Roll-to-roll plasma device for enhancing chemical vapor deposition

A plasma and vapor deposition technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of unevenness and inaccessibility, improve quality, improve operation efficiency, reduce surface unevenness, etc. The effect of flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

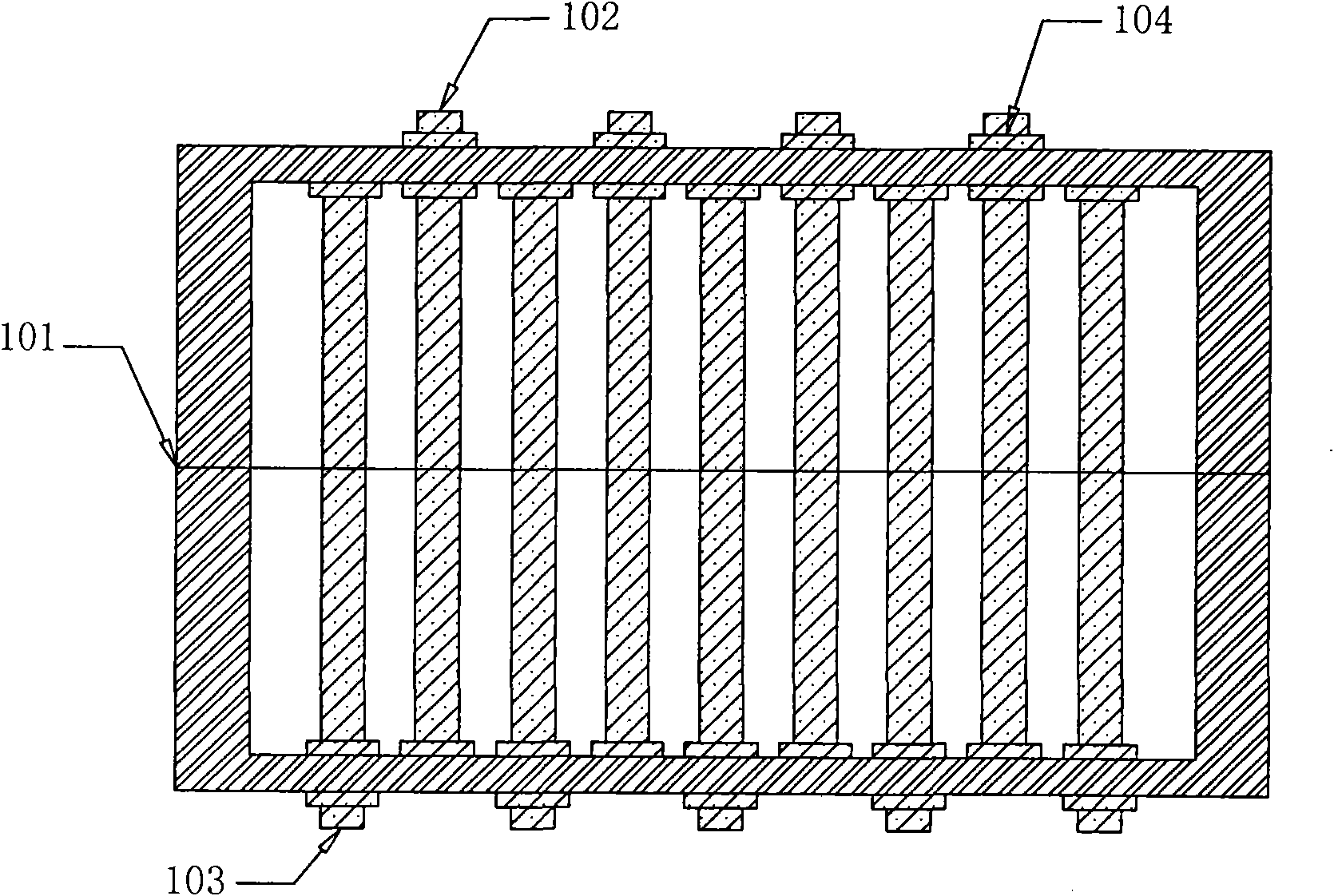

[0036] Such as Figure 1-5 shown.

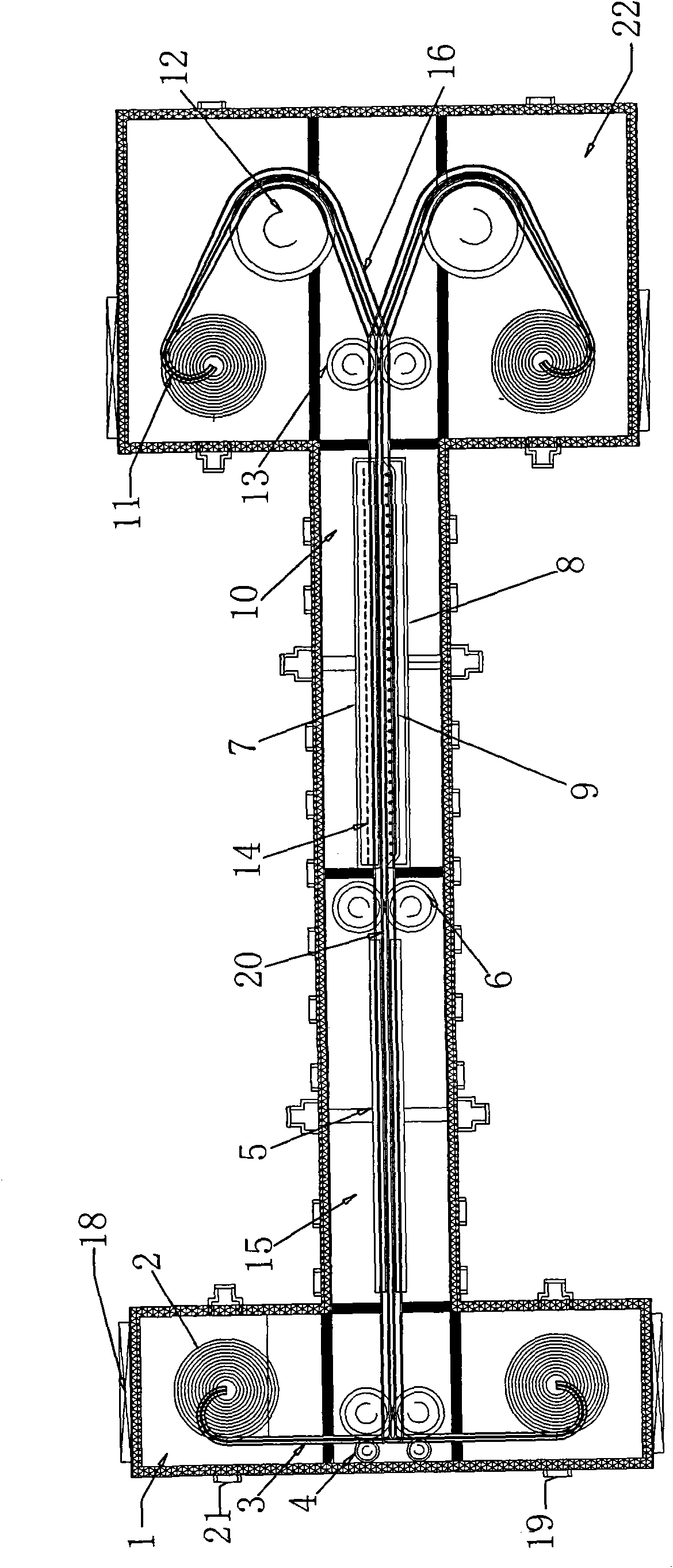

[0037] A roll-to-roll plasma-enhanced chemical vapor deposition device, which mainly consists of the following parts (such as figure 1 shown):

[0038] A roll-out roller 2, the roll-out roll 2 is wound with a strip-shaped flexible base material that is unwound, and the roll-out roll 2 is installed in the vacuum chamber 1;

[0039] A winding roller 11, the winding roller 11 rewinds the flexible base material unwound by the aforementioned unwinding roller 2 into rolls in a roll-to-roll manner, and the winding roller 11 is installed in the vacuum chamber 22;

[0040] A heating chamber 15, one end of the heating chamber 15 is connected with the vacuum chamber 1, and the other end is connected with the deposition chamber 10, and one end of the deposition chamber 10 is connected with the vacuum chamber 22, a heating devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com