Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Reduce surface irregularities" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

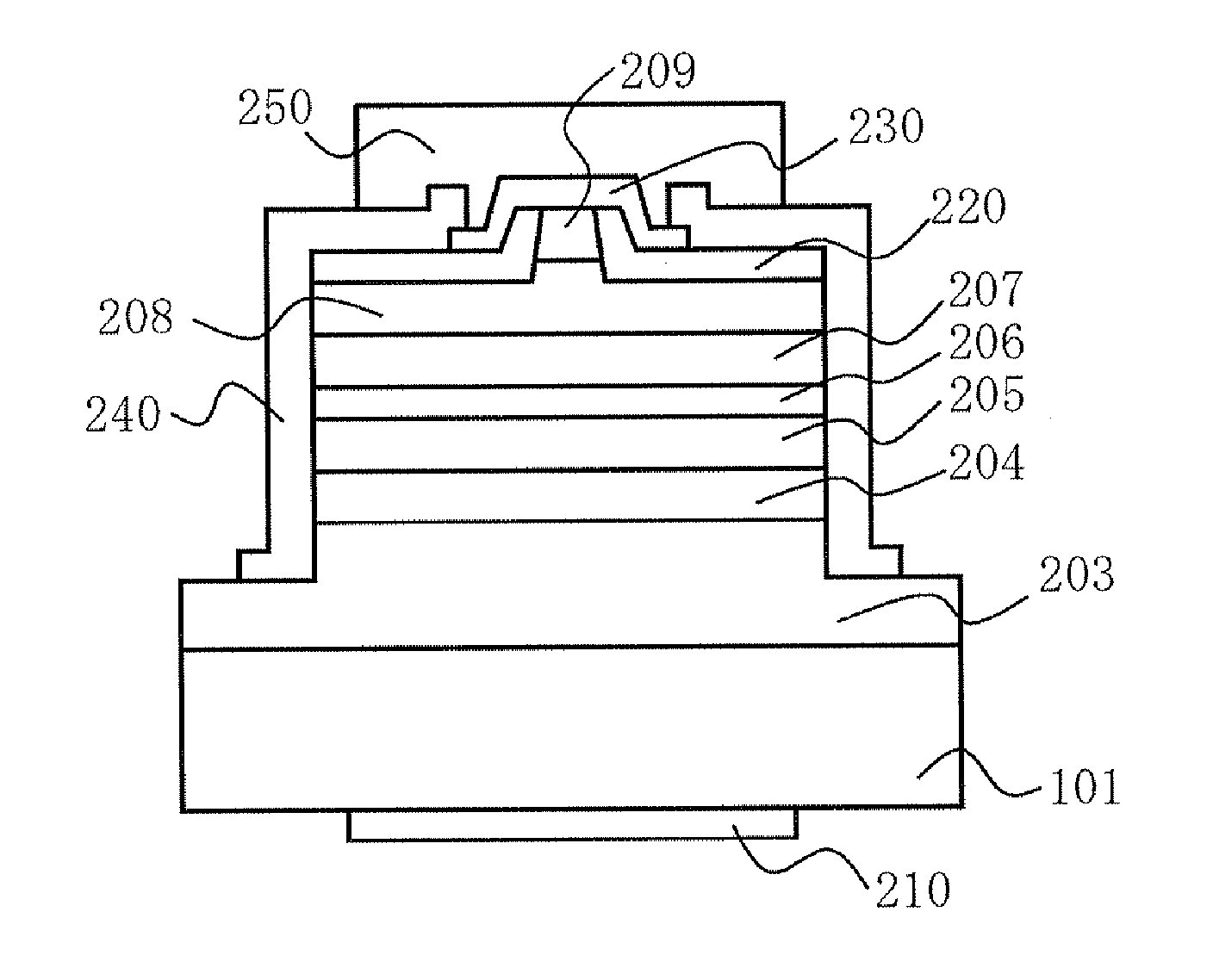

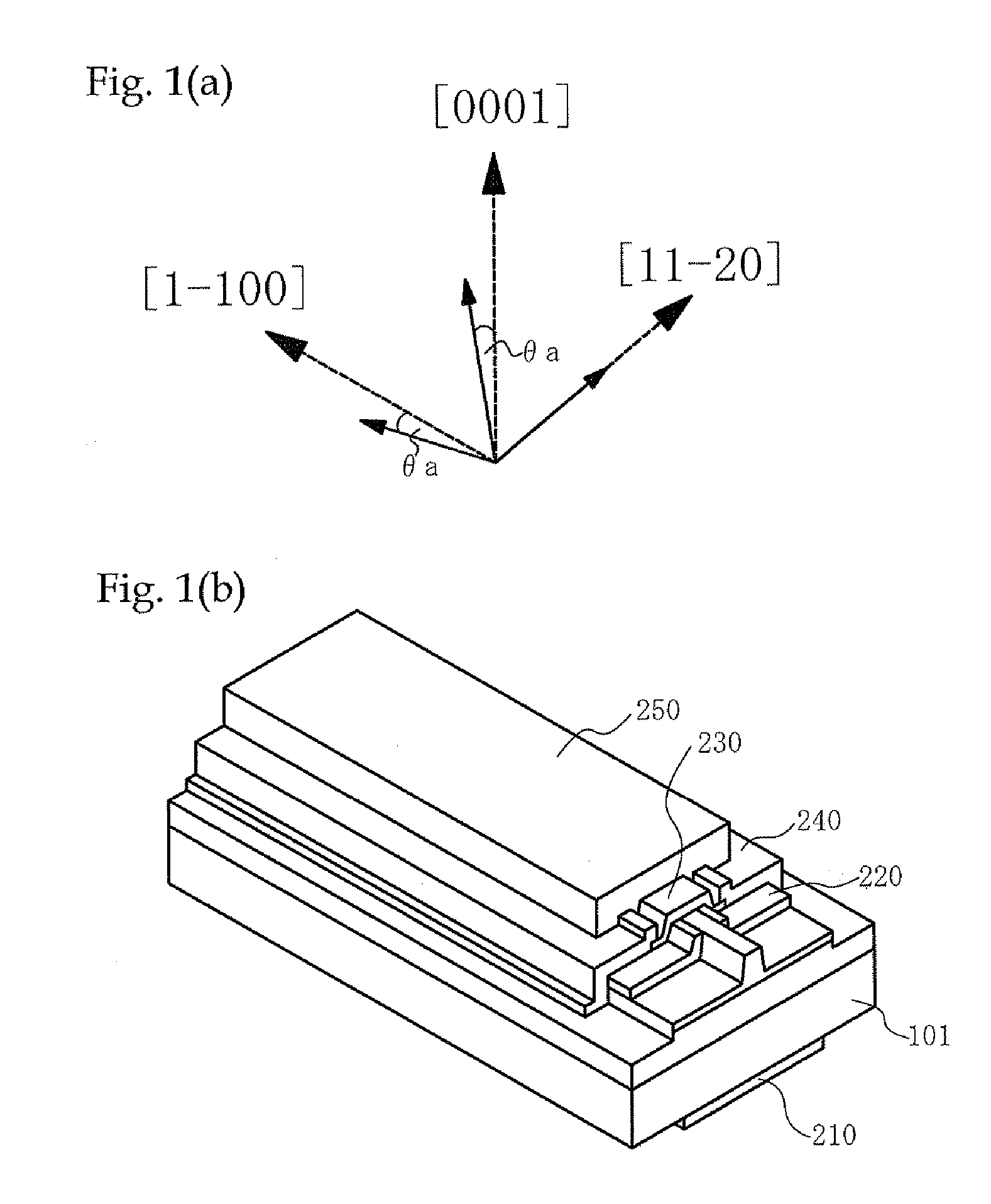

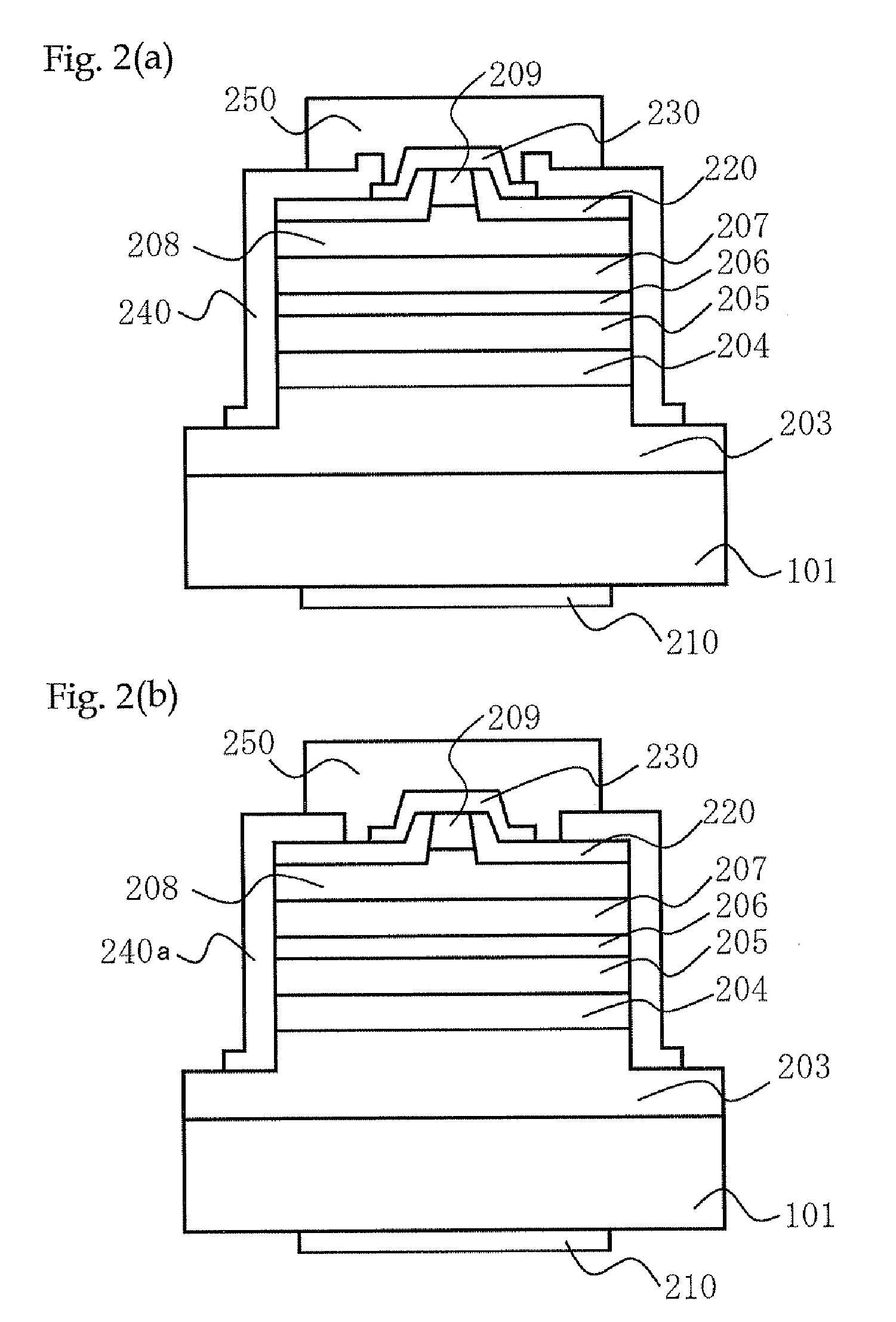

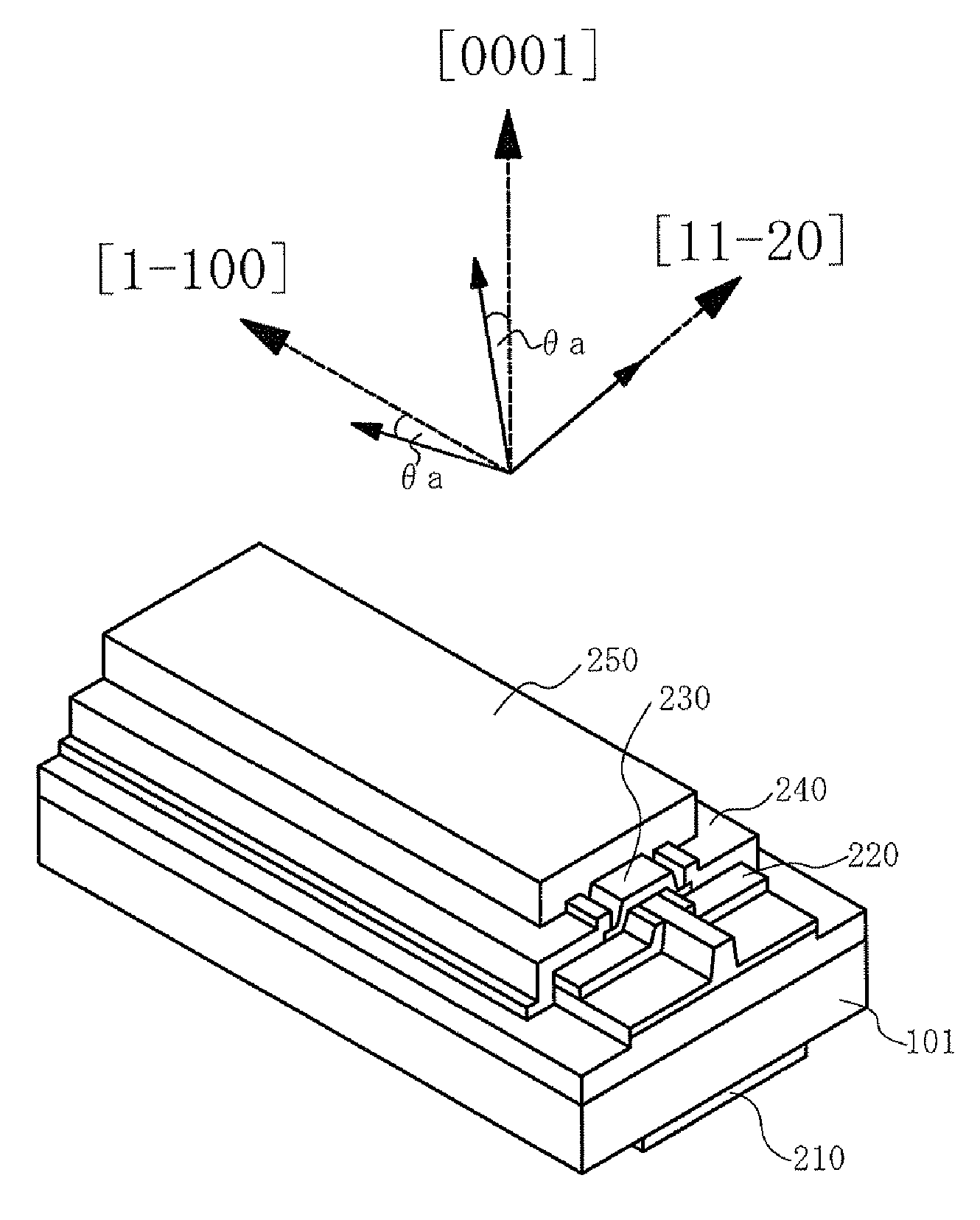

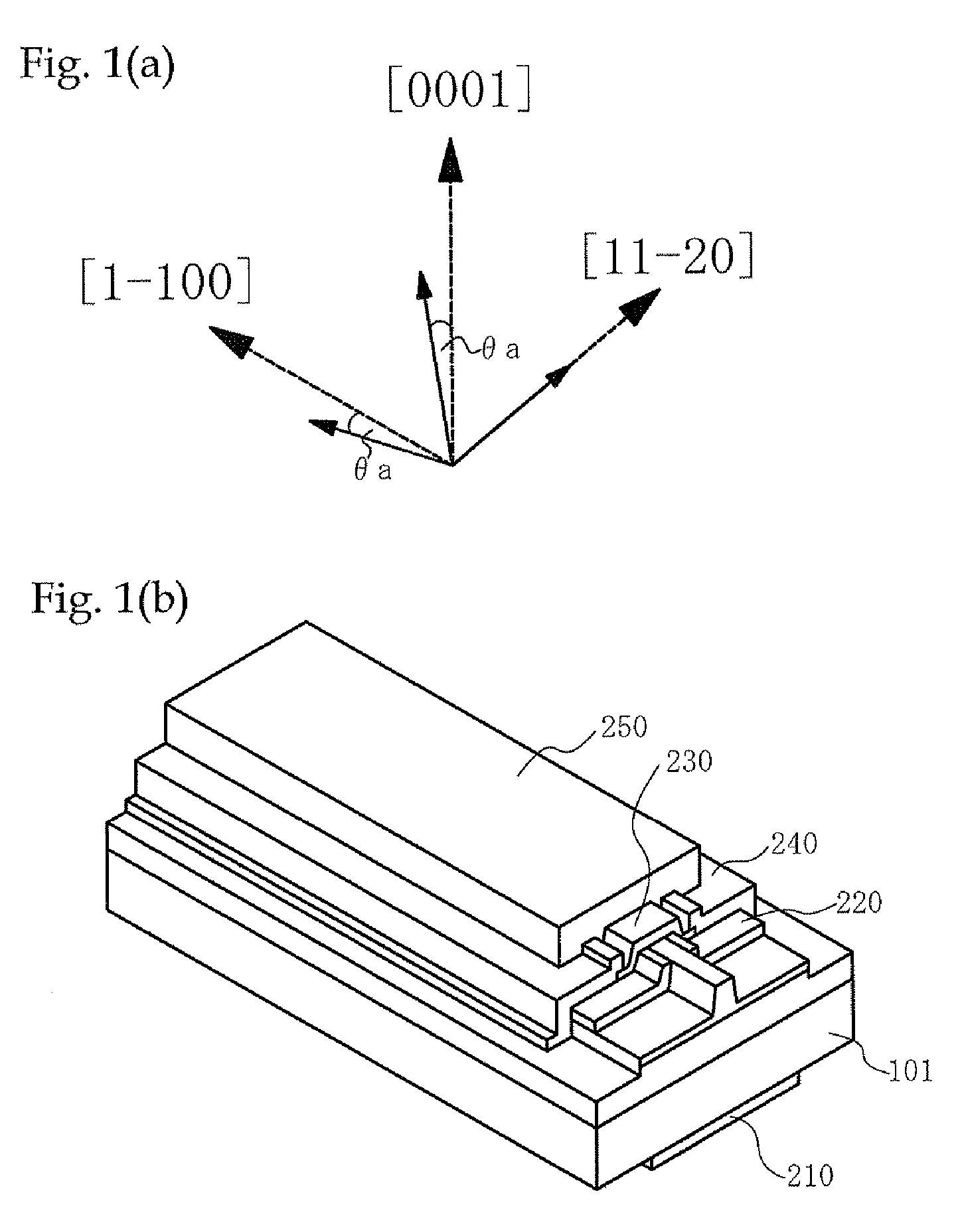

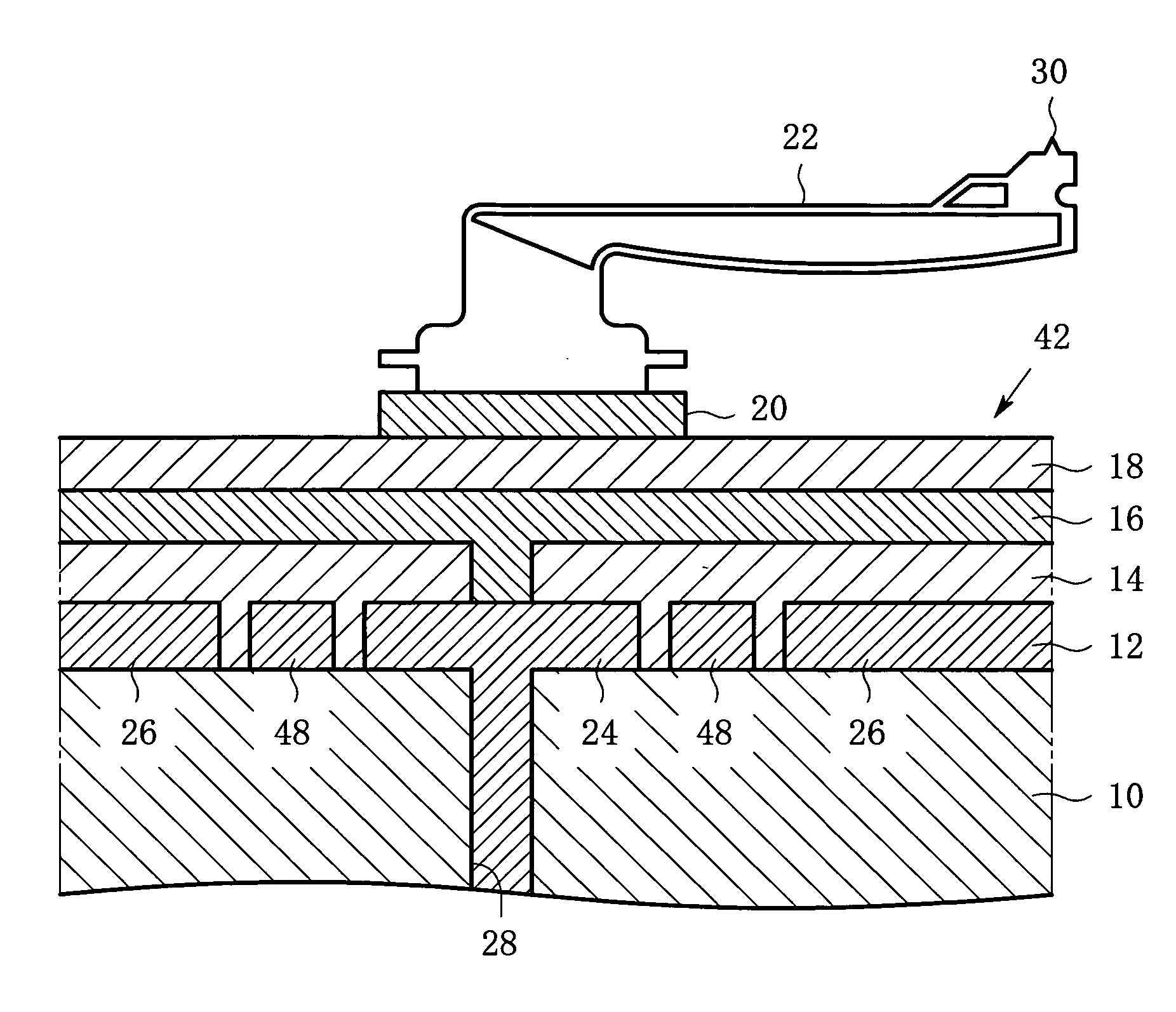

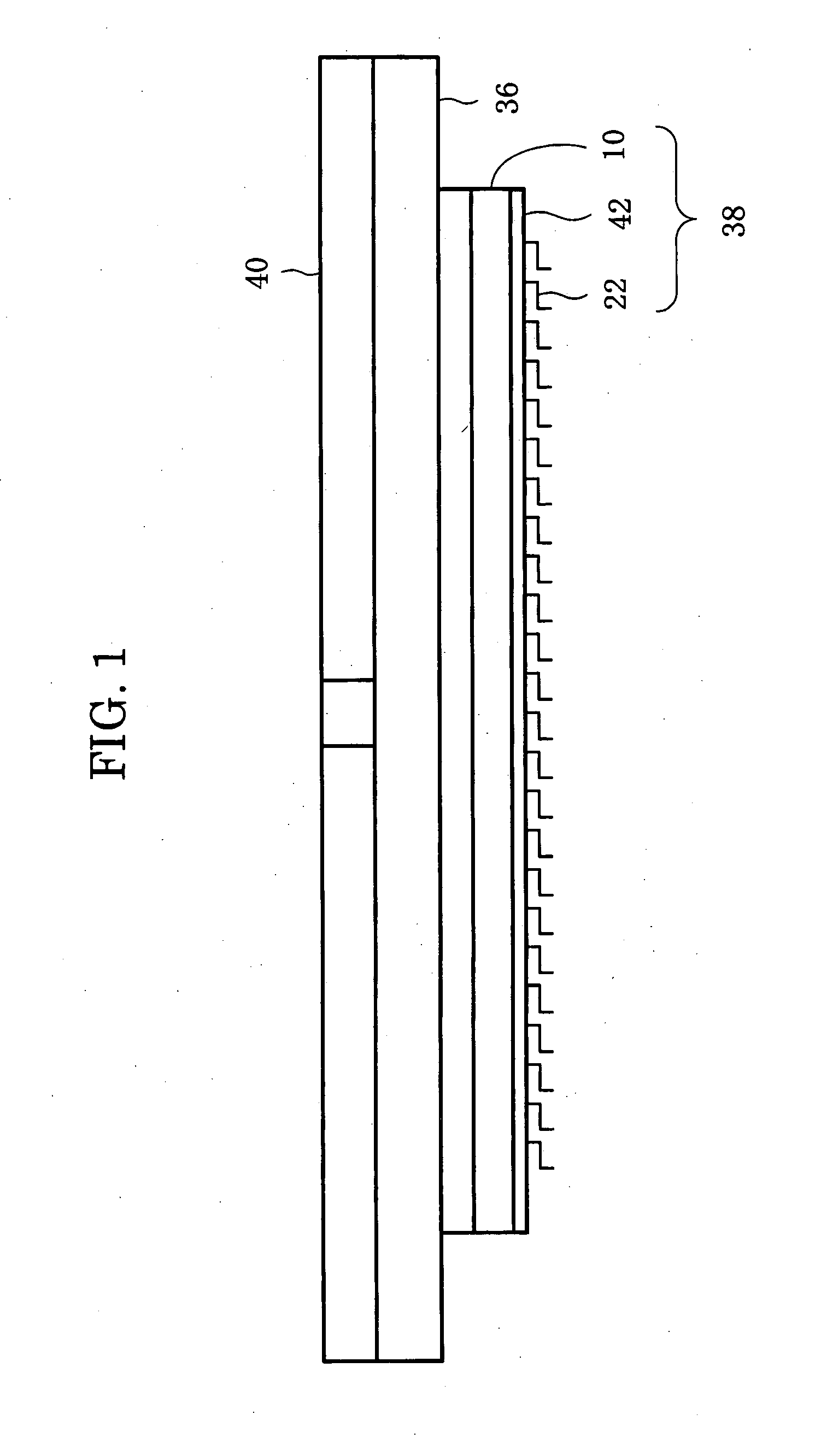

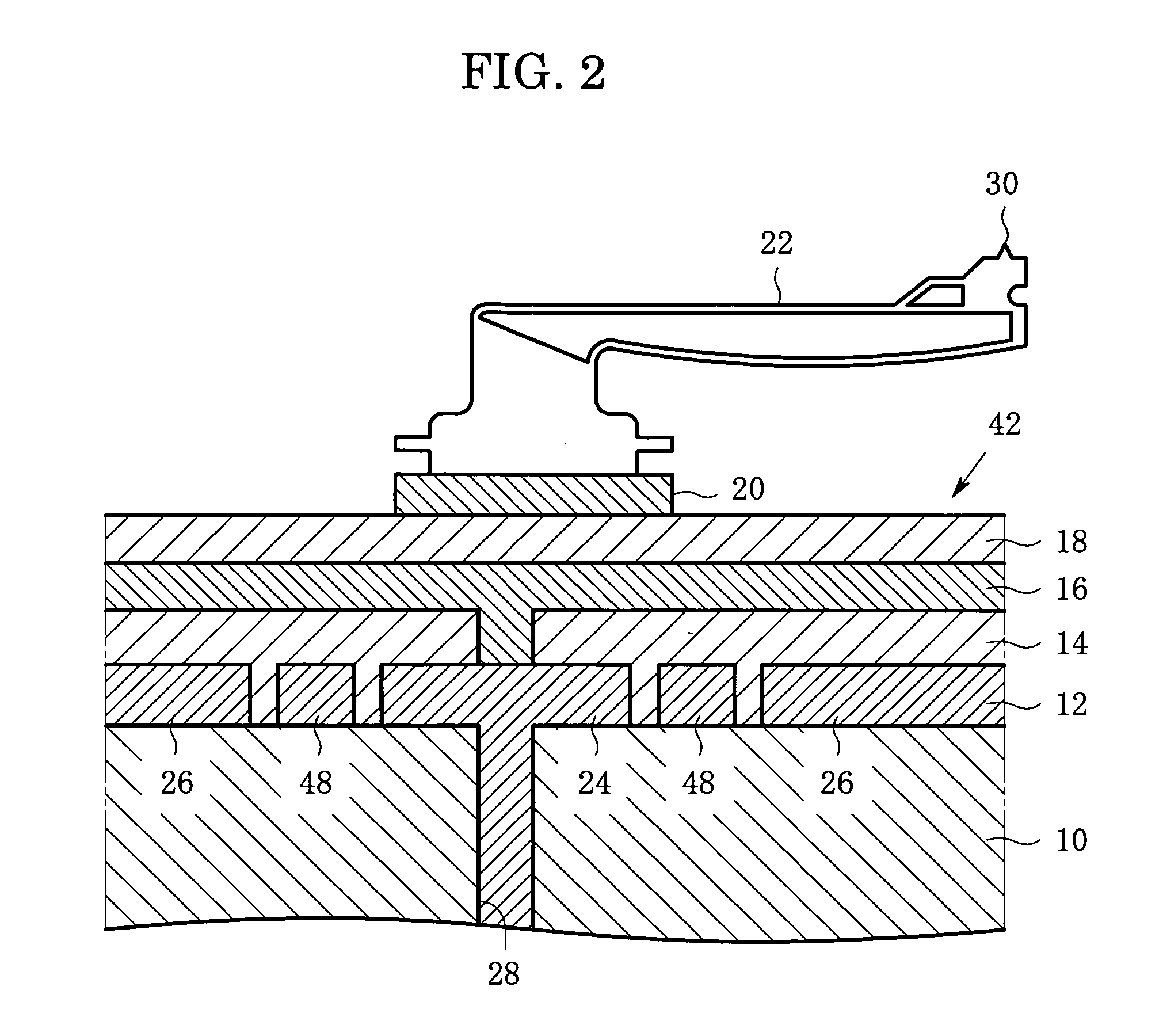

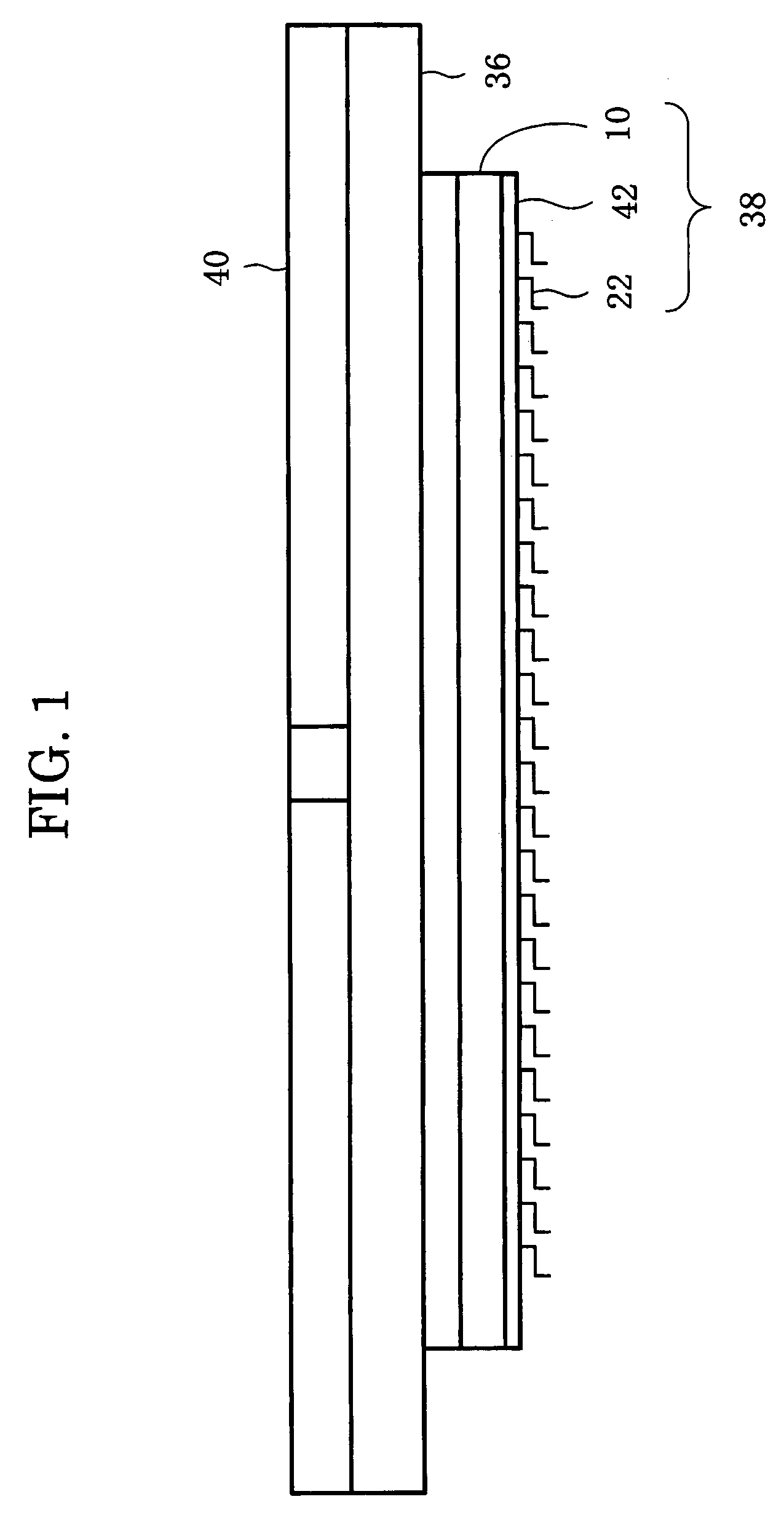

Nitride semiconductor laser device and nitride semiconductor device

ActiveUS20050224783A1Excellent characteristicsProlong lifeOptical wave guidanceLaser detailsIndiumCrystal plane

A nitride semiconductor laser device comprises, on a principle face of a nitride semiconductor substrate: a nitride semiconductor layer having a first conductivity type; an active layer comprising indium, and a nitride semiconductor layer having a second conductivity type that is different from said first conductivity type, and on the surface of which is formed a stripe ridge; said principal face of said nitride semiconductor substrate having an off angle a (θa) with respect to a reference crystal plane, in at least a direction substantially parallel to said stripe ridge.

Owner:NICHIA CORP

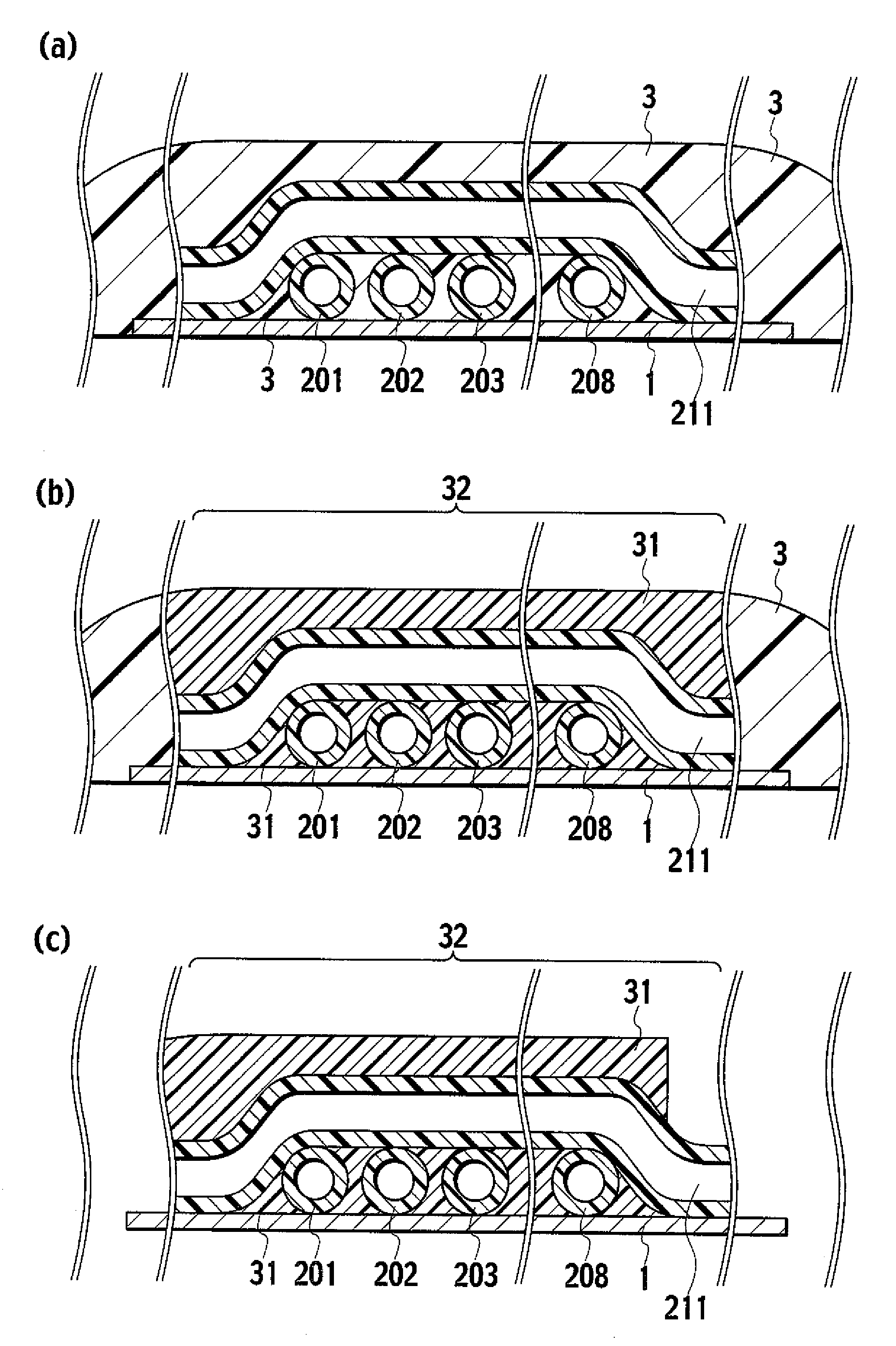

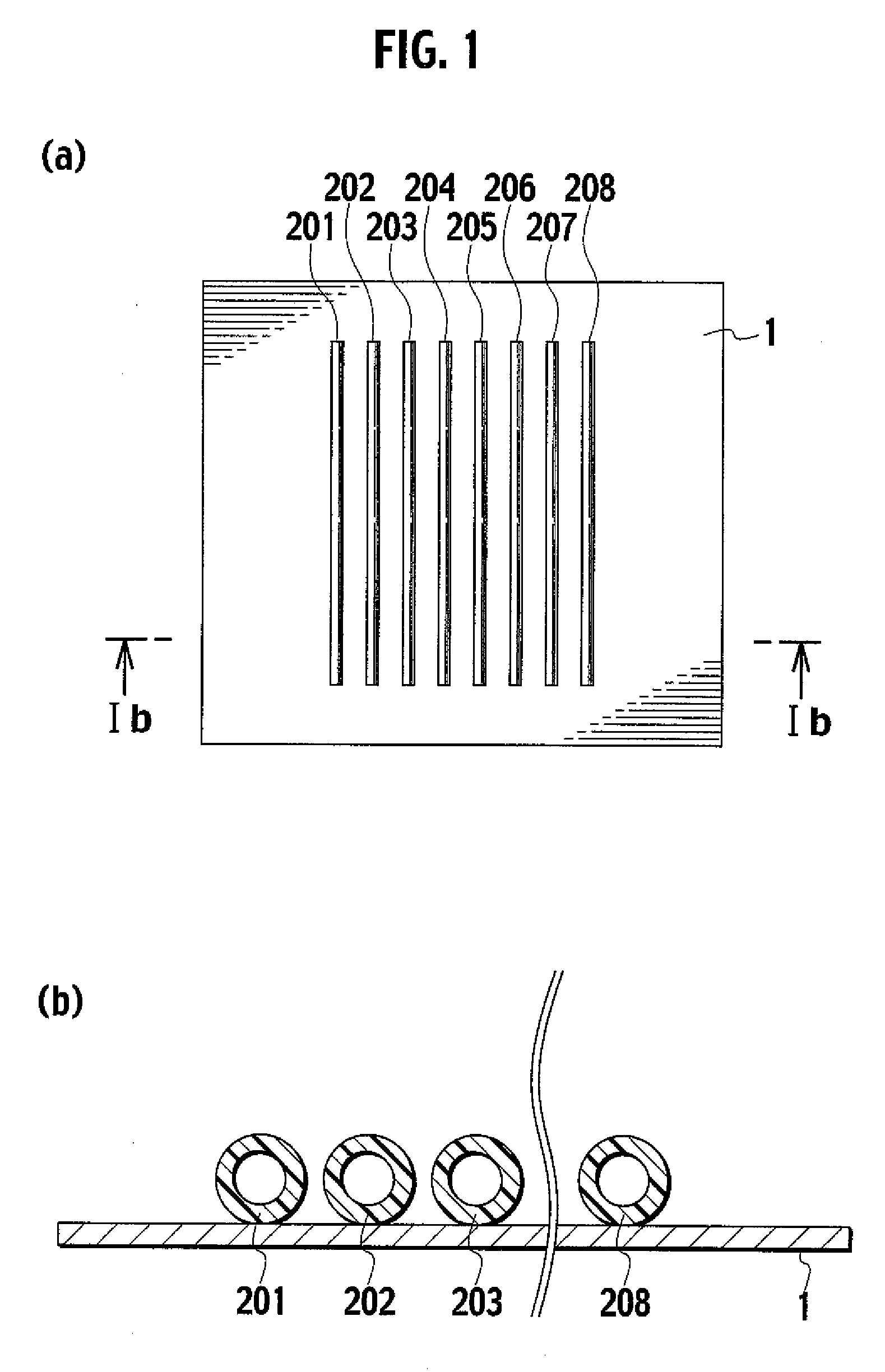

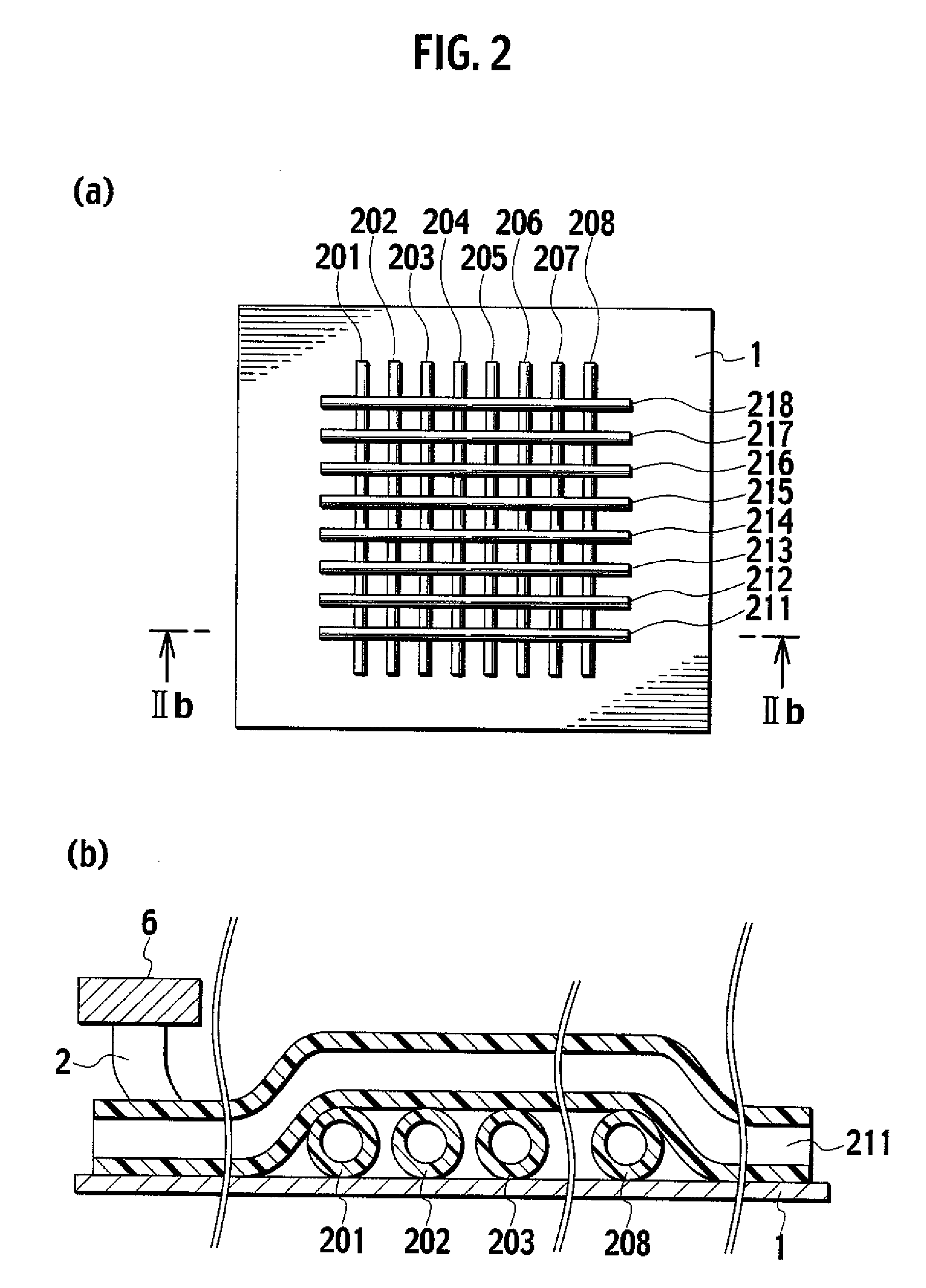

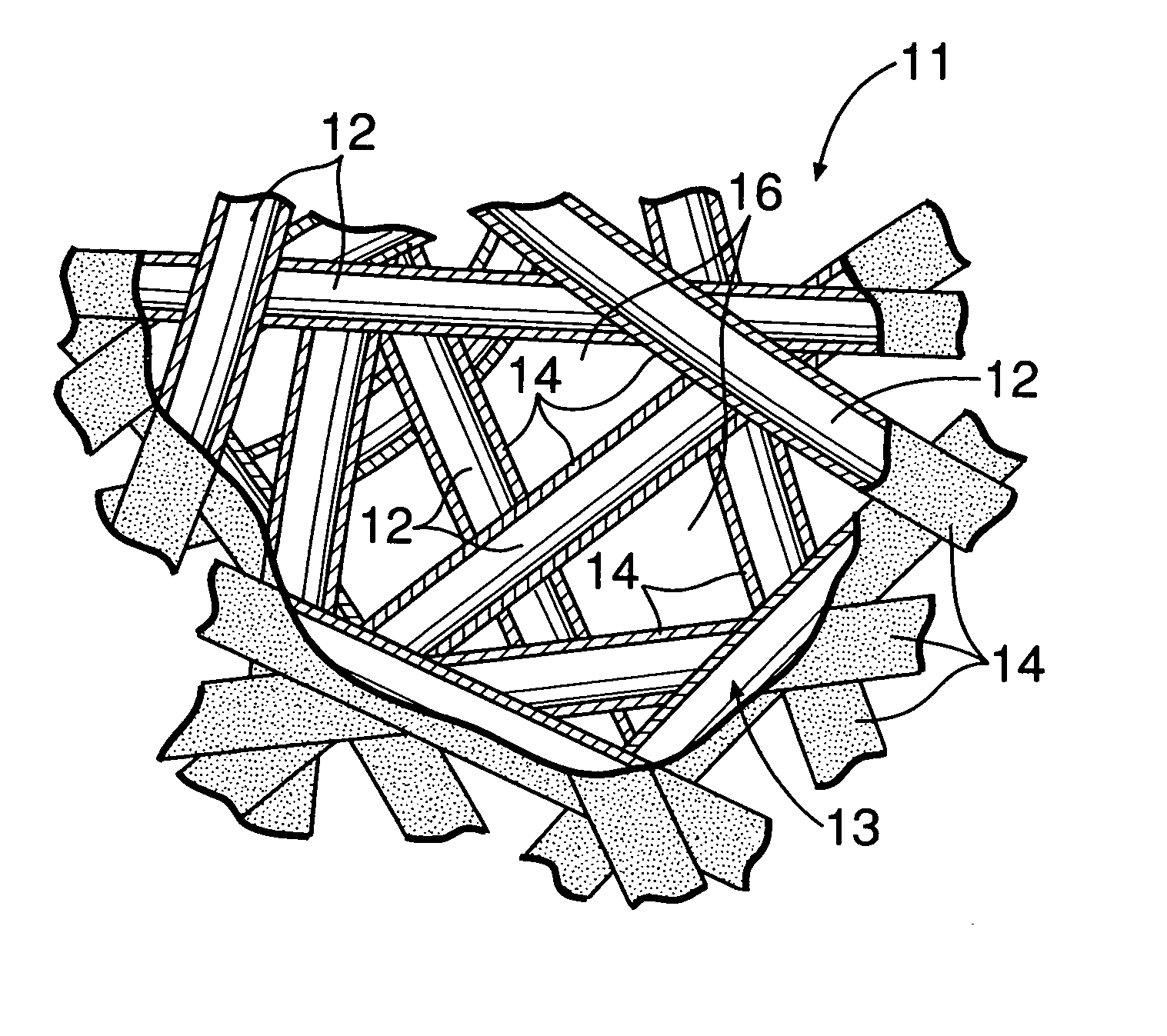

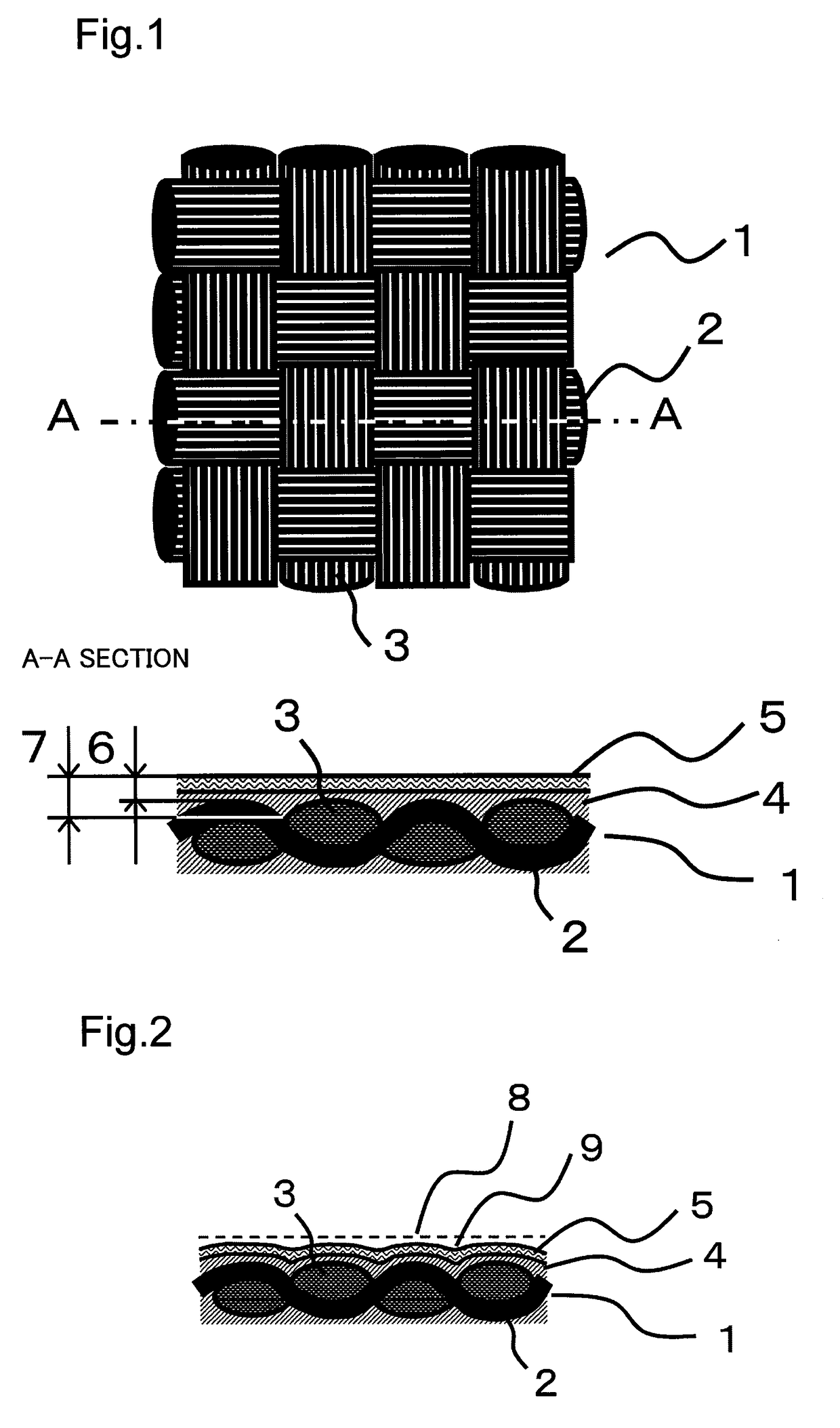

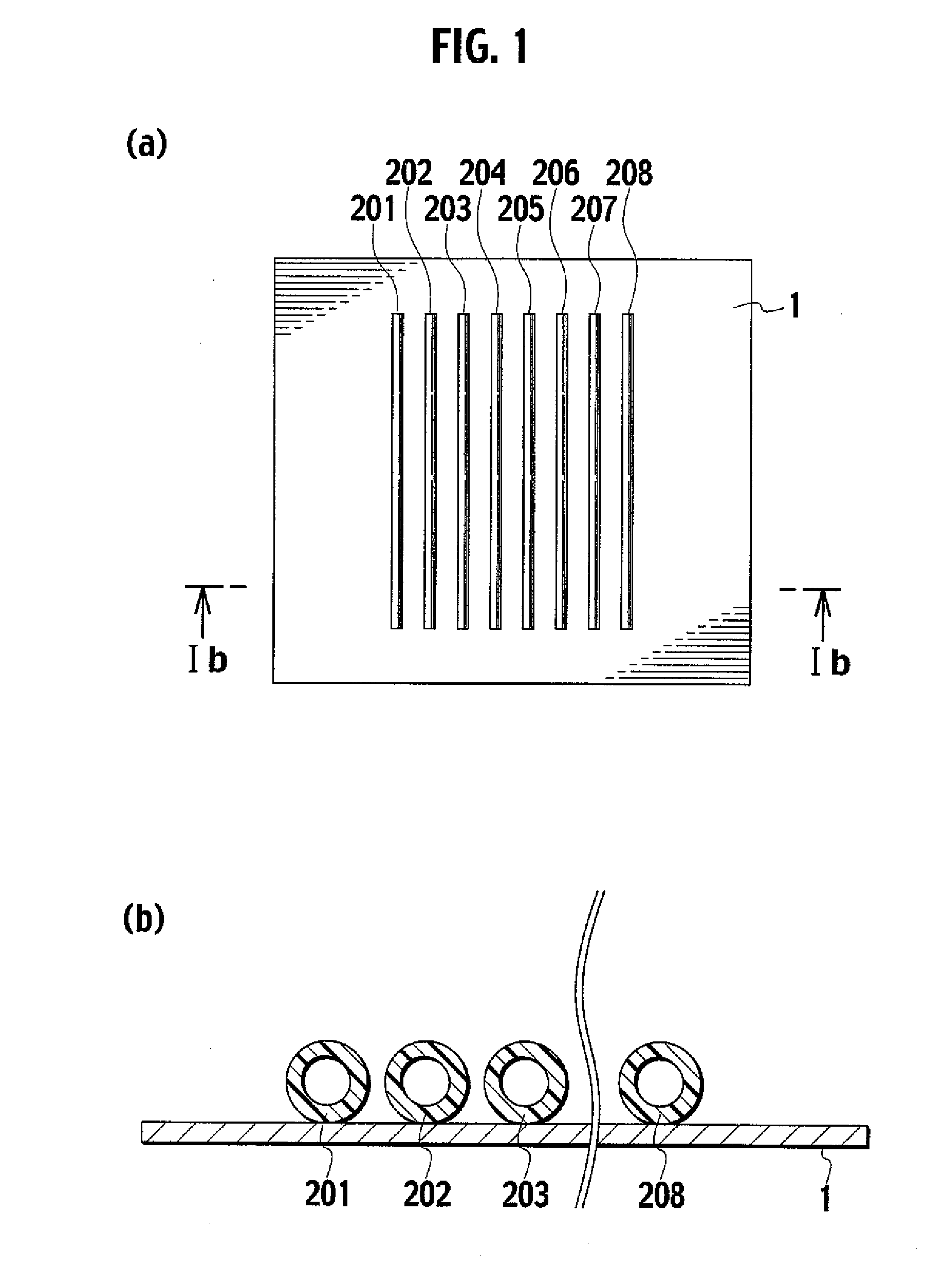

Microfluid-System-Supporting Unit And Production Method Thereof

InactiveUS20090291264A1Restricted fluid flowSignificant pressure dropFixed microstructural devicesVolume/mass flow measurementMethods of productionBiomedical engineering

The present invention relates to a microfluid-system-supporting unit, comprising a fixing layer formed on a substrate, a protective layer or a fixing layer, wherein part of at least one hollow filament in any shape is placed and fixed in the fixing layer. Thus, it provides a microfluid-system-supporting unit lower in surface irregularity even when there are multiple hollow filaments different in external diameter or the hollow filaments crosses each other and resistant to positional deviation of the hollow filament in the crossing regions, and a production method thereof.

Owner:HITACHI CHEM CO LTD

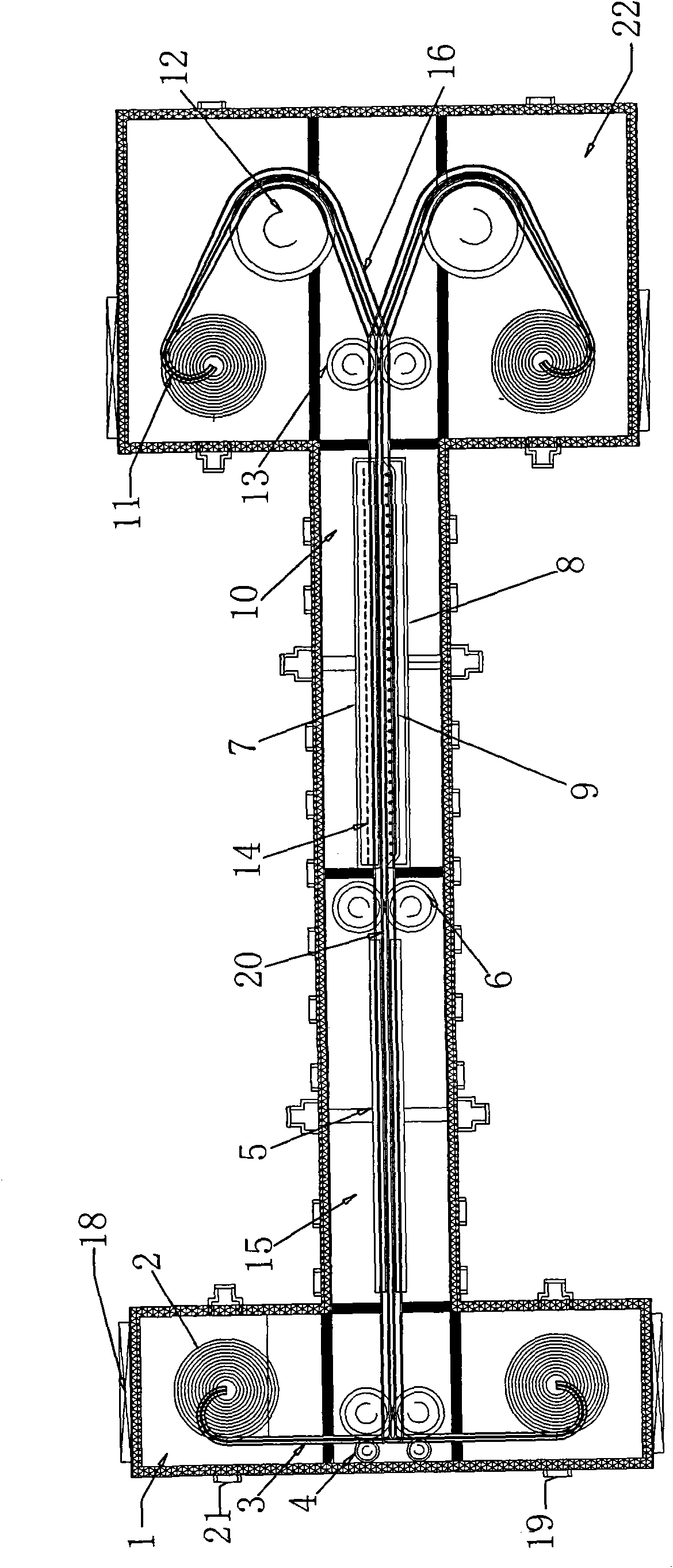

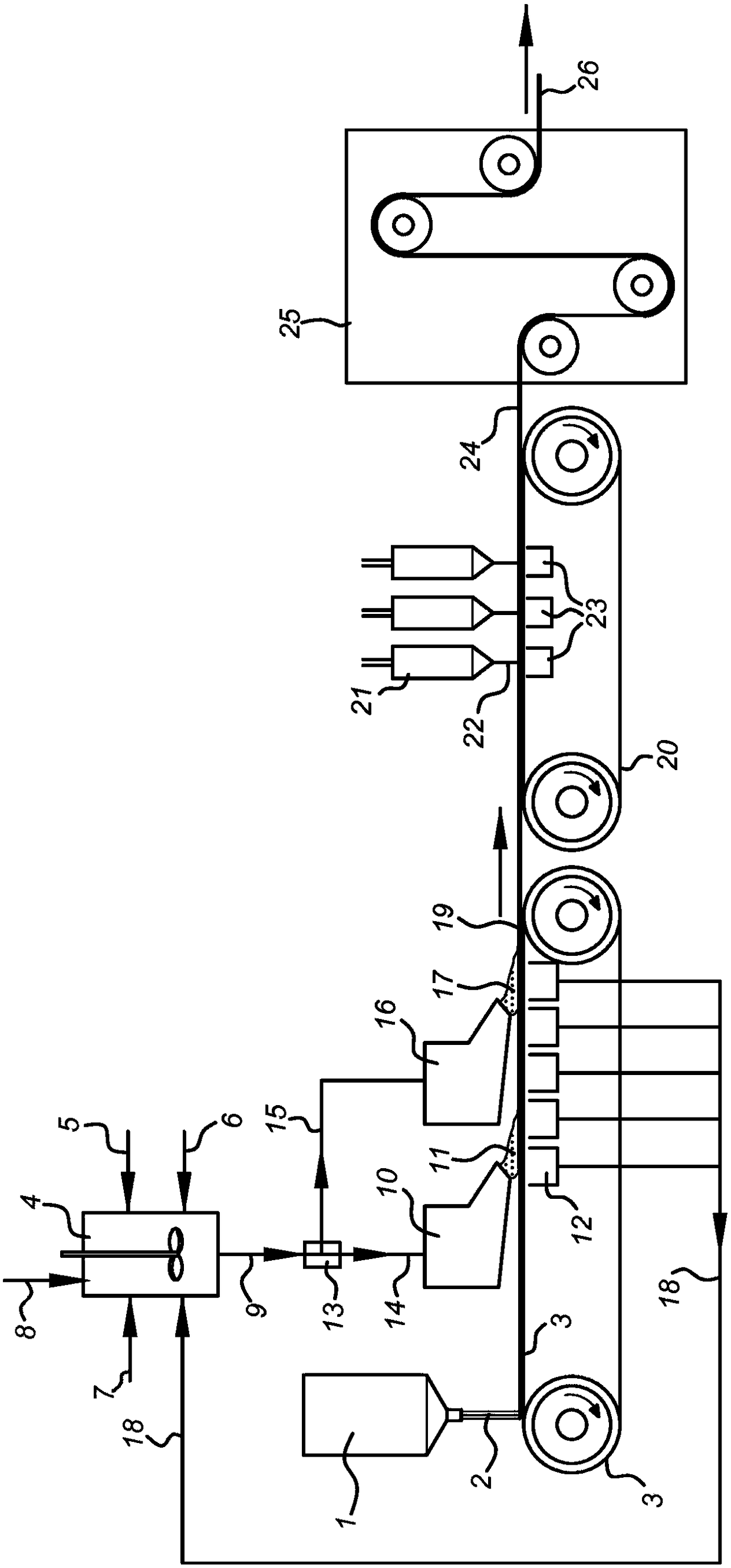

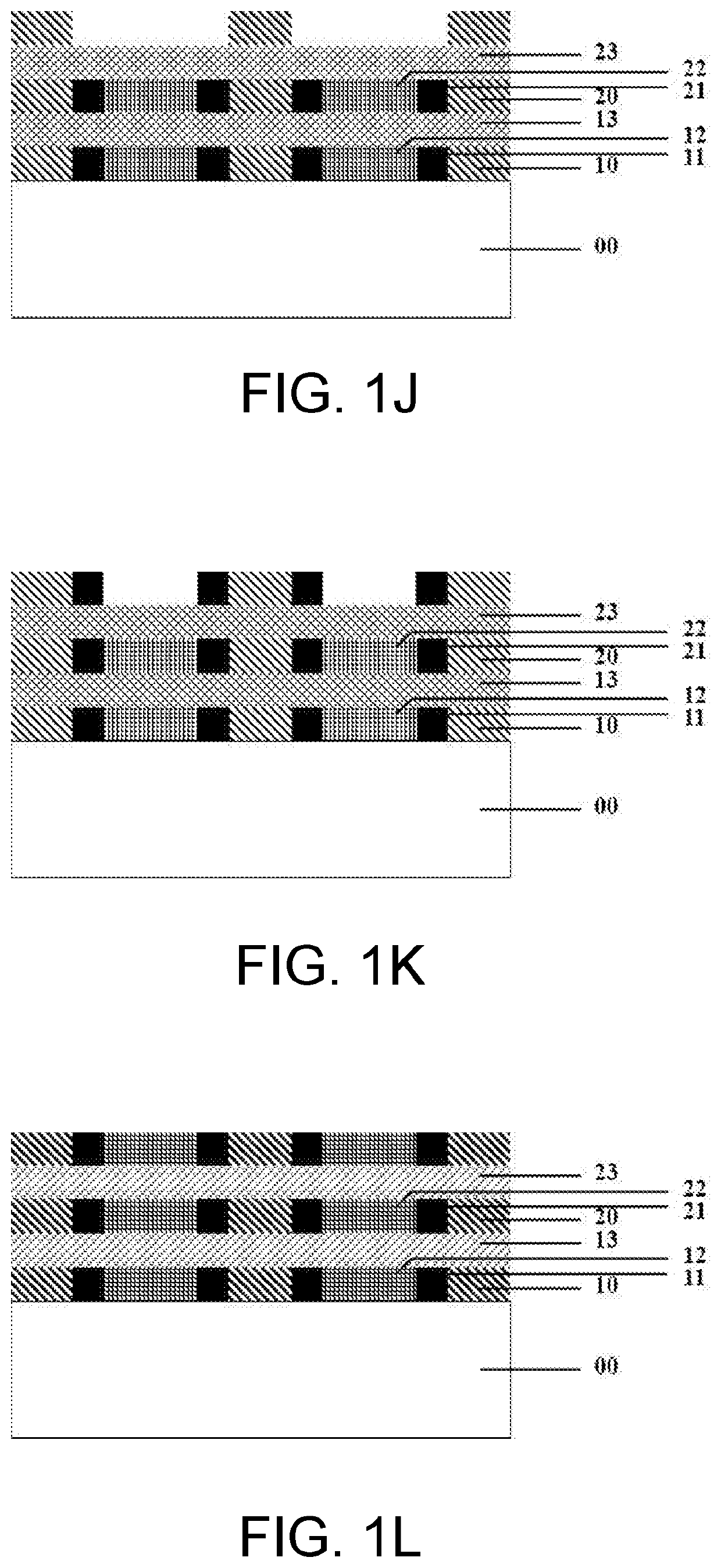

Roll-to-roll plasma device for enhancing chemical vapor deposition

InactiveCN101629283AImprove transportation efficiencyReduce surface irregularitiesChemical vapor deposition coatingThermal contractionEngineering

The invention relates to a roll-to-roll plasma device for enhancing chemical vapor deposition, which is characterized in that the device comprises a roll-out roller (2), a winding roller (11), a heating cavity (15), a vertical transmission rail (3), a rail (16), tension pulley groups (4,6,13) and a cooling roller (12), wherein the rail (16) connected with a horizontal transmission rail (20) and arranged in a vacuum chamber (22) is used for feeding deposited flexible matrix material into the winding roller (11); the tension pulley groups (4,6,13) are respectively arranged in a vacuum chamber (1), the vacuum chamber (22) and the heating chamber (15) and used for keeping the tensile force of the matrix material in the transmission process, and the cooling roller (12) is arranged in the vacuum chamber (22) and used for cooling the deposited flexible matrix material loaded on the winding roller (11). The device greatly improves the transport efficiency of the flexible matrix in the vacuum cavity, furthermore accurately controls the surface tension of the matrix at high temperature conveniently, and greatly reduces the phenomenon of uneven surface of the flexible matrix caused by thermal contraction at high temperature.

Owner:SHUANGDENG GRP

Nitride semiconductor laser device and nitride semiconductor device

ActiveUS7408199B2Excellent characteristicsProlong lifeOptical wave guidanceLaser detailsIndiumCrystal plane

A nitride semiconductor laser device comprises, on a principle face of a nitride semiconductor substrate: a nitride semiconductor layer having a first conductivity type; an active layer comprising indium, and a nitride semiconductor layer having a second conductivity type that is different from said first conductivity type, and on the surface of which is formed a stripe ridge; said principal face of said nitride semiconductor substrate having an off angle a (θa) with respect to a reference crystal plane, in at least a direction substantially parallel to said stripe ridge.

Owner:NICHIA CORP

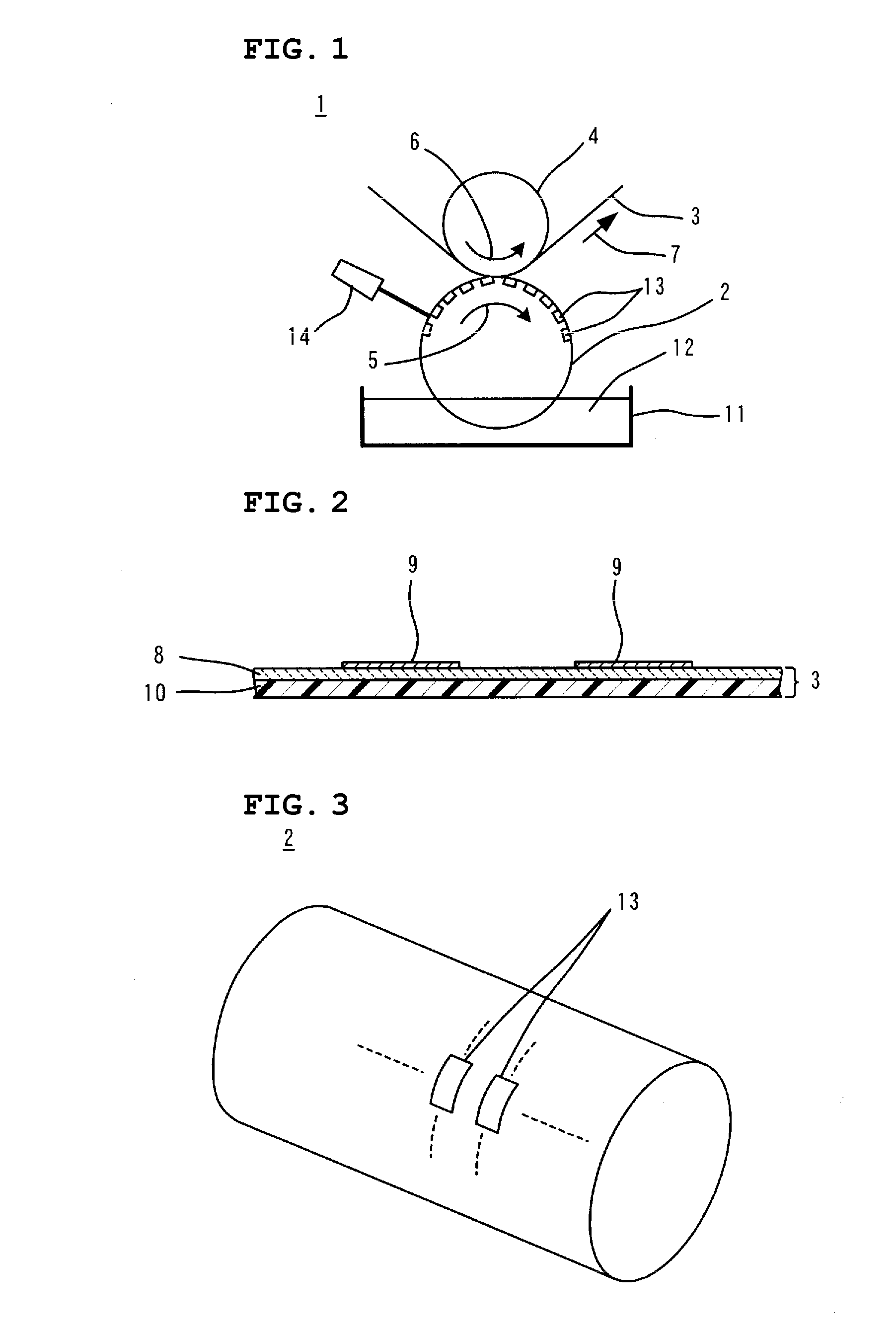

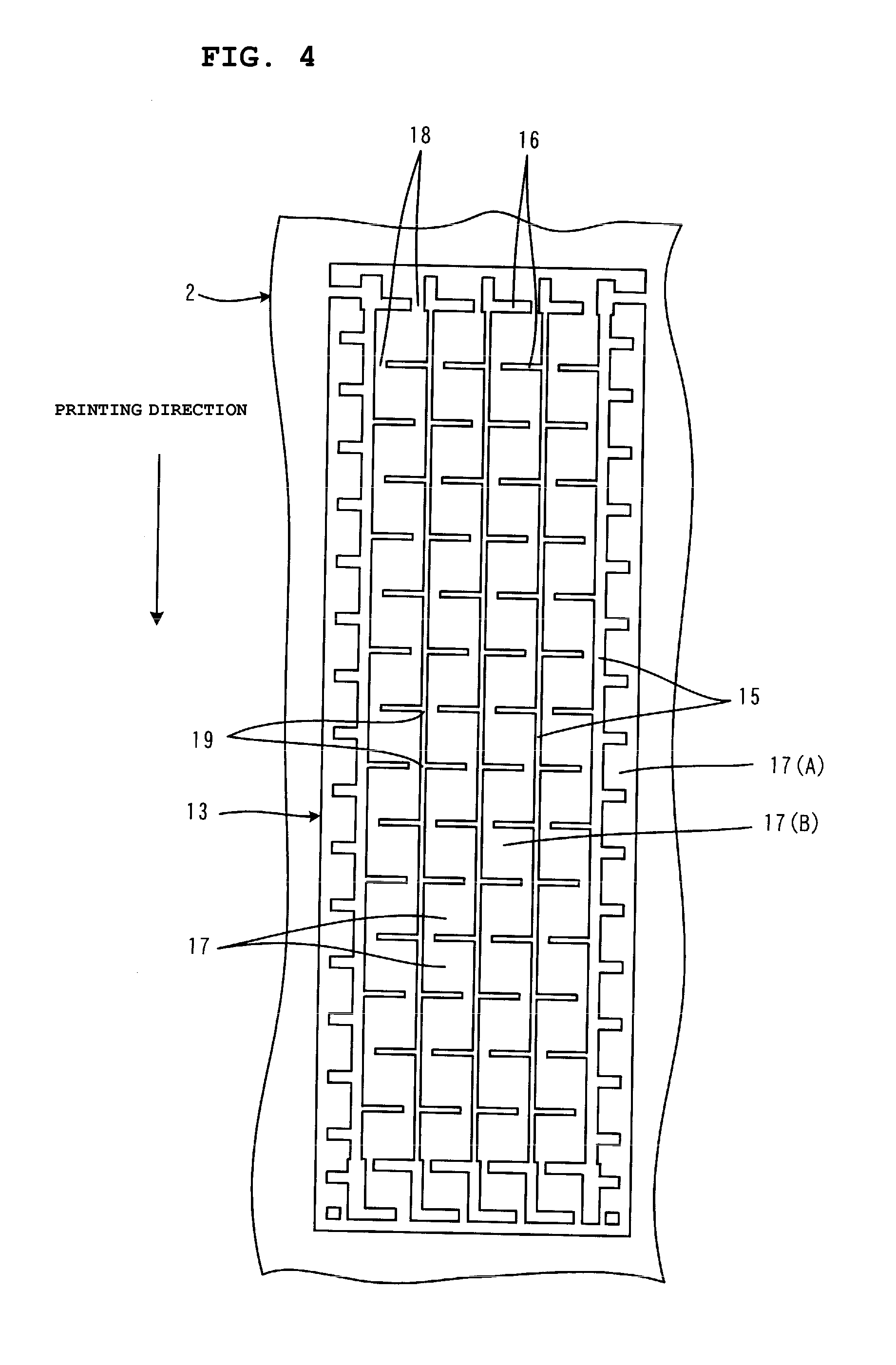

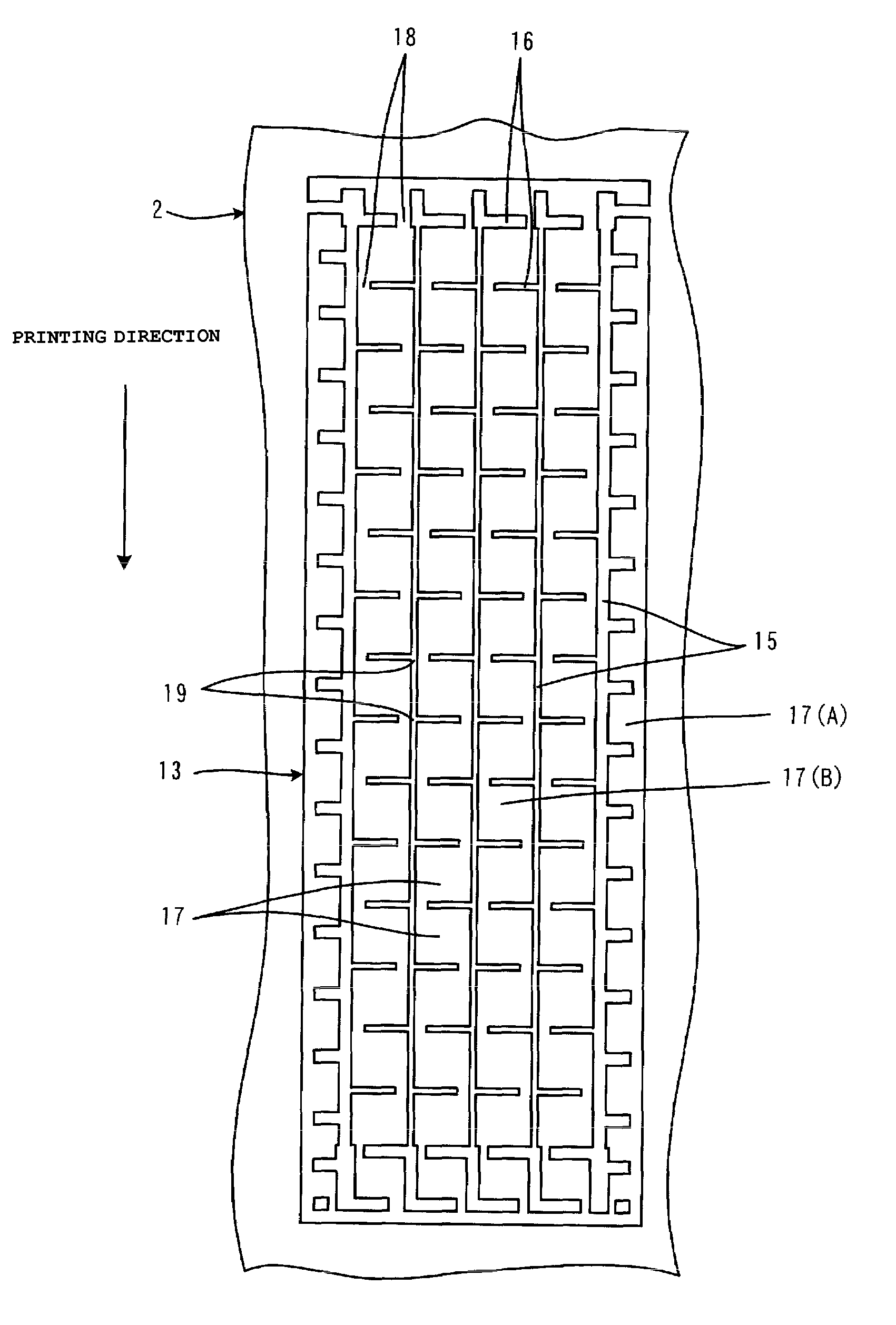

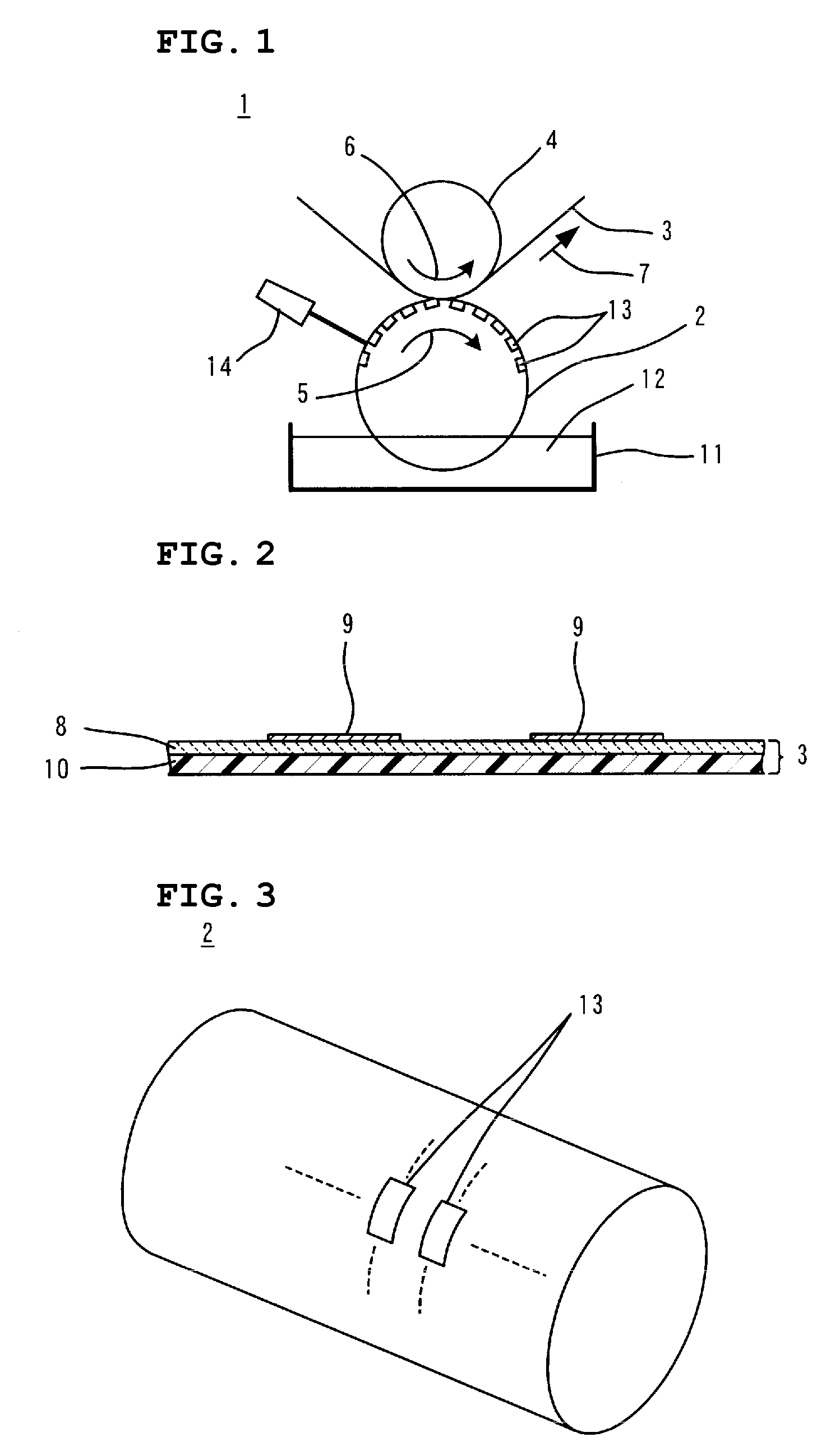

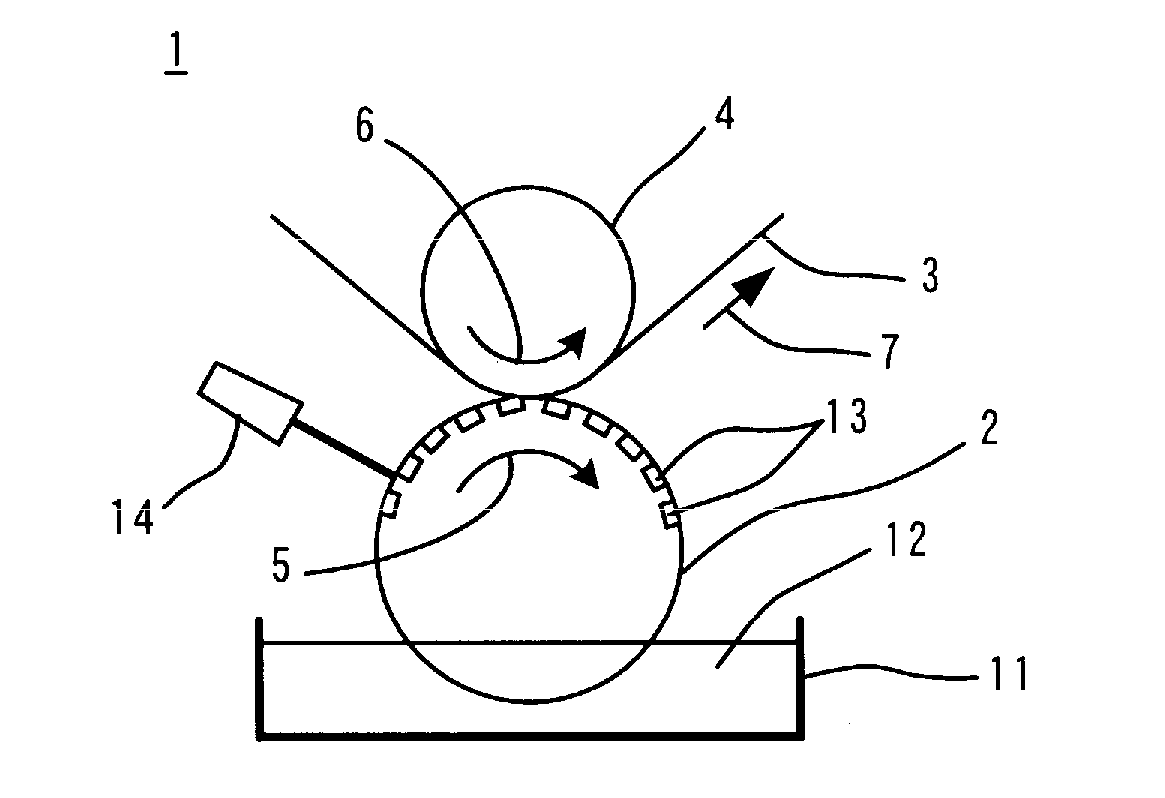

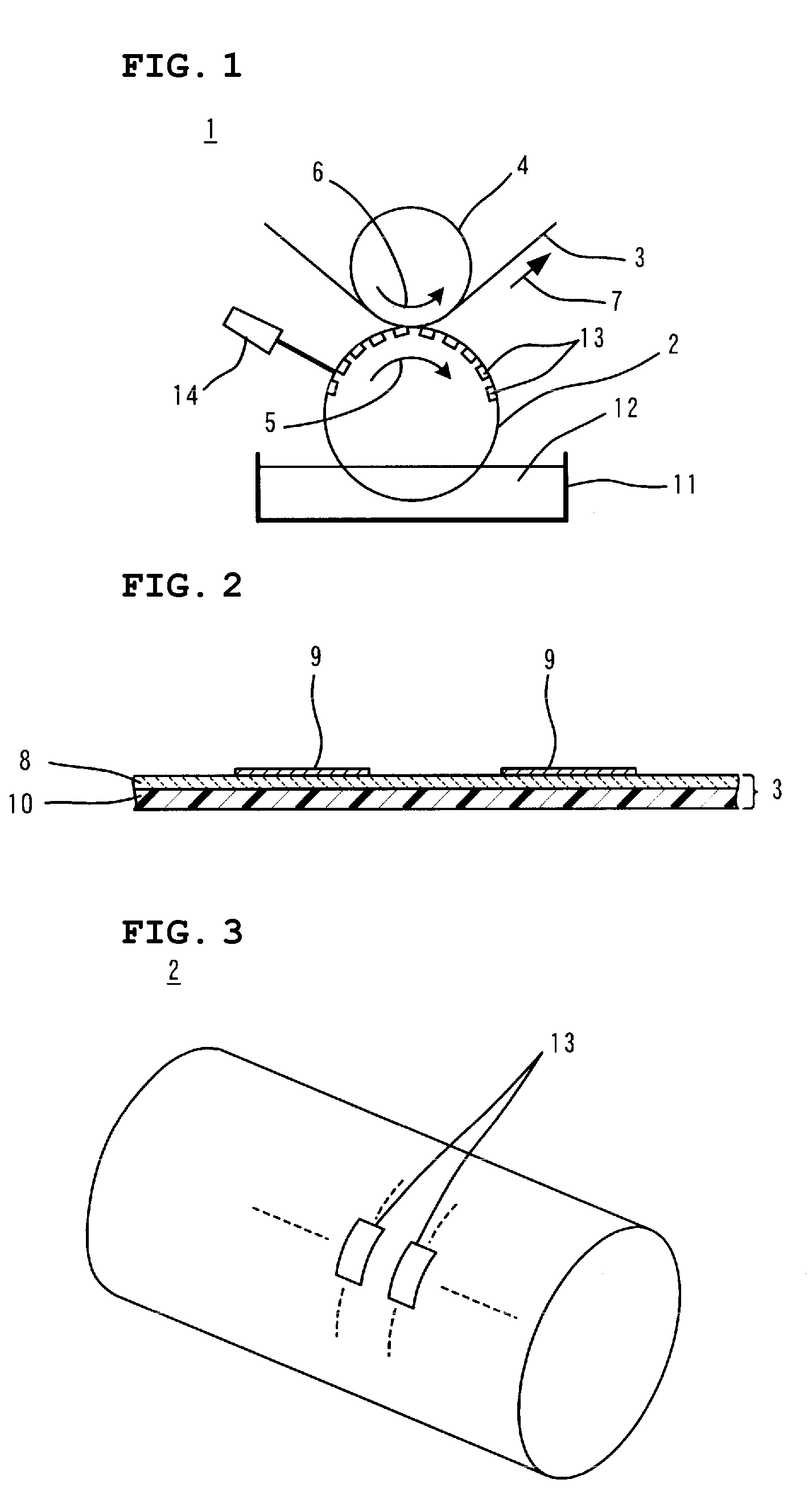

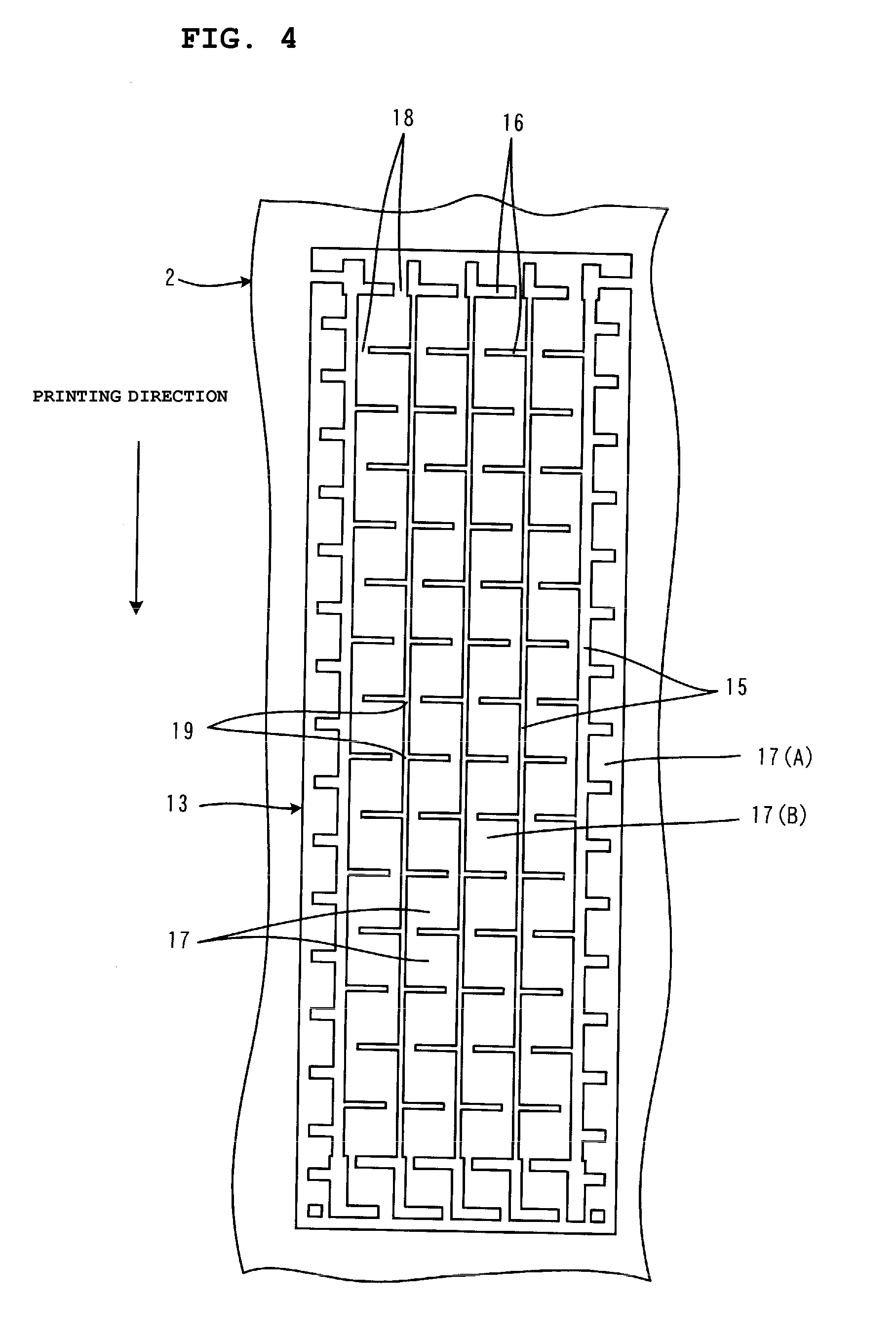

Photogravure press and method for manufacturing multilayer ceramic electronic component

ActiveUS20070107611A1Uniform thicknessImprove smoothnessRotary intaglio printing pressFixed capacitor electrodesEngineeringPhotogravure

In a print area provided on a peripheral surface of a gravure roll, a plurality of cells are defined by printing-direction walls and perpendicular walls, and each perpendicular wall has a plurality of cuts. In a center portion of the print area, most intersections of the printing-direction walls and the perpendicular walls are defined by T-shaped intersections where the perpendicular walls do not cross the printing-direction walls, but meet the printing-direction walls in a T-shaped arrangement. Preferably, round chamfers are provided at corners where a portion of each printing-direction wall and a portion of each perpendicular wall intersect, and at leading ends of the perpendicular walls pointing toward the cuts.

Owner:MURATA MFG CO LTD

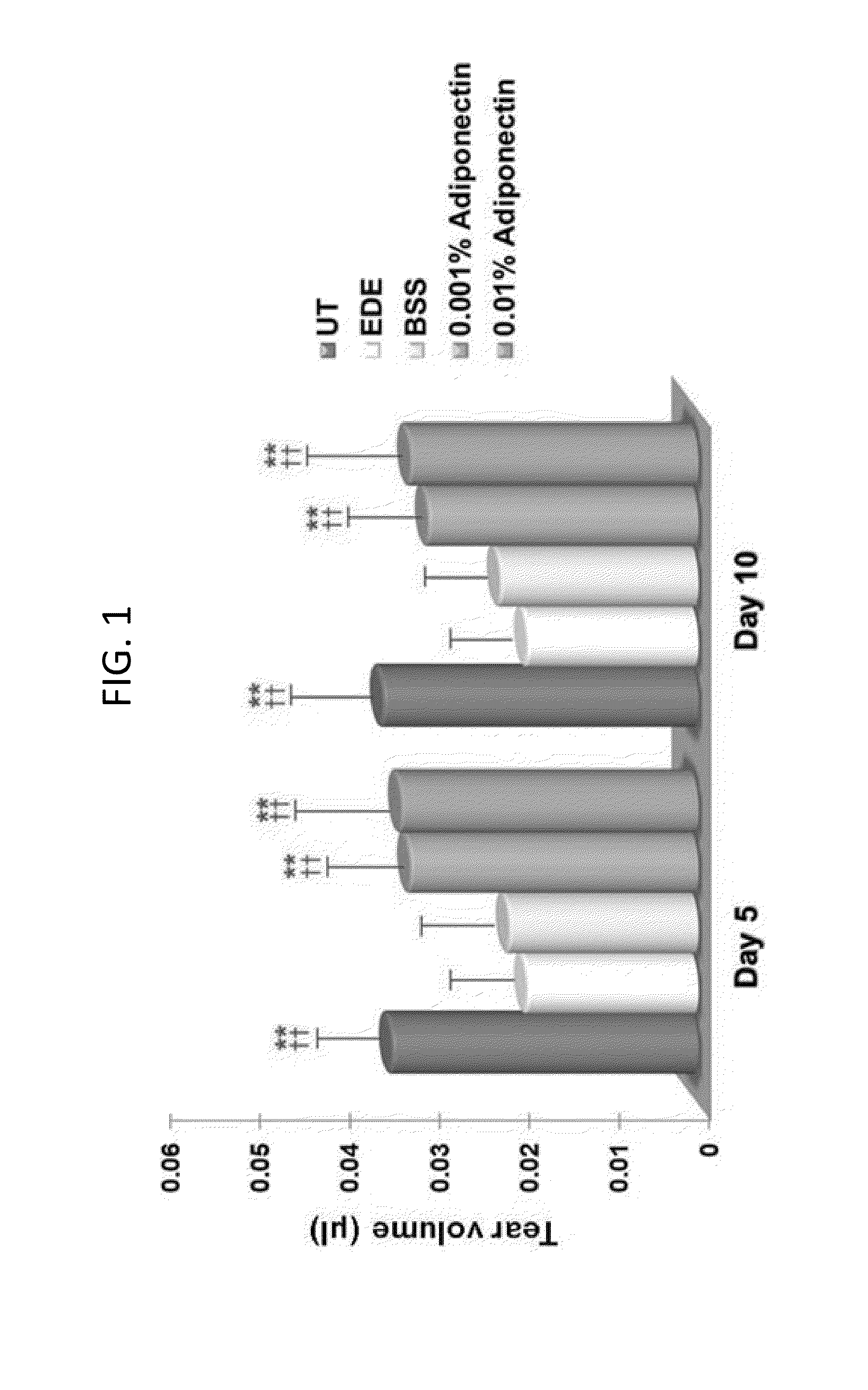

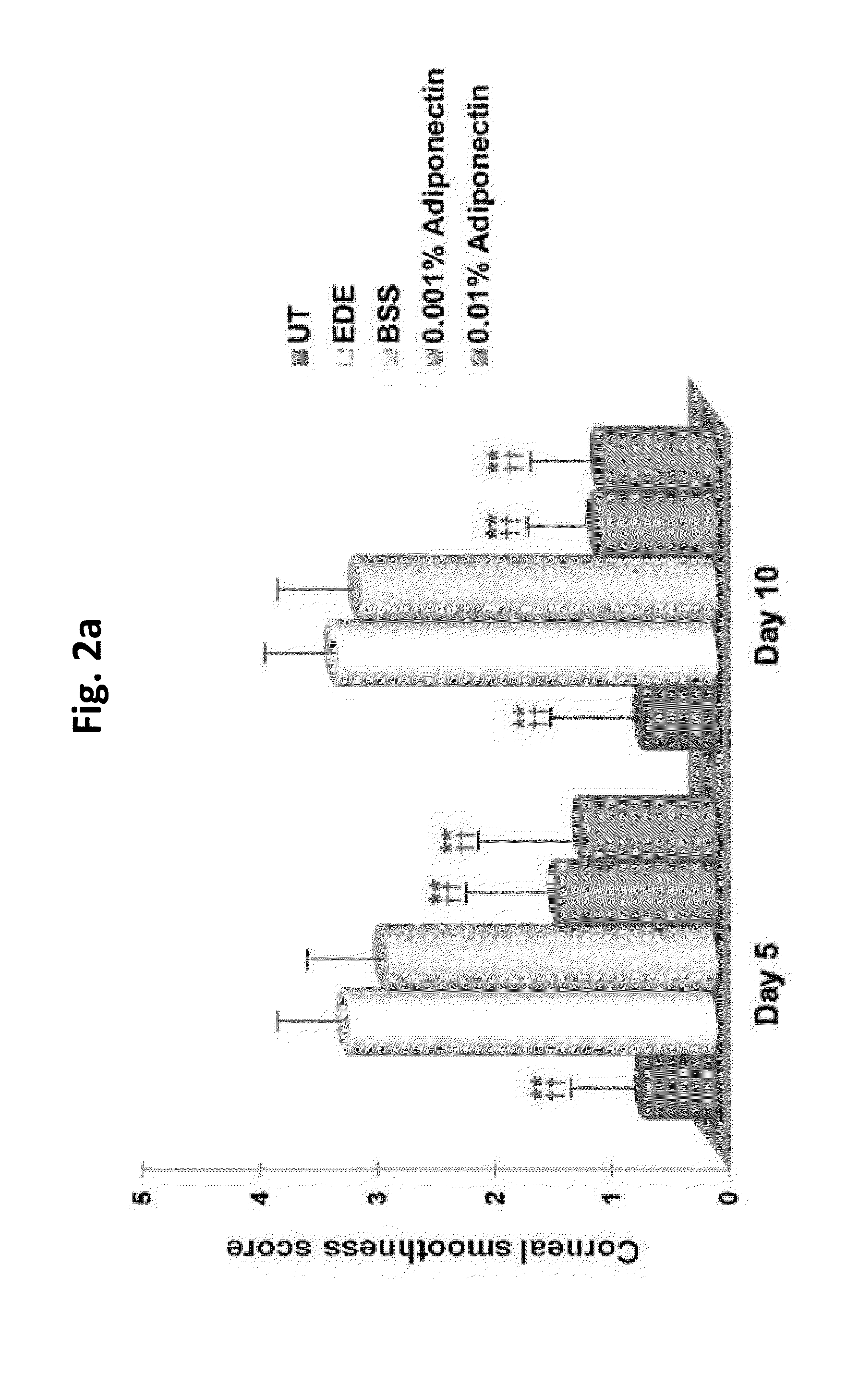

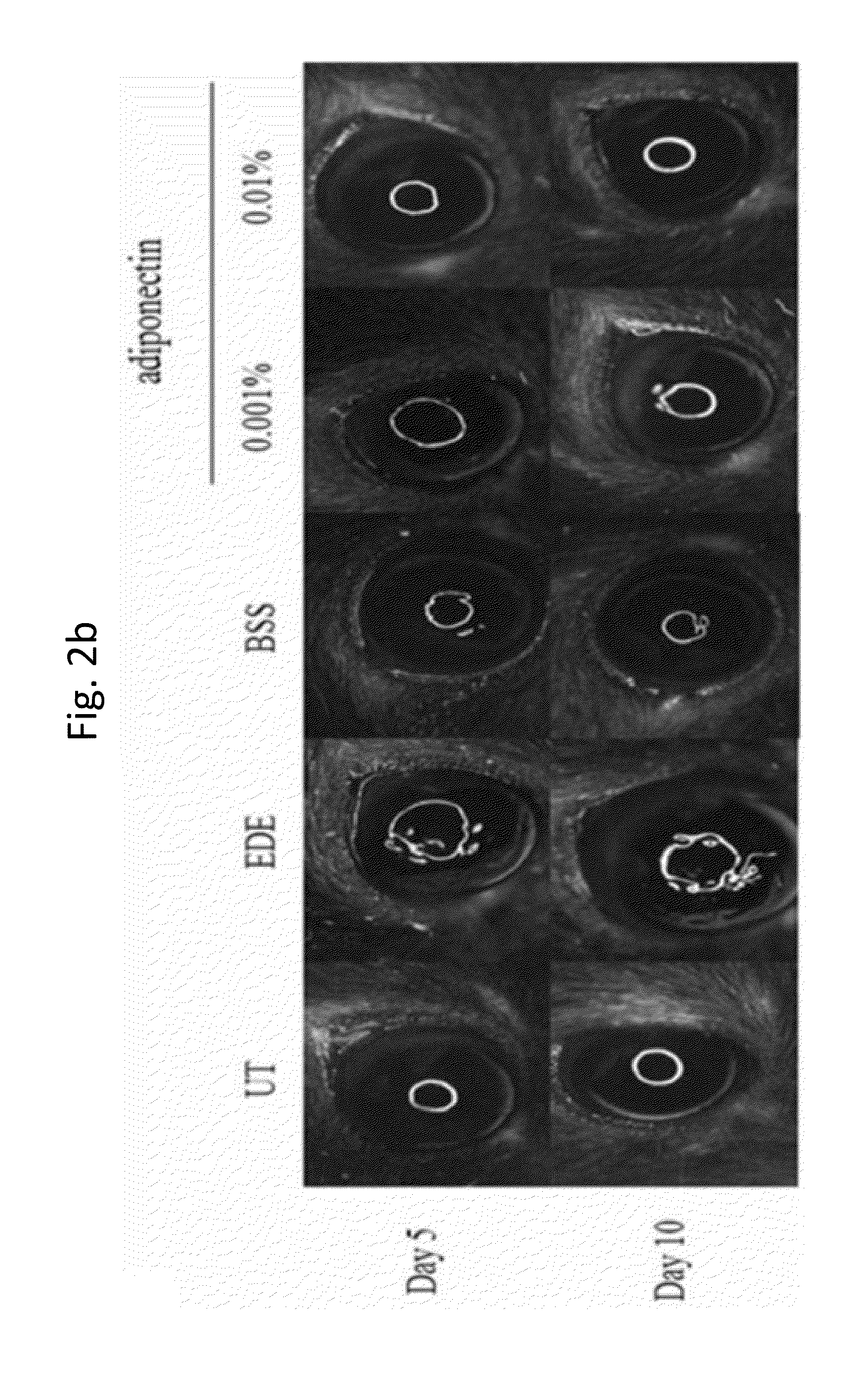

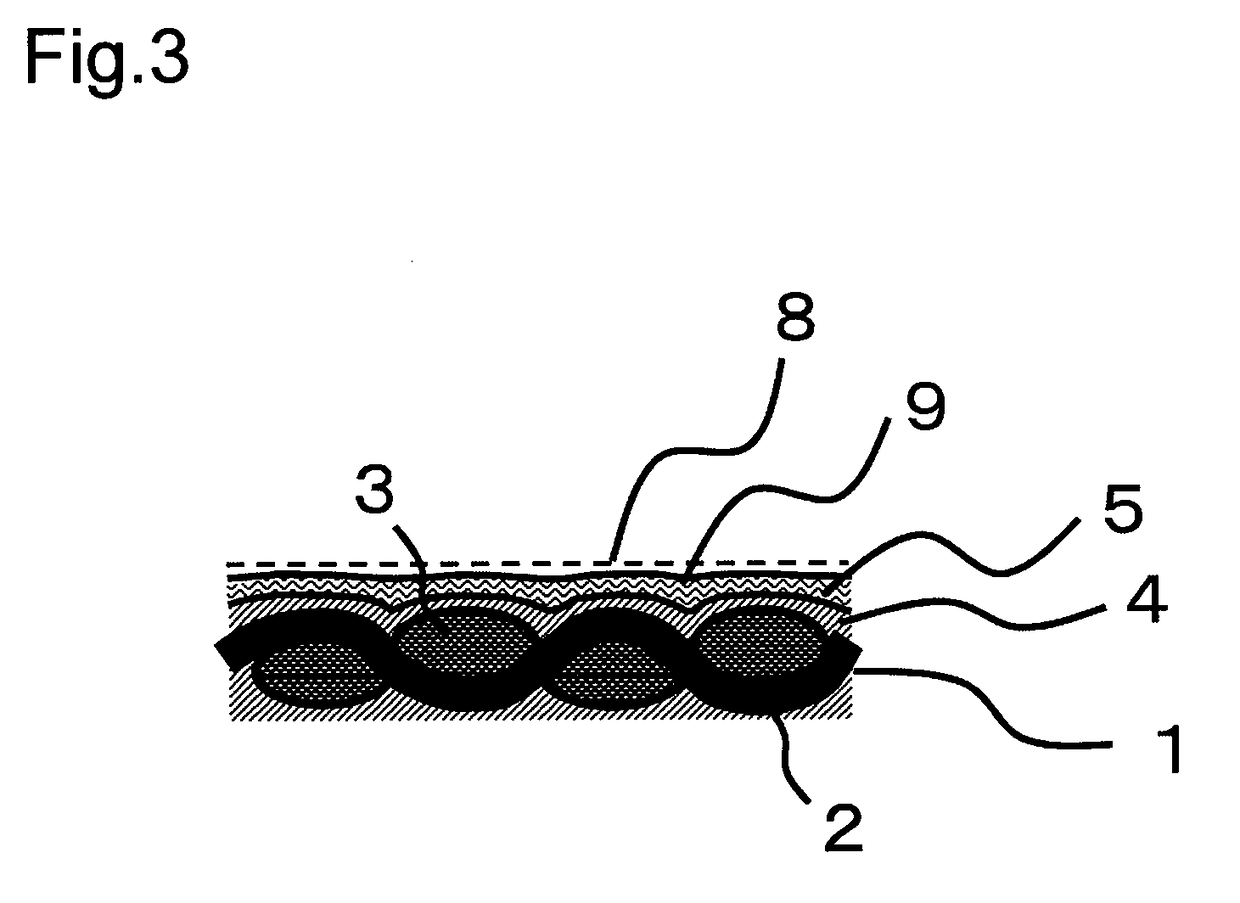

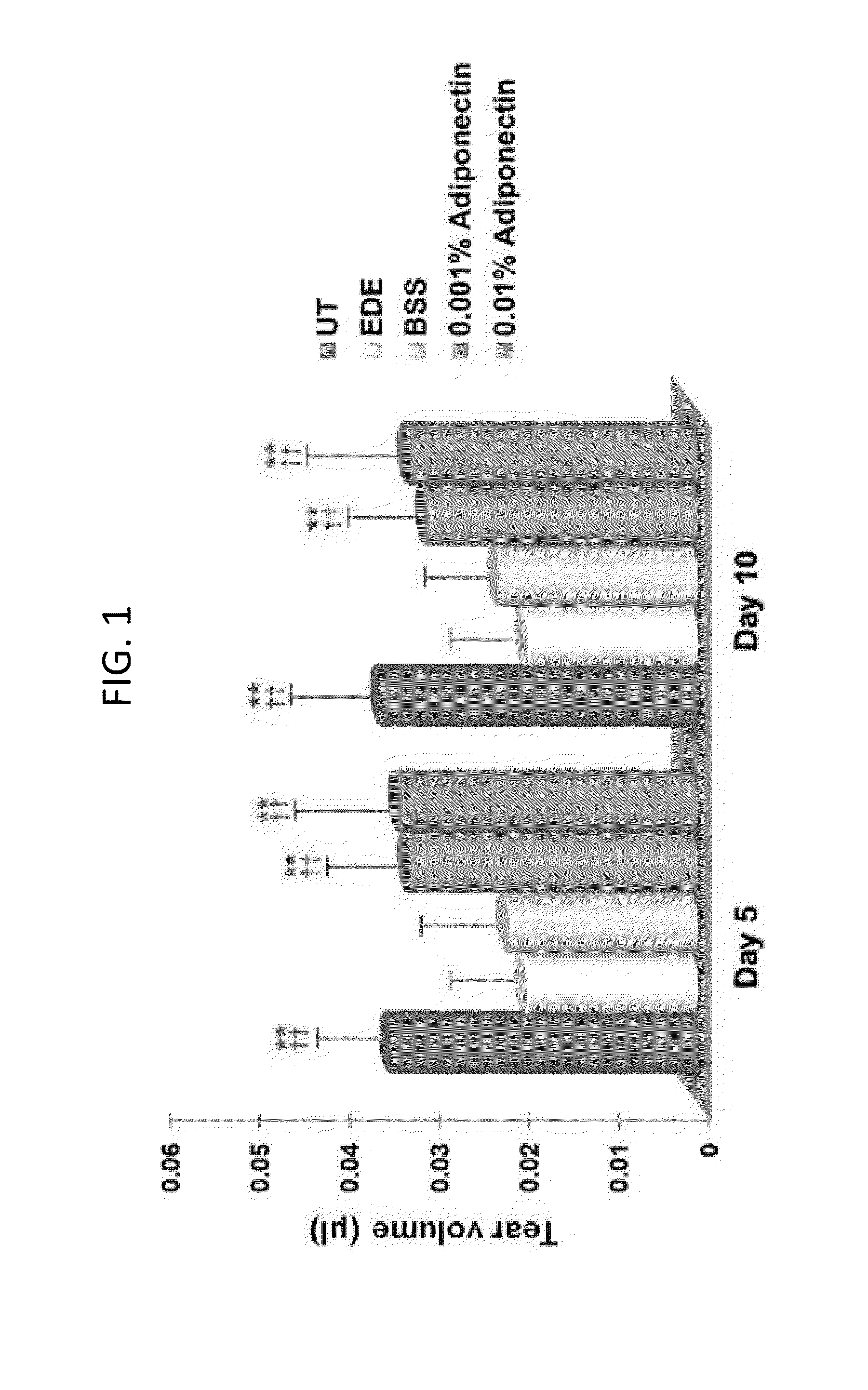

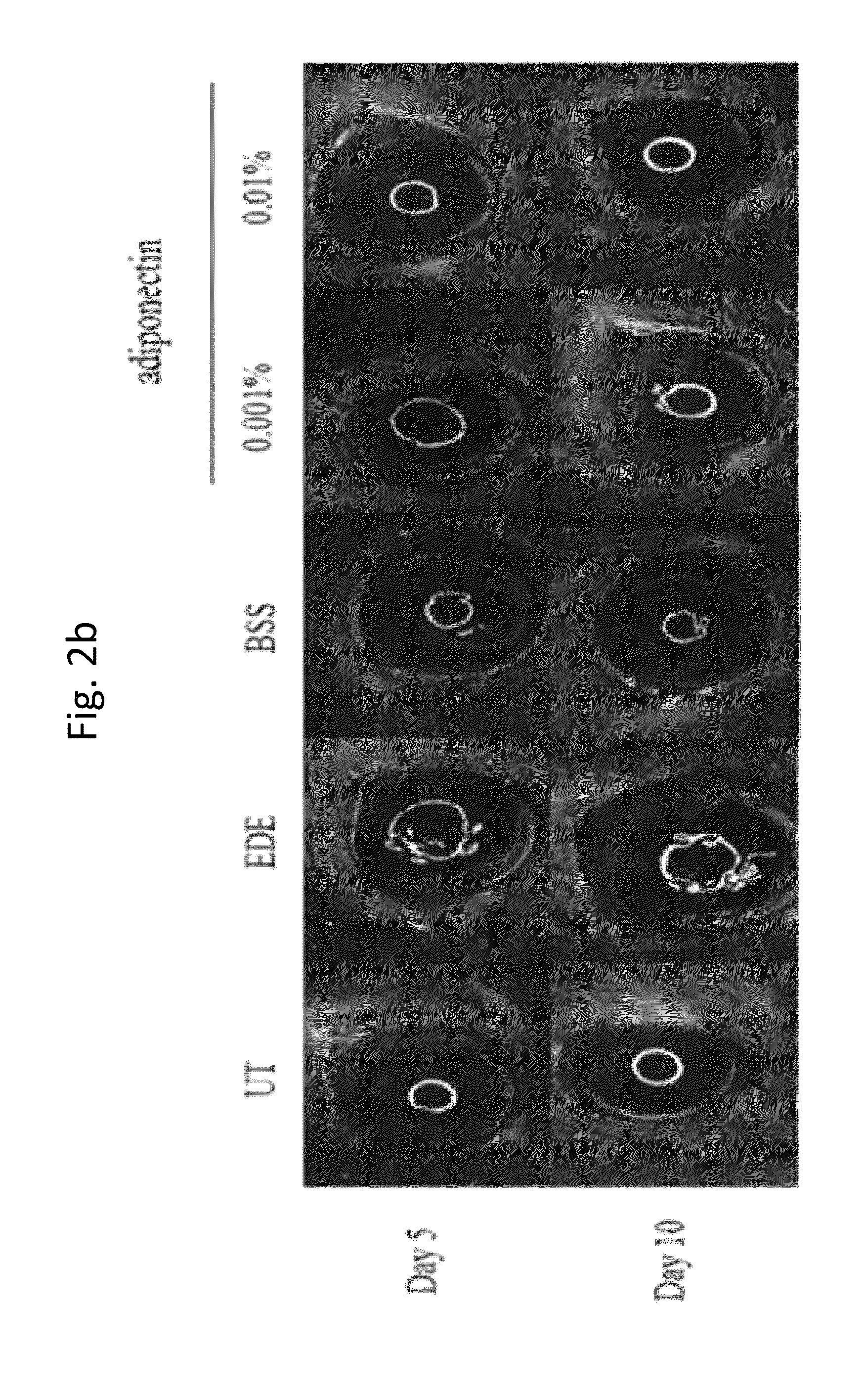

Methods for preventing or treating eye diseases using adiponectin

ActiveUS20140037712A1Stimulate tear productionAlleviating ocular surface irregularityHormone peptidesSenses disorderDiseaseSide effect

A composition for preventing or treating an eye disease includes adiponectin as an active ingredient. Adiponectin as an active ingredient is eventually revealed to show prevention or therapeutic efficacies for eye diseases such as dry eye (syndrome), inflammatory eye disease and side effects due to the use of contact lenses by promoting tear secretion, alleviating ocular surface irregularities, decreasing inflammatory cytokines on the ocular surface and lacrimal gland, and increasing conjunctival goblet cell density. In addition, the composition having eye contact lubrication effects may be used as cleaners or lubricants for preventing non-bacterial inflammation due to wearing contact lenses.

Owner:IND FOUND OF CHONNAM NAT UNIV

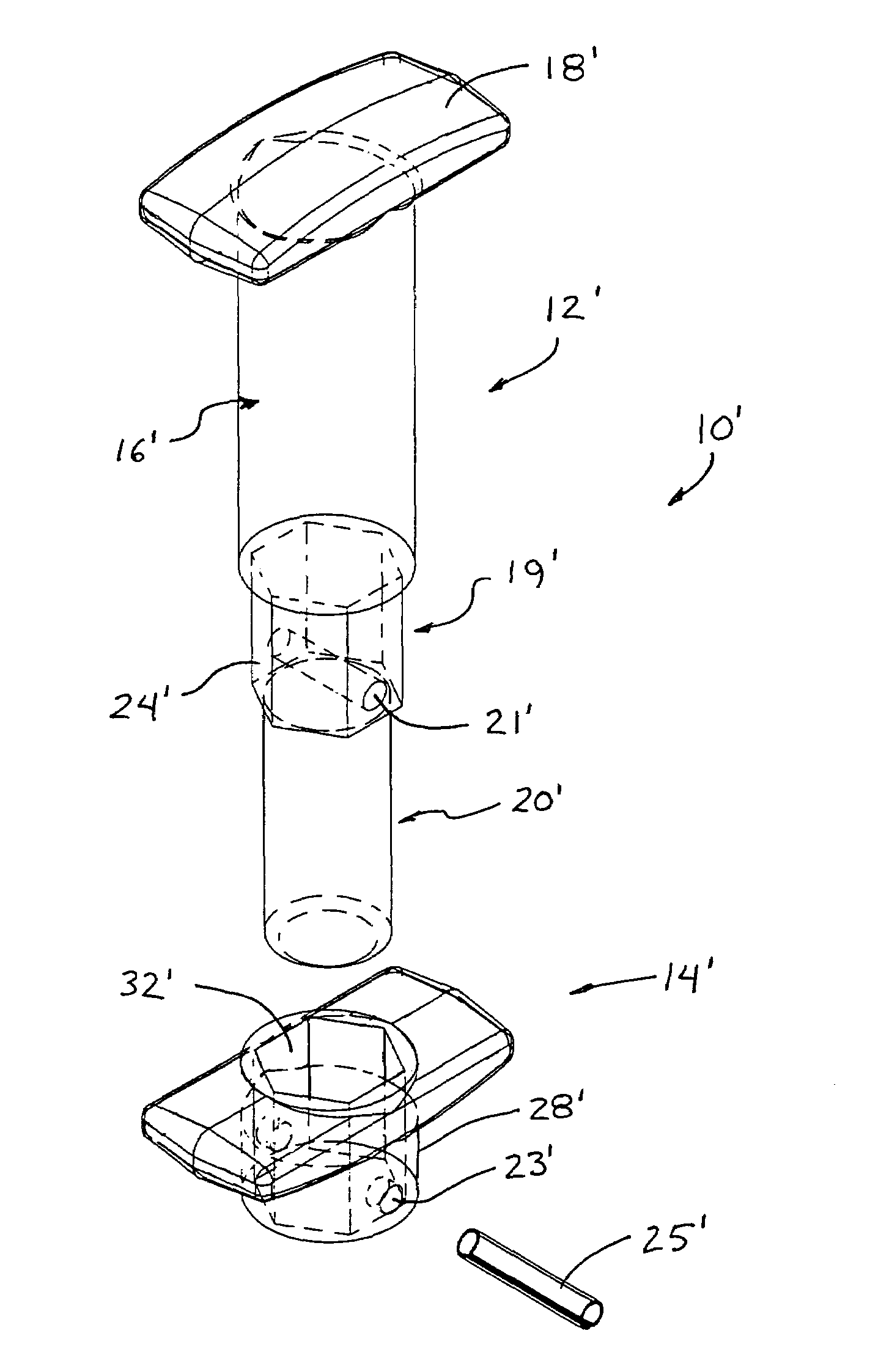

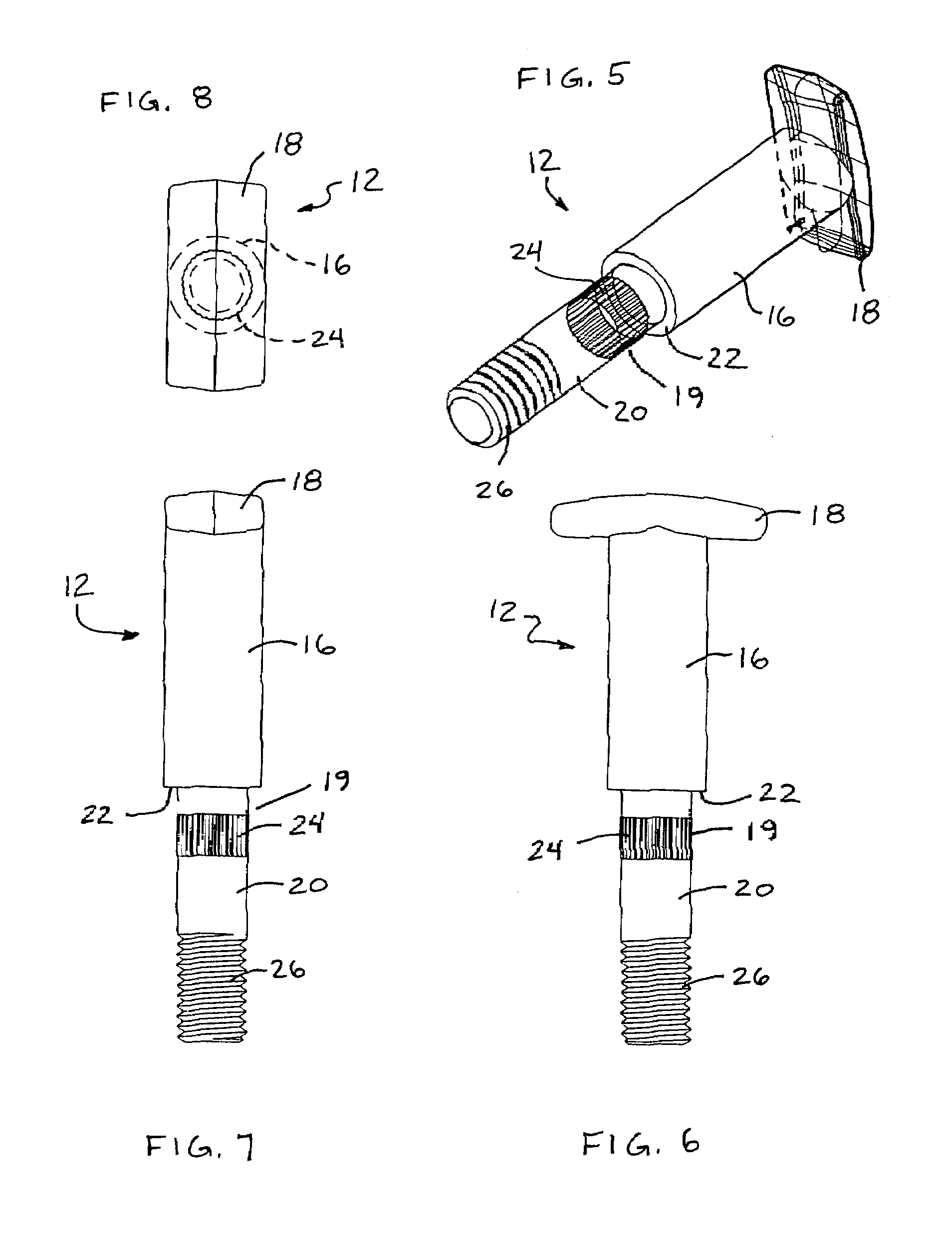

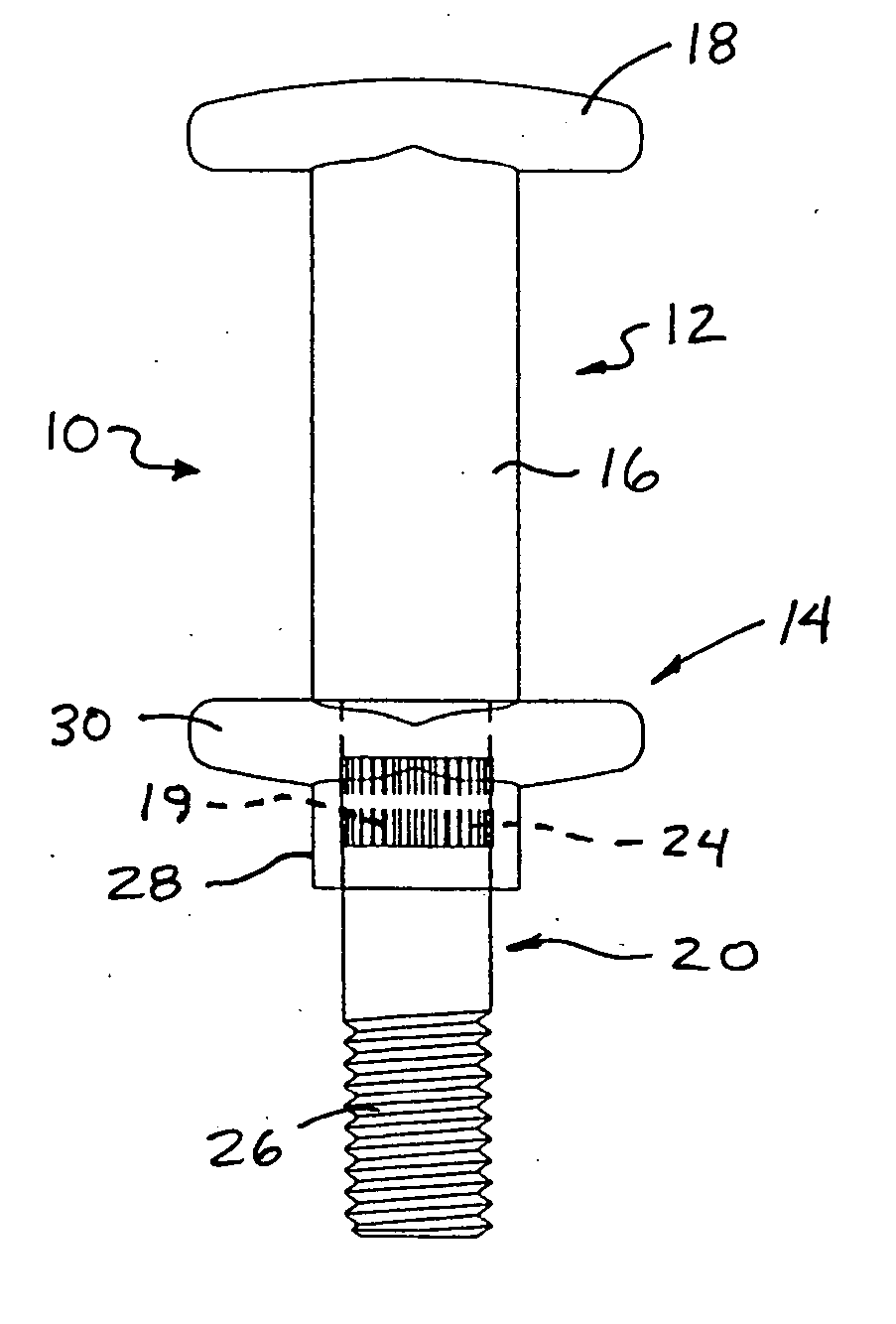

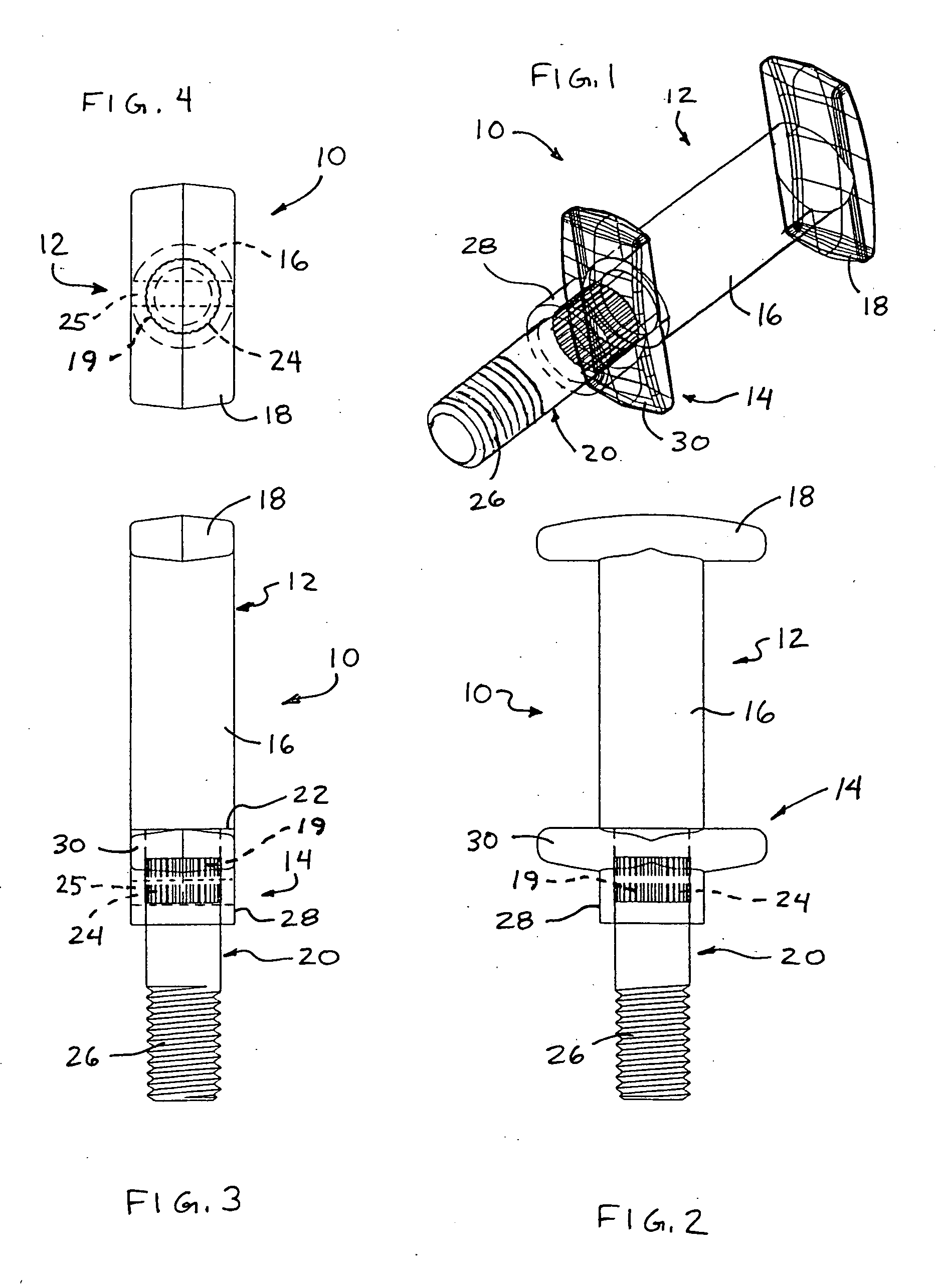

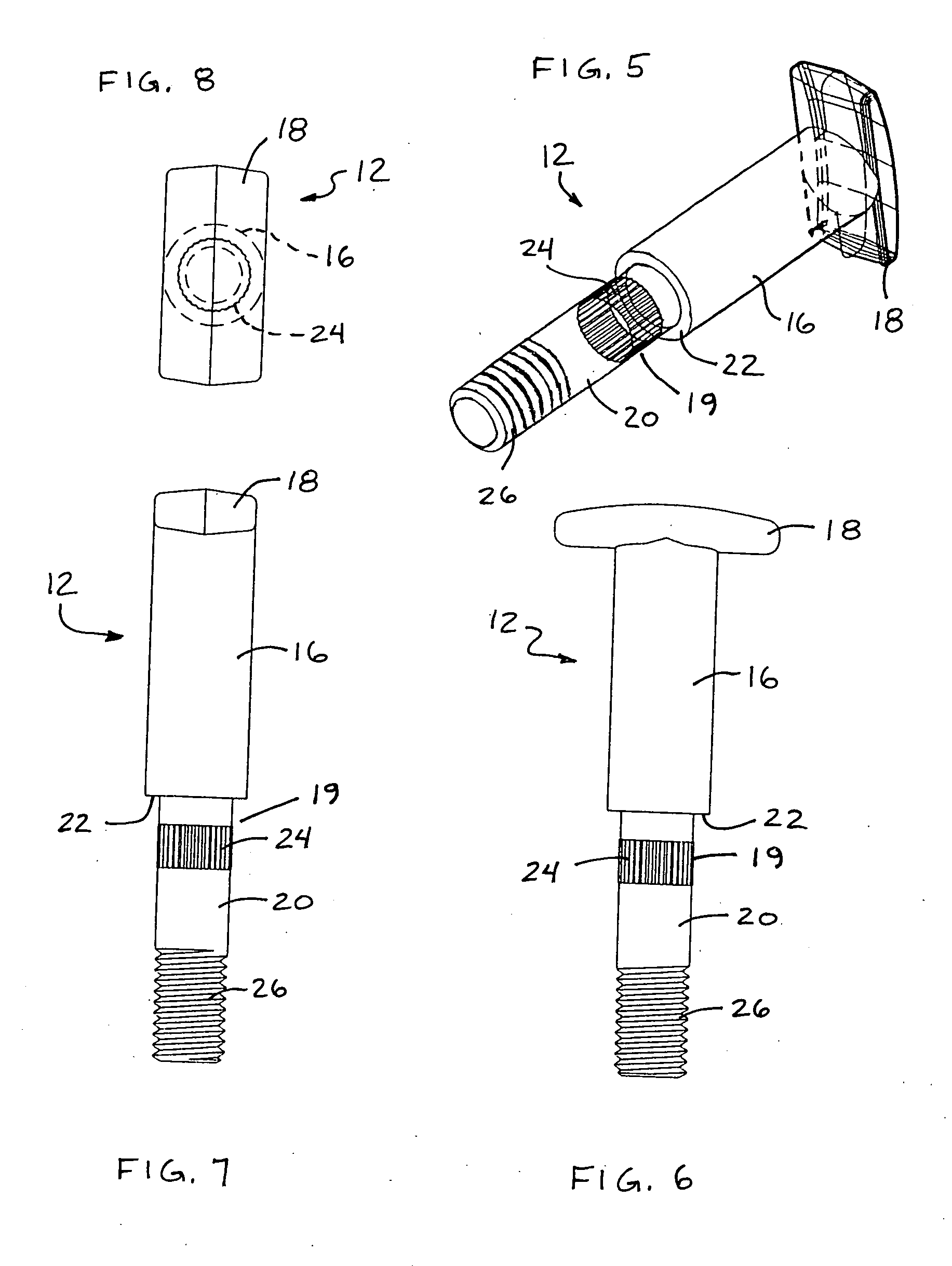

Pin assembly for conveyor chain

InactiveUS7600633B2Well formedReduce surface irregularitiesCoupling device connectionsConveyorsMechanical engineering

A pin assembly for a chain of a material handling system includes a pin element and an attachment element. The pin element includes a shaft portion, a head portion at an end of the shaft portion, and an attachment portion at an end of the shaft portion opposite the head portion. The attachment element is configured to attach to the attachment portion of the pin element, and is positionable at the attachment portion and is retainable thereto. The attachment element may comprise a second head portion to define an I-type pin assembly or may comprise a side link and pusher member construction or other element or member. A mounting extension may extend from the attachment portion for mounting an object to the pin assembly after the attachment is attached to the pin element.

Owner:FROST TECH

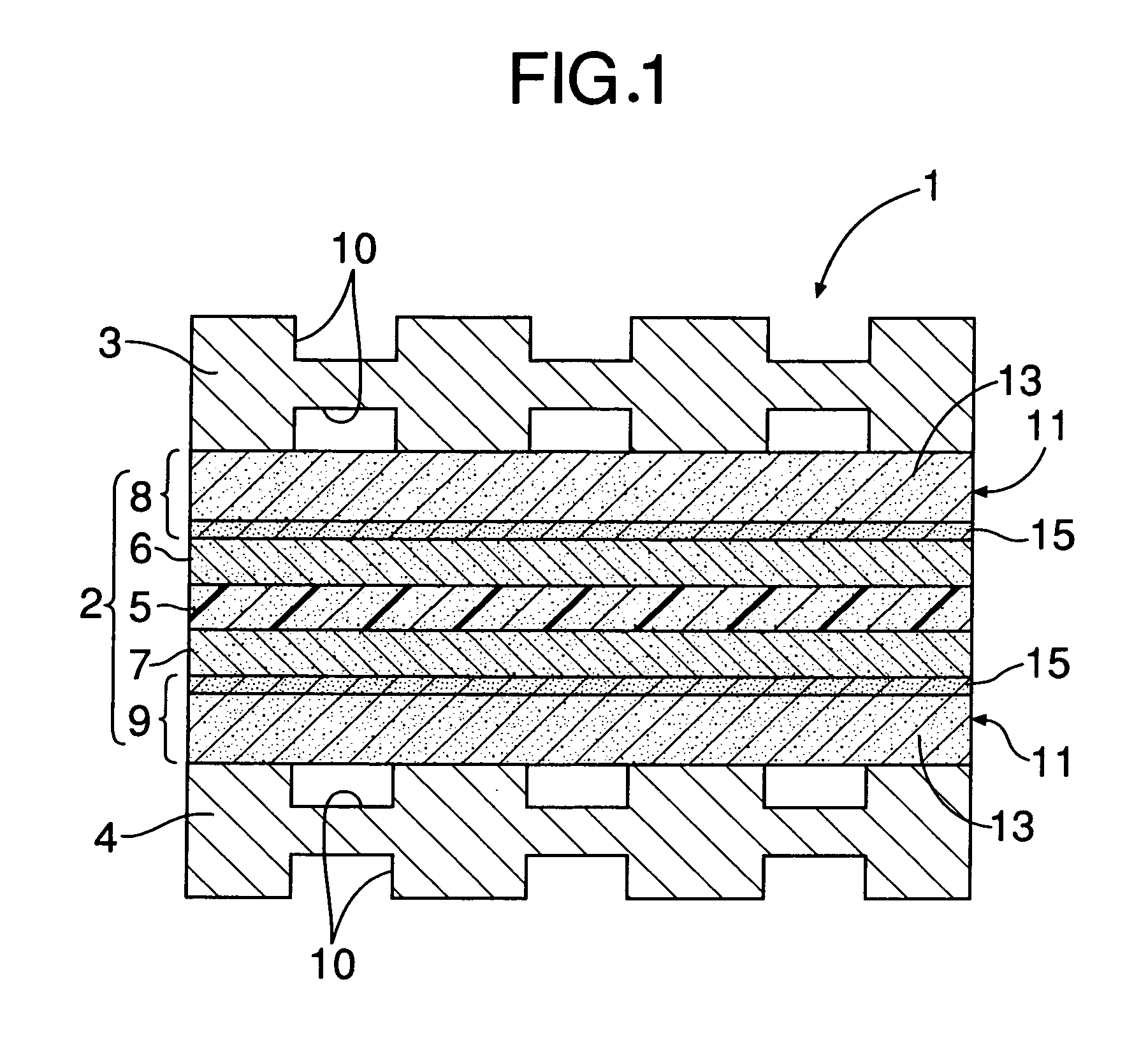

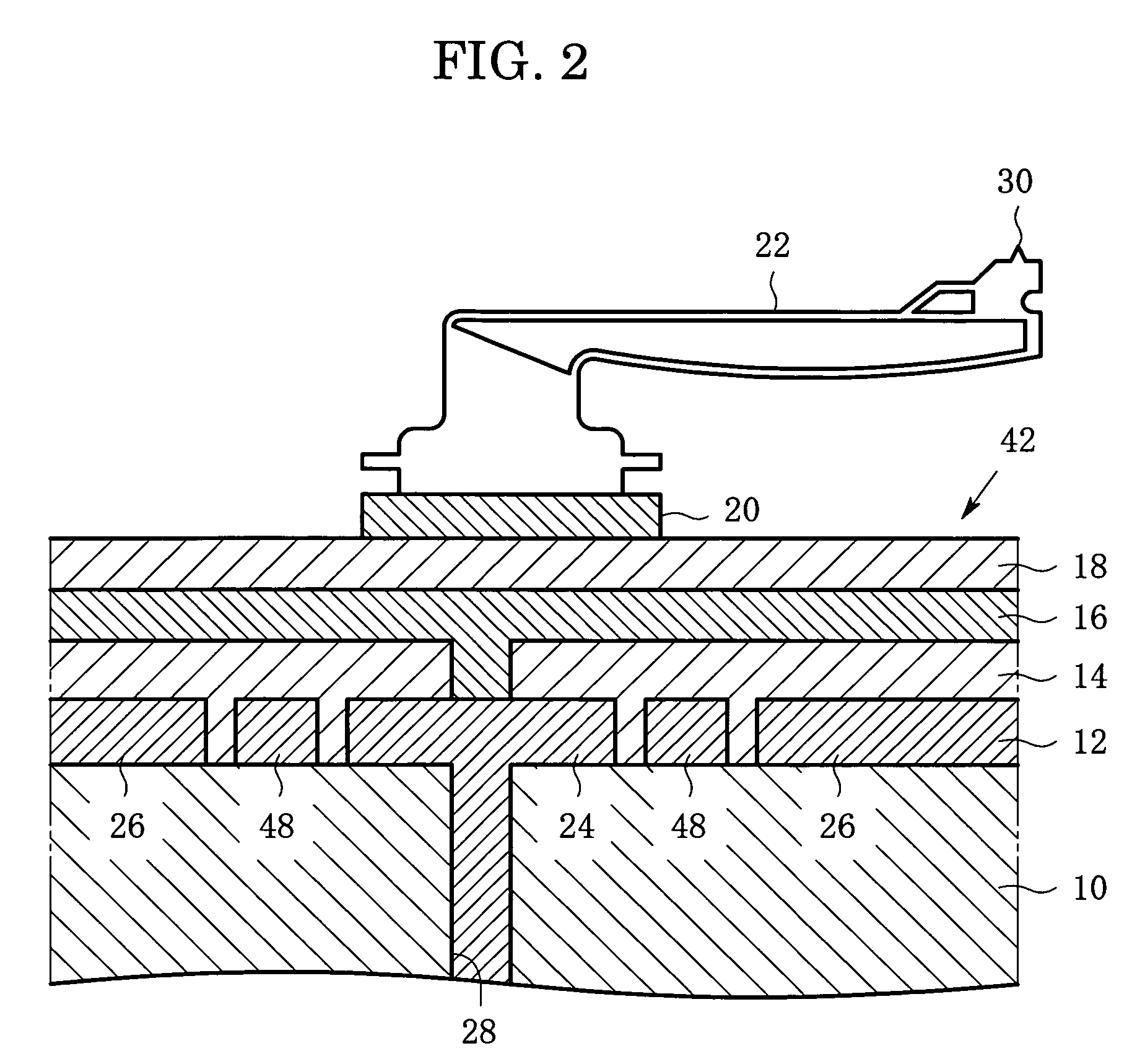

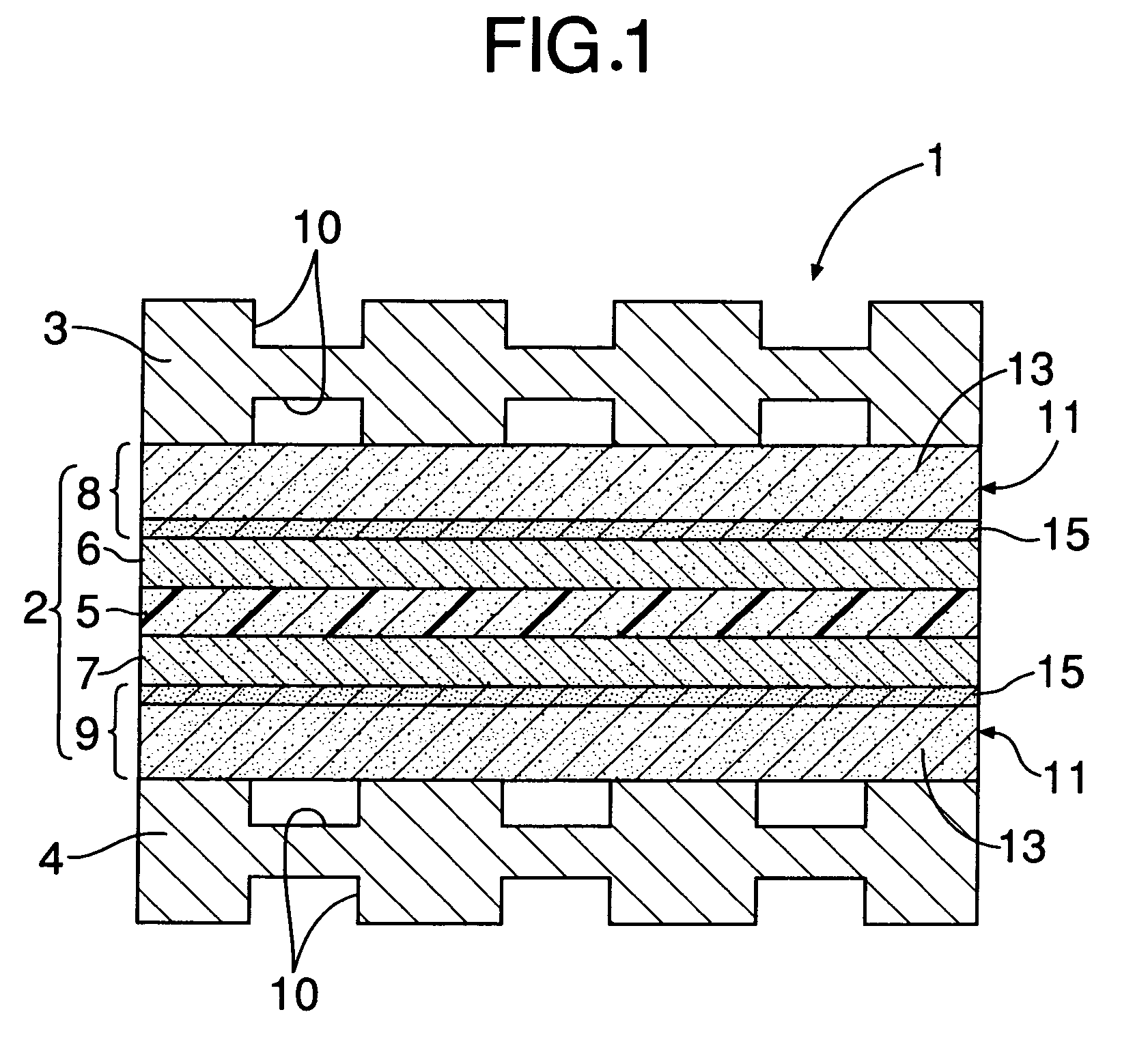

Fuel cell

ActiveUS20050130028A1Avoid cloggingReduce surface irregularitiesCell electrodesCell component detailsPolymer electrolytesFuel cells

A fuel cell includes a laminated, plate-shaped membrane electrode assembly and first and second separator plates sandwiching the membrane electrode assembly. The membrane electrode assembly includes a polymer electrolyte membrane; first and second electrode layers sandwiching the polymer electrolyte membrane; and first and second gas-diffusion layers disposed on an outer side of the electrode layers, respectively. The first and second gas-diffusion layers are made of an air-permeable metallic material. An arithmetic average roughness Ra of a surface of the air-permeable metallic material on the side contacting one of the electrode layers is in a range of 0.1 μm≦Ra≦1.0 μm.

Owner:HONDA MOTOR CO LTD

Coated fiber-reinforced resin molded article and manufacturing method of the same

An object is to provide a manufacturing method of a fiber-reinforced resin that significantly reduces a resin filling defect on the surface and surface irregularity caused by a temperature difference between a molding temperature (curing temperature) and ordinary temperature in the course of molding the fiber-reinforced resin, and a product manufactured by the manufacturing method. There is accordingly provided a manufacturing method of a coated fiber-reinforced resin molded article and a product manufactured by the manufacturing method. The manufacturing method comprises a first molding process that cures a matrix resin which a reinforcing fiber is impregnated with at a temperature T1(° C.) to obtain a fiber-reinforced resin molded article; and a second molding process that places the fiber-reinforced resin molded article in a cavity of a mold, sets the cavity to a temperature T2(° C.) that is lower than the temperature T1(° C.), injects a liquid coating layer-forming resin material into the cavity such as to coat at least part of a surface layer of the fiber-reinforced resin molded article, and cures the coating layer-forming resin material at the temperature T2(° C.), so as to obtain the coated fiber-reinforced resin molded article, wherein the mold is comprised of at least two pieces and has the cavity in a shape that is approximately same as a shape of the fiber-reinforced resin molded article.

Owner:TORAY IND INC

Methods for preventing or treating eye diseases using adiponectin

ActiveUS8815795B2Significantly effectivePromote productionHormone peptidesSenses disorderDiseaseSide effect

A composition for preventing or treating an eye disease includes adiponectin as an active ingredient. Adiponectin as an active ingredient is eventually revealed to show prevention or therapeutic efficacies for eye diseases such as dry eye (syndrome), inflammatory eye disease and side effects due to the use of contact lenses by promoting tear secretion, alleviating ocular surface irregularities, decreasing inflammatory cytokines on the ocular surface and lacrimal gland, and increasing conjunctival goblet cell density. In addition, the composition having eye contact lubrication effects may be used as cleaners or lubricants for preventing non-bacterial inflammation due to wearing contact lenses.

Owner:IND FOUND OF CHONNAM NAT UNIV

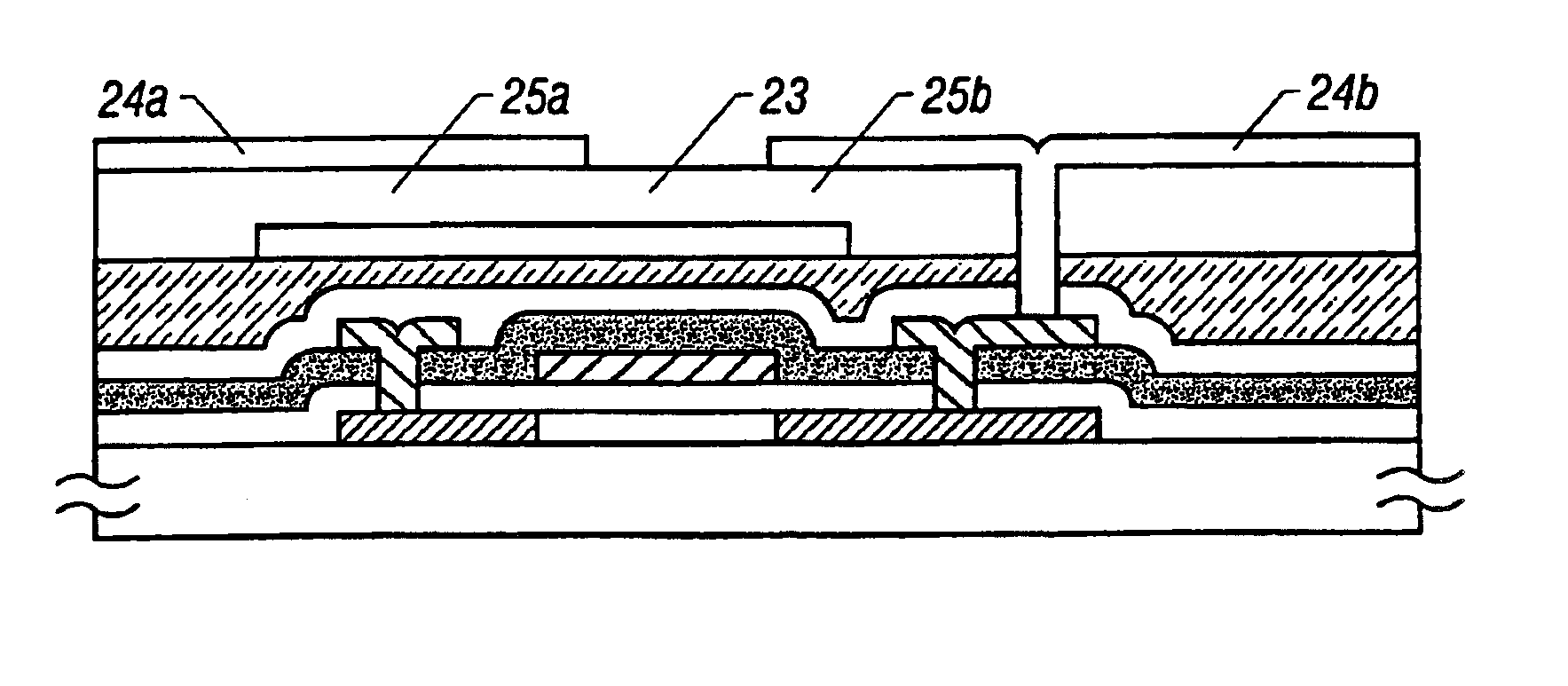

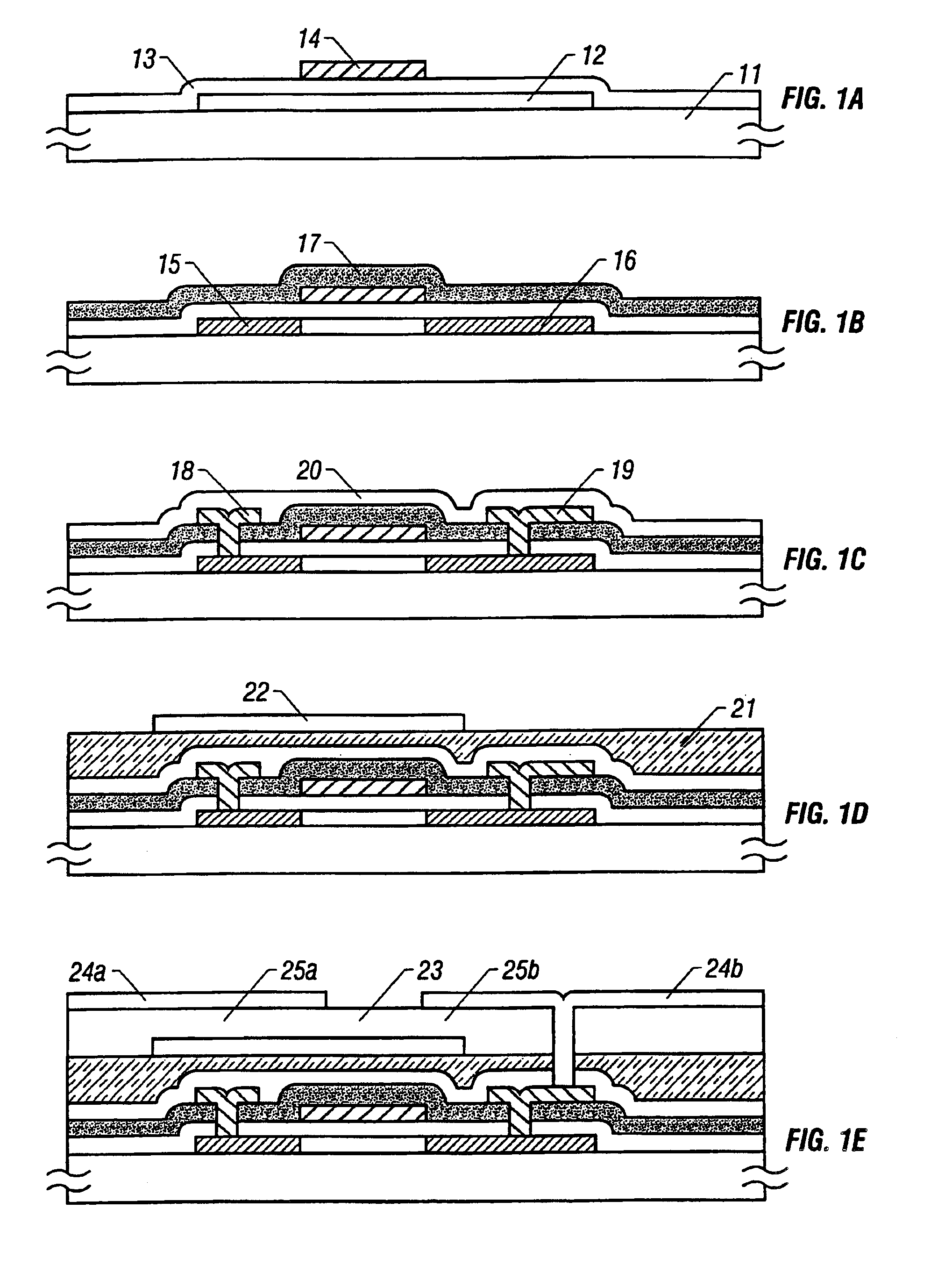

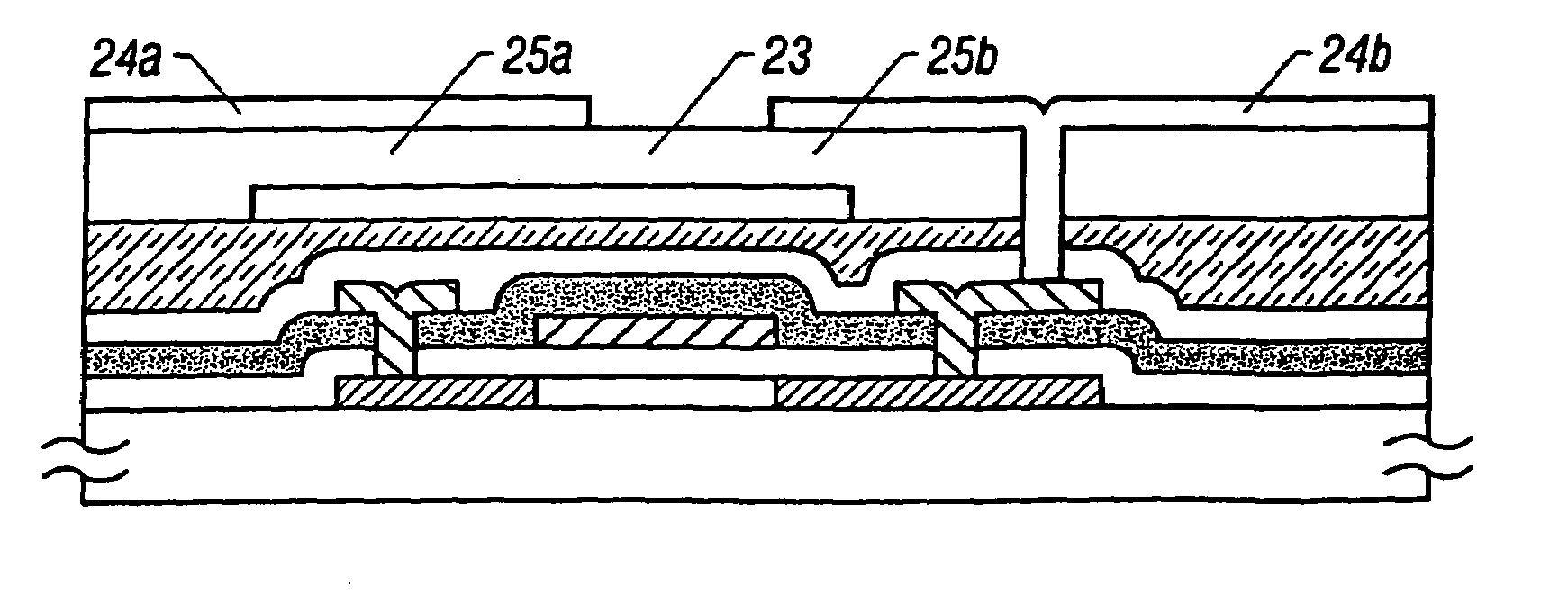

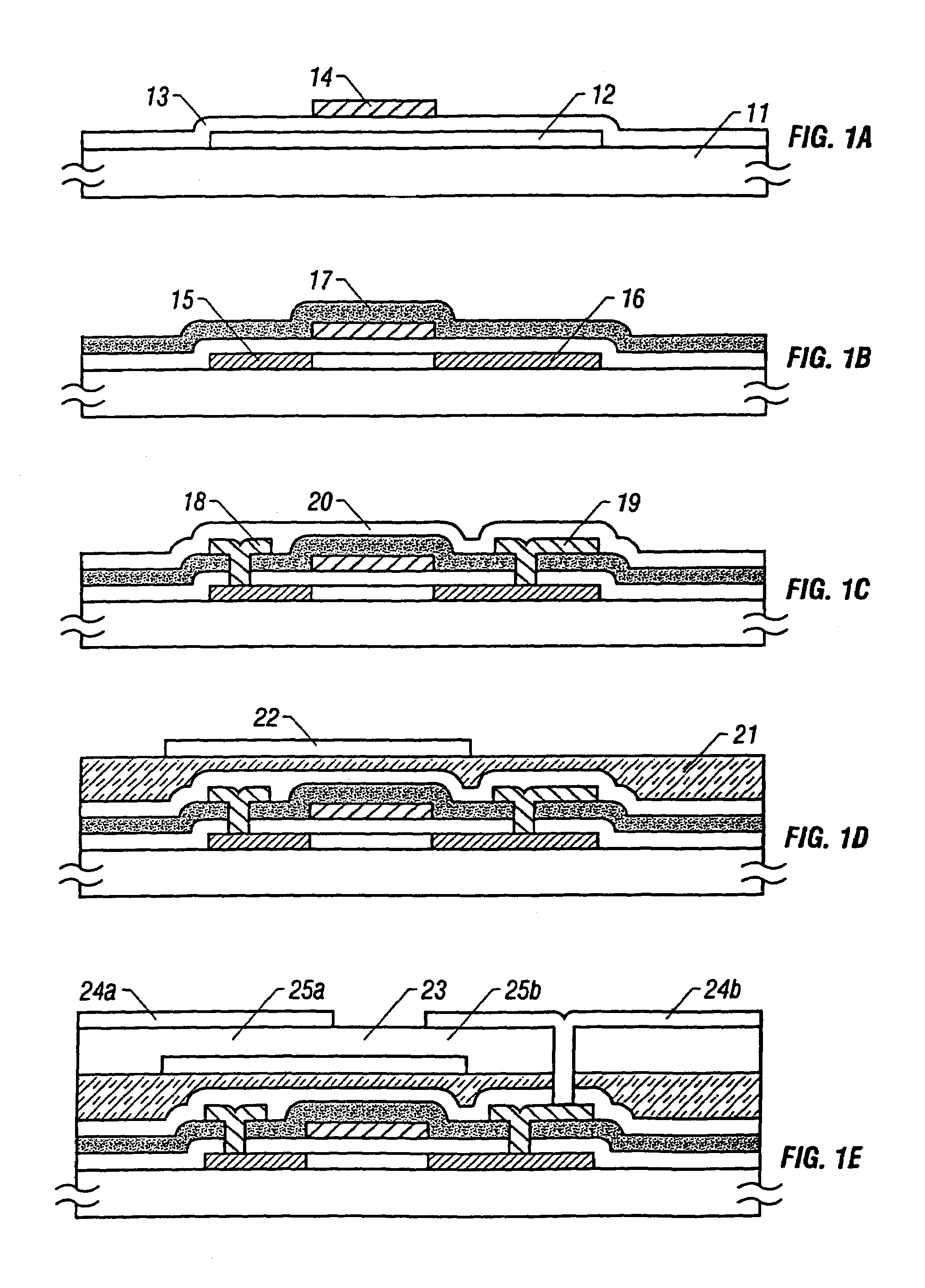

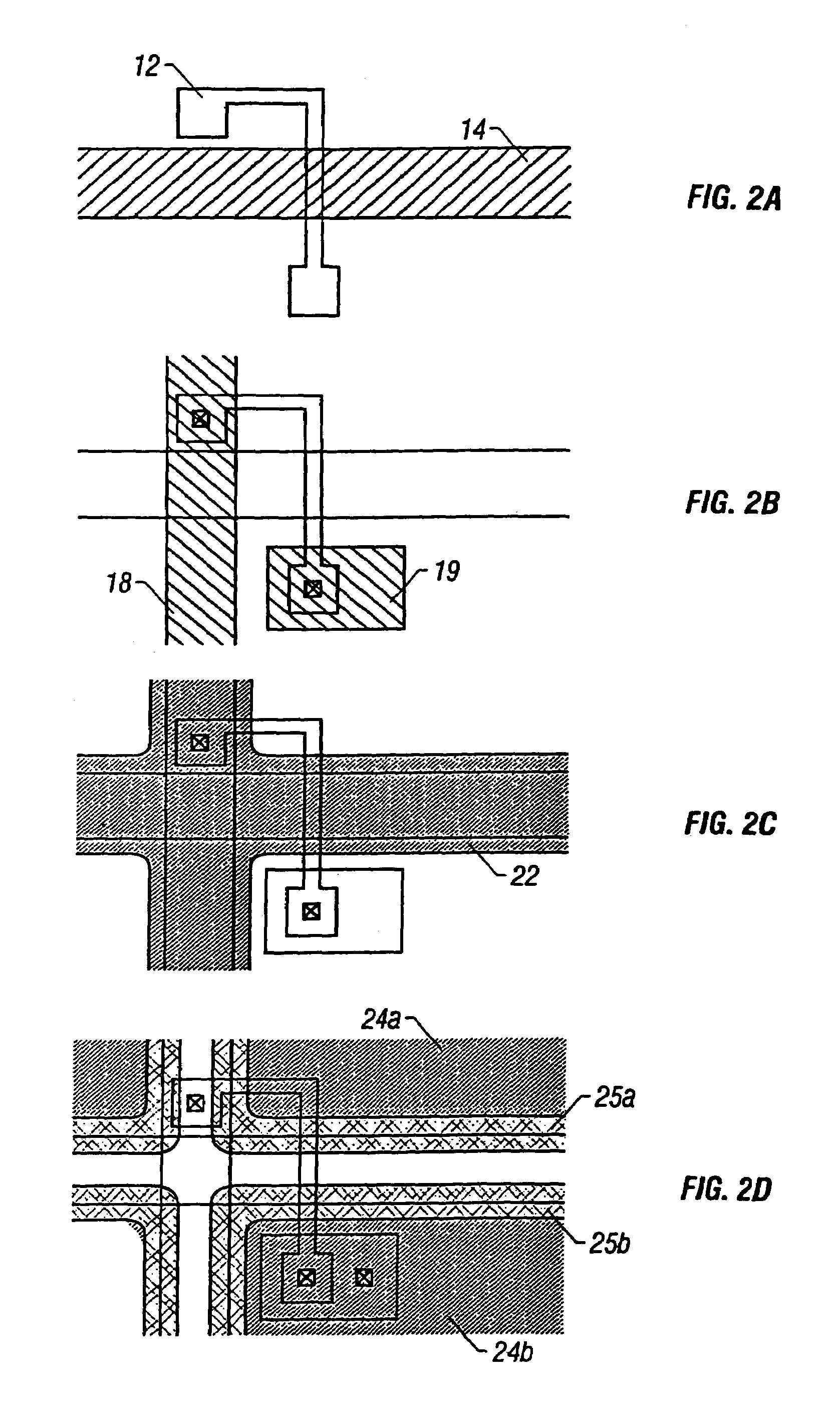

Electro-optical device

InactiveUS6914260B2Aperture ratio is maintainedConducive to stable operationTransistorSolid-state devicesLiquid-crystal displayActive matrix

An auxiliary capacitor for a pixel of an active matrix type liquid crystal display is provided without decreasing the aperture ratio. A transparent conductive film for a common electrode is formed under a pixel electrode constituted by a transparent conductive film with an insulation film provided therebetween. Further, the transparent conductive film for the common electrode is maintained at fixed potential, formed so as to cover a gate bus line and a source bus line, and configured such that signals on each bus line are not applied to the pixel electrode. The pixel electrode is disposed so that all edges thereof overlap the gate bus line and source bus line. As a result, each of the bus lines serves as a black matrix. Further, the pixel electrode overlaps the transparent conductive film for the common electrode to form a storage capacitor.

Owner:SEMICON ENERGY LAB CO LTD

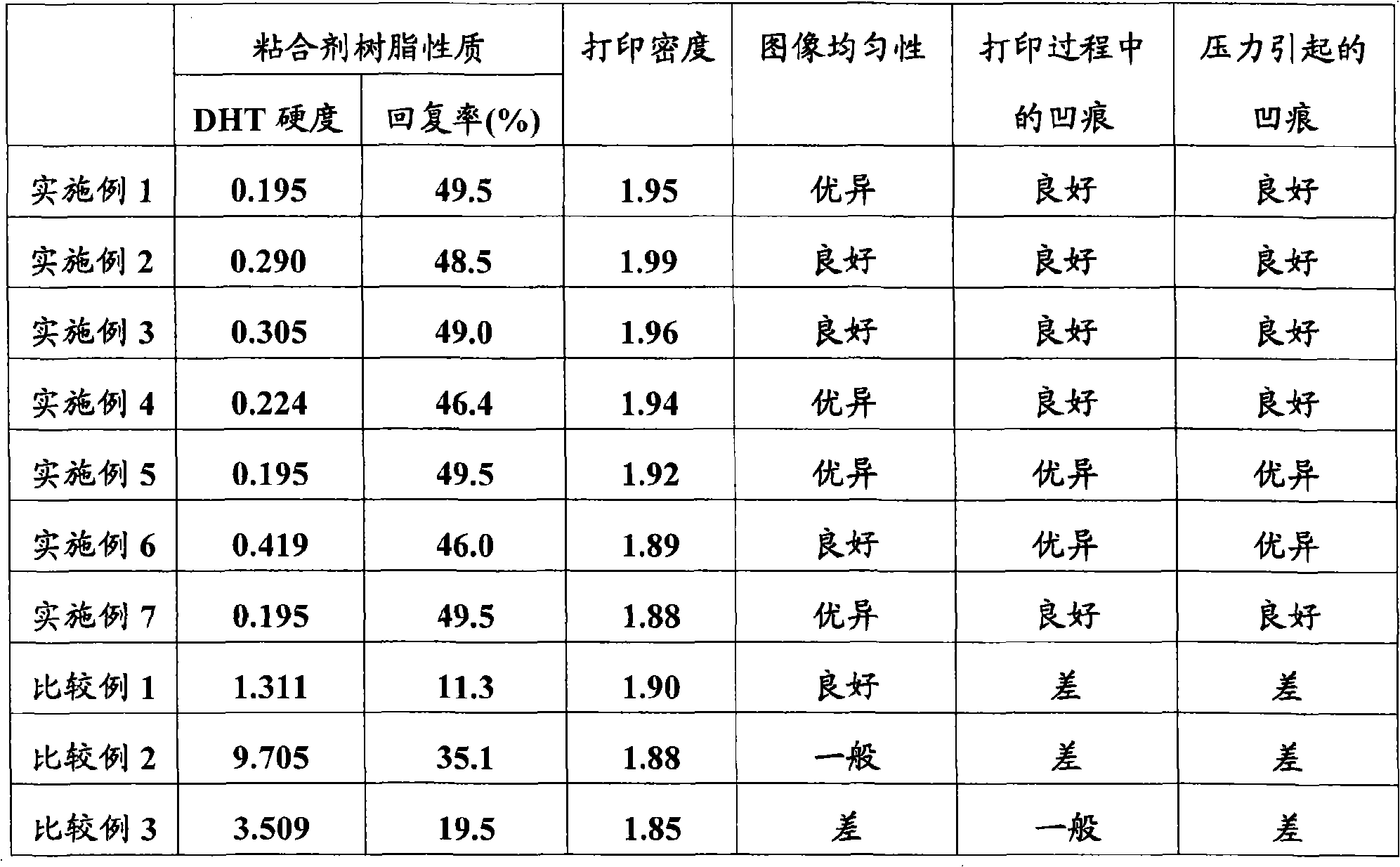

Thermal transfer receiving sheet

InactiveCN101318423AReduce surface irregularitiesThermographyOther printing apparatusMethacrylateAcrylonitrile

Owner:OJI PAPER CO LTD

Photogravure pressure and method for manufacturing multilayer ceramic electronic component

ActiveUS7481162B2High metal contentHigh viscosityFixed capacitor electrodesRotary intaglio printing pressEngineeringElectronic component

In a print area provided on a peripheral surface of a gravure roll, a plurality of cells are defined by printing-direction walls and perpendicular walls, and each perpendicular wall has a plurality of cuts. In a center portion of the print area, most intersections of the printing-direction walls and the perpendicular walls are defined by T-shaped intersections where the perpendicular walls do not cross the printing-direction walls, but meet the printing-direction walls in a T-shaped arrangement. Preferably, round chamfers are provided at corners where a portion of each printing-direction wall and a portion of each perpendicular wall intersect, and at leading ends of the perpendicular walls pointing toward the cuts.

Owner:MURATA MFG CO LTD

Pin assembly for conveyor chain

InactiveUS20070184698A1Well formedReduce surface irregularitiesCoupling device connectionsConveyorsEngineeringMechanical engineering

A pin assembly for a chain of a material handling system includes a pin element and an attachment element. The pin element includes a shaft portion, a head portion at an end of the shaft portion, and an attachment portion at an end of the shaft portion opposite the head portion. The attachment element is configured to attach to the attachment portion of the pin element, and is positionable at the attachment portion and is retainable thereto. The attachment element may comprise a second head portion to define an I-type pin assembly or may comprise a side link and pusher member construction or other element or member. A mounting extension may extend from the attachment portion for mounting an object to the pin assembly after the attachment is attached to the pin element.

Owner:FROST TECH

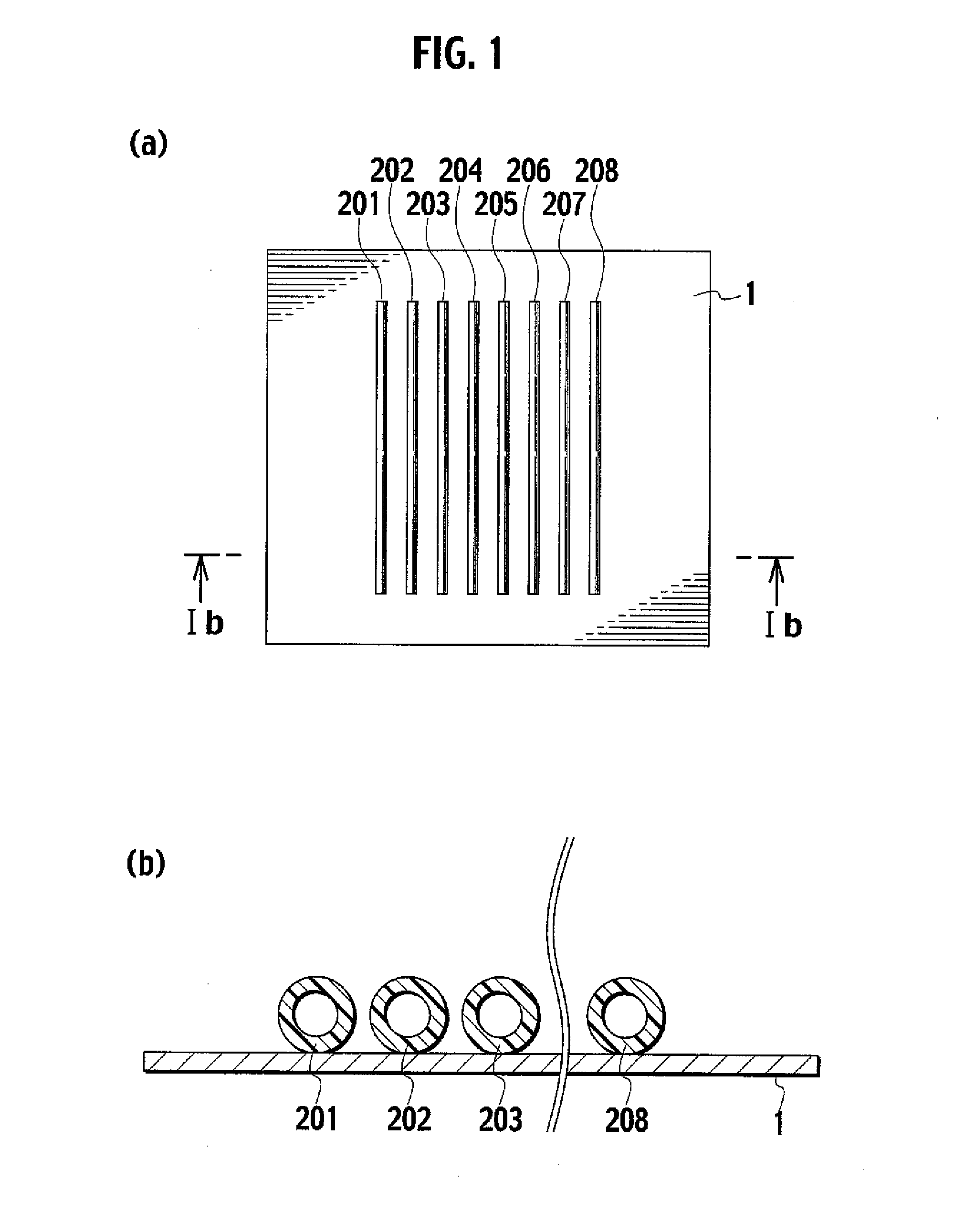

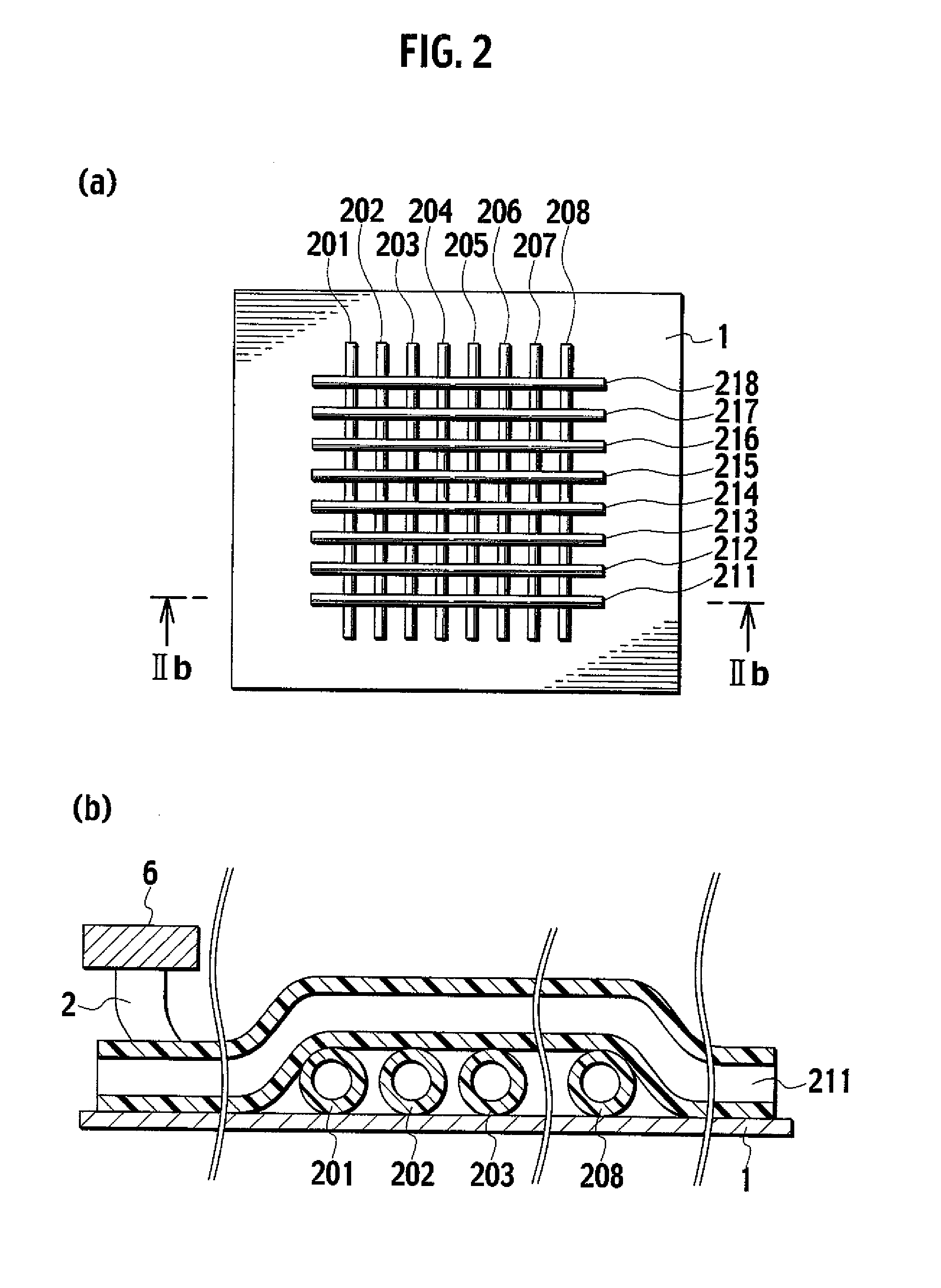

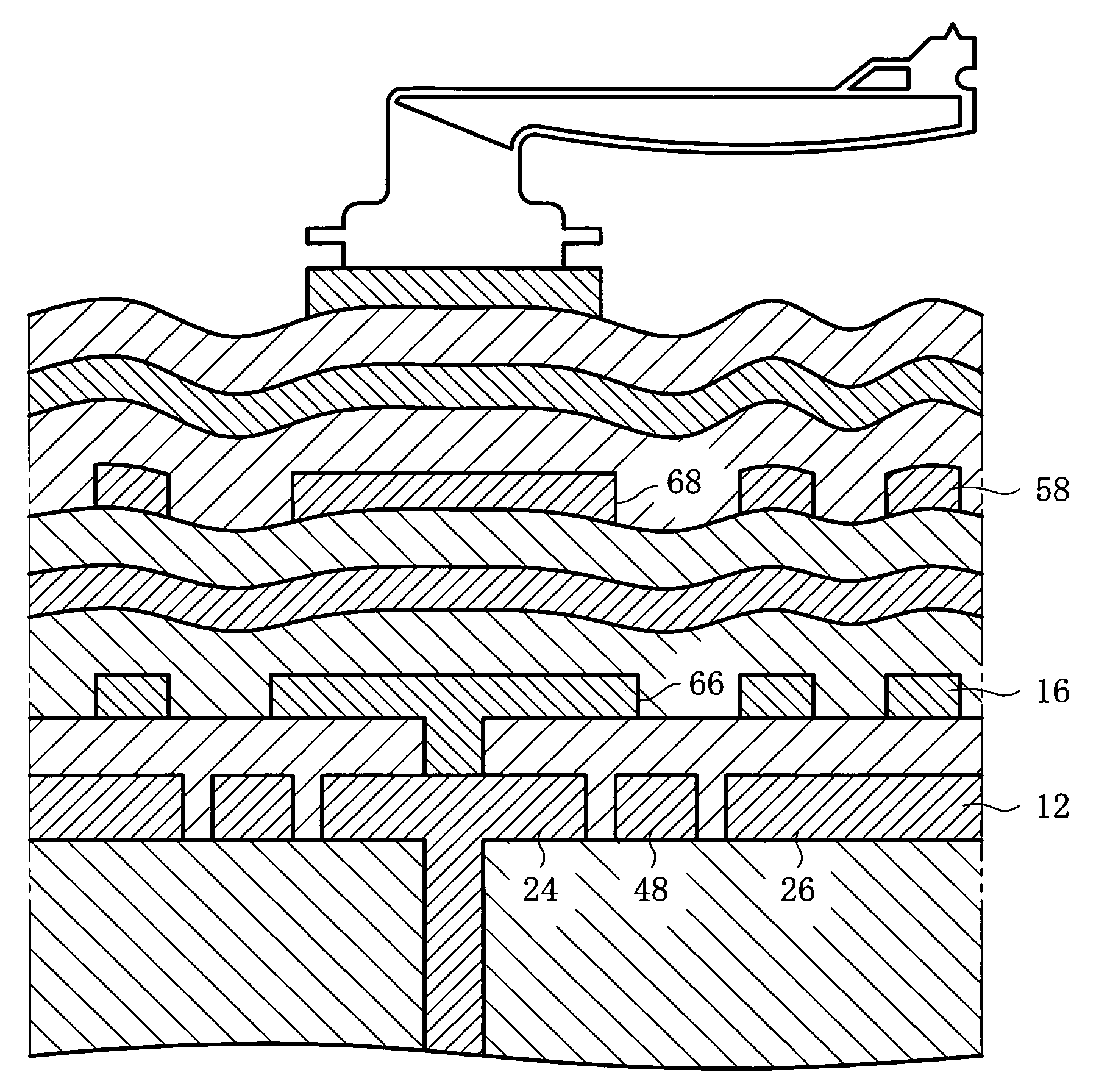

Probe unit substrate

ActiveUS20080157794A1Reduce surface irregularitiesElectrical measurement instrument detailsElectrical testingElectrical conductorEngineering

A ceramic substrate has, on its surface, a multilayer wiring division, on which micro cantilever type probes are fixed. The multilayer wiring division has the first conductor layer, which includes through-hole junction pads, flatness improvement rings surrounding the through-hole junction pads and a grounding region further surrounding the flatness improvement rings. Since the flatness improvement rings are located around the through-hole junction pads, the surface of the first insulating layer, which is located above the first conductor layer, is free from severe undulation even near the through-hole junction pads. Accordingly, the multilayer wiring division has less irregularity in shape as a whole, and thus the probe mounting pads on the surface of the second insulating layer do not slope but keep almost horizontal. The probe unit substrate according to the invention has an advantage of less surface undulation and having non-sloping probe mounting pads without using a complicated manufacturing process.

Owner:NIHON MICRONICS

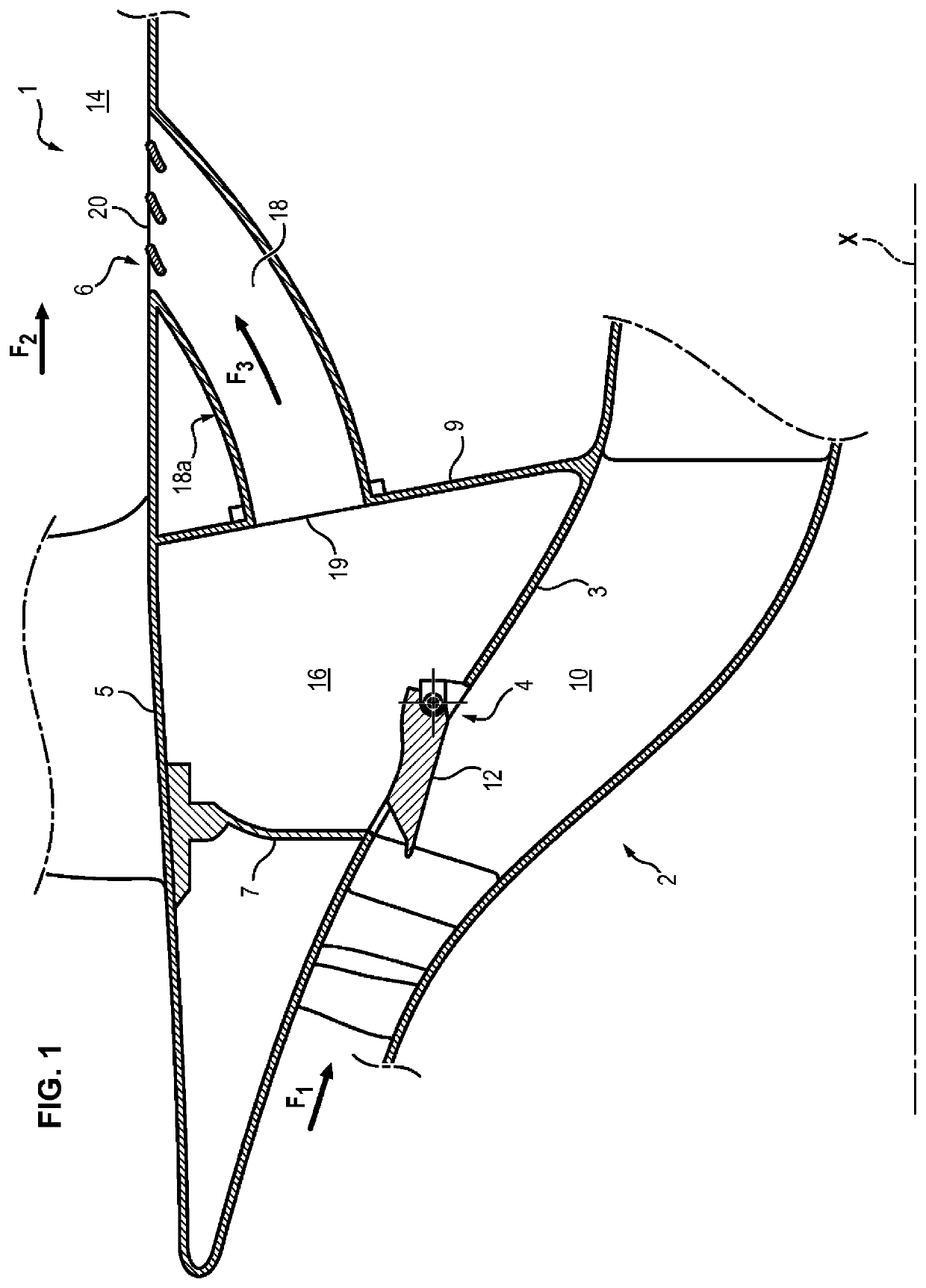

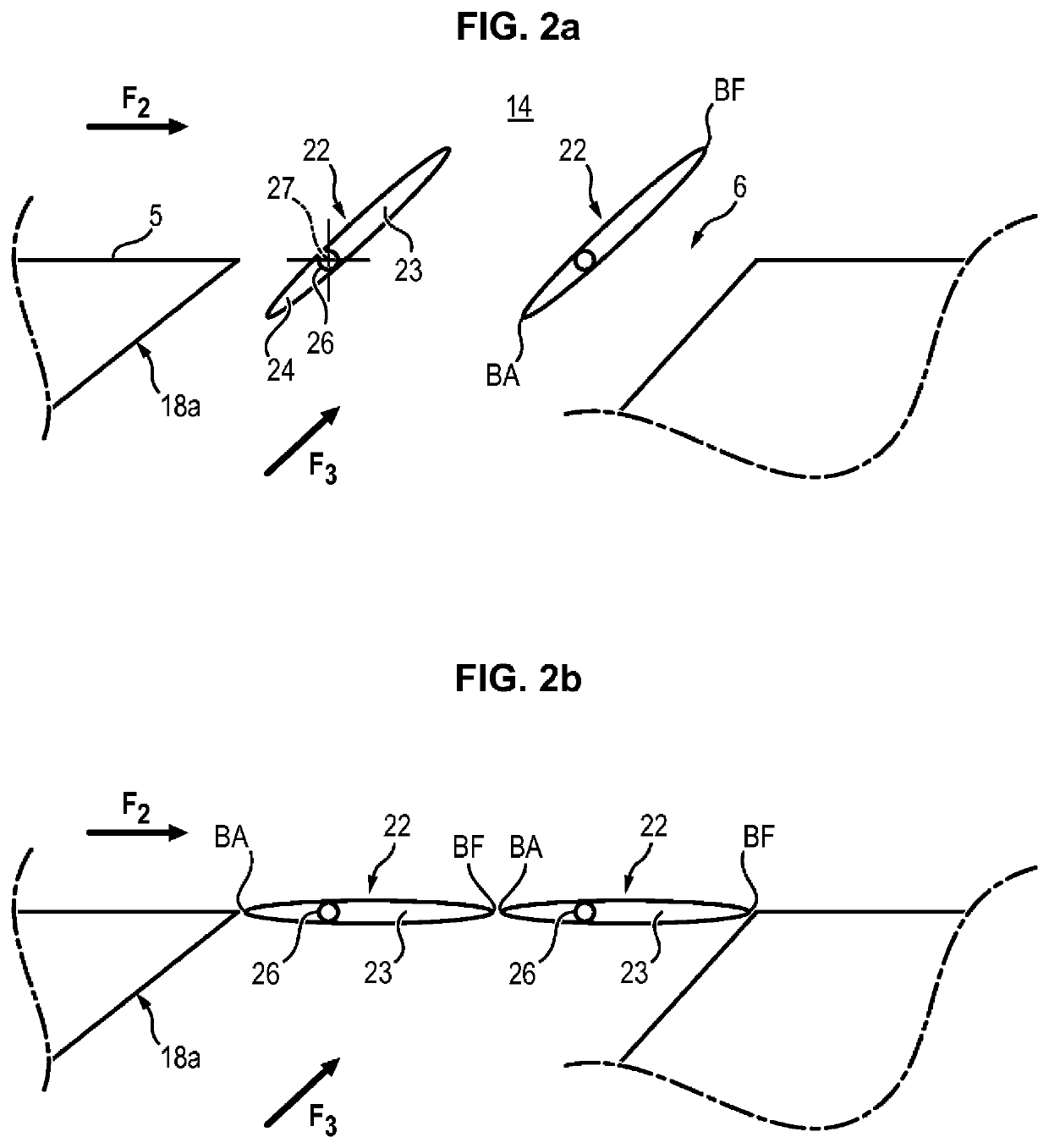

Bleed flow duct for a turbomachine comprising a passively actuated variable cross section VBV grating

ActiveUS10480454B2Quality improvementReduce surface irregularitiesGas turbine plantsEngine componentsLeading edgeGrating

The invention relates to a hub (2) of an intermediate casing (1) for a bypass turbomachine comprising: —a bleed stream duct (18), —a bleed valve, comprising a mobile door at the inlet orifice to the bleed stream duct (18), —a set of bleed vanes (22) which are mounted with the ability to rotate about a pivot (26) in the bleed stream duct (18) between an open configuration in which a flow of air coming from the inlet orifice (4) passes between the bleed vanes (22) and a closed configuration, the pivot (26) for each bleed vane (22) being closer to its leading edge (BA) than to its trailing edge (BF).

Owner:SN DETUDE & DE CONSTR DE MOTEURS DAVIATION S N E C M A

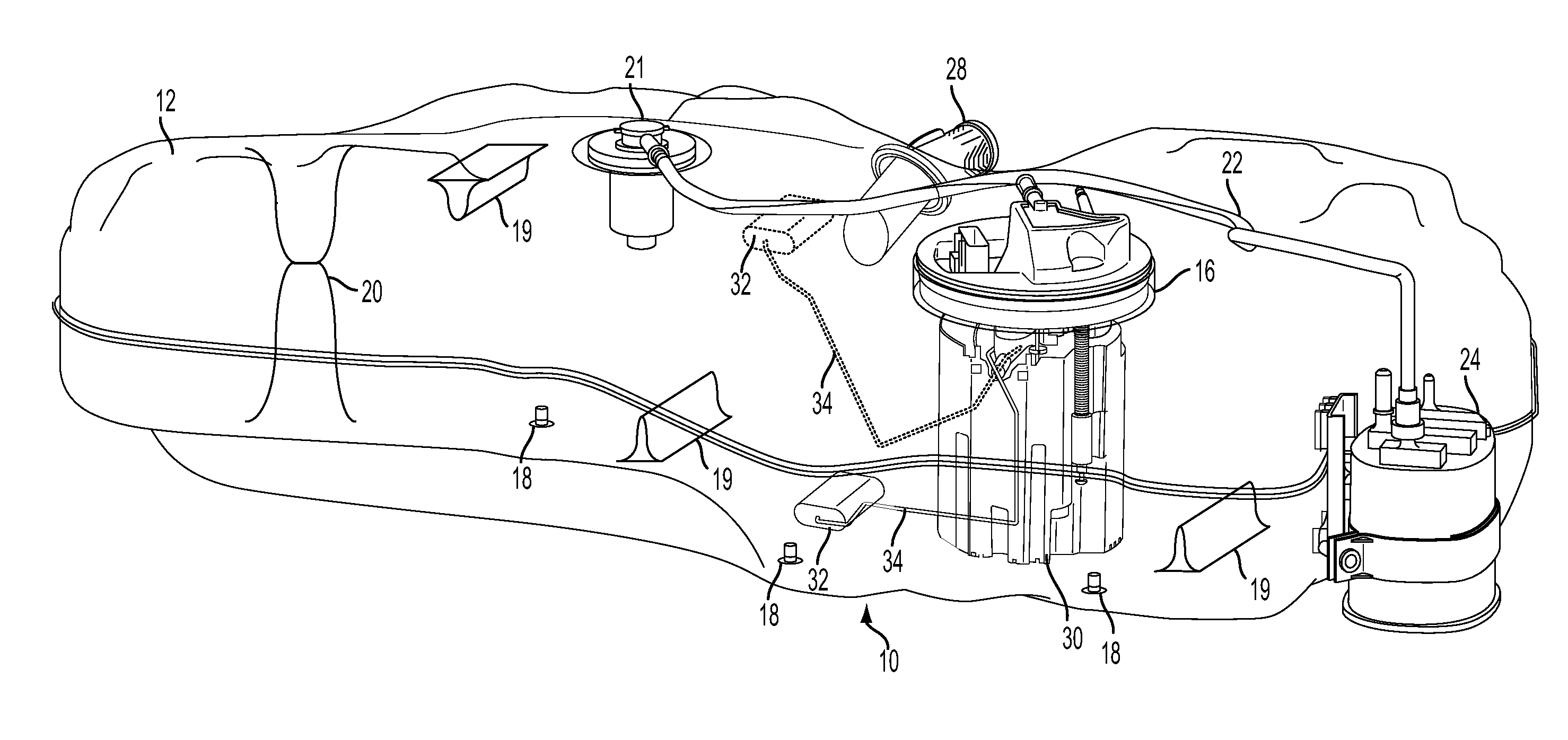

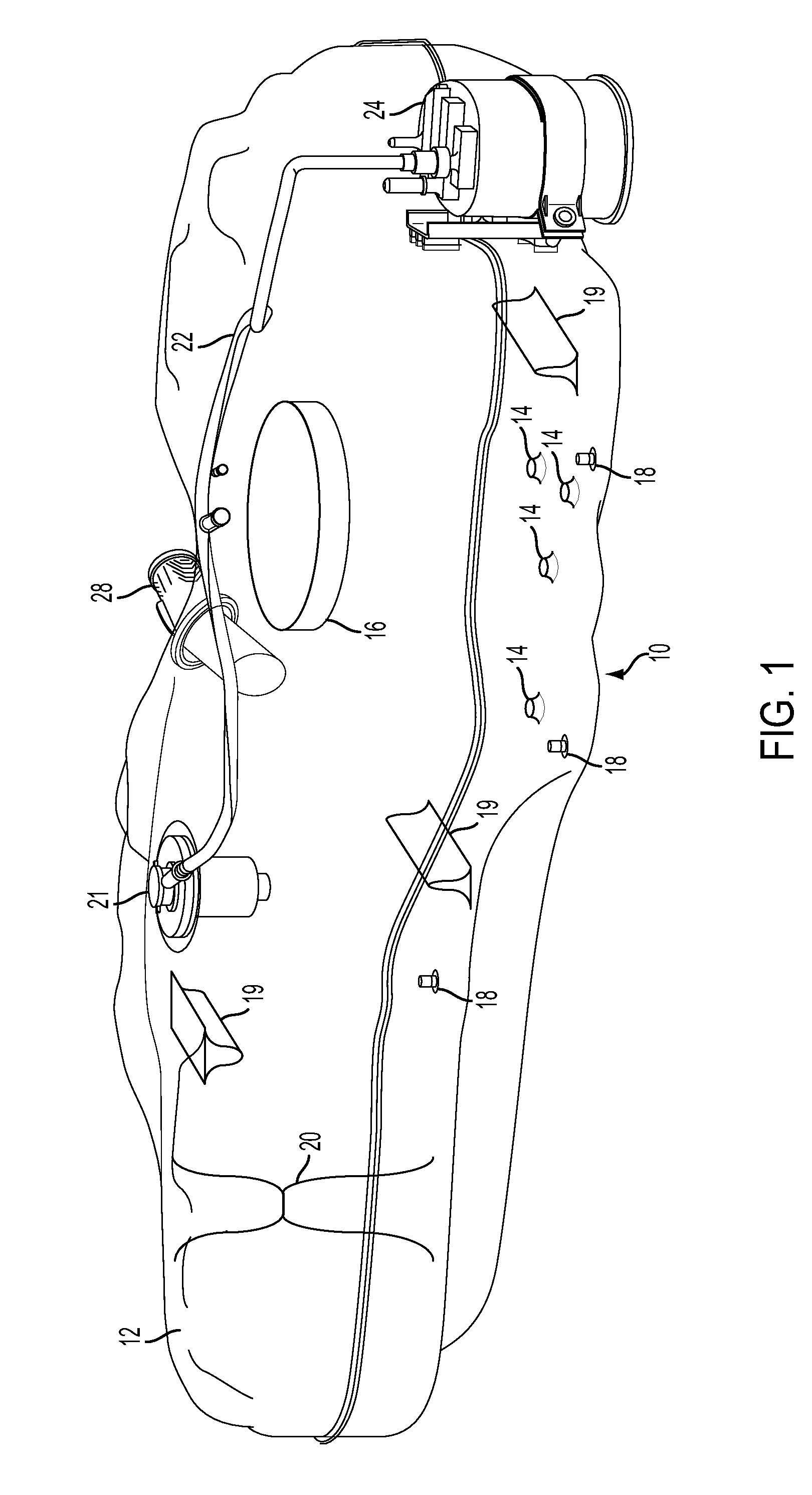

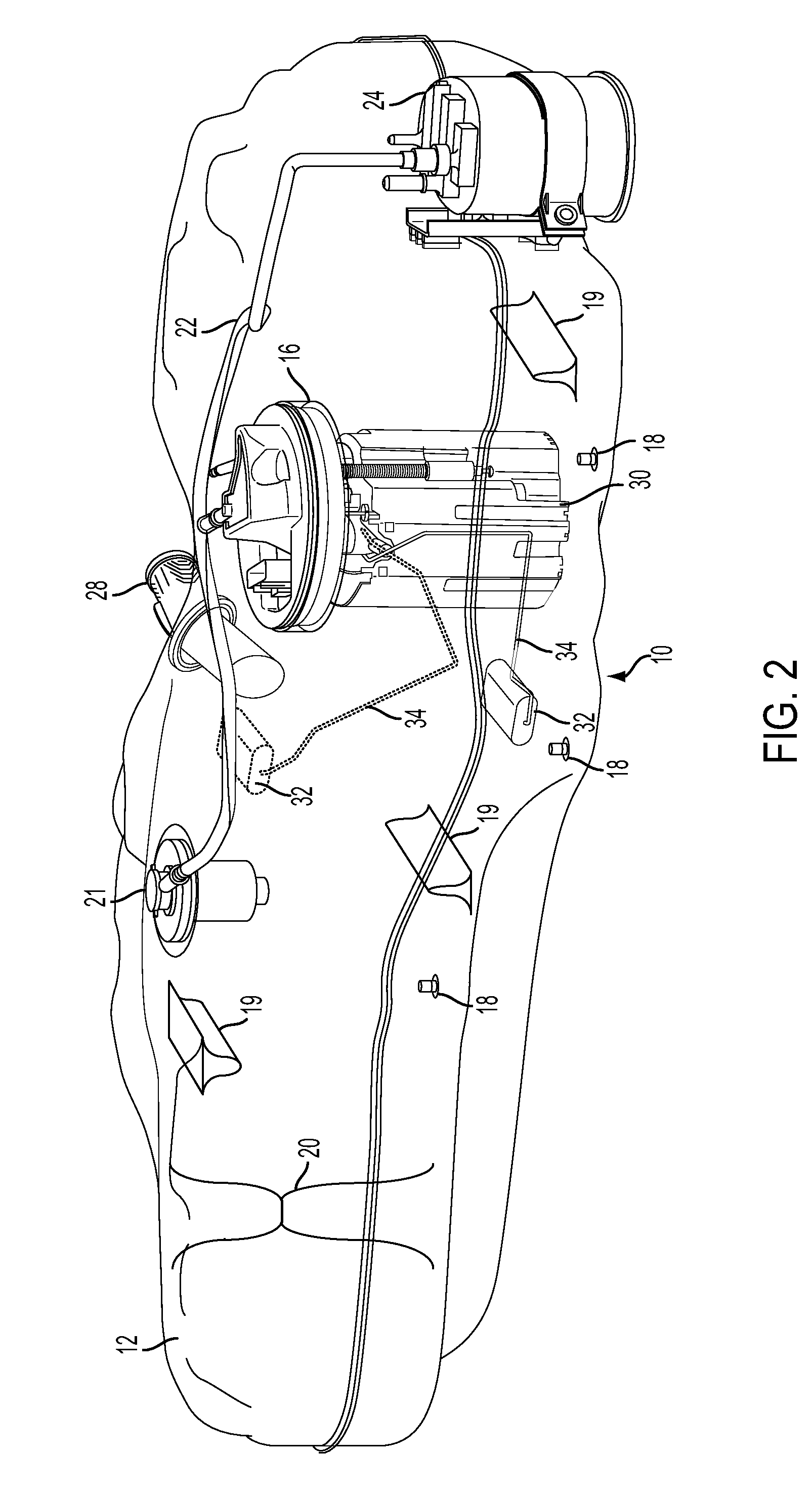

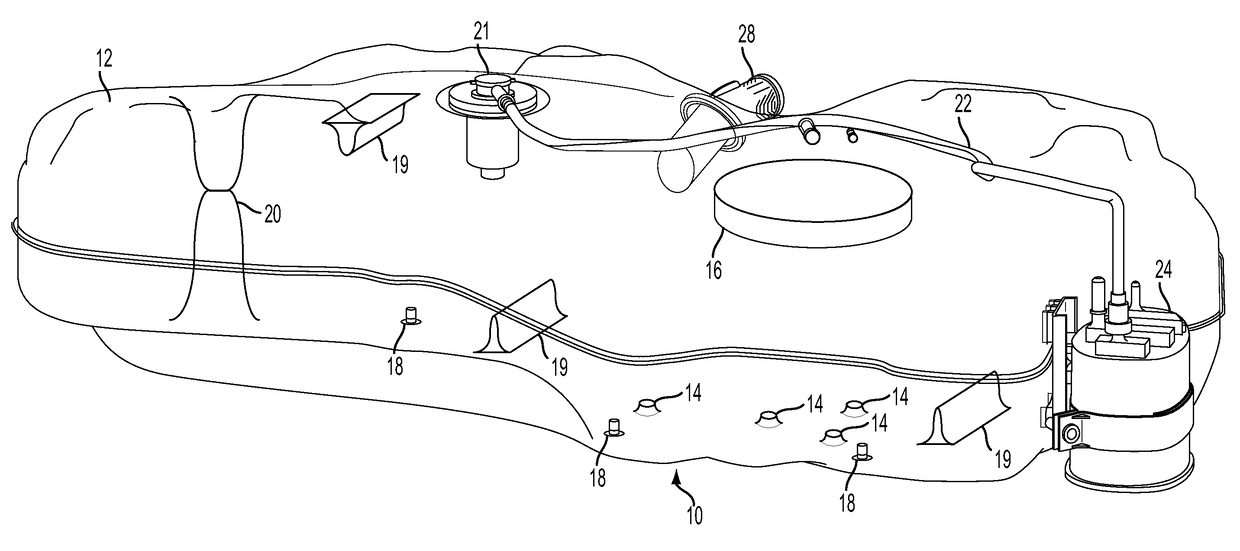

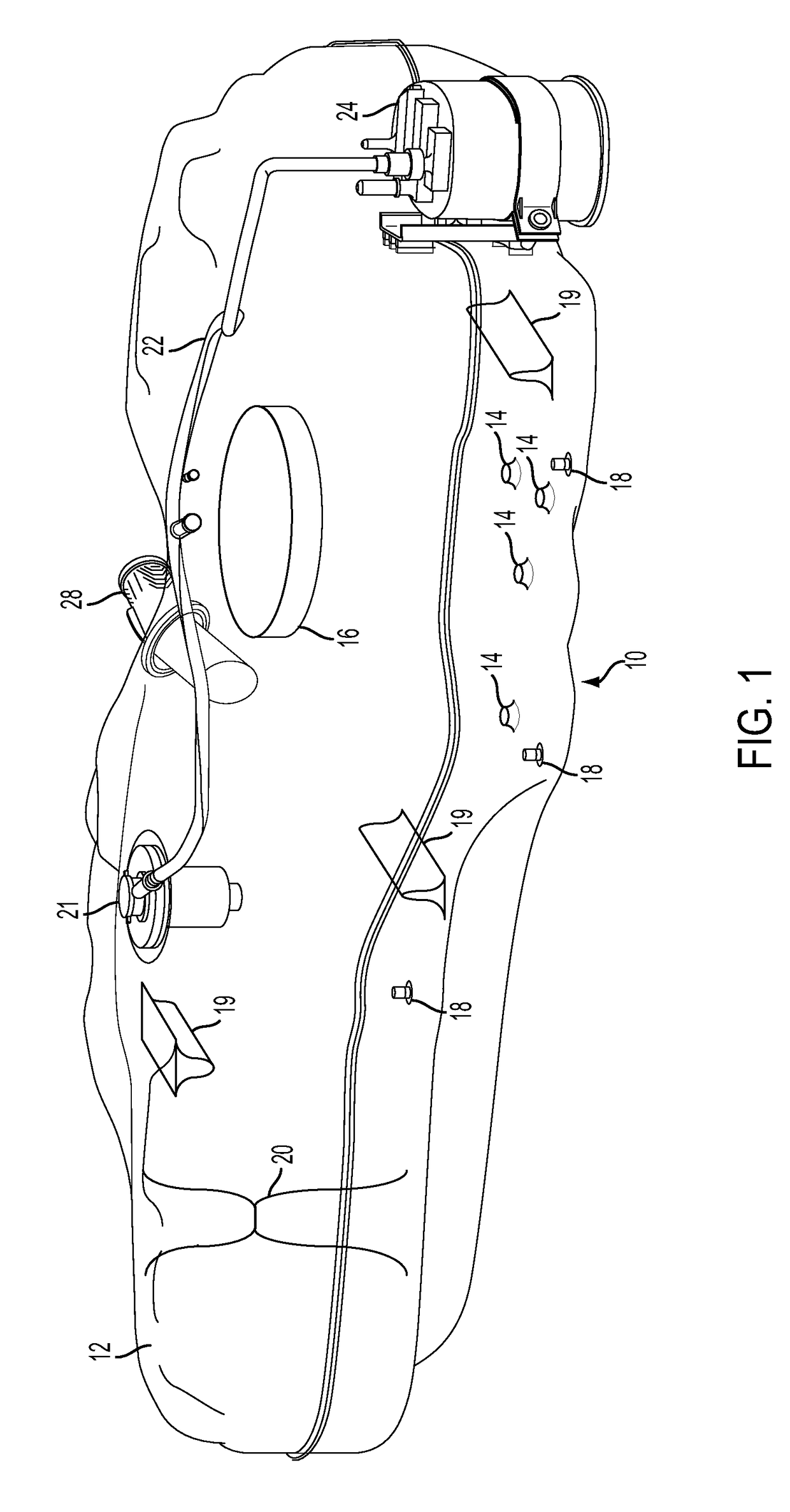

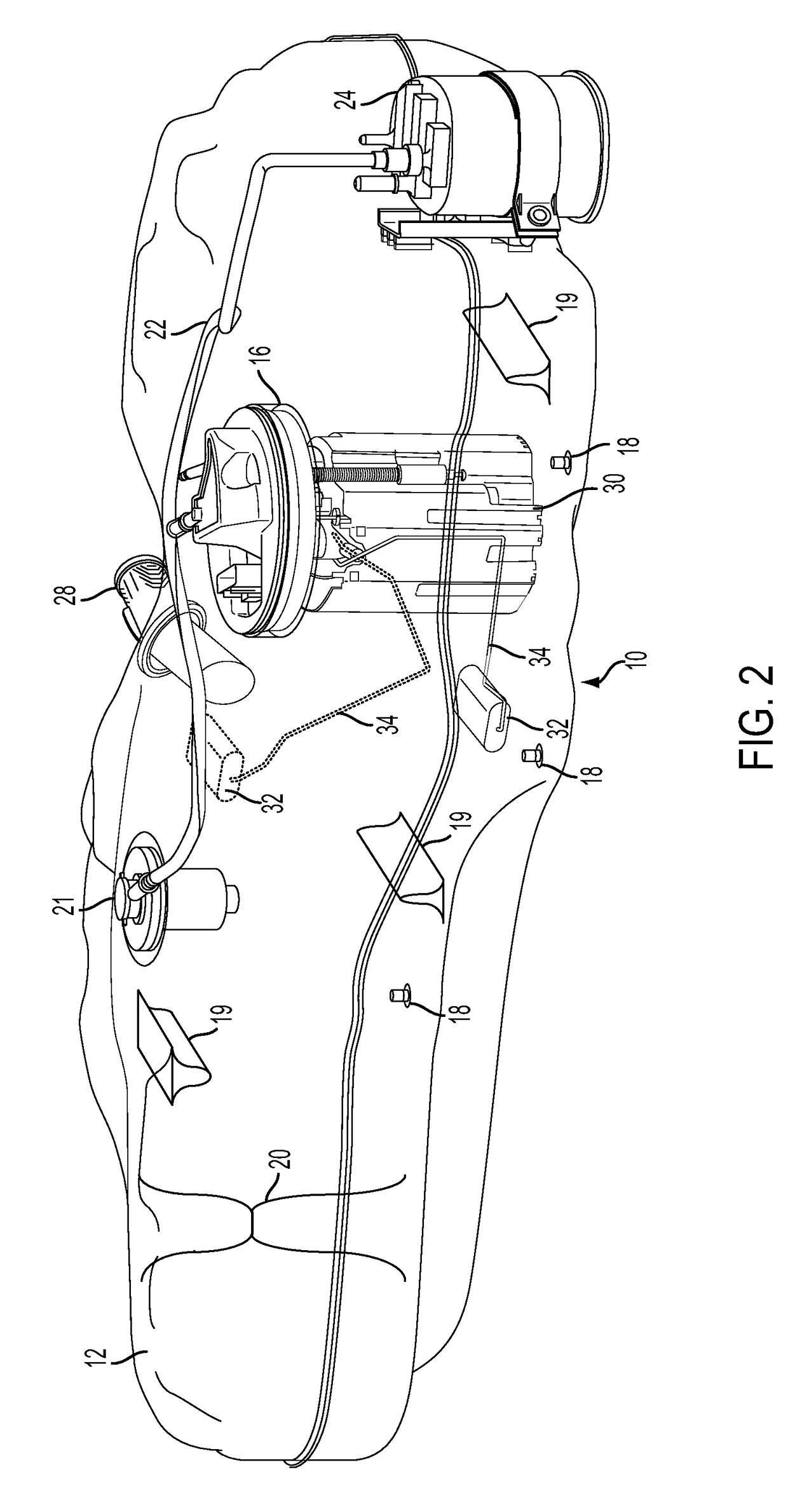

Object positioning method

InactiveUS20150328981A1Easy to manageReduce surface irregularitiesLarge containersItem transportation vehiclesFuel tankEngineering

Owner:FORD GLOBAL TECH LLC

Electro-optical device

InactiveUS7206053B2Aperture ratio is maintainedConducive to stable operationTransistorNon-linear opticsLiquid-crystal displaySignal on

An auxiliary capacitor for a pixel of an active matrix type liquid crystal display is provided without decreasing the aperture ratio. A transparent conductive film for a common electrode is formed under a pixel electrode constituted by a transparent conductive film with an insulation film provided there between. Further, the transparent conductive film for the common electrode is maintained at fixed potential, formed so as to cover a gate bus line and a source bus line, and configured such that signals on each bus line are not applied to the pixel electrode. The pixel electrode is disposed so that all edges thereof overlap the gate bus line and source bus line. As a result, each of the bus lines serves as a black matrix. Further, the pixel electrode overlaps the transparent conductive film for the common electrode to form a storage capacitor.

Owner:SEMICON ENERGY LAB CO LTD

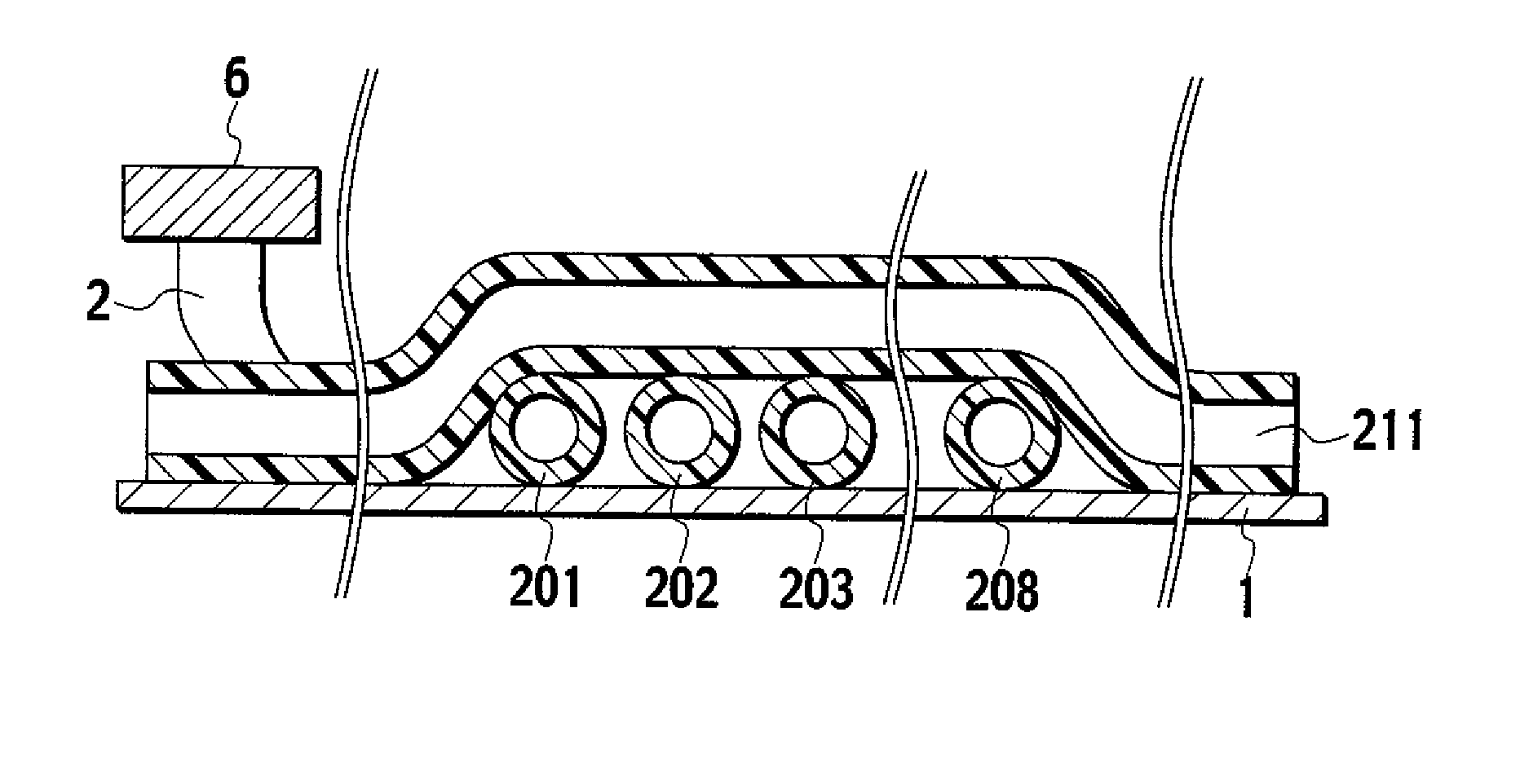

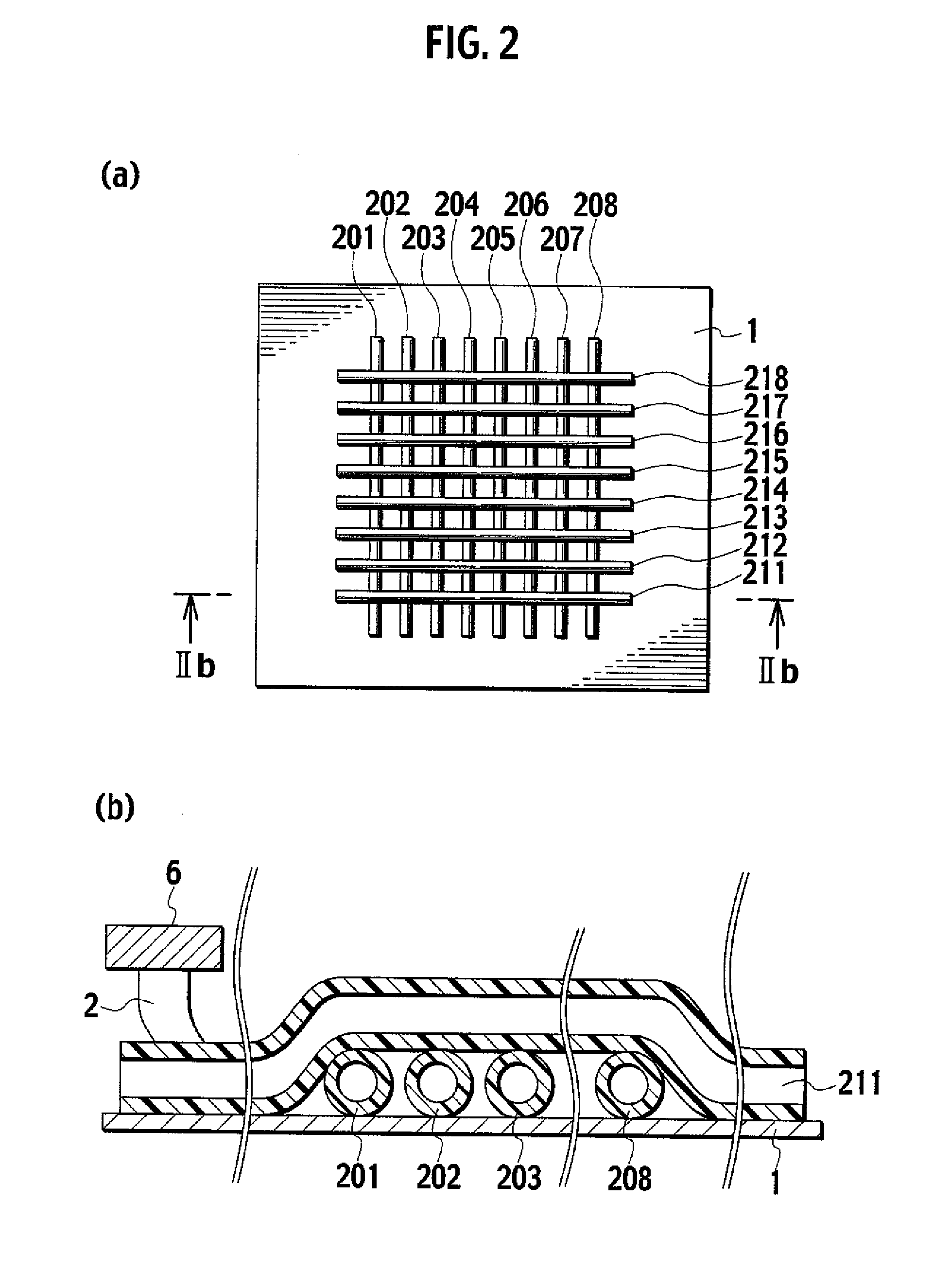

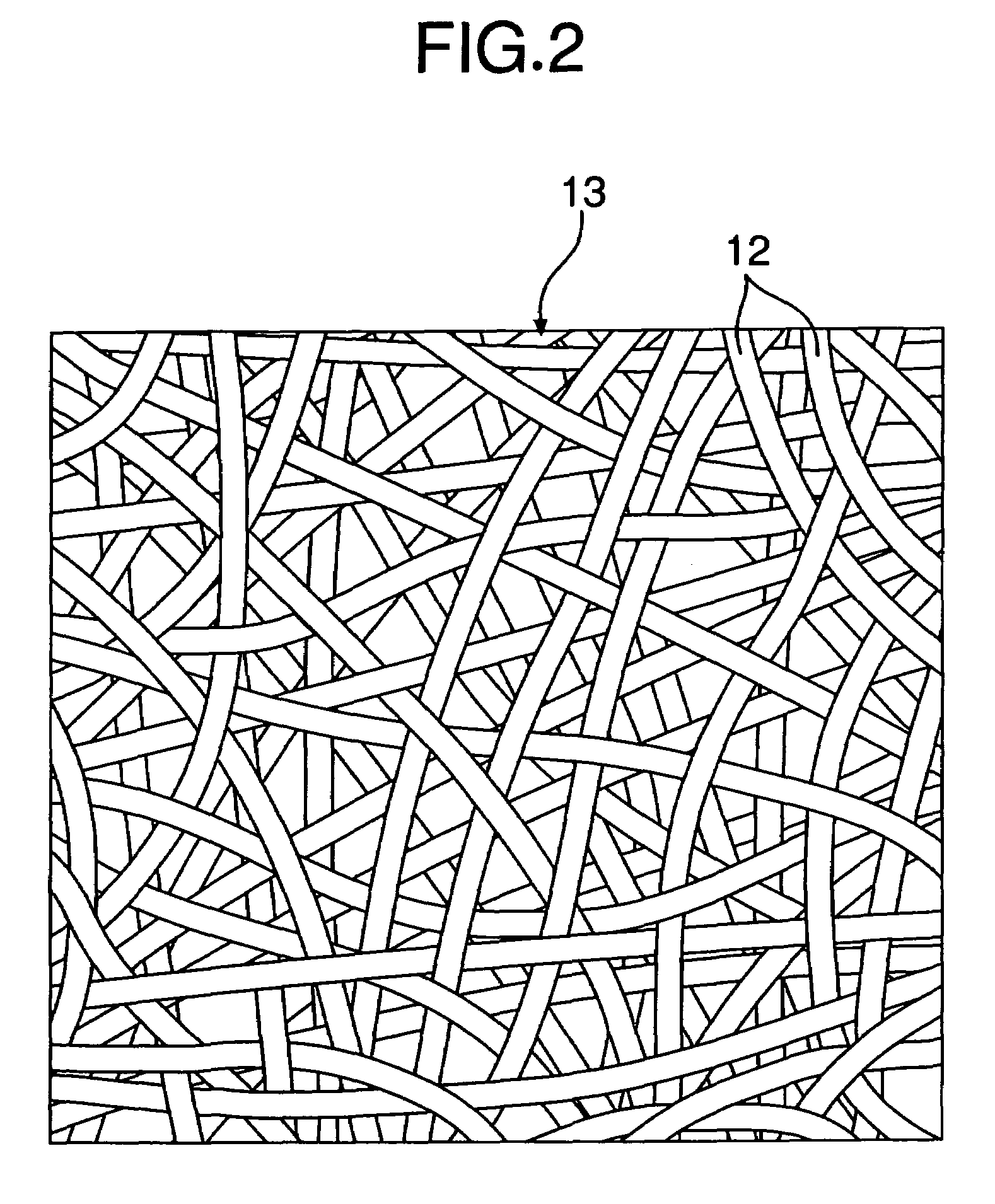

Microfluid-System-Supporting Unit And Production Method Thereof

InactiveUS20110135817A1Reduce surface irregularitiesResistant to breakageLiquid surface applicatorsFixed microstructural devicesProtection layerBiomedical engineering

The present invention relates to a microfluid-system-supporting unit, comprising a fixing layer formed on a substrate, a protective layer or a fixing layer, wherein part of at least one hollow filament in any shape is placed and fixed in the fixing layer. Thus, it provides a microfluid-system-supporting unit lower in surface irregularity even when there are multiple hollow filaments different in external diameter or the hollow filaments crosses each other and resistant to positional deviation of the hollow filament in the crossing regions, and a production method thereof.

Owner:RESONAC CORPORATION

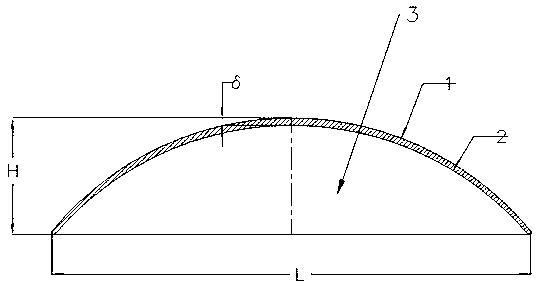

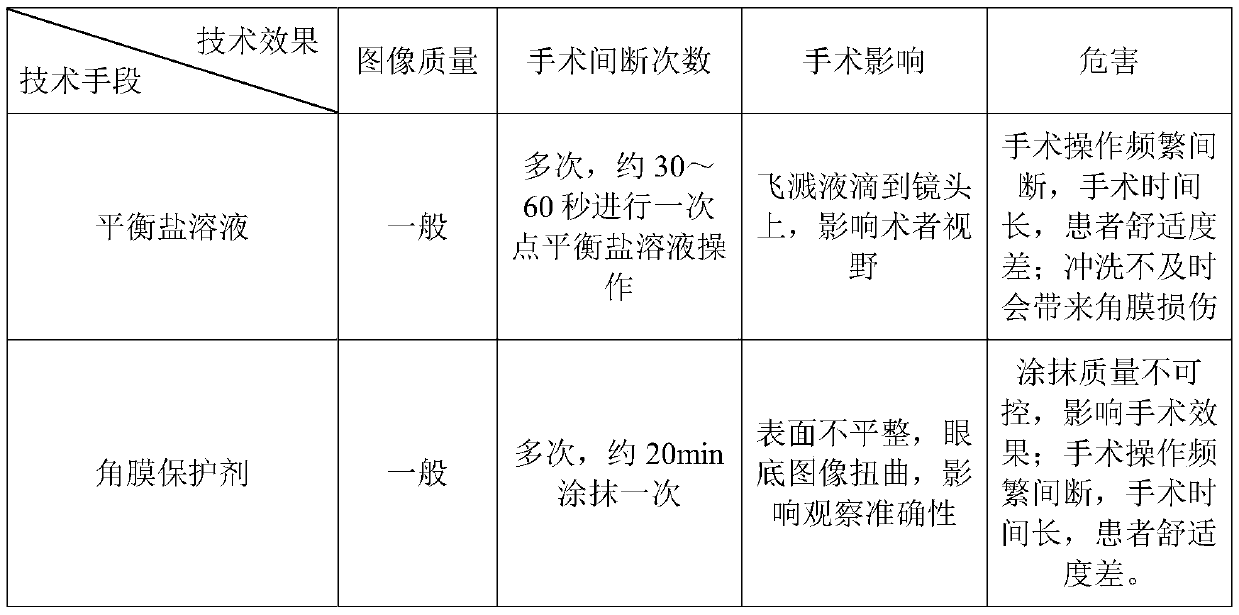

Intraoperative protective mirror and application thereof

InactiveCN110433031AReduce surface irregularitiesRemove distortionEye surgeryCorneal surfaceVitrectomy

The invention discloses an intraoperative protective mirror. The protective mirror comprises an outer lens surface and an inner lens surface, and is characterized in that the outer lens surface and the inner lens surface consist of two arc surfaces; and the outer lens surface and the inner lens surface are connected into a whole to form a bowl-shaped transparent lens body. The invention also discloses an application of the intraoperative protective mirror in the vitrectomy. A method comprises the following steps of: finishing operation preparation, and smearing a corneal protective agent on the corneal surface; placing the intraoperative protective mirror above the corneal protective agent after the corneal protective agent is smeared; and after the contact surface of the intraoperative protective mirror and the corneal protective agent has no bubbles, carrying out the operation. The protective mirror can avoid or reduce the use of a balance liquid and the corneal protective agent, save the operation time, make images more clear in the operation, reduce the operation difficulty and improve the comfort level of the patient.

Owner:江苏金云医疗器械有限公司

Photogravure press and method for manufacturing multilayer ceramic electronic component

ActiveUS20090022882A1High metal contentHigh viscosityRotary intaglio printing pressFixed capacitor electrodesEngineeringElectronic component

In a print area provided on a peripheral surface of a gravure roll, a plurality of cells are defined by printing-direction walls and perpendicular walls, and each perpendicular wall has a plurality of cuts. In a center portion of the print area, most intersections of the printing-direction walls and the perpendicular walls are defined by T-shaped intersections where the perpendicular walls do not cross the printing-direction walls, but meet the printing-direction walls in a T-shaped arrangement. Preferably, round chamfers are provided at corners where a portion of each printing-direction wall and a portion of each perpendicular wall intersect, and at leading ends of the perpendicular walls pointing toward the cuts.

Owner:MURATA MFG CO LTD

Probe unit substrate

ActiveUS7504843B2Reduce surface irregularitiesElectrical measurement instrument detailsElectrical testingElectrical conductorEngineering

A ceramic substrate has, on its surface, a multilayer wiring division, on which micro cantilever type probes are fixed. The multilayer wiring division has the first conductor layer, which includes through-hole junction pads, flatness improvement rings surrounding the through-hole junction pads and a grounding region further surrounding the flatness improvement rings. Since the flatness improvement rings are located around the through-hole junction pads, the surface of the first insulating layer, which is located above the first conductor layer, is free from severe undulation even near the through-hole junction pads. Accordingly, the multilayer wiring division has less irregularity in shape as a whole, and thus the probe mounting pads on the surface of the second insulating layer do not slope but keep almost horizontal. The probe unit substrate according to the invention has an advantage of less surface undulation and having non-sloping probe mounting pads without using a complicated manufacturing process.

Owner:NIHON MICRONICS

Object positioning method

InactiveUS9770979B2Easy to manageReduce surface irregularitiesUnderstructuresMachines/enginesFuel tankEngineering

Owner:FORD GLOBAL TECH LLC

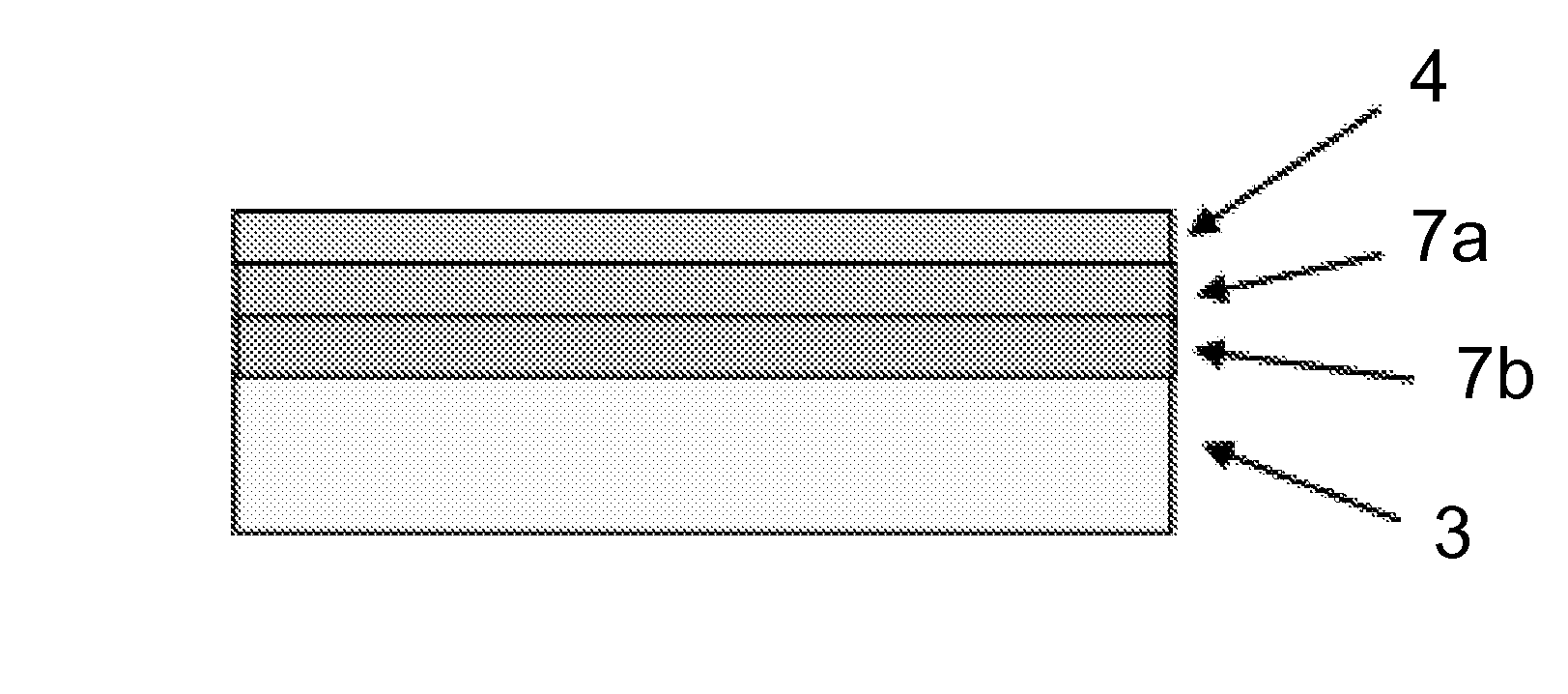

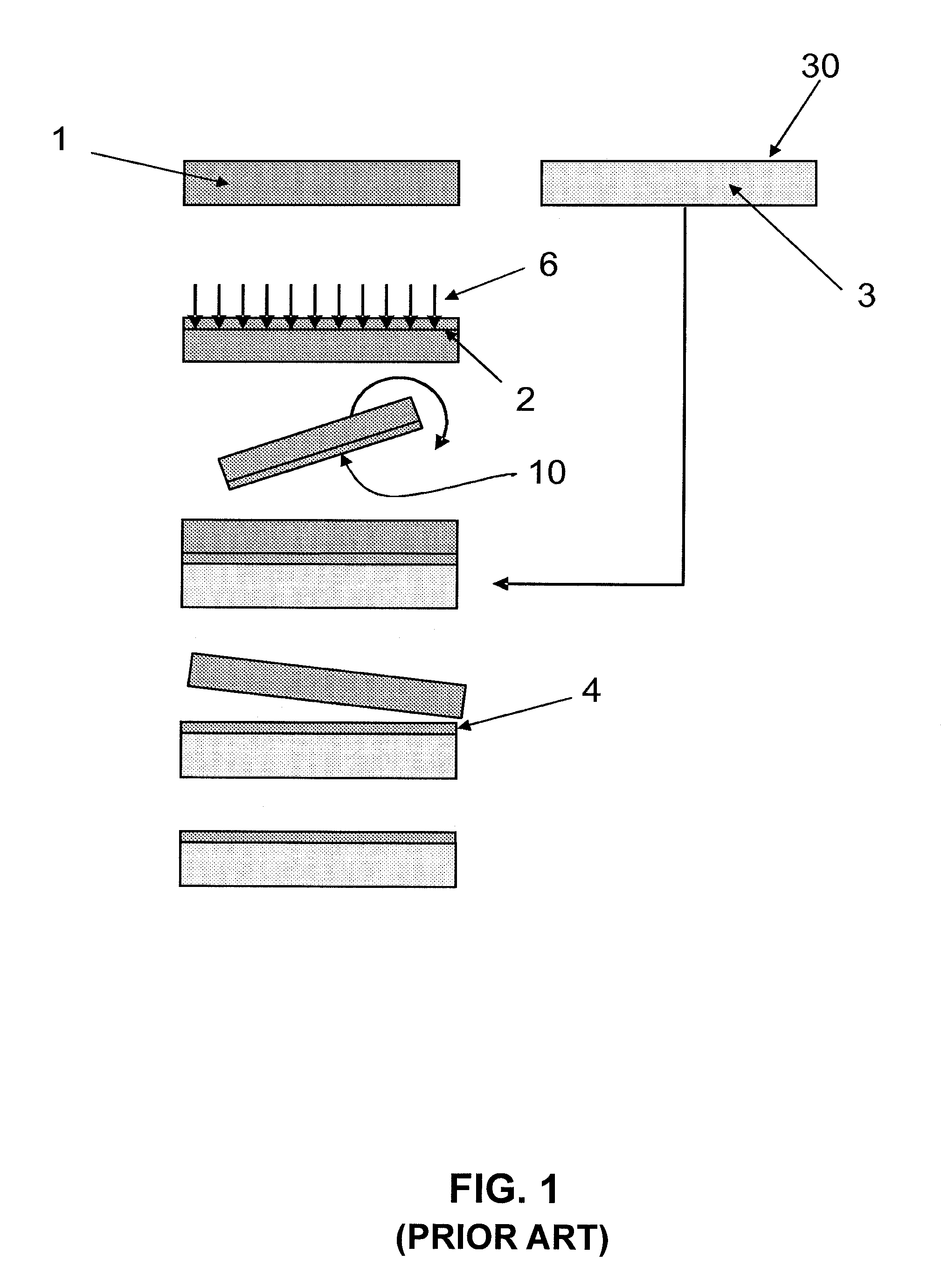

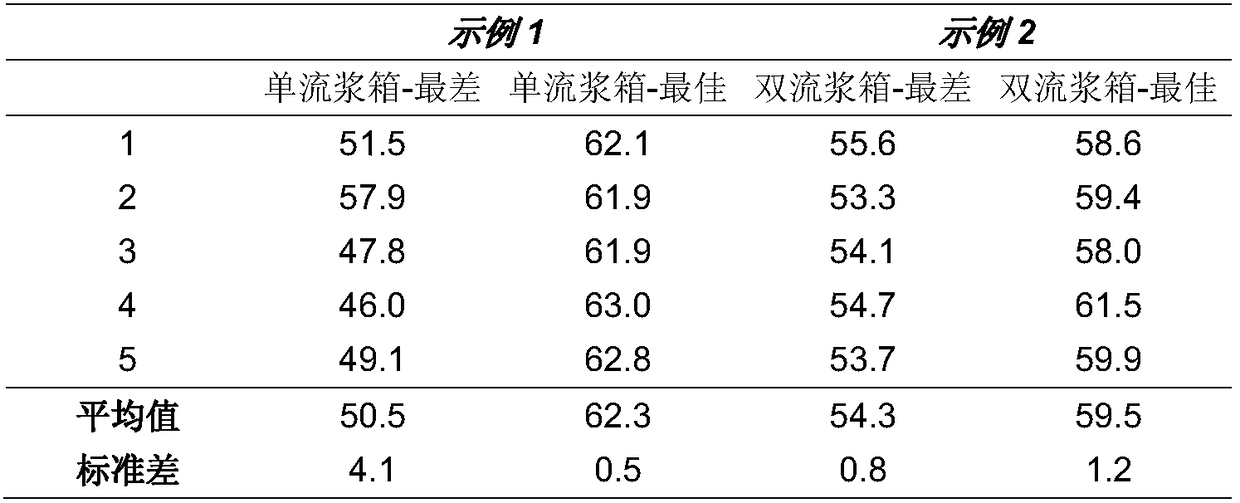

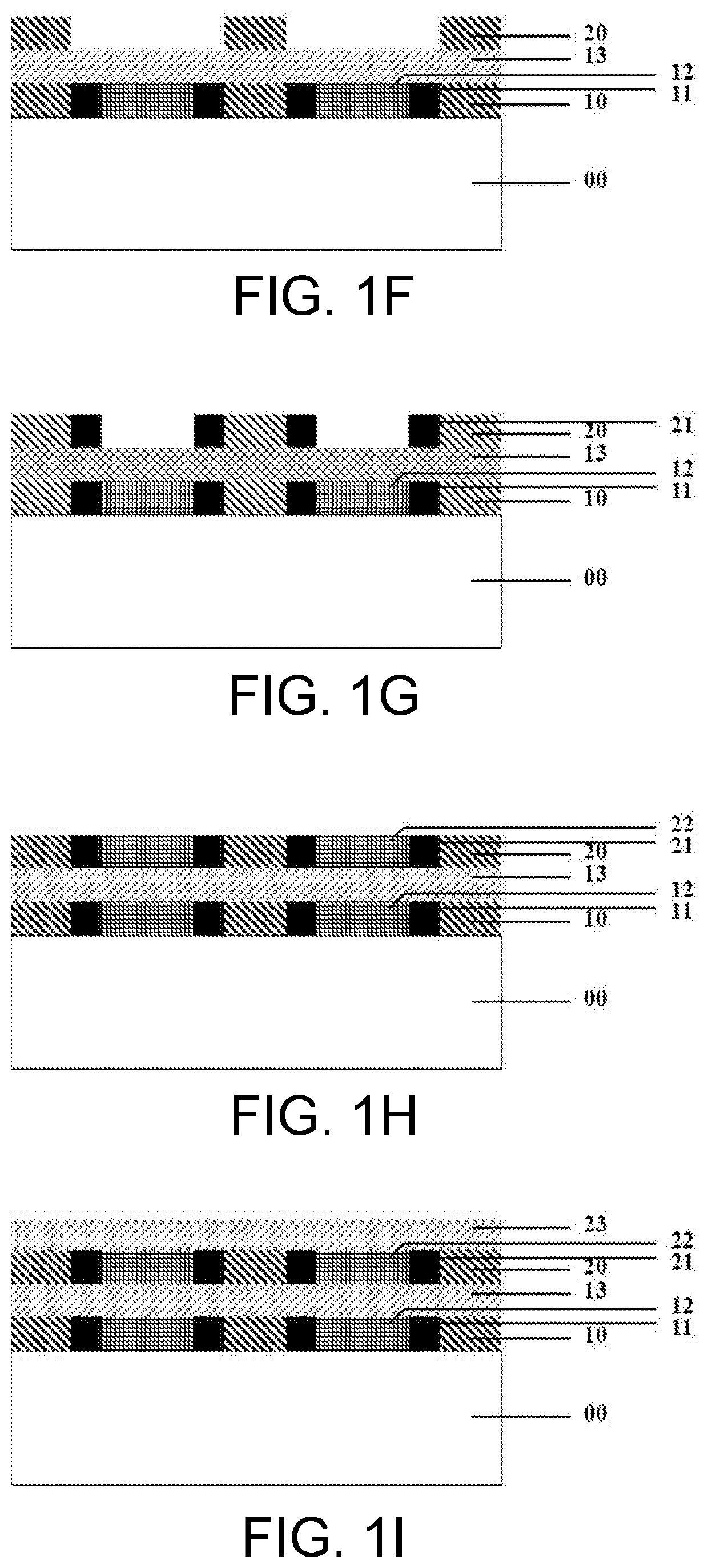

Method for reducing irregularities at the surface of a layer transferred from a source substrate to a glass-based support substrate

ActiveUS8946053B2Small surface areaReduce surface irregularitiesSemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronics

Owner:SOITEC SA

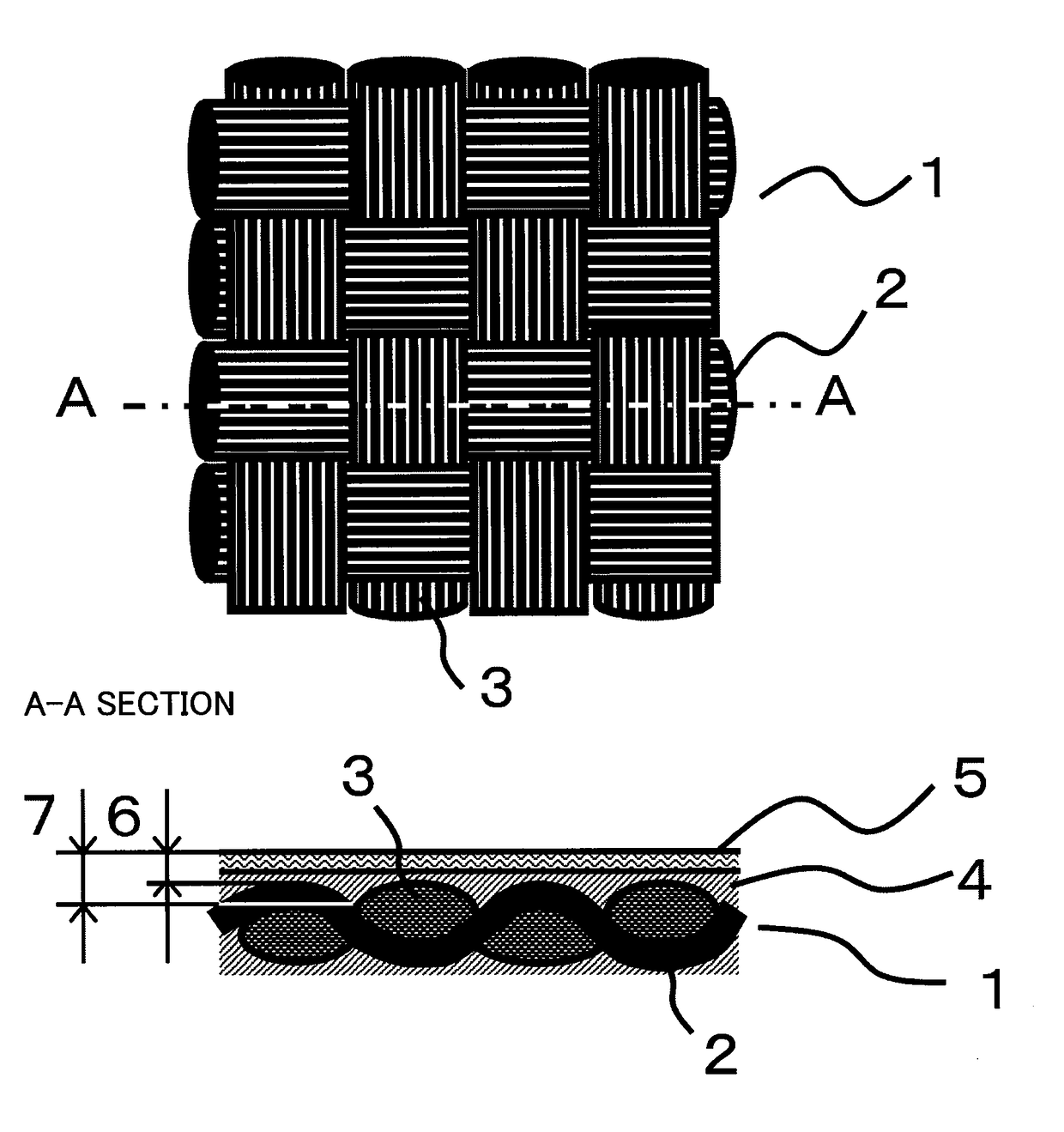

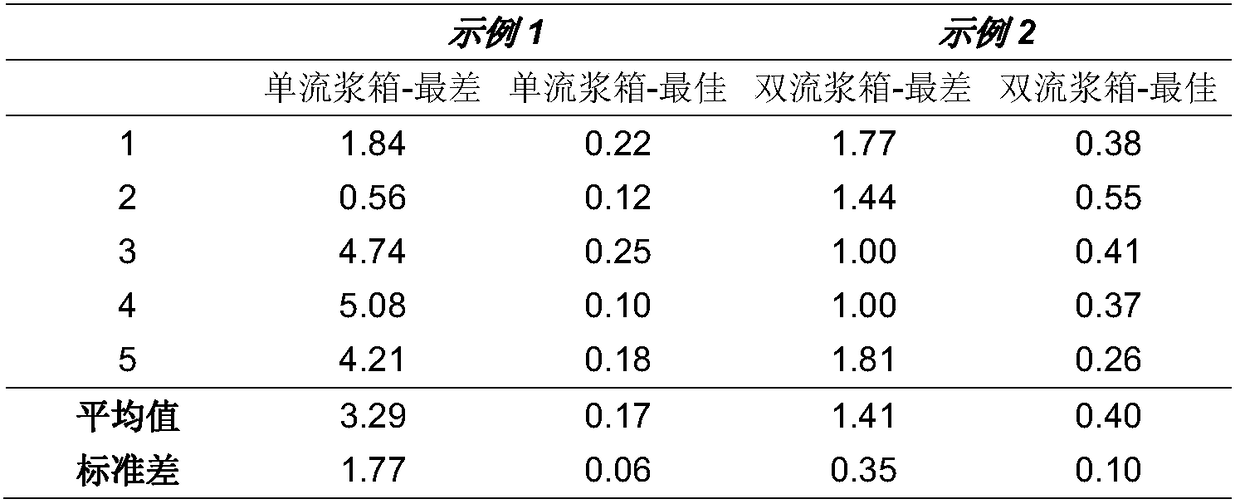

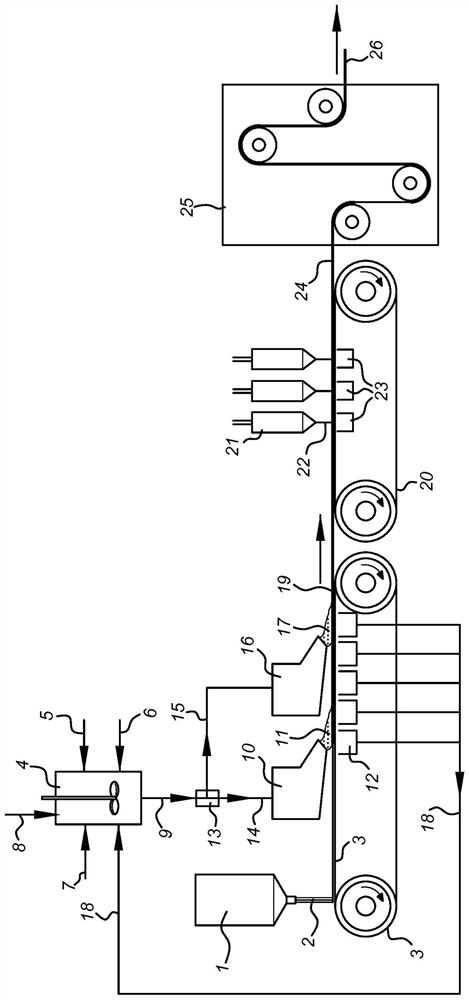

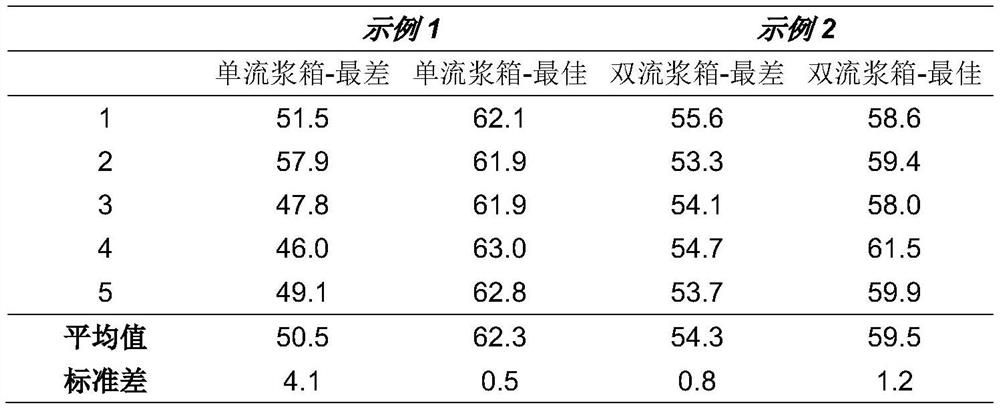

Process for producing nonwoven with improved surface properties

ActiveCN108291345AReduce surface irregularitiesHigh strengthSurfactants additionPaper/cardboardPolymer scienceSheet material

A hydroentangled nonwoven sheet material can be produced by a process which comprises: 0) optionally providing a polymer web on a carrier, a) providing an aqueous suspension containing short fibres and a surfactant; b) depositing the aqueous suspension on the carrier, c) removing aqueous residue of the aqueous suspension deposited in step b) to form a fibrous web, b') depositing aqueous suspensionon a surface of the fibrous web formed in step c), c') removing aqueous residue of the aqueous suspension deposited in step b') to form a combined fibrous web, d) hydroentangling the combined fibrousweb, and optionally e) drying the hydroentangled web, and / or f) further processing and finalising the dried, hydroentangled web the web to produce the nonwoven end material. The hydroentangled non-woven sheet material obtainable by this process has a low degree of surface irregularity and contains low residues of surfactants.

Owner:ESSITY HYGIENE & HEALTH AB

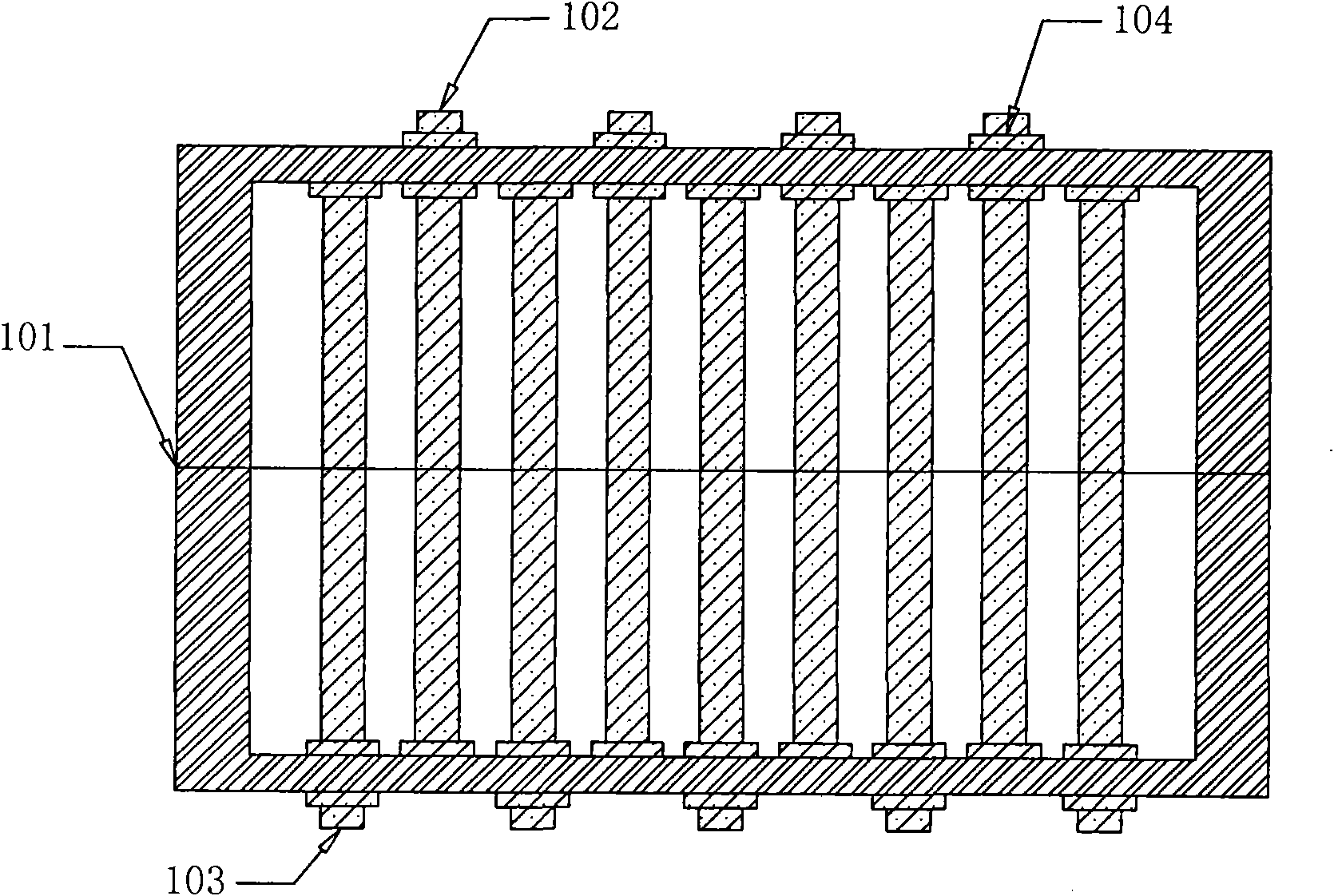

Three-dimensional stacked phase change memory and preparation method thereof

ActiveUS20210280784A1Reduce the number of timesEffectively reducing costSolid-state devicesSemiconductor devicesPhase-change memoryEngineering physics

A three-dimensional stacked phase change memory and a preparation method thereof are provided. The method comprises: preparing first horizontal electrodes spaced apart from each other on a substrate; preparing first strip-shaped phase change layers, each having a central gap, between the first horizontal electrodes; preparing first selectors in the central gaps of the first strip-shaped phase change layers; preparing a first insulating layer; preparing second strip-shaped phase change layers at same vertical positions on the first insulating layer; preparing second selectors; then preparing horizontally-oriented insulating holes between the horizontal electrodes; and preparing vertical electrodes between the adjacent insulating holes, thereby forming a multilayer stacked phase change memory with a vertical structure.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for producing nonwovens with improved surface properties

ActiveCN108291345BReduce surface irregularitiesHigh strengthSurfactants additionPaper/cardboardFiberPolymer science

A hydroentangled nonwoven sheet material capable of being manufactured by a process comprising: 0) providing a polymeric web, optionally on a carrier, a) providing an aqueous suspension comprising staple fiber surfactant b) depositing the aqueous suspension on a carrier, c) removing the aqueous residue of the aqueous suspension deposited in step b) to form a fibrous web, b') on the surface of the fibrous web formed in step c) depositing the aqueous suspension, c') removing the aqueous residue of the aqueous suspension deposited in step b') to form a combined fibrous web, d) hydroentangling the combined fibrous web, and optionally e) drying The hydroentangled web, and / or f) further processing and styling the dried hydroentangled web to produce a nonwoven final material. The hydroentangled nonwoven sheet material obtainable by this method has a lower degree of surface irregularities and contains lower residues of surfactants.

Owner:ESSITY HYGIENE & HEALTH AB

Microfluid-System-Supporting Unit And Production Method Thereof

InactiveUS20110132535A1Reduce surface irregularitiesResistant to breakageAdhesive processesLamination ancillary operationsBiomedical engineering

The present invention relates to a microfluid-system-supporting unit, comprising a fixing layer formed on a substrate, a protective layer or a fixing layer, wherein part of at least one hollow filament in any shape is placed and fixed in the fixing layer. Thus, it provides a microfluid-system-supporting unit lower in surface irregularity even when there are multiple hollow filaments different in external diameter or the hollow filaments crosses each other and resistant to positional deviation of the hollow filament in the crossing regions, and a production method thereof.

Owner:RESONAC CORPORATION

Preparation method of enamel paint

The invention discloses a preparation method of enamel paint. the enamel paint is prepared from the following raw materials in parts by weight: 35-45 parts of an emulsion, 48-56 parts of pigment, 48-56 parts of filler, 3-7 parts of an aid, 20-30 parts of silica, 5-15 parts of boron oxide, 3-13 parts of alumina and 1-3 parts of calcium oxide. According to the preparation method of the enamel paint,the enamel paint has better heat preservation property and very good prospects.

Owner:河南中釉环保科技有限公司

Fuel cell

ActiveUS7297433B2Reduce surface irregularitiesAvoid damageCell electrodesCell component detailsPolymer electrolytesFuel cells

A fuel cell includes a laminated, plate-shaped membrane electrode assembly and first and second separator plates sandwiching the membrane electrode assembly. The membrane electrode assembly includes a polymer electrolyte membrane; first and second electrode layers sandwiching the polymer electrolyte membrane; and first and second gas-diffusion layers disposed on an outer side of the electrode layers, respectively. The first and second gas-diffusion layers are made of an air-permeable metallic material. An arithmetic average roughness Ra of a surface of the air-permeable metallic material on the side contacting one of the electrode layers is in a range of 0.1 μm≦Ra≦1.0 μm.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com