Thermal transfer receiving sheet

A technology of receiving sheet and thermal transfer, applied in printing, printing device, copying/marking method, etc., can solve the problems of reduced printing density, no special restrictions on resin composition, limitation of the degree of quality balance adjustment, etc., to achieve dents The effect of reduced degree, excellent image uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

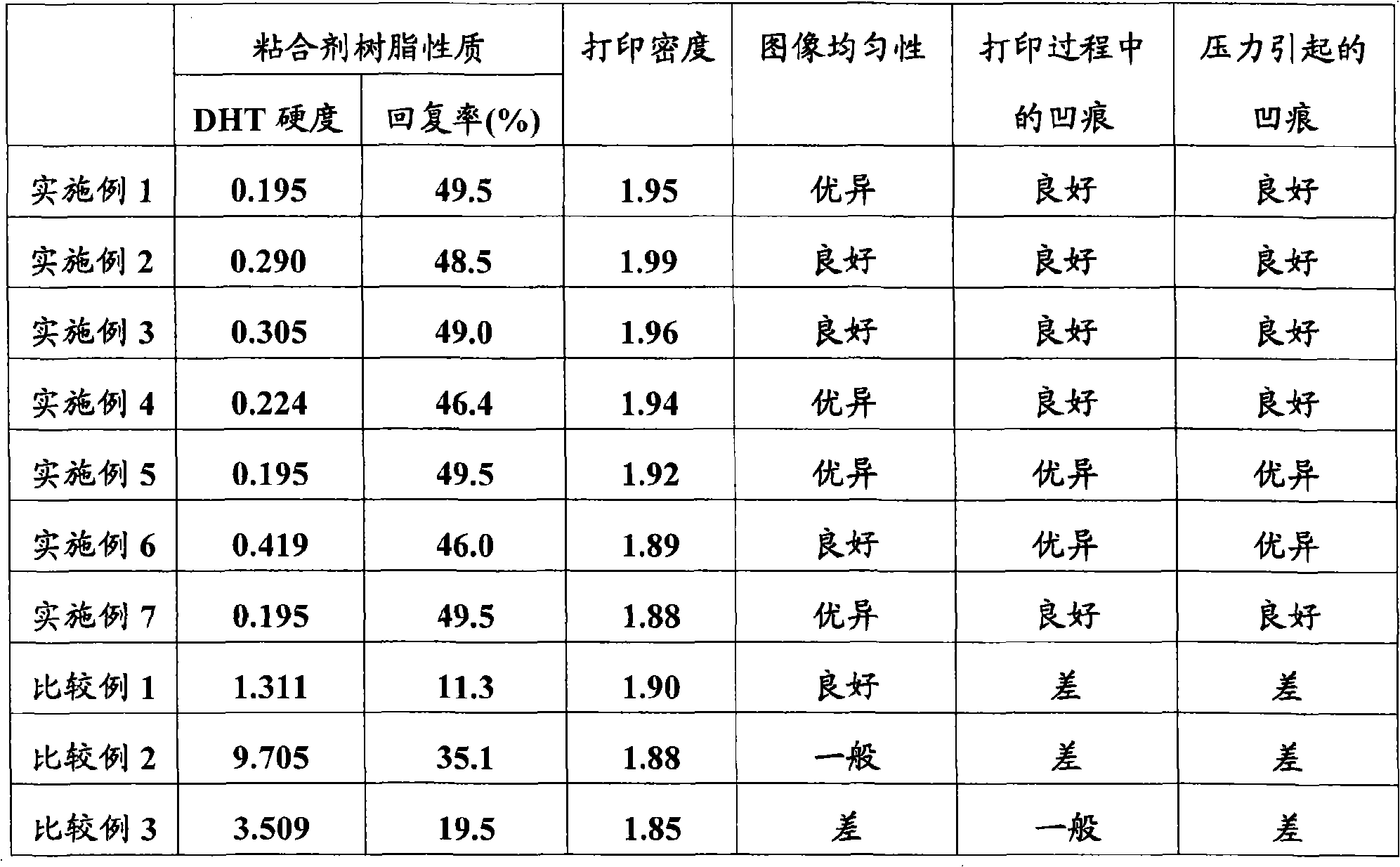

Examples

Embodiment 1

[0100] [Formation of low density layer]

[0101] 150μm thick coated paper (trade name: OK Kinfuji N, 174.4g / m 2 , Oji Paper Co., Ltd.) was used for a sheet-shaped support, and a low-density coating solution 1 having the following composition was coated on one side thereof until its solid matter coating amount was 18 g / m 2 , followed by drying to form a low density layer.

[0102] Low Density Coating Solution 1

[0103] Foams containing copolymers consisting essentially of acrylonitrile and methacrylonitrile 45 parts

[0104] Hollow particles (average particle diameter: 3.2 μm, volume hollow ratio: 85%)

[0105] Polyvinyl alcohol (trade name: PVA205, Kuraray Co., Ltd.) 10 parts

[0106] Polybutadiene resin (trade name: LX111, Tg=-80°C, Zeon Corp.) 45 parts

[0107] 200 parts of water

[0108] [Formation of barrier layer and receiving layer]

[0109] Next, a barrier layer coating solution having the following composition was coated on the low density layer to a solid ma...

Embodiment 2

[0131] A receiving sheet was obtained in the same manner as in Example 1, except that a low-density layer was formed with a low-density layer coating solution 2 having the composition described below in Example 1 "Formation of a low-density layer".

[0132] Low Density Layer Coating Solution 2

[0133] 45 parts of hollow particles (average particle diameter: 3.2 μm, volume hollow ratio: 85%) in foamed medium comprising a copolymer mainly composed of acrylonitrile and methacrylonitrile

[0134] Polyvinyl alcohol (trade name: PVA205, Kuraray Co., Ltd.) 10 parts

[0135] Styrene-butadiene-acrylonitrile copolymer resin (trade name: LX426, 45 parts, Tg=-39°C, Zeon Corp.)

[0136] 200 parts of water

[0137] In addition, the DHT hardness of this styrene-butadiene-acrylonitrile copolymer resin was 0.290, and the recovery rate was 48.5%.

Embodiment 3

[0139] A receiving sheet was obtained in the same manner as in Example 1, except that a low-density layer was formed with a low-density layer coating solution 3 having the composition described below in Example 1 "Formation of a low-density layer".

[0140] Low Density Layer Coating Solution 3

[0141] 45 parts of hollow particles (average particle diameter: 3.2 μm, volume hollow ratio: 85%) in foamed medium comprising a copolymer mainly composed of acrylonitrile and methacrylonitrile

[0142] Polyvinyl alcohol (trade name: PVA205, Kuraray Co., Ltd.) 15 parts

[0143] Butadiene-acrylonitrile copolymer resin (trade name: LX555, Tg=-35°C, 35 parts of Zeon Corp.)

[0144] 200 parts of water

[0145] In addition, the DHT hardness of this butadiene-acrylonitrile copolymer resin was 0.305, and the recovery rate was 49.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com