Aluminum alloy material for new energy power battery shells and covers and application of aluminum alloy material

A technology of aluminum alloy materials and power batteries, which is applied in the direction of battery box/case material, battery pack parts, battery box/coating, etc., can solve the problems such as the overall performance needs to be improved, achieve low incidence of abnormal weld pools, and facilitate processing , the effect of good appearance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

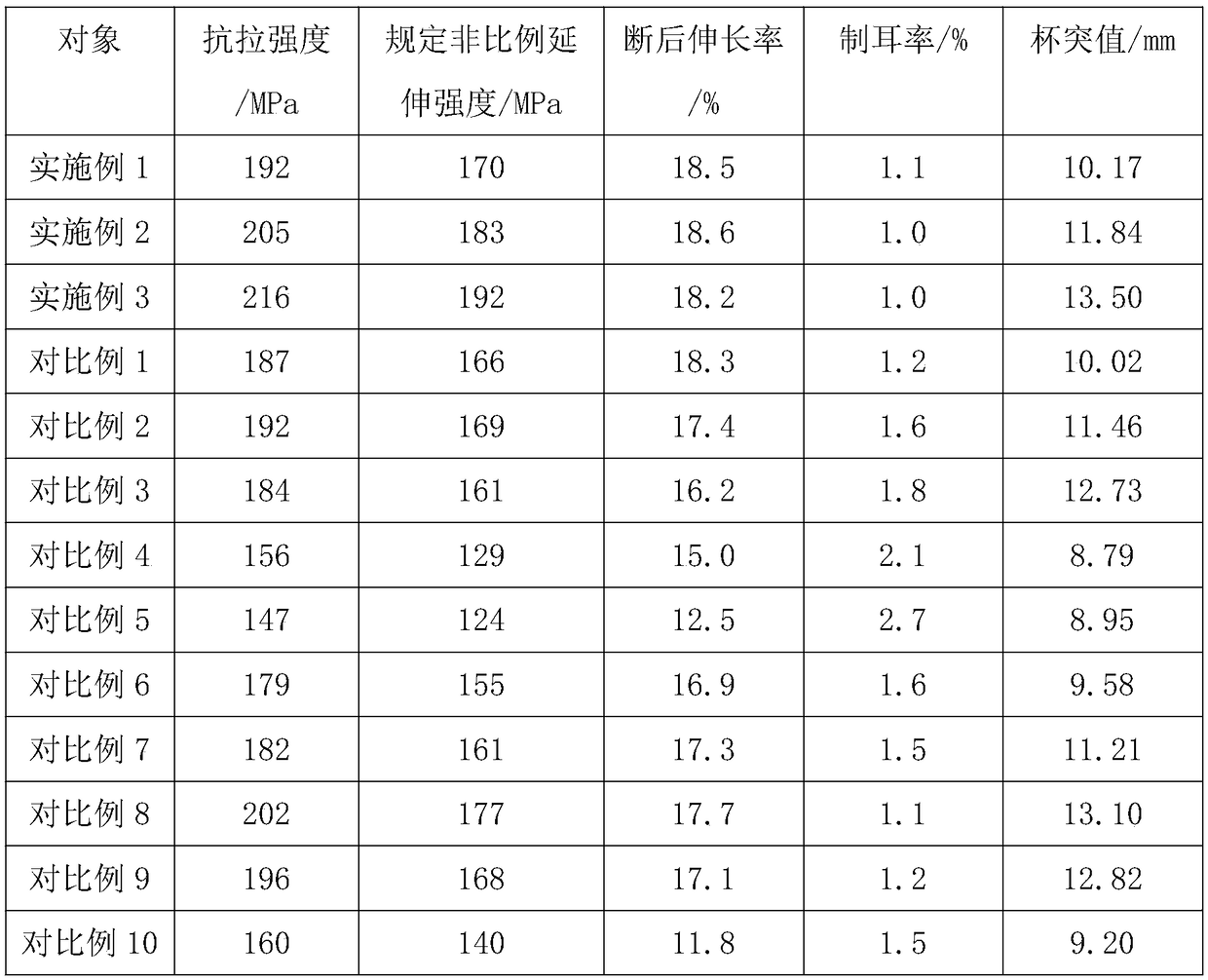

Embodiment 1

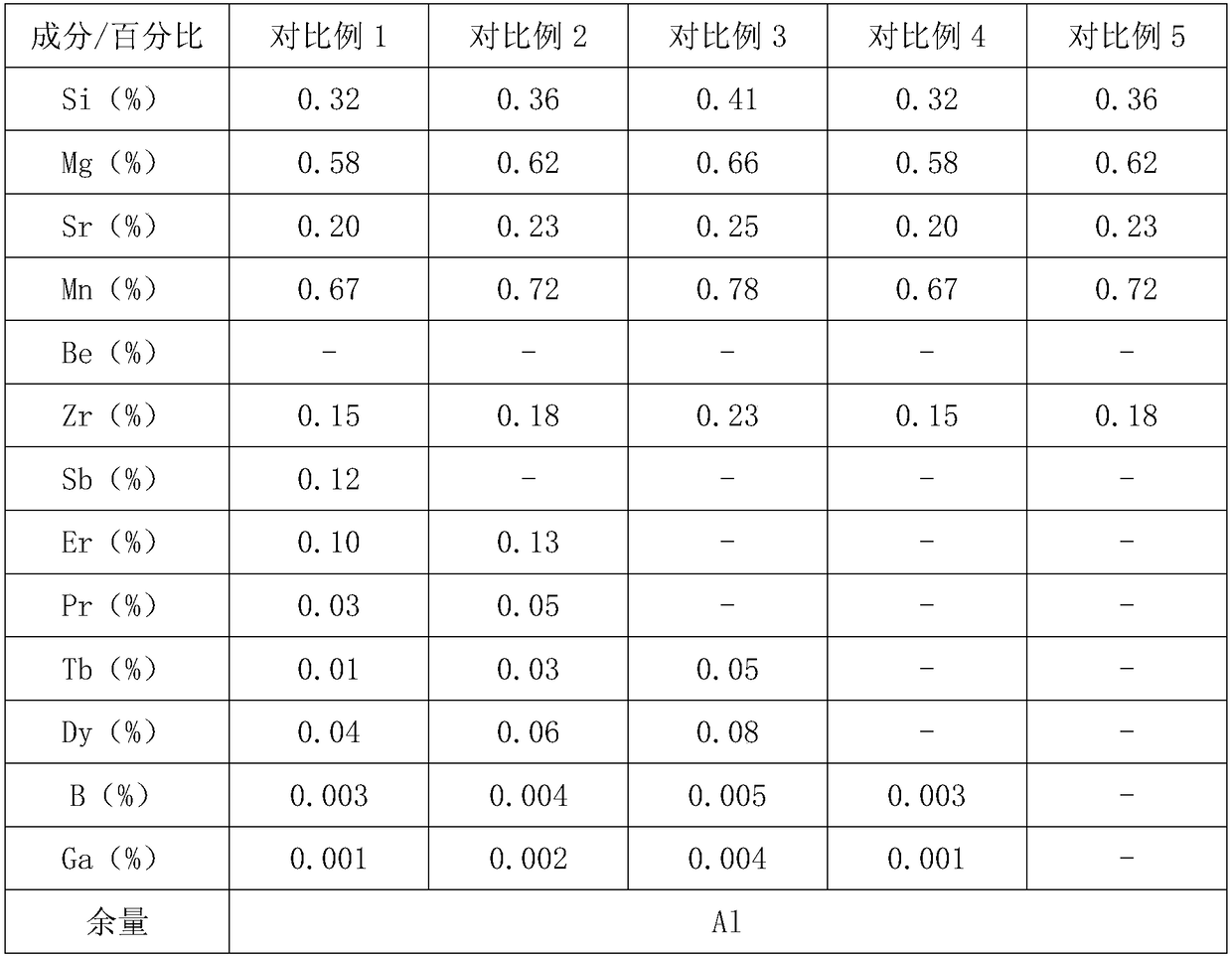

[0044] This embodiment relates to an aluminum alloy material for a new energy power battery case and cover. The aluminum alloy material is composed of the following components by weight percentage:

[0045] Si: 0.32%, Mg: 0.58%, Sr: 0.20%, Mn: 0.67%, Be: 0.18%, Zr: 0.15%, Sb: 0.12%, Er: 0.10%, Pr: 0.03%, Tb: 0.01%, Dy: 0.04%, B: 0.003%, Ga: 0.001%, and the balance is Al.

[0046] The preparation method of the above-mentioned new energy power battery shell and cover aluminum alloy plate and strip is generally carried out according to the following steps:

[0047] Step 1: Take the aluminum ingot, the required aluminum intermediate alloy ingot and the metal element and transport them to the smelting furnace, and carry out smelting, refining, slag removal, online degassing successively to obtain the molten metal; in step 1, the refining uses an argon furnace Bottom purge refining, the refining temperature is 740°C, and the refining time is 25 minutes. The refining agent selected ...

Embodiment 2

[0057] This embodiment relates to an aluminum alloy material for a new energy power battery case and cover. The aluminum alloy material is composed of the following components by weight percentage:

[0058] Si: 0.36%, Mg: 0.62%, Sr: 0.23%, Mn: 0.72%, Be: 0.21%, Zr: 0.18%, Sb: 0.16%, Er: 0.13%, Pr: 0.05%, Tb: 0.03%, Dy: 0.06%, B: 0.004%, Ga: 0.002%, and the balance is Al.

[0059] The preparation method of the above-mentioned new energy power battery shell and cover aluminum alloy plate and strip is generally carried out according to the following steps:

[0060] Step 1: Take the aluminum ingot, the required aluminum intermediate alloy ingot and the metal element and transport them to the smelting furnace, and carry out smelting, refining, slag removal, online degassing successively to obtain the molten metal; in step 1, the refining uses an argon furnace Bottom purge refining, the refining temperature is 745°C, and the refining time is 22 minutes. The refining agent selected ...

Embodiment 3

[0070] This embodiment relates to an aluminum alloy material for a new energy power battery case and cover. The aluminum alloy material is composed of the following components by weight percentage:

[0071] Si: 0.41%, Mg: 0.66%, Sr: 0.25%, Mn: 0.78%, Be: 0.24%, Zr: 0.23%, Sb: 0.20%, Er: 0.16%, Pr: 0.06%, Tb: 0.05%, Dy: 0.08%, B: 0.005%, Ga: 0.004%, and the balance is Al.

[0072] The preparation method of the above-mentioned new energy power battery shell and cover aluminum alloy plate and strip is generally carried out according to the following steps:

[0073] Step 1: Take the aluminum ingot, the required aluminum intermediate alloy ingot and the metal element and transport them to the smelting furnace, and carry out smelting, refining, slag removal, online degassing successively to obtain the molten metal; in step 1, the refining uses an argon furnace Bottom purge refining, the refining temperature is 750°C, and the refining time is 20 minutes. The refining agent selected ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com