Tube segment shipping and trolley towing integrated device of shield machine

A technology of shield machine and segment assembling machine, which is applied in transportation and packaging, cranes, shaft equipment, etc., can solve the problems of increased labor intensity of staff, increased equipment failure rate, reduced transportation efficiency, etc., so as to reduce the labor intensity of workers , The effect of reducing equipment cost and high transportation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

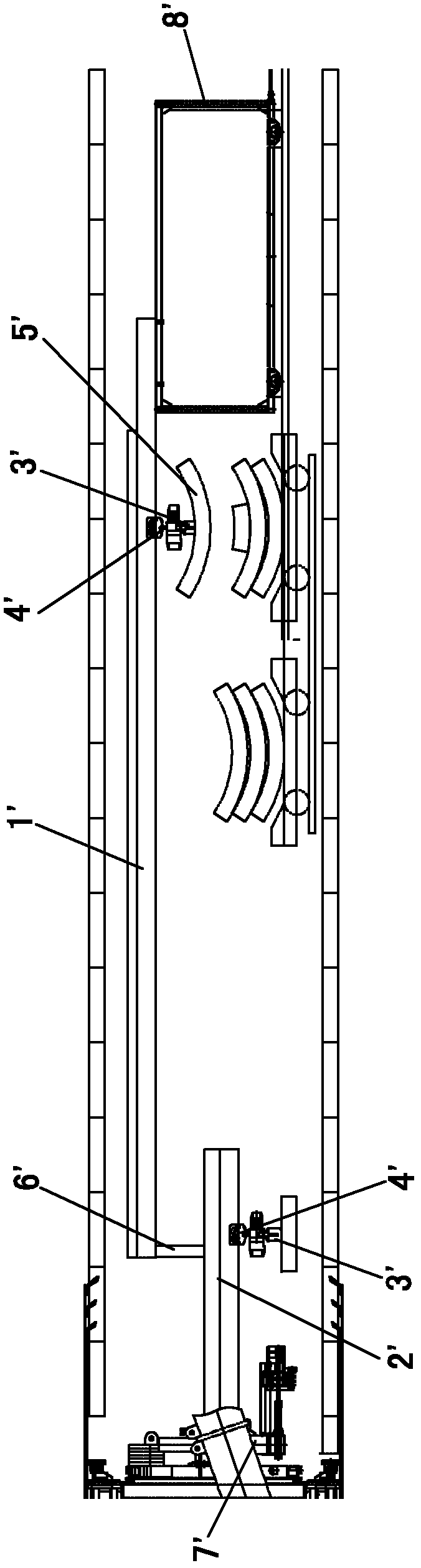

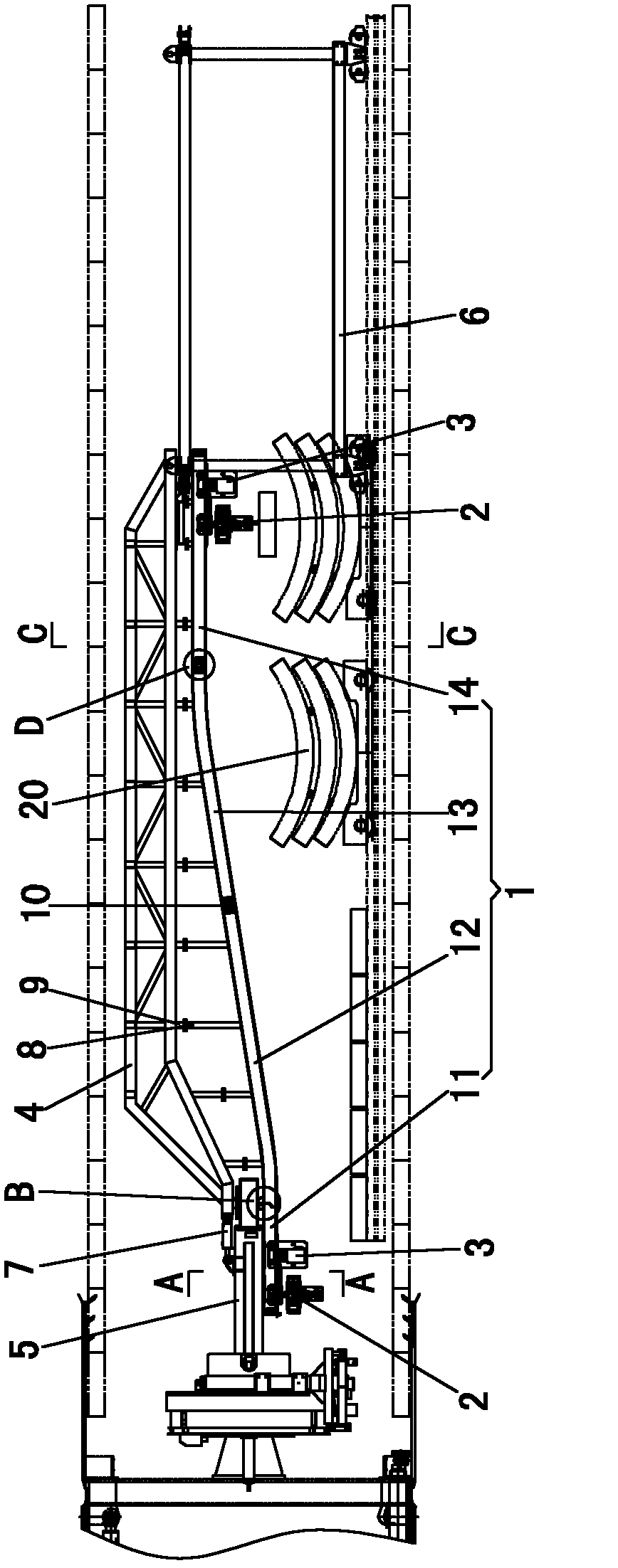

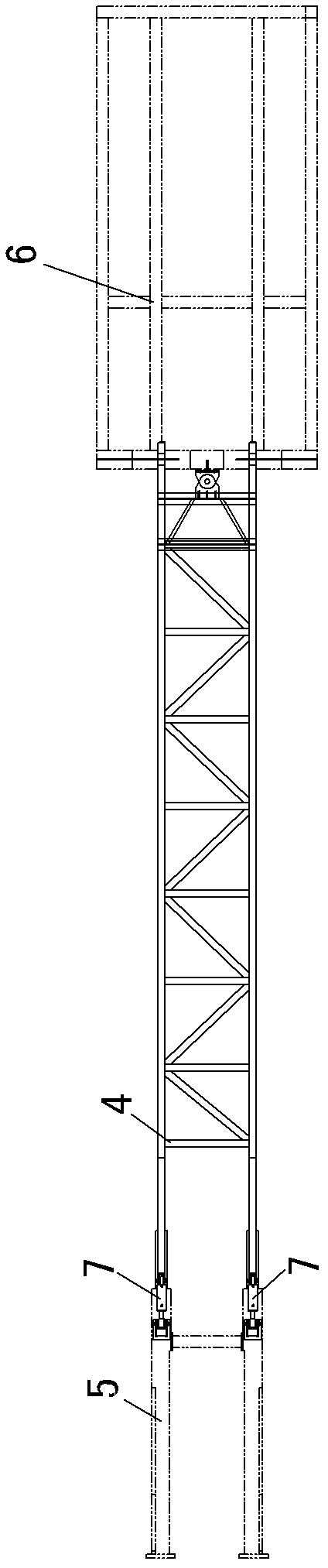

[0021] like figure 2 , image 3 and Image 6 As shown, the integrated device for segment hoisting and trolley traction of the shield tunneling machine of the present invention includes a double-rail beam 1, a pair of electric hoists 2 hoisted under the double-rail beam 1, a walking trolley 3 for pulling the electric hoist 2, and a connecting frame 4 , the double-track beam 1 is installed between the traveling beam 5 of the segment assembly machine and the supporting first trolley 6 in the rear.

[0022] combine figure 2 As shown, the double-track beam 1 is an I-beam, the front and rear ends of the double-track beam 1 are horizontal beams, and the middle part is an inclined beam. The inclined middle front beam 12, the inclined middle rear beam 13 whose front end height is smaller than the rear end height, and the horizontal rear beam 14 are connected end to end. The double-track beam 1 is composed of multi-section beam connections, which facilitates the transportation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com