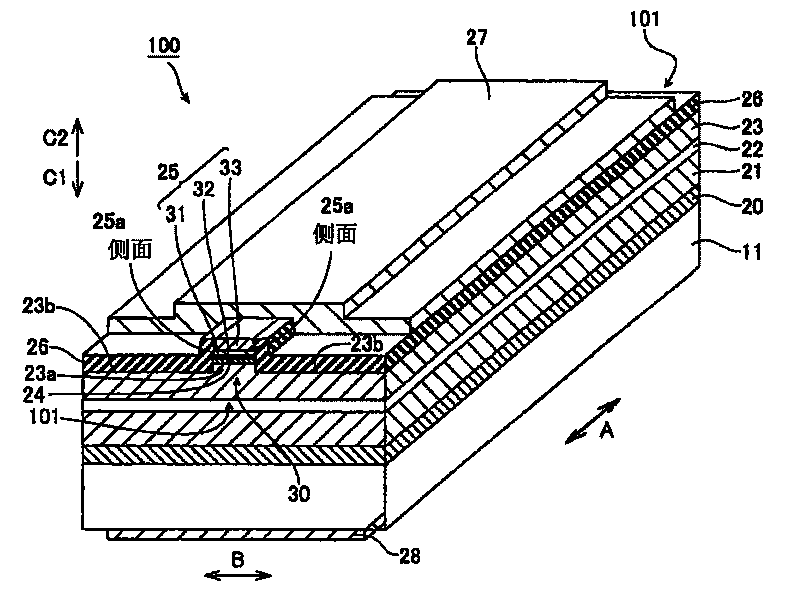

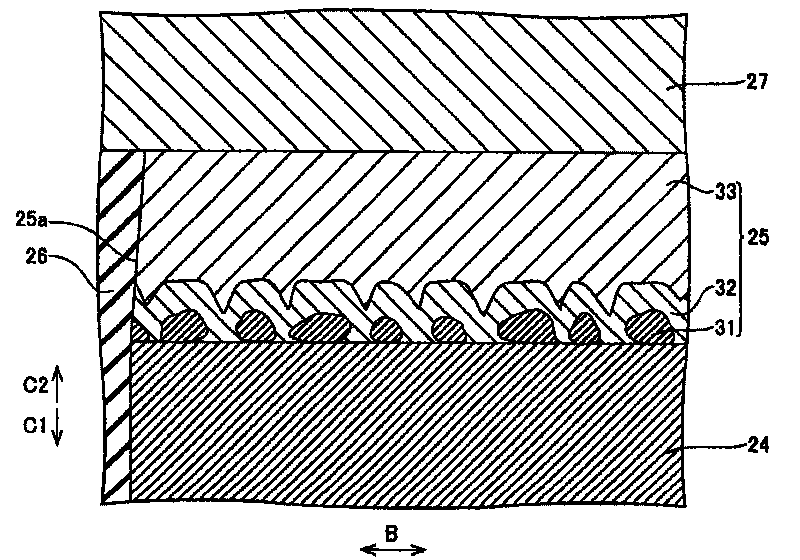

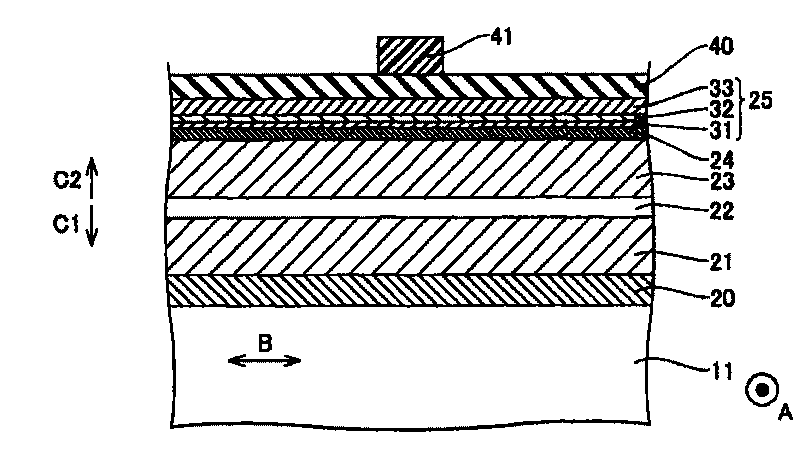

Nitride-based semiconductor laser device and method of manufacturing the same

InactiveCN101714743AReduce the amount of splatterReduce formationOptical wave guidanceLaser detailsActive layerNitride

A nitride-based semiconductor laser device includes a nitride-based semiconductor layer formed on an active layer made of a nitride-based semiconductor, and an electrode layer including a first metal layer, made of Pt, formed on a far side of a surface of the nitride-based semiconductor layer from the active layer, a second metal layer, made of Pd, formed on a surface of the first metal layer, and a third metal layer, made of Pt, formed on a surface of the second metal layer, and having a shape necessary for the device in plan view. A thickness of the third metal layer is at least 10 times and not more than 30 times a thickness of the first metal layer.

Owner:SANYO ELECTRIC CO LTD

A medical tray disinfection instrument for hospital nursing department

InactiveCN108580368BEasy to scrubImprove scrubbing effectCleaning using toolsCleaning using liquidsNursing careSewage

Owner:THE AFFILIATED HOSPITAL OF QINGDAO UNIV

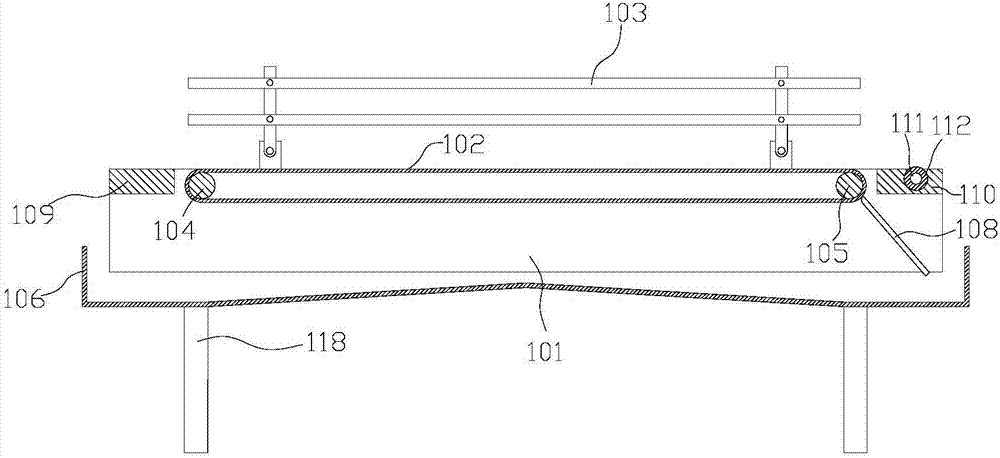

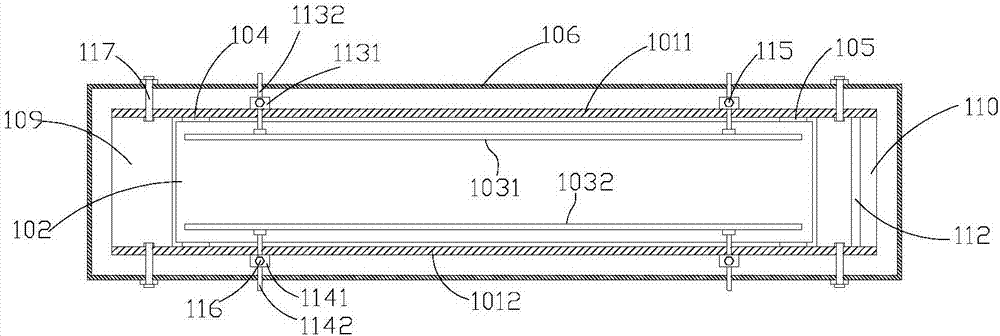

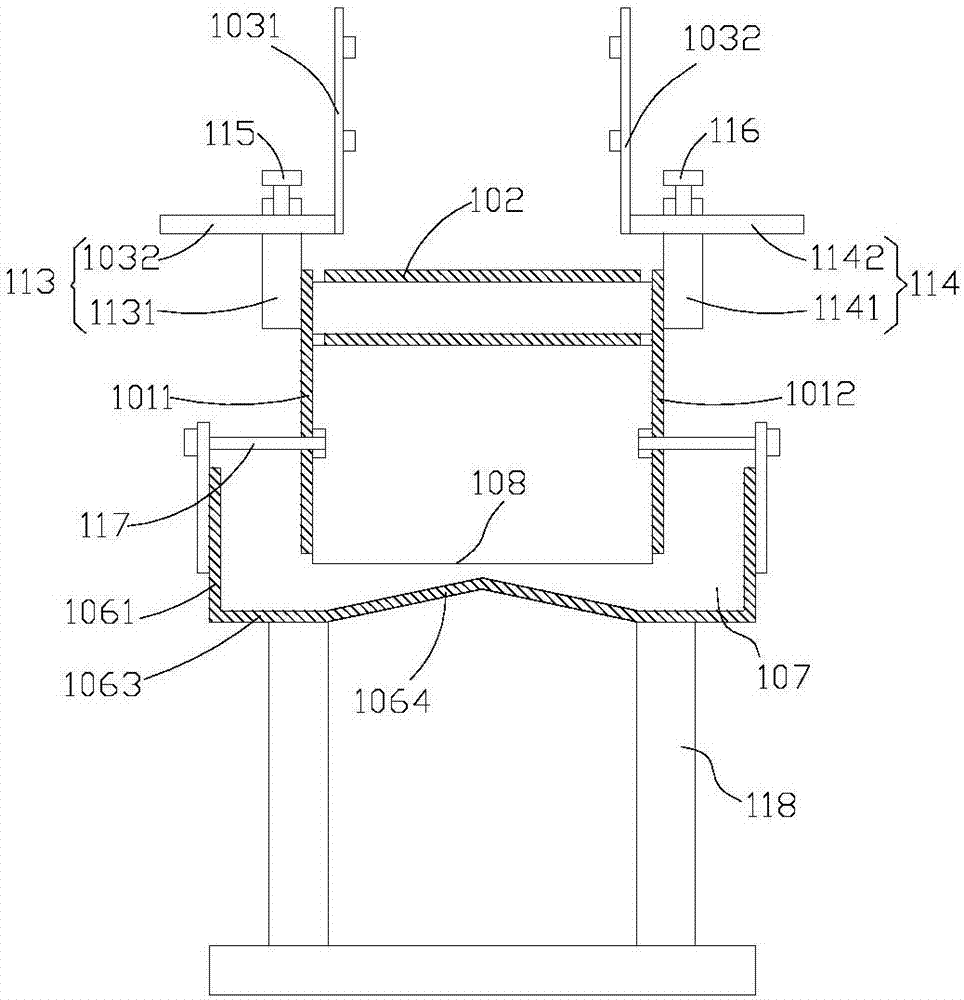

Conveying device

InactiveCN107336952AReduce the amount of splatterPlay a protective effectConveyorsCleaningEngineeringBottle

The invention discloses a conveying device and belongs to the field of medicament bottle production auxiliary devices. The conveying device comprises a machine frame, a conveyer belt and a guardrail. The machine frame is provided with a front roller and a back roller. The front roller and the back roller are connected through the conveyer belt. The guardrail comprises a left guardrail body and a right guardrail body which are in parallel. The left guardrail body and the right guardrail body are arranged on the two sides of the machine frame in the width direction. The machine frame is provided with a recycling box used for recycling medicament bottles. The top of the recycling box is provided with an opening. The recycling box is located below the conveyer belt. After the recycling box is arranged on the machine frame, the medicament bottles fallen onto the conveyer belt can fall into the recycling box, the recycling box can recycle the medicament bottles, the recycled medicament bottles can be utilized again, and therefore the conveying device is economical and environmentally friendly.

Owner:NINGBO HONGKUN ELECTRIC APPLIANCE CO LTD

Automatic nanometer material production equipment

InactiveCN110652915AReduce the amount of splatterReduce lossRotary stirring mixersTransportation and packagingDrive shaftElectric machinery

The invention relates to automatic nanometer material production equipment. The automatic nanometer material production equipment comprises a base, a main body, a driving shaft and a second stirring disc, and also comprises an anti-splashing mechanism and a mixing mechanism; the anti-splashing mechanism comprises a first driving assembly, a first transmission rod, a cover plate, two supporting sleeves and two lifting rods; the mixing mechanism comprises a storage groove, a second driving assembly, a connecting rod, a lifting ring, a rotating sleeve, a first stirring disc, a limiting assembly and an annular groove; the first driving assembly comprises a first motor, a second transmission rod and a third transmission rod; the second driving assembly comprises a second motor, a screw rod anda moving block; the limiting assembly comprises a limiting groove and a limiting block. In the automatic nano-material production equipment, a container for containing raw materials can be covered bythe anti-splashing mechanism, so that the splashing quantity of the raw materials in the working process of a dispersion machine is reduced, the loss of the raw materials is reduced, the stirring range of the dispersion machine is expanded by the mixing mechanism, and the dispersion effect of the dispersion machine is improved.

Owner:南京思甲宁新材料科技有限公司

Soldering tin preheating principle and application

The invention discloses a soldering tin preheating principle and application. According to the invention, a bonding wire comprises a solder layer and scaling powder arranged in the solder layer, the soldering tin preheating principle is applied to carry out preheating treatment on solder before soldering iron is used for welding tin at a high temperature, and enables the solder to become the soft state after preheating from the solid state before preheating; after the solder layer and the scaling powder arranged in the solder layer are preheated, the solder layer is enabled to become soft from the solid state, and during the high-temperature welding process, the soft solder layer relieves the sharp expansive force of the scaling powder, weakens the power of welding spot explosion caused by instantaneous, rapid and sharp heated expansion of the scaling powder during the welding process, and reduces the phenomenon that welding spot explosion generates tin balls, and the tin balls splash to the surfaces of electronic elements to cause a short circuit. The preheating time, the temperature, the supply current and the power-on or power-off states can be intelligently controlled according to the production demands, the intelligent operation degree is high, the tin ball splashing quantity during welding spot explosion can be controlled and greatly reduced, the operation is very safe, the yield of the electronic elements is high, the quality effect is excellent, and the production cost is lowered.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

Method for eliminating laser welding pores of aluminum-lithium alloy T-shaped joint

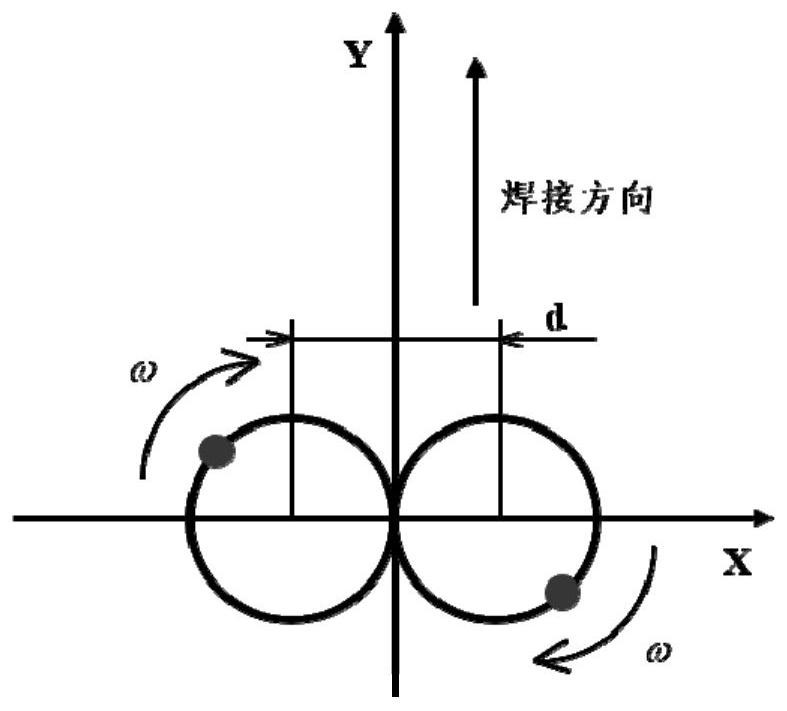

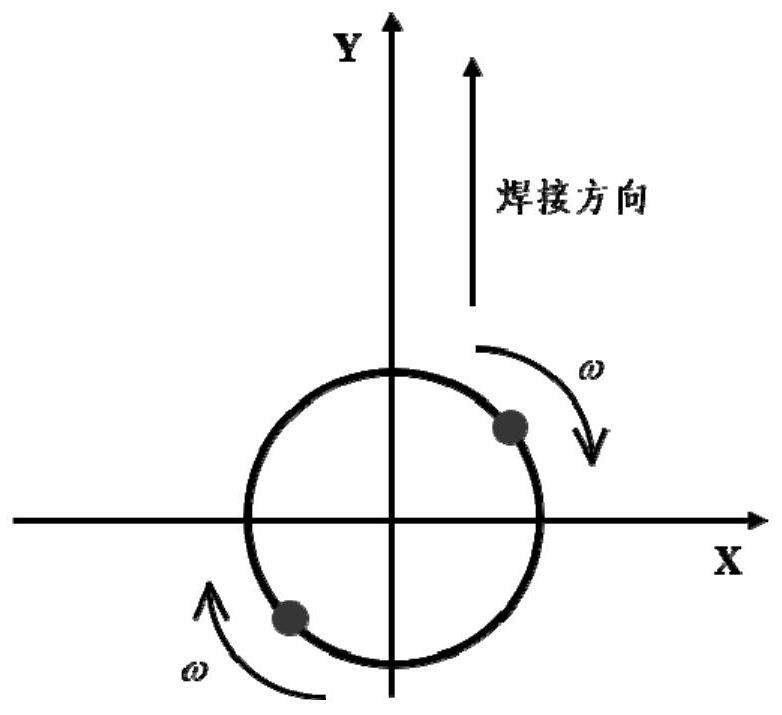

The invention discloses a method for eliminating laser welding pores of an aluminum-lithium alloy T-shaped joint, and relates to the field of material processing engineering. The method aims at solving the problem that pores are prone to occurring in the laser welding process of the aluminum-lithium alloy T-shaped joint. According to the method, a double-beam rotary laser welding head is adopted to realize the rotary motion of double light beams through an internal lens module, and the rotary motion can comprise the rotary motion of the double light beams around a self-axis and the rotary motion of the double light beams around a revolution axis; the rotating double light beams enable a keyhole to be more stable to a certain extent, and the keyhole is relatively not prone to being closed;meanwhile, the collapse of a keyhole wall is avoided due to the rotation effect of the double light beams, so that the formation of process pores is reduced; active regulation and control of molten drop transition can be realized through high-frequency rotation of two beams of laser during double-beam rotary laser welding; and meanwhile, the rotating laser beam can refine grains, so that the mechanical property of the aluminum-lithium alloy T-shaped joint is improved. The method is applied to the field of welding.

Owner:HARBIN INST OF TECH

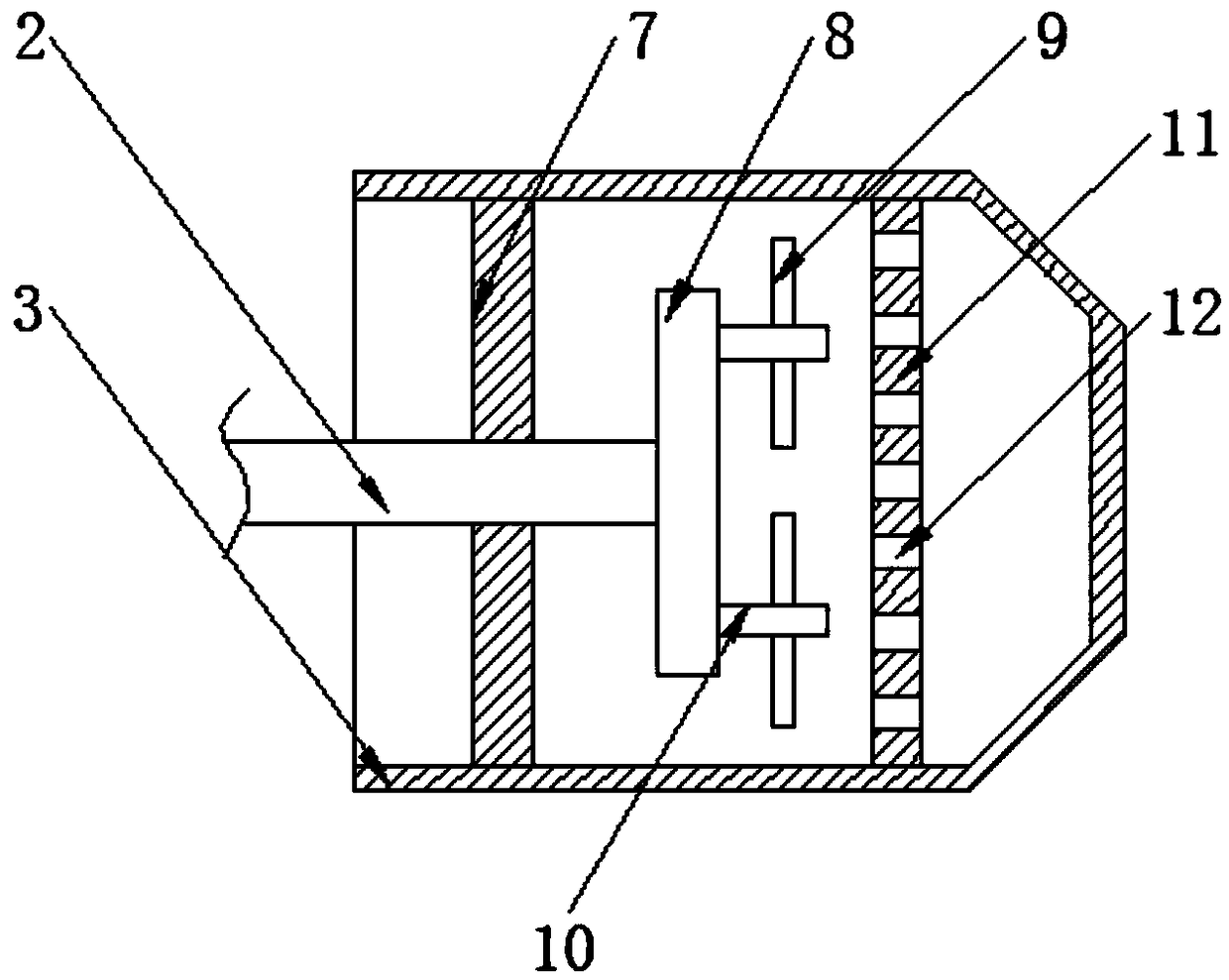

Aluminum alloy produced with metal casting technology and ingot casting method

The invention discloses an aluminum alloy produced with a metal casting technology and an ingot casting method. The aluminum alloy is prepared from components in percentage by weight as follows: 4%-12% of Si, 4%-6% of Fe, 1%-3% of Ni, 3%-5% of V, 2%-6% of V, 2%-6% of Na, 2%-6% of Mg, 1%-3% of Bi and the balance of Al and 0.5%-1% of impurities. The ingot casting method comprises the steps as follows: S1, Si, Fe, Ni, V, Mg, Al and impurities are all put into a furnace, refining is performed after smelting, aluminum ash on the surface of molten aluminum in the furnace is thoroughly stripped afterrefining, the site is cleared, a furnace door is closed after slagging off, any other operation on the molten aluminum in the furnace is prevented, and the molten aluminum is left to stand for 15 min. The effects of increasing tensile strength and hardness are realized, the discharging speed of the molten aluminum can be decreased, the splash amount can be reduced, and meanwhile, the molten aluminum can be fully contacted during discharging and cannot cake.

Owner:广东华劲金属型材有限公司

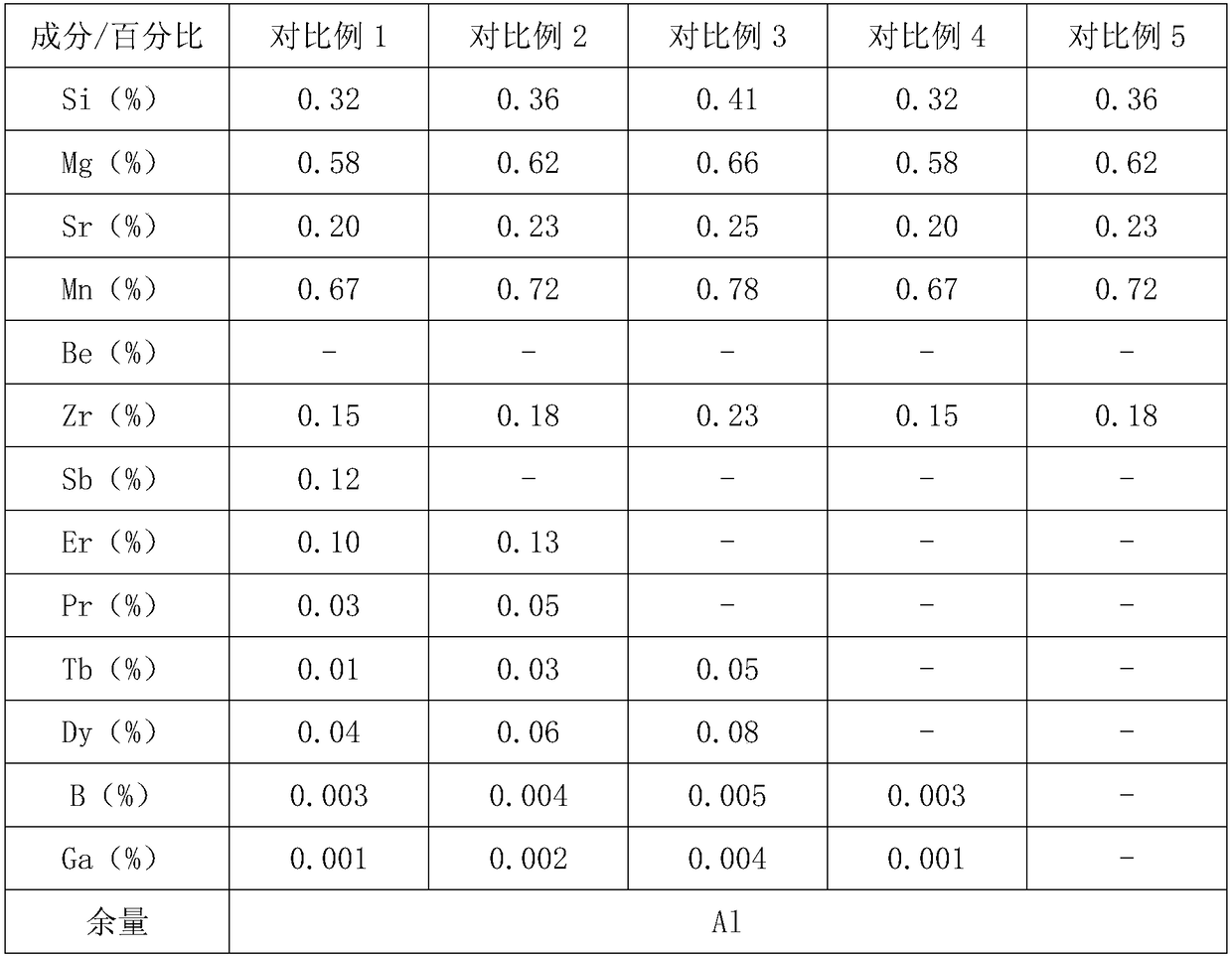

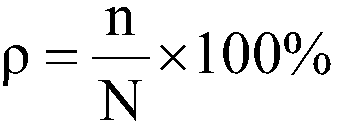

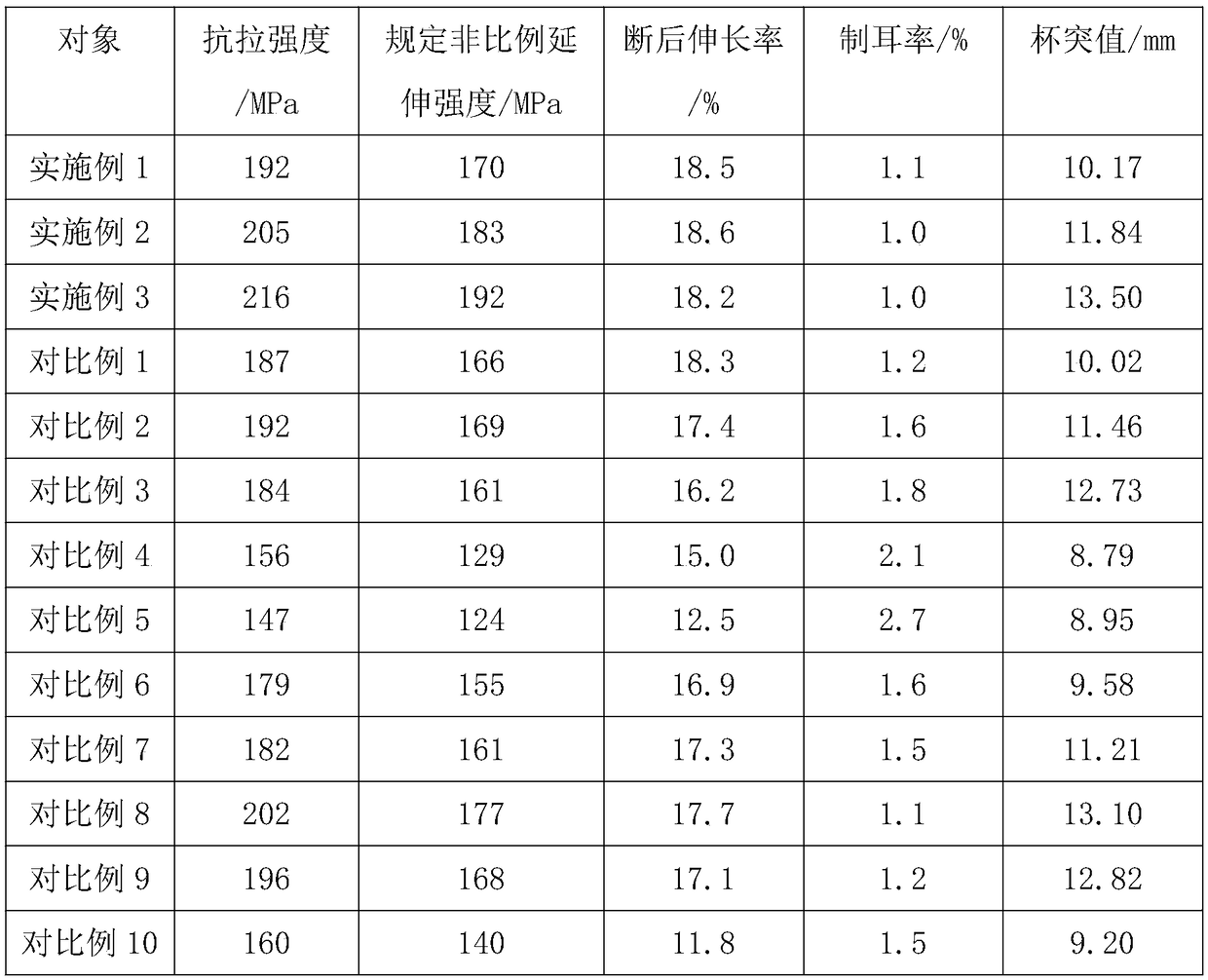

Aluminum alloy material for new energy power battery shells and covers and application of aluminum alloy material

InactiveCN109371294AImprove mechanical propertiesHigh outburstJackets/cases materialsPower batteryNew energy

The invention discloses an aluminum alloy material for new energy power battery shells and covers and application of the aluminum alloy material, and relates to the technical field of new energy batteries. The aluminum alloy material is composed of following element components including Si, Mg, Sr, Mn, Be, Zr, Sb, Er, Pr, Tb, Dy, B, Ga and Al. An aluminum alloy for the new energy power battery shells and covers is excellent in comprehensive performance; the components, content and preparation process of the aluminum alloy are overall improved and optimized, the application performance of prepared new energy power battery shell and cover products is improved remarkably, substantive breakthroughs are achieved especially on the index aspects of tensile strength, prescribed non-proportional extension strength, percentage elongation after fracture, stability, punching performance and welding performance, and the application occasion and field are wide; and the active demands of the new energy market for high-performance power battery cover and shell products can be greatly met.

Owner:合肥天沃能源科技有限公司

Steel wire for carbon dioxide shielded arc welding and welding process asing the same

InactiveCN1254348CAchieve Jet TransitionGood effectArc welding apparatusWelding/cutting media/materialsRare-earth elementShielding gas

In carbon dioxide gas-shielded arc welding using a shielding gas composed of carbon dioxide as a main component, a welding wire is proposed which makes jet transfer of molten droplets possible and provides excellent bead shape, and a welding method using this wire is proposed. As a specific method, a welding wire according to the present invention is used, which comprises a steel rod containing 0.003-0.20% by mass of C, 0.05-2.5% by mass of Si, 0.25-3.5% by mass of Mn, 0.015-0.100% by mass of rare earth elements , 0.001-0.05% by mass of P, 0.001-0.05% by mass of S, Fe and unavoidable impurities, and may also contain 0.0100% by mass or less of O, or 0.02-0.50% by mass of Ti, 0.02-0.50% by mass of One or more elements in Zr and 0.02-3.00% by mass of Al.

Owner:JFE STEEL CORP

Welding device with air purification function

InactiveCN111872553APlay a warm-up effectAvoid burnsLaser beam welding apparatusEngineeringErbium lasers

The invention relates to a welding device with an air purification function. The device comprises a workbench, a control box and a laser device, wherein the control box is arranged above the workbenchand fixedly connected with the workbench, the laser device is arranged at the bottom of the control box, an execution system is arranged in the control box, and a purification mechanism and an auxiliary mechanism are arranged at the bottom of the control box; the auxiliary mechanism comprises a fixed pipe, a rotating pipe, a rotating ring, a first bearing, a driving assembly and two auxiliary assemblies; each auxiliary assembly comprises a cleaning rod, a sliding block, a supporting rod, a spring and two fixed blocks; and the purification mechanism comprises a fixed bevel gear and two purification assemblies. According to the welding device with the air purification function, the function of removing impurities on a workpiece is achieved through the auxiliary mechanism, so that the welding effect is prevented from being affected by the impurities; and in addition, the air purification function is achieved through the purification mechanism.

Owner:GUANGZHOU LINDIAN TECH CO LTD

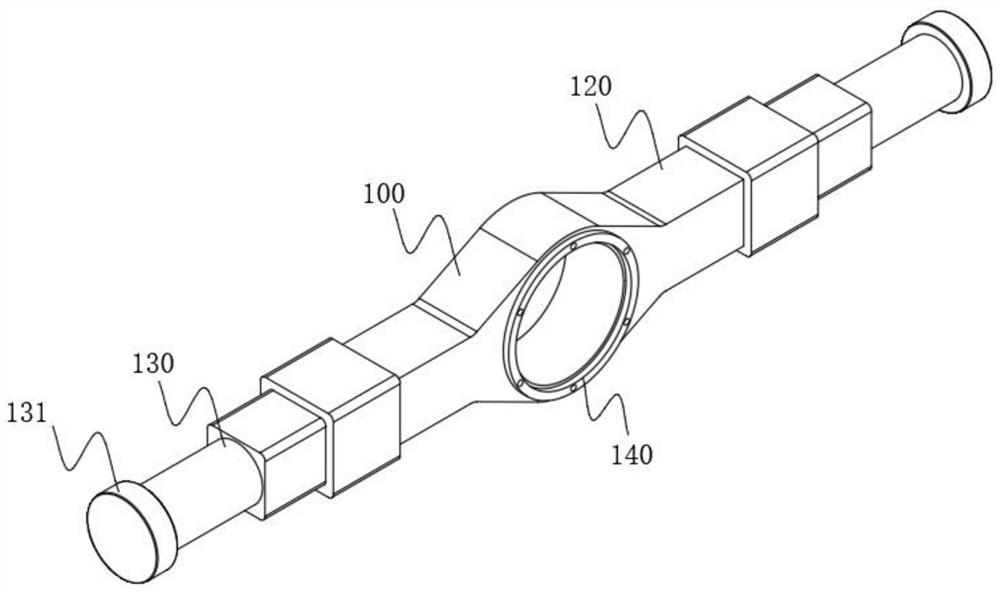

Lubricating device and method for an axial oil collector ring and an aeroengine main bearing ring

ActiveCN110748419BReduce the amount of splatterImprove oil recovery efficiencyTurbine/propulsion engine coolingTurbine/propulsion lubricationAviationRolling-element bearing

The invention provides an axial oil collector ring and an aeroengine main bearing ring lubricating device and method. The axial oil collector ring includes a cylindrical oil collector ring body. Arranged oil collection grooves, and one end of the oil collection groove is connected to the opening of the oil inlet end of the oil collection ring body to form an oil collection inlet, and the other end of the oil collection groove is not connected to form an oil collection retaining wall; The bottom of the oil tank is provided with an oil delivery hole through the wall of the oil collection ring body; the under-ring lubricating device includes an axial oil collection ring, a main shaft, a bearing, a bearing seat set outside the bearing, and a bearing seat set on the bearing seat and connected to the oil supply circuit. The oil supply nozzle penetrates into the bearing seat; the axial oil collector ring is sleeved on the main shaft, the bearing is sleeved on the axial oil collector ring, and both the axial oil collector ring and the bearing can rotate synchronously with the main shaft. The invention can realize quantitative distribution of lubricating oil under high oil collection efficiency, meet the lubricating and cooling requirements of high-speed rolling bearings, and improve the safety and reliability of the bearings.

Owner:西安瑞谱捷特动力技术有限公司

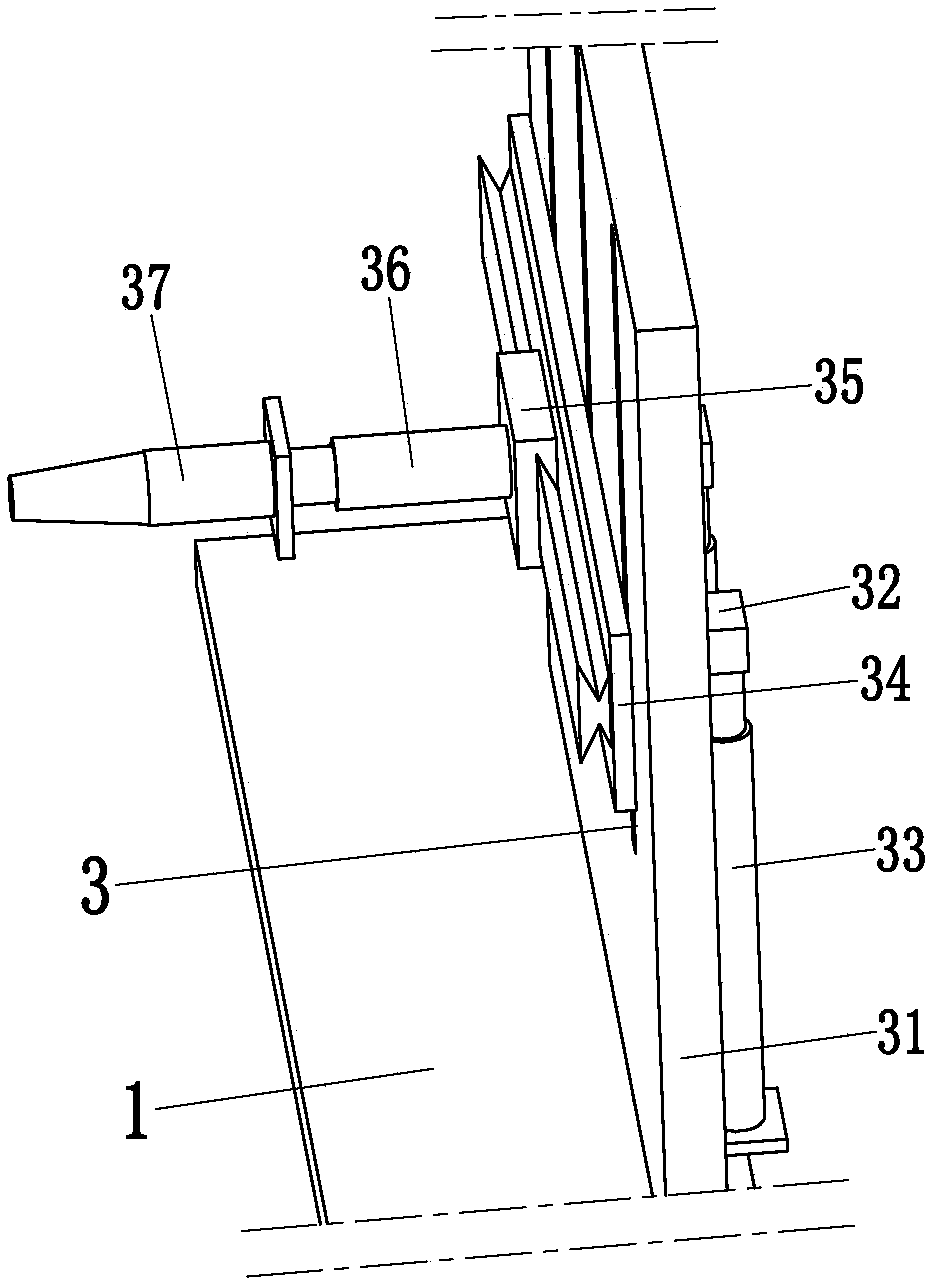

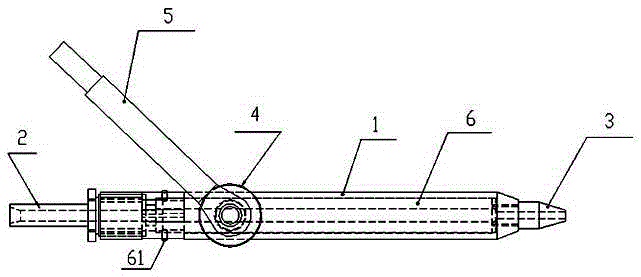

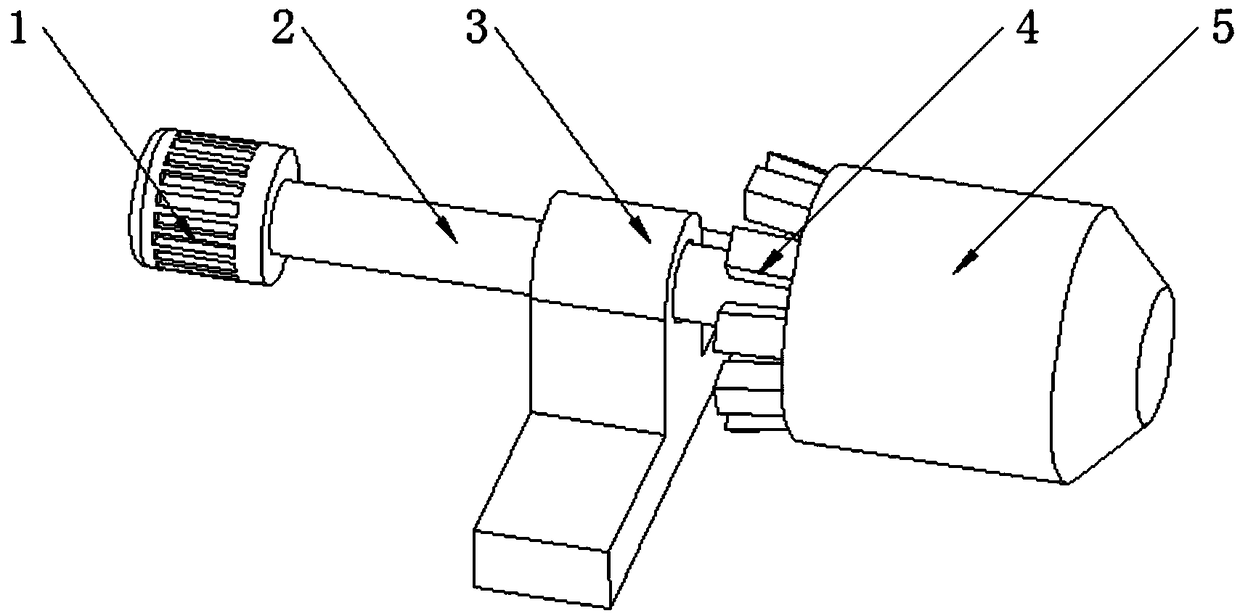

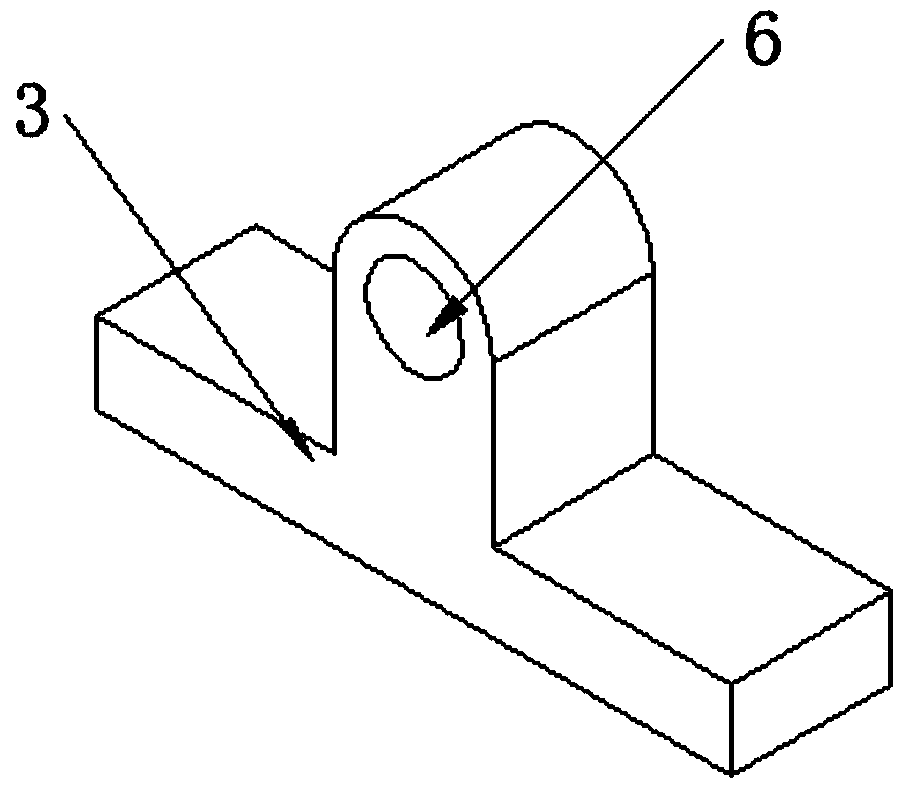

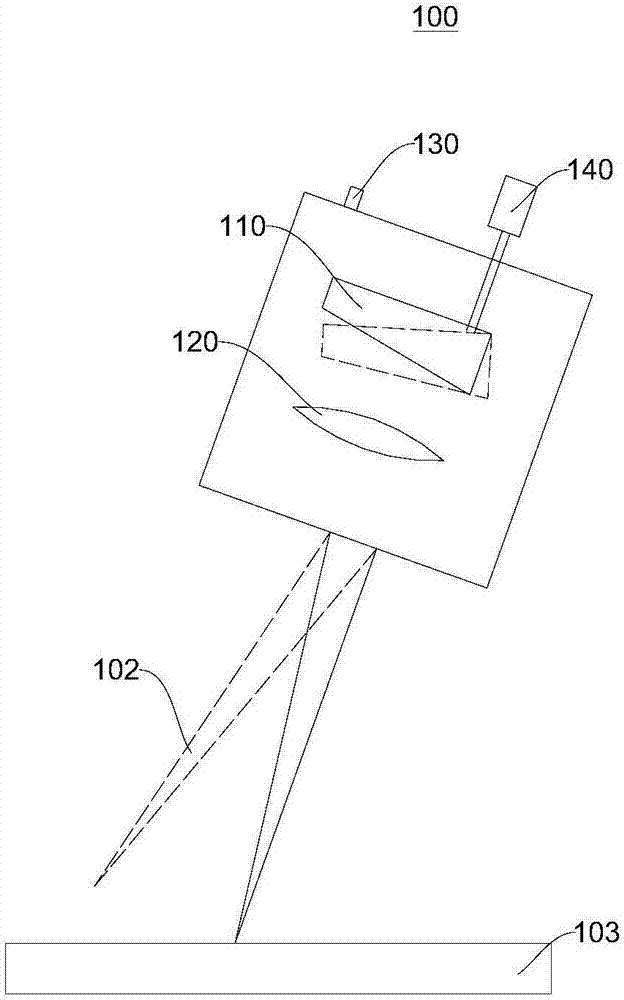

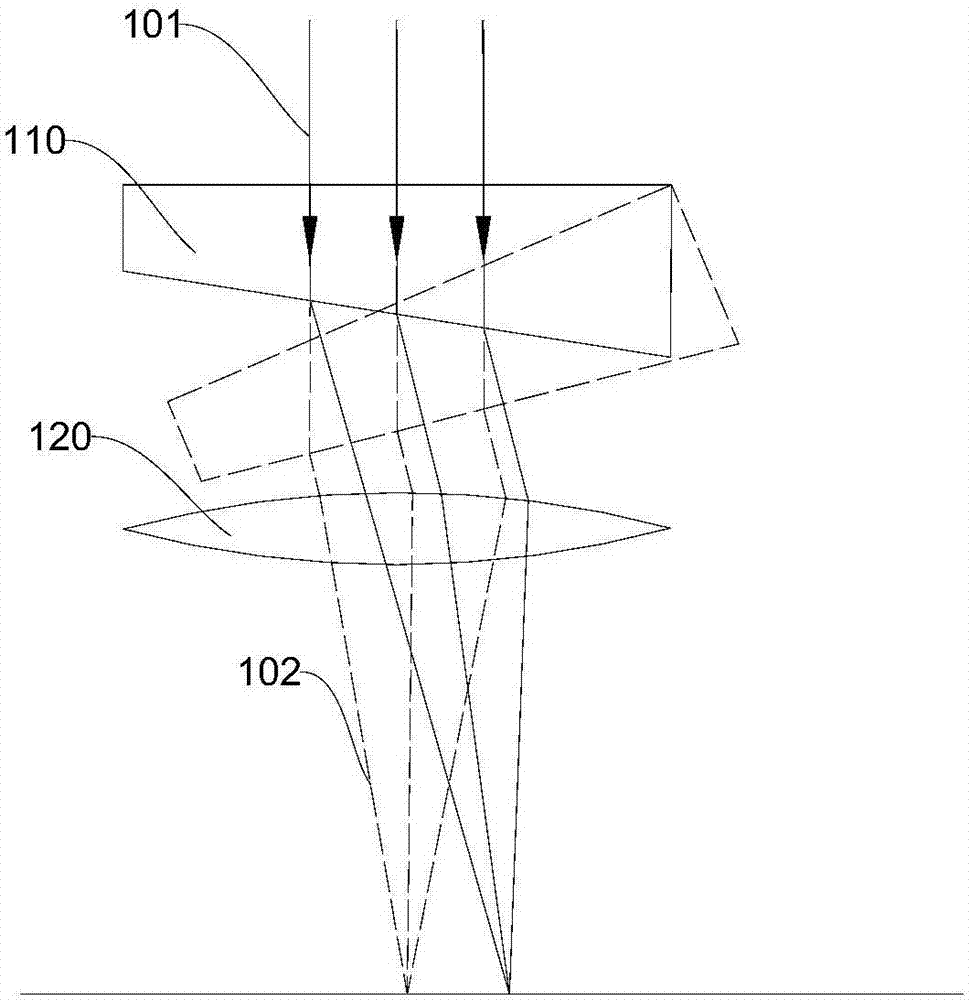

Laser enhancement device and electric arc welding system

PendingCN107175415AOvercoming the problem of unstable welding processIncrease temperatureWelding apparatusLaser lightMelt depth

The invention relates to the field of welding, in particular to a laser enhancement device and an electric arc welding system. The laser enhancement device comprises an optical element, a focusing lens, an optical connector and a driving unit. Laser light can sequentially pass through the optical connector, the optical element and the focusing lens to form a laser beam. The driving unit can drive the optical element to rotate so as to rotate the laser beam. The electric arc welding system comprises the laser enhancement device. The laser beam is driven by the driving unit to rotate along a preset path. Molten drops are transitioned at uniform sizes and frequencies. The laser beam heats the surface of a to-be-welded parent metal zone while cleaning the surface of the to-be-welded parent metal zone, so that the temperature of the surface of the to-be-welded parent metal zone is increased, the stability of the welding process is improved, and the welding quality is improved; and electric arcs are more stable by increasing the temperature of gas of the to-be-welded zone. The welding quality with the same fusion depth is achieved with low current, and low-spatter welding is achieved.

Owner:裴向东

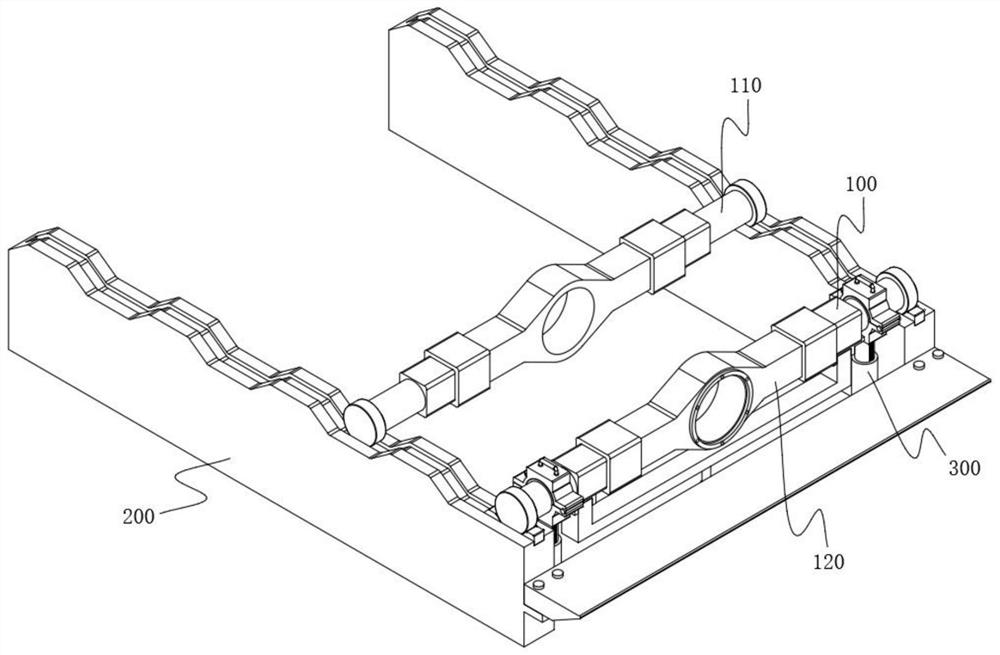

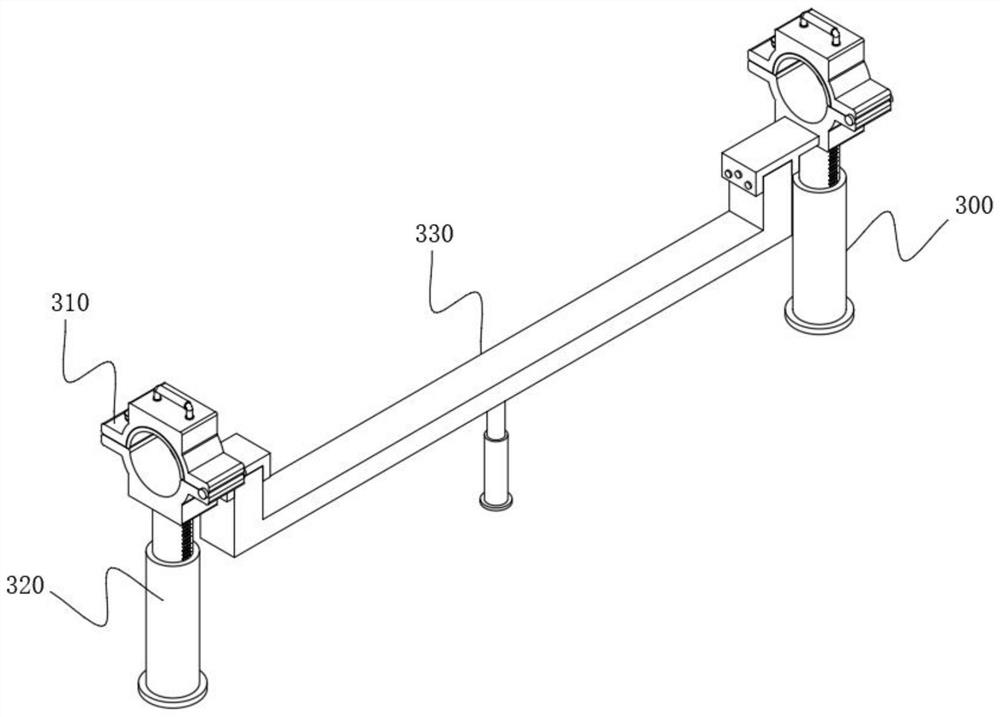

Rear axle flange ring welding device with adjusting structure and for automobile

ActiveCN112059503AReduce the difficulty of operationPrevent rotationWelding/cutting auxillary devicesAuxillary welding devicesFlangeTransaxle

The invention relates to the technical field of flange ring welding, in particular to a rear axle flange ring welding device with an adjusting structure and for an automobile. The rear axle flange ring welding device comprises a rear axle and a welding frame arranged at the bottom of the rear axle. The welding frame comprises two supporting plates, the two supporting plates are correspondingly arranged on the left side and the right side of the rear axle, the rear axle comprises a drive axle housing, a hub is arranged at the end of the drive axle housing, and an adjusting mechanism is arrangedat the position, close to the front side, between the two supporting plates. A fixing device is arranged, the drive axle housing is fixed through static friction force generated by an anti-skid pad and a bottom fixing groove, the phenomena of rotation and skid of the drive axle housing are avoided, and the operation difficulty of welding personnel during welding is reduced; and the height of thewelding rear axle is adjusted through a telescopic cross beam, so that the welding position at the bottom is flush with the face of the welding personnel, the splashing amount of welding sparks flyingto the face is reduced, and the risk that the face is scalded by the welding sparks is reduced.

Owner:CHANGDE JIAHONG MACHINERY

Automatic filling device for beverage production and using method

ActiveCN113753826AImprove filling efficiencyImprove stabilitySafety device in filling machineryEngineeringBottle

The invention discloses an automatic filling device for beverage production and a using method. The automatic filling device comprises two conveying belts and a PLC electrical cabinet. Each conveying belt is sleeved with two conveying frames, servo motors and conveying rollers are connected to the conveying frames, the servo motors are connected with the conveying rollers, and a plurality of gravity sensing connecting plates are connected to the conveying belts. Bottle clamping plates are elastically connected to a gravity sensing connecting plate, a discharging frame is arranged between the two conveying frames, a discharging pipe is connected to the discharging frame, an electronic valve is arranged on the discharging pipe, and a servo motor, the gravity sensing connecting plate and the electronic valve are all electrically connected with the PLC electrical cabinet. According to the automatic filling device for beverage production and the using method, a traditional single conveying platform is changed into double conveying platforms, the bottle clamping plates meshed with each other are arranged on the double conveying platforms, the bottle clamping plates can control the filling capacity through the PLC electrical cabinet according to gravity induction, the filling efficiency is high, the stability is good, manual investigation is not needed, and secondary pollution is avoided.

Owner:普迈科(芜湖)机械有限公司

Metal wire of filling titanium dioxide flux

ActiveCN1597236AAvoid disconnectionLow moisture absorptionWelding/cutting media/materialsWelding electrode featuresPotassiumTitanium

The wire has a steel outer shell which is filled with a flux in an amount of 10-20 mass% as the ratio to the total mass of the wire. The flux contains 10-60 mass% of titanium and titanium oxide in terms of TiO2, 0.5-10 mass% of sodium compound in terms of Na2O, and 0.5-10 mass% of potassium compound in terms of K2O. Additionally the specific surface area of the titanium oxide is adjusted to 0.4-2.0 m2 / g.To provide a titania-based flux cored wire for arc welding which gives excellent welding workability and weld metal performance, and has less moisture absorption quantity.

Owner:KOBE STEEL LTD

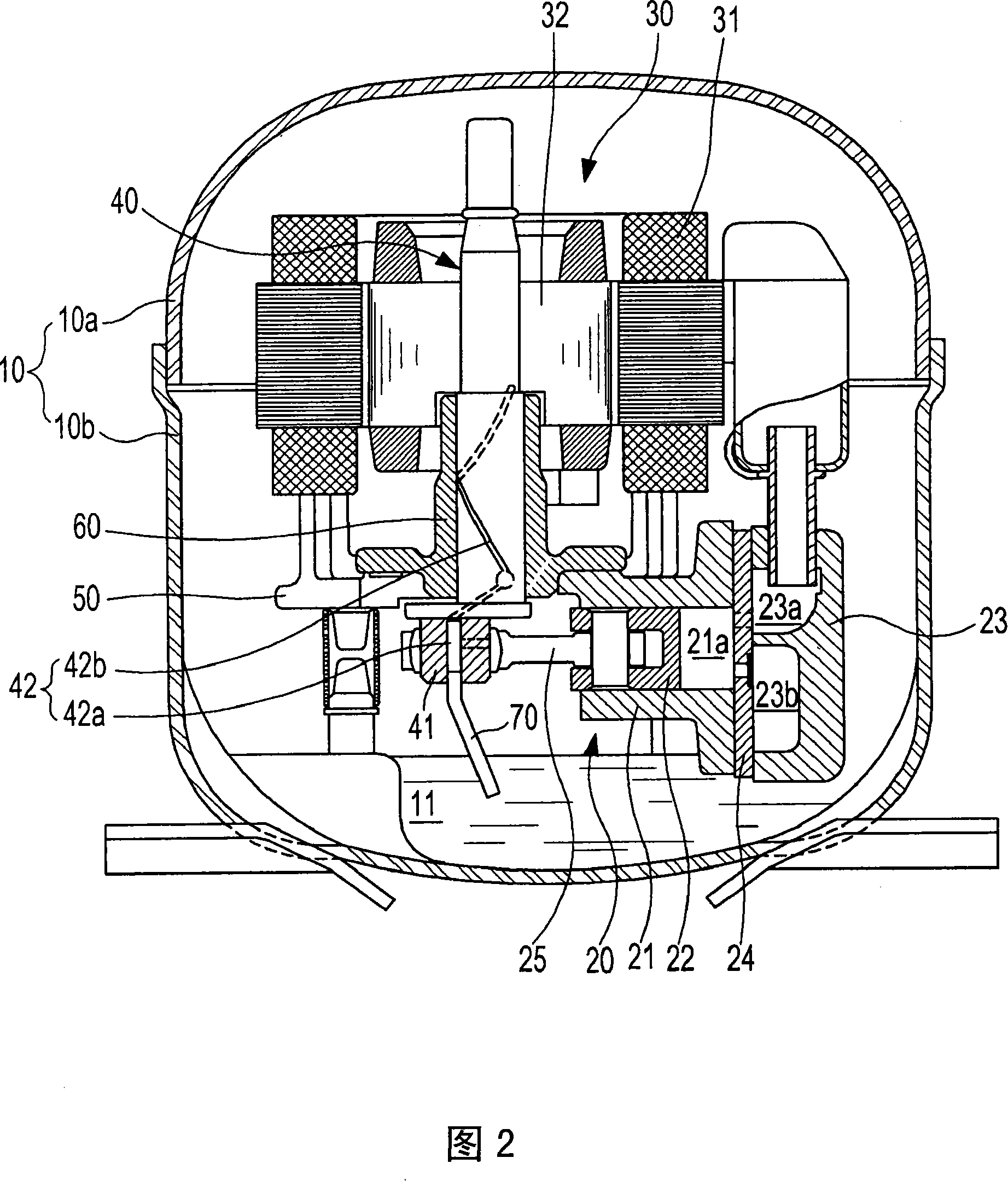

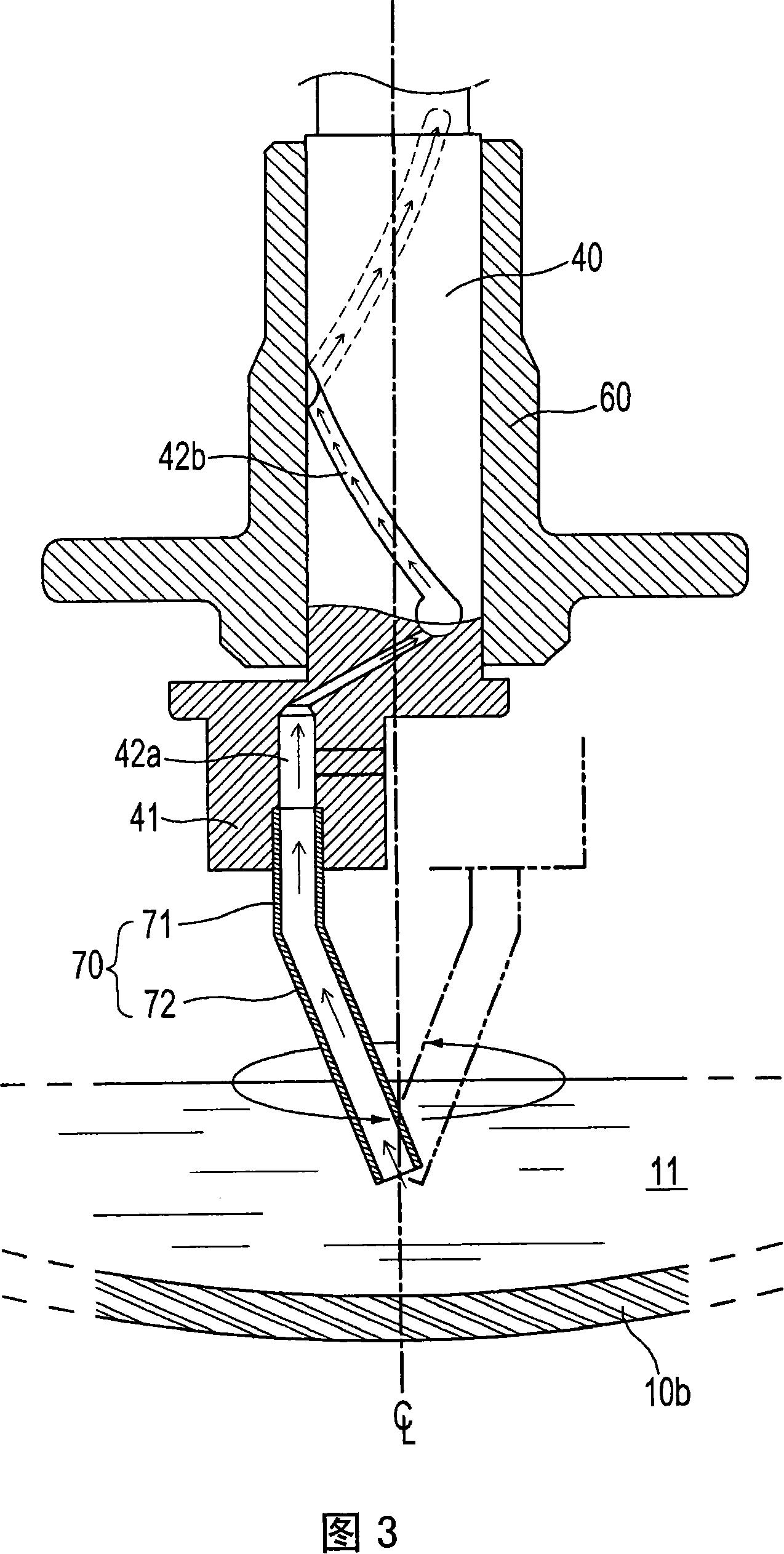

Sealing type compressor

InactiveCN101131154AReduce sizeReduced oil splashCompressorPositive displacement pump componentsEngineeringMechanical engineering

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com