Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce size change" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

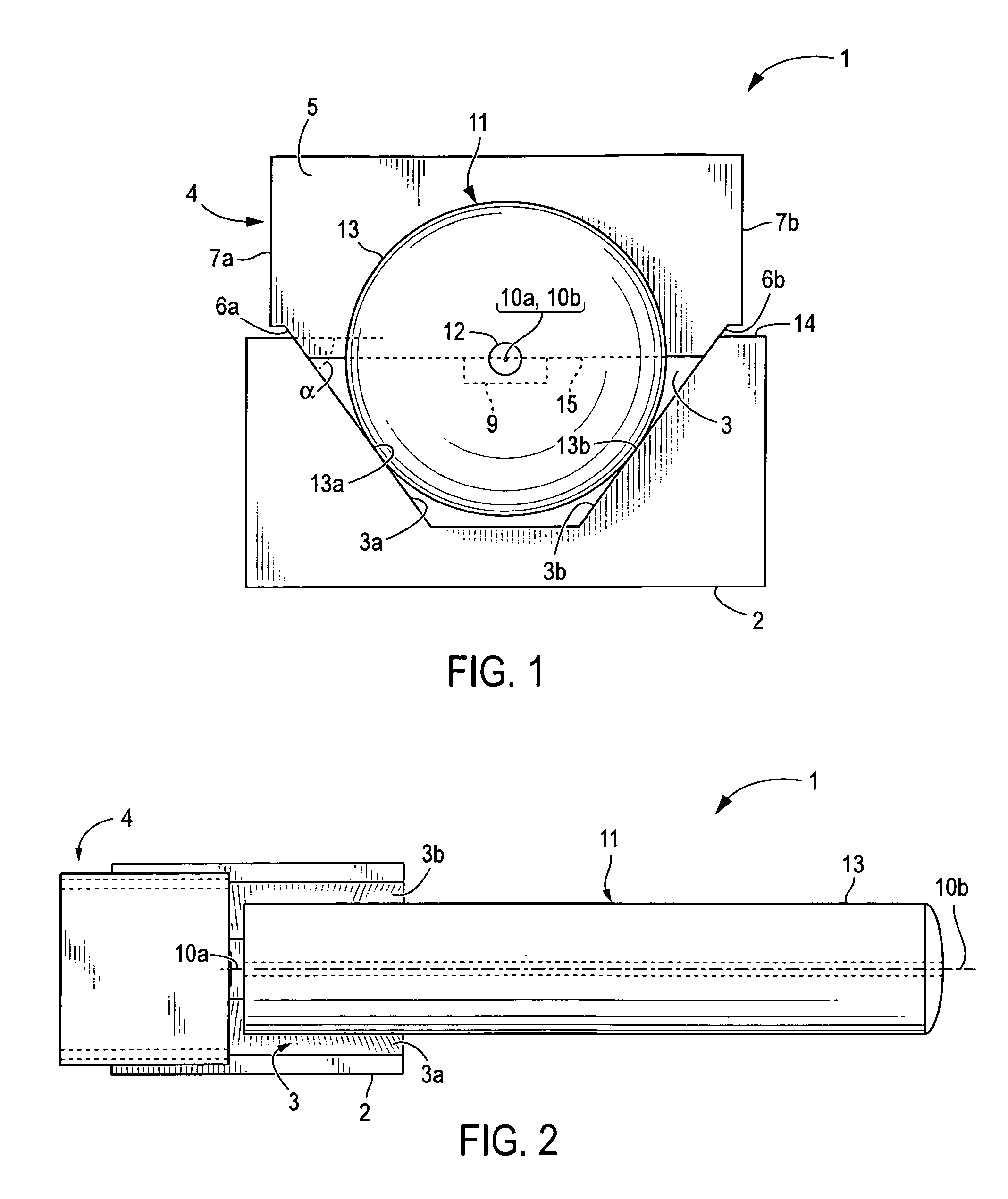

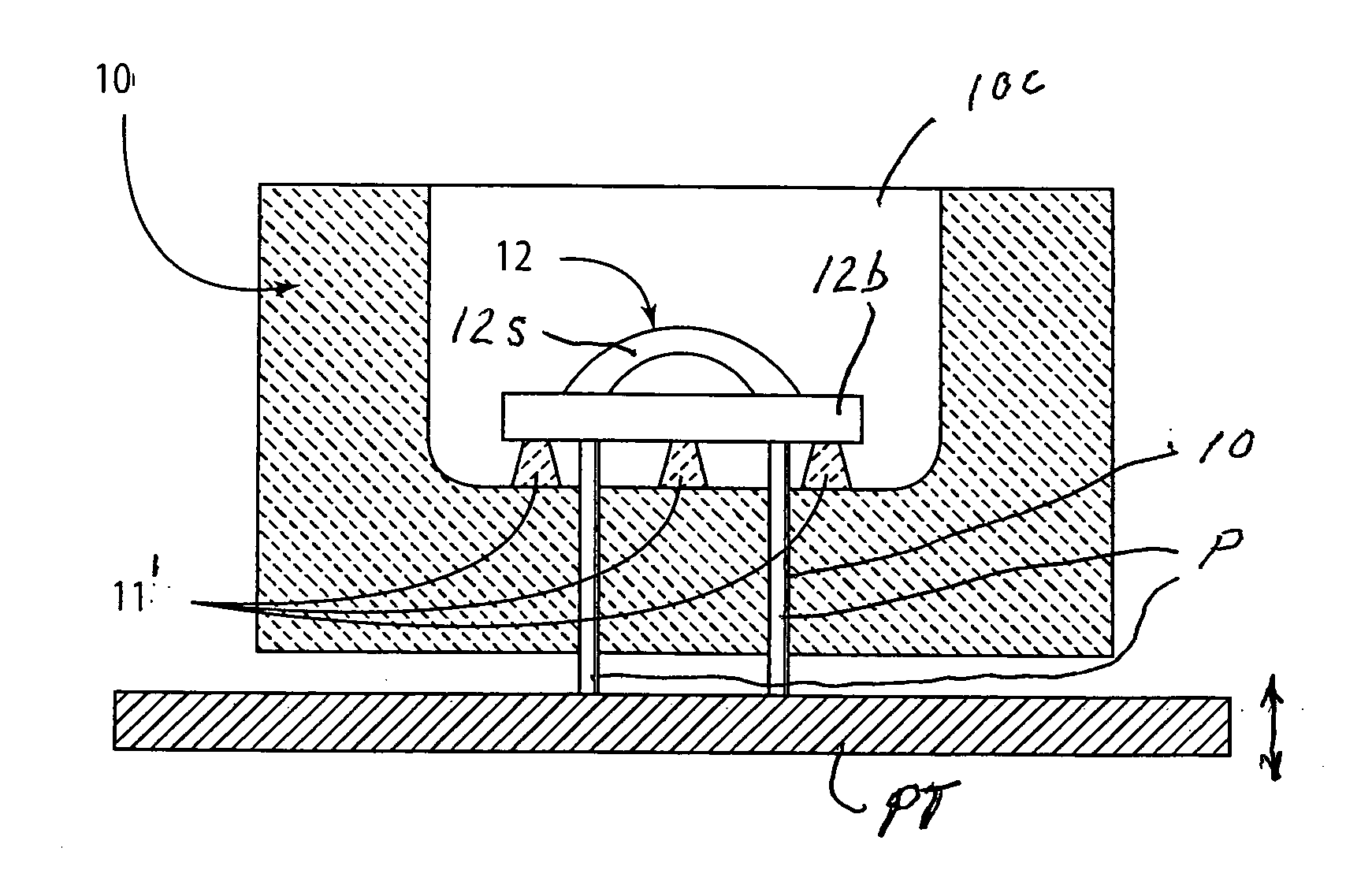

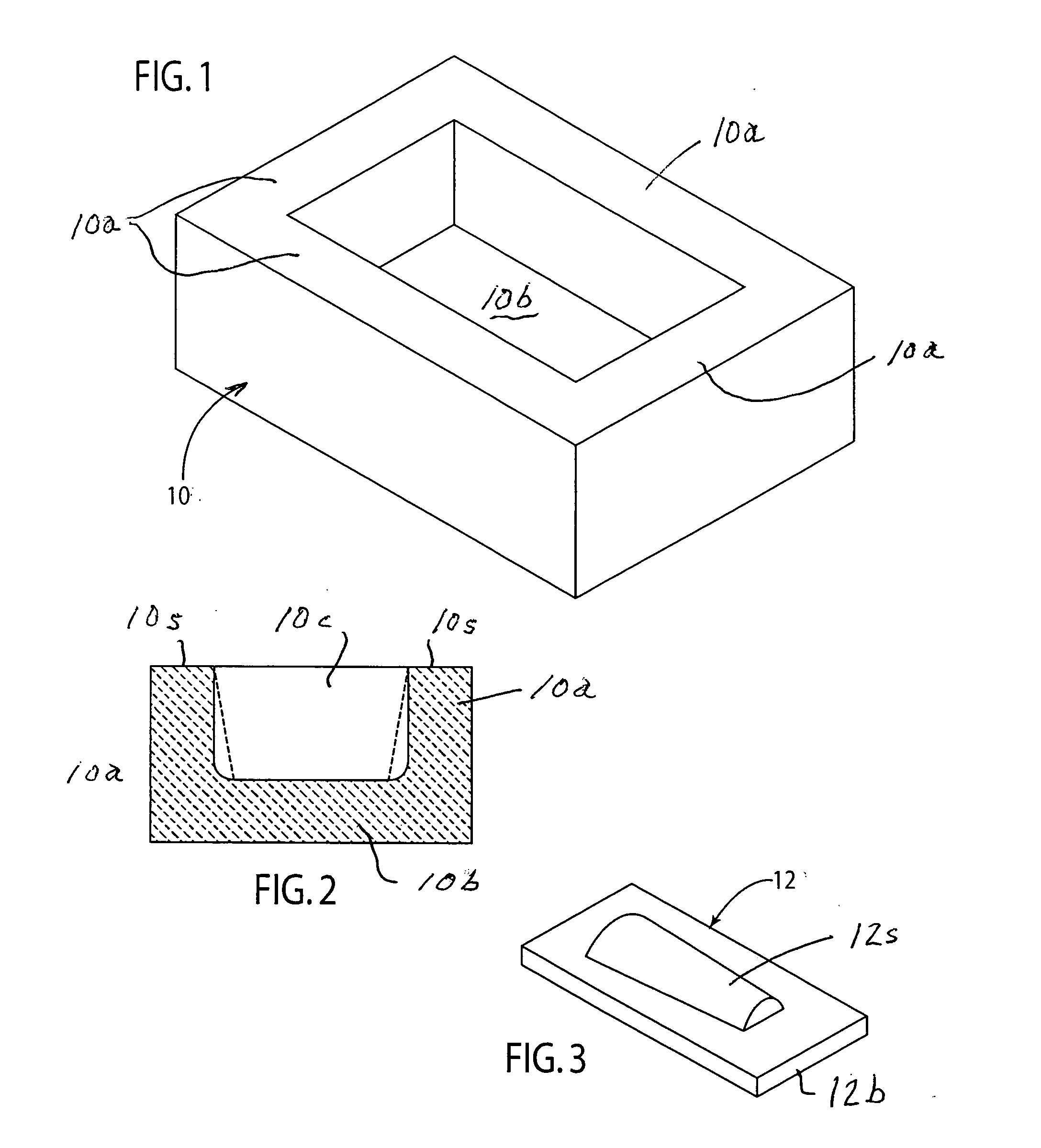

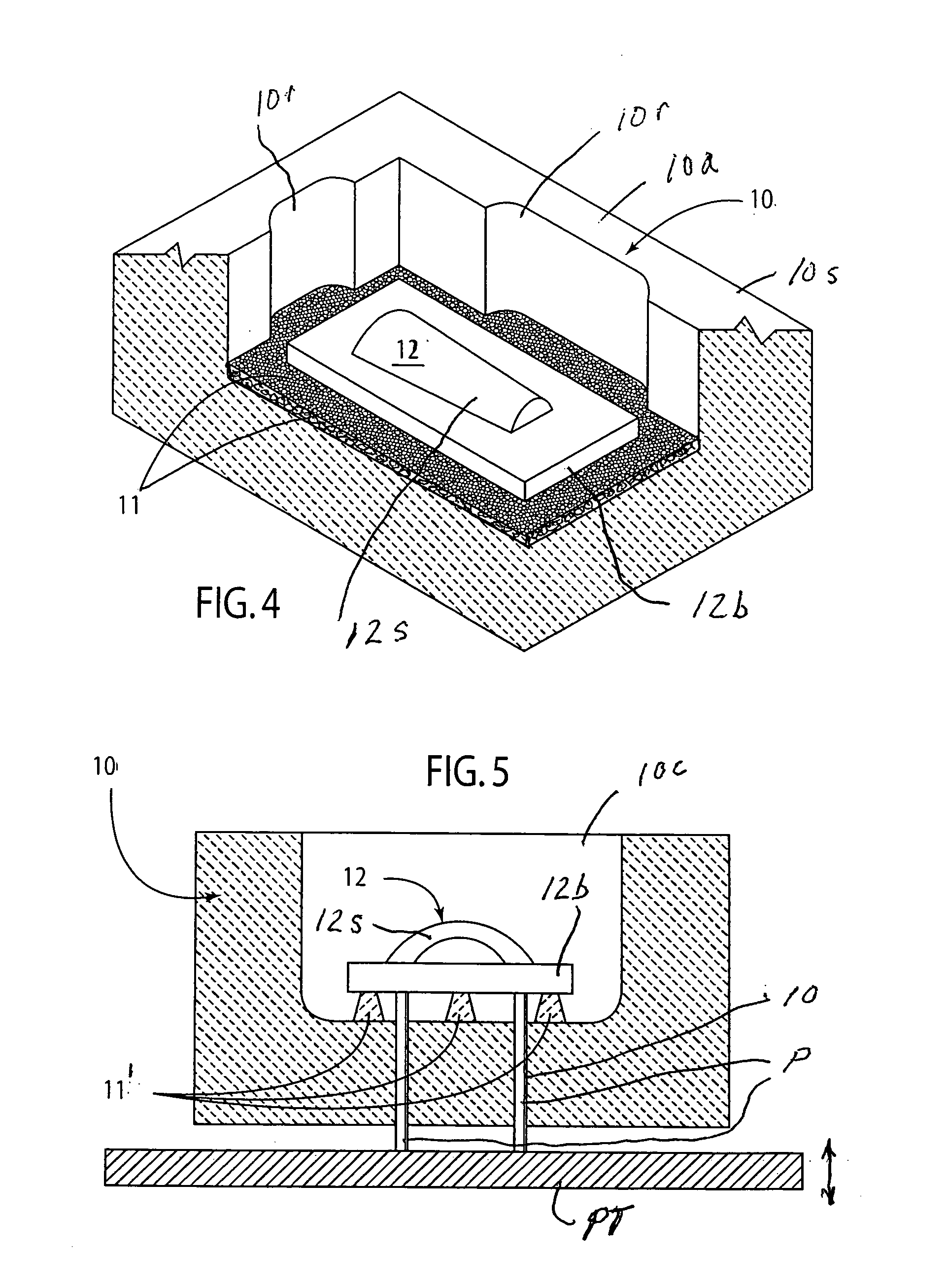

Optical bench having V-groove for aligning optical components

InactiveUS7511258B2The environment is moreMinimize impactLaser detailsBeam/ray focussing/reflecting arrangementsOptical axisOptical table

An optical package having a top and bottom orientation and comprising: (a) a platform defining a V-groove with walls of a certain pitch; (b) a first optical component having a reference surface and two sides, each side being beveled at the certain pitch outwardly from the reference surface, the first optical component having a first optical axis, the first optical component being disposed in the V-groove such that the reference surface faces downward and the sides are in parallel contact with the walls of the V-groove; and (c) a second optical component having an outer periphery with at least two contact points and a second optical axis, the second optical component being disposed in the V-groove such that the contact points contact the walls of the V-groove and the second optical axis is coaxial with the first optical axis.

Owner:TE CONNECTIVITY CORP

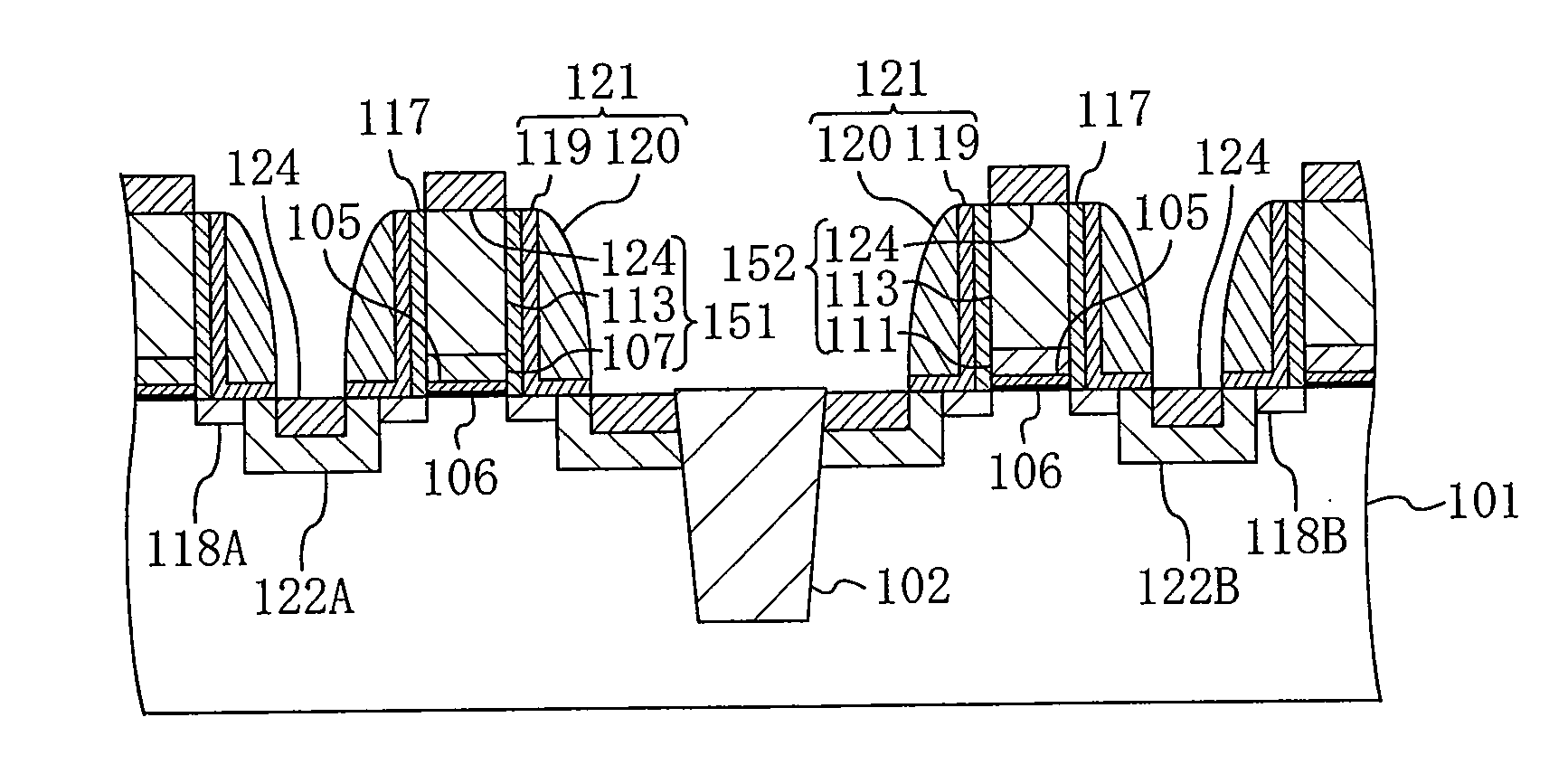

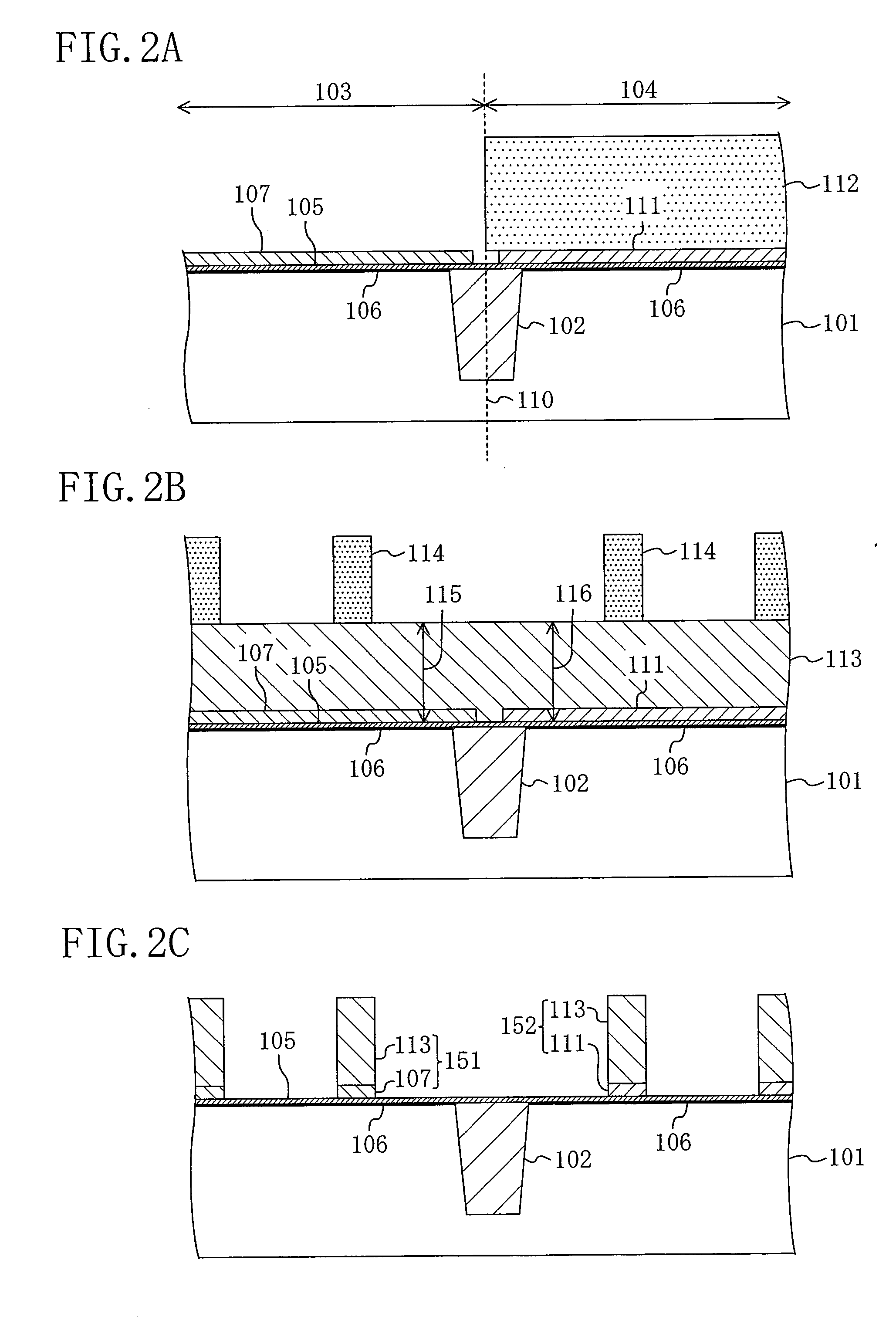

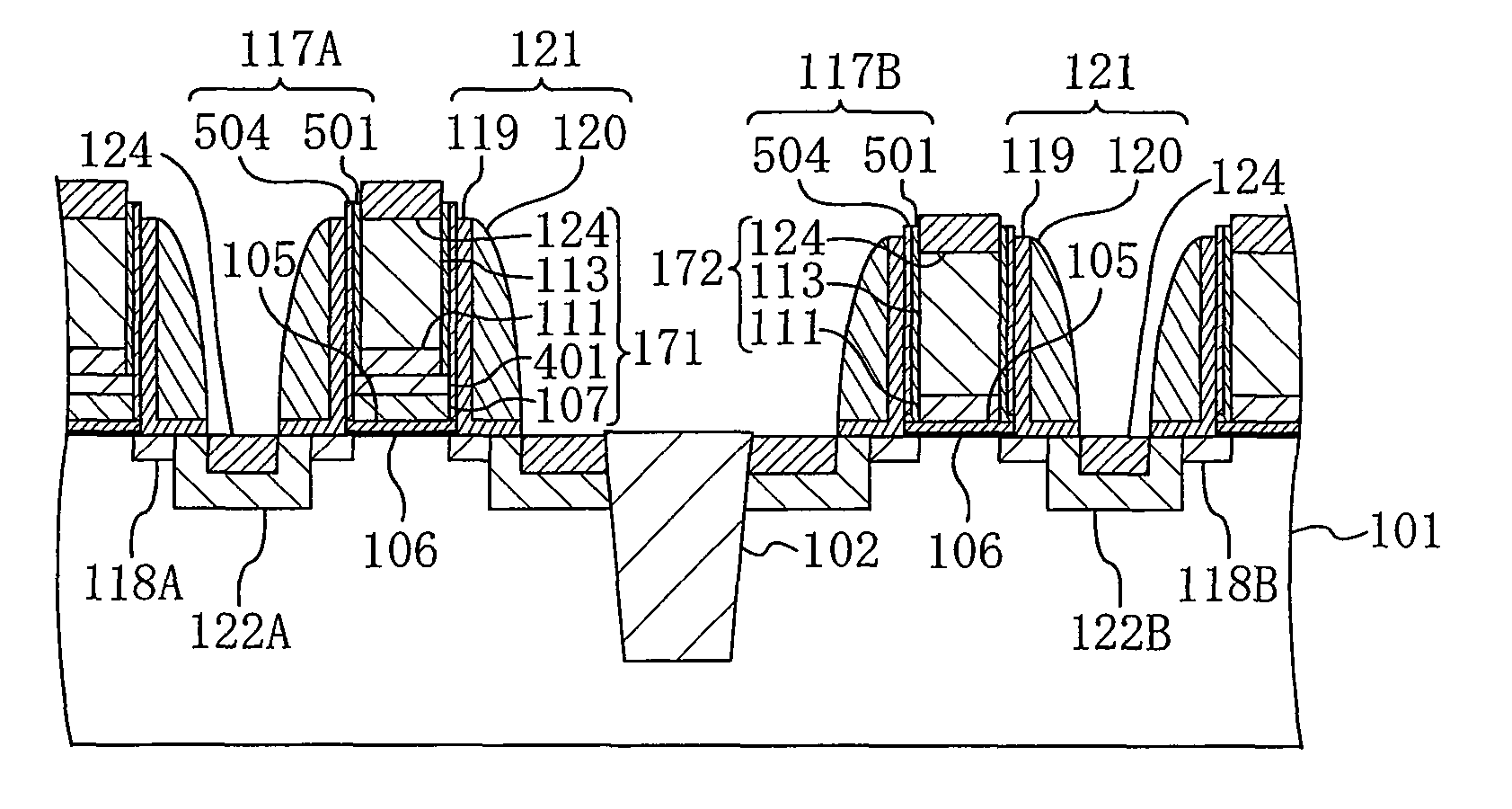

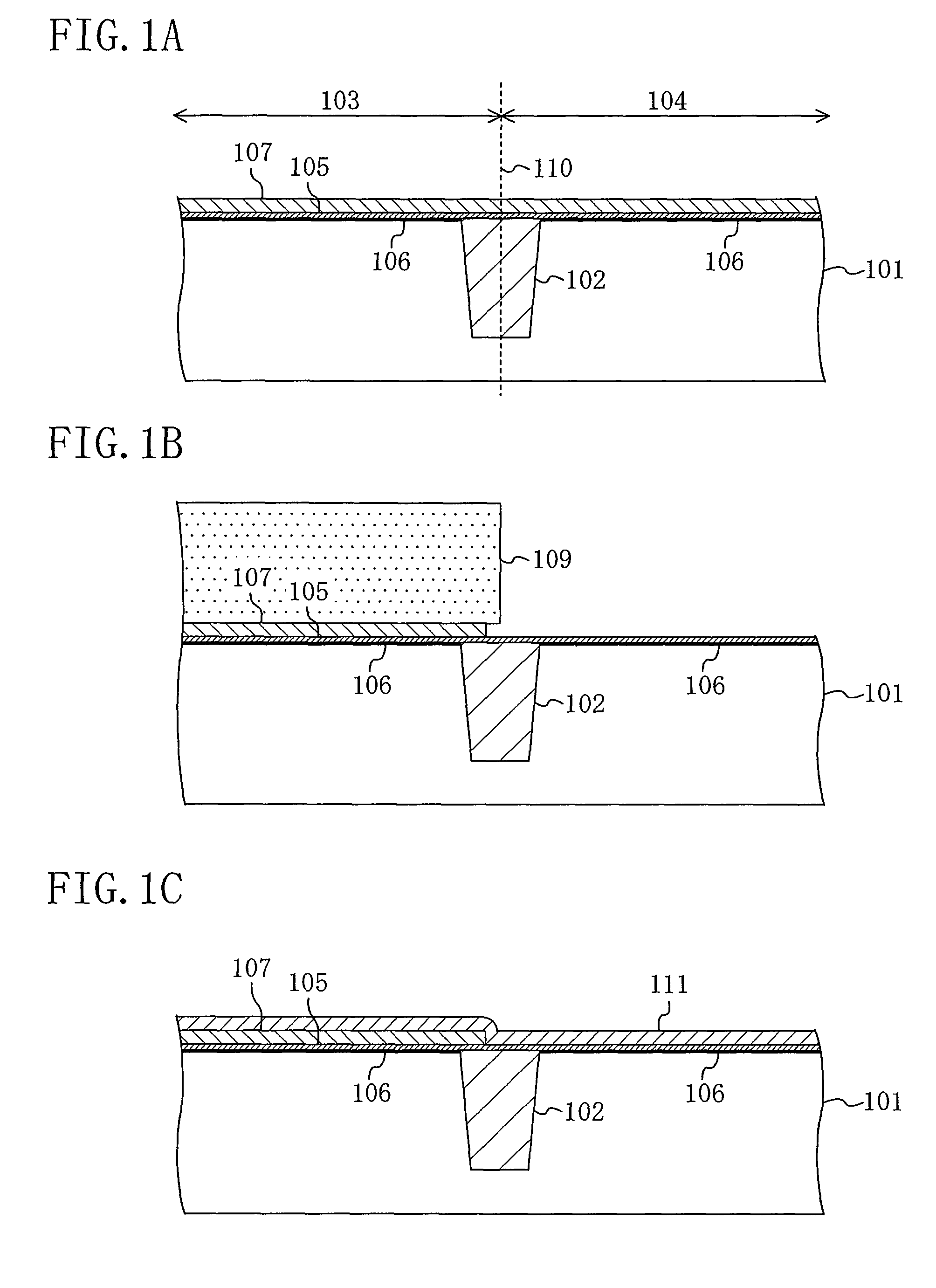

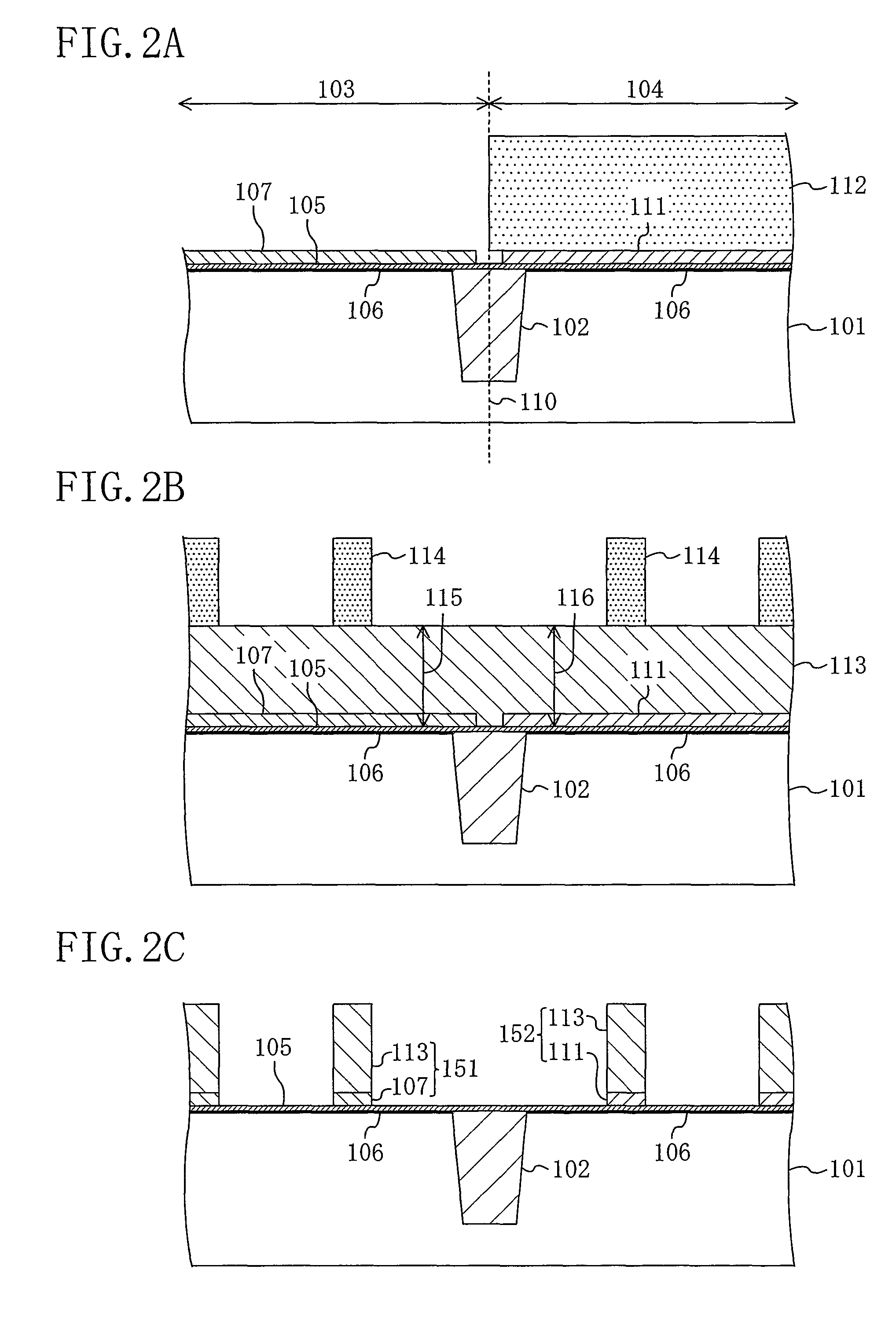

Semiconductor device and method for manufacturing the same

A gate electrode of one of an nFET and a pFET includes a metal-containing layer in contact with a gate insulating film and a first silicon-containing layer formed on the metal-containing layer, and a gate electrode of the other FET includes a second silicon-containing layer in contact with a gate insulating film and a third silicon-containing layer formed on the second silicon-containing layer. The first silicon-containing layer and the third silicon-containing layer are formed by the same silicon-containing material film.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

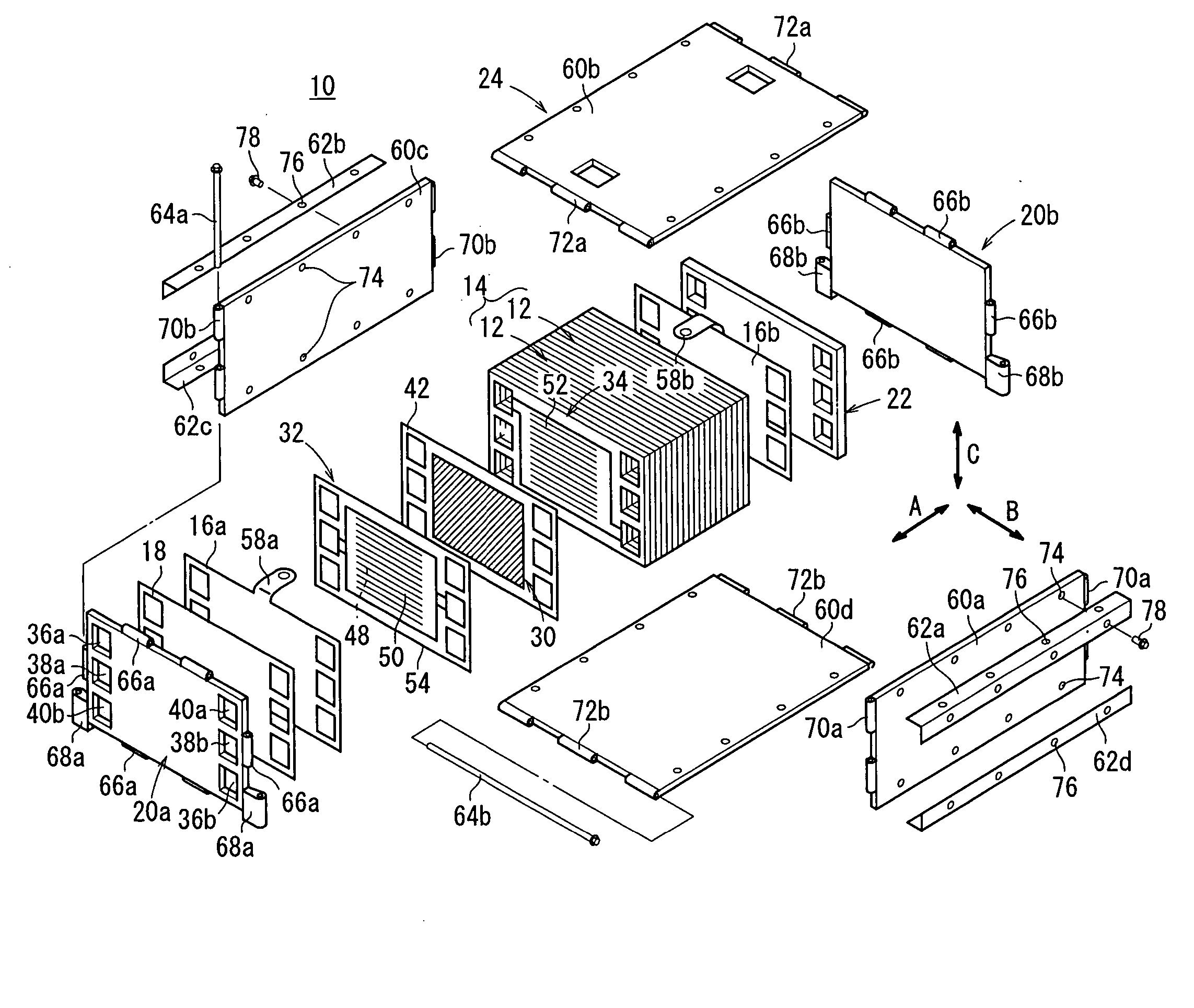

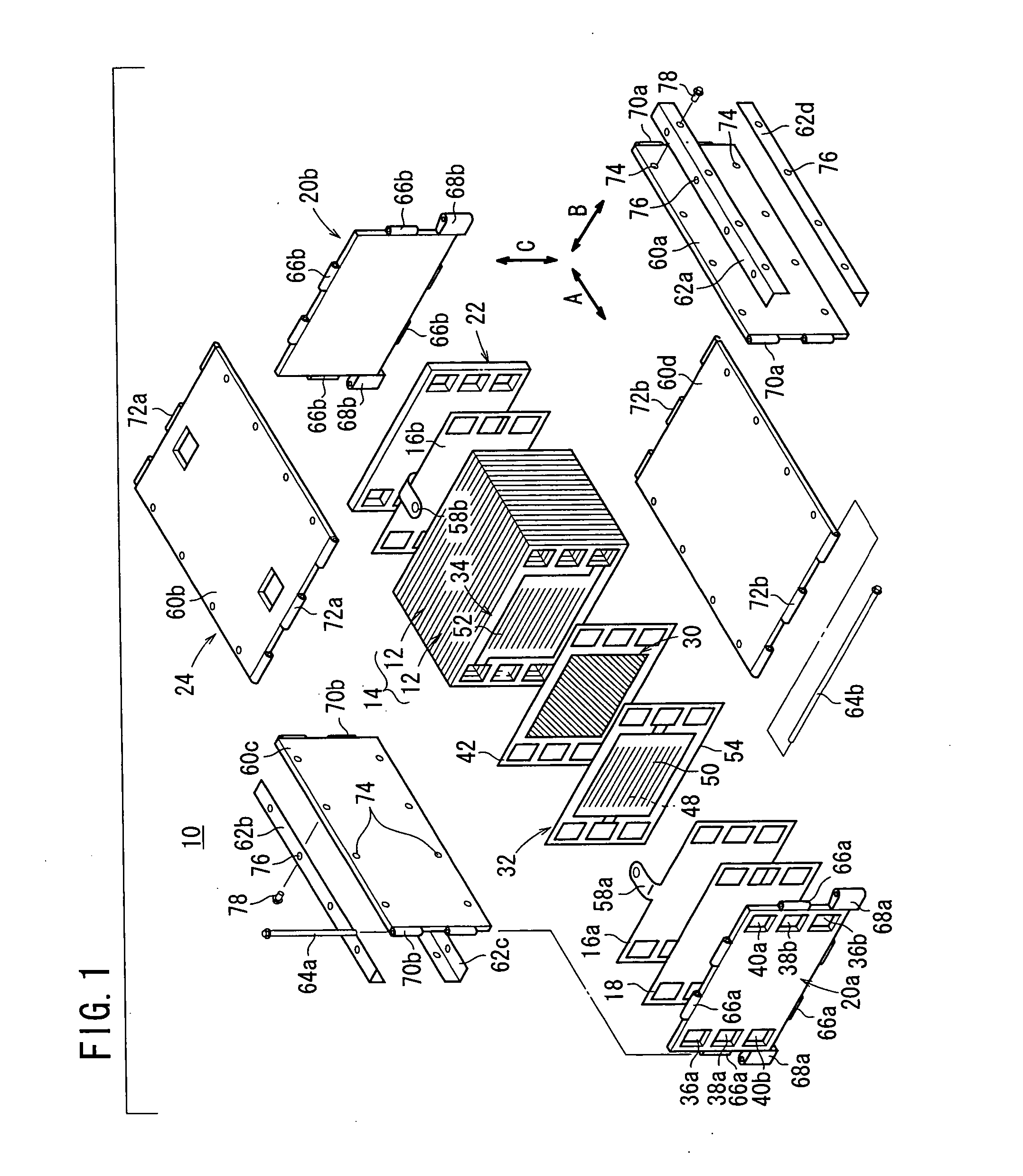

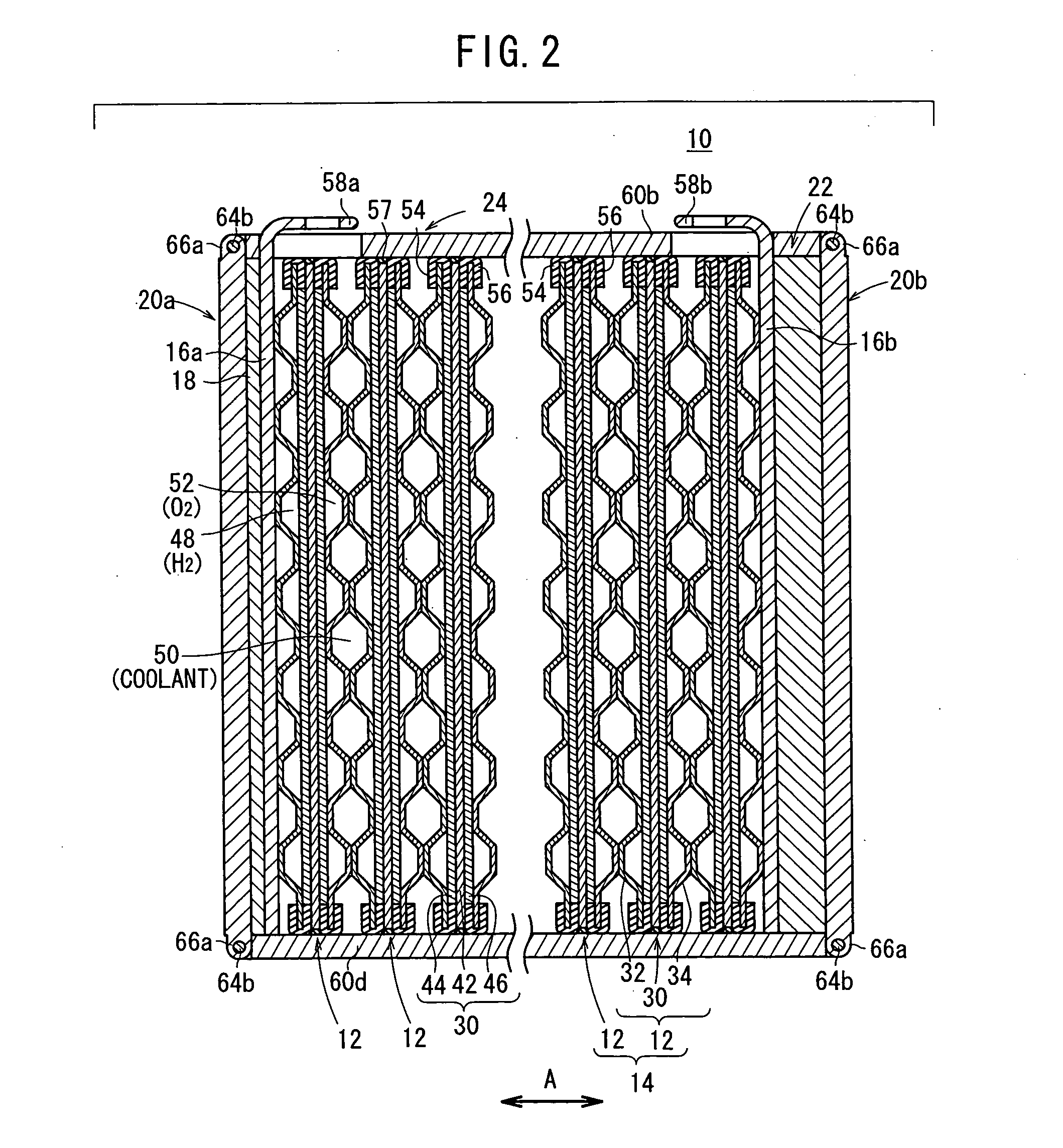

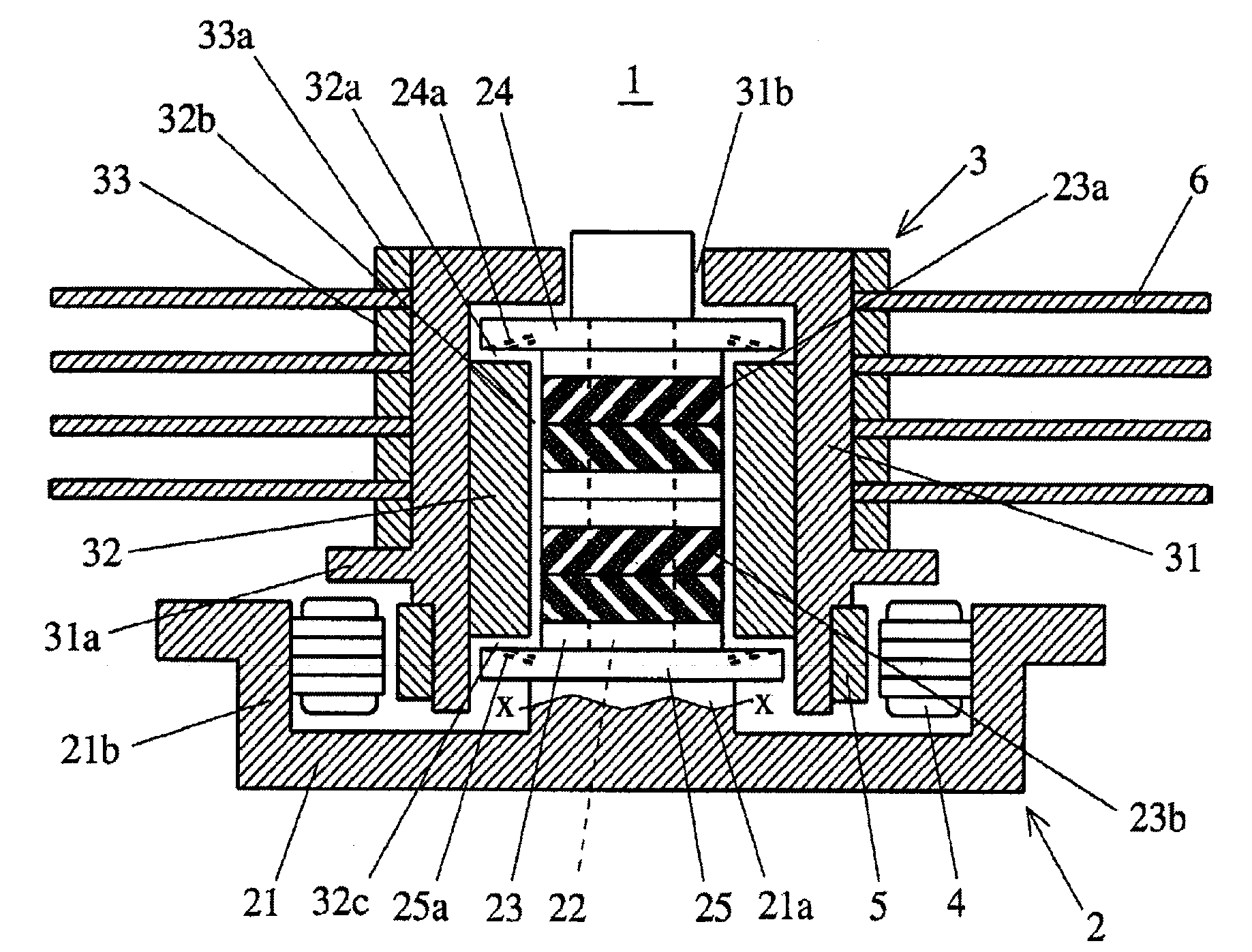

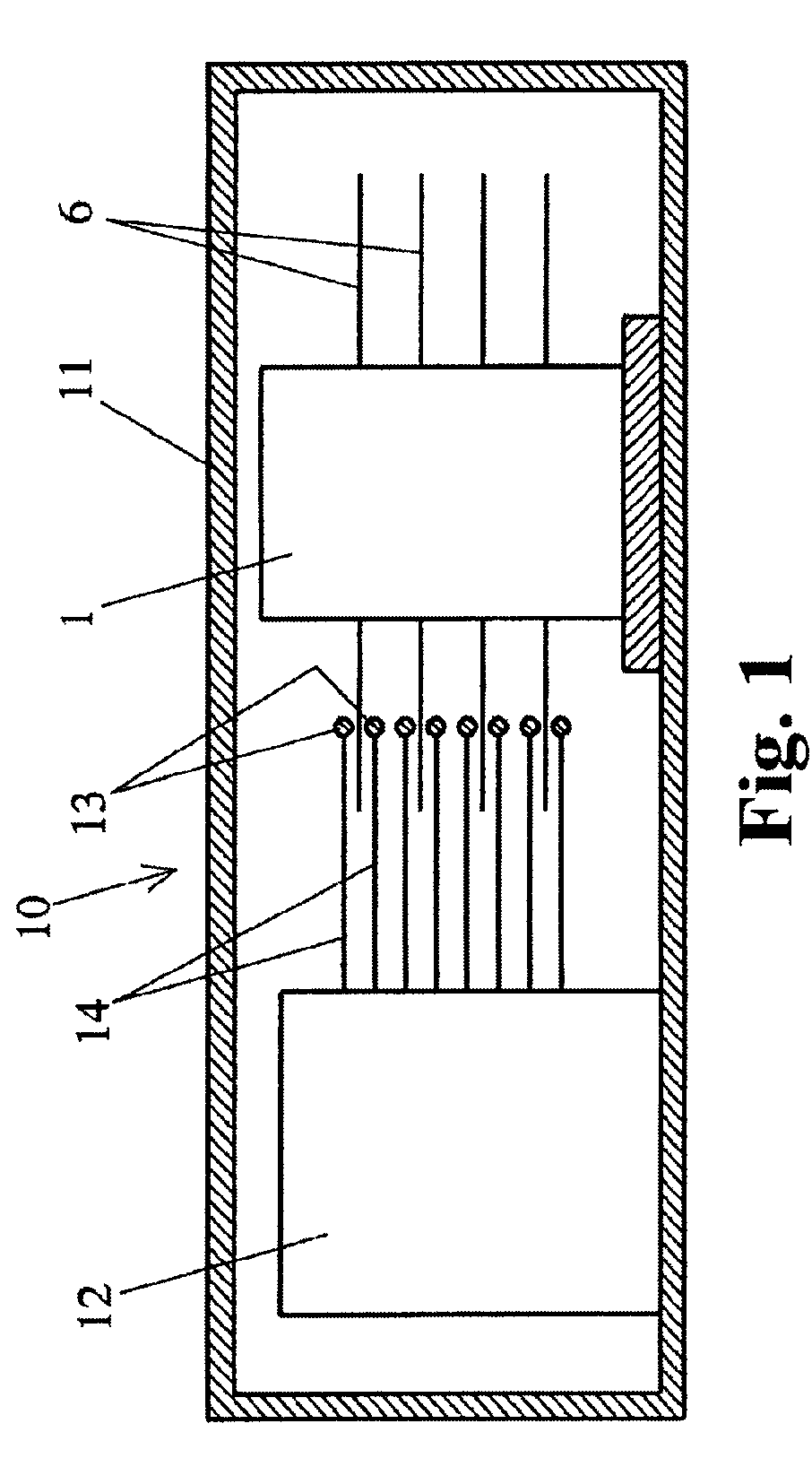

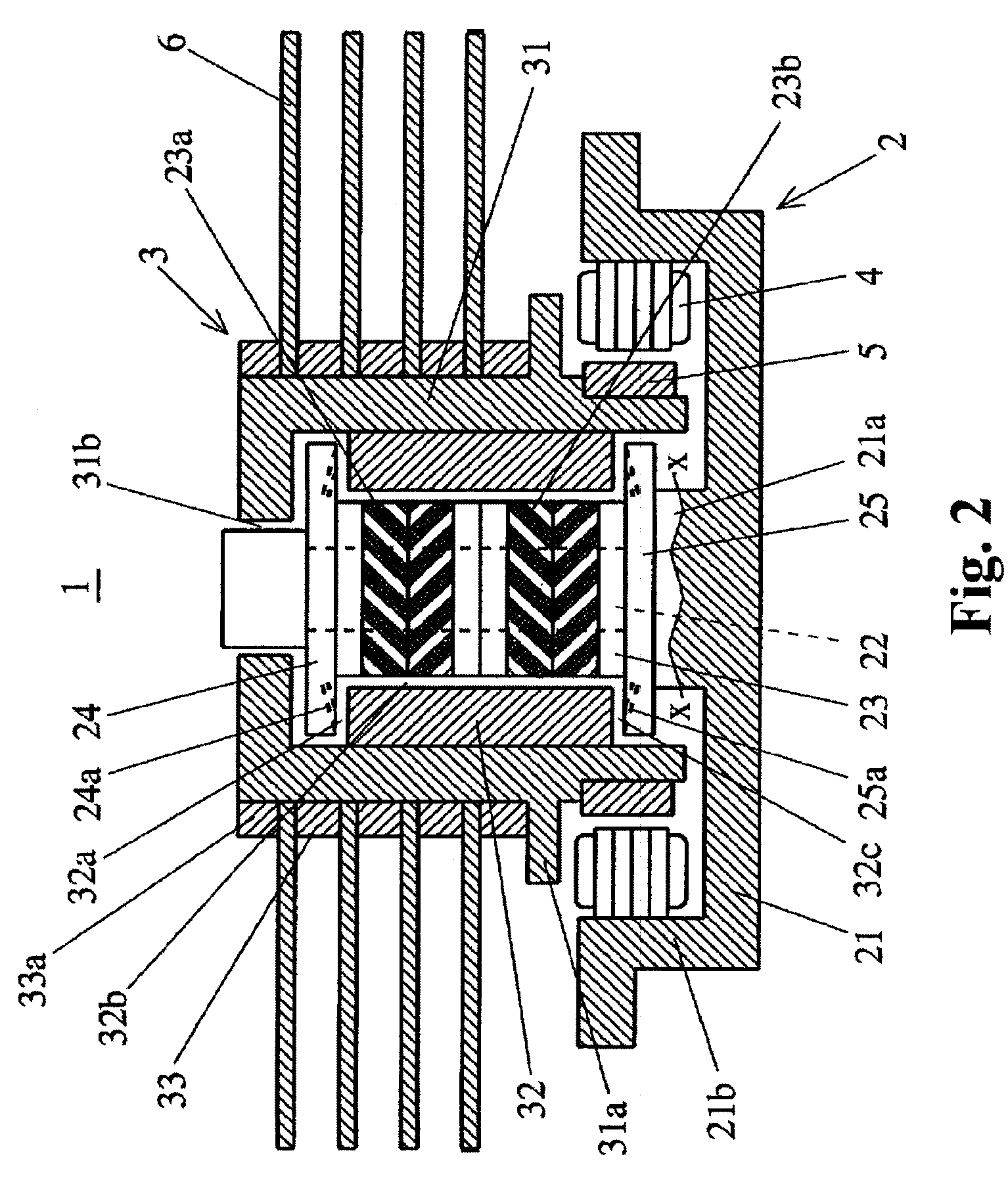

Fuel cell stack

ActiveUS20050019643A1Small sizeExcellent characteristicsFuel cells groupingFuel cell auxillariesFuel cellsEngineering

A fuel cell stack includes a box-shaped casing and a stack body in the box-shaped casing. The stack body is formed by stacking a plurality of unit cells. The casing includes end plates, a plurality of side plates, angle members, and coupling pins. The angle members couple adjacent ends of the side plates. The coupling pins couple the end plates and the side plates.

Owner:HONDA MOTOR CO LTD

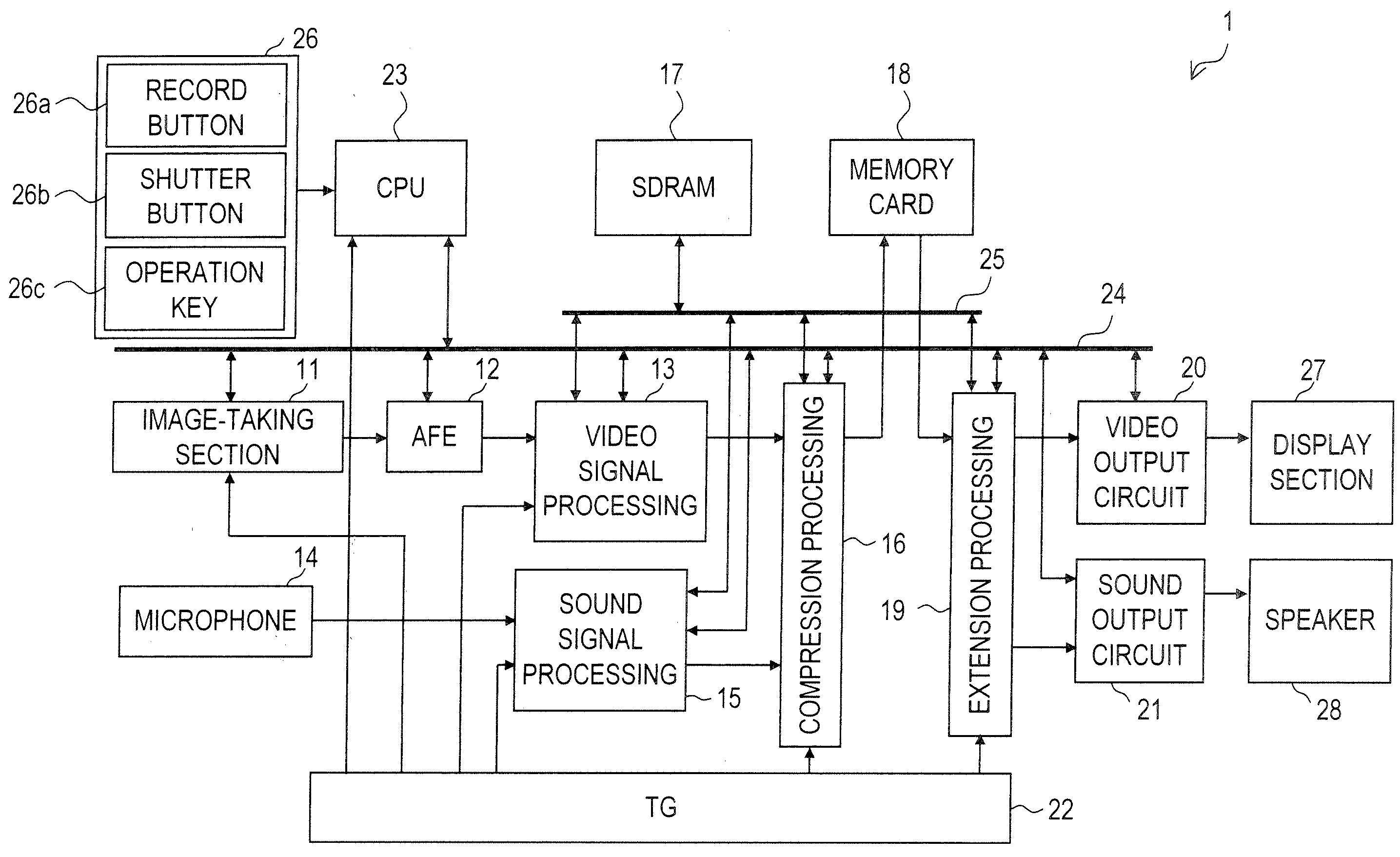

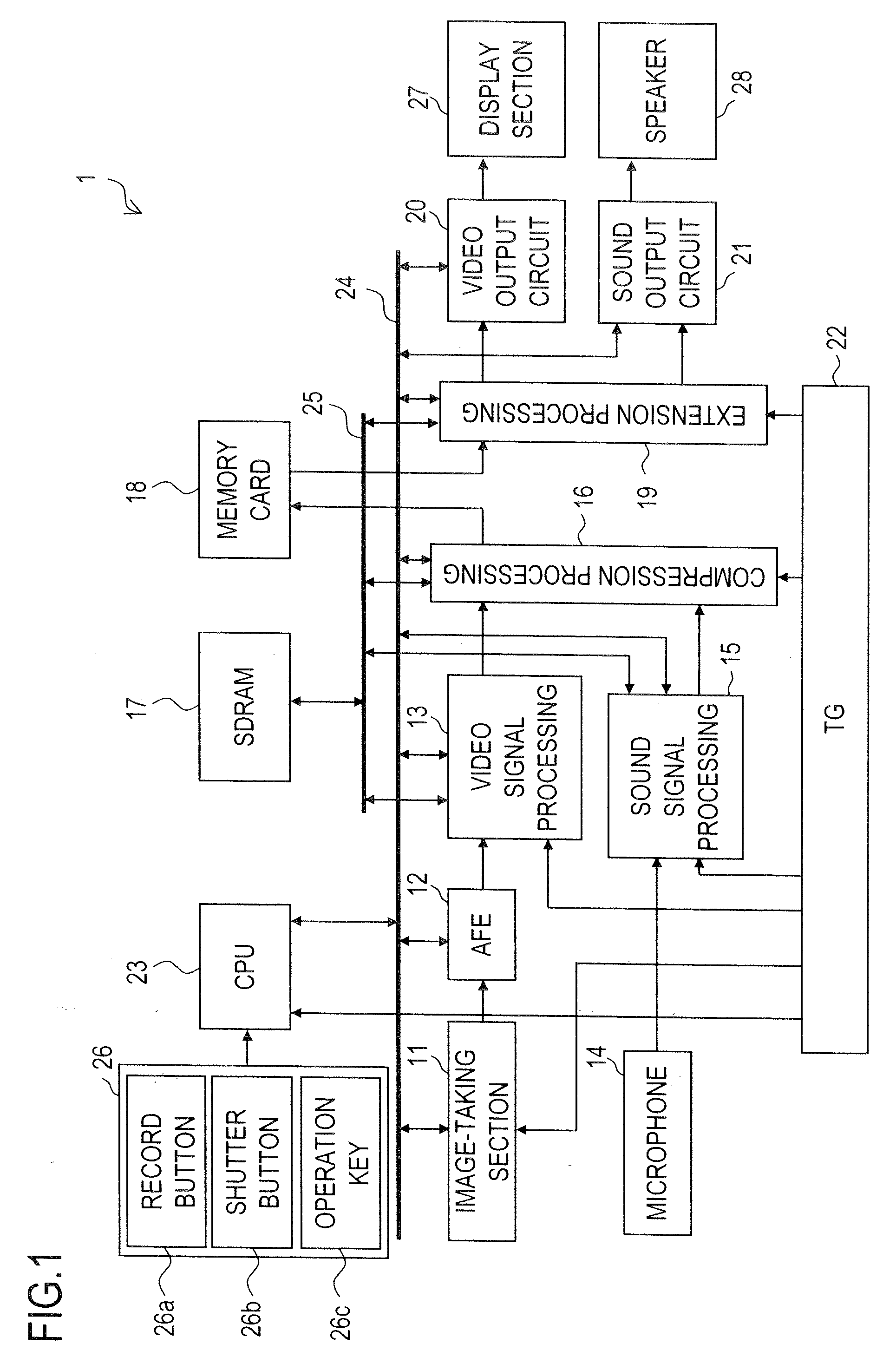

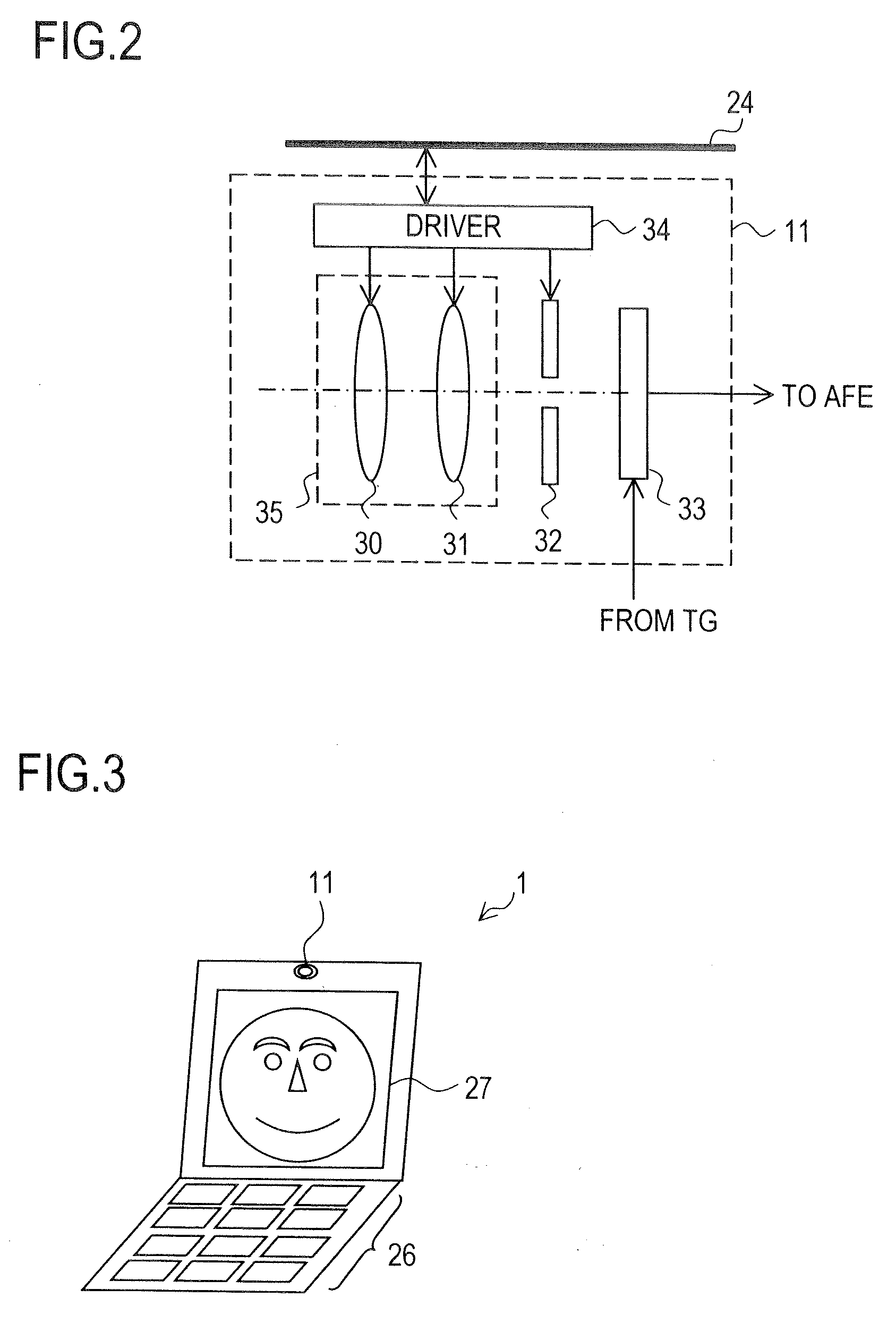

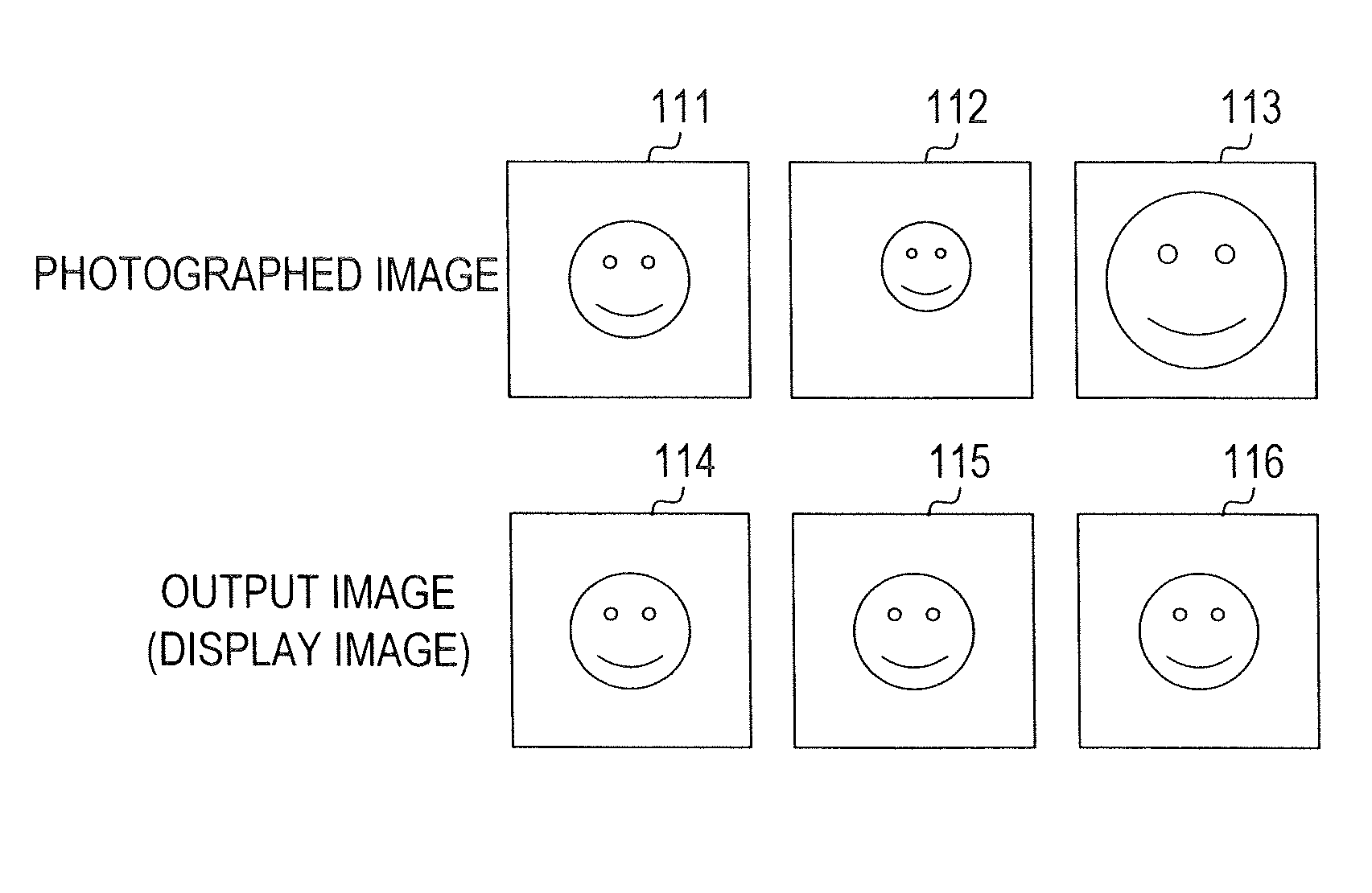

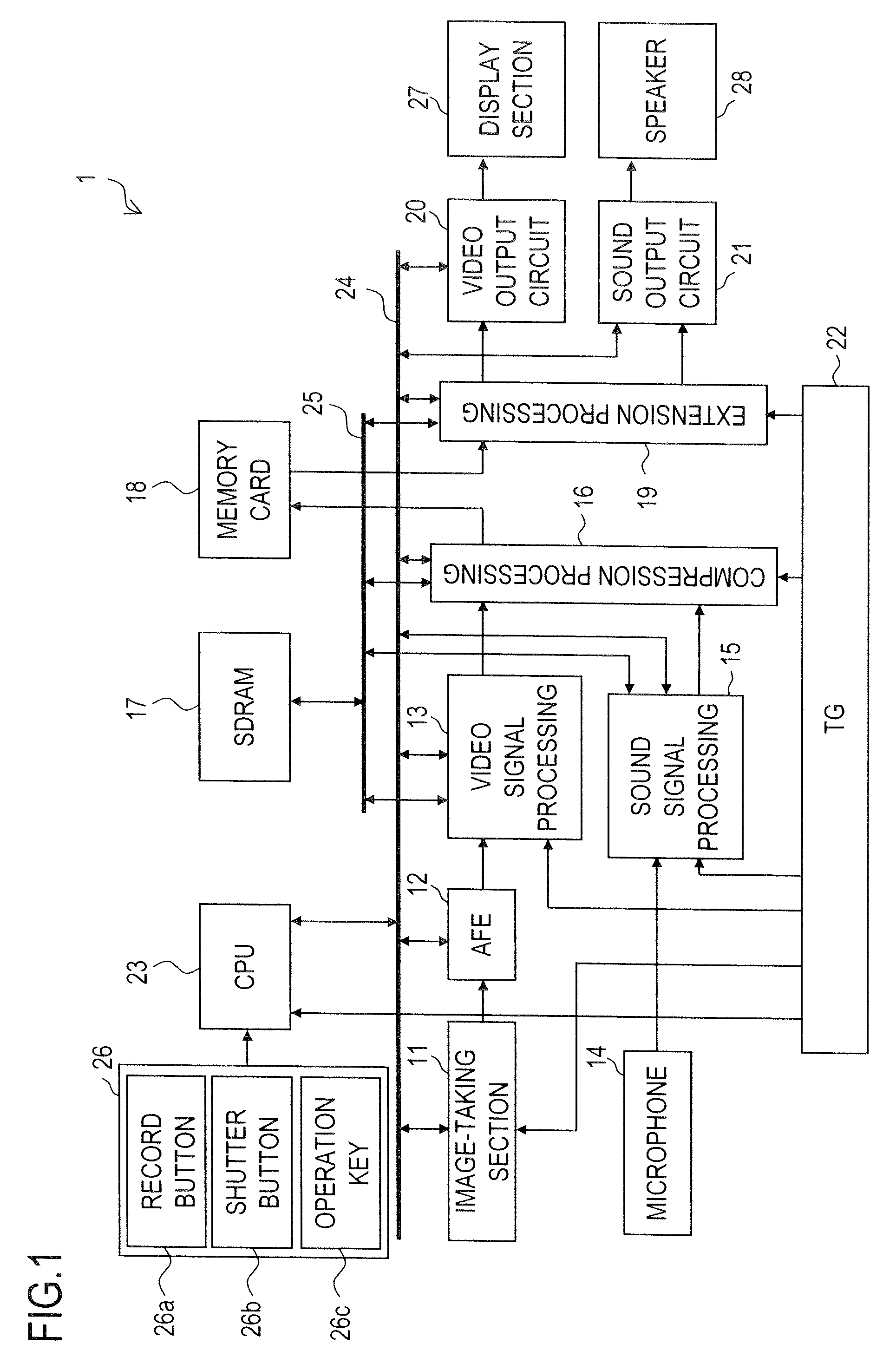

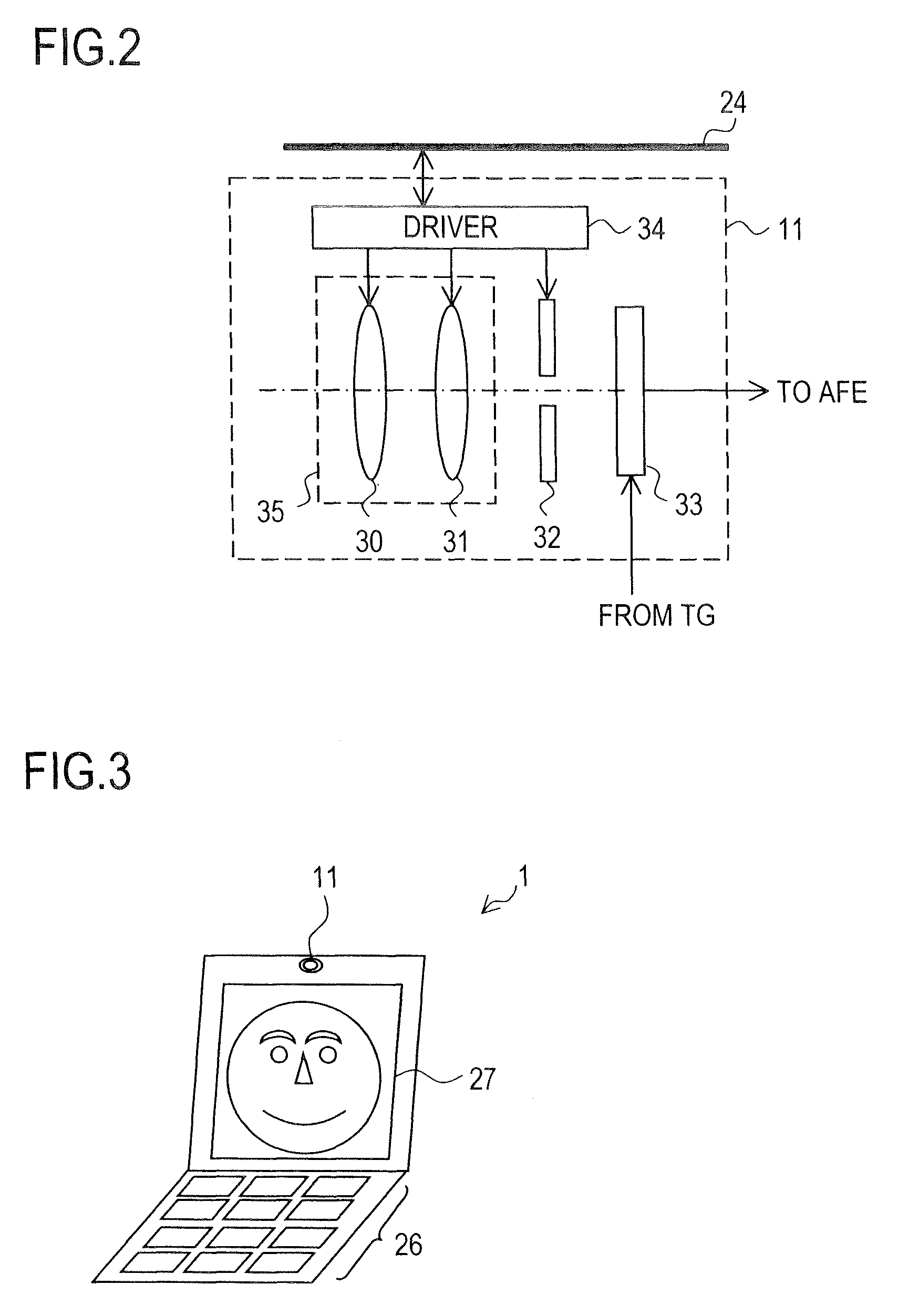

Image-taking apparatus and output image generation method

ActiveUS20080024620A1Slow changeReduce size changeTelevision system detailsCharacter and pattern recognitionComputer graphics (images)Facial region

An image-taking apparatus generates an output image from a photographed image obtained by photographing and displays this output image on a display screen of a display section. The image-taking apparatus includes a recognition processing section for recognizing a specific subject (facial region of a person, or a facial component such as eyes) included in the photographed image. Referring to results of this recognition, the image-taking apparatus evaluates the dimension of the specific subject in each photographed image. If the dimension evaluated is relatively large, a relatively small magnification ratio to be employed upon the generation of the output image from the photographed image is provided. If the dimension evaluated is relatively small, a relatively large magnification ratio to be employed upon the generation of the output image from the photographed image is provided. As a result, the dimension of the specific subject in the output image is kept substantially constant.

Owner:XACTI CORP

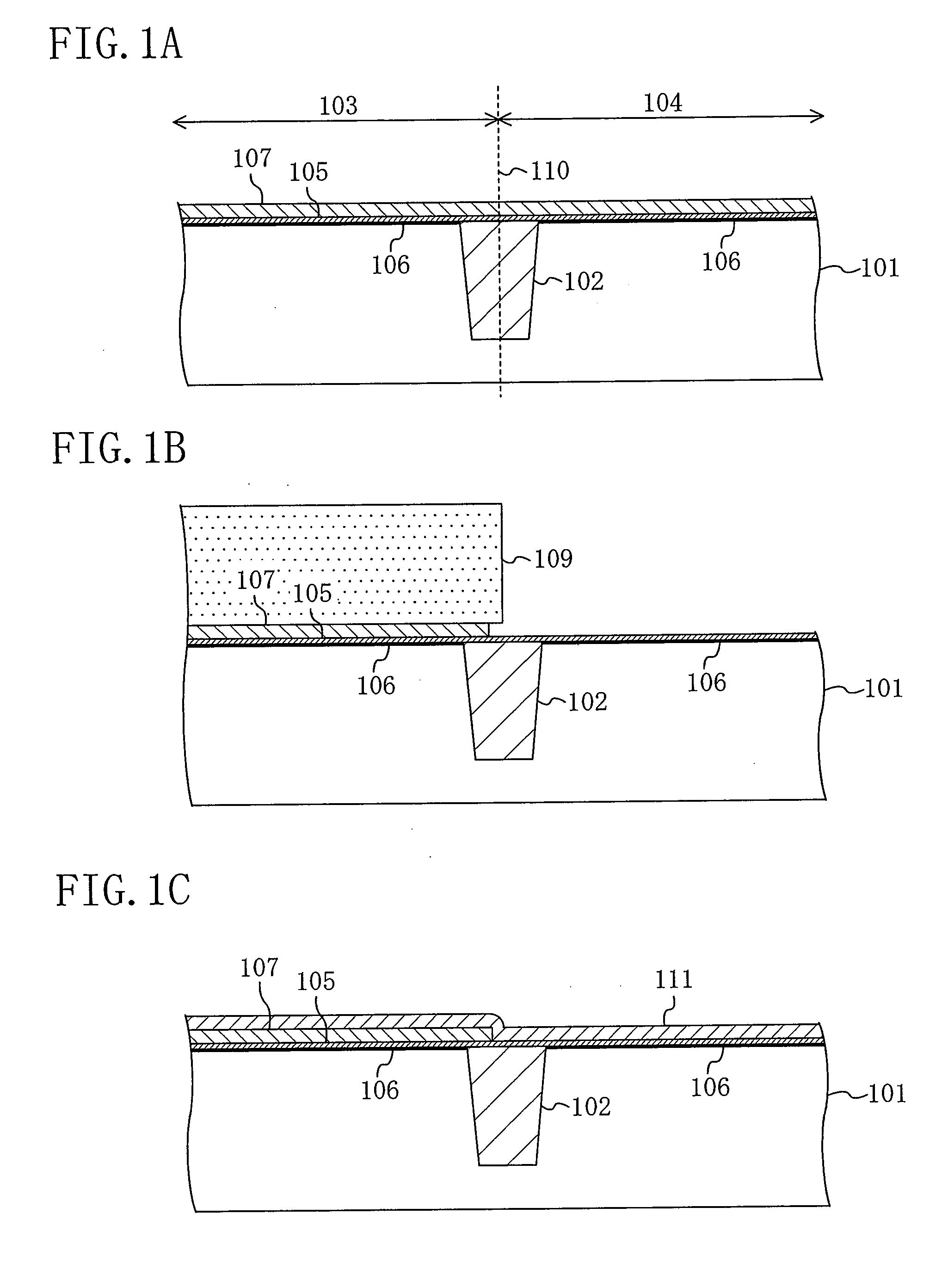

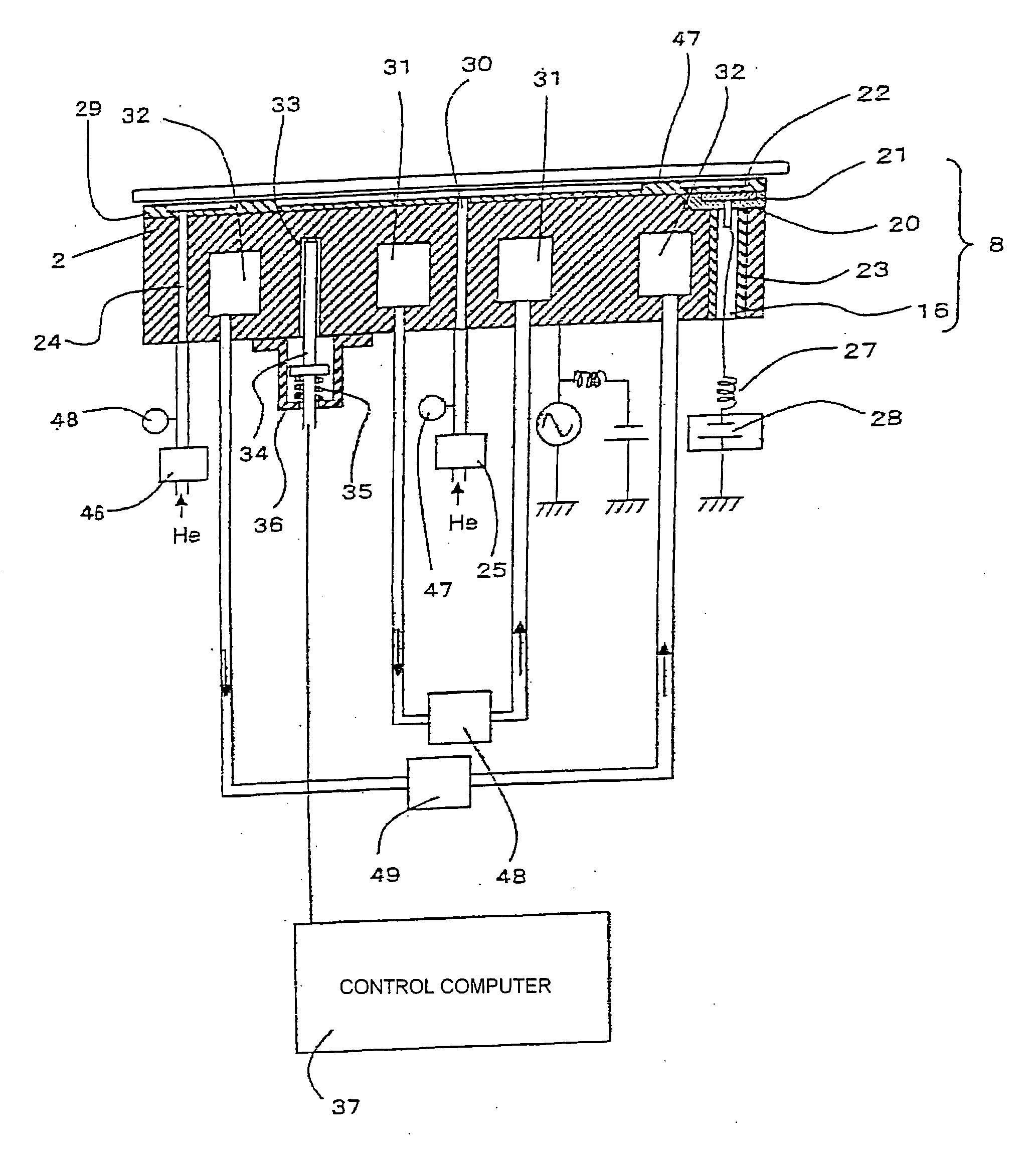

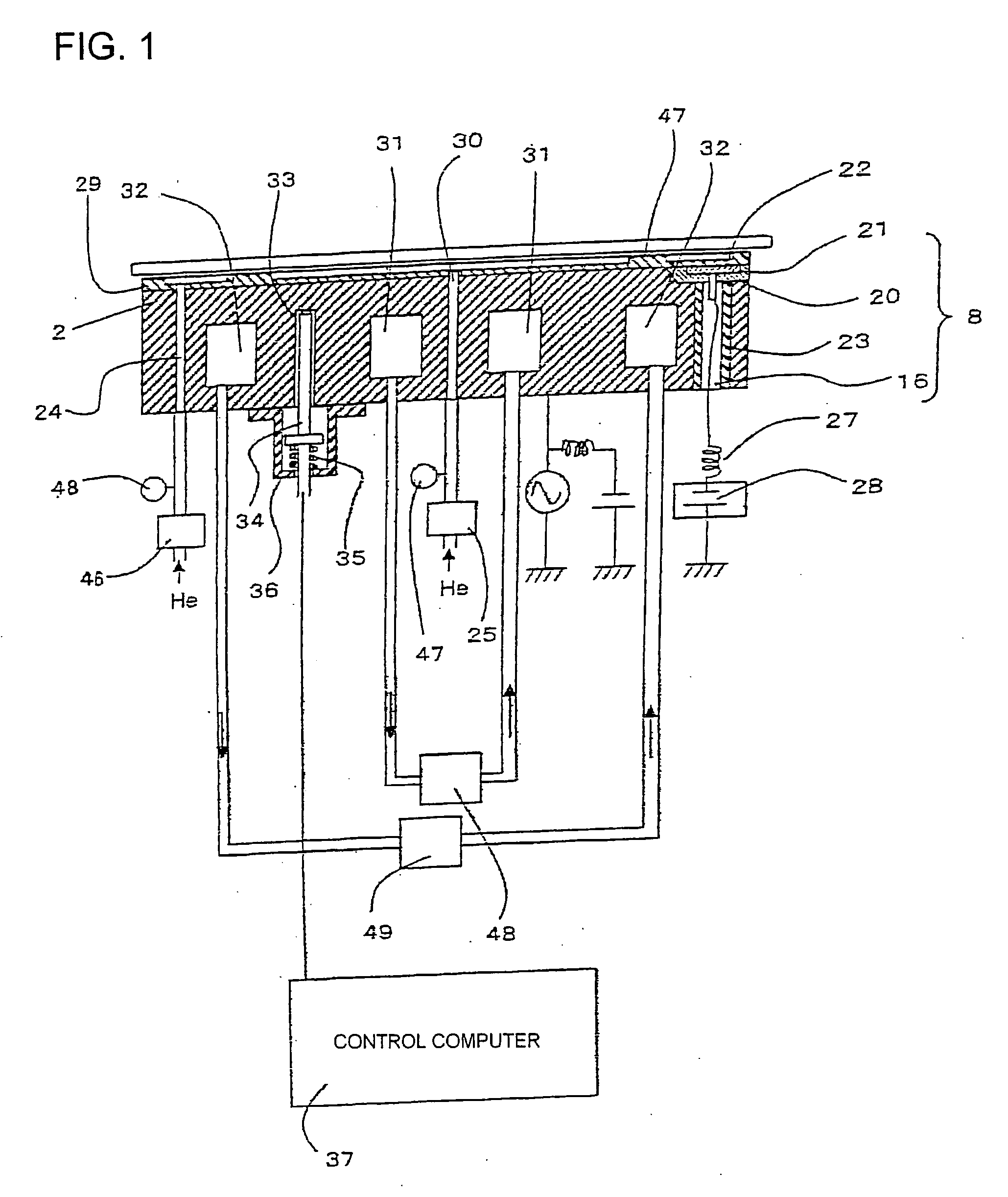

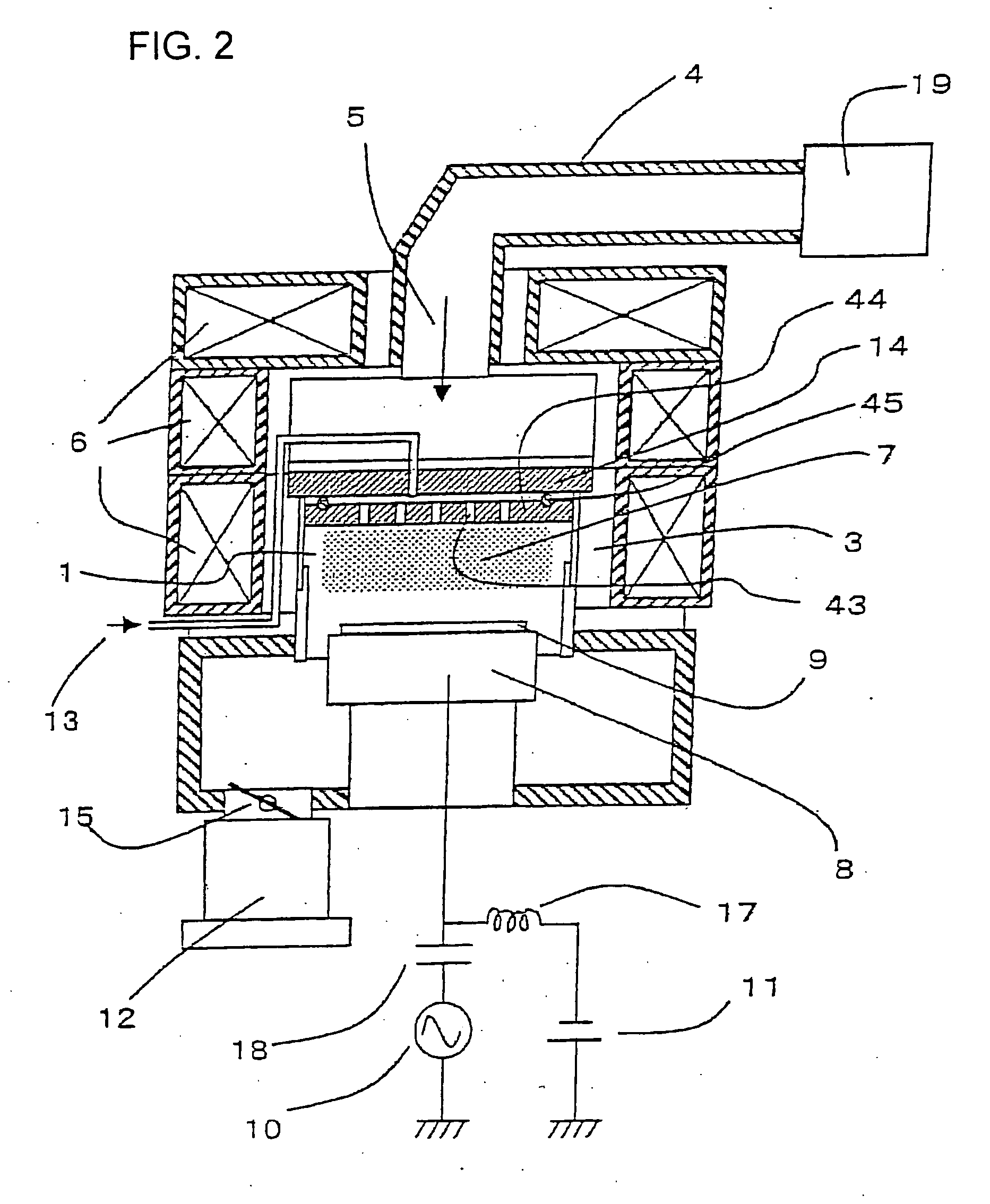

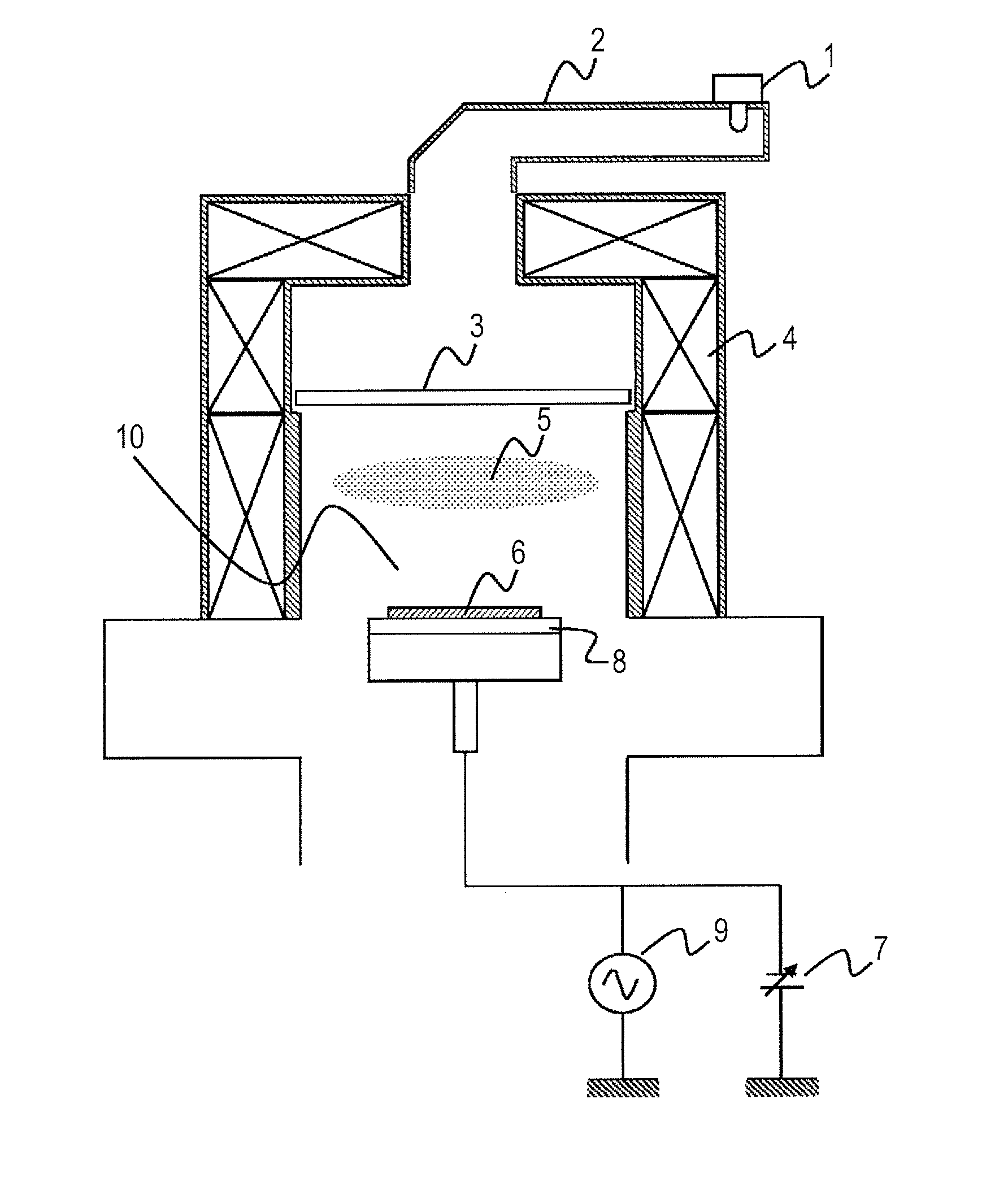

Apparatus and method for processing wafer

InactiveUS20060191482A1Reduce size changeEvenly distributedElectric discharge tubesSemiconductor/solid-state device manufacturingLine widthEngineering

A wafer processing apparatus capable of obtaining a uniform CD distribution within a wafer is provided. The wafer processing apparatus comprises at least two separate circuits of temperature regulating means provided in a wafer stage, a plurality of cooling gas pressure regulating means for feeding cooling gas between the semiconductor wafer and the wafer stage, means for regulating heater input power, and a control computer. The control computer receives input of line width dimensions resulting from processes in an arbitrary plurality of temperature conditions obtained by changing at least one of the conditions of the temperature of the temperature regulating agent, the cooling gas pressure, and the input power of the heater. The line width dimensions are used to calculate, and control, at least one of the temperature of the temperature regulating agent, the cooling gas pressure, and the input power of the heater for obtaining an arbitrary etching line width dimension.

Owner:HITACHI HIGH-TECH CORP

Semiconductor device and method for manufacturing the same

ActiveUS7964918B2Reduce the non-uniformity in the amount of overetchReduce riskTransistorSolid-state devicesPower semiconductor deviceSemiconductor

A gate electrode of one of an nFET and a pFET includes a metal-containing layer in contact with a gate insulating film and a first silicon-containing layer formed on the metal-containing layer, and a gate electrode of the other FET includes a second silicon-containing layer in contact with a gate insulating film and a third silicon-containing layer formed on the second silicon-containing layer. The first silicon-containing layer and the third silicon-containing layer are formed by the same silicon-containing material film.

Owner:PANASONIC SEMICON SOLUTIONS CO LTD

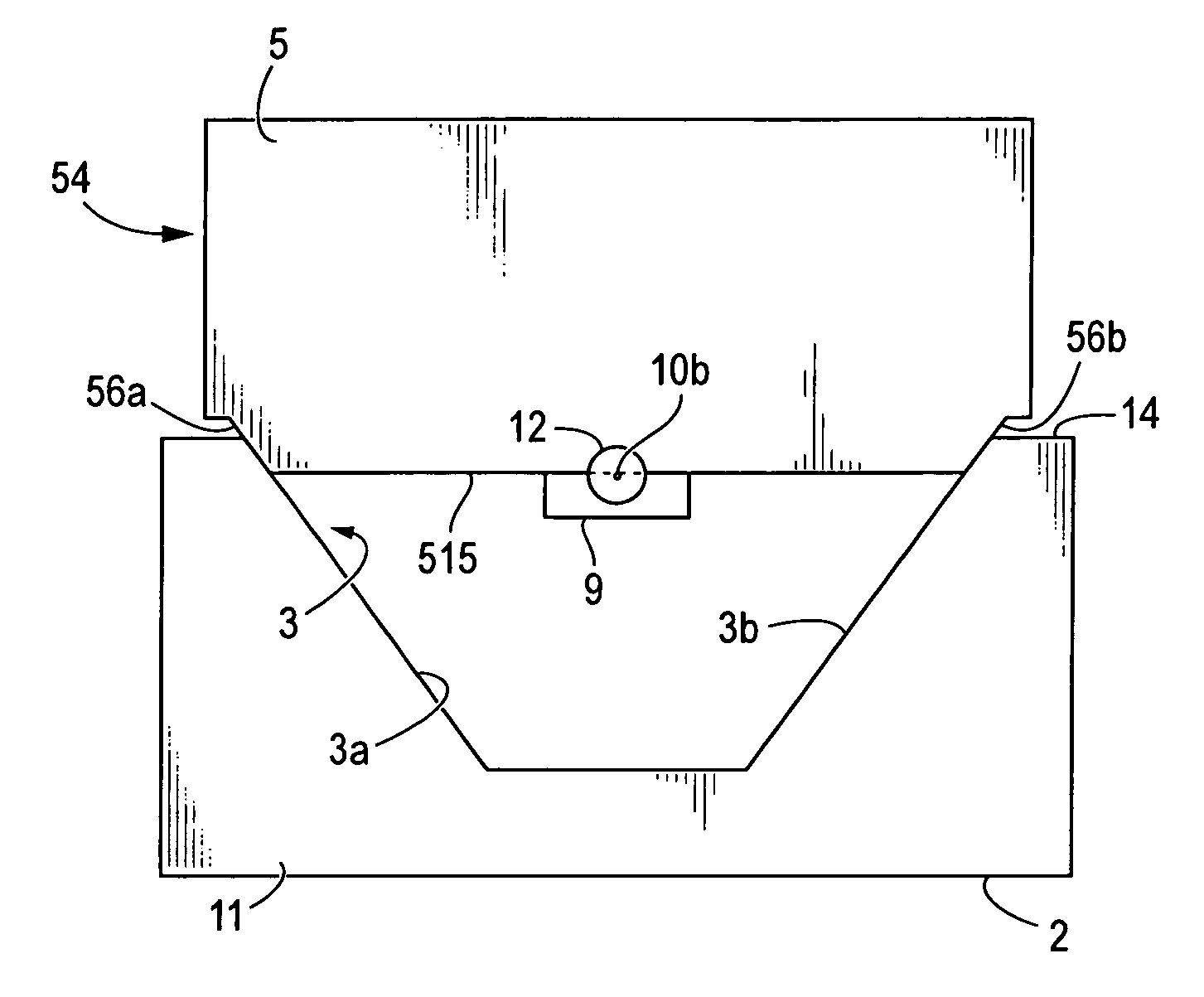

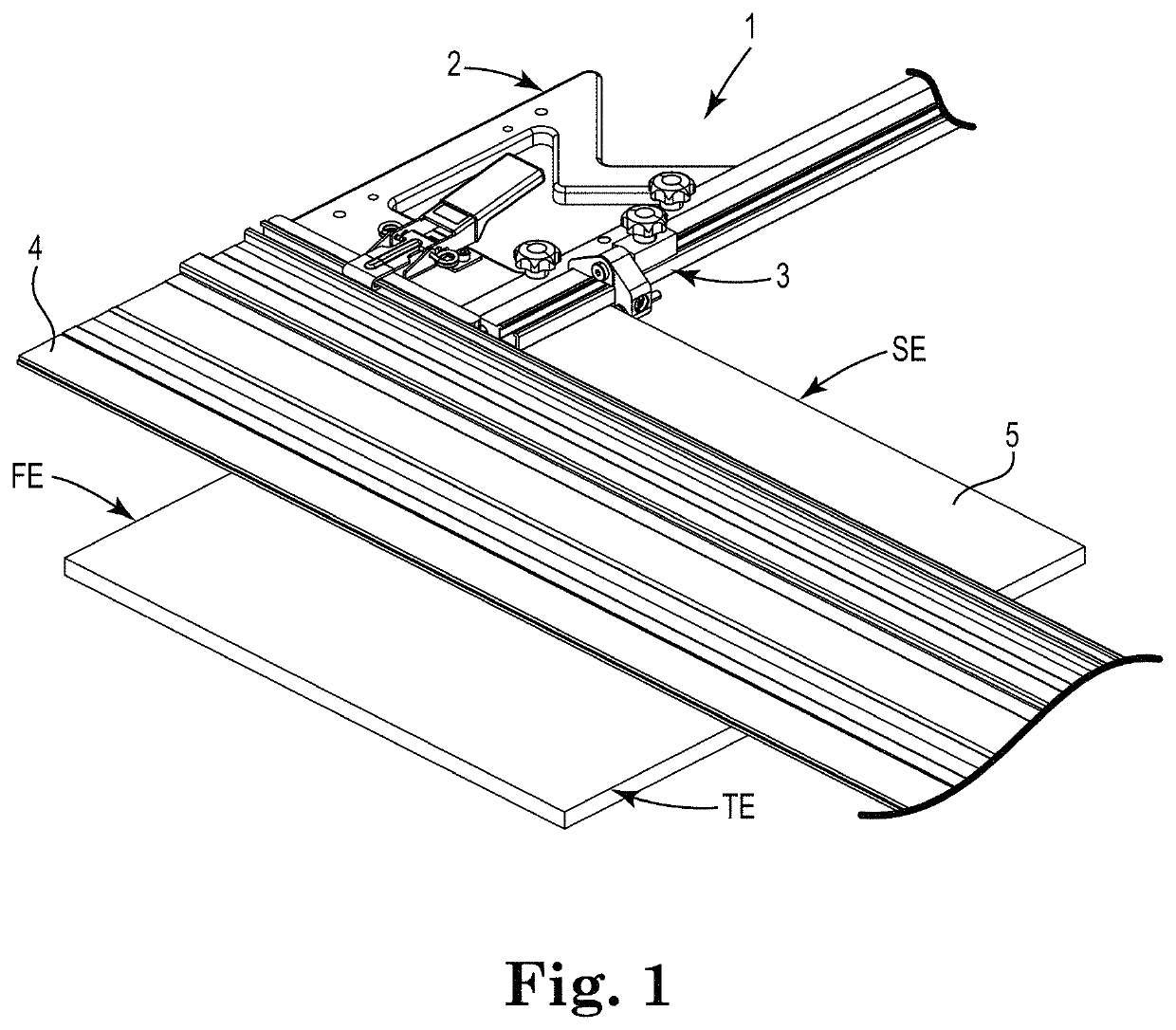

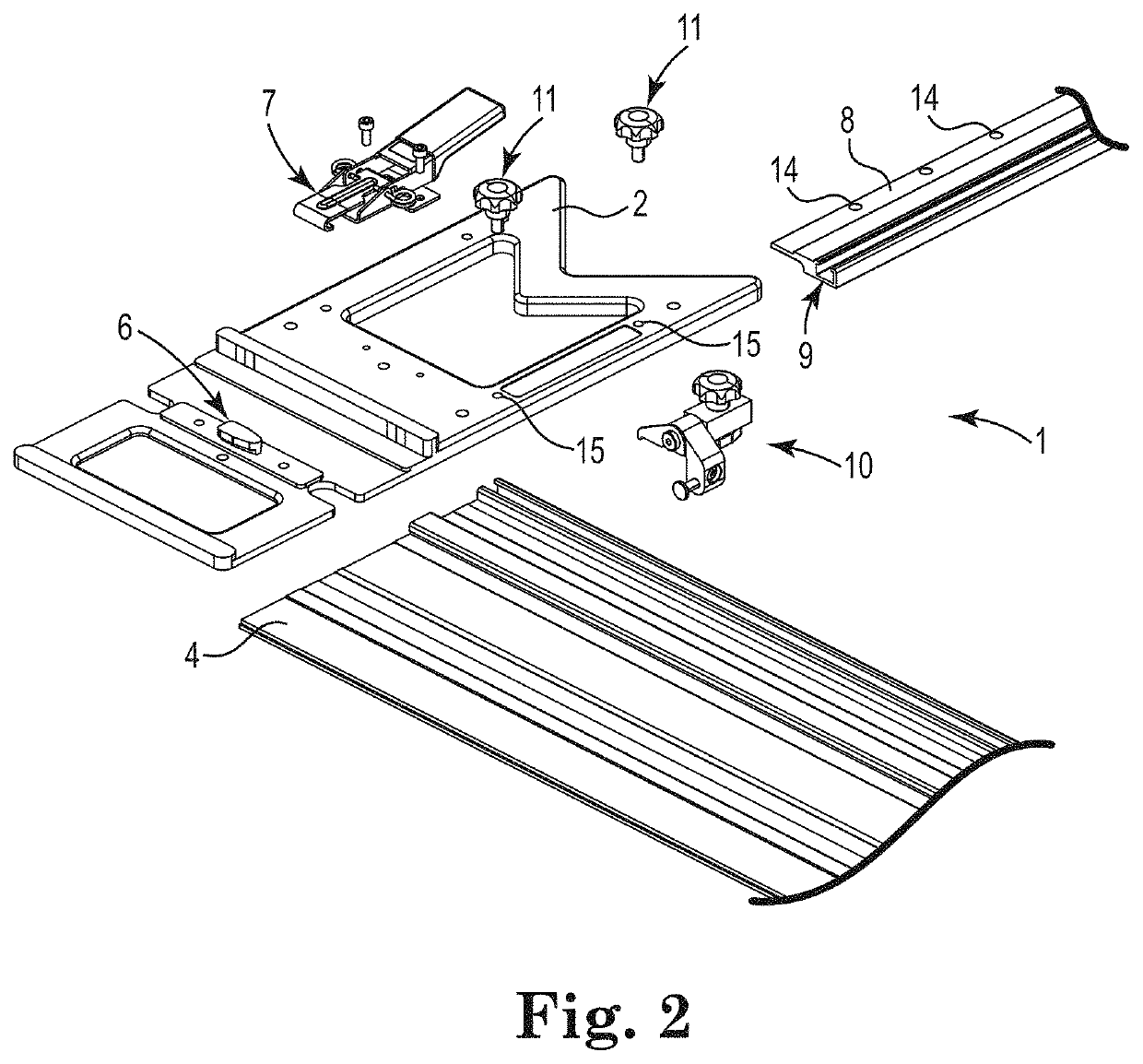

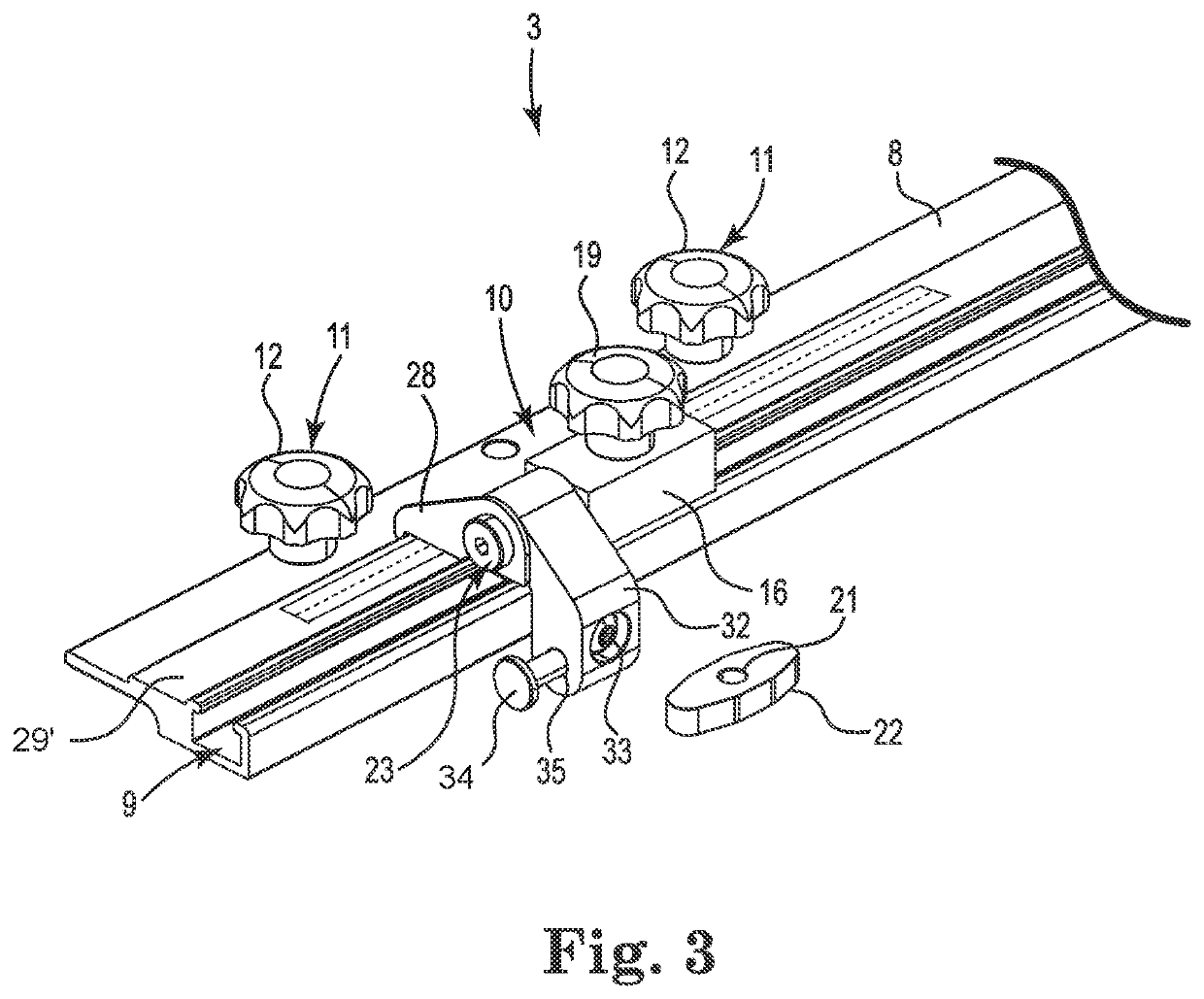

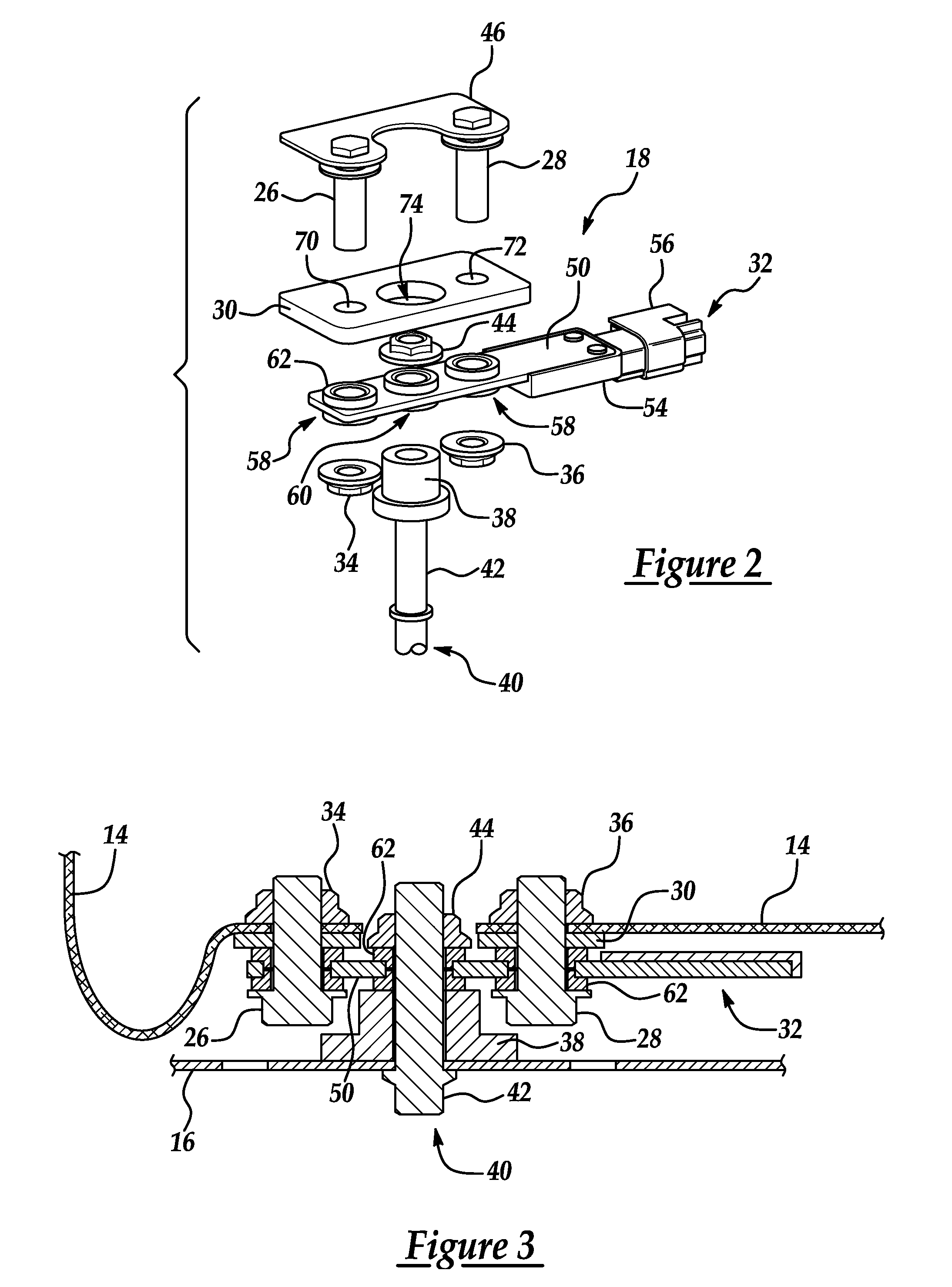

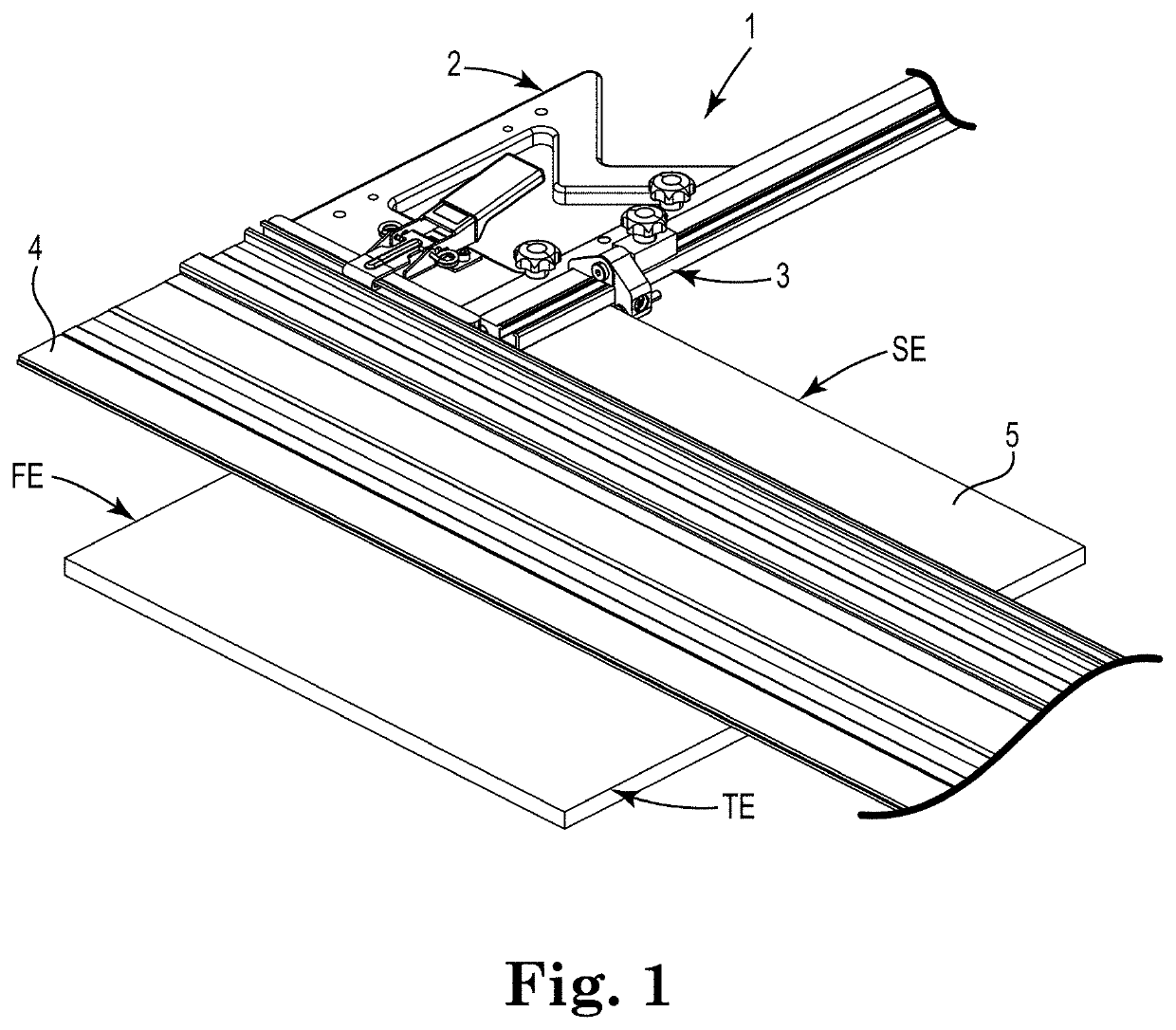

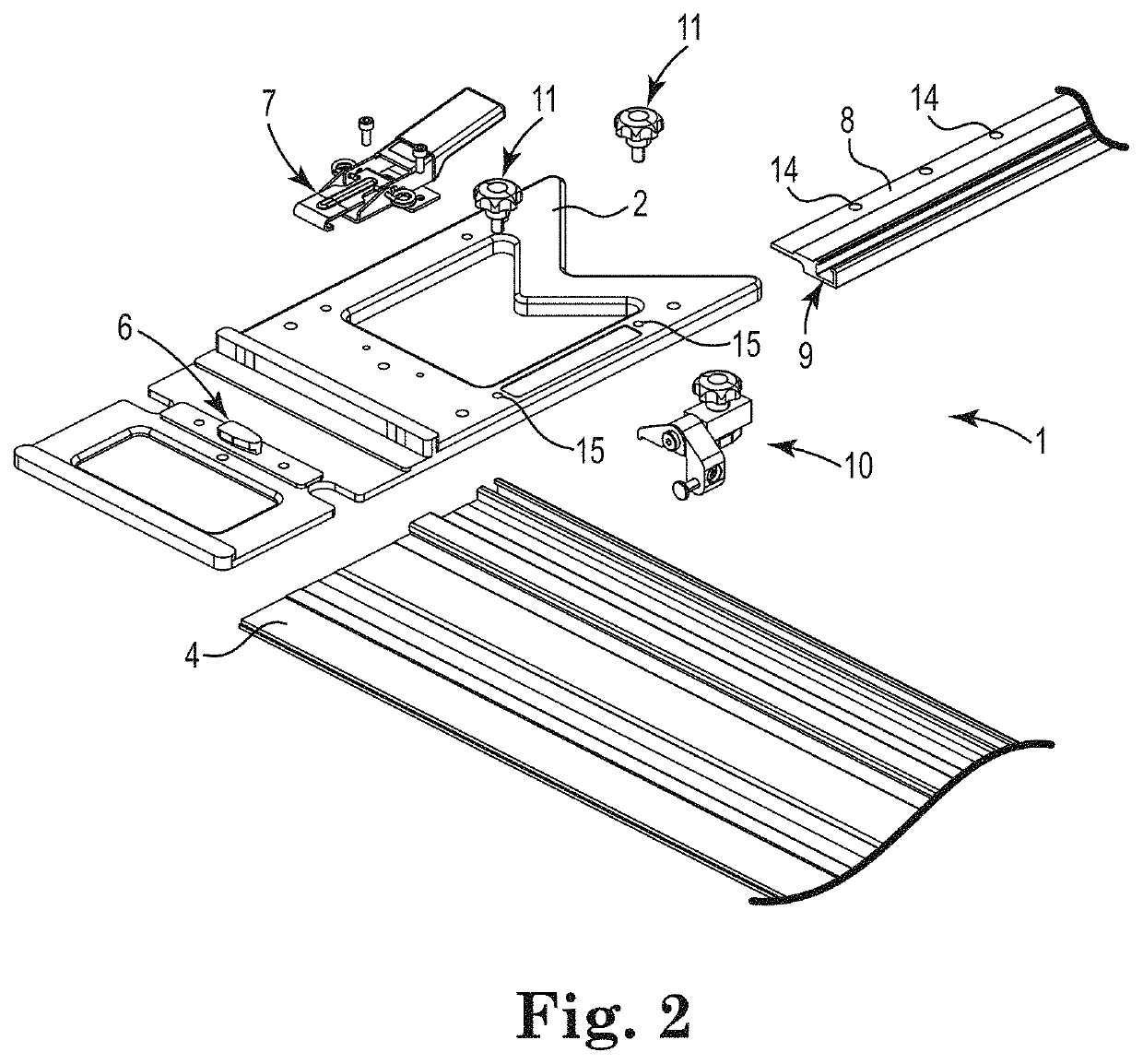

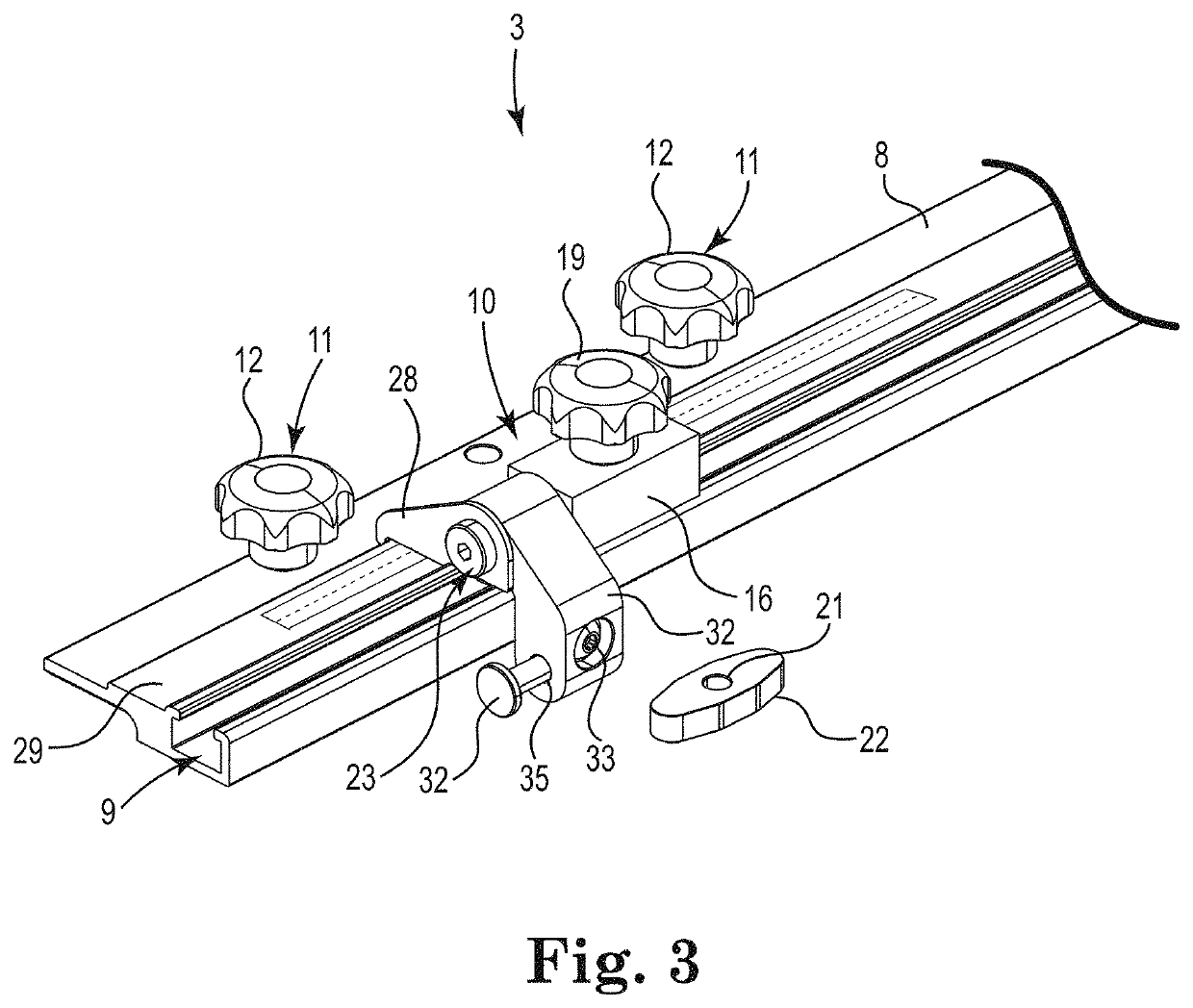

Parallel and square alignment tool

ActiveUS10843368B2Improve accuracyImprove efficiencyPortable power driven sawsMetal working apparatusMarking outEngineering

An alignment tool is disclosed for connection to a work component and for use in aligning the work component with a work piece to establish a repeatable set up for cutting or routing of the work piece, and wherein the alignment tool provides for parallel and square alignment of the work component relative to first and second edges of the work piece that are perpendicular to each other. Use of the parallel and square alignment tool aligns the work component for an operation parallel to the second edge of the work piece and the operation may be conveniently repeated on further work pieces without need to measure and mark the work pieces. Optional use of first and second parallel and square alignment tools along opposed second and third edges of a work piece that are perpendicular to a first edge provides for greater accuracy for operations having a greater length.

Owner:TSO PROD LLC

Gas dynamic pressure bearing, motor having the gas dynamic pressure bearing, and disk drive having the motor

InactiveUS20060023981A1Reduce the amount of variationIncrease choiceBearing assemblySliding contact bearingsEngineeringMicro gap

A gas dynamic pressure bearing comprises a shaft, a sleeve whose inner peripheral surface is opposed to an outer peripheral surface of the shaft through a micro-gap, and a substantially cylindrical hub which applies a surface pressure to an outer side of the sleeve and which is fitted to the sleeve, and at least one of the outer peripheral surface of the shaft and the inner peripheral surface of the sleeve is formed with a dynamic pressure generating groove, and if linear expansion coefficients of the shaft, the sleeve and the hub are defined as a0, a1 and a2, respectively, a relation of a1<α0<α2 is satisfied.

Owner:NIPPON DENSAN CORP

Image-taking apparatus and output image generation method

ActiveUS8363146B2Reduce size changeSlow changeTelevision system detailsCharacter and pattern recognitionComputer graphics (images)Facial region

An image-taking apparatus generates an output image from a photographed image obtained by photographing and displays this output image on a display screen of a display section. The image-taking apparatus includes a recognition processing section for recognizing a specific subject (facial region of a person, or a facial component such as eyes) included in the photographed image. Referring to results of this recognition, the image-taking apparatus evaluates the dimension of the specific subject in each photographed image. If the dimension evaluated is relatively large, a relatively small magnification ratio to be employed upon the generation of the output image from the photographed image is provided. If the dimension evaluated is relatively small, a relatively large magnification ratio to be employed upon the generation of the output image from the photographed image is provided. As a result, the dimension of the specific subject in the output image is kept substantially constant.

Owner:XACTI CORP

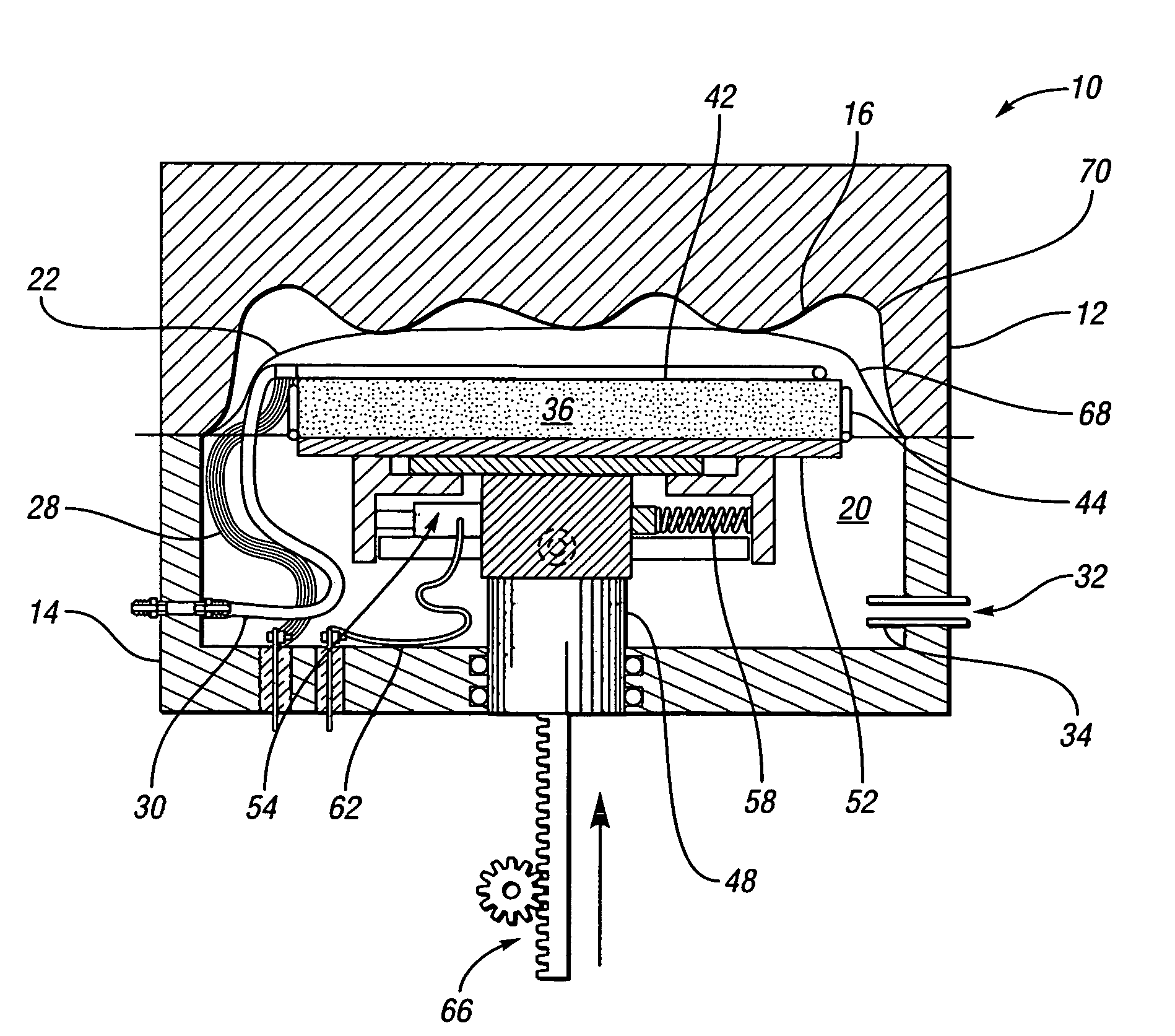

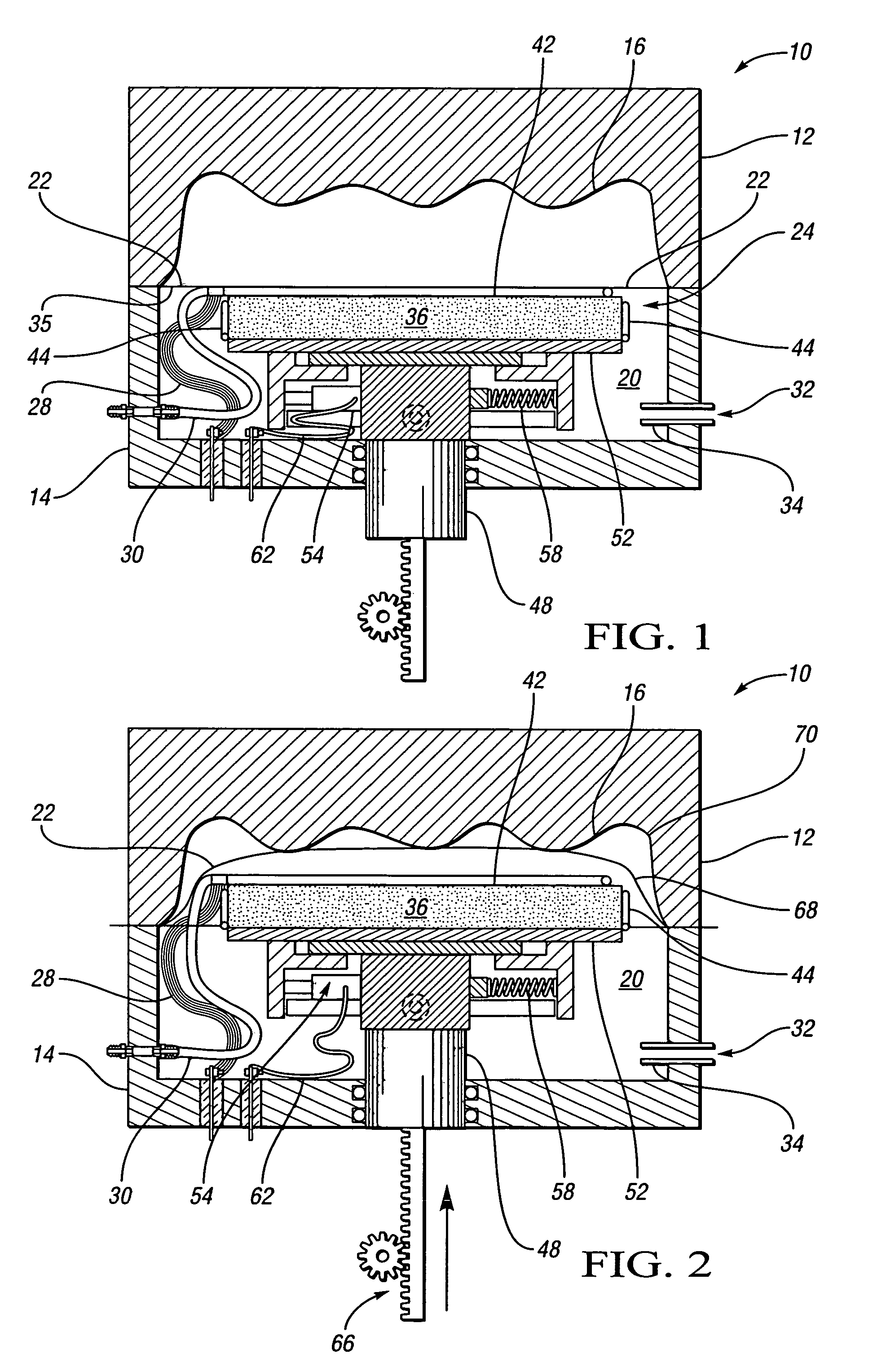

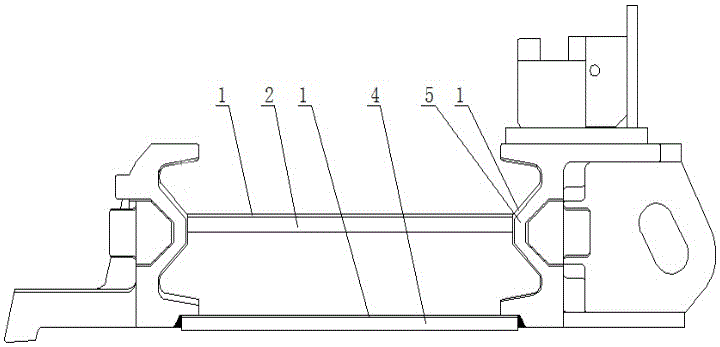

Apparatus and method for sheet material forming

ActiveUS7574884B2Low costShorten the timeShaping toolsConfectioneryBiomedical engineeringSheet material

The present invention relates to a heating and forming apparatus for sheet material and method for rapid heating and shaping of sheet material. The apparatus comprises a first and second respectively movable forming dies, with the first forming die having a forming surface and defining a cavity with the second forming die. The apparatus is adaptable to receive a sheet material positionable within the cavity. A heating mechanism is placed within the cavity to heat the sheet material. The forming surface of the first forming die is not substantially heated. A pressurization mechanism is in communication with the cavity to move the sheet material into conformity with the forming surface of the first die. An improvement in the process of stretch forming a sheet material into a product by using quick plastic forming (QPF) or superplastic forming (SPF) is provided.

Owner:GM GLOBAL TECH OPERATIONS LLC

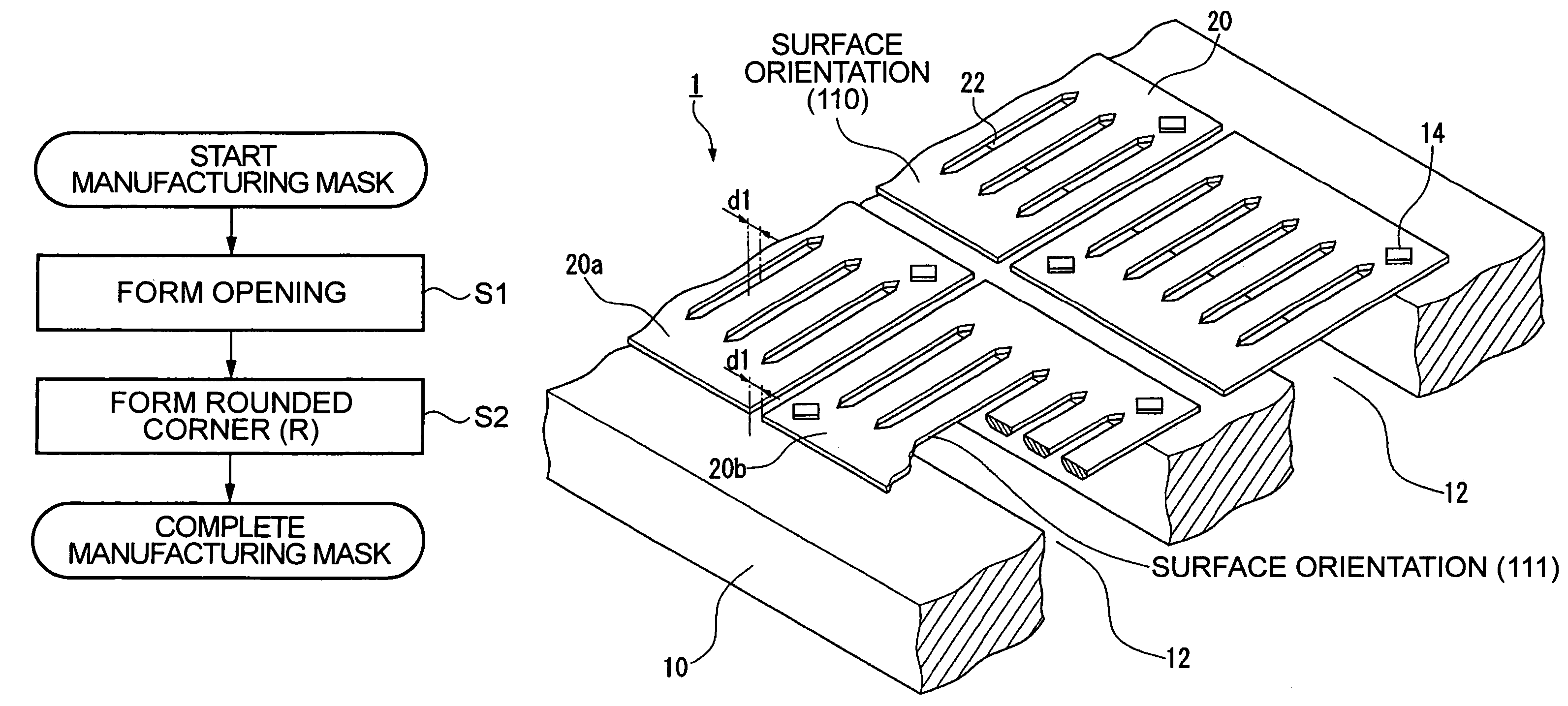

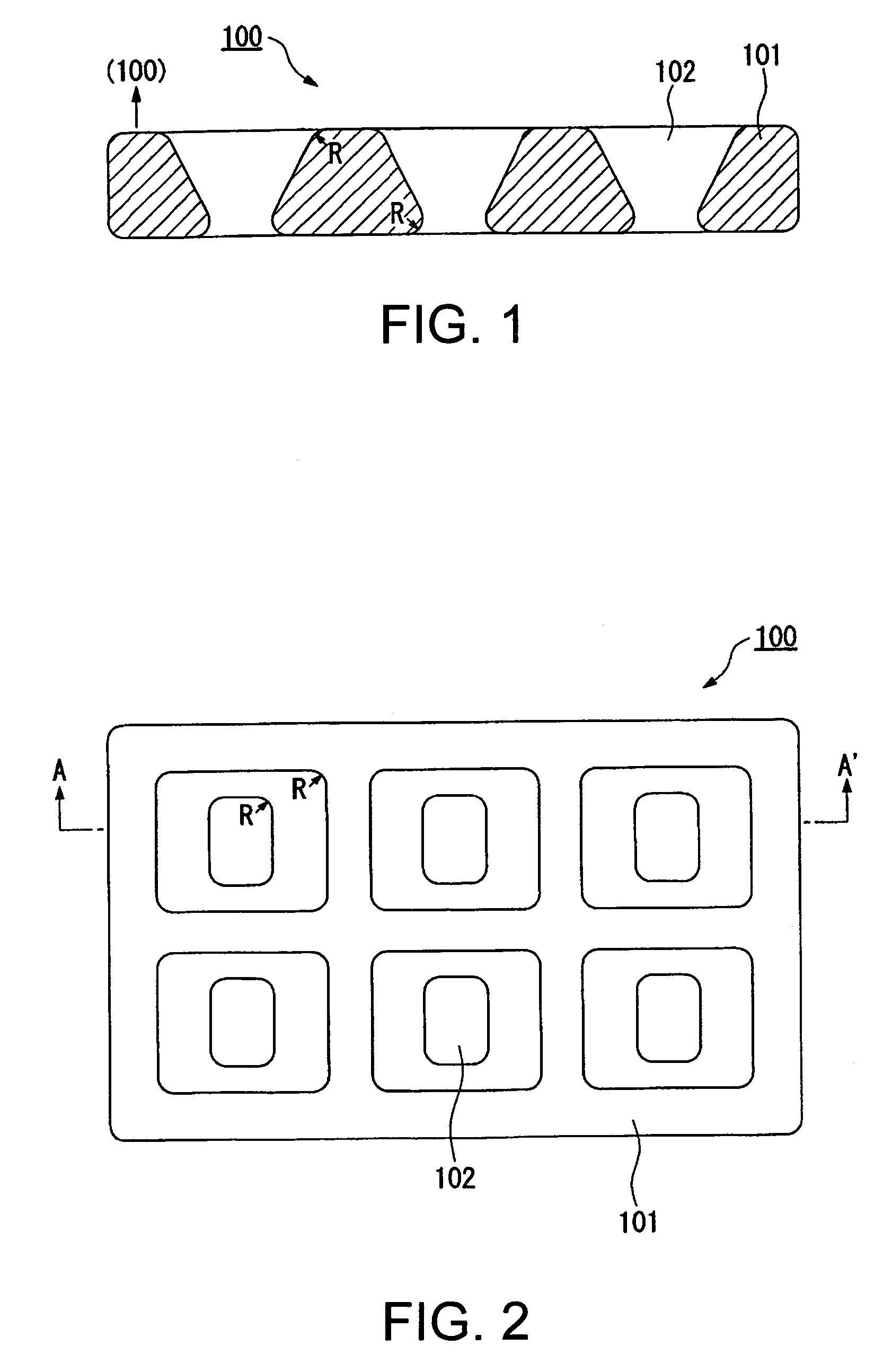

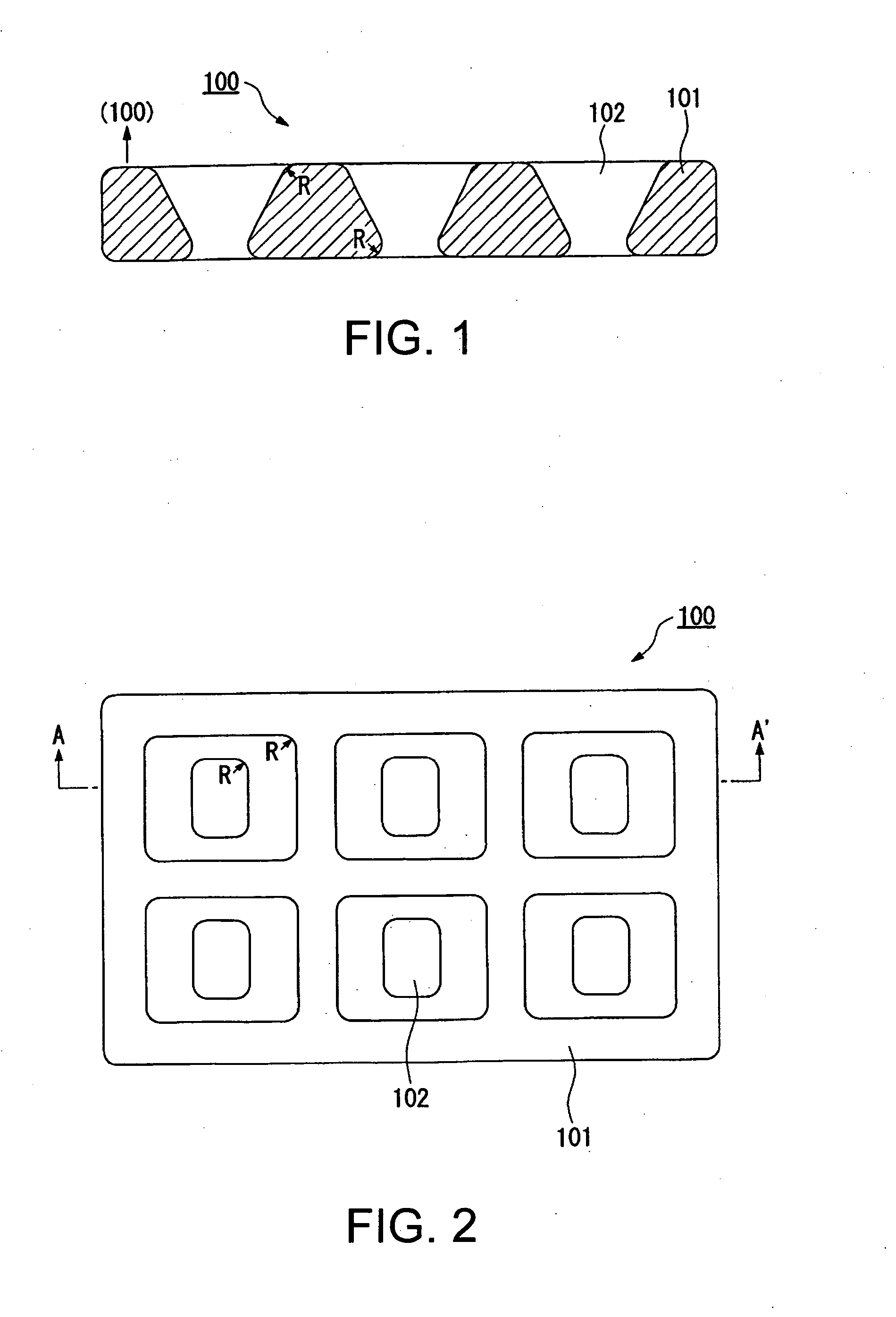

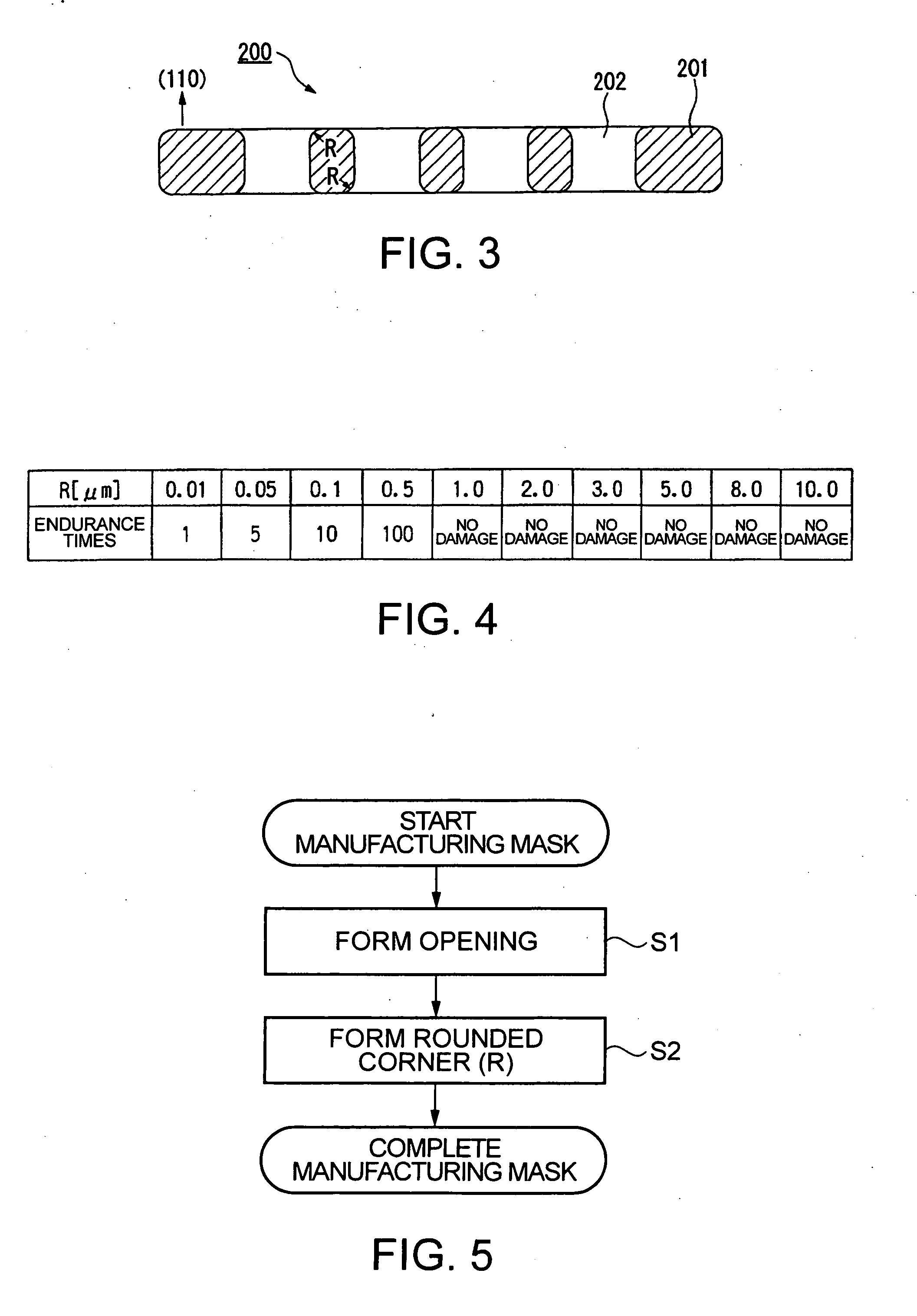

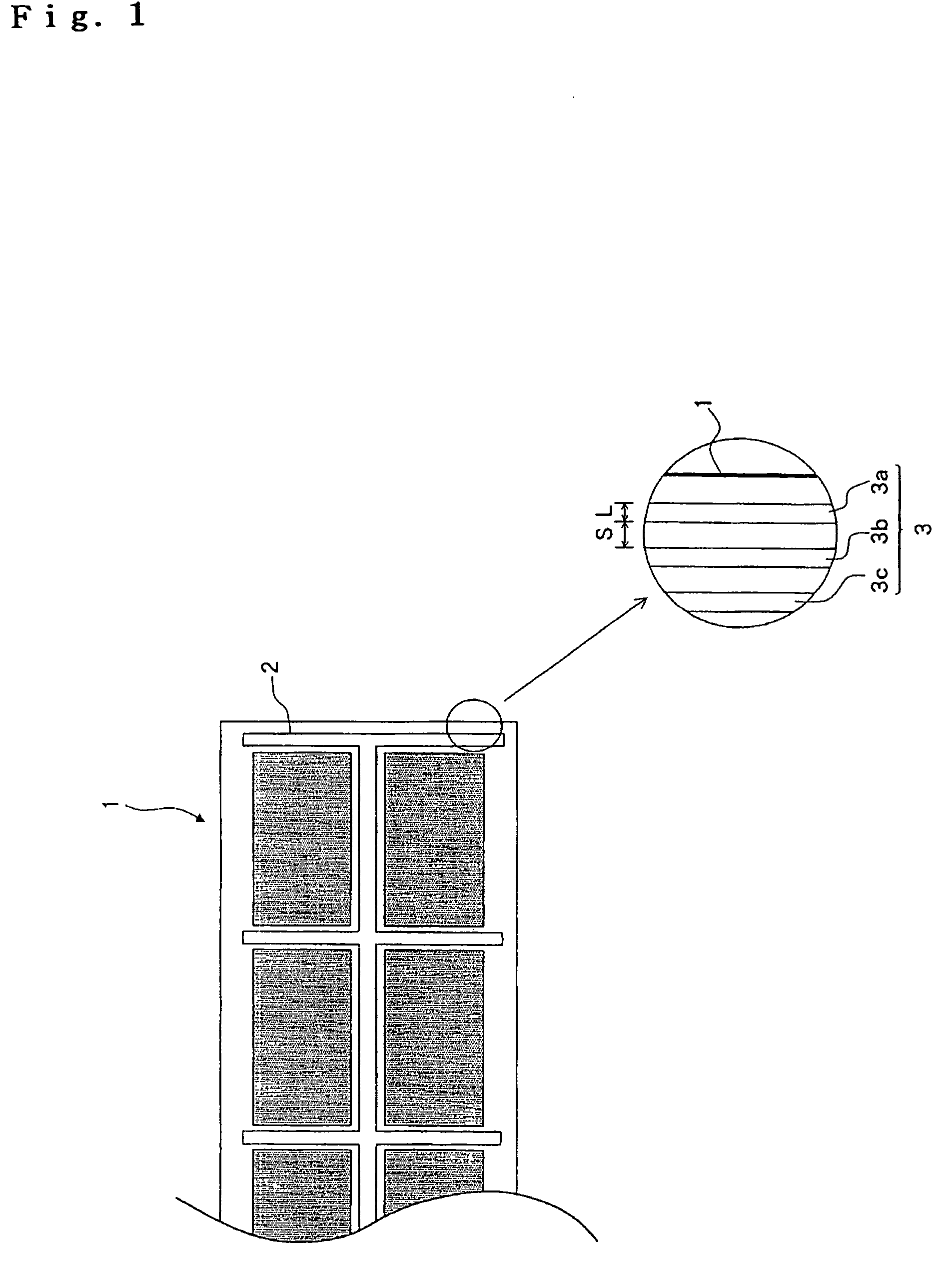

Mask, method for manufacturing a mask, method for manufacturing an electro-optical device, and electronic equipment

InactiveUS7285497B2Reduce size changeImprove machining accuracySewerage structuresPipesEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

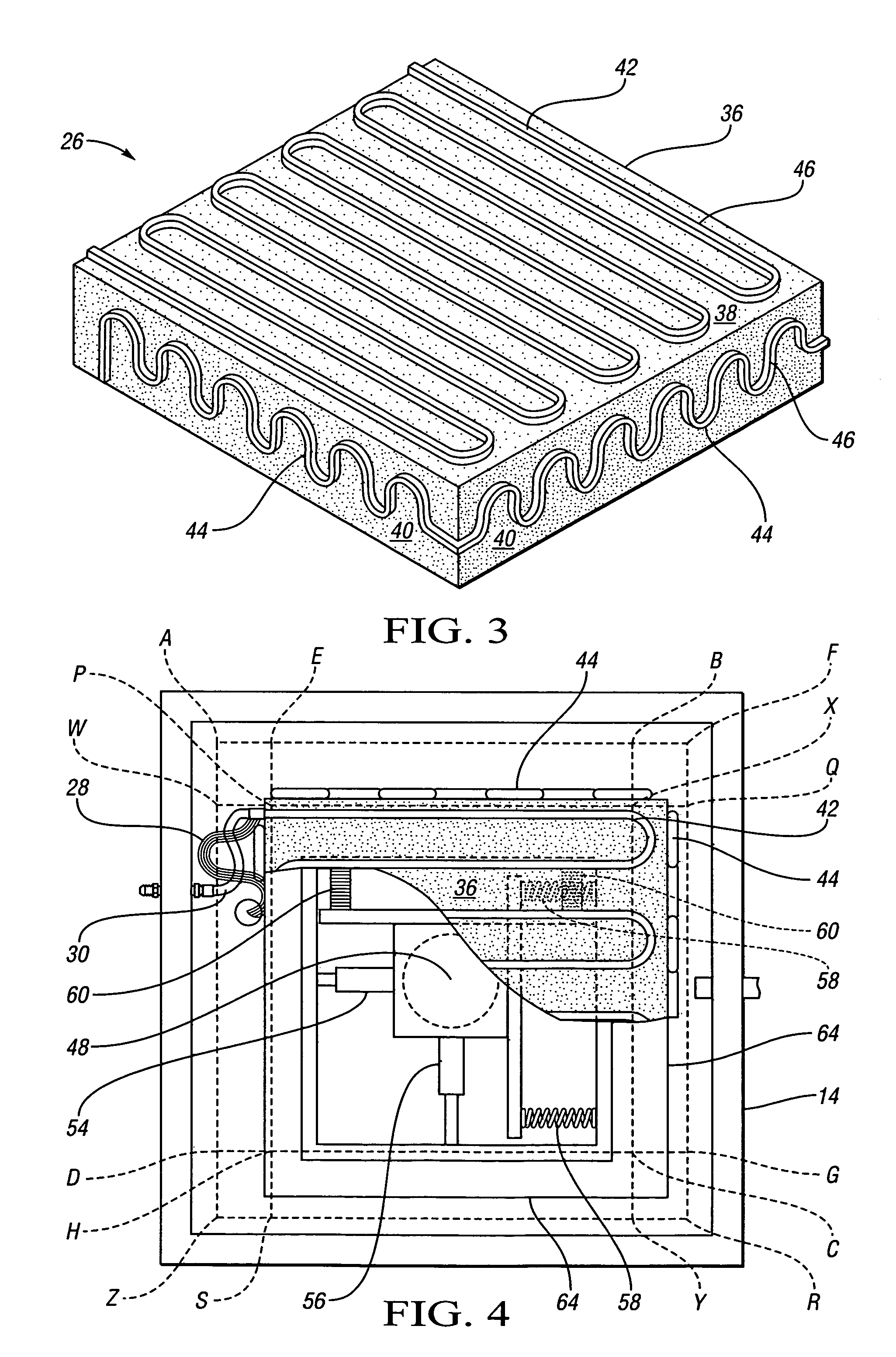

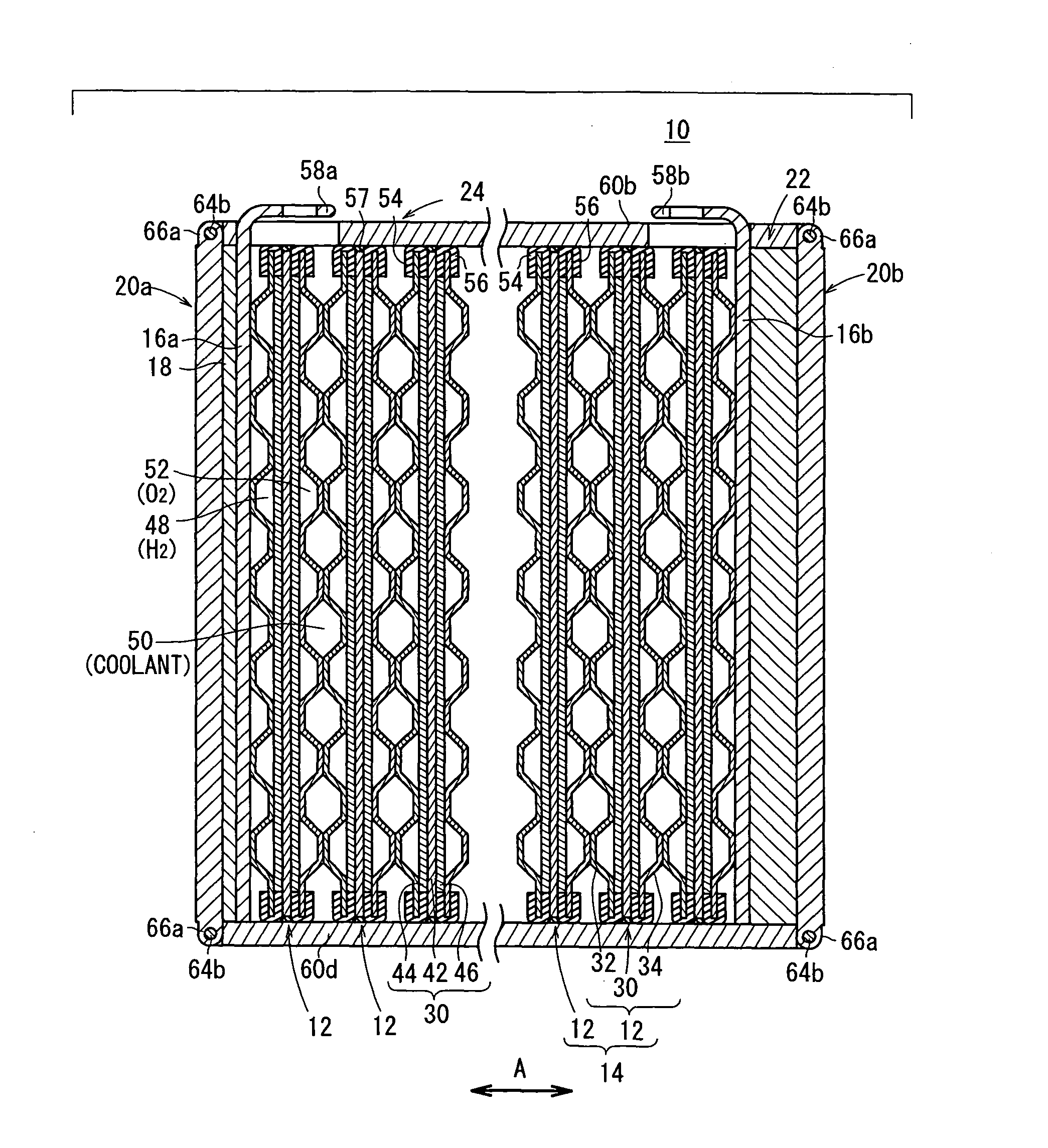

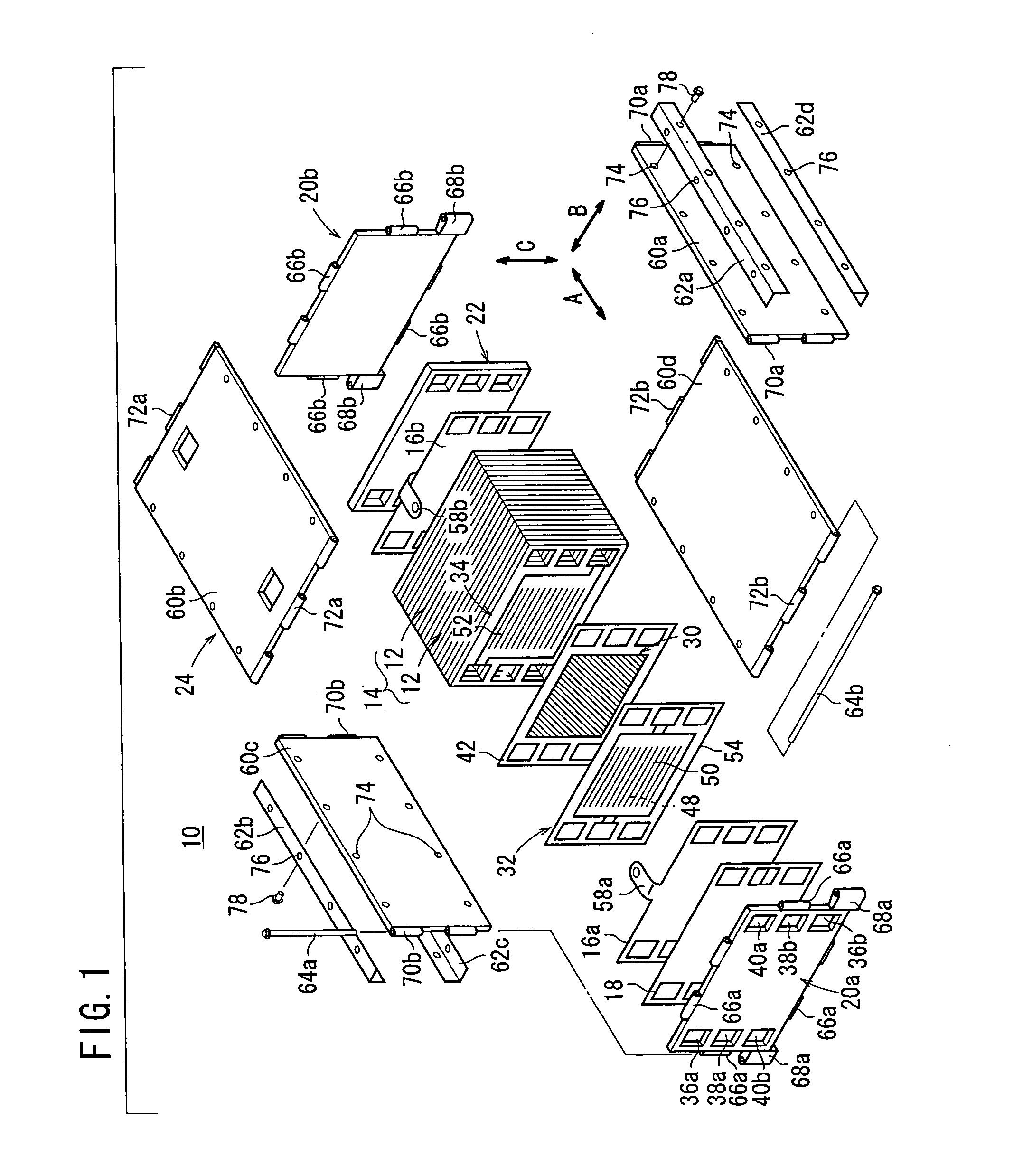

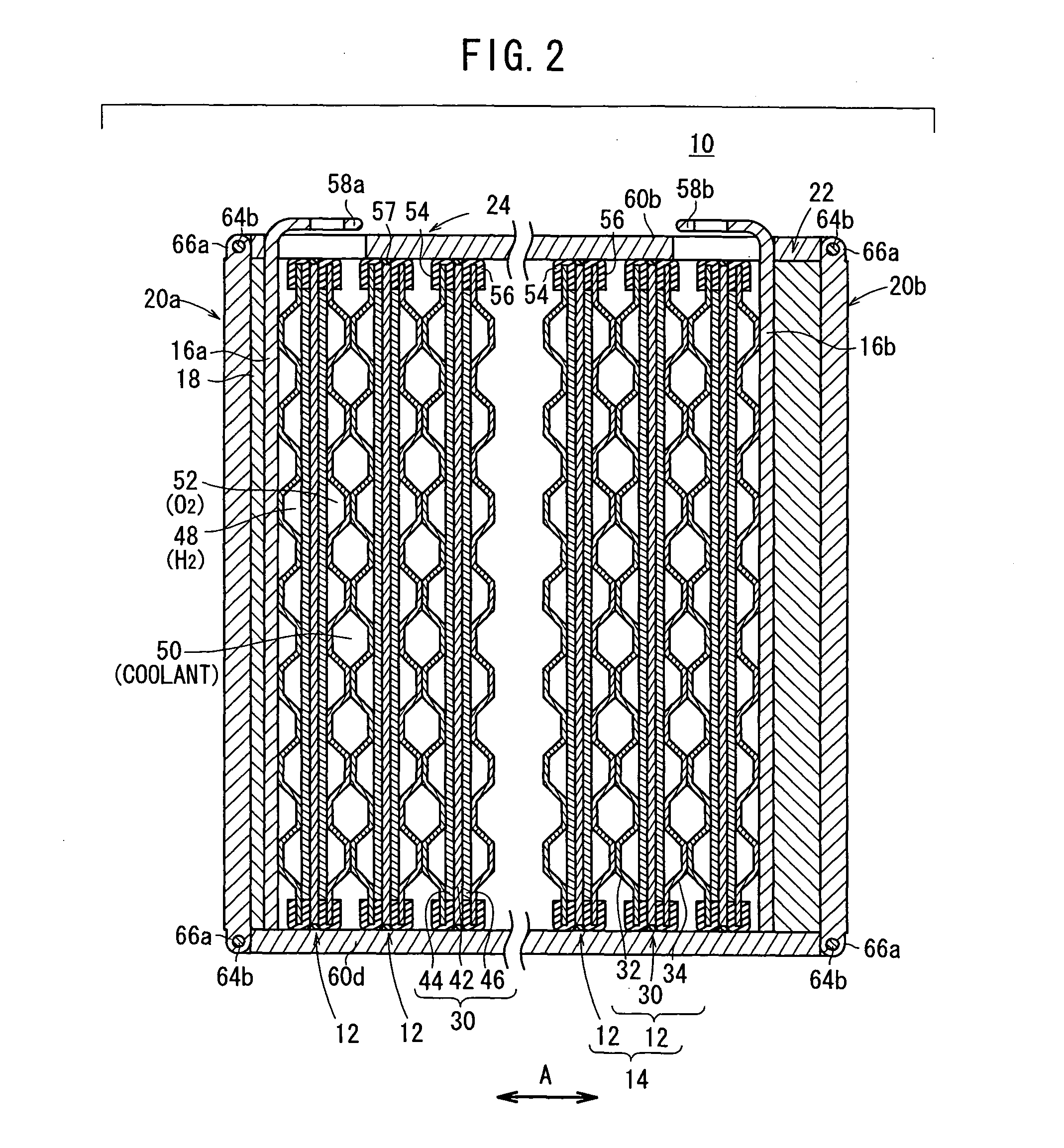

Fuel cell stack

ActiveUS8197984B2Small sizeExcellent characteristicsFuel cells groupingElectrode carriers/collectorsFuel cellsEngineering

A fuel cell stack includes a box-shaped casing and a stack body in the box-shaped casing. The stack body is formed by stacking a plurality of unit cells. The casing includes end plates, a plurality of side plates, angle members, and coupling pins. The angle members couple adjacent ends of the side plates. The coupling pins couple the end plates and the side plates.

Owner:HONDA MOTOR CO LTD

Mask, method for manufacturing a mask, method for manufacturing an electro-optical device, and electronic equipment

InactiveUS20050221609A1High-precision patternReduce size changeSewerage structuresPipesEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Preparation method of moisture-proof mildew-resistant medium density fiberboard

InactiveCN109822701ASimple methodHigh strengthWood treatment detailsDomestic articlesMedium density fiberboardMoisture

The invention mainly belongs to the technical field of artificial board processing, and discloses a preparation method of a moisture-proof mildew-resistant medium density fiberboard. The preparation method comprises steps of fiber drying, acid and alkali treatment, high pressure processing, glue applying processing, and hot pressing moulding. The preparation method is simple; the obtained moisture-proof mildew-resistant medium density fiberboard is high in strength and excellent in wear resistance; water absorption capacity is low; moistureproof and mildew resistance are excellent; defect of commercially available medium density fiberboards that water absorption is easily caused is avoided. According to the preparation method, plant raw material is crushed so as to obtain crushed fiber, asulphamic acid solution is added into the crushed fiber, after uniform infiltration, freeze drying is carried out, it is beneficial for increasing of the bonding force between cellulose and lignin, expansion and defomation of density boards caused by water absorption are avoided, and density board structure integrity is maintained.

Owner:李振洋

Load detecting vehicle seat assembly

A load detecting vehicle seat assembly includes a discrete strain gage mounting plate having a specified flatness to produce desired strain gage performance. The strain gage mounting plate is disposed between a strain gage and a vehicle seat component, such as a cushion frame, so that vehicle seat loading is transferred to the strain gage through the mounting plate. The strain gage may be mounted with a central portion secured to a lower vehicle seat component and outward portions secured to an upper vehicle seat component such that only the outward portions of the strain gage contact the strain gage mounting plate, which has a controlled flatness tolerance to produce desired strain gage performance.

Owner:LEAR CORP

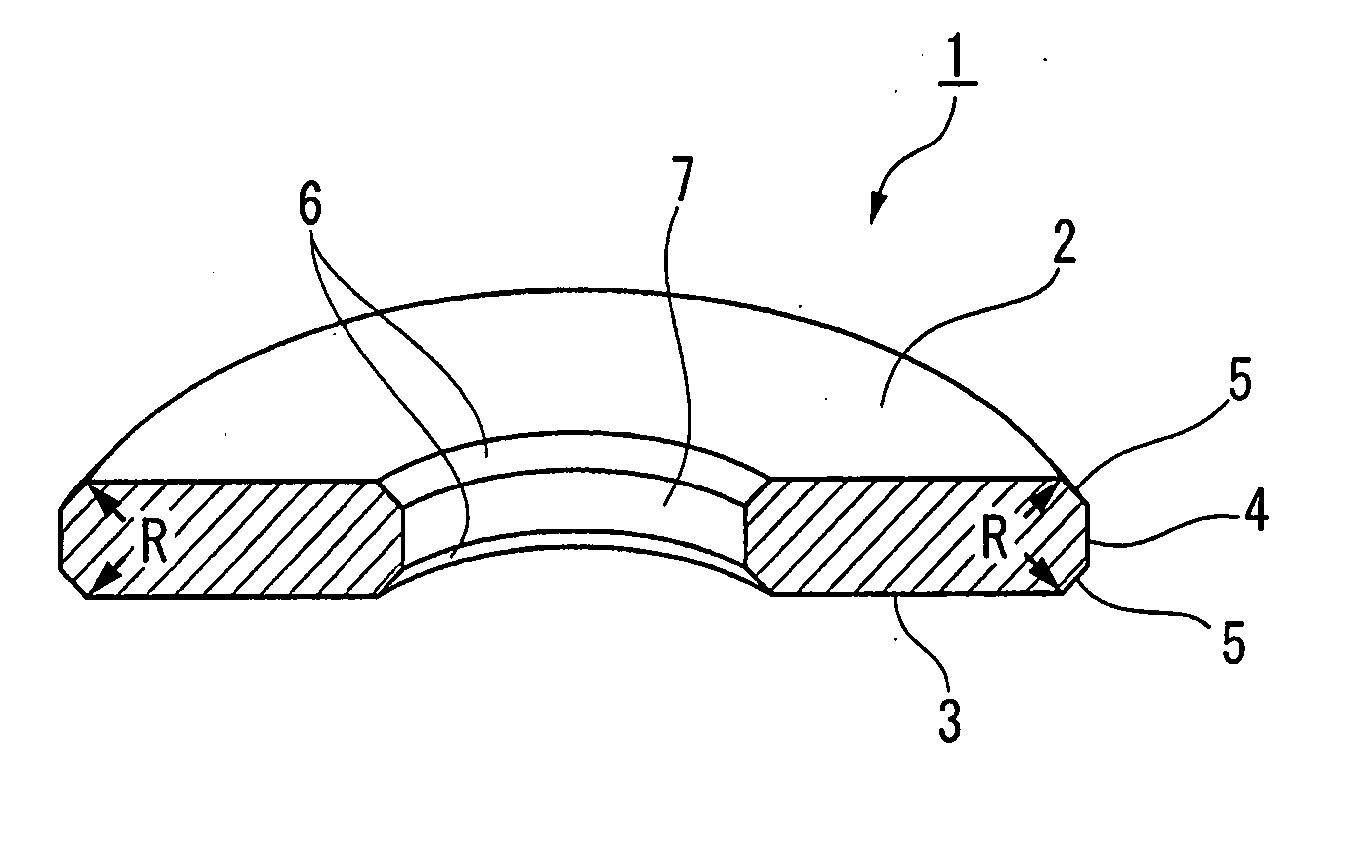

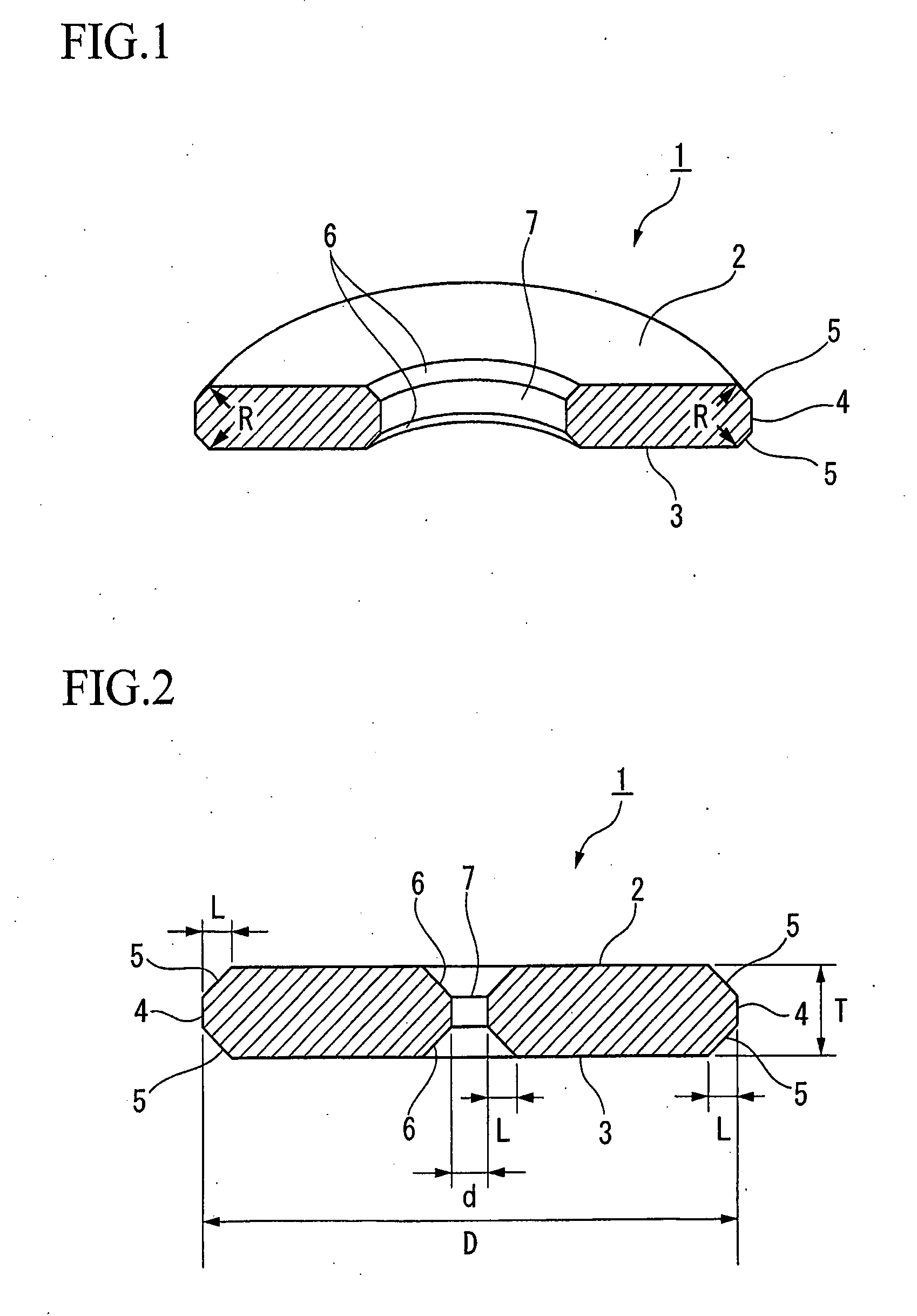

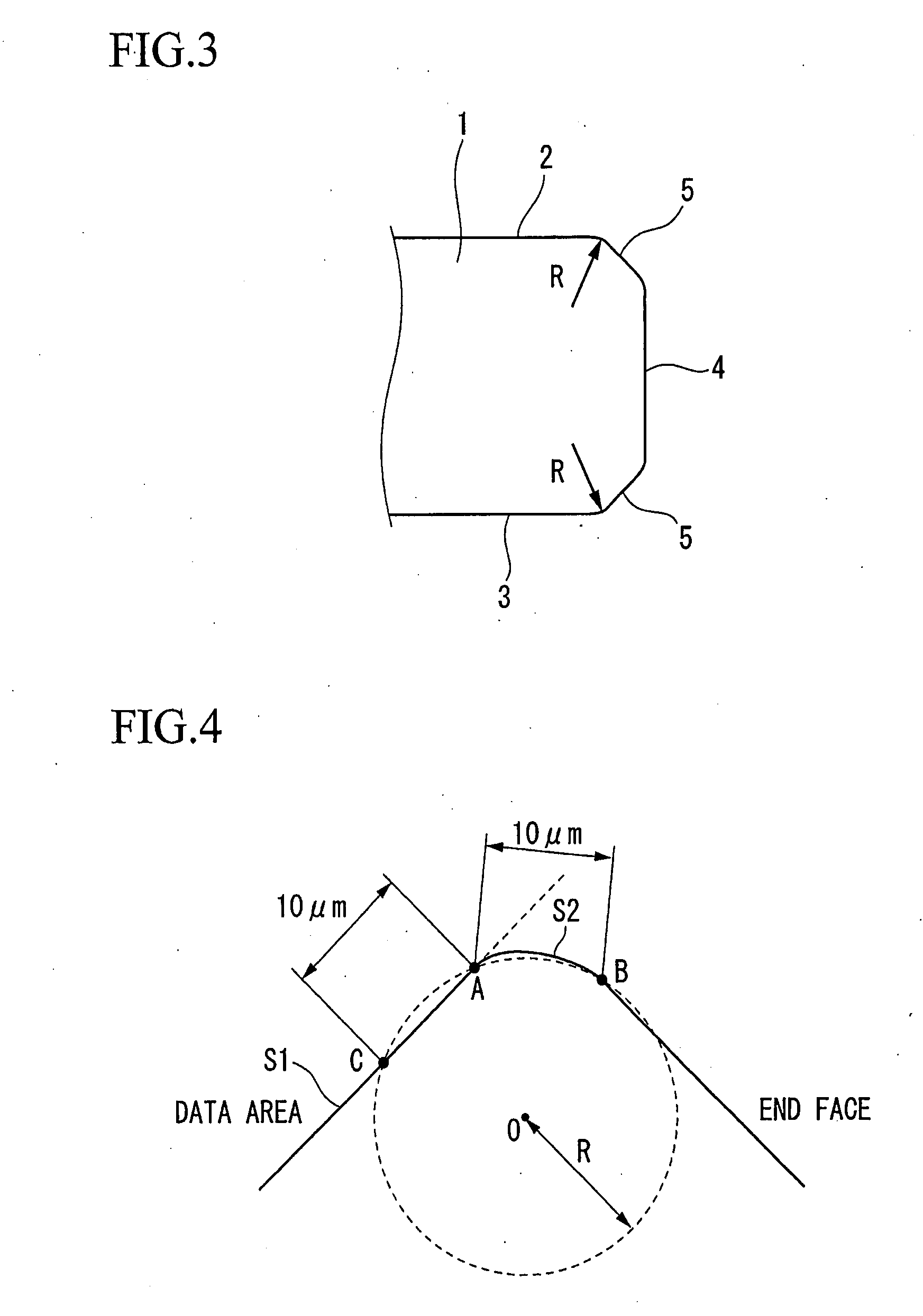

Method of Manufacturing Silicon Substrates for Magnetic Recording Medium, Silicon Substrate for Magnetic Recording Medium, Magnetic Recording Medium, and Magnetic Recording Apparatus

InactiveUS20070270084A1Accuracy is strictlyEasy to mass produceEdge grinding machinesPolishing machinesSiliconMagnetism

A manufacturing method for silicon substrates for a magnetic recording medium has the steps of forming a stack body of a number of silicon substrates which are stacked via spacers therebetween, wherein each silicon substrate has a circular hole at a center of the substrate; immersing the stack body of the silicon substrates in a polishing liquid in which grains are suspended; and polishing inner peripheral end faces of the circular holes of the silicon substrates, wherein in polishing, a polishing brush contacts the end faces while performing a relative rotation between the end faces and the polishing brush, and the stack body of the silicon substrates is inverted during polishing. The step of polishing the inner peripheral end faces may be performed before inner and outer peripheries of the silicon substrate are subjected to chamfering. Preferably, the polishing brush is made of polyamide resin.

Owner:SHOWA DENKO KK

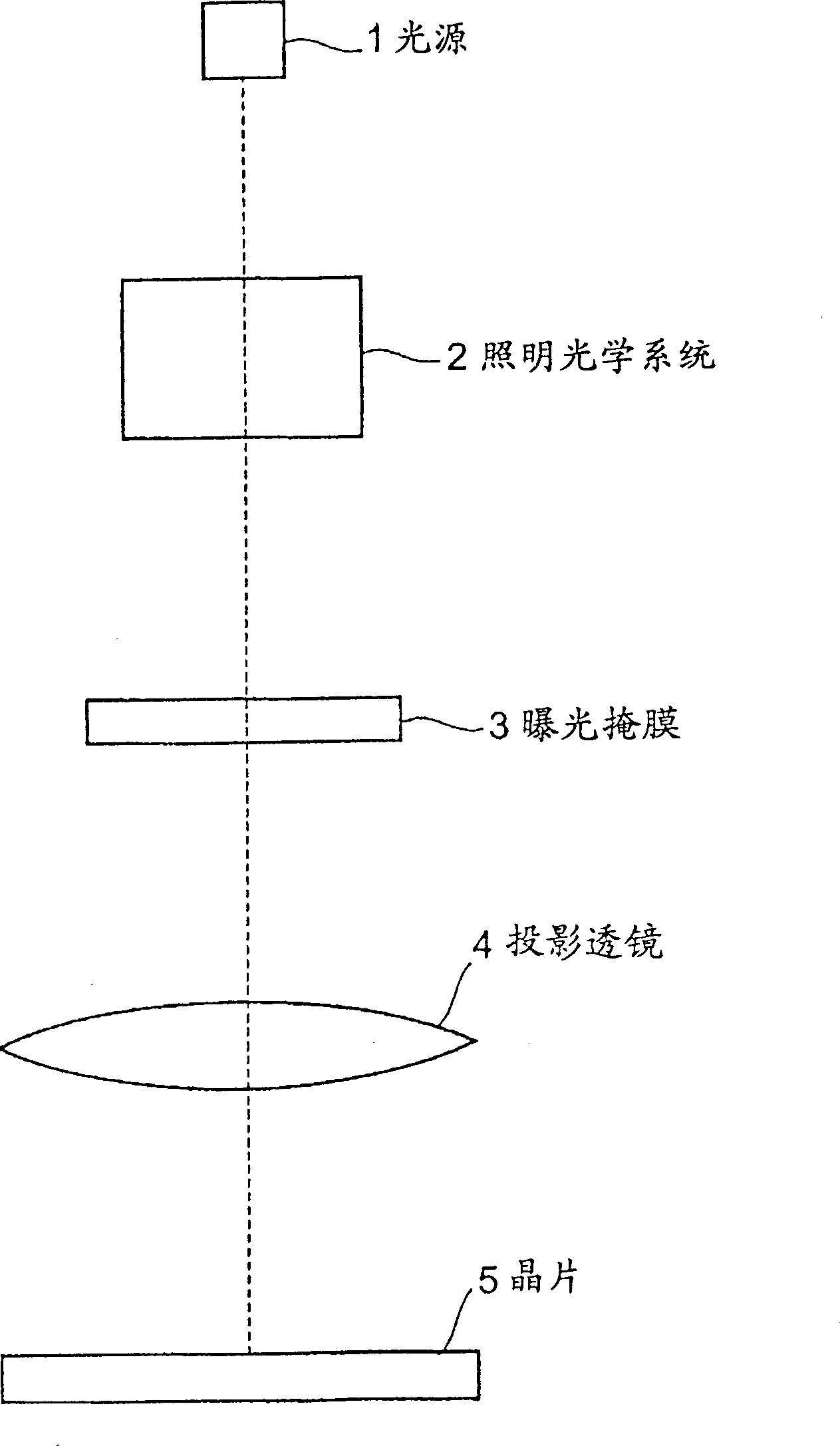

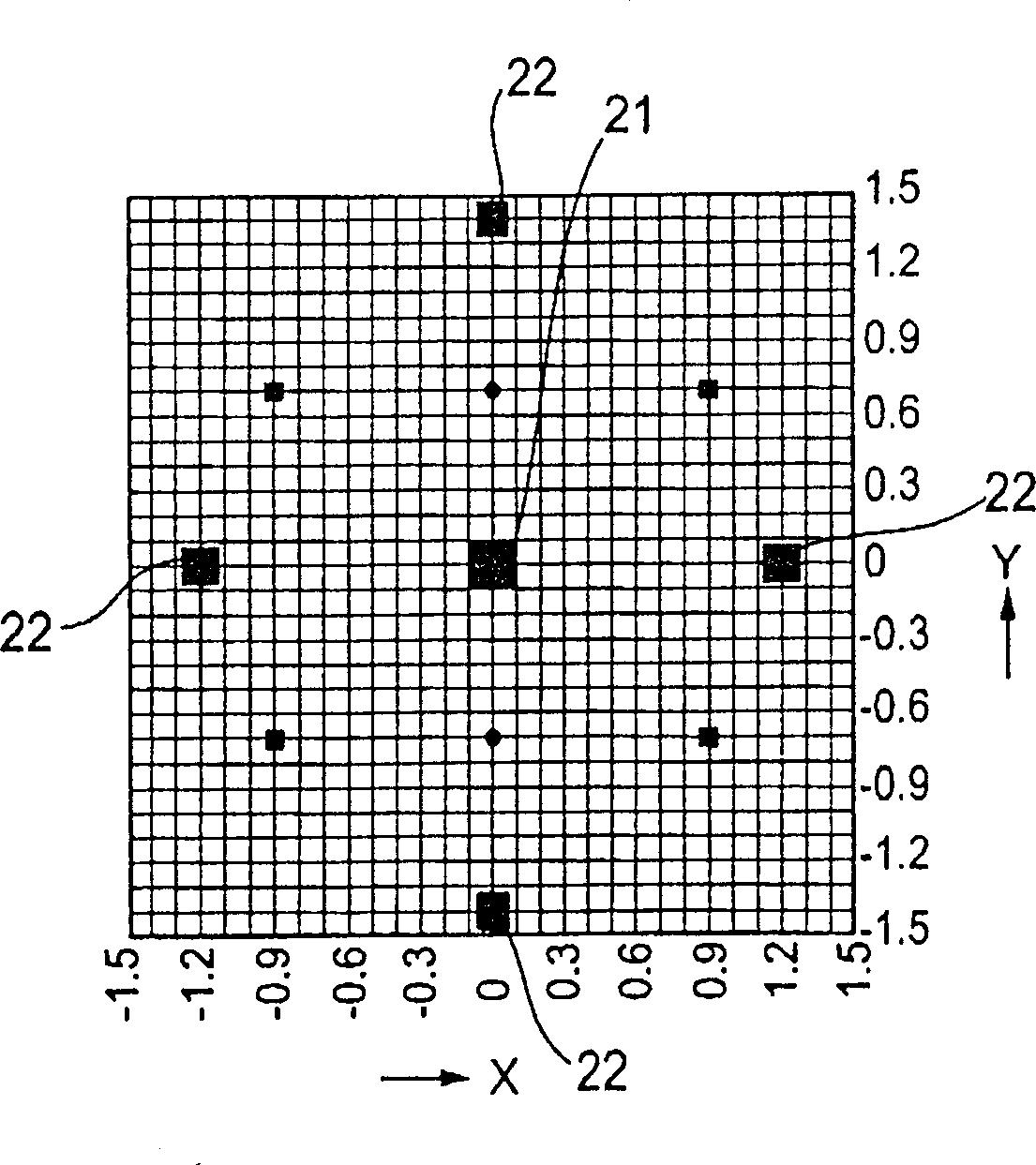

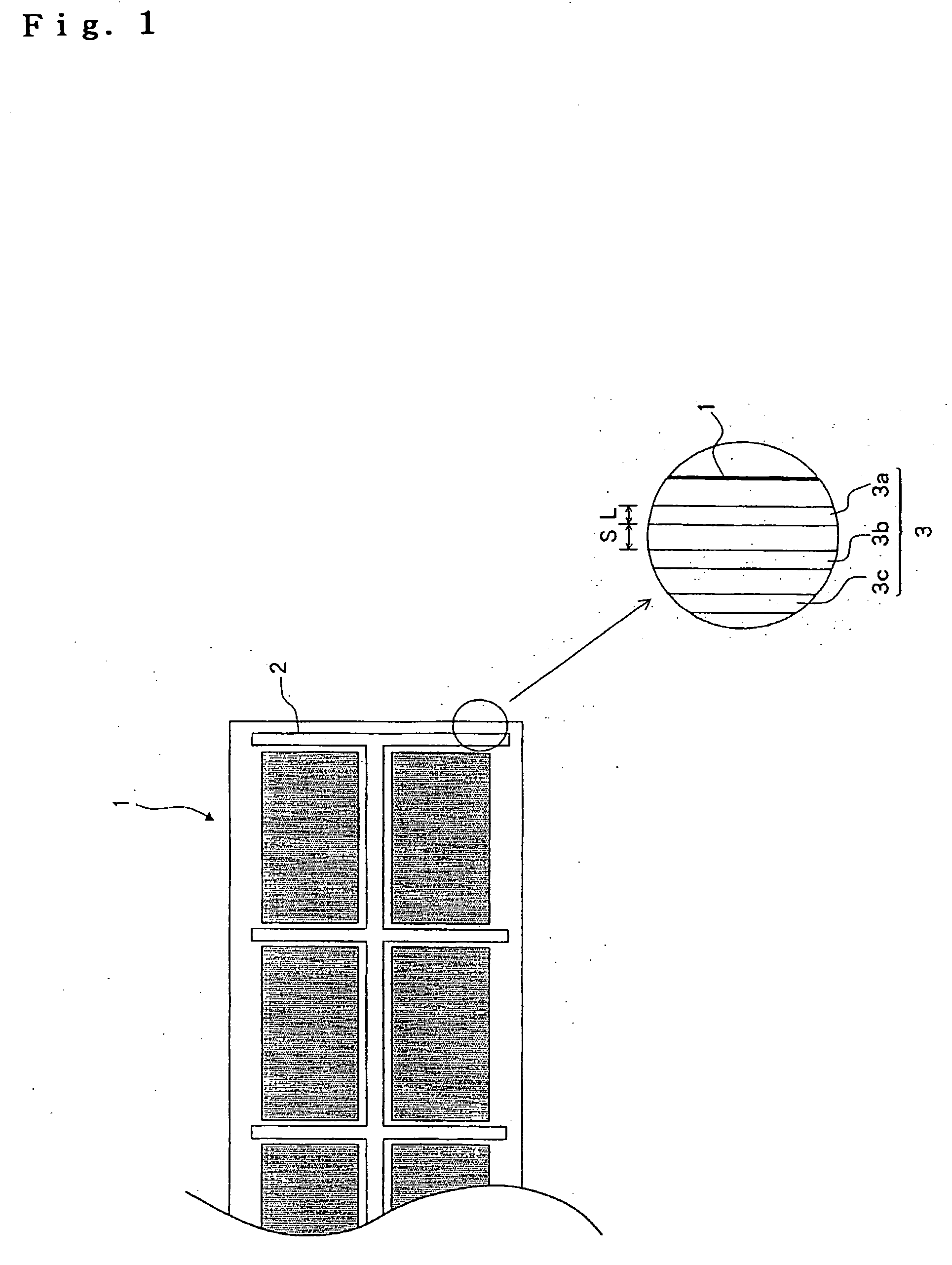

Exposure process

InactiveCN1400506AReduce size changeLittle changeSemiconductor/solid-state device manufacturingDiffraction gratingsLight spotOptoelectronics

Disclosed is an exposure method comprising preparing an exposure apparatus including an illumination system and a projection lens, setting, in the exposure apparatus, a photomask having a mask pattern including a plurality of unit circuit patterns arranged like a checkered flag pattern and a plurality of unit auxiliary patterns arranged between the unit circuit patterns, and projecting the mask pattern onto a substrate through the projection lens by irradiating the photomask with light from the illumination system, wherein the unit circuit patterns and the unit auxiliary patterns generate a plurality of diffraction light spots on a pupil plane of the projection lens, and the four diffraction light spots having higher light intensities than the remaining diffraction light spots are distributed on the pupil plane in a cycle of 90°.

Owner:KK TOSHIBA

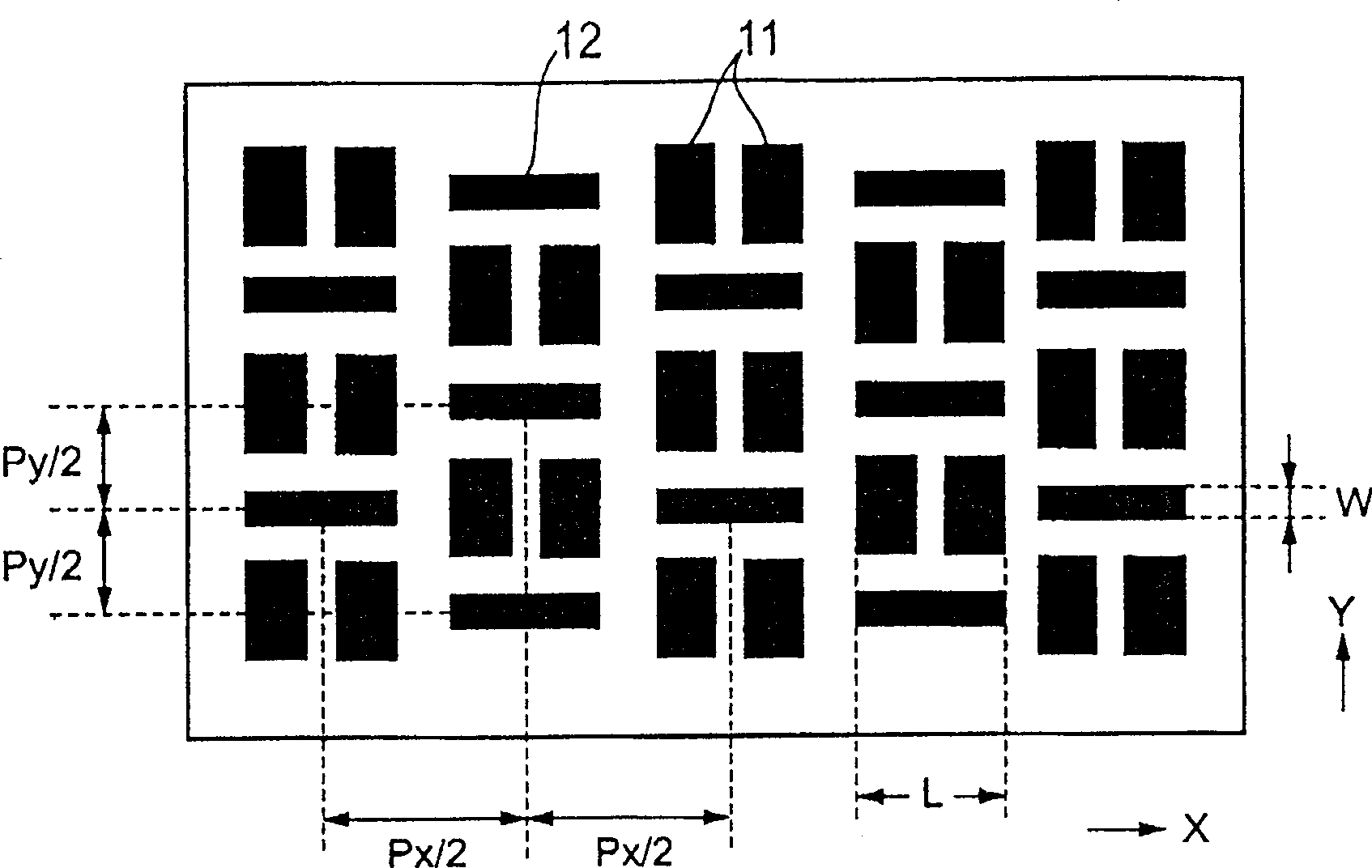

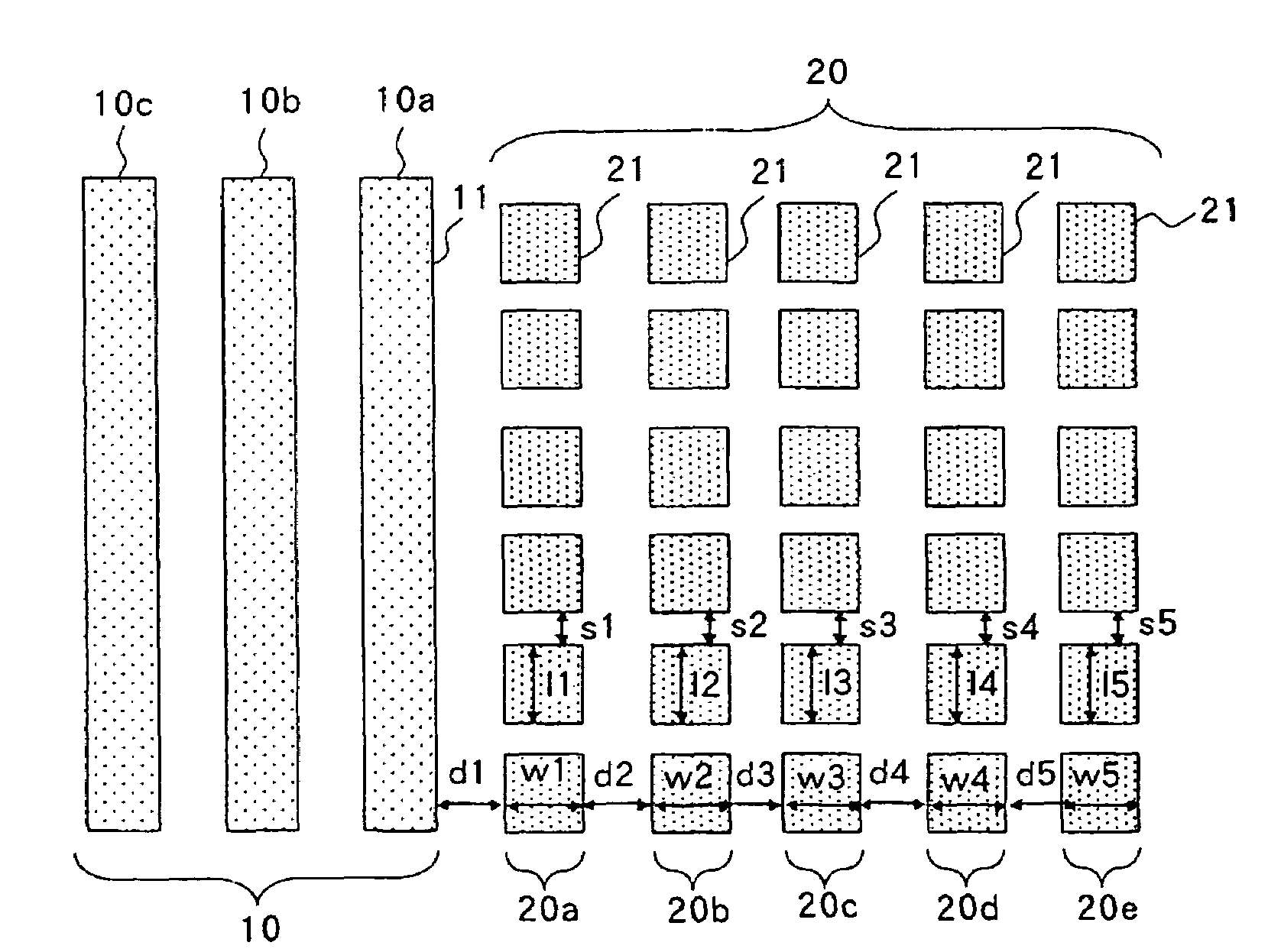

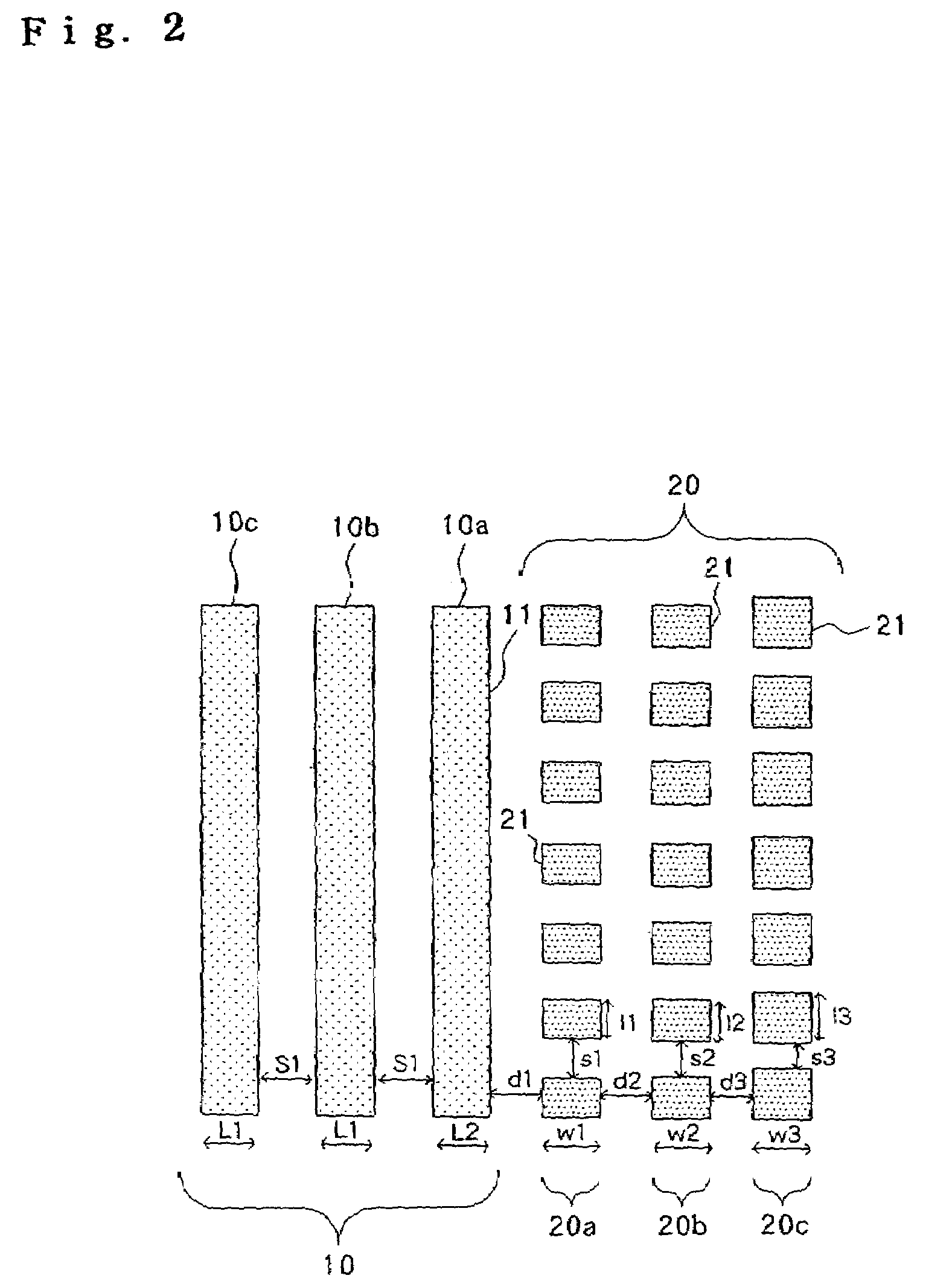

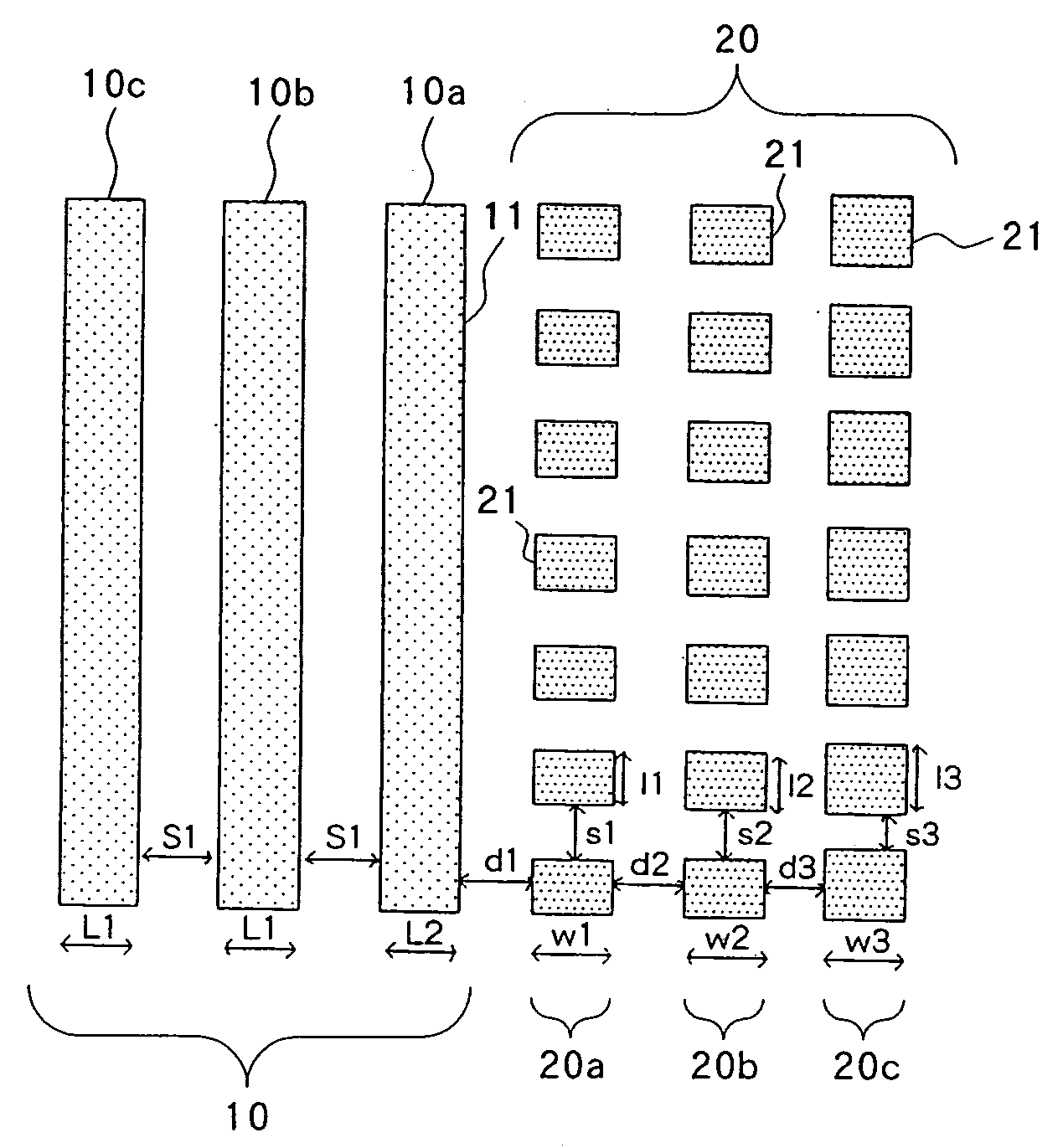

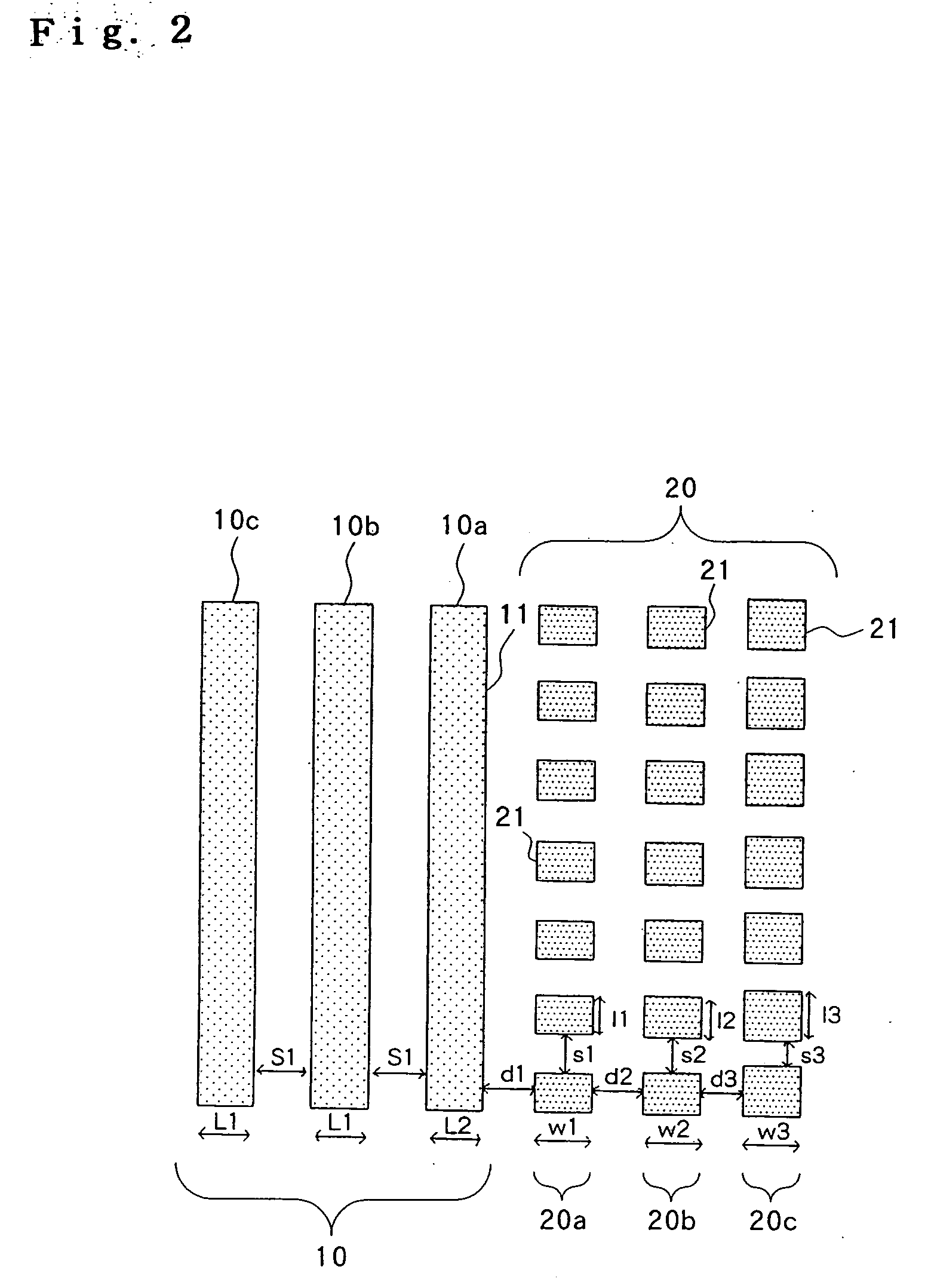

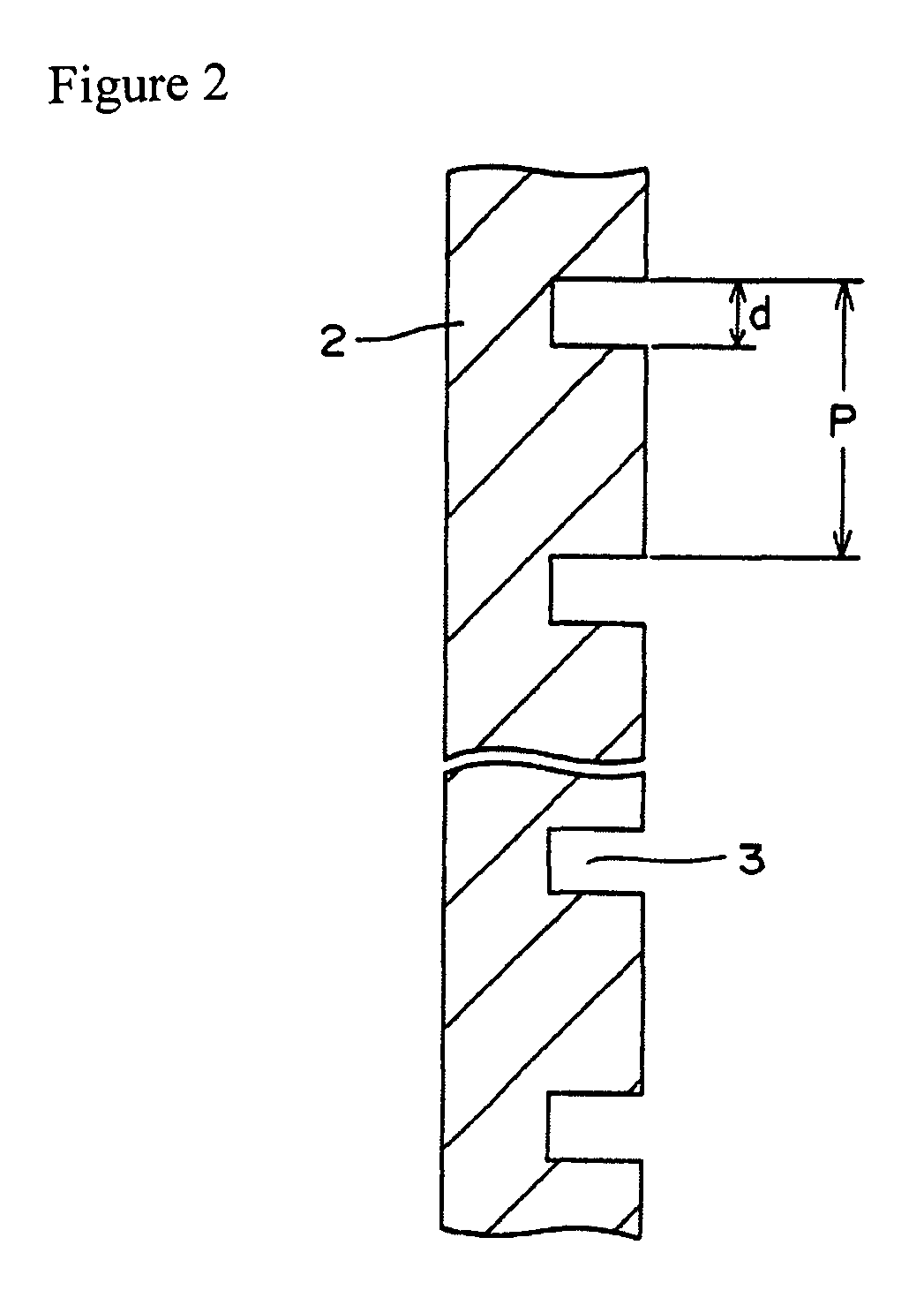

Circuit pattern exposure method and mask

ActiveUS7632614B2Reduce size changePhotomechanical apparatusSemiconductor/solid-state device manufacturingSemiconductor

A circuit pattern exposure method for irradiating illumination light onto a mask to transfer (offset) mask patterns that are formed in the mask to a semiconductor substrate, wherein the mask includes a plurality of main mask patterns that are arranged at a prescribed pitch and auxiliary mask patterns that are arranged outside the outermost main mask pattern and that are not to be transferred (offset) to the semiconductor substrate; the auxiliary mask patterns are provided with a first auxiliary mask row that is arranged adjacent to the outermost main mask pattern and a second auxiliary mask row that is arranged adjacent to the first auxiliary mask row; and the first auxiliary mask row and the second auxiliary mask row are arranged at a pitch that is narrower than the pitch of arrangement of the main mask patterns.

Owner:MICRON TECH INC

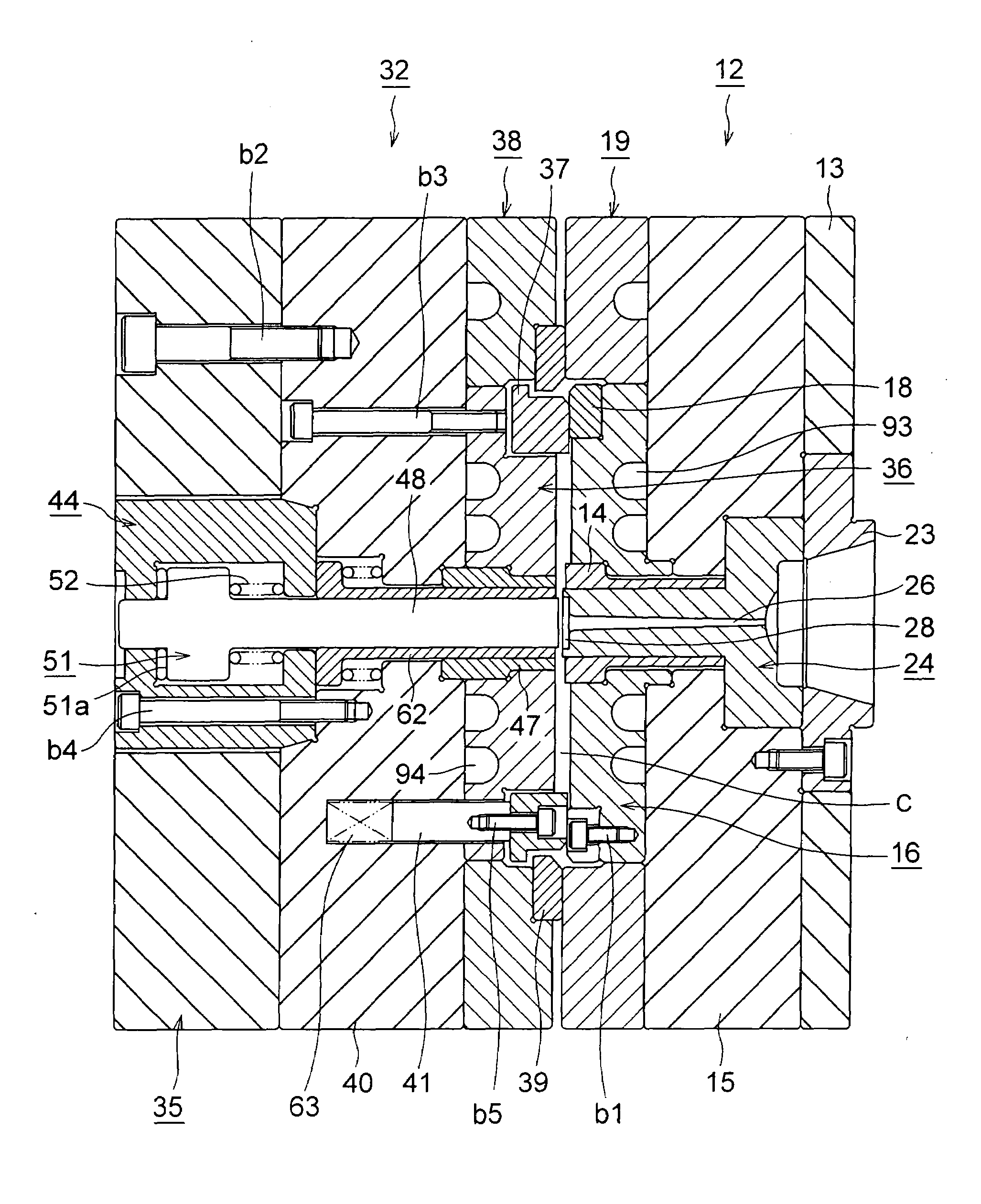

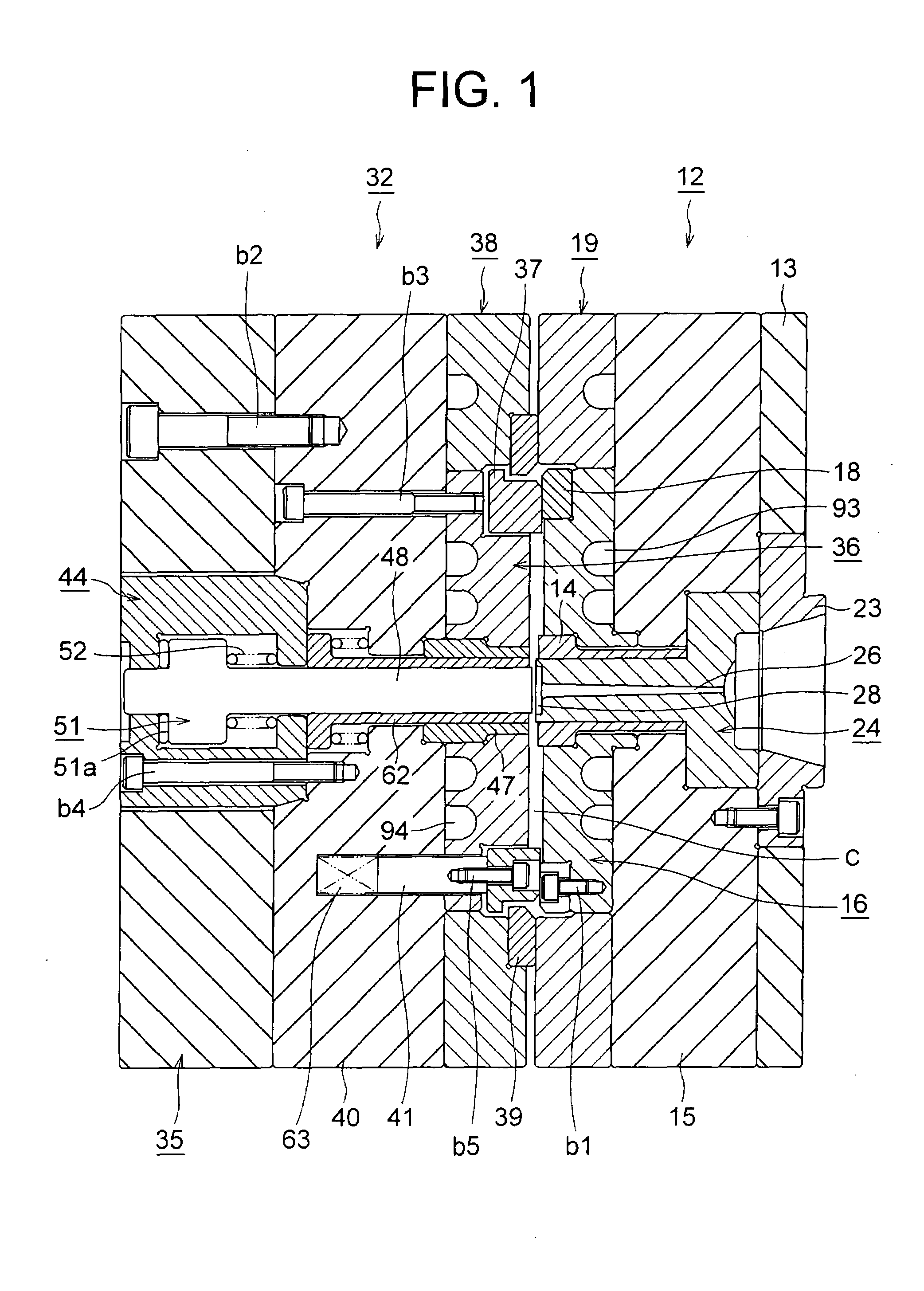

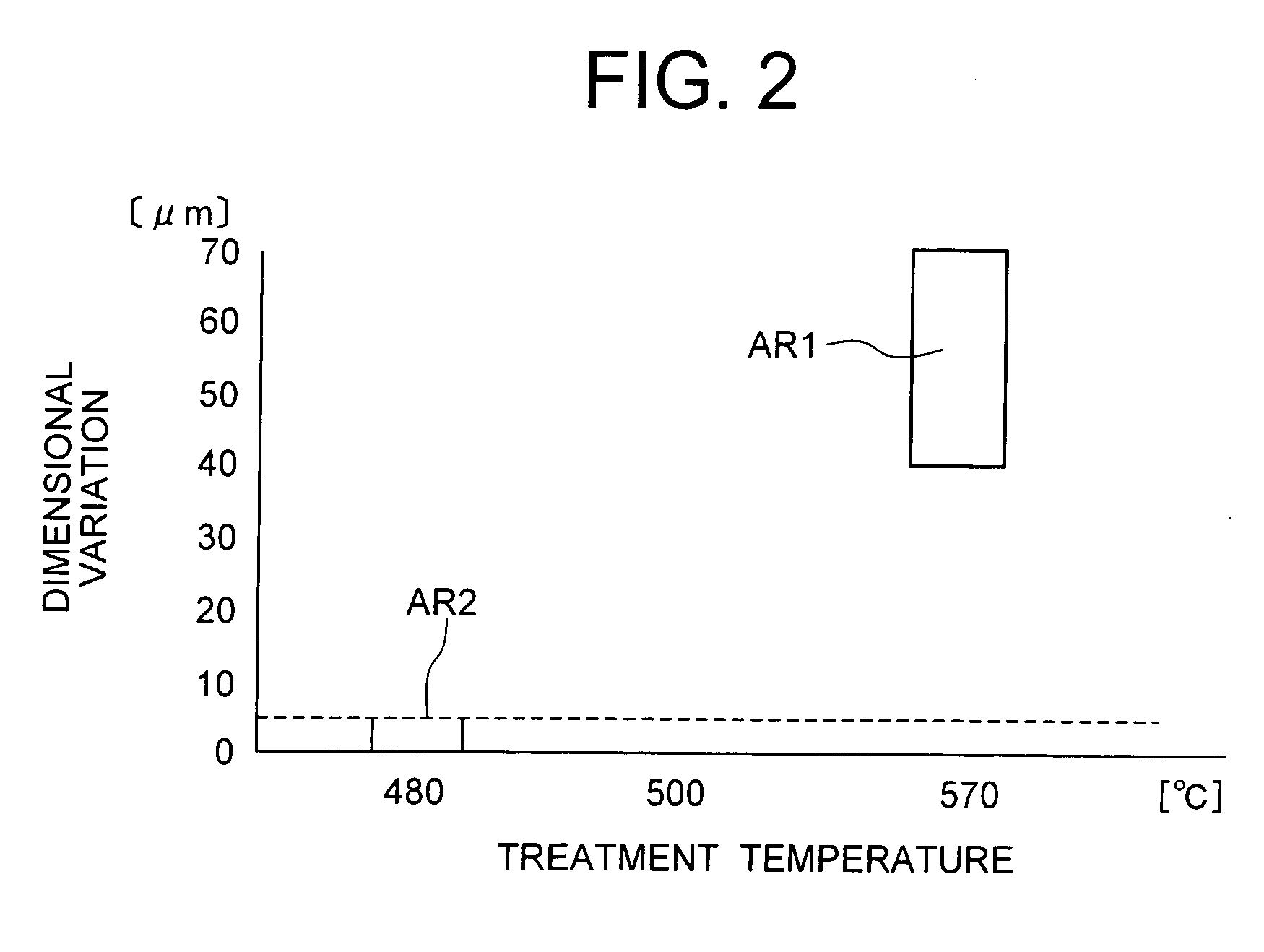

Mold for forming disc, method for manufacture same, and mold parts

InactiveUS20090074904A1Improve wear resistanceReduce size changeRecord carriersFoundry mouldsWear resistanceMaterials science

An object is to improve the wear resistance of a mold part and improve accuracy of disc substrates. A disc-molding mold comprises a first mold including a first support plate and a first mirror-surface disc attached to the first support plate; and a second mold including a second support plate and a second mirror-surface disc attached to the second support plate. A sliding surface of a mold part disposed on one of the first and second molds is treated by means of low-temperature nitriding. In this case, since the mold part is treated by means of low-temperature nitriding, the wear resistance of the mold part can be improved. In addition, since the treatment temperature is low, even when low-temperature nitriding is performed on a mold part which is complicated in shape, the mold part does not deform, and its dimensional variation can be decreased.

Owner:SUMITOMO HEAVY IND LTD +1

Melting compound process for abrasion-resistant layers of scraper plate conveyor and scraper plate conveyor with abrasion-resistant layers

The invention discloses a melting compound process for abrasion-resistant layers of a scraper plate conveyor and the scraper plate conveyor with the abrasion-resistant layers. The scraper plate conveyor comprises a bottom plate, a middle plate and an E-shaped ledge. The bottom plate, the middle plate and the E-shaped ledge are all provided with the abrasion-resistant layers. The melting compound process for the abrasion-resistant layers comprises the steps that firstly, the middle plate is horizontally arranged on the upper face, and the upper surface of the middle plate is pressed by a pressing plate and faces upwards; secondly, welding machine parameters are adjusted; and finally, surfacing is conducted, specifically, the welding machine runs in the width direction of the middle plate and then runs in the length direction of the middle plate, and a continuous melt plated band is formed through sequential cycles. The middle plate, the bottom plate and the E-shaped ledge of the scraper plate conveyor are provided with the abrasion-resistant layers, so that the abrasion resistance of the scraper plate conveyor is improved. Meanwhile, through melting compound of the abrasion-resistant layers, the abrasion-resistant layers subjected to melting compound is even in thickness, low in cost and good in application effect.

Owner:过秉坤

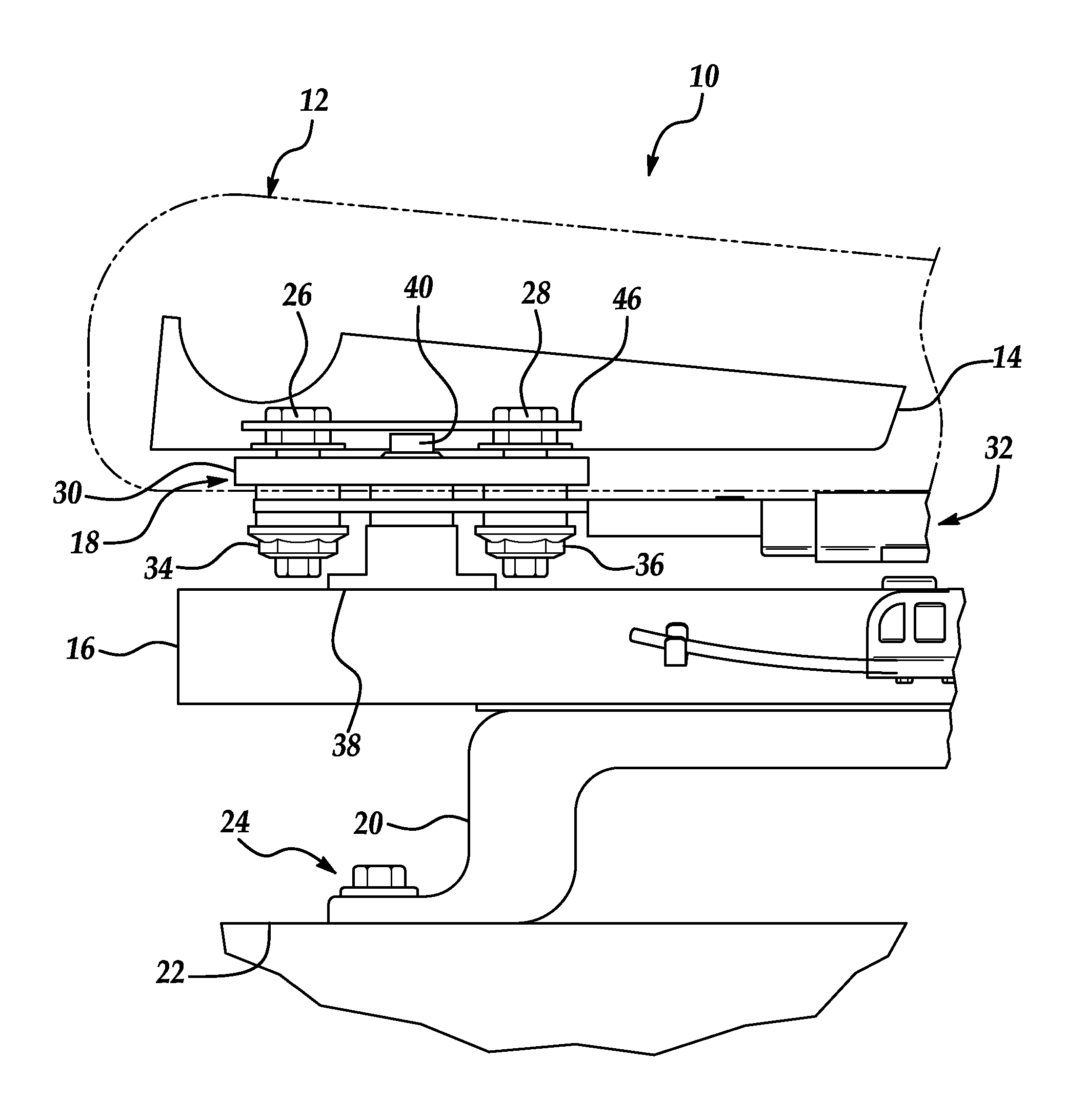

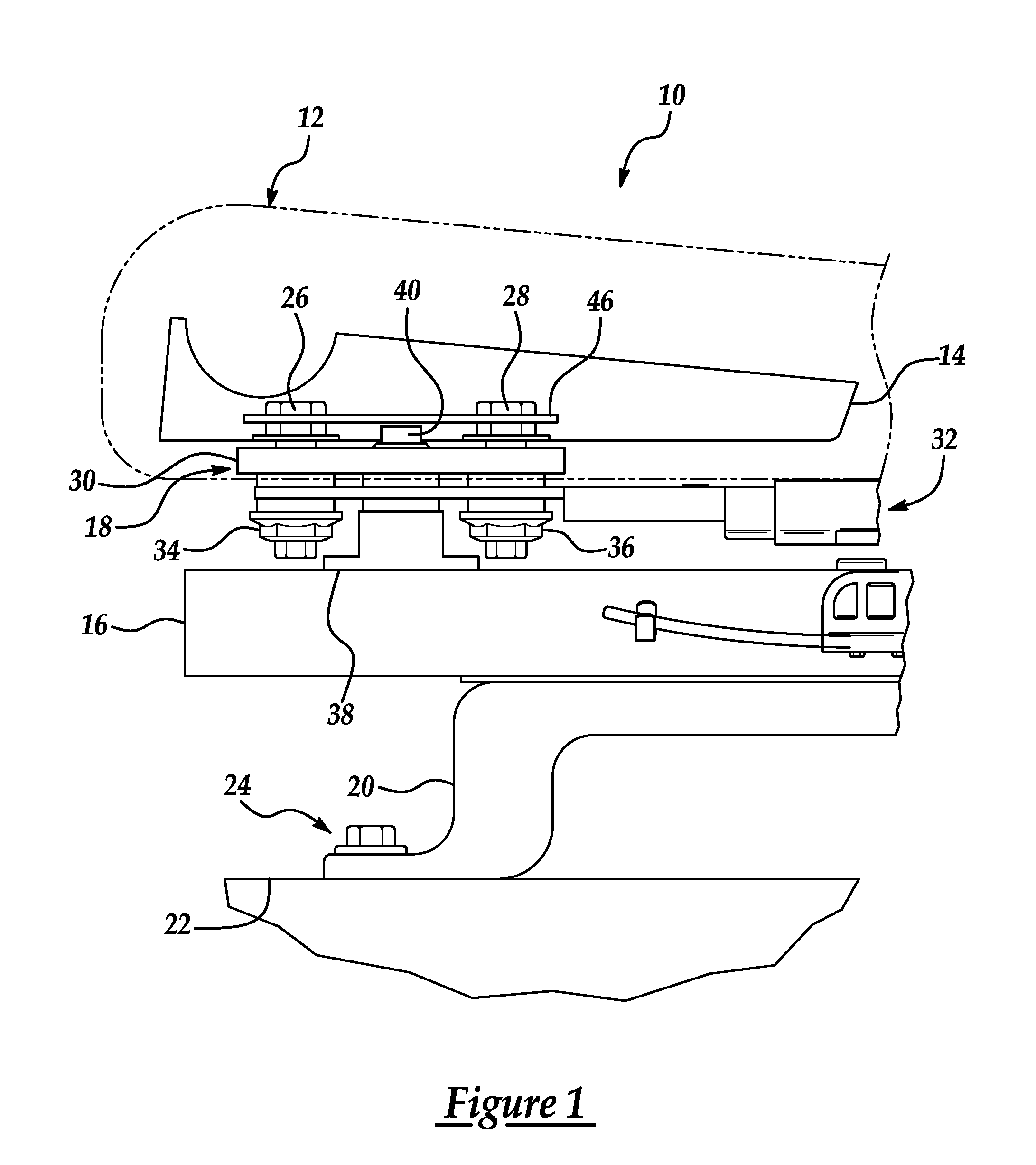

Apparatus and method for use in firing cores

Apparatus and method for use in firing a ceramic casting core includes a saggar and a core setter insert disposed in the saggar. The core setter insert can be disposed on a refractory particulate grog bed and / or refractory supports inside the saggar on a bottom wall of the saggar. The core setter insert has a core-receiving surface, which can have an airfoil shape to receive an airfoil-shaped ceramic casting core used in casting hollow airfoil castings.

Owner:HOWMET CORPORATION

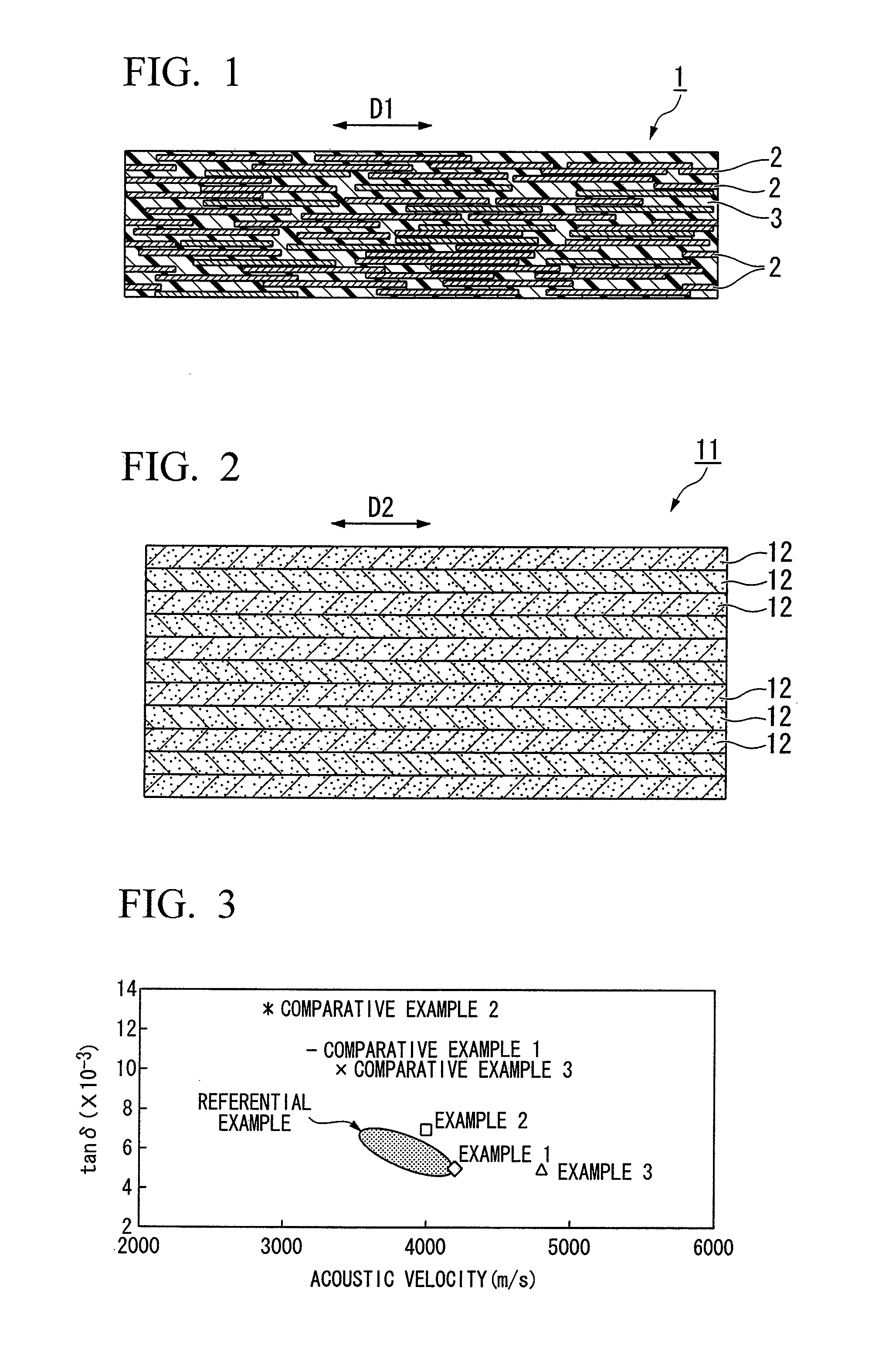

Acoustic timber for musical instrument

ActiveUS8217249B2Improve sound qualityReduce size changeWood working apparatusGlass/slag layered productsFiberEpoxy

An acoustic timber for use in an acoustic musical instrument is constituted of a plurality of woody members, such as woody fibers, woody veneers, blasted bamboo fibers, and defibrated bamboo fibers, whose fiber length is 50 mm or more. An epoxy resin is impregnated into the woody members with an impregnation factor of 5 weight-percent through 50 weight-percent. The woody members impregnated with the epoxy resin are joined together by way of heating and compressive molding so that the fibers thereof are uniformly aligned in the desired fiber-aligning direction.

Owner:YAMAHA CORP

Circuit pattern exposure method and mask

ActiveUS20070160918A1Reduced dimensional variationReduce size changeSemiconductor/solid-state device manufacturingPhotomechanical exposure apparatusEngineeringElectrical and Electronics engineering

A circuit pattern exposure method for irradiating illumination light onto a mask to transfer (offset) mask patterns that are formed in the mask to a semiconductor substrate, wherein the mask includes a plurality of main mask patterns that are arranged at a prescribed pitch and auxiliary mask patterns that are arranged outside the outermost main mask pattern and that are not to be transferred (offset) to the semiconductor substrate; the auxiliary mask patterns are provided with a first auxiliary mask row that is arranged adjacent to the outermost main mask pattern and a second auxiliary mask row that is arranged adjacent to the first auxiliary mask row; and the first auxiliary mask row and the second auxiliary mask row are arranged at a pitch that is narrower than the pitch of arrangement of the main mask patterns.

Owner:MICRON TECH INC

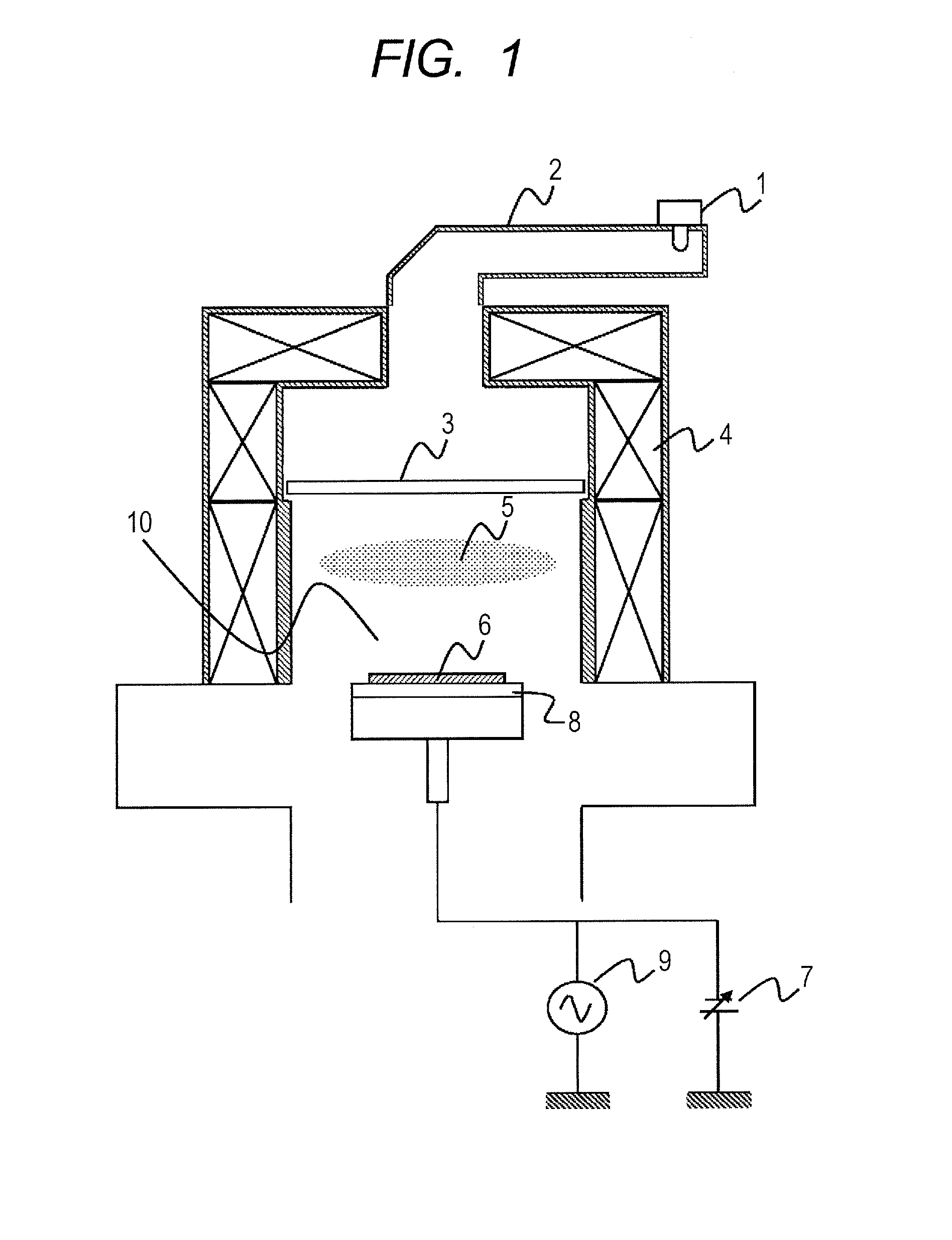

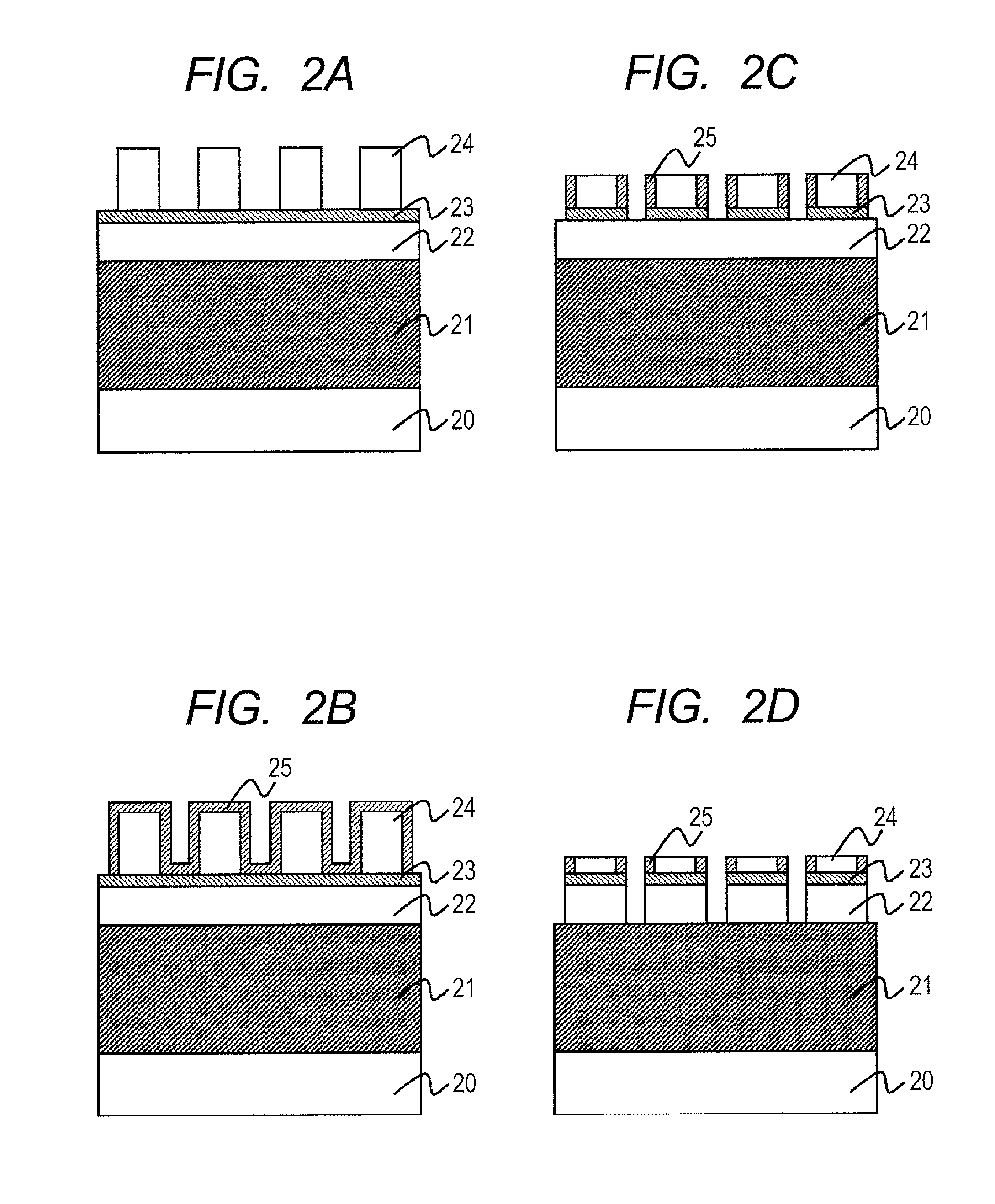

Plasma etching method

InactiveUS20140151327A1Reduce feature dimension variationReduce size changeSemiconductor/solid-state device manufacturingOptical articlesResistOrganic film

The present invention provides a plasma etching method with an EUV-exposed resist capable of preventing variations of device feature dimensions. The plasma etching method of the present invention is to plasma-etch a target material with a multilayer resist that serves as a mask and composed of an EUV-exposed resist, an antireflective coating, an inorganic film and an organic film. The plasma etching method includes a first step of depositing a deposition film on a surface of the EUV-exposed resist before the antireflective coating is etched, a second step of etching the deposition film deposited on the antireflective coating and the antireflective coating with a gas mixture of Cl2 gas, HBr gas and N2 gas after the first step, a third step of etching the inorganic film after the second step, and a fourth step of etching the organic film after the third step.

Owner:HITACHI HIGH-TECH CORP

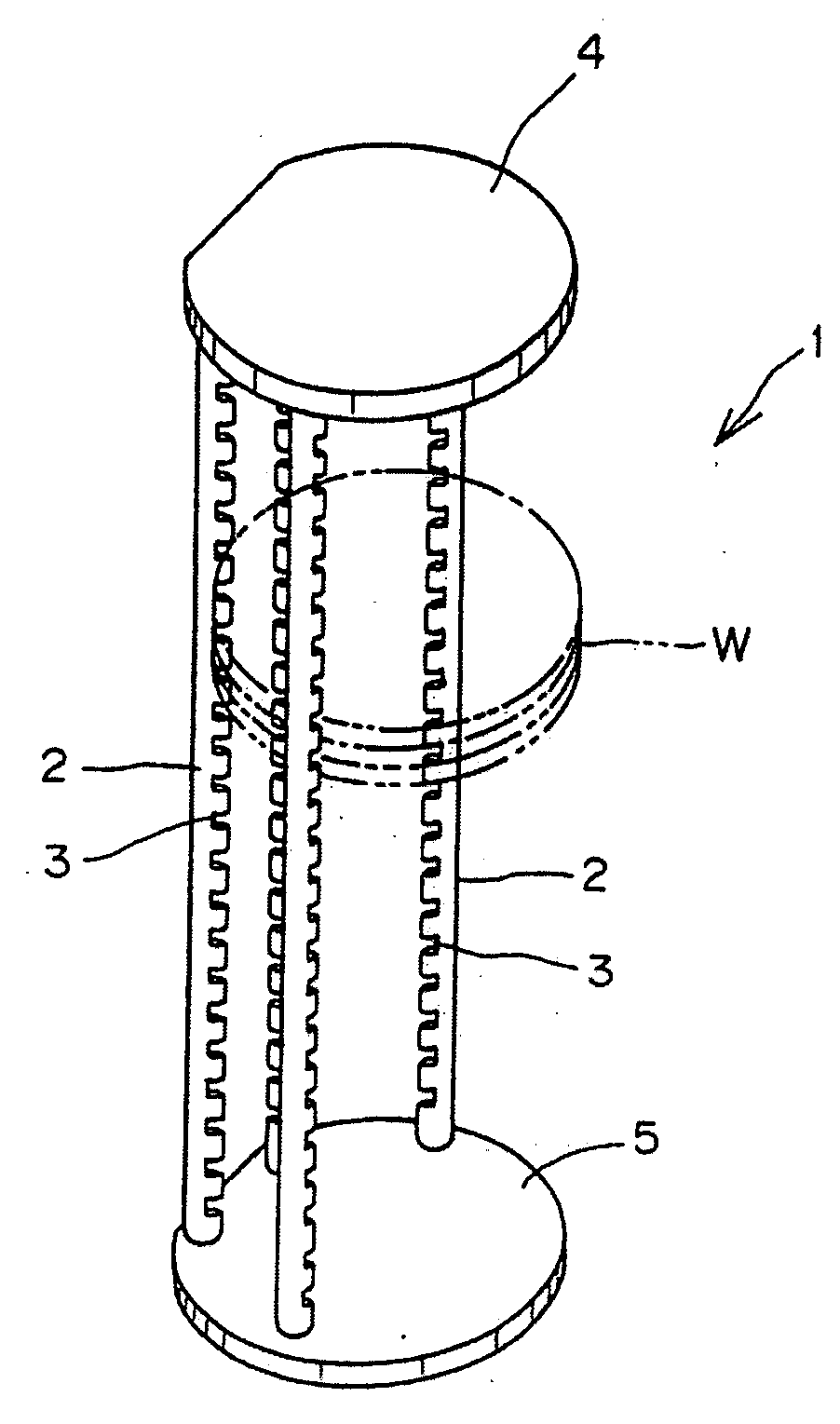

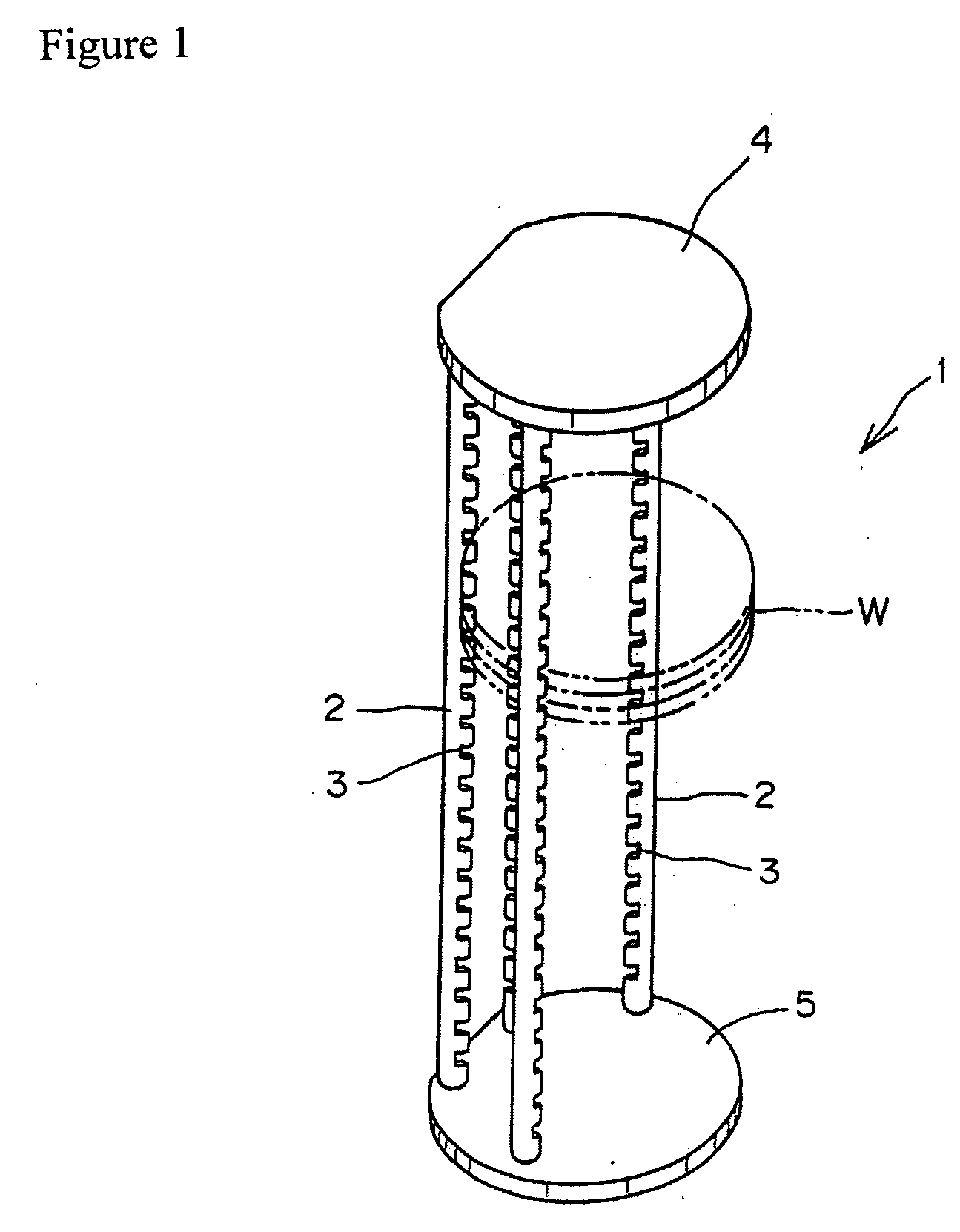

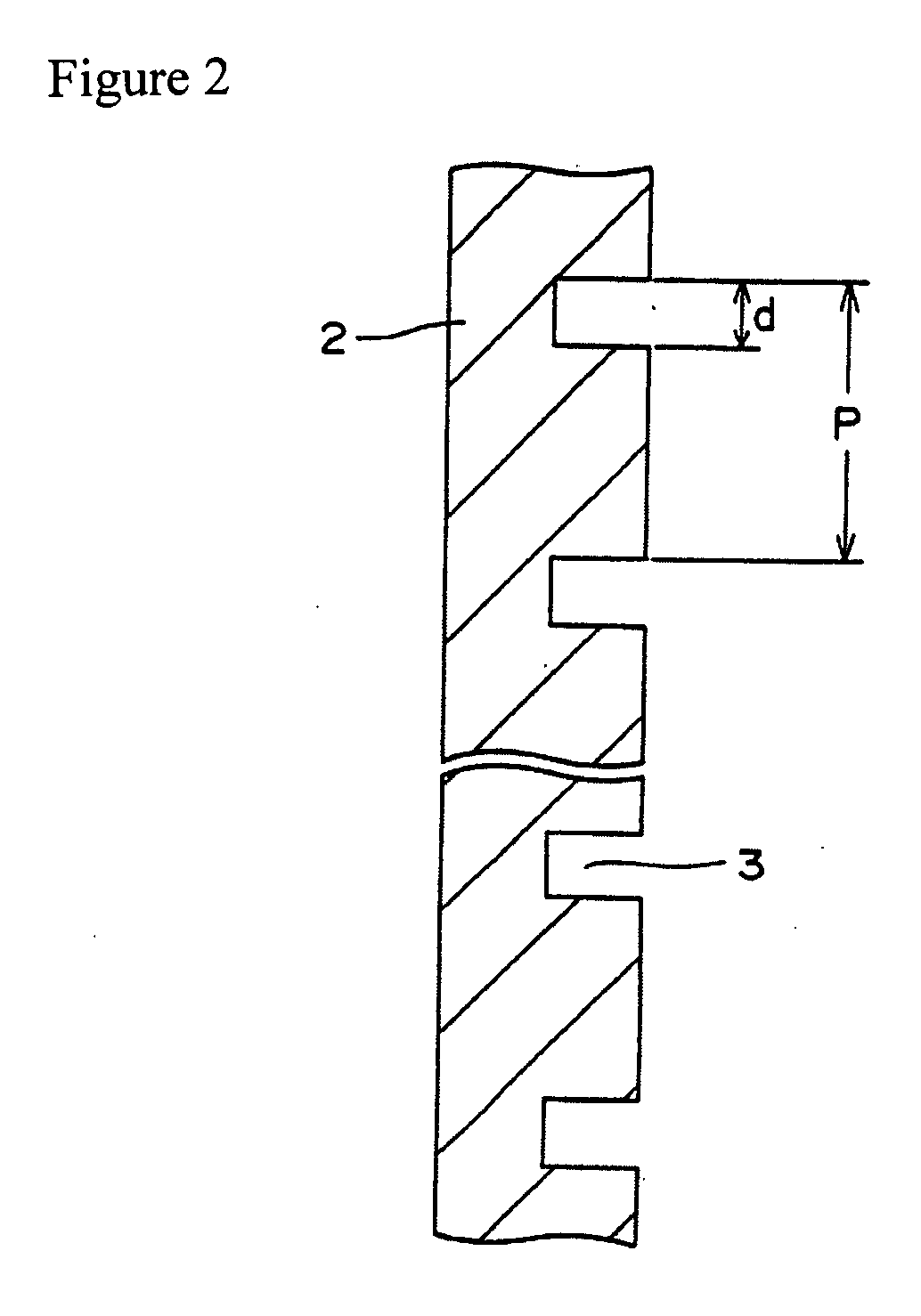

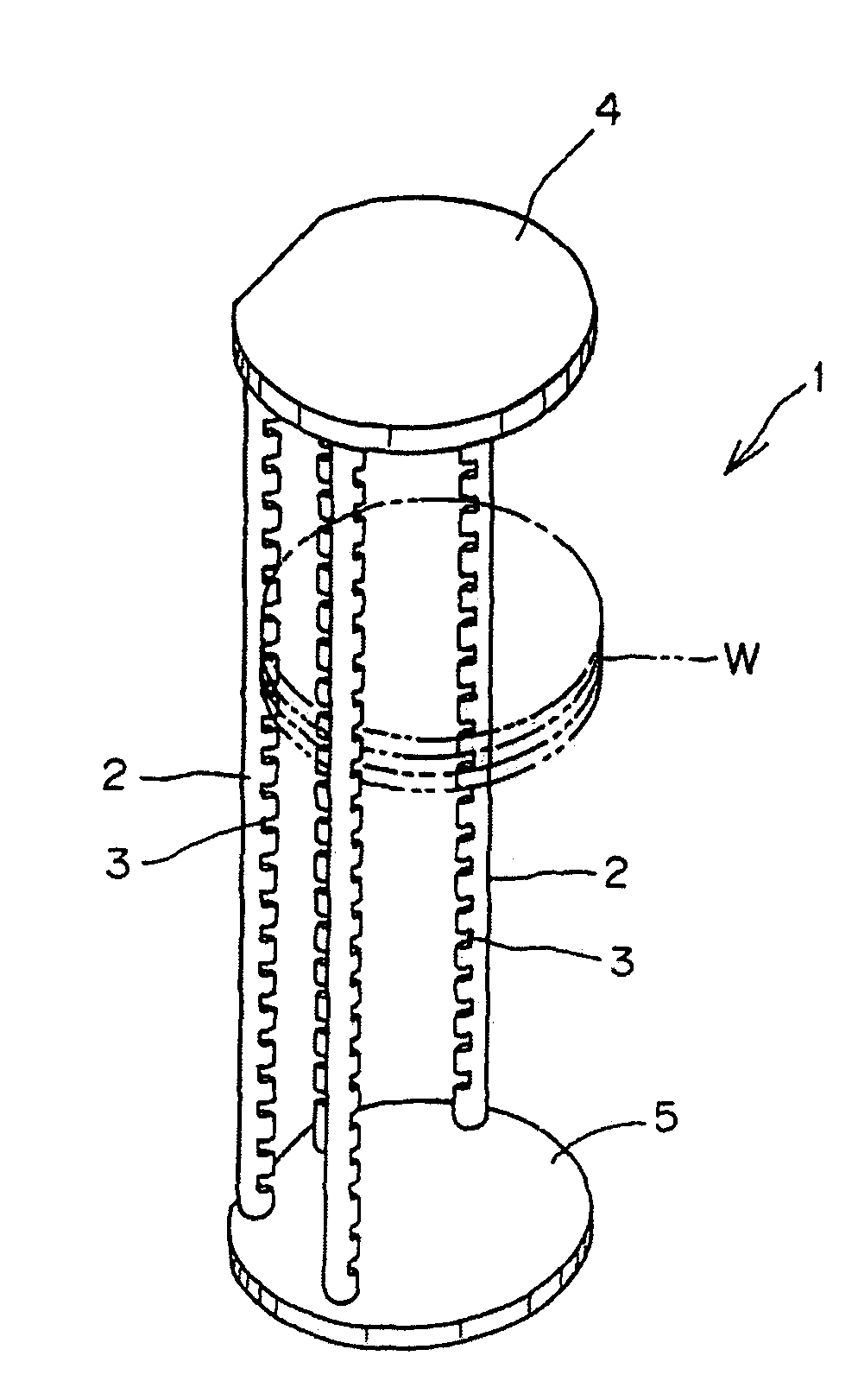

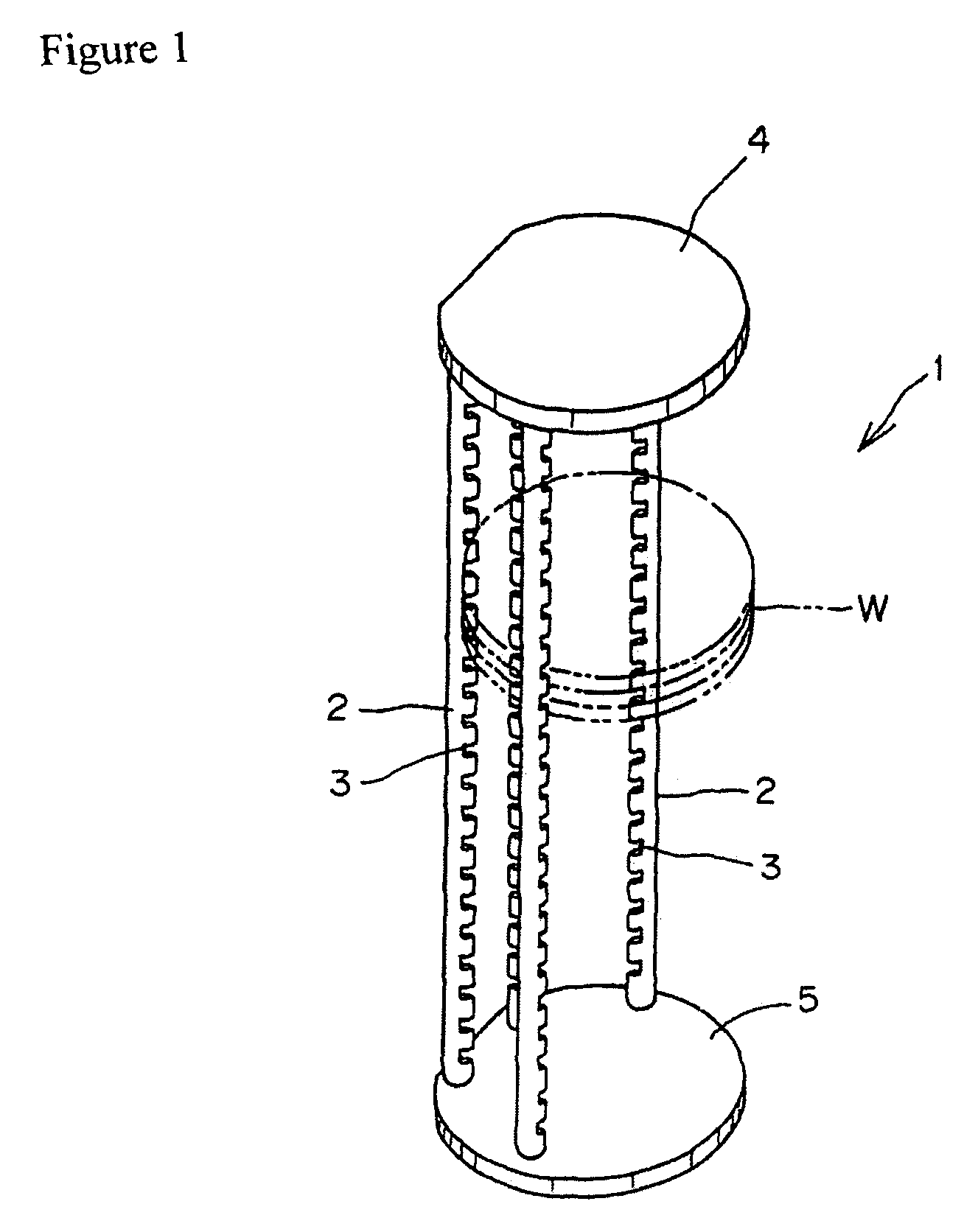

Quartz Glass Tool for Heat Treatment of Silicon Wafer and Process for Producing the Same

ActiveUS20080149575A1Reduce size changeEasy to produceSemiconductor/solid-state device manufacturingFine working devicesMicro cracksMetal

Owner:SHIN ETABU QUARTZ PRODS

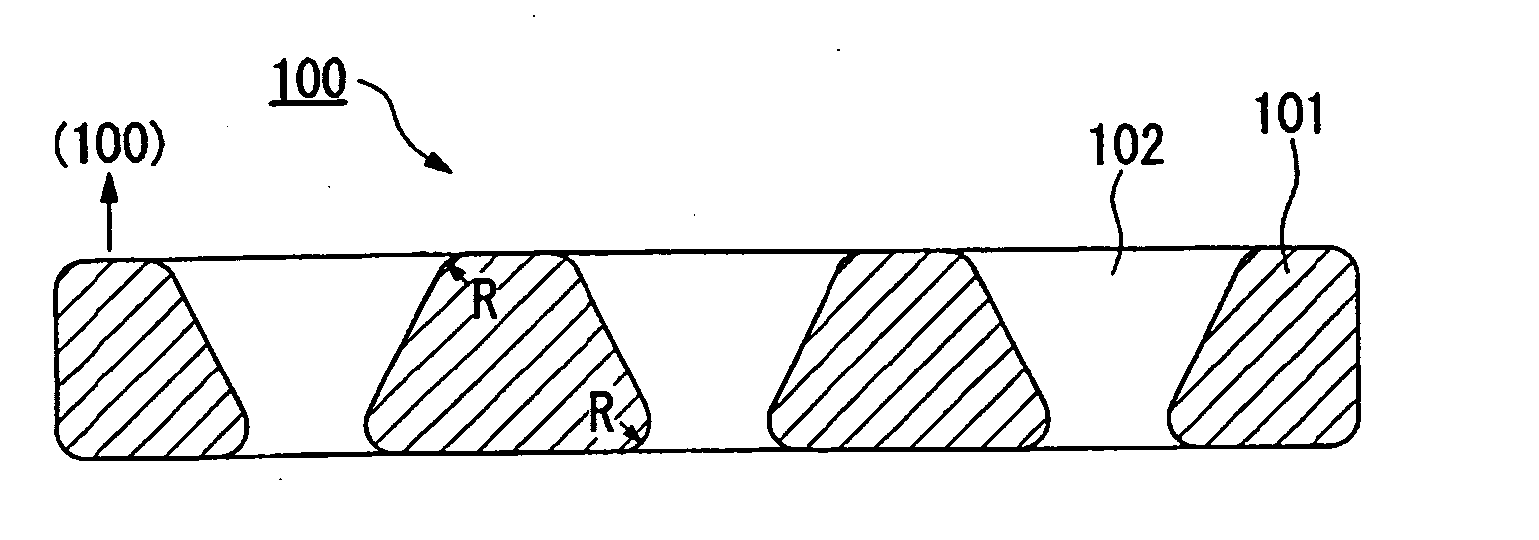

Quartz glass tool for heat treatment of silicon wafer and process for producing the same

InactiveUS7997956B2Easy to produceImprove cleanlinessSemiconductor/solid-state device manufacturingFine working devicesForeign matterHeat treated

To provide a quartz glass tool, for silicon wafer heat treatment, having a transparent grooving face, which is free from the deposition of particles of a transition metal element foreign material derived from glass dust or diamond blade produced by breakdown of acute irregularities based on opening of very small concaves and convexes and microcracks, causes no significant change in dimension also in cleaning with hydrofluoric acid, and can maintain a high degree of cleanness even after use of a long period of time, and to provide a process for producing the same. A quartz glass tool for silicon wafer heat treatment, comprising a wafer mounting member having a grooving face formed by machining, characterized in that the whole grooving face of the wafer mounting member is transparent, the surface roughness is 0.03 to 0.3 μm in terms of center line average roughness (Ra) and 0.2 to 3.0 μm in terms of maximum roughness (Rmax), and a change in center line average roughness and maximum roughness after etching with a 5% aqueous hydrogen fluoride solution for 24 hr is not more than 50%. A process for producing a quartz glass tool for silicon wafer heat treatment, comprising roughly machining a wafer mounting member with a diamond blade having a rough particle size, conducting remachining with a diamond blade having a finer particle size than the above diamond blade, and then subjecting the inside of the groove to firing finishing.

Owner:SHIN ETABU QUARTZ PRODS

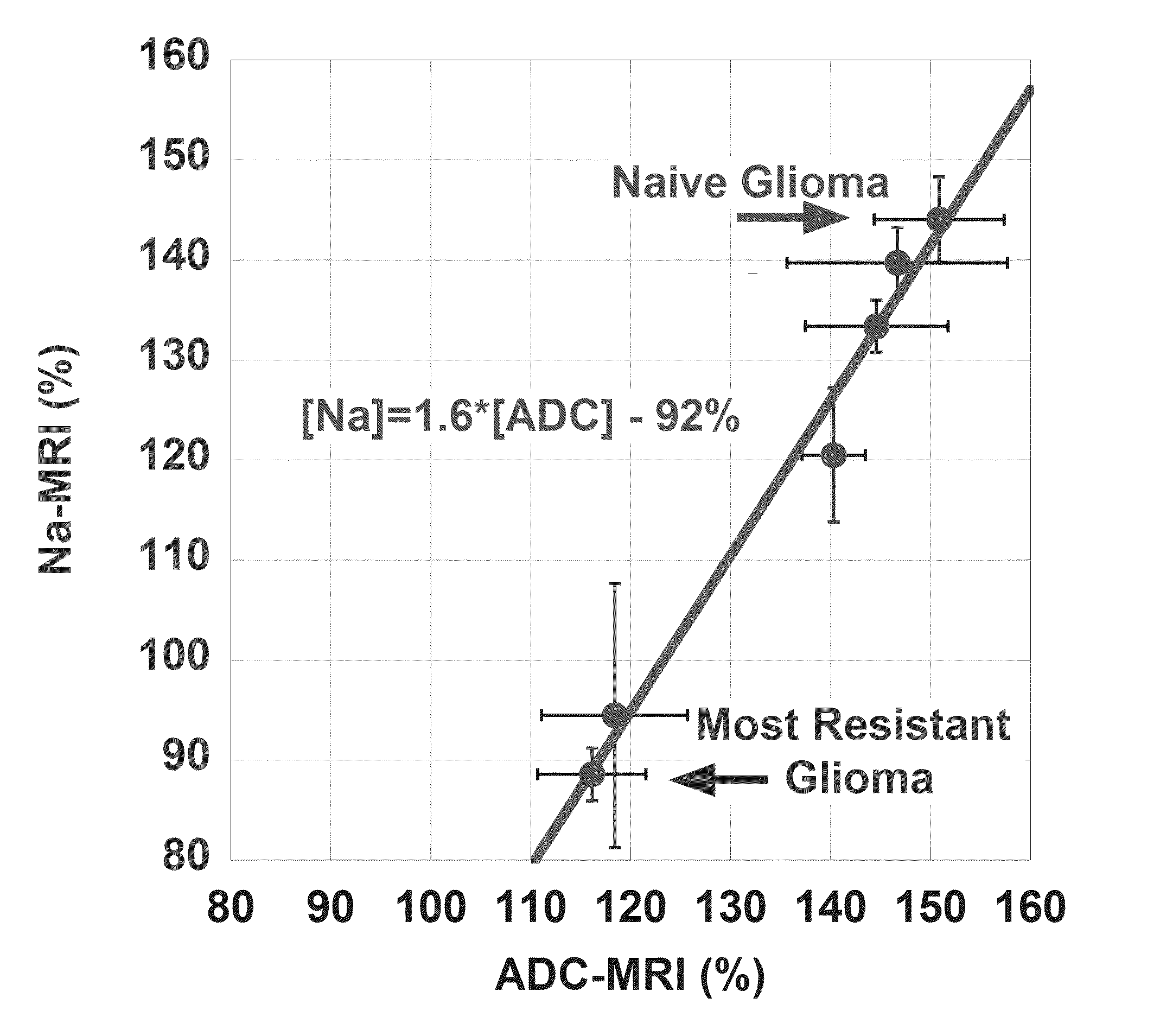

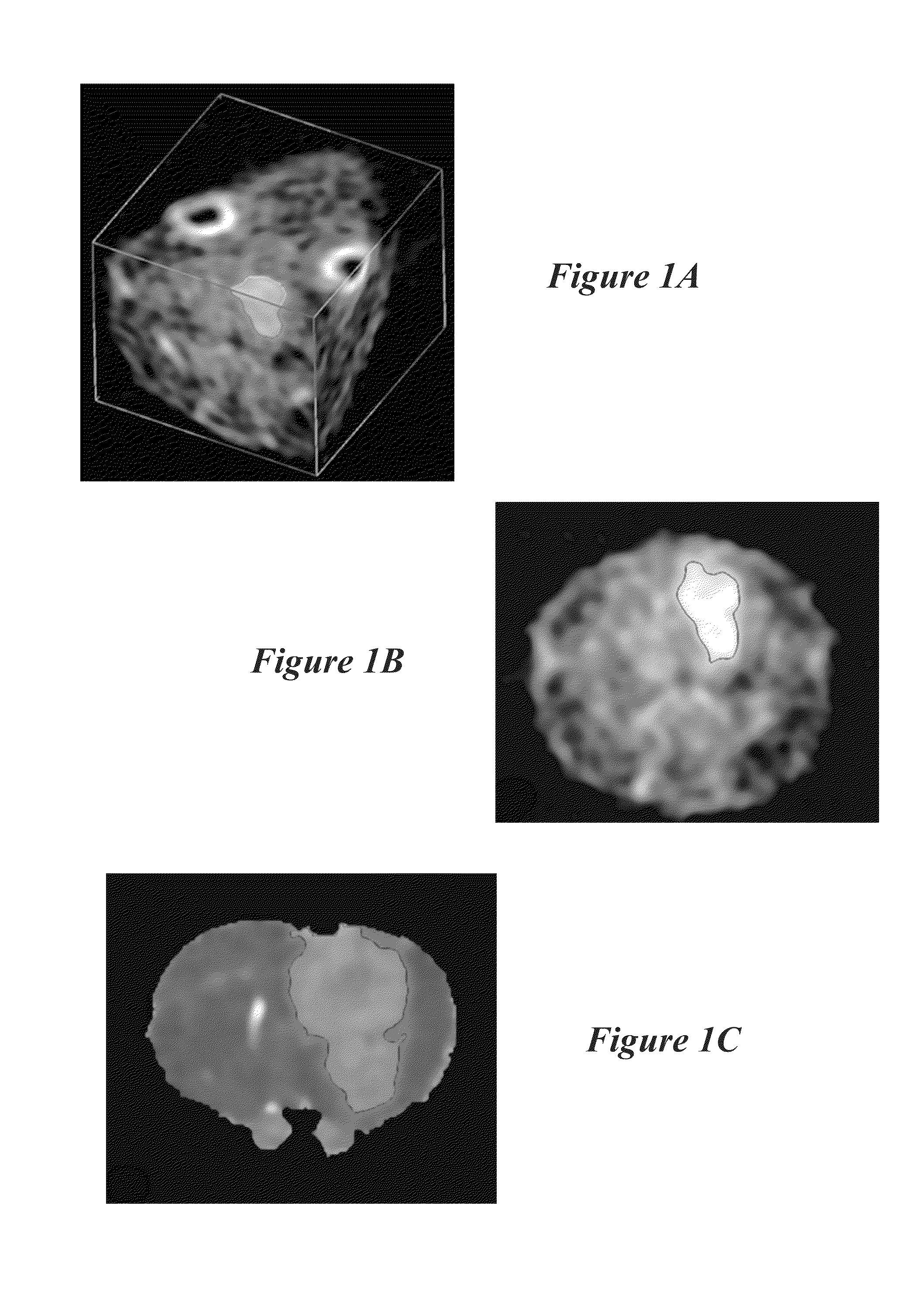

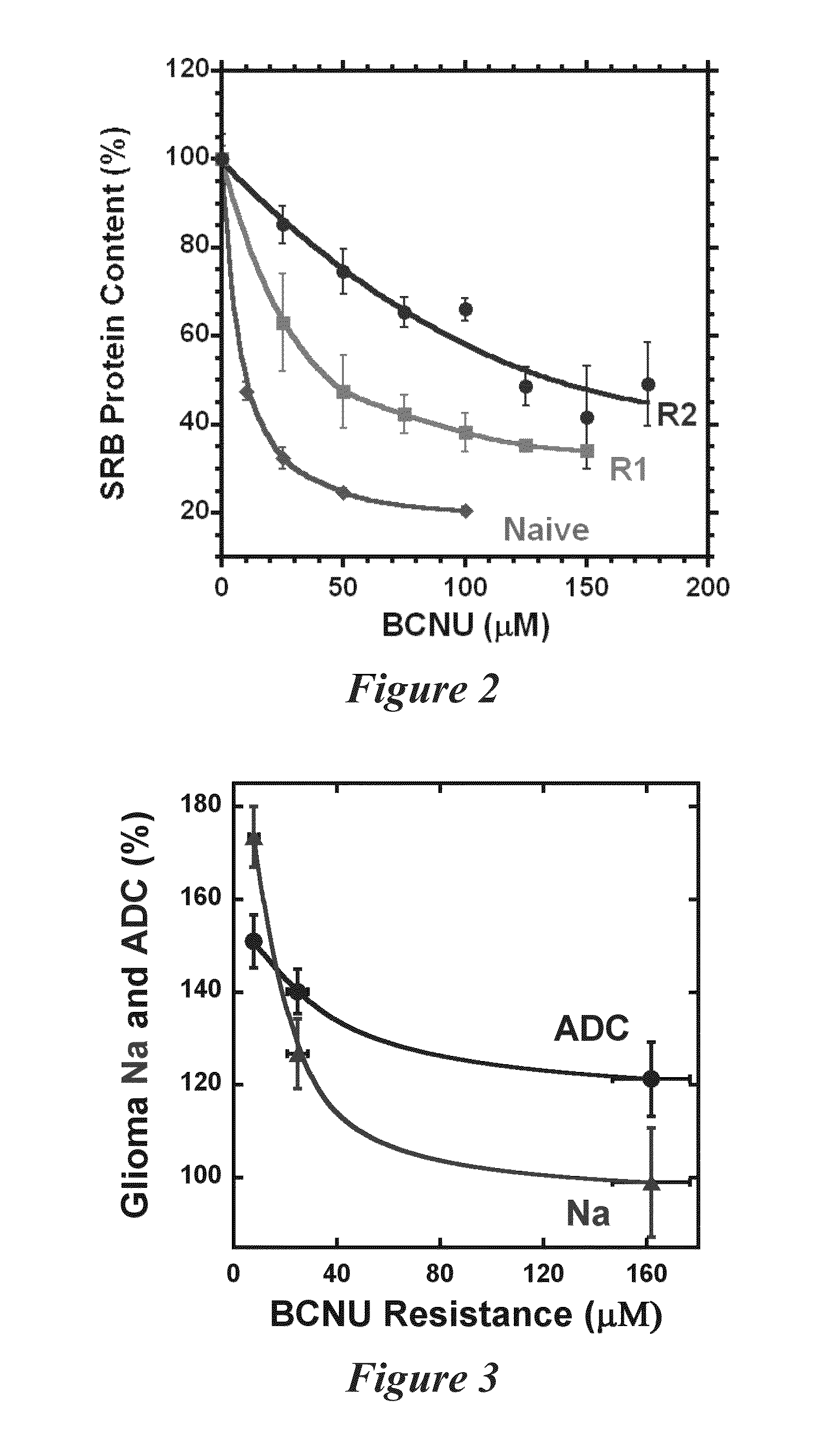

Tumor resistance and sodium/ diffusion MRI

ActiveUS8880146B1Safe and noninvasive assessment of tumor resistanceEasy to separateCharacter and pattern recognitionDiagnostic recording/measuringDiffusionBiomedical engineering

The present invention enables a safe and noninvasive assessment of tumor resistance using one diffusion or sodium MRI scan over the entire tumor. The evaluation can be done before therapy and can help select a strategy of treatment. The invention can be used in different types of tumors in most parts of the human body. The level of tumor resistance can be determined reproducibly and quickly. The results can be used immediately to create individualized therapy. The invention allows clinicians to avoid ineffective therapies, which may be more harmful than useful, or come up with the other more appropriate alternatives.

Owner:FLORIDA STATE UNIV RES FOUND INC

Parallel and Square Alignment Tool

ActiveUS20200215713A1Improve accuracyImprove efficiencyPortable power driven sawsMetal working apparatusMarking outEngineering

An alignment tool is disclosed for connection to a work component and for use in aligning the work component with a work piece to establish a repeatable set up for cutting or routing of the work piece, and wherein the alignment tool provides for parallel and square alignment of the work component relative to first and second edges of the work piece that are perpendicular to each other. Use of the parallel and square alignment tool aligns the work component for an operation parallel to the second edge of the work piece and the operation may be conveniently repeated on further work pieces without need to measure and mark the work pieces. Optional use of first and second parallel and square alignment tools along opposed second and third edges of a work piece that are perpendicular to a first edge provides for greater accuracy for operations having a greater length.

Owner:TSO PROD LLC

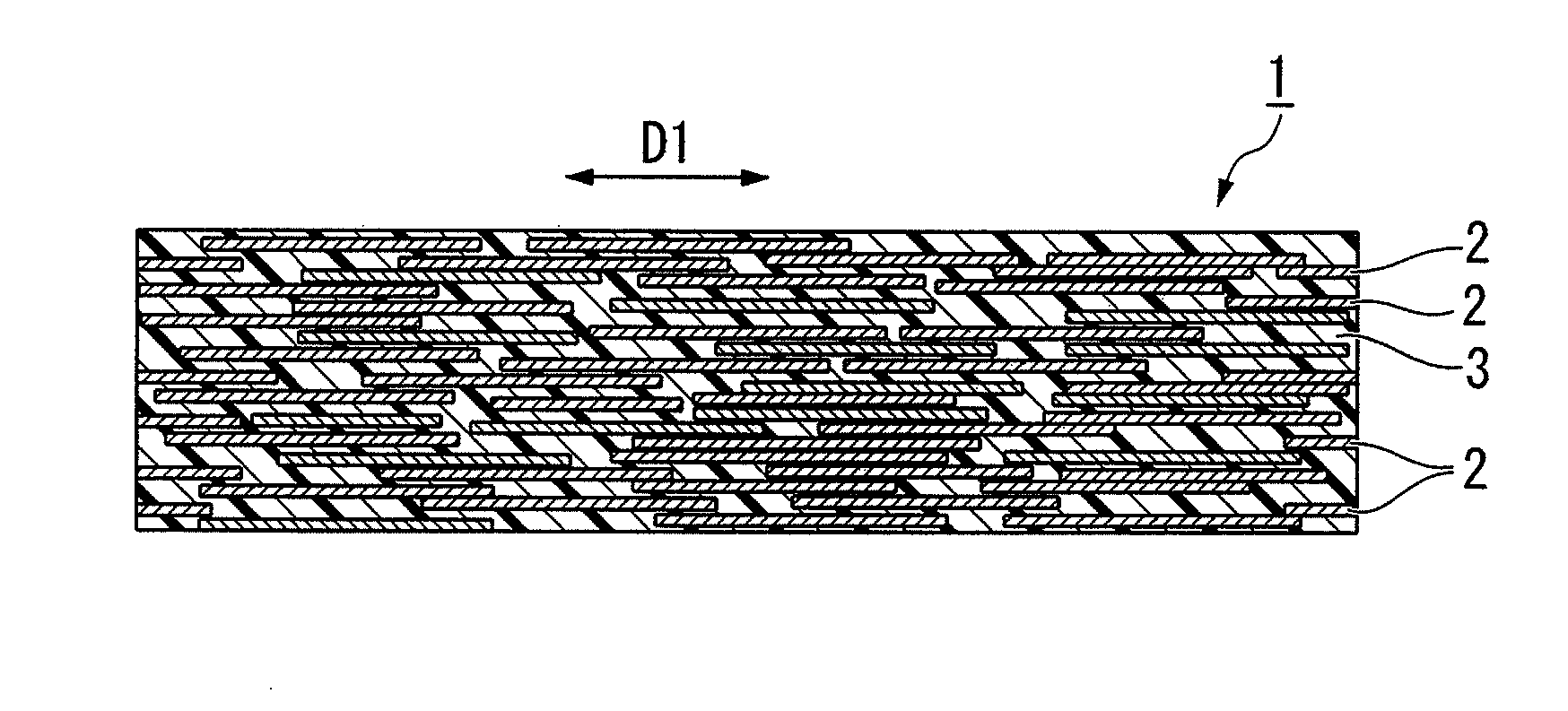

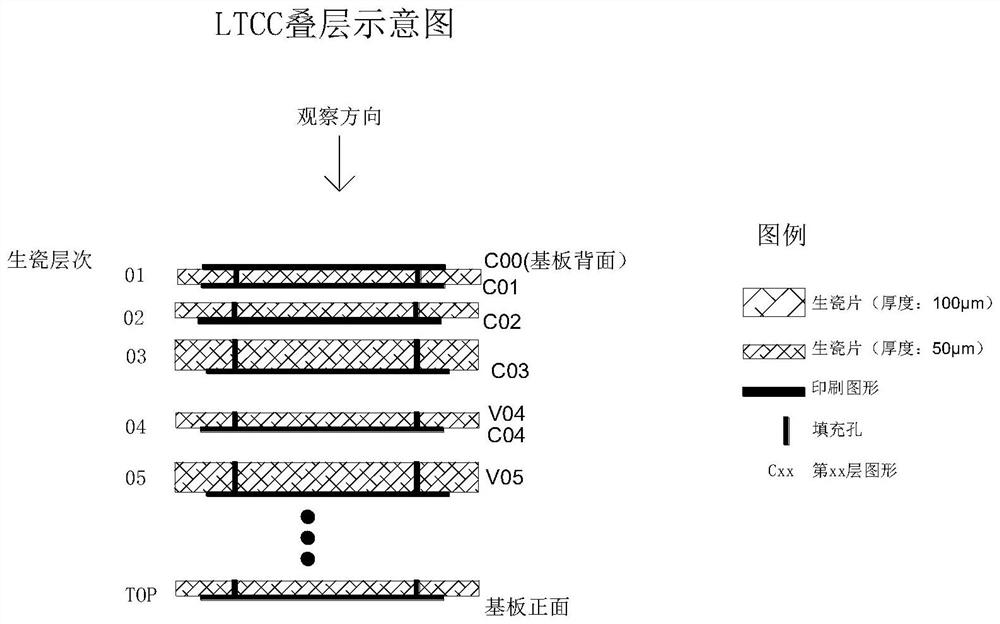

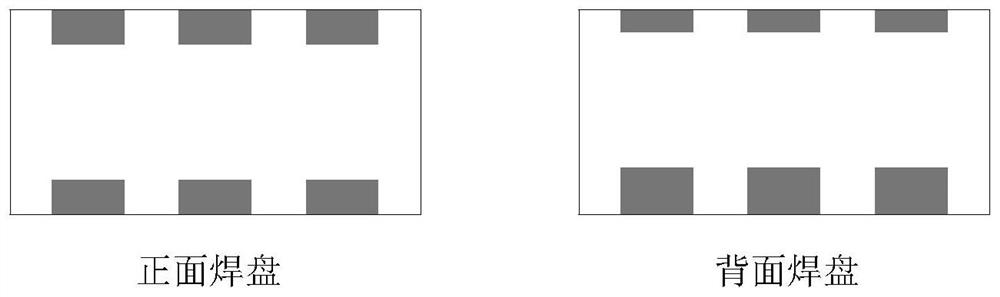

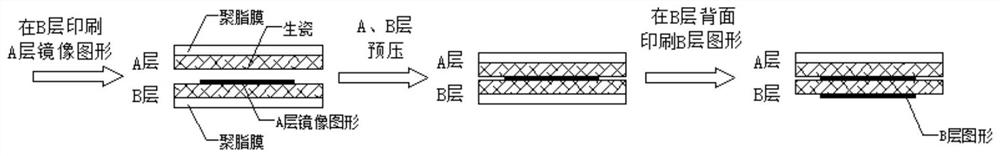

Method for improving LTCC interlayer alignment precision and preparation method of LTCC chip device

PendingCN114121896AImprove alignment accuracyEliminate the effect of bit accuracy between layersSemiconductor/solid-state device detailsSolid-state devicesMaterials sciencePhysics

The invention provides a method for improving the interlayer alignment precision of LTCC and a preparation method of an LTCC chip device, and the alignment method comprises the steps: printing two adjacent layers of patterns with higher alignment precision requirements on the front and back surfaces of the same piece of raw ceramic, employing the same printing aligner during the printing of the front and back surfaces, eliminating the influence of positioning pins and punching precision on the interlayer alignment precision, and improving the alignment precision of the LTCC chip device. And the interlayer alignment precision of adjacent layers of the LTCC substrate is improved.

Owner:SUZHOU R&D CENT OF NO 214 RES INST OF CHINA NORTH IND GRP

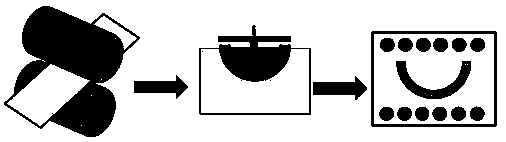

Method for improving performance of bearing bush steel backing

InactiveCN109402366AAdjustable lifting hardnessHigh hardnessFurnace typesHeat treatment furnacesHardnessUltimate tensile strength

The invention discloses a method for improving performance of a bearing bush steel backing. The method comprises the following steps that S1, rolling treatment is conducted, specifically, a platy bearing bush raw material passes through a gap between a pair of rotating rollers, the platy bearing bush raw material is compressed by the rollers, and thus the section of the platy bearing bush raw material is reduced; S2, press-bending shaping is conducted, specifically, the rolled platy bearing bush raw material is bent in a pressed mode through a bending press, and thus the rolled platy bearing bush raw material is in a semicircular shape; and S3, low-temperature heat treatment is conducted, specifically, the platy bearing bush raw material subjected to press-bending shaping is put into a heat treatment machine to be heated, after heating, dimensional processing and coating treatment are conducted, and thus a finished bearing bush is obtained. According to the method for improving the performance of the bearing bush steel backing, the hardness of the bearing bush steel backing can be adjusted and improved, the deformation stability of the bearing bush is improved, by controlling the hardness of the steel backing, the design requirement is met, the dimensional change amount of the bearing bush is decreased, the stability of assembly and operation is improved, and the problem that the strength of an existing bearing bush steel backing is low, consequently, the bearing bush steel backing is prone to deforming in the assembly and operation processes, and normal use is affected issolved.

Owner:MIBA PRECISION COMPONENTS CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com