Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39results about How to "High-precision pattern" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

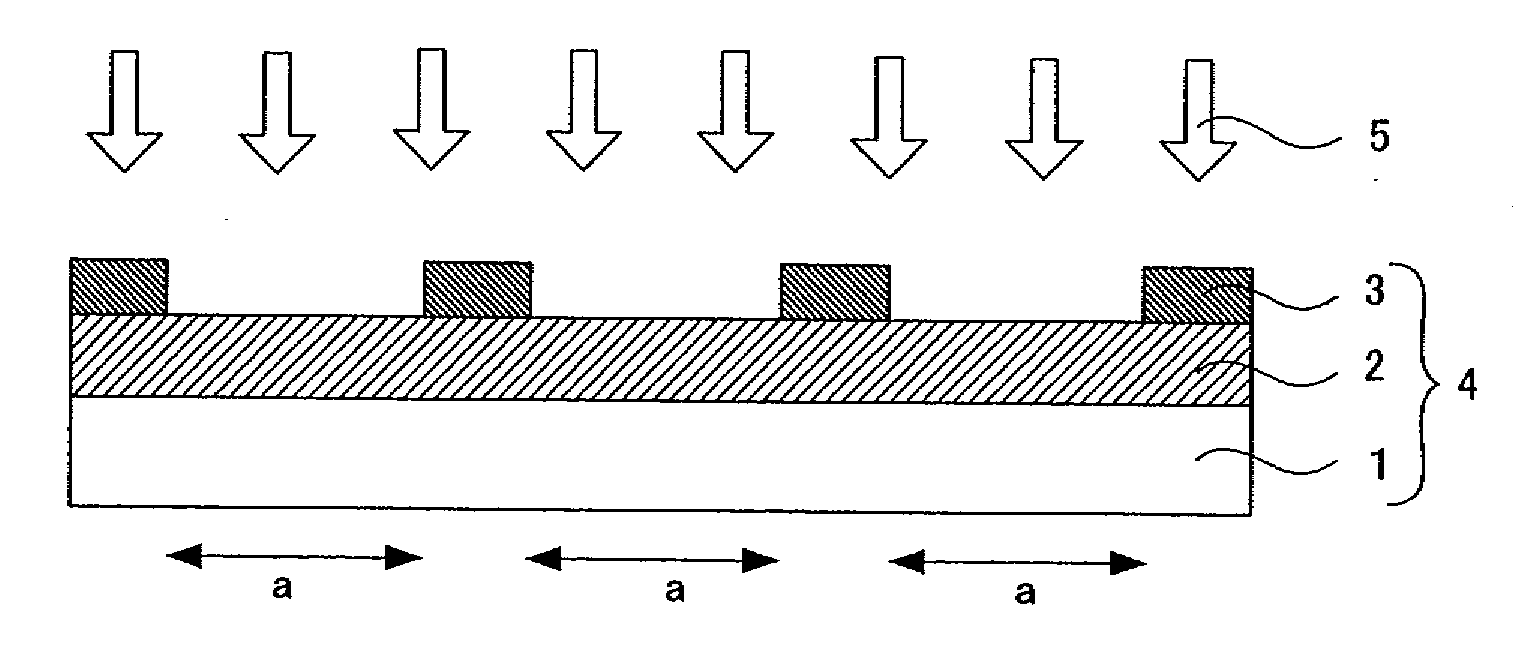

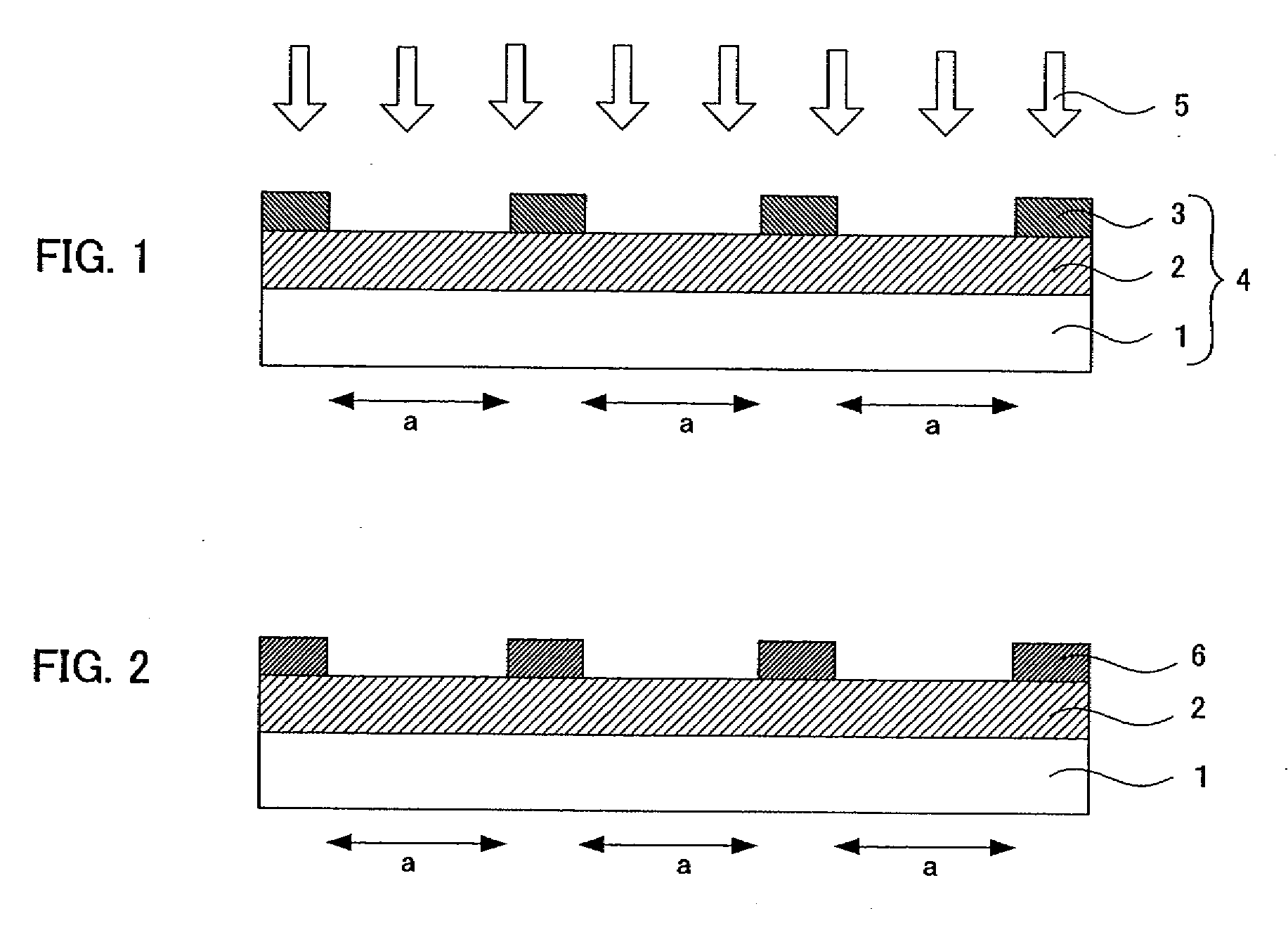

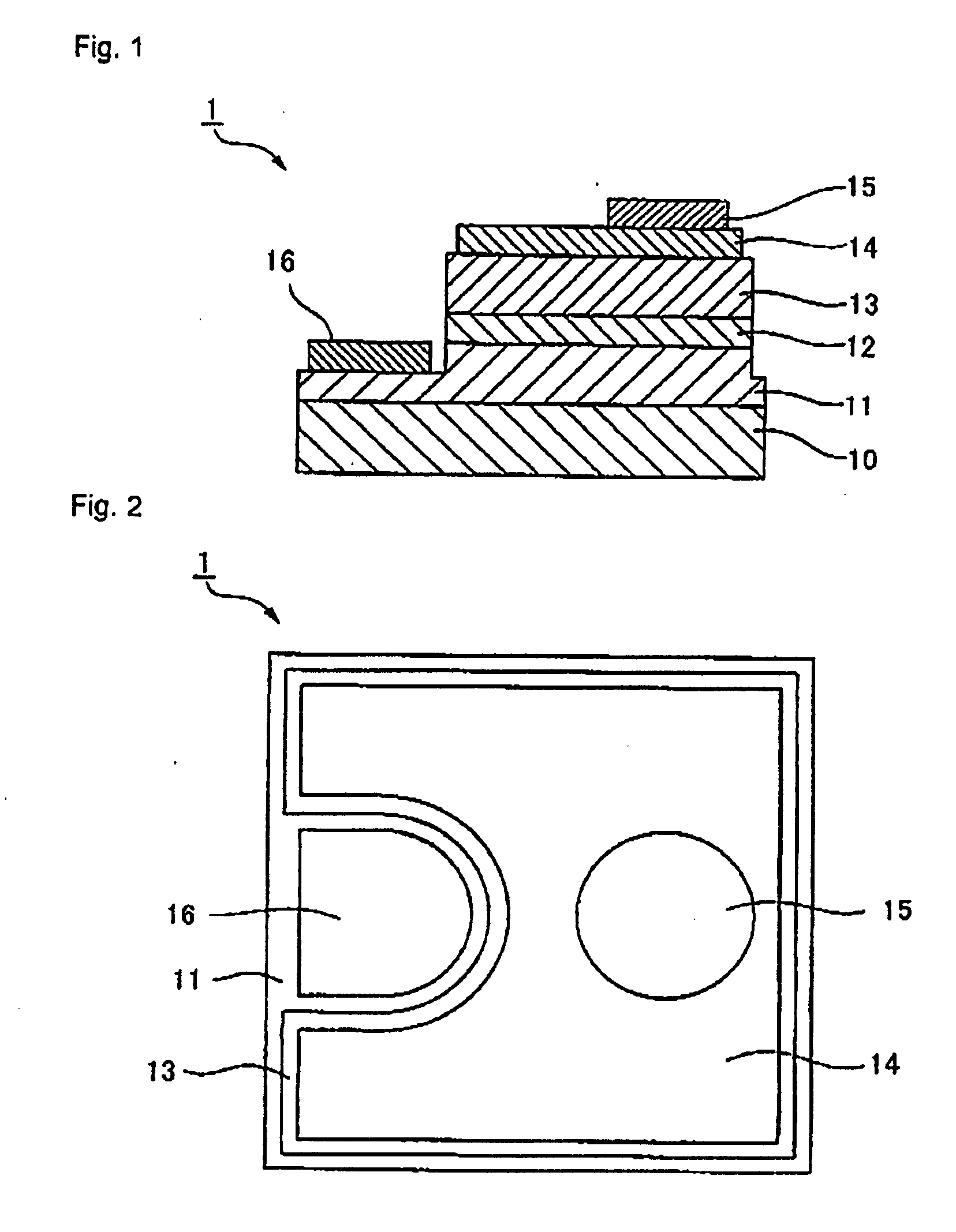

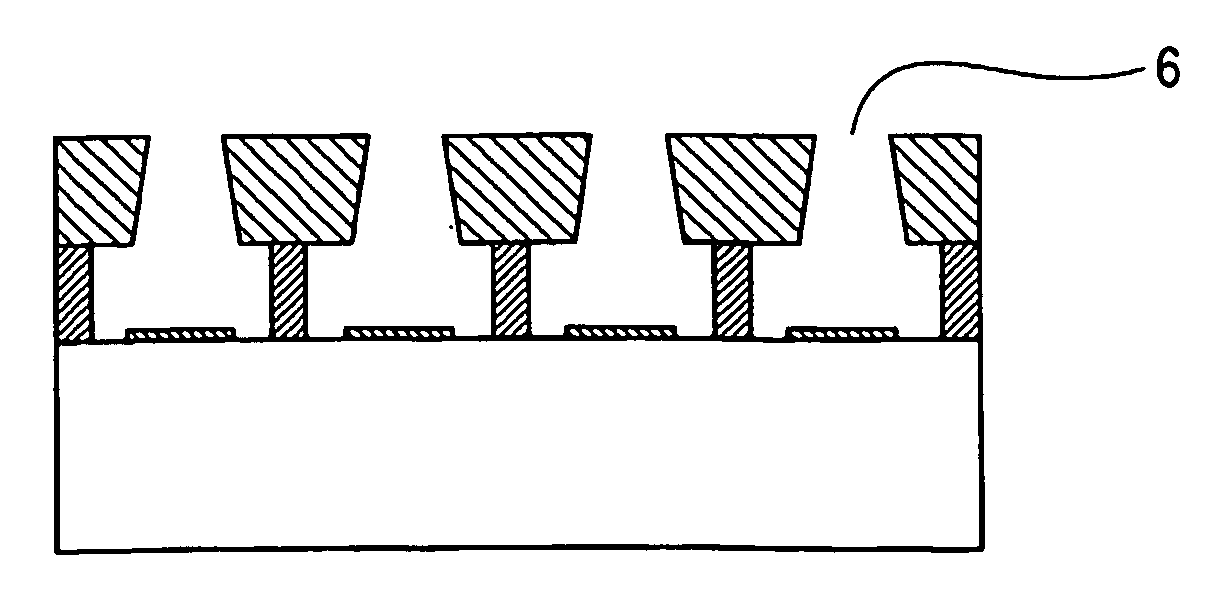

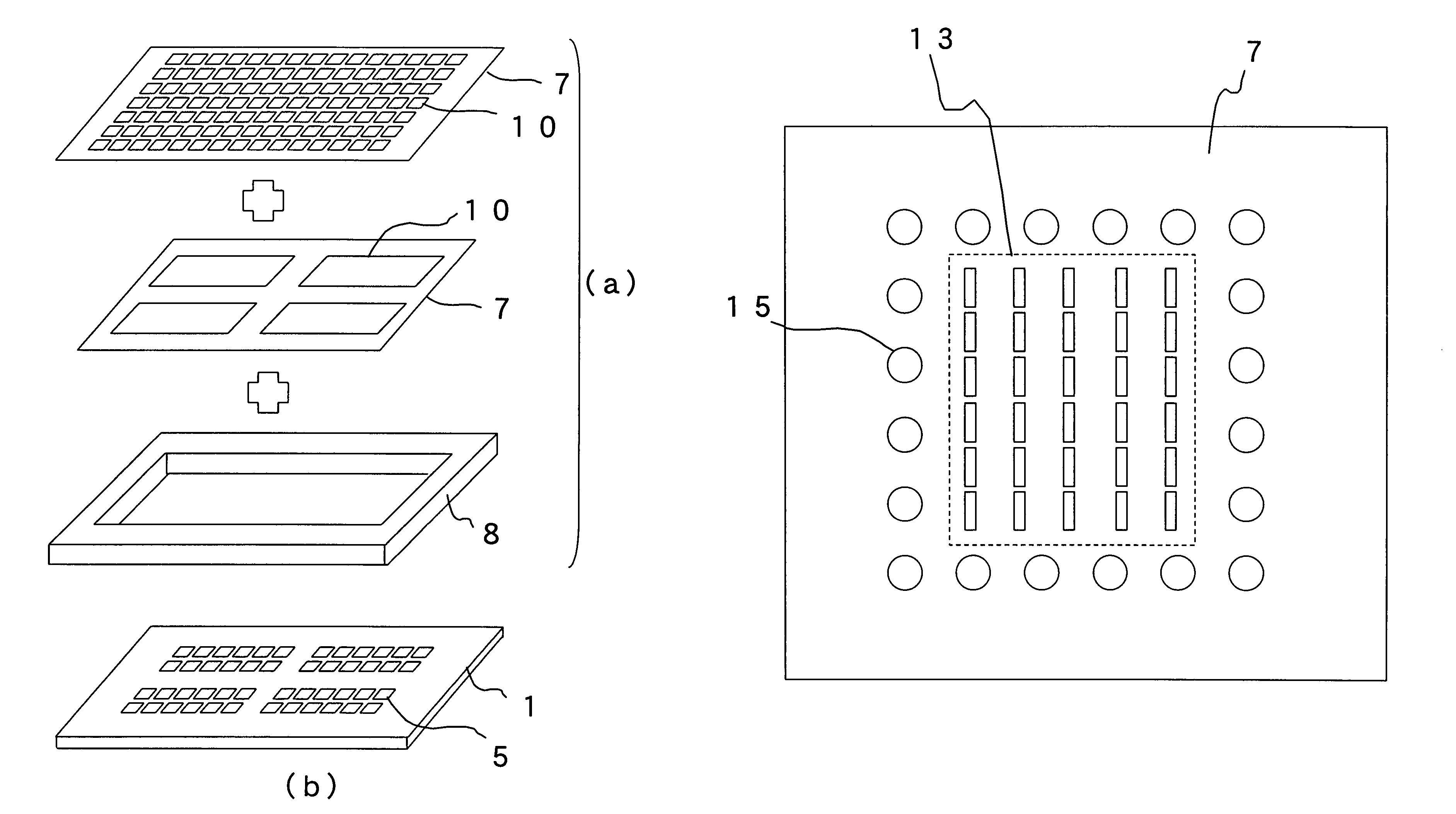

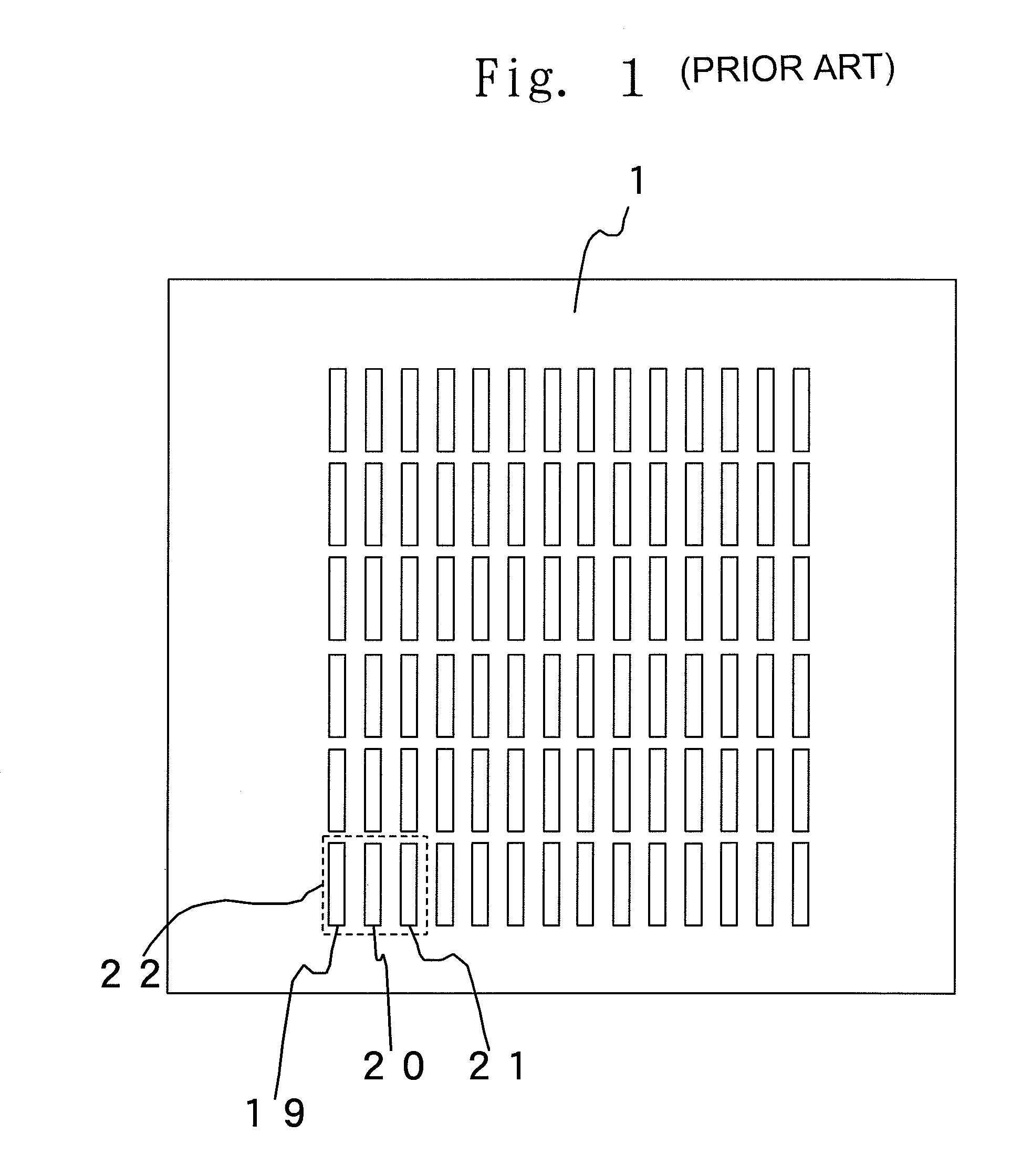

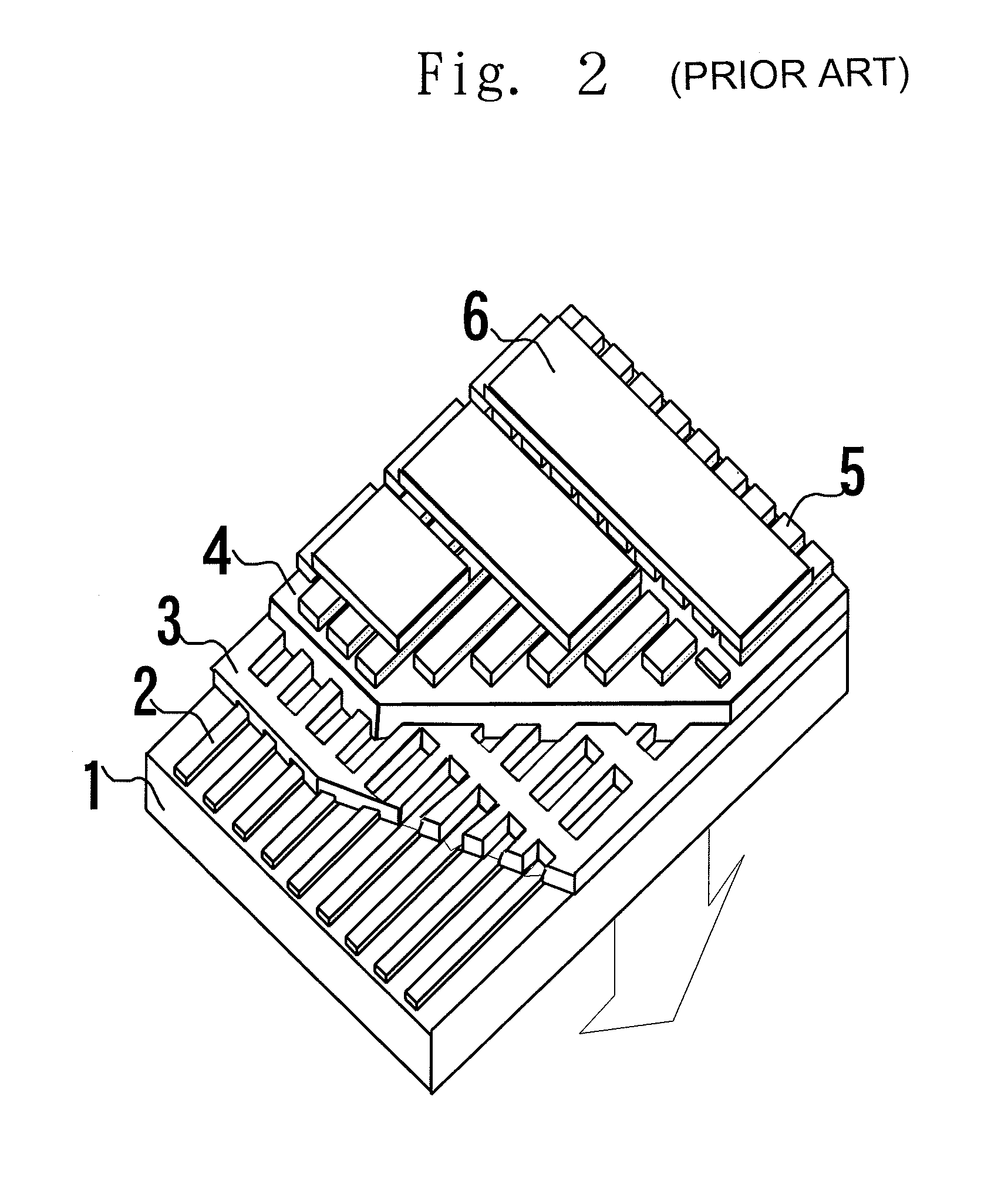

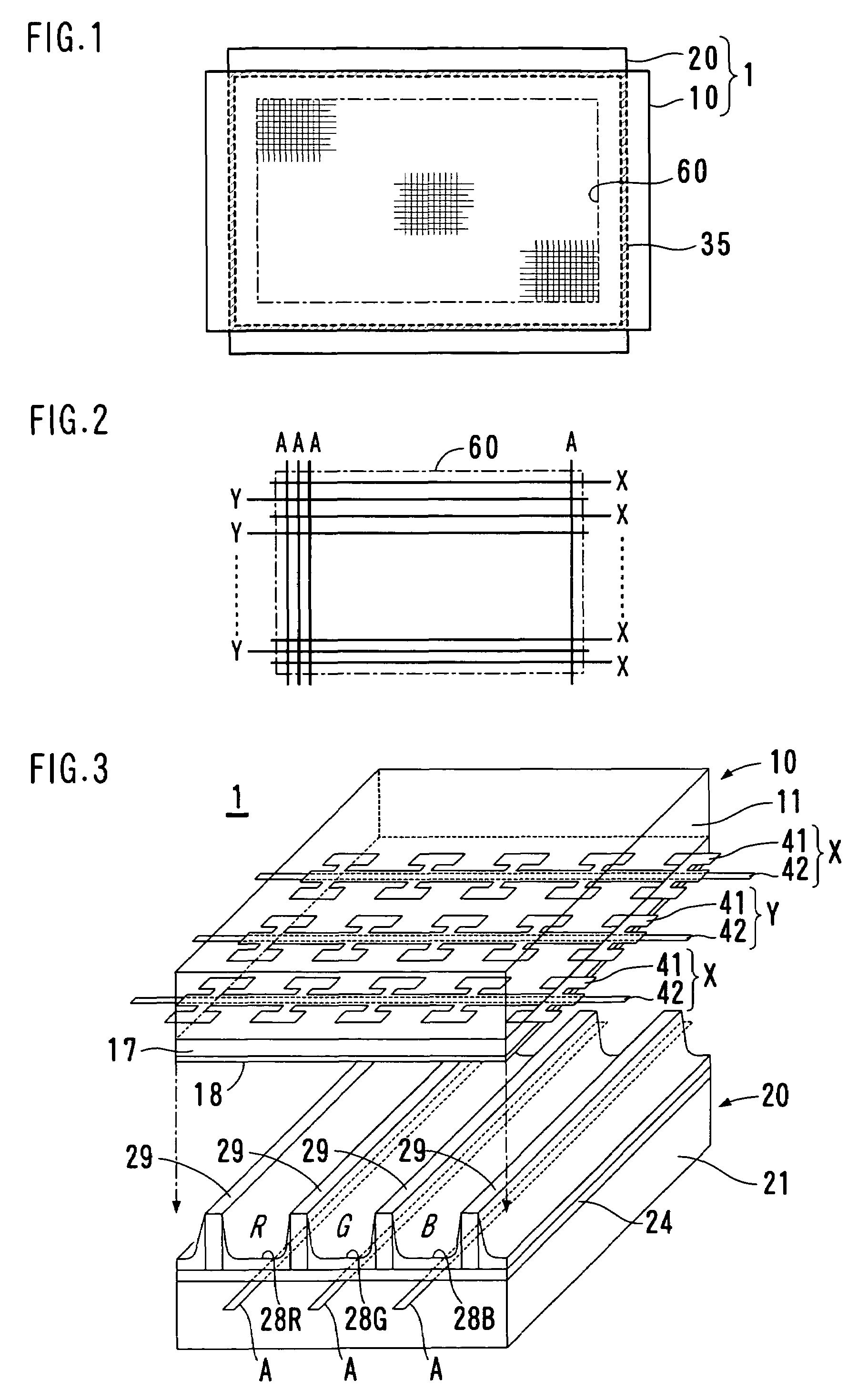

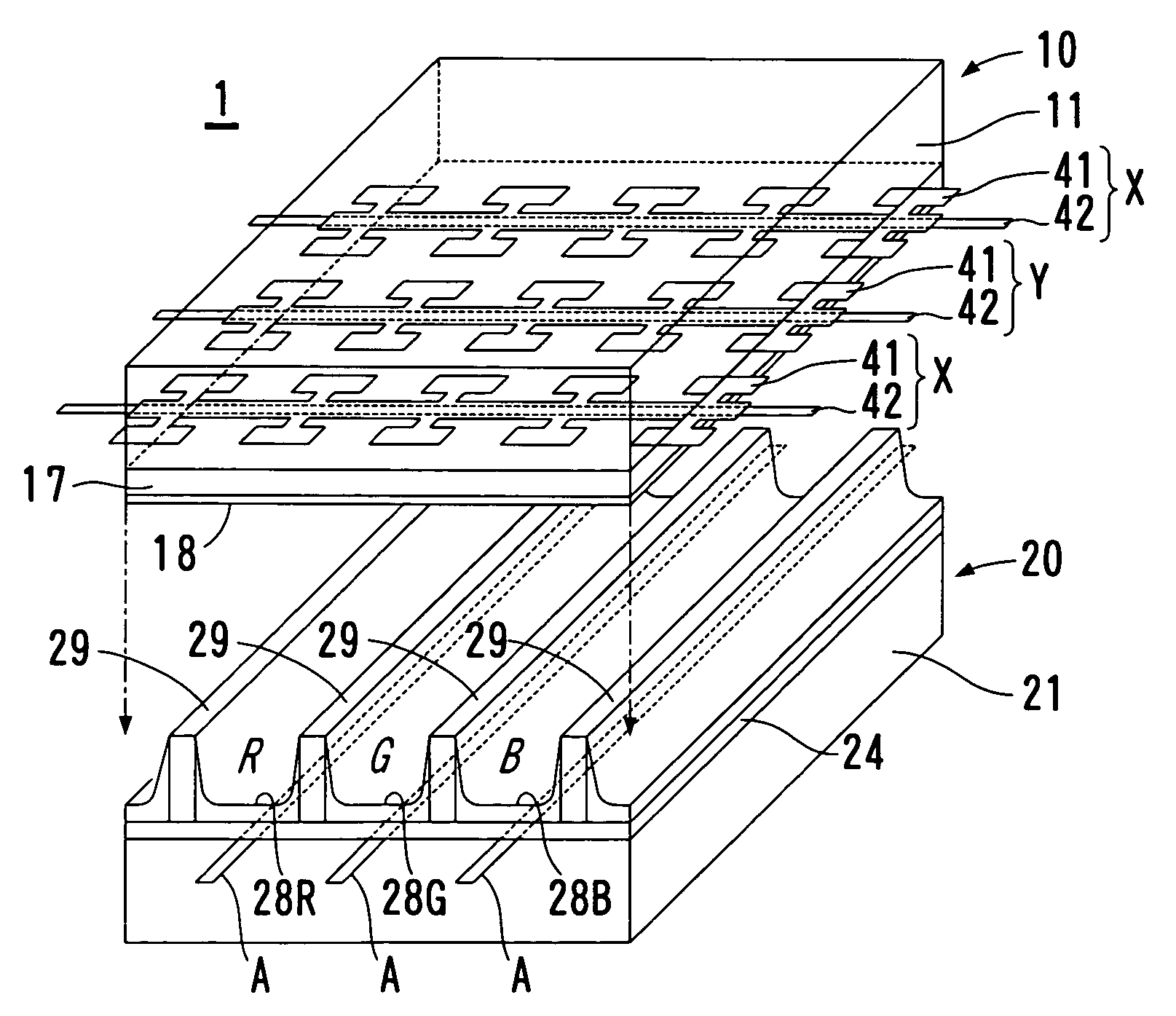

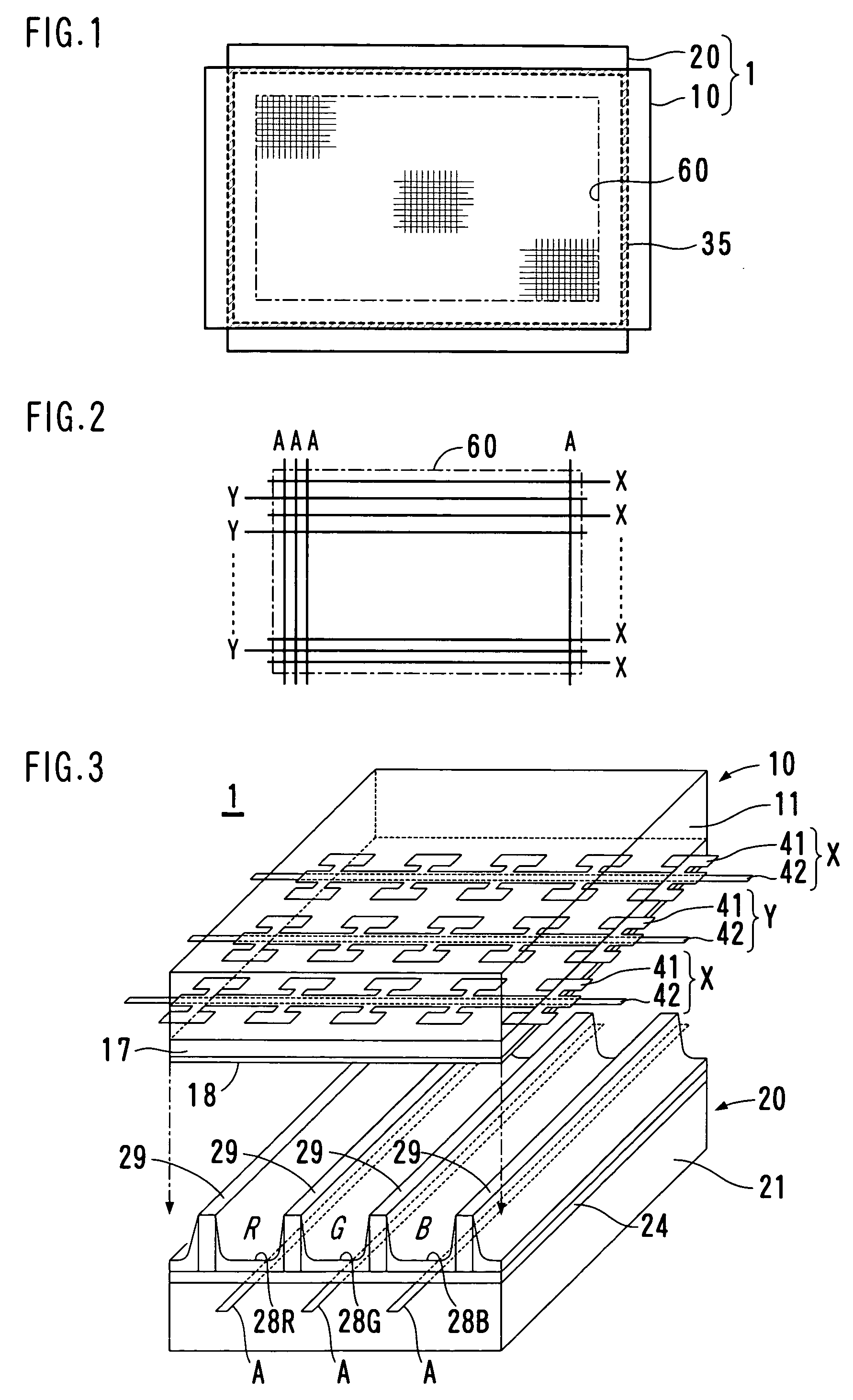

Organic Electroluminescent Device and Manufacturing Method Thereof

InactiveUS20080018236A1Improve display qualityHigh-precision patternLiquid surface applicatorsDischarge tube luminescnet screensOrganic electroluminescenceLight-emitting diode

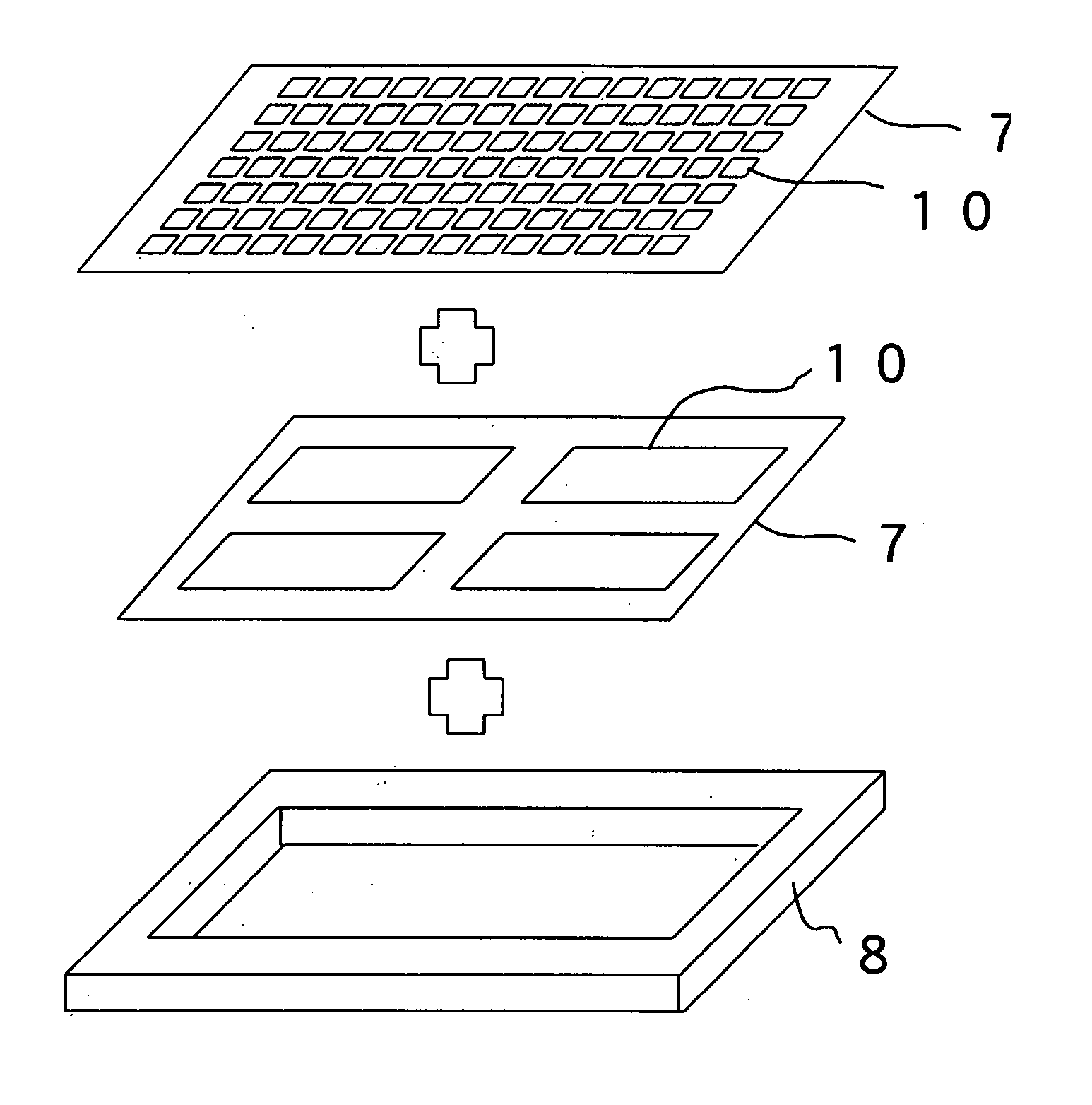

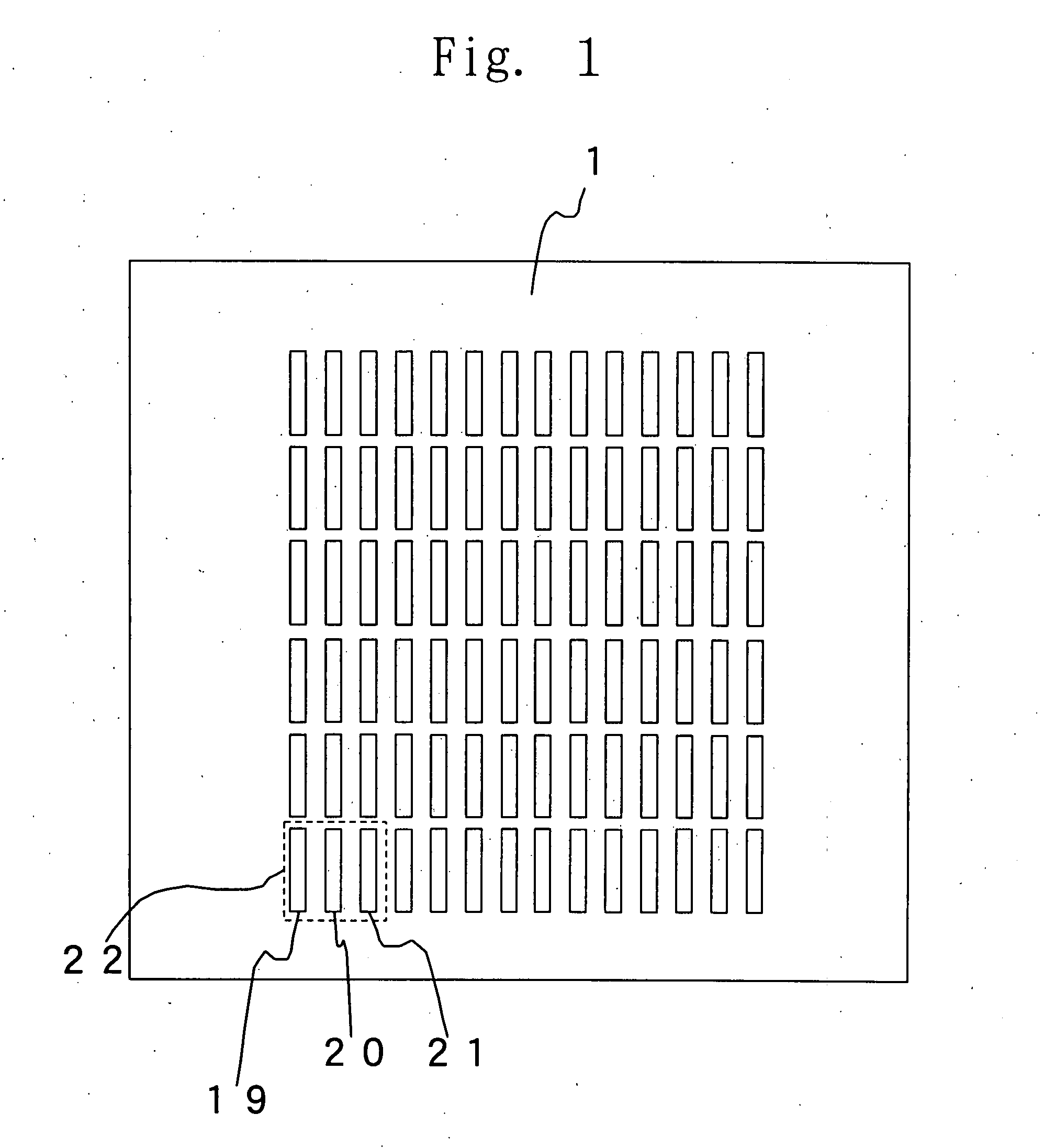

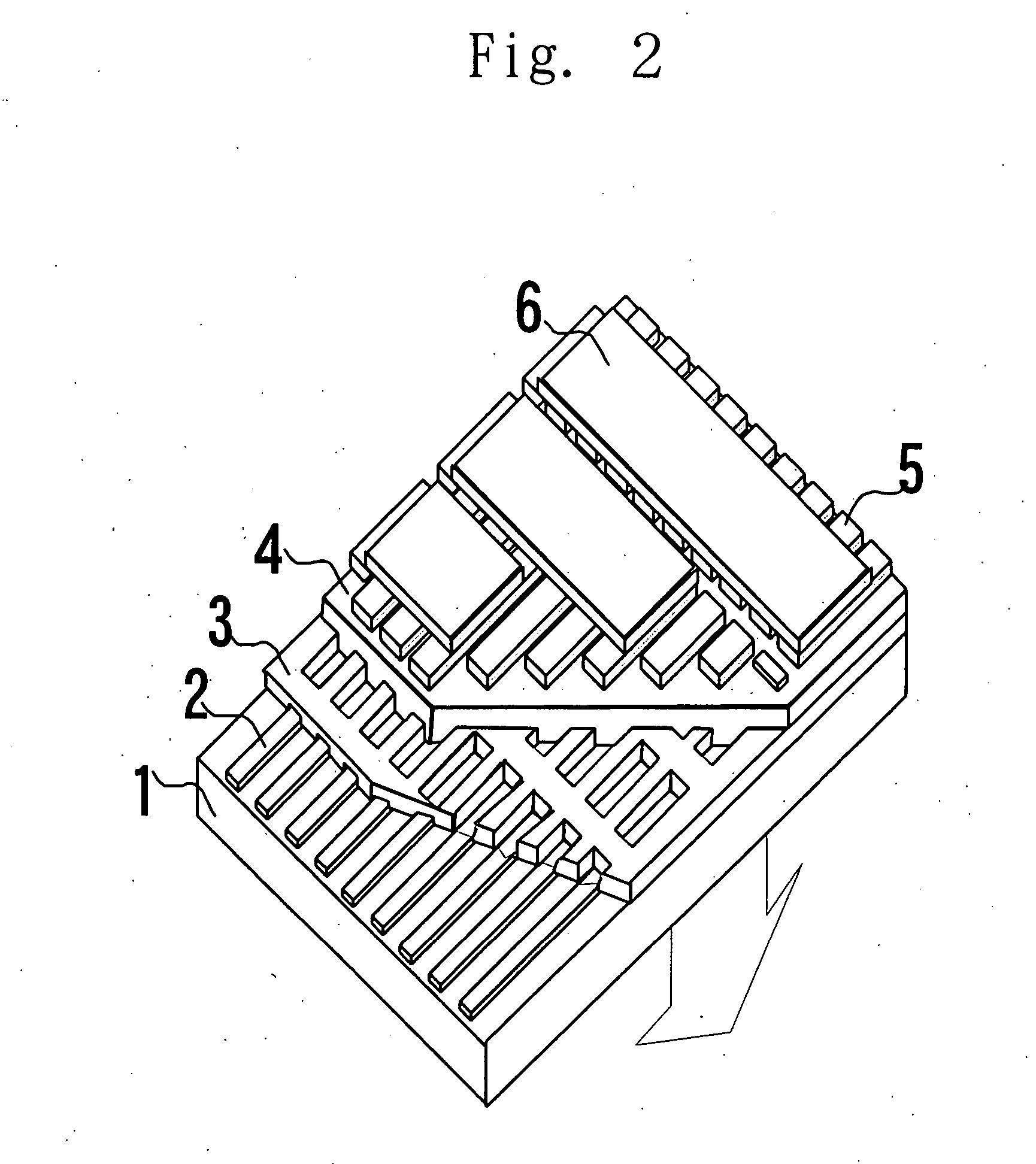

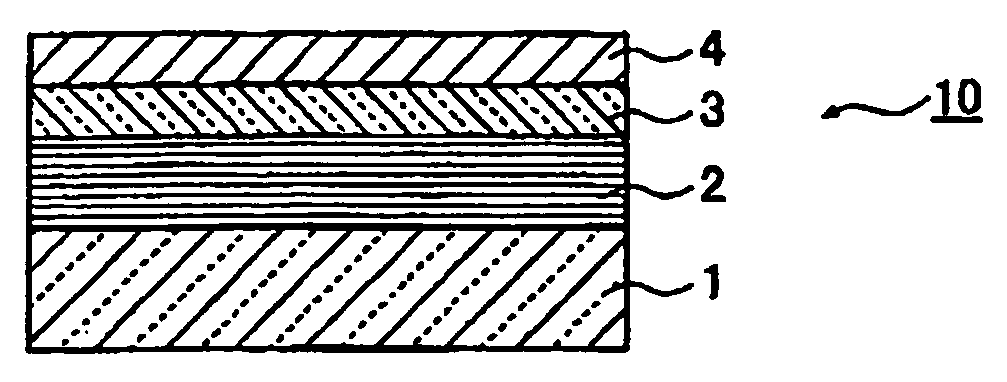

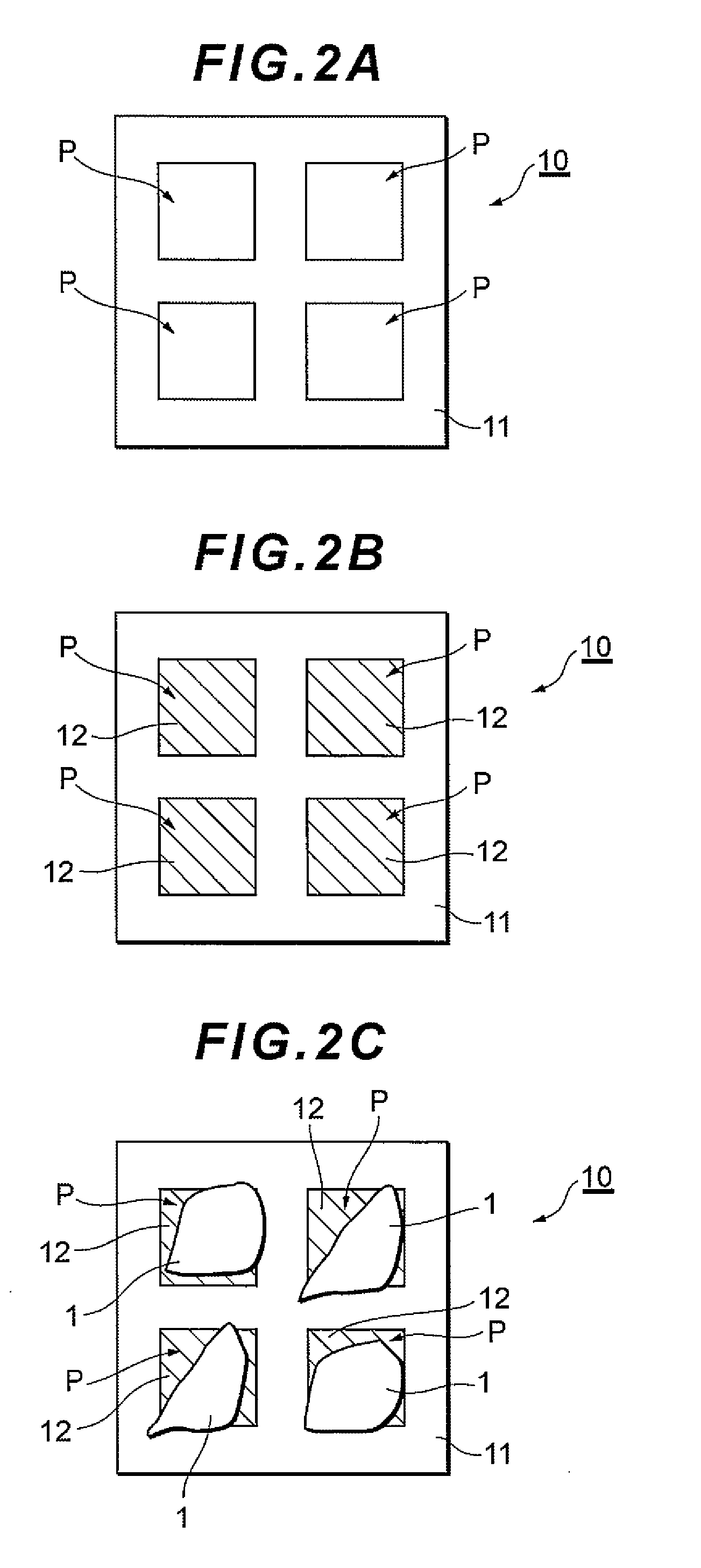

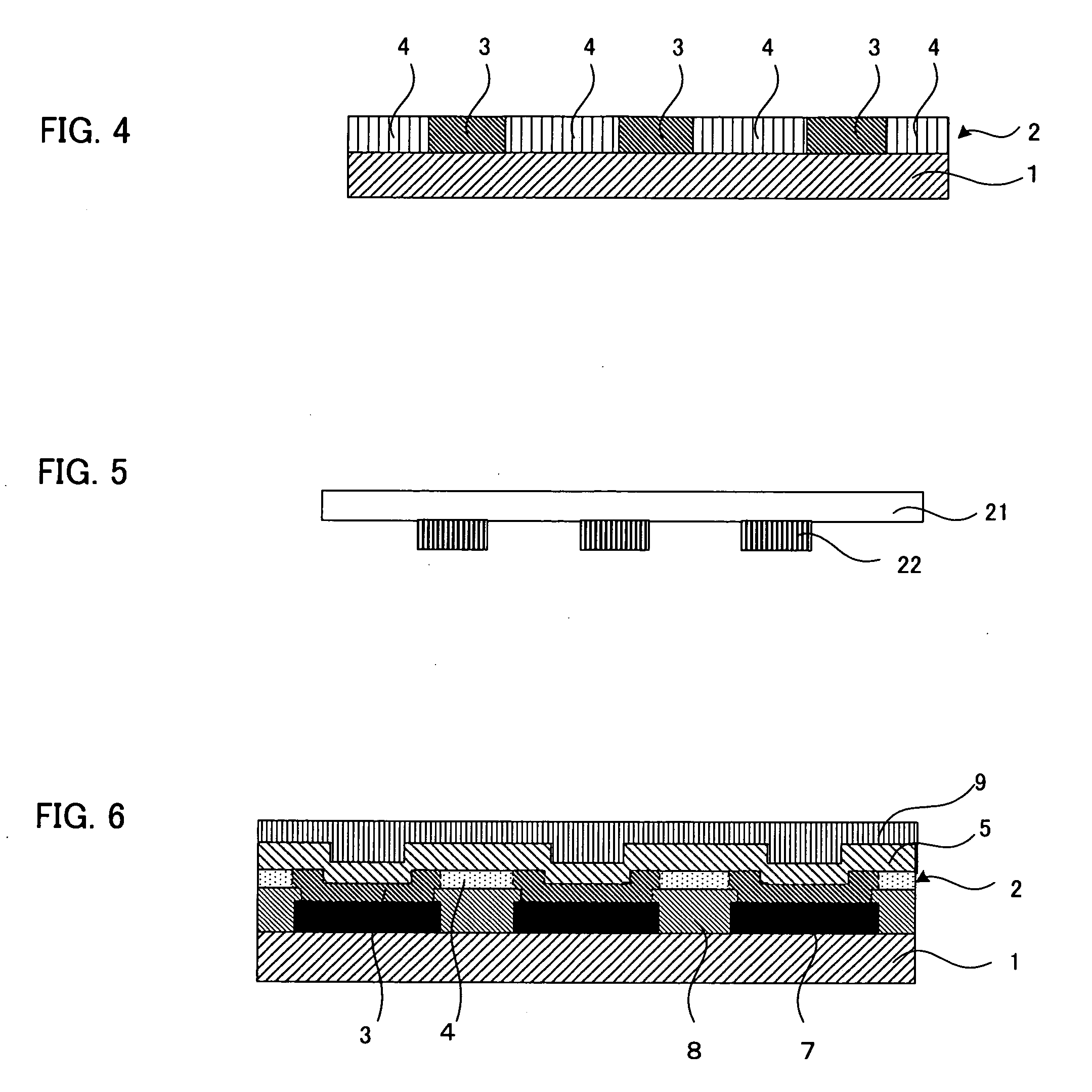

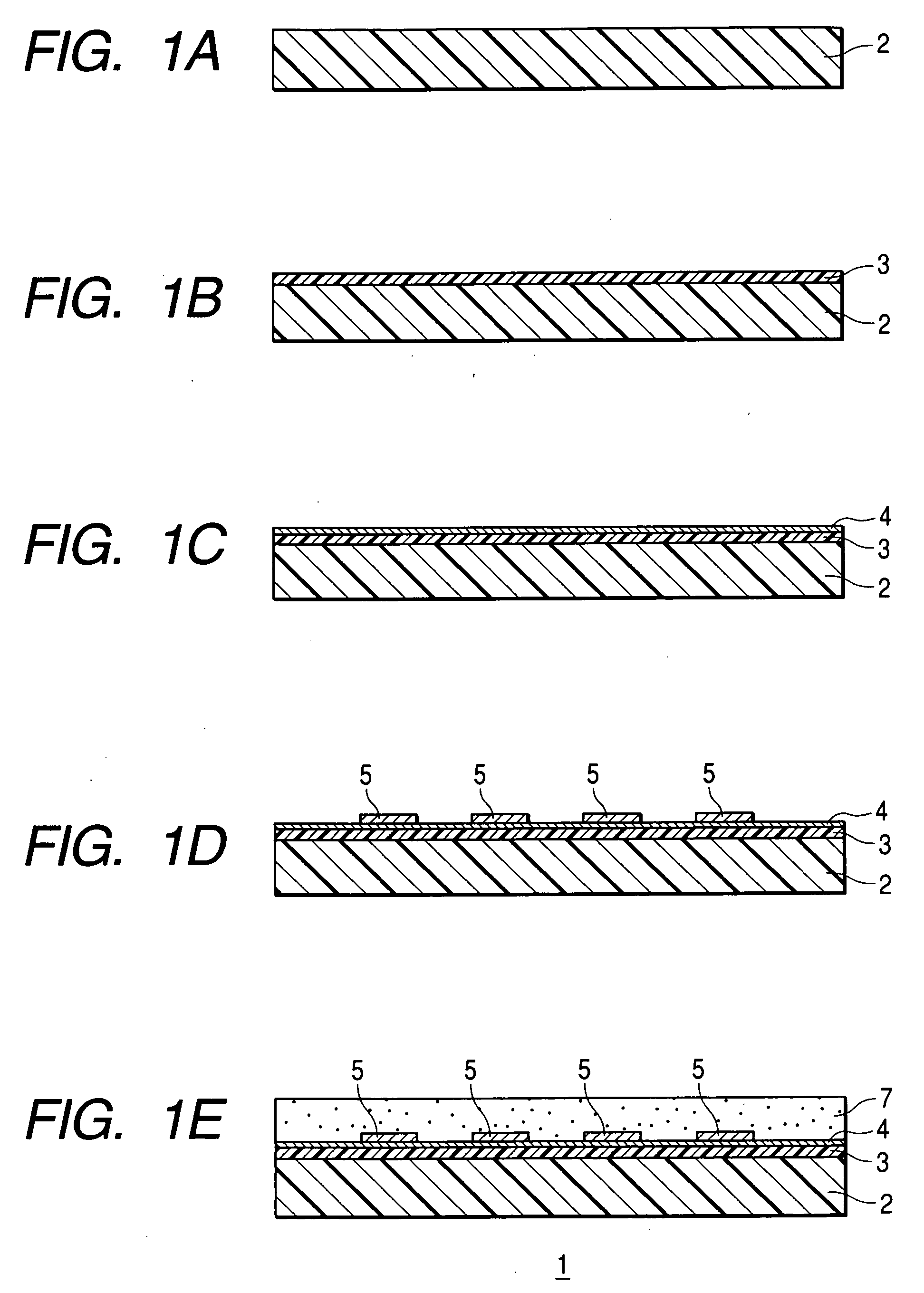

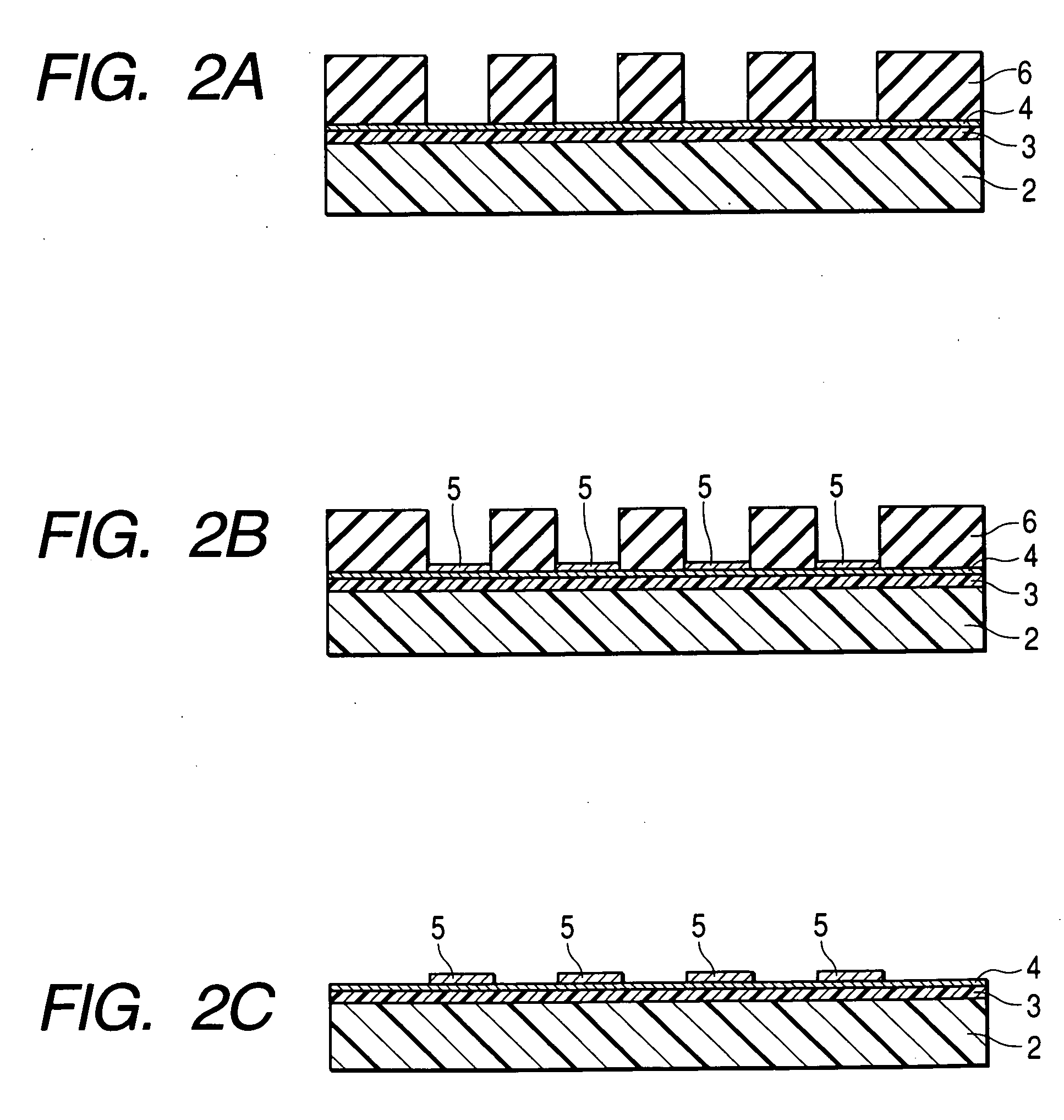

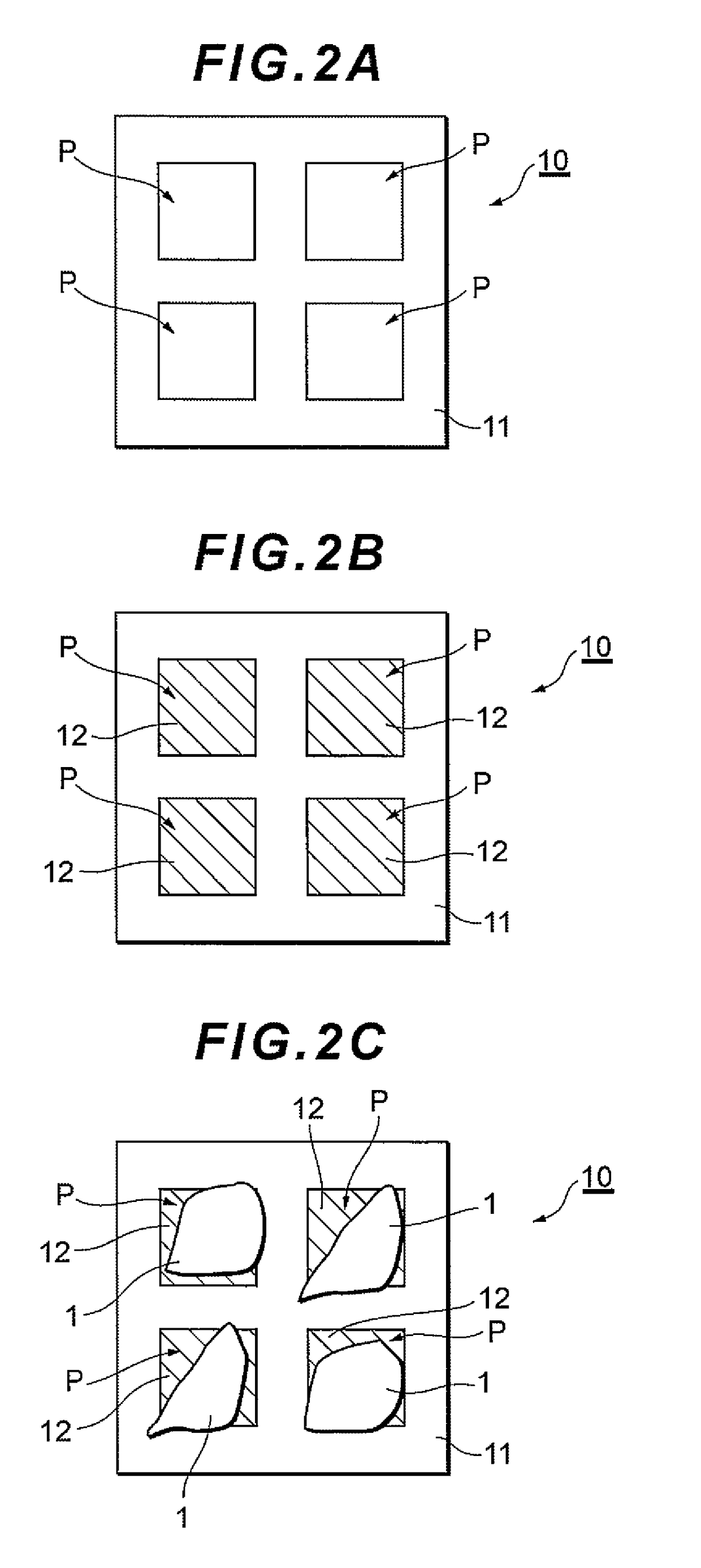

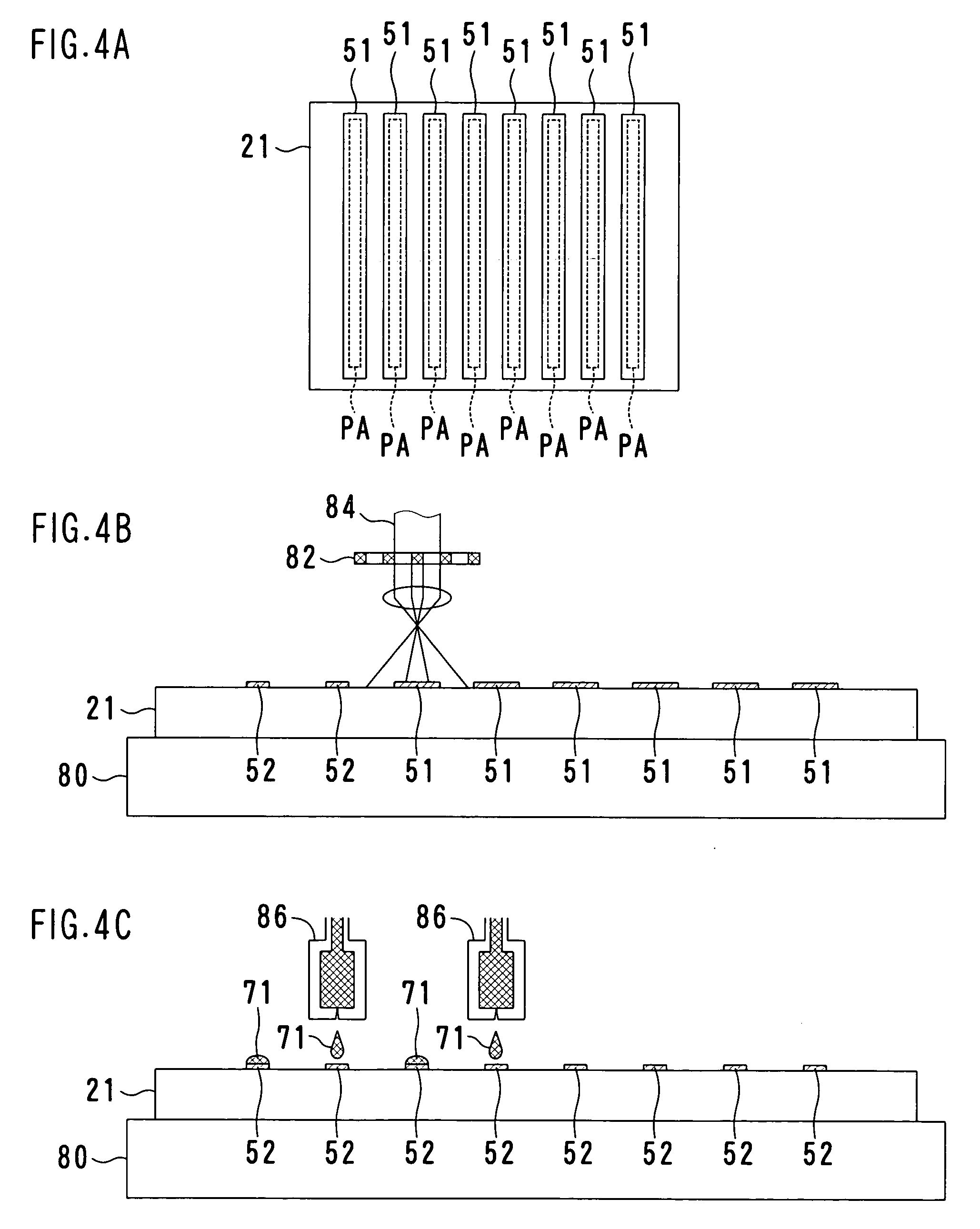

A highly fine organic electroluminescent device is provided. A method for manufacturing the organic electroluminescent device is provided for patterning a very fine light emitting layer, and a deposition mask is provided to be used in the patterning. For deposition of the light emitting layer, a mask member is provided with apertures (effective apertures) for forming the light emitting layer to be used for light emitting pixel and apertures (dummy apertures) not to be used for forming the light emitting pixel around an area (effective aperture area) separated by the outer edge of a group of the apertures. The light emitting layer is deposited by using the deposition mask.

Owner:TORAY IND INC

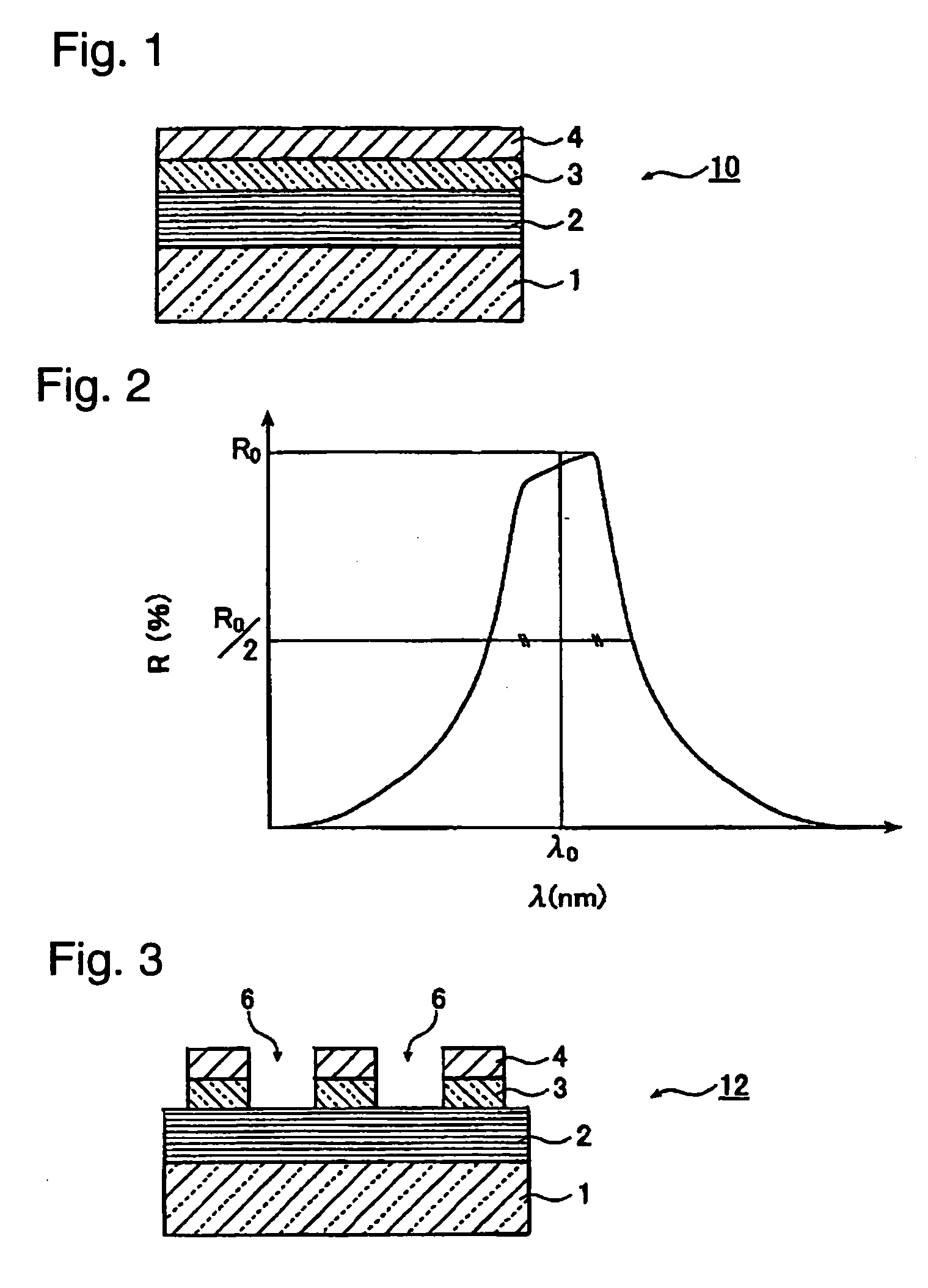

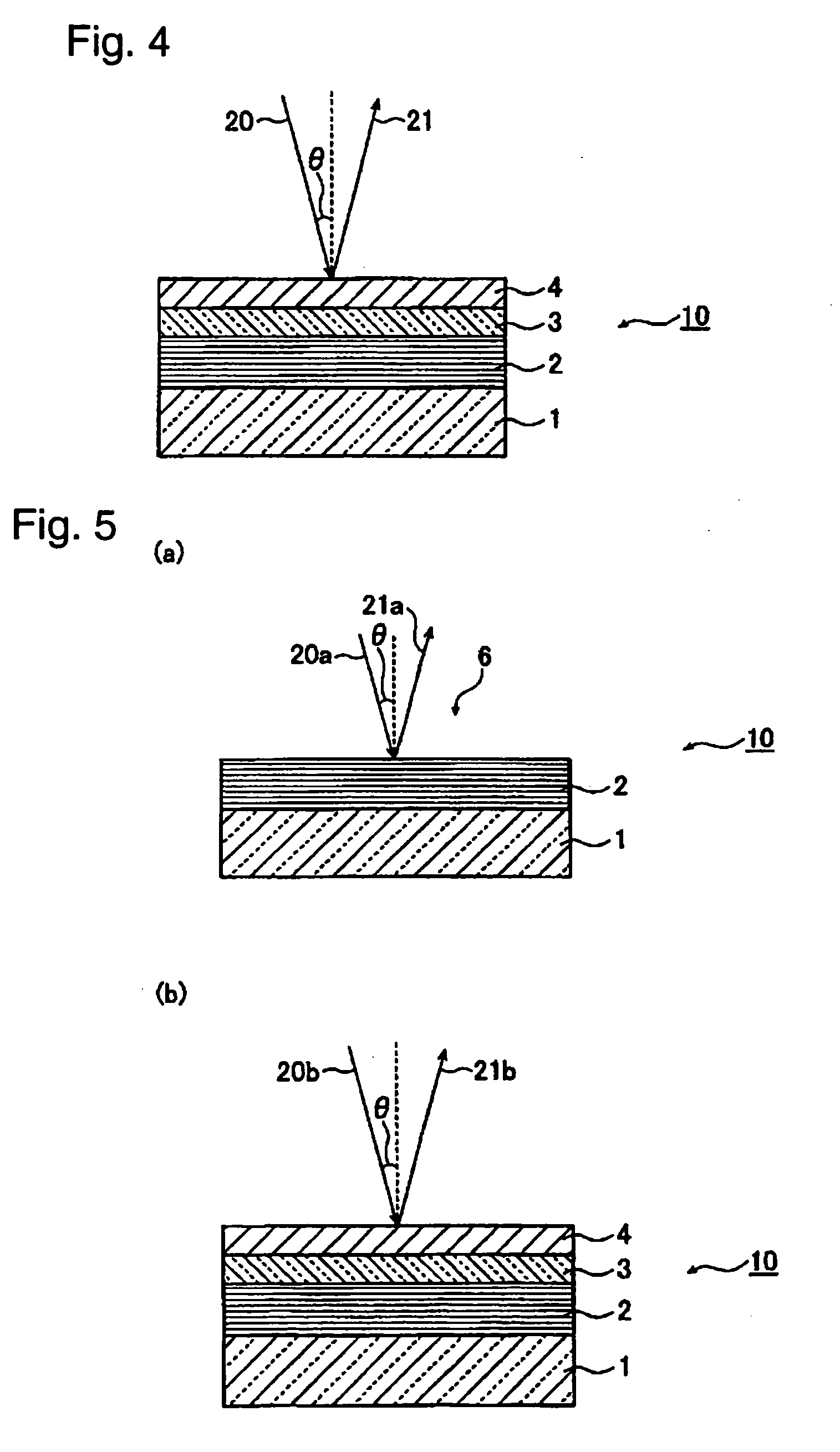

Reflective-type mask blank for EUV lithography and method for producing the same

InactiveUS20060251973A1Increase contrastImprove accuracyRadiation/particle handlingNanoinformaticsLithographic artistReflective layer

A reflective-type mask blank for EUV lithography for reducing the EUV ray reflectance at the absorbing layer and a method for producing the mask blank are presented. A reflective-type mask blank for EUV lithography comprising a substrate and a reflective layer for reflecting EUV light and an absorbing layer for absorbing EUV light, which are formed on the substrate in this order, the reflective-type mask blank for EUV lithography being characterized in that the absorbing layer is a Cr layer of low EUV ray reflectance deposited by an ion beam sputtering method.

Owner:ASAHI GLASS CO LTD

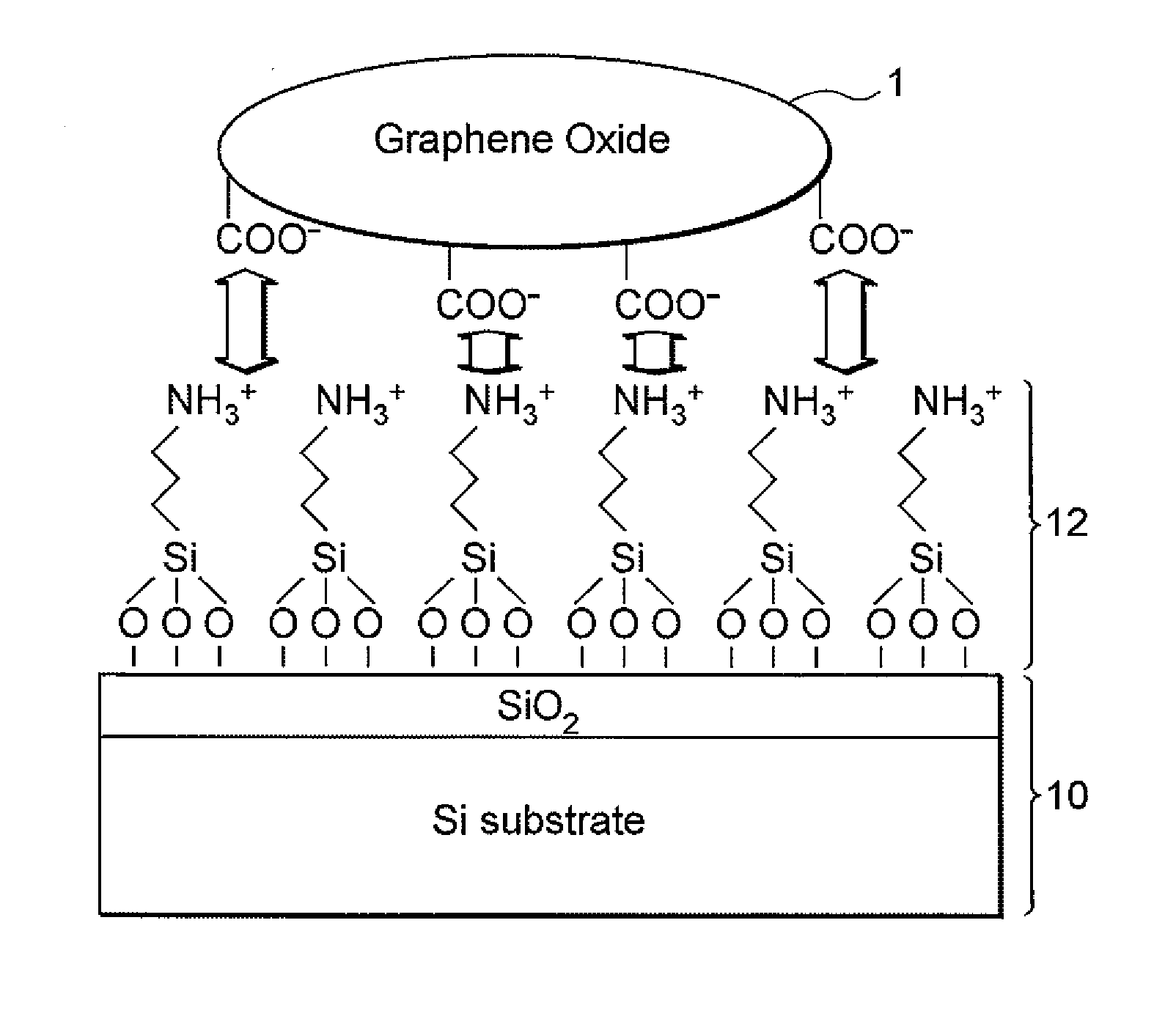

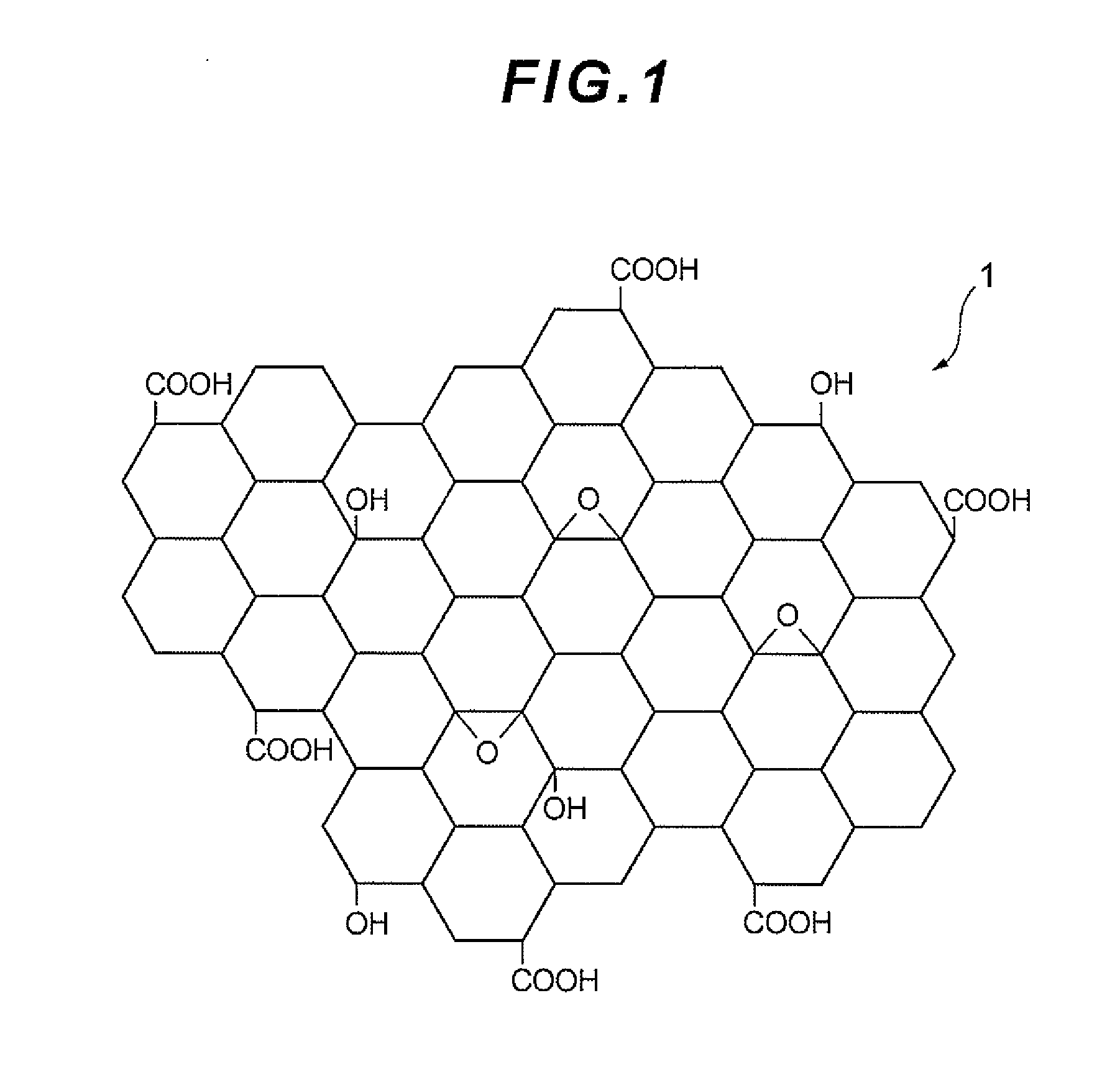

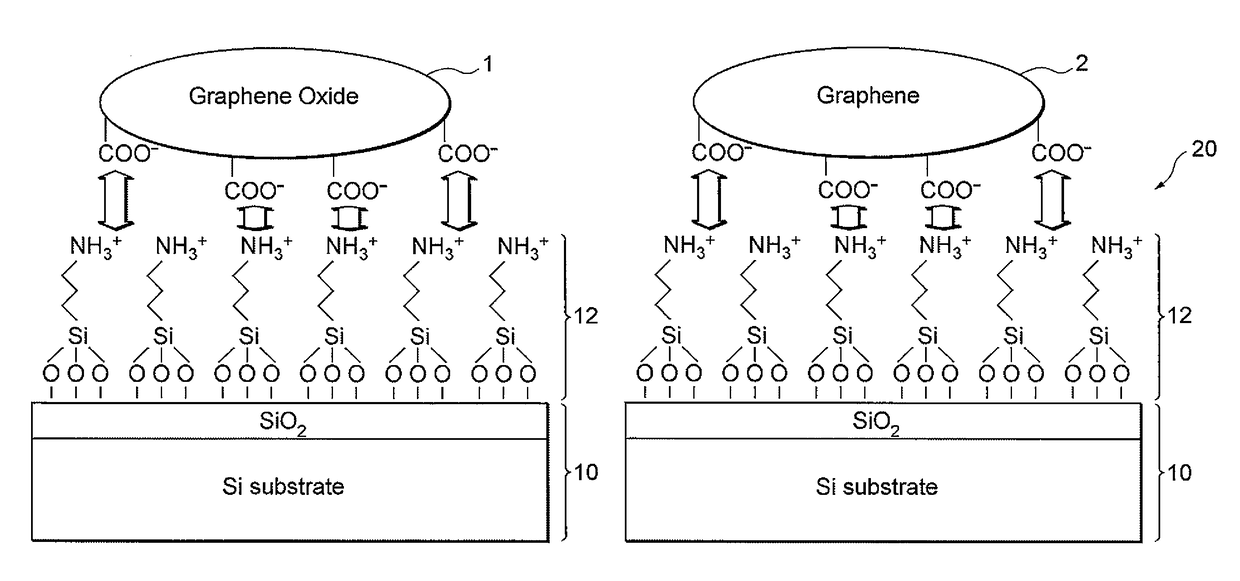

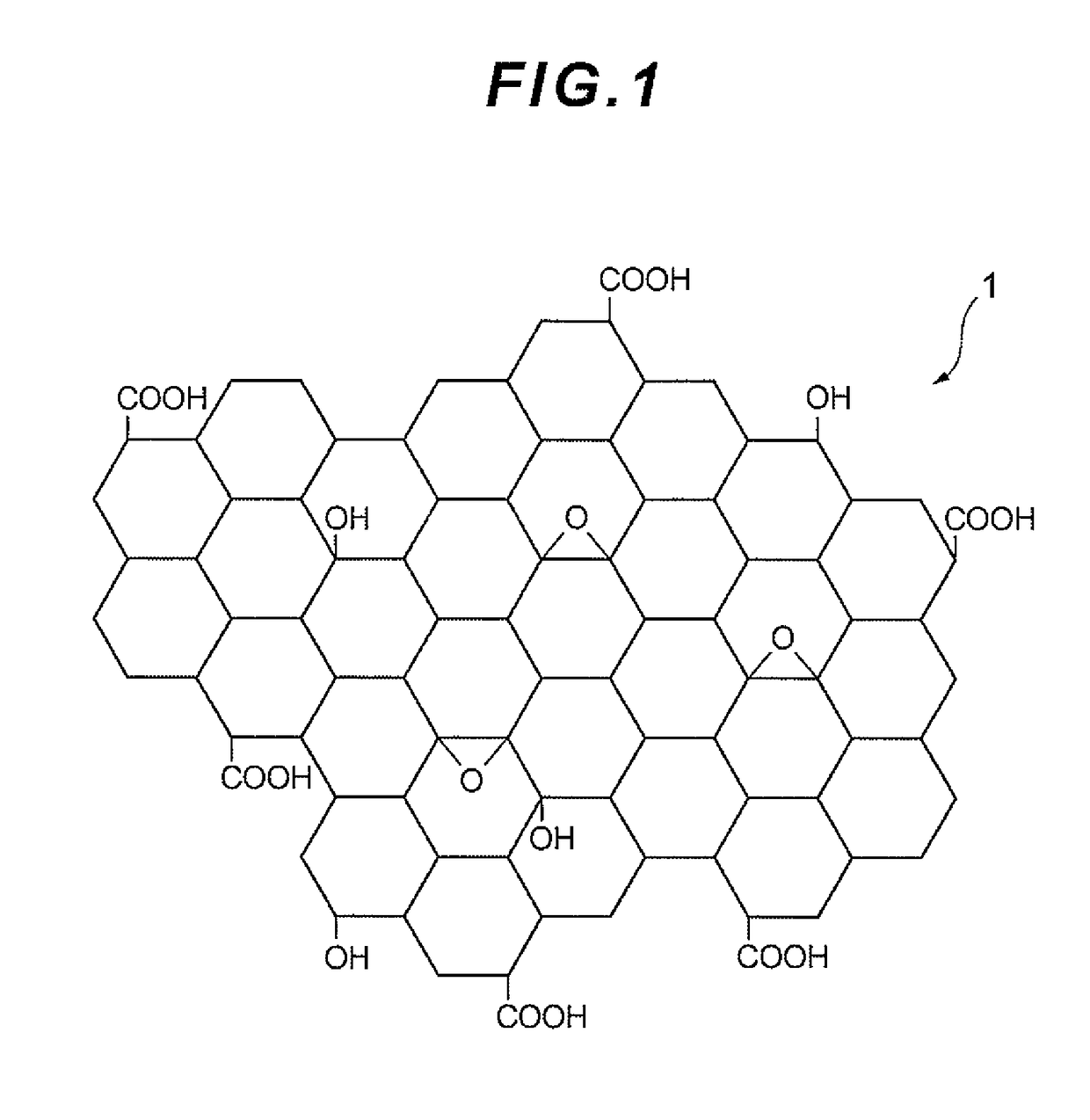

Graphene structure, method for producing the same, electronic device element and electronic device

InactiveUS20110143101A1Low costIncrease the areaMaterial nanotechnologyLayered productsResistHydrophilization

Provided are a graphene structure and a method for producing the same in which graphene can be patterned with high precision, and thereby microfabrication of electronic device elements and electronic devices using graphene is possible and the manufacturing cost can be notably reduced. A resist film is precisely patterned on a substrate, hydrophilized films are formed in openings of the resist film, and then GO is selectively fixed on the portions of the hydrophilized films by a chemical bond utilizing the hydrophilicity of the GO, and the GO is reduced to obtain a graphene structure in which graphene is selectively fixed to only the portions of the hydrophilized films. Thus, the graphene structure is constituted by disposing graphene on a substrate and forming a bond, by hydrophilization treatment, between the hydrophilized portion of the substrate and the graphene and / or between the unhydrophobized portion of the substrate and the graphene.

Owner:EMPIRE TECH DEV LLC

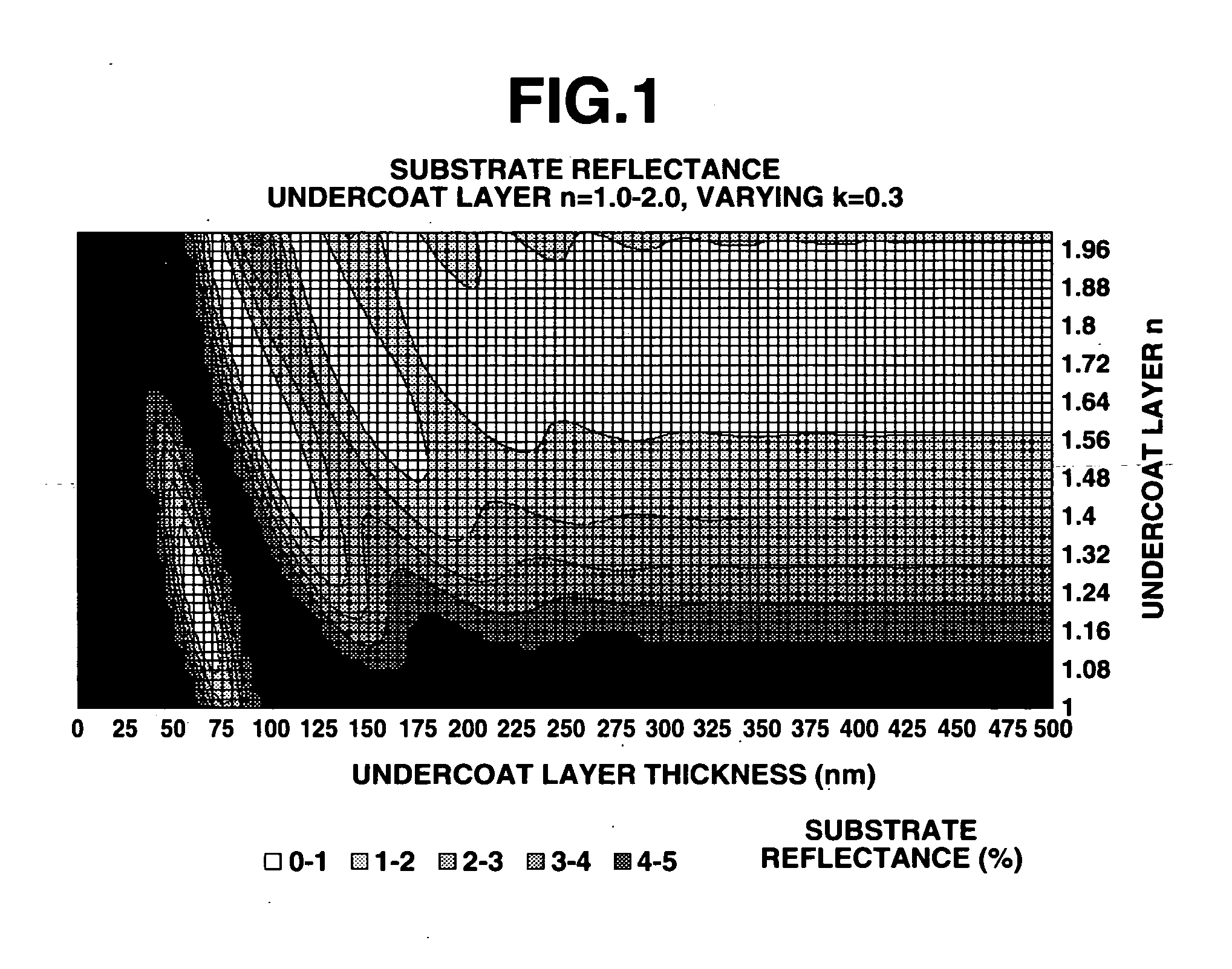

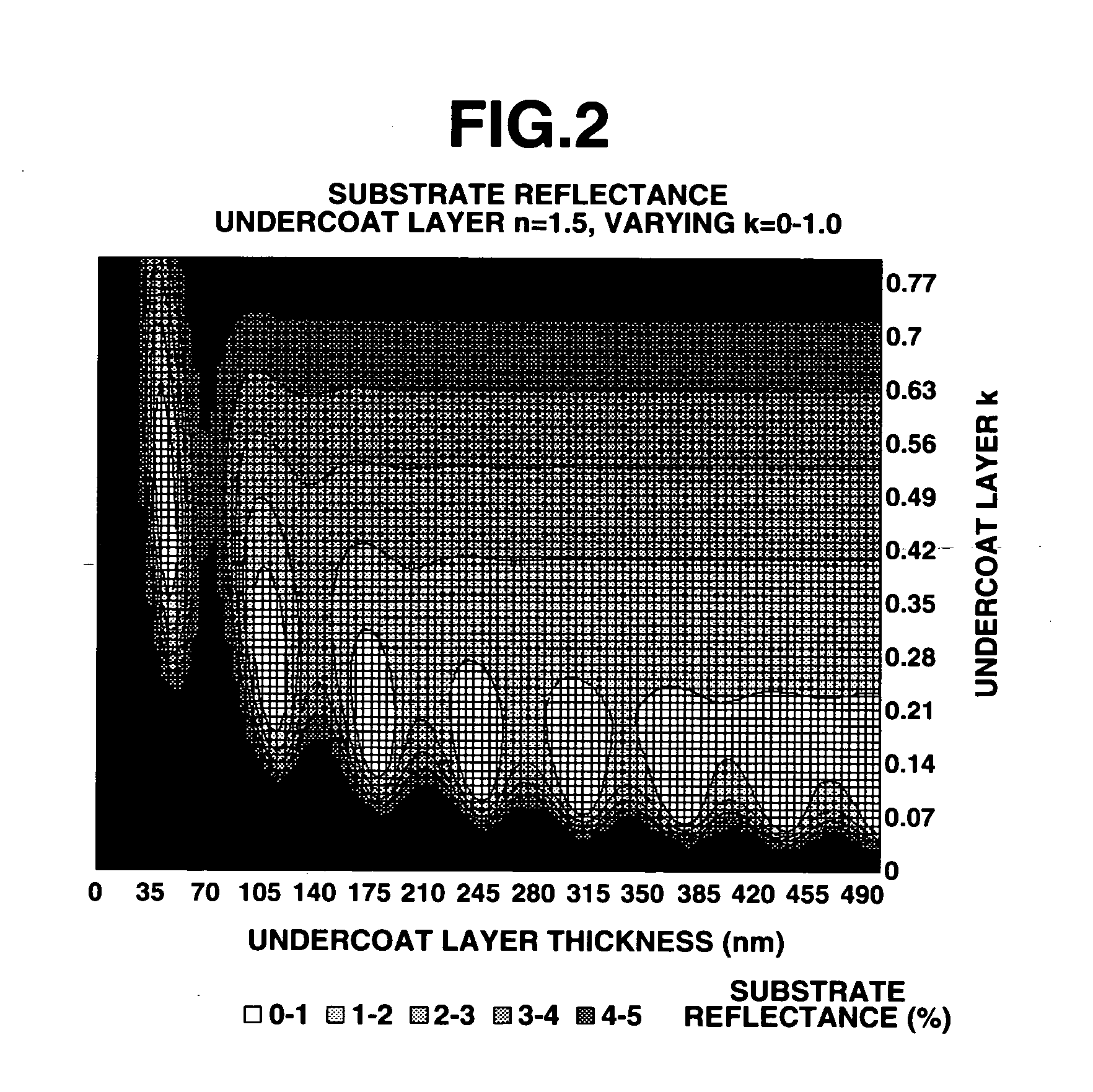

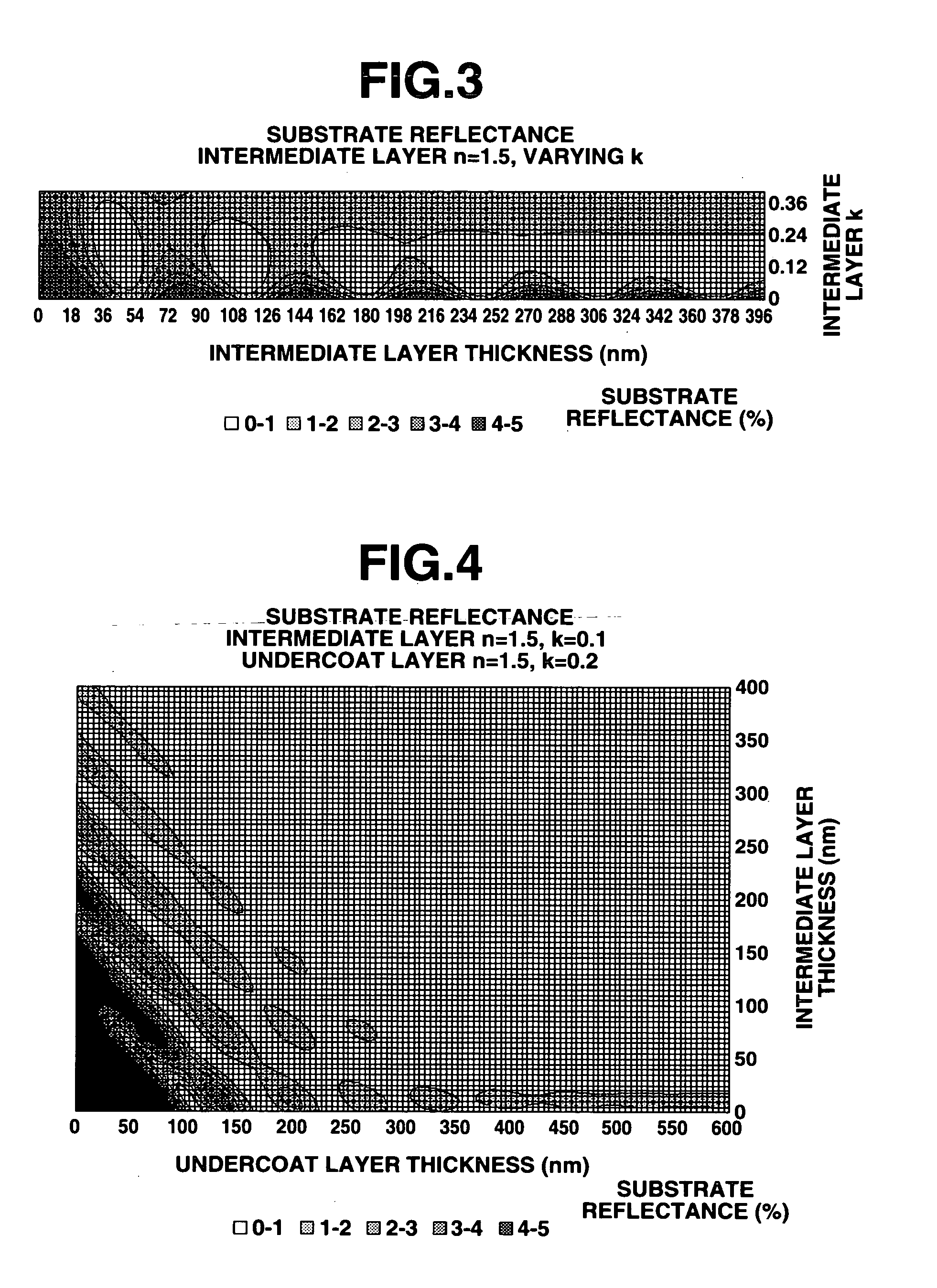

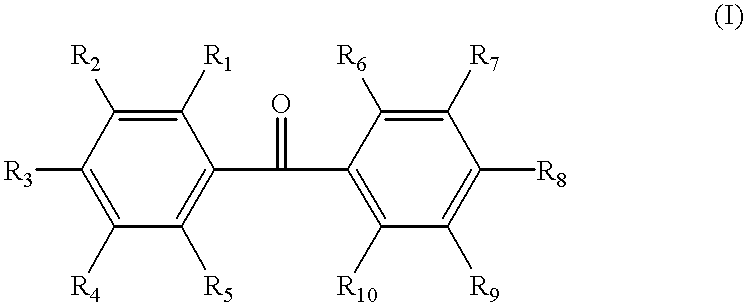

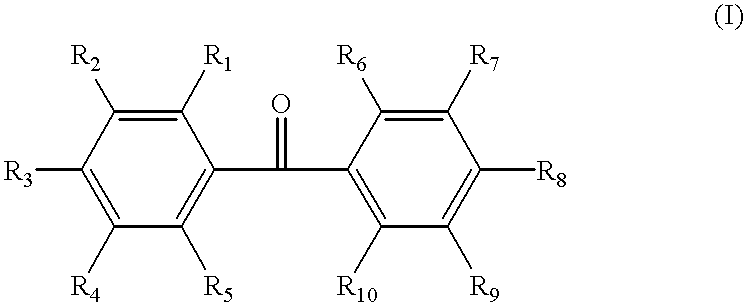

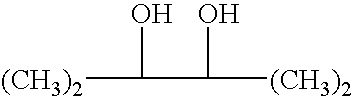

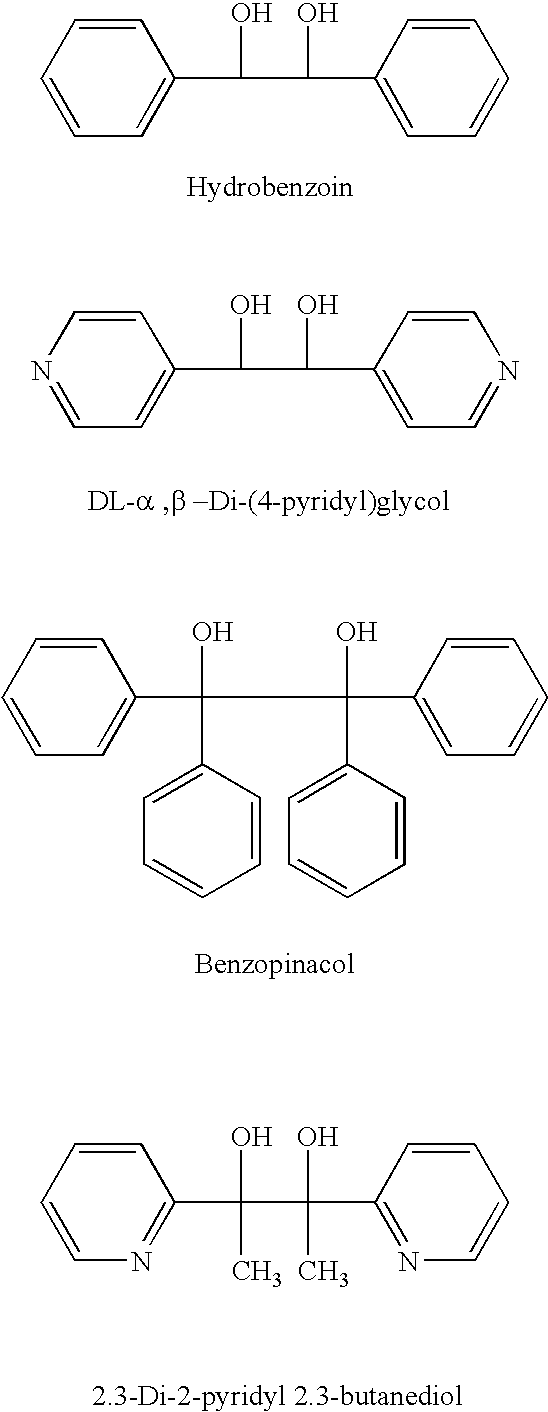

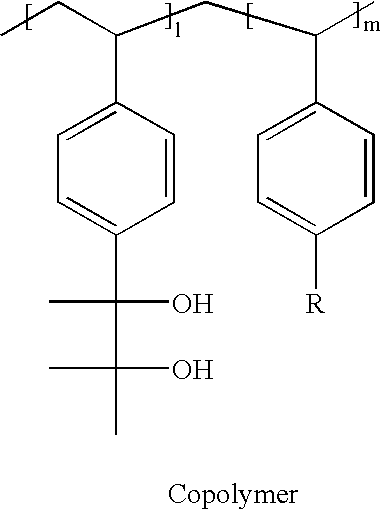

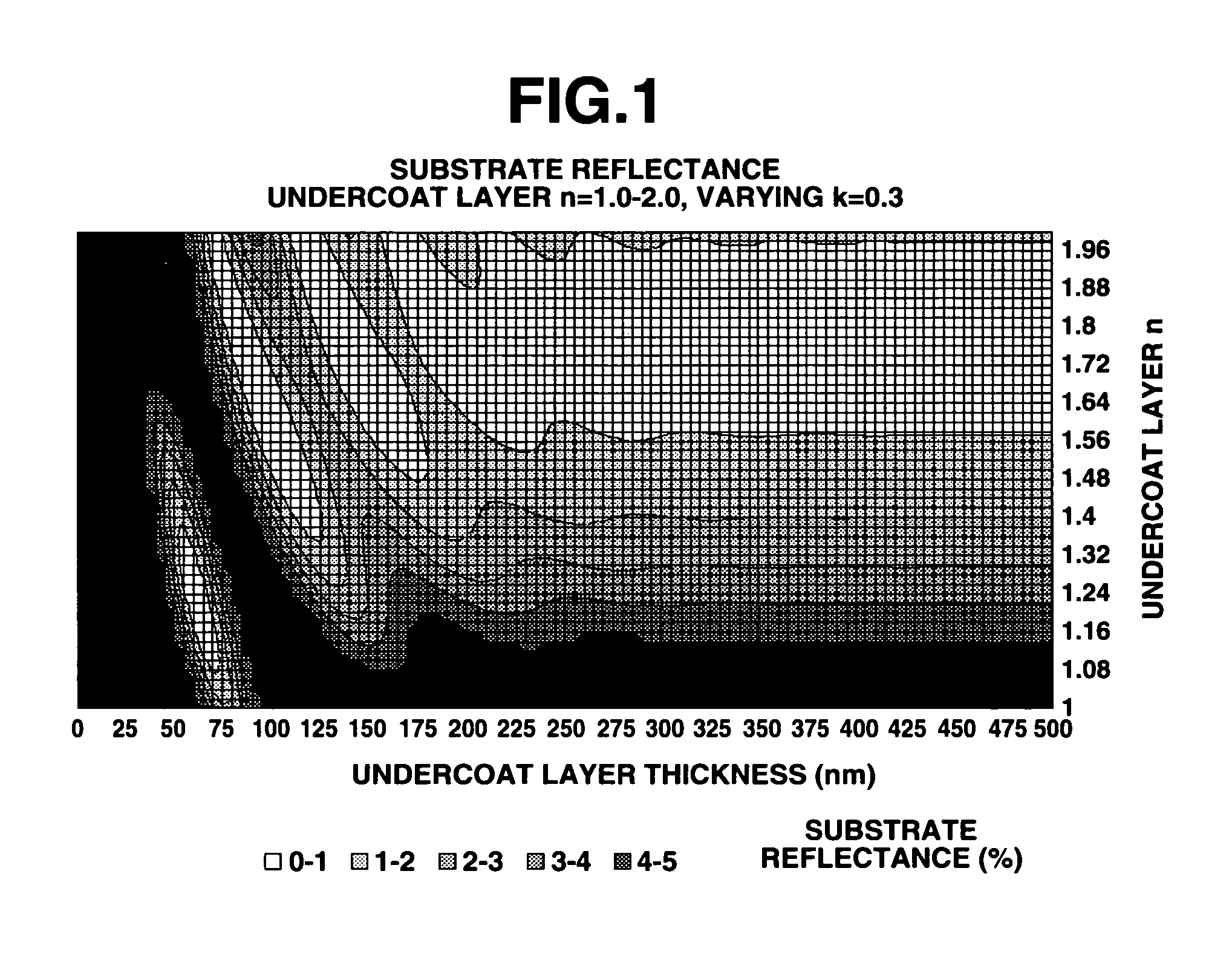

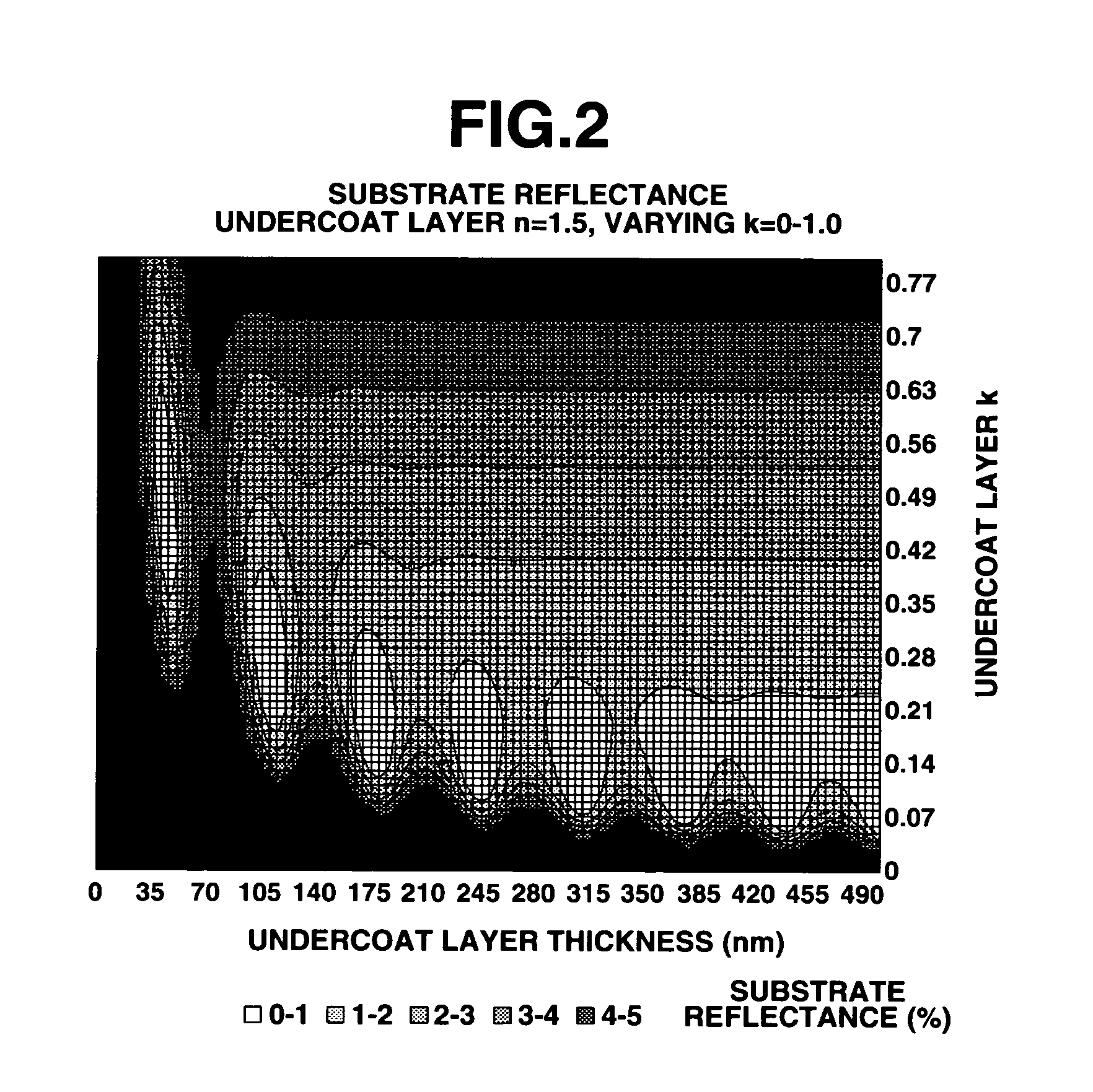

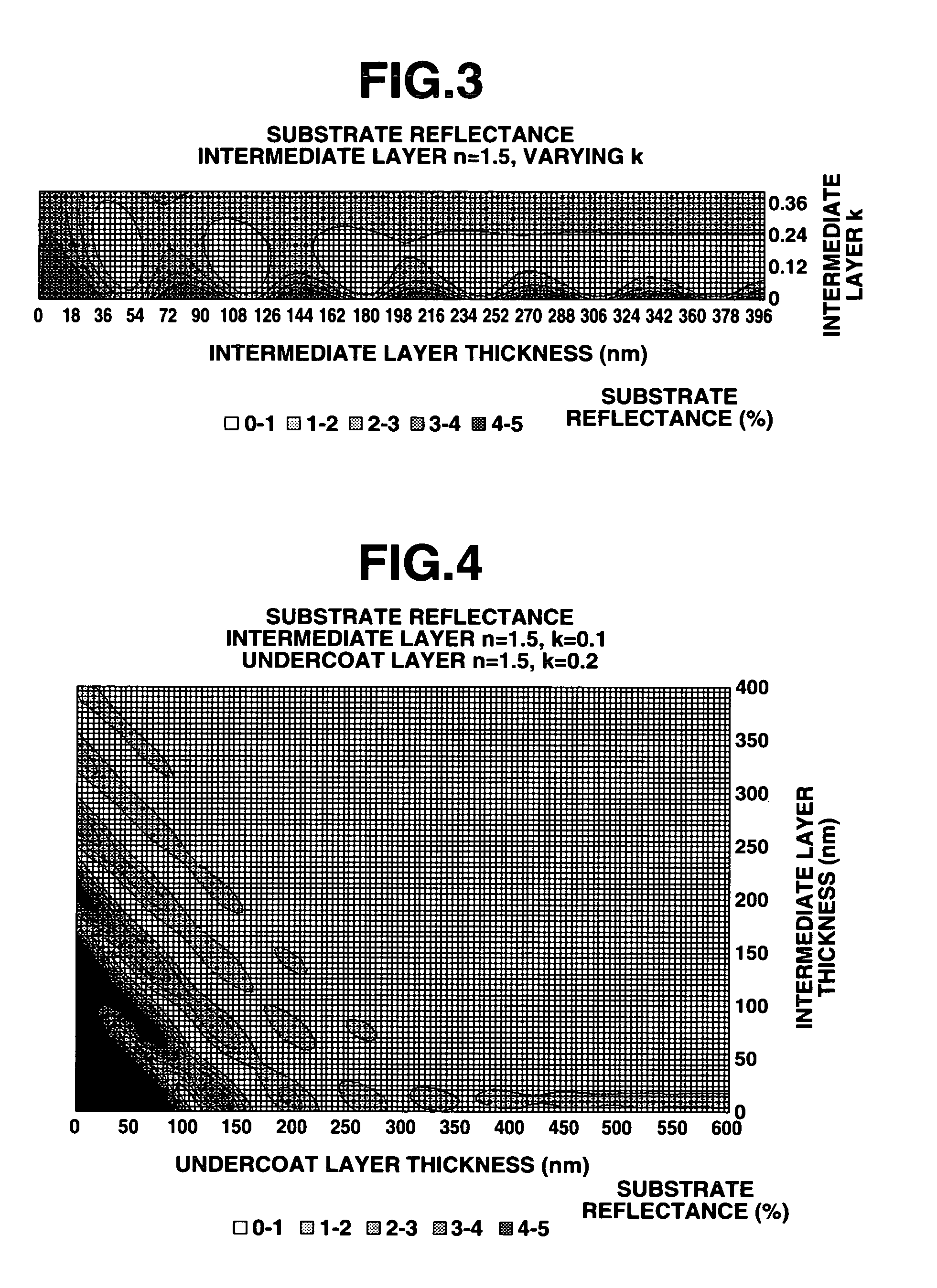

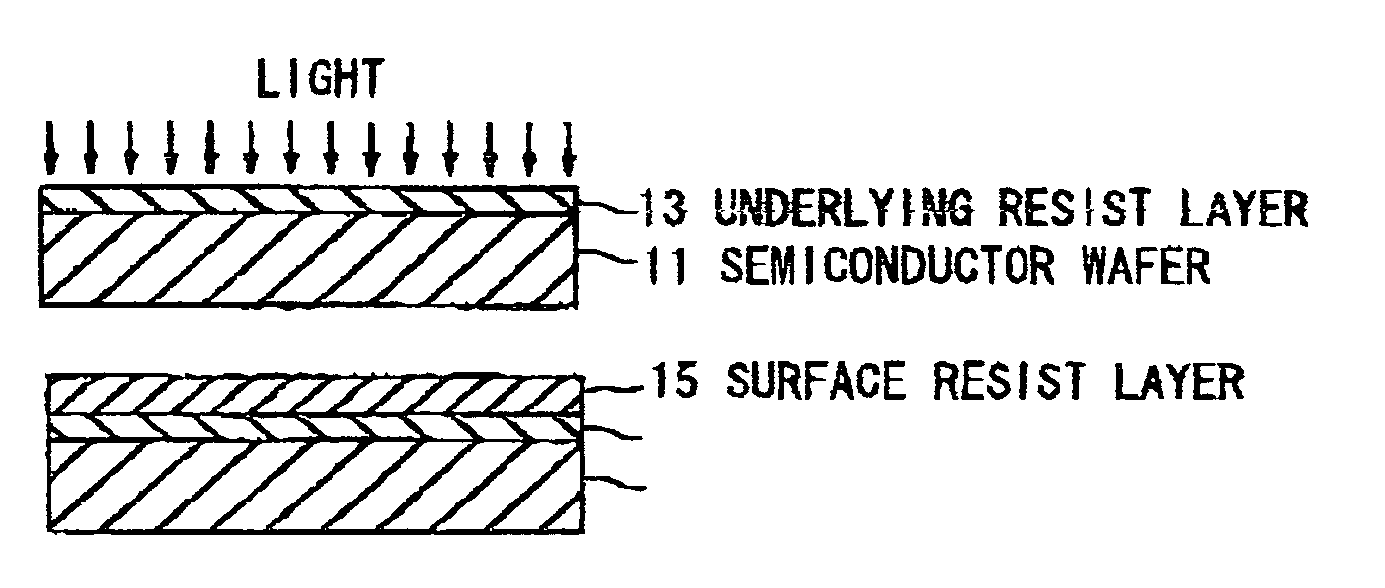

Resist undercoat-forming material and patterning process

ActiveUS20070122740A1High transparencyExcellent etch resistancePhotosensitive materialsSemiconductor/solid-state device manufacturingResistAnti-reflective coating

In the lithographic multilayer resist process, a material comprising a copolymer of a hydroxy-containing vinylnaphthalene with hydroxy-free olefins is useful in forming a resist undercoat. The undercoat-forming material has a high transparency and optimum values of n and k so that it functions as an antireflective coating during short-wavelength exposure, and has etching resistance during substrate processing by etching.

Owner:SHIN ETSU CHEM IND CO LTD

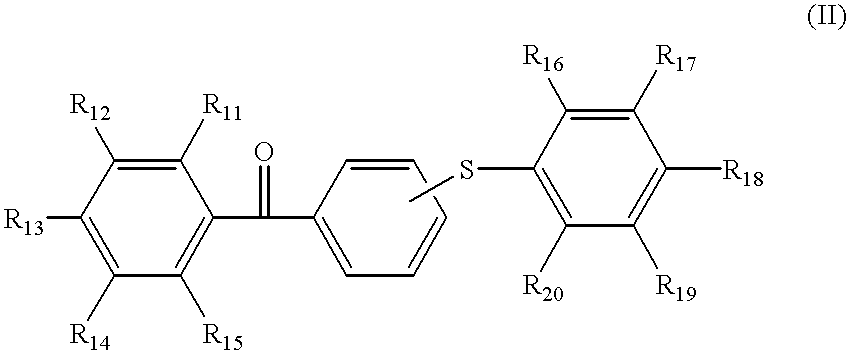

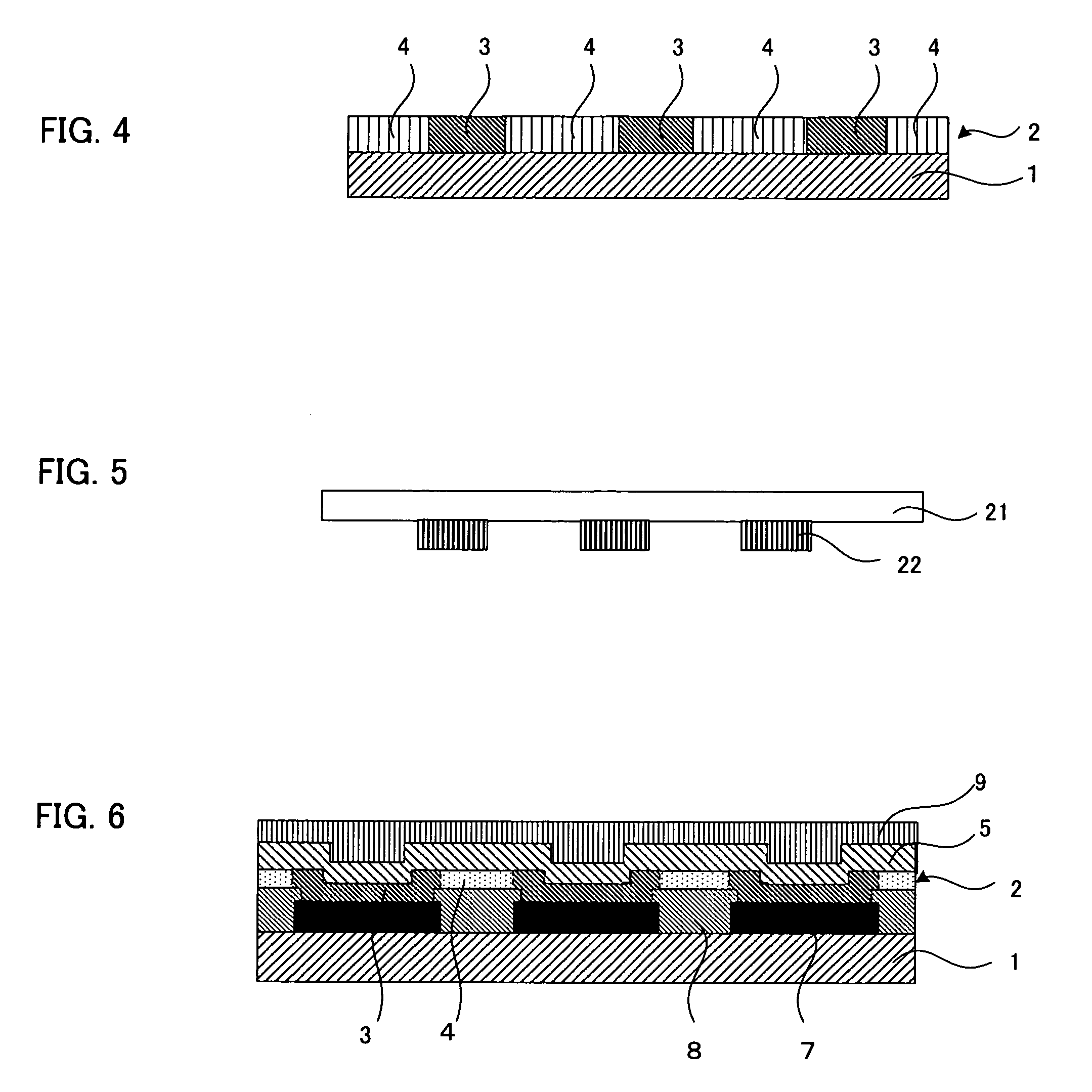

Fluorescent conversion filter and organic light-emitting device equipped with the fluorescent conversion filter

InactiveUS6358652B1Easy to controlSuppress decomposition and quenchingDischarge tube luminescnet screensElectroluminescent light sourcesFluorescenceDecomposition

A fluorescent conversion filter suppresses decomposition and quenching of fluorescent dyes or pigments. An organic light-emitting device may be equipped with such a fluorescent conversion filter. The fluorescent conversion filter is formed by coating with a coating material, followed by patterning by photolithography. The coating material consists of a mixture of organic fluorescent dye or pigment that absorbs light in the ultraviolet to visible light region. The coating also includes a photo-setting or photo-and-thermo-setting resin containing a photopolymerizaion initiator of a hydrogen abstraction type having a benzophenone skeleton within the molecule. As a result, an organic light-emitting device is produced by combining the a fluorescent conversion filter with an organic light-emitting element.

Owner:SHARP KK

Micropattern forming material, micropattern forming method and method for manufacturing semiconductor device

InactiveUS20040029047A1Improve the immunityImprove accuracyElectric discharge tubesSemiconductor/solid-state device manufacturingResistOrganic solvent

A micropattern forming material comprises a polar change material formed on a resist pattern capable of generating an acid, the polar change material being soluble in water or an alkali, a portion of the polar change material in contact with the resist pattern undergoing a polar change caused by the acid from the resist pattern to form an insolubilized film insoluble in water and the alkali; and water or a mixed solvent of water and a water-soluble organic solvent.

Owner:RENESAS TECH CORP

Resist undercoat-forming material and patterning process

ActiveUS7510820B2High transparencySpeed up the processPhotosensitive materialsSemiconductor/solid-state device manufacturingResistAnti-reflective coating

In the lithographic multilayer resist process, a material comprising a copolymer of a hydroxy-containing vinylnaphthalene with hydroxy-free olefins is useful in forming a resist undercoat. The undercoat-forming material has a high transparency and optimum values of n and k so that it functions as an antireflective coating during short-wavelength exposure, and has etching resistance during substrate processing by etching.

Owner:SHIN ETSU CHEM IND CO LTD

Pattern formed body and method for manufacturing same

InactiveUS20100051579A1Difference in wettabilityAdhesive propertyDecorative surface effectsPhotomechanical apparatusProduct gasMaterials science

A main object of the present invention is to provide a pattern formed body capable of forming highly precise functional parts on various base materials, and a method for manufacturing the same. To achieve the object, the present invention provides a method for manufacturing a pattern formed body, having a plasma radiating step of radiating plasma to a patterning substrate having: a base material; an intermediate layer formed on the base material and containing a silane coupling agent or a polymer of the silane coupling agent; and a resin layer formed in a pattern form on the intermediate layer, wherein a fluorine gas is used as an introduction gas to radiate the plasma from the resin layer side.

Owner:DAI NIPPON PRINTING CO LTD

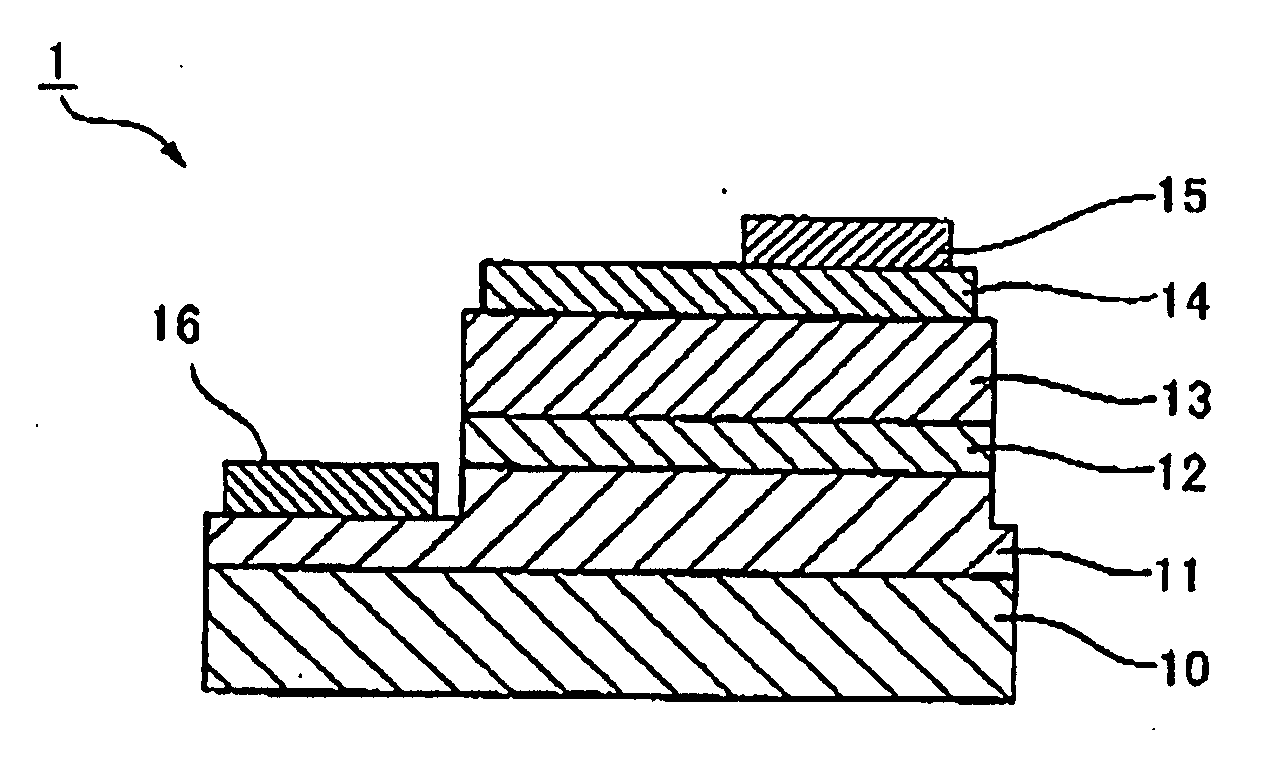

Semiconductor light-emitting element, method for manufacturing the semiconductor light-emitting element and lamp that uses the semiconductor light-emitting element

InactiveUS20110062485A1Good light transmissionIncrease productionSolid-state devicesSemiconductor/solid-state device manufacturingIndiumUltraviolet lights

Provided are a semiconductor light-emitting element that is capable of efficiently outputting blue color or ultraviolet light, and a lamp using the semiconductor light-emitting element.The semiconductor light-emitting element is obtained by a manufacturing method that, when manufacturing the semiconductor light-emitting element that comprises a compound semiconductor layer that includes at least a p-type semiconductor layer, and a transparent electrode that is provided on the p-type semiconductor layer, includes a step of forming a film comprising an oxide of indium and gallium, or forming a film comprising an oxide of indium, gallium and tin, in an amorphous state on the p-type semiconductor layer, so as to form a transparent conductive film, followed by a step of performing an annealing process on the transparent conductive film at a temperature of 200° C. to 480° C.

Owner:SUMITOMO METAL MINING CO LTD

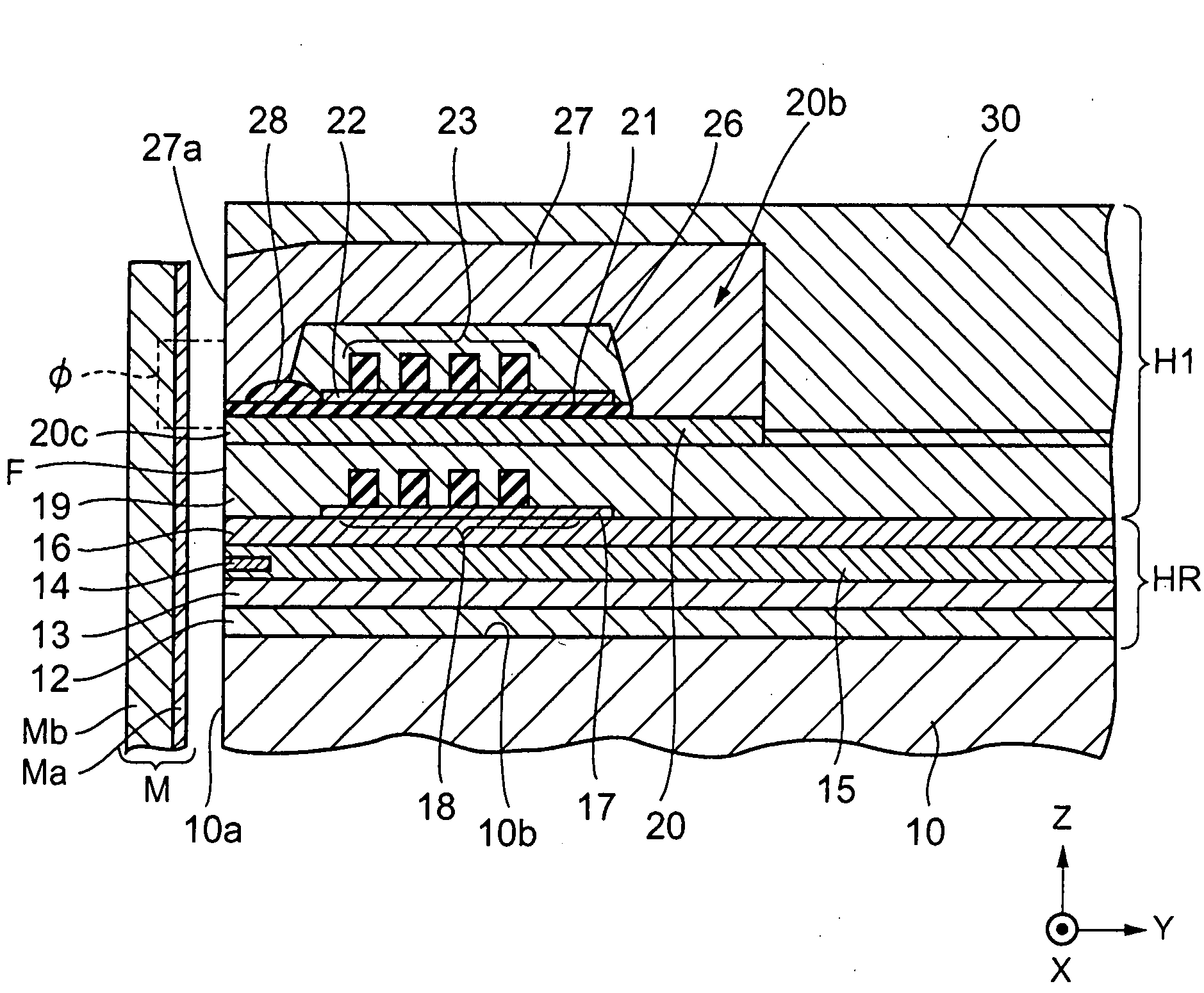

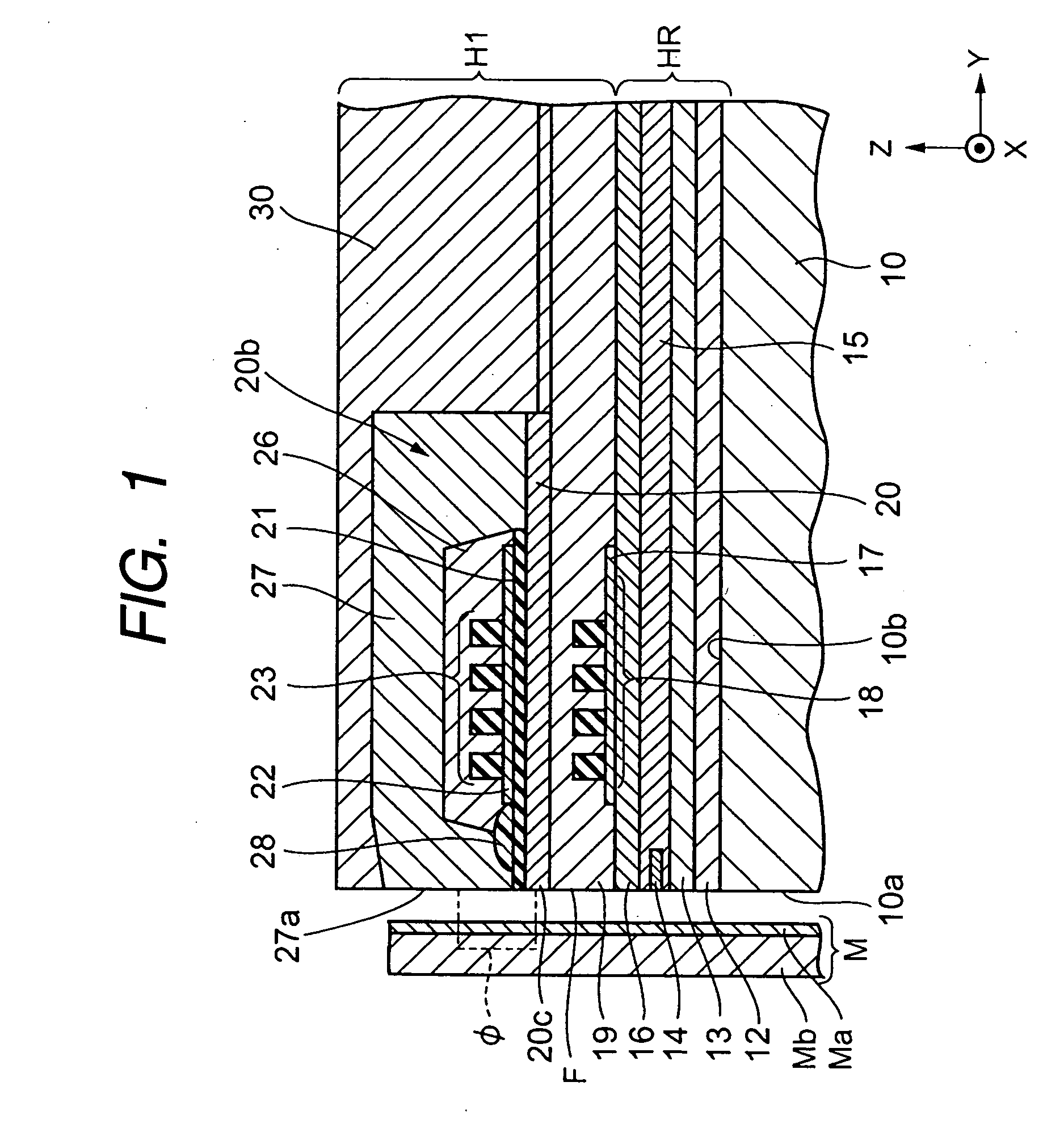

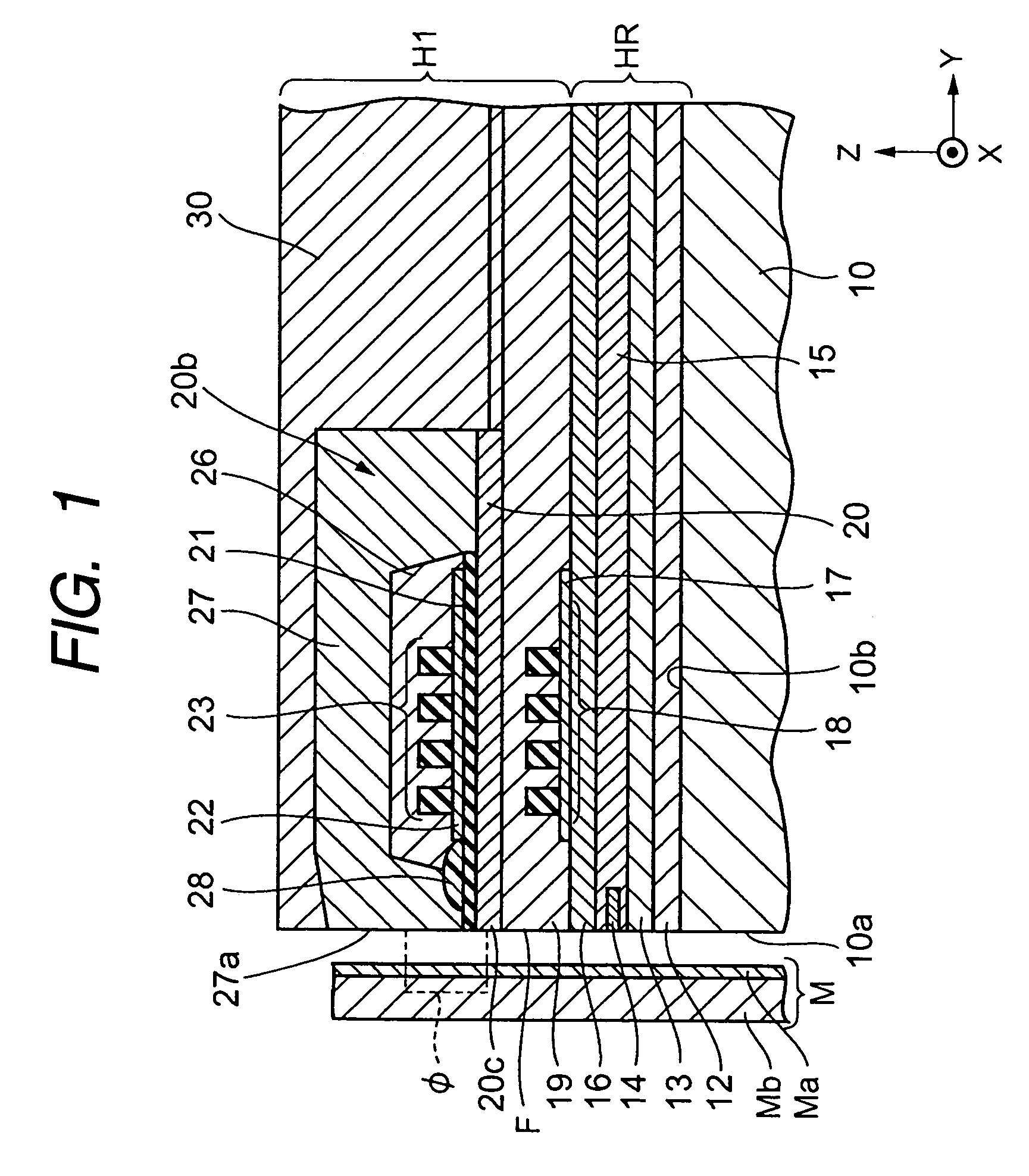

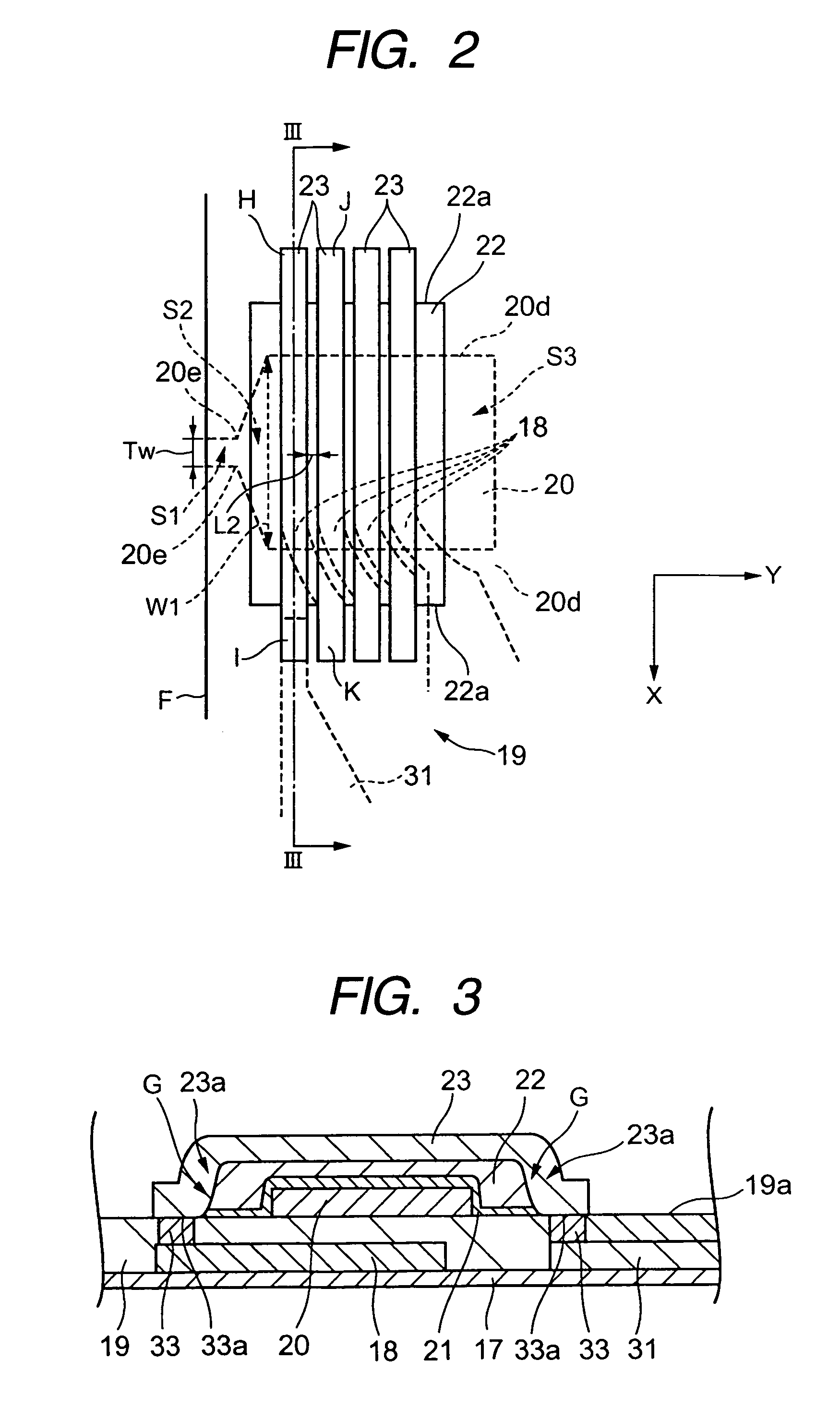

Magnetic head having toroidal coil layer and manufacturing method thereof

ActiveUS20060126221A1Suppress deterioration in pattern precisionImprove accuracyConstruction of head windingsRecord information storageEngineeringToroidal coil

First and second magnetic layers of a magnetic head face each other. A toroidal coil layer having upper and lower layer coil pieces (ULCP and LLCP) is wound around one of the magnetic layers. The ULCP extend from a first insulating layer by downward steps to a top of a second insulating layer which is widened at ends of the first insulating layer. Side ends of the first insulating layer extend parallel to a height direction. The ULCP are orthogonal to the side ends. Each of the LLCP is formed on a third insulating layer and has a straight region extending in the same direction as the upper layer coil pieces and a curved region curved toward a facing surface or in a height direction on one end in the track width direction. An end of each of the straight and curved region is connected to an ULCP.

Owner:TDK CORPARATION

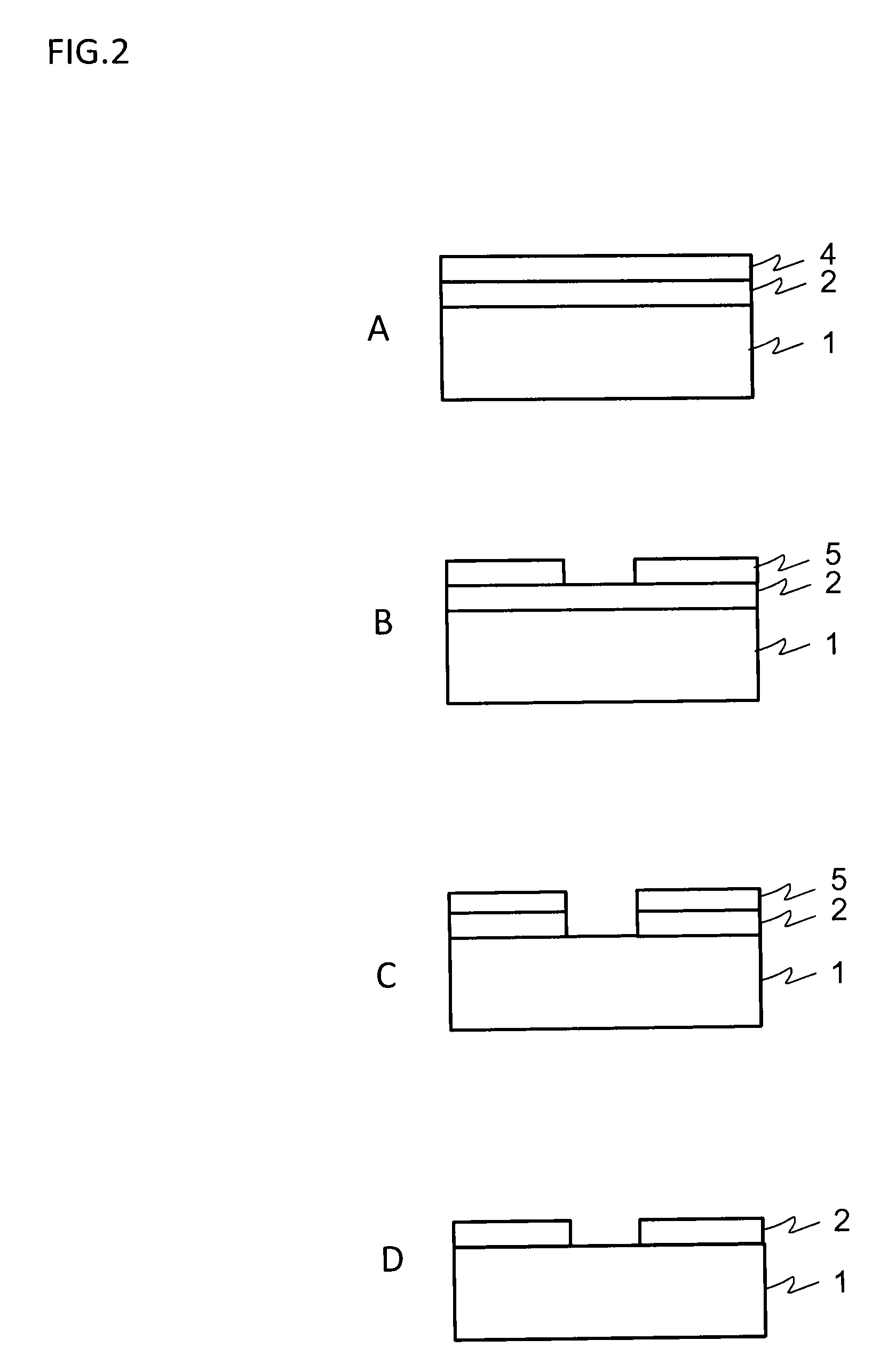

Photomask blank, method for manufacturing photomask, and method for manufacturing phase shift mask

ActiveUS20130309601A1Increase etch rateImprove accuracySemiconductor/solid-state device manufacturingOriginals for photomechanical treatmentOptoelectronicsOxygen

A light-shielding film 2 formed on a transparent substrate 1 has a monolayer structure or a multilayer structure. At least one layer is formed by film-formation with a chromium-containing material including tin. The light-shielding film 2 has an optical density of 2 or higher and 4 or lower and has a reflection-preventing function. The layer made of a chromium-containing material including tin, which constitutes the light-shielding film 2, can cause a significant increase in the etching rate at the time of chlorine-containing dry etching including oxygen. Thus, burden on the resist pattern or hard mask pattern at the time of transferring a pattern on the light-shielding film is reduced, and therefore it is possible to carry out pattern transfer with high precision.

Owner:SHIN ETSU CHEM IND CO LTD

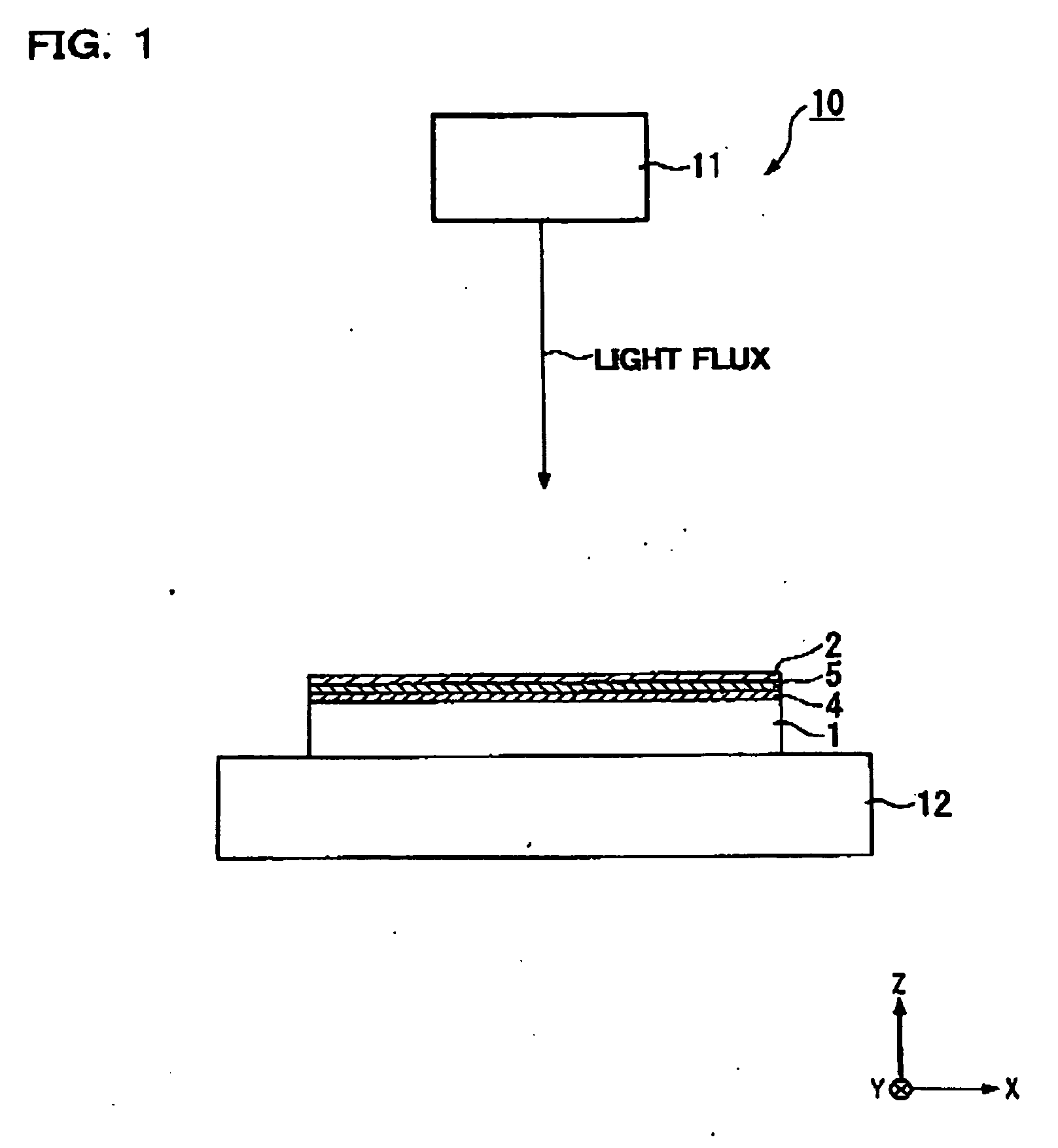

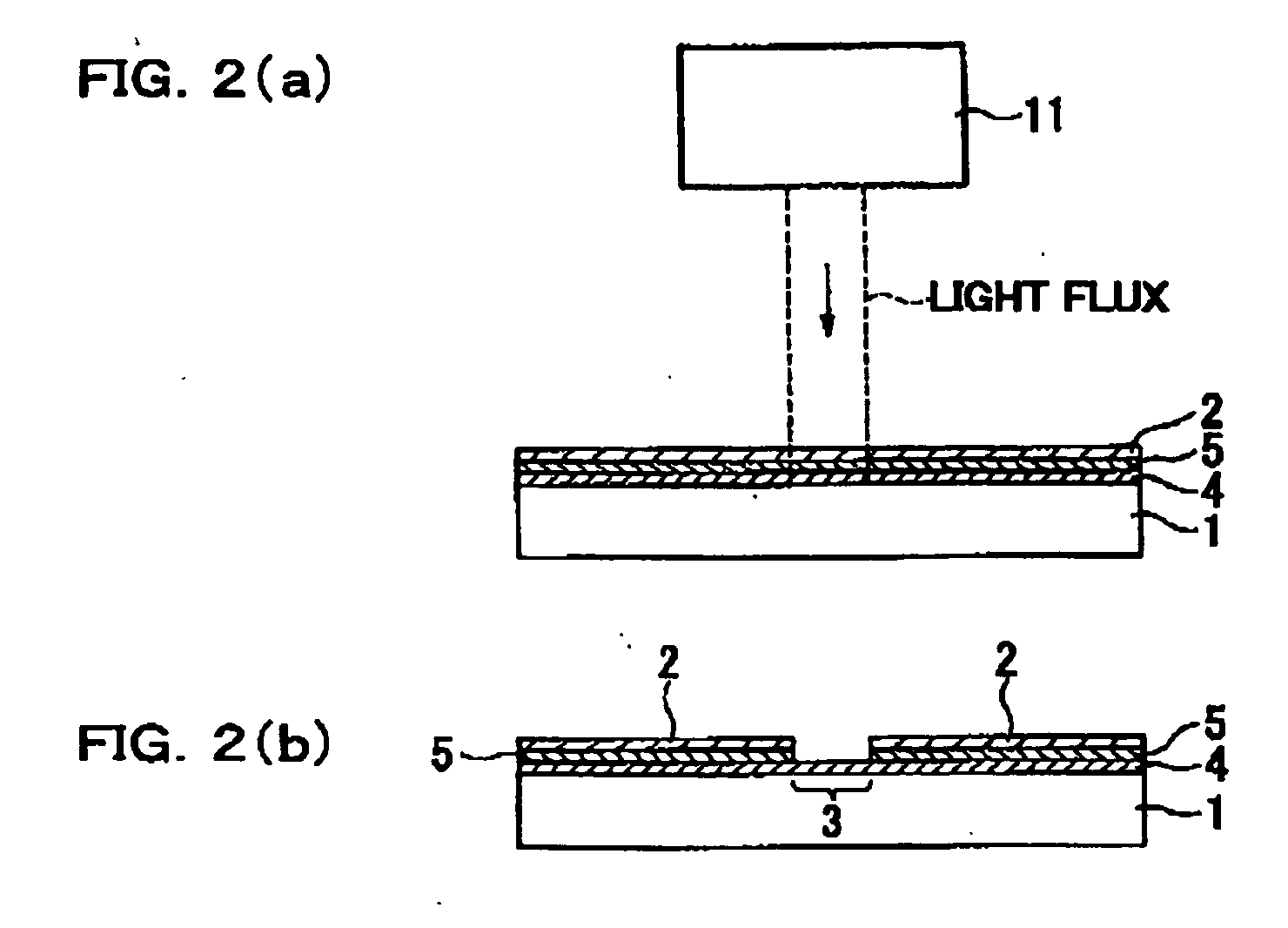

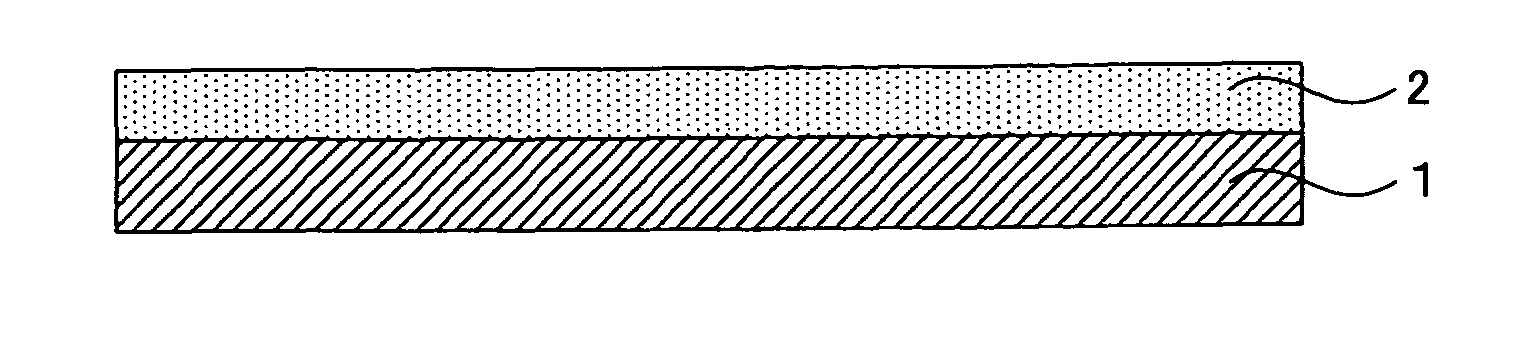

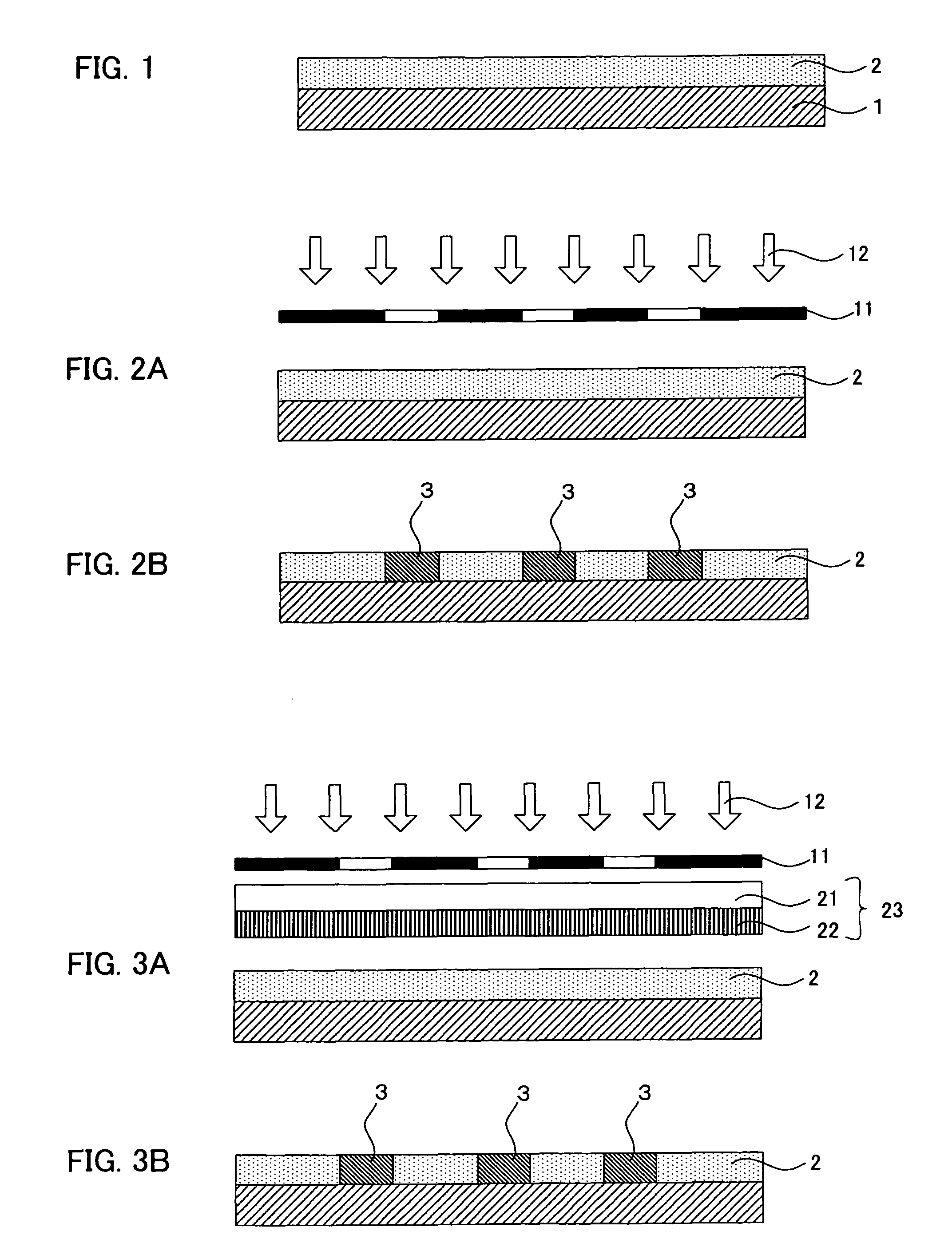

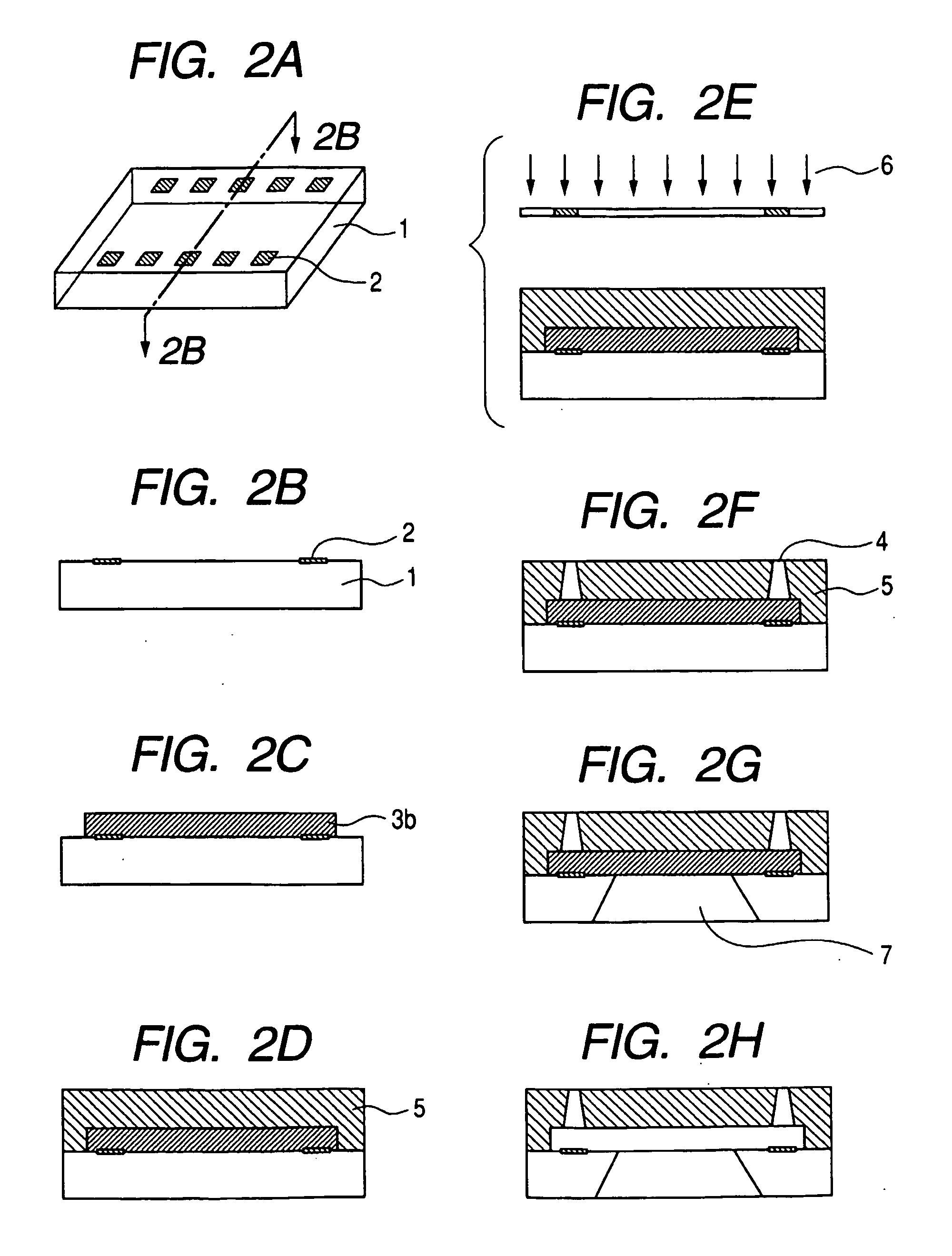

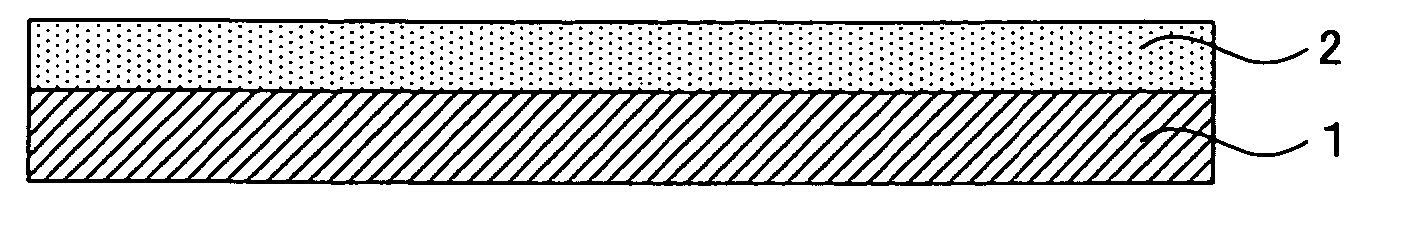

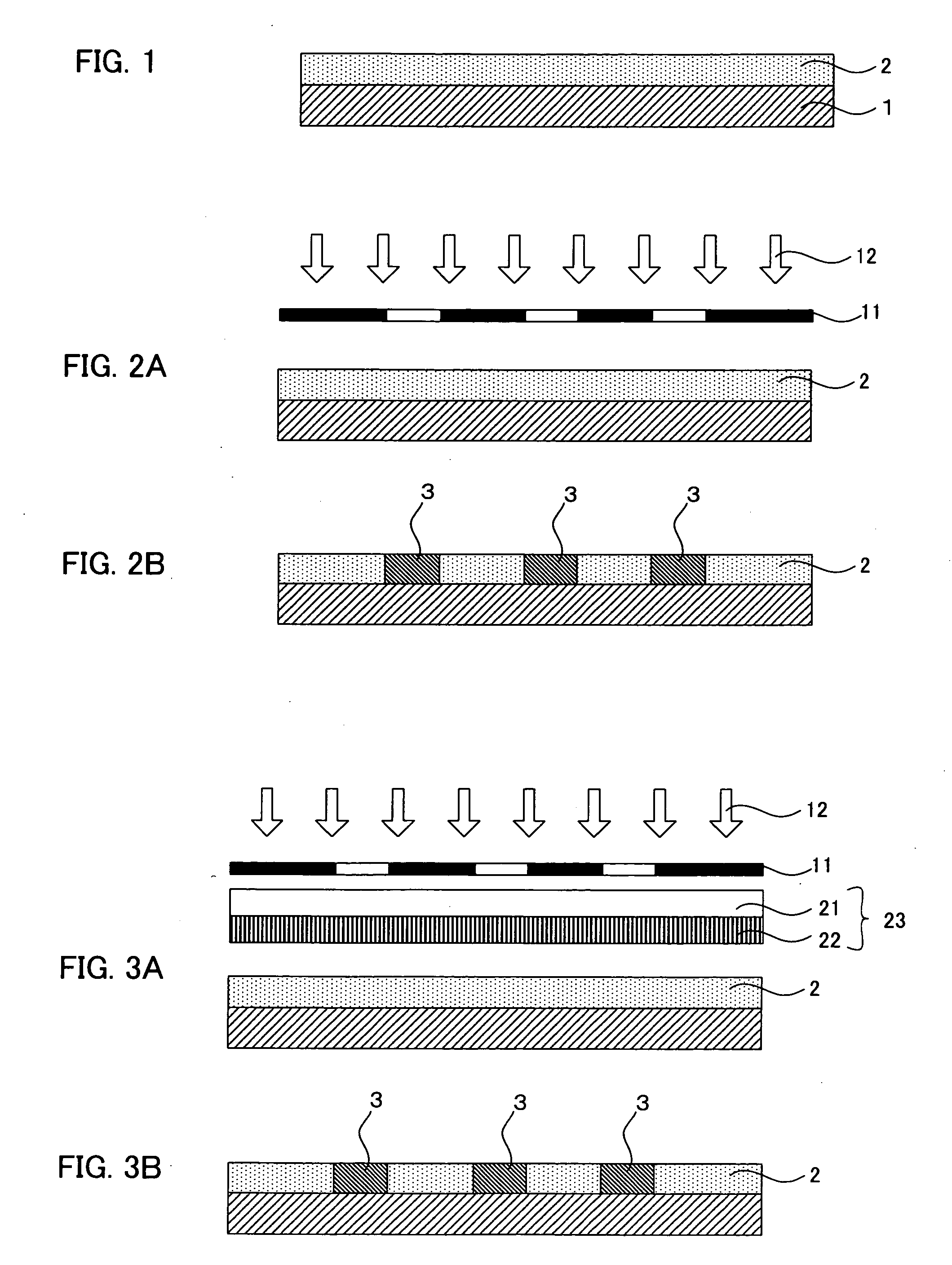

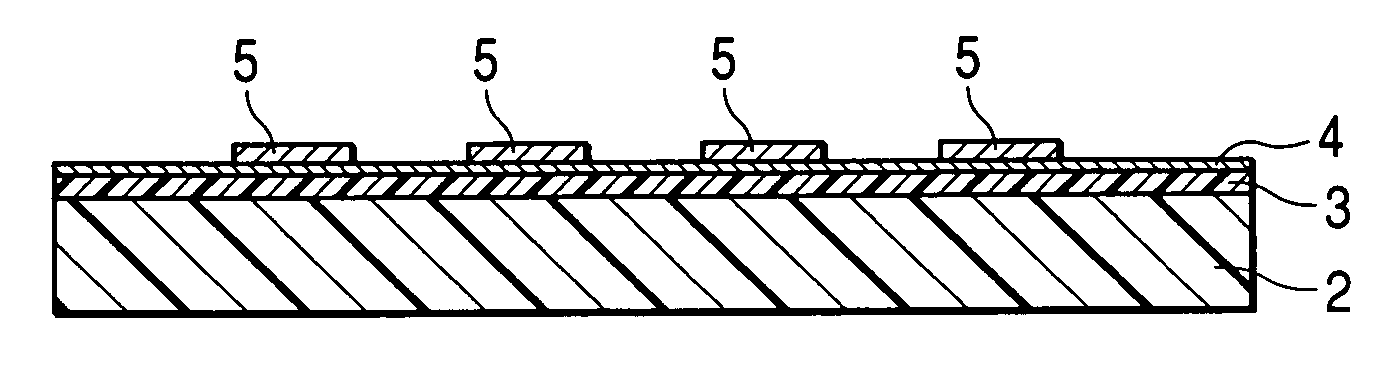

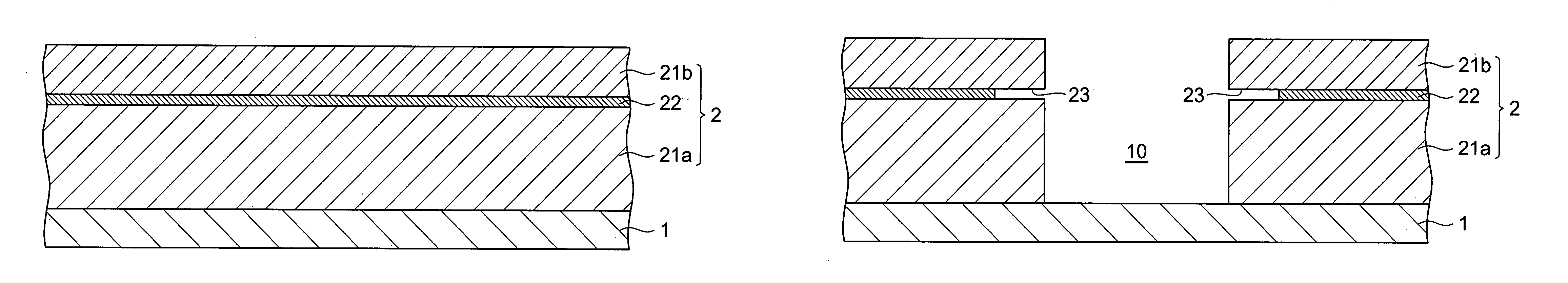

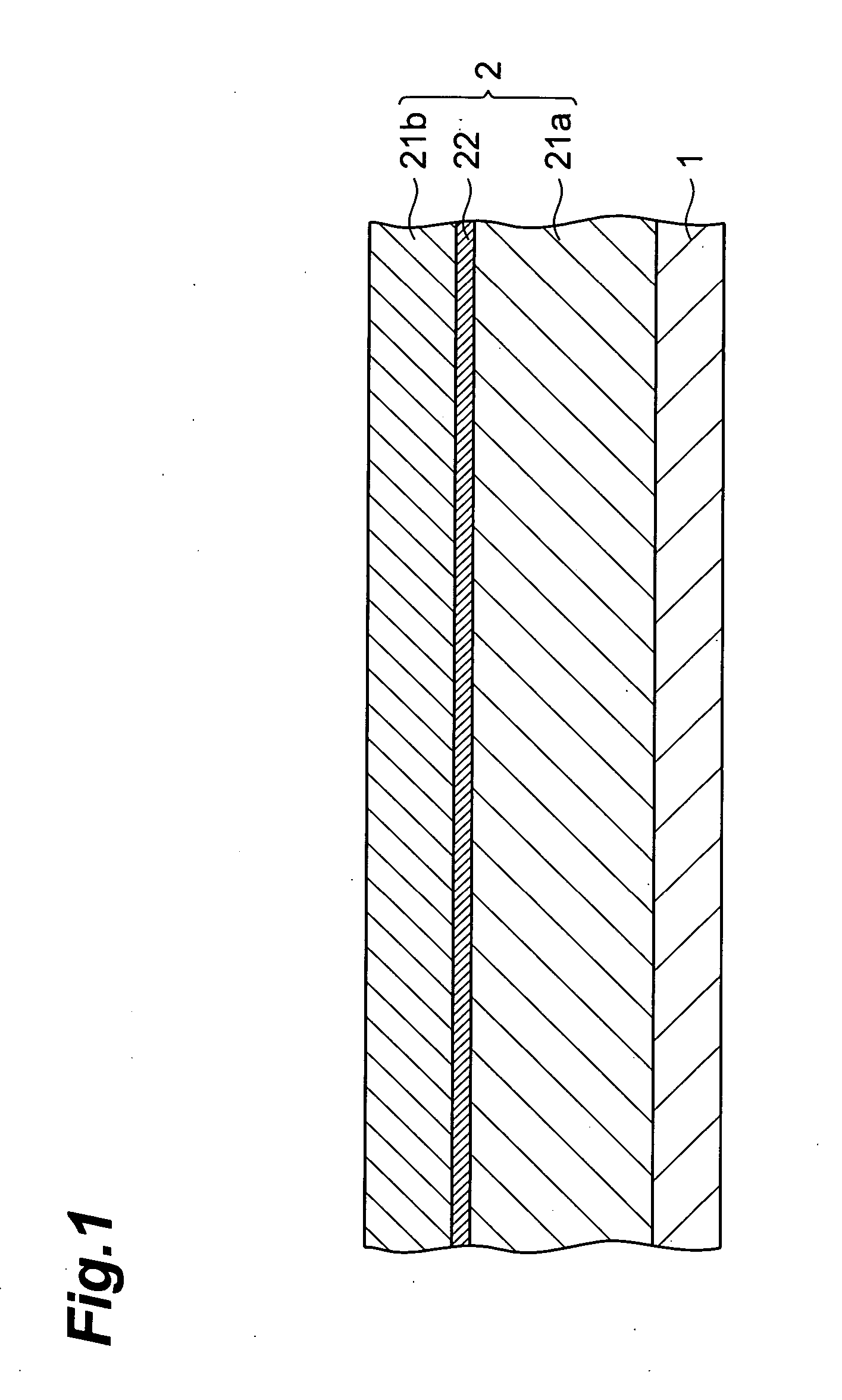

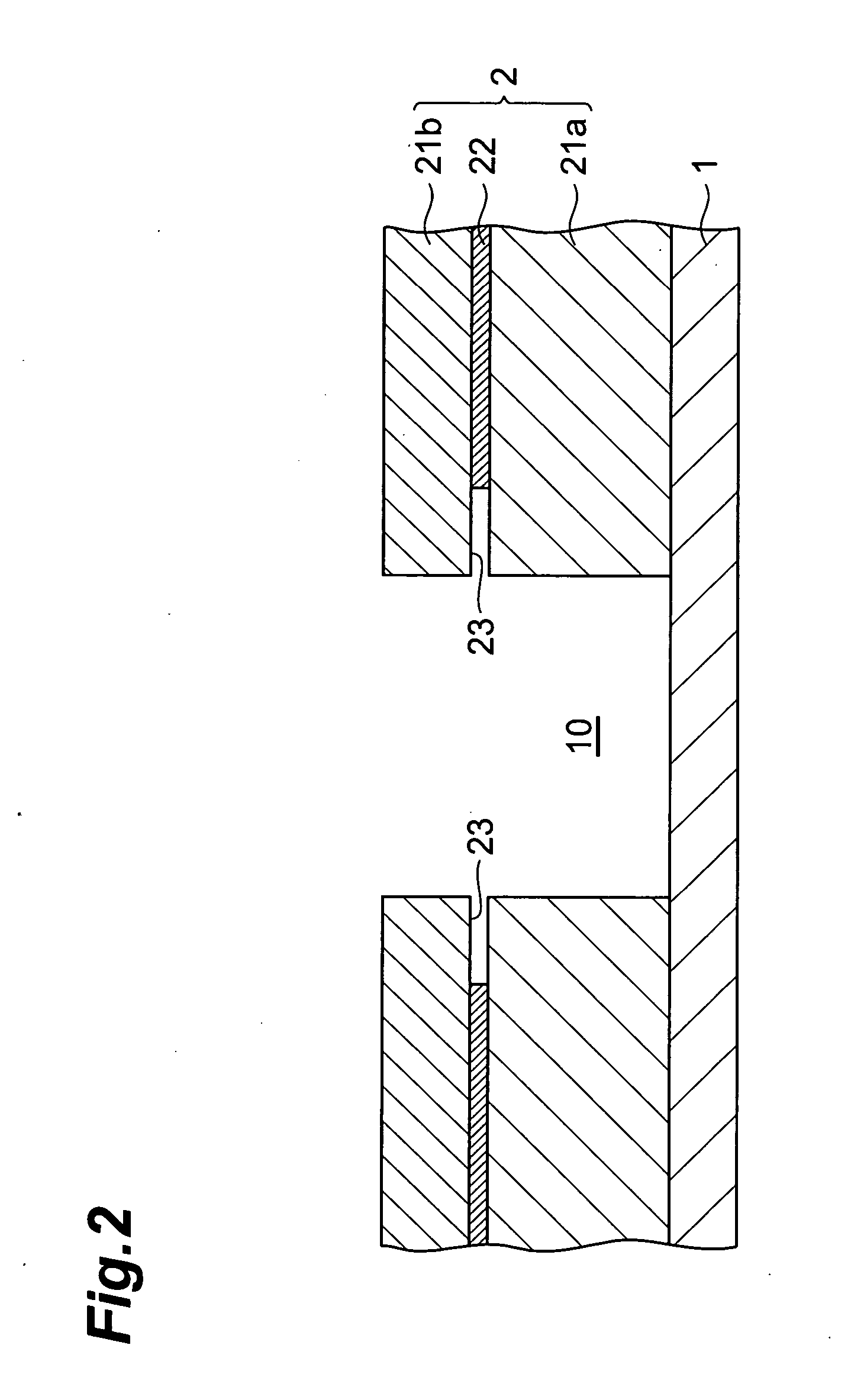

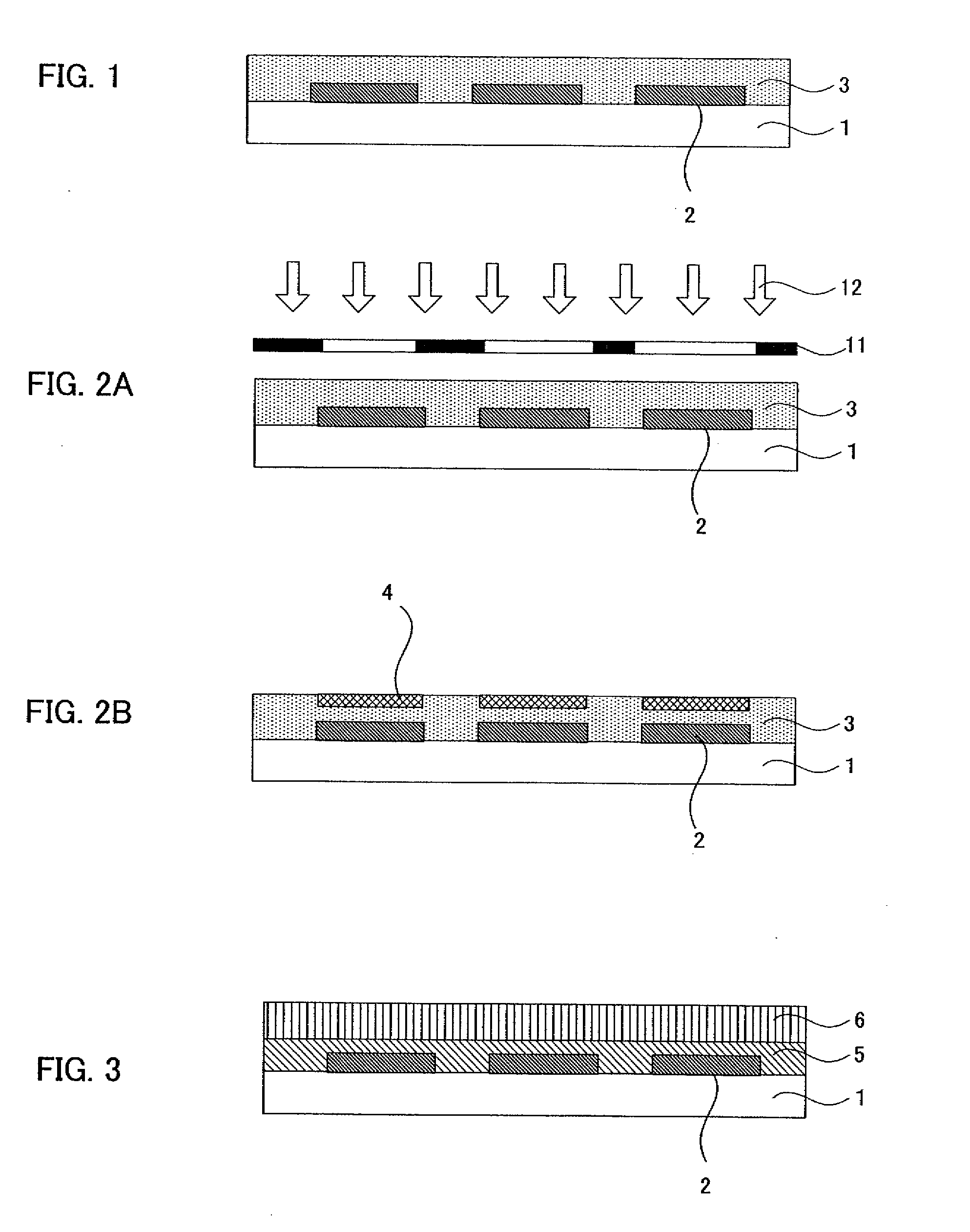

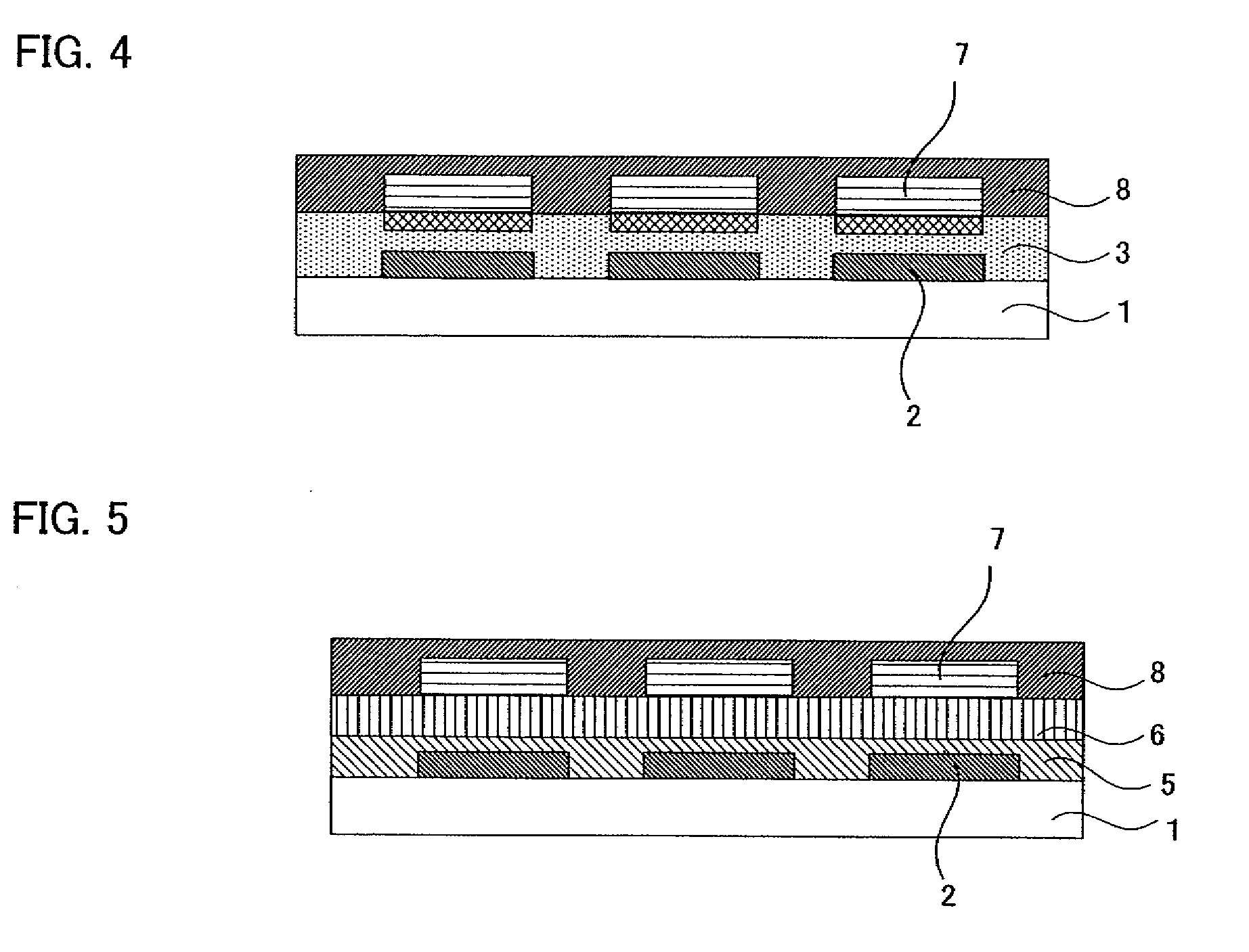

Pattern forming method and wiring pattern forming method, and electro-optic device and electronic equipment

InactiveUS20070010038A1High-precision patternEasy and low-cost techniqueDiffusion transfer processesMaterial nanotechnologyLight irradiationEngineering

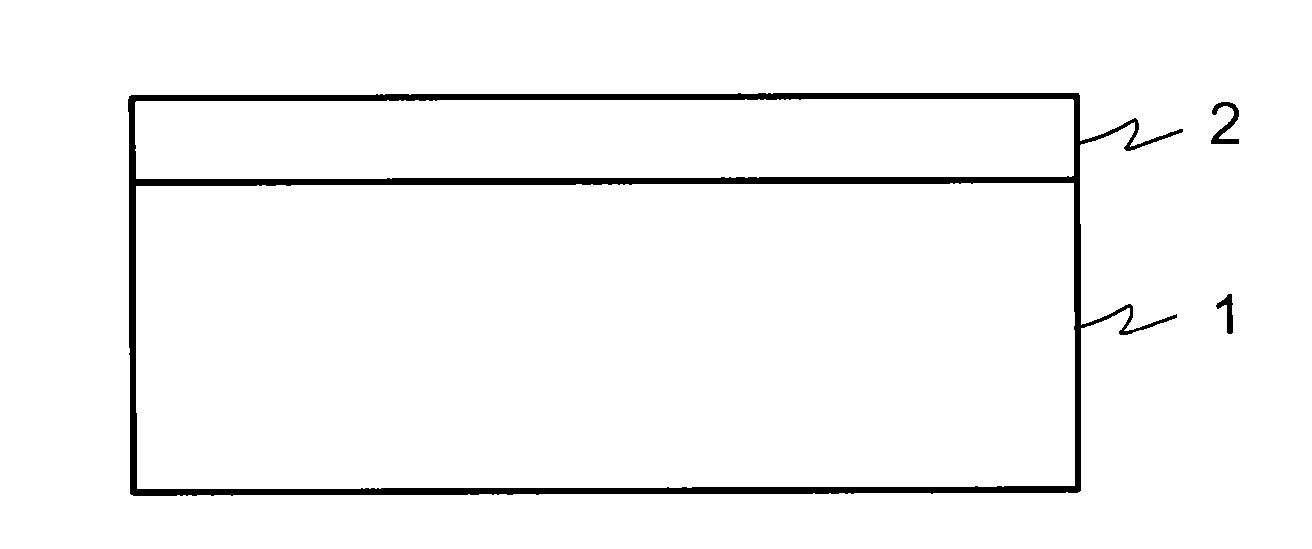

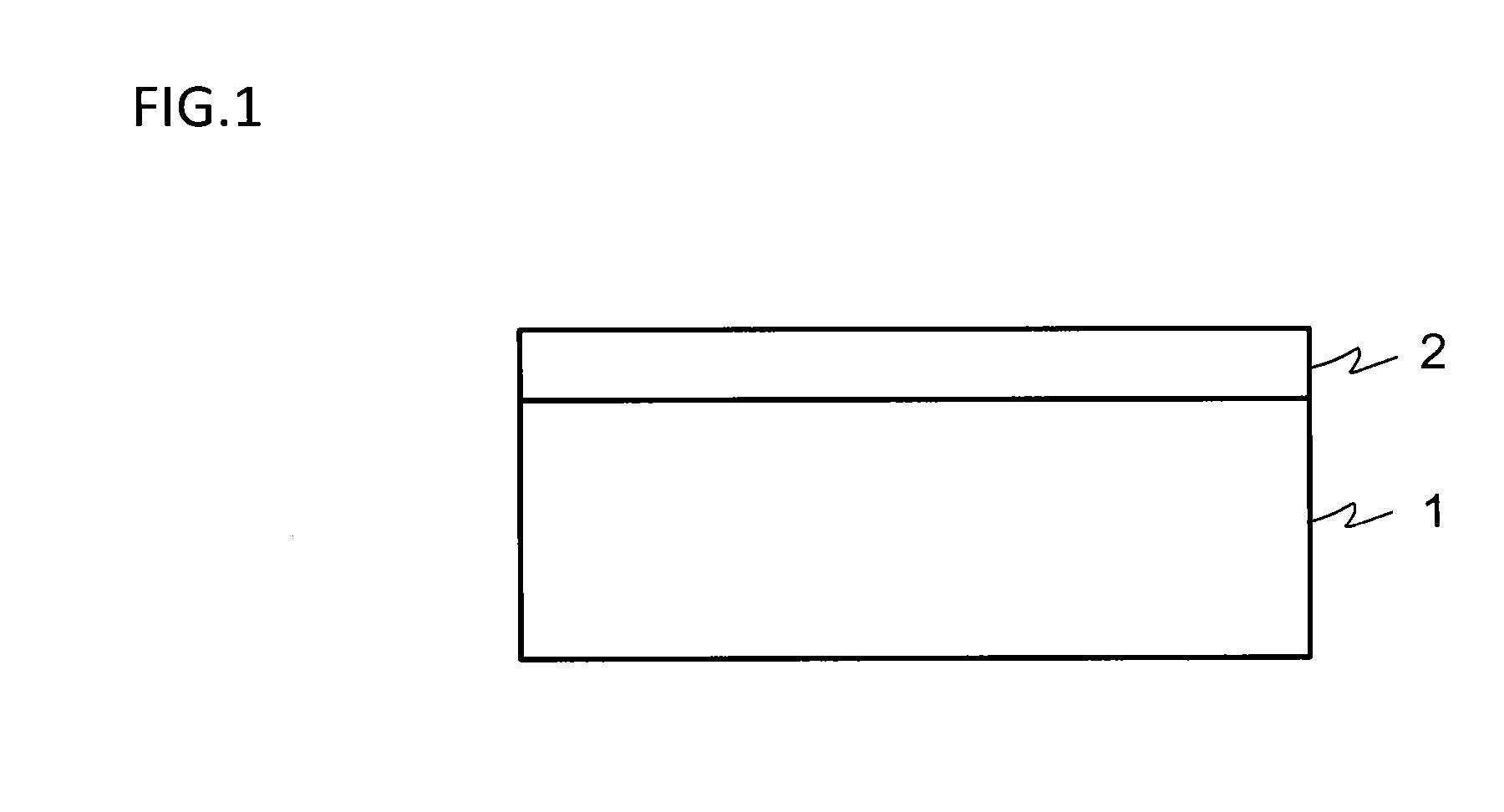

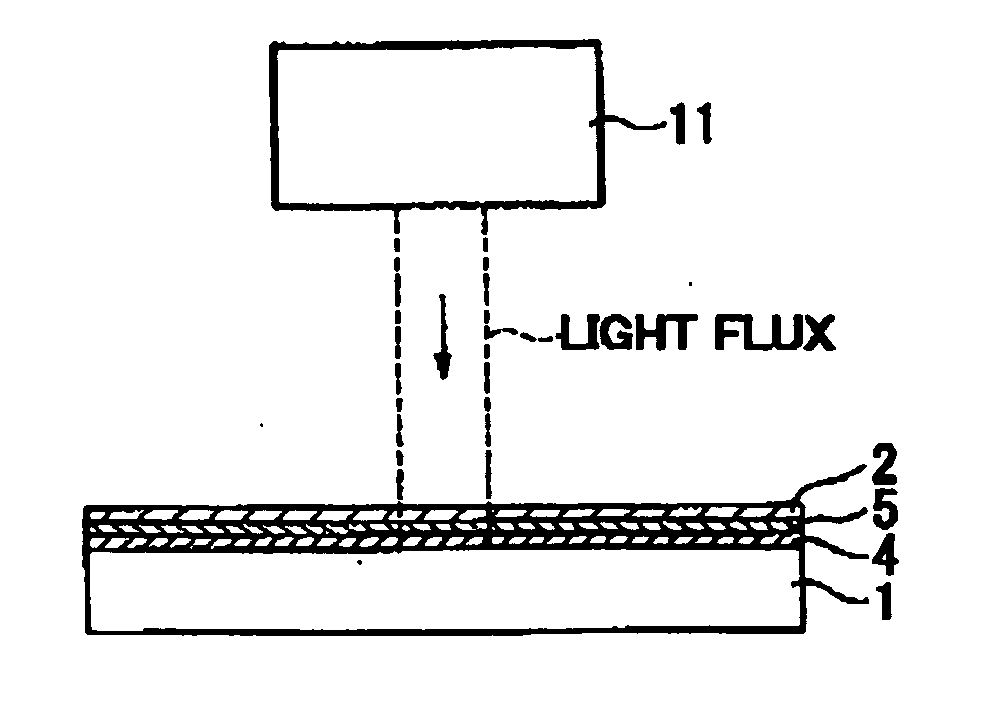

To provide a pattern forming method enabling a thin film to be patterned with high precision by easy and low cost techniques. A thin film 2 is provided on a base material 1 containing a sublimable dyestuff, light is irradiated to the base material 1, and heat generated by the light irradiation sublimates the sublimable dyestuff in a desired region, thereby removing the thin film 2 corresponding to an irradiation region where the light is irradiated to thereby pattern this thin film 2.

Owner:SEIKO EPSON CORP

Conductivity variable composition, conductivity variable laminated body, and conductive pattern formed body

InactiveUS8142688B2Easy to changeProvides insulating propertiesPhotosensitive materialsConductive materialInorganic materialsElectrical resistivity and conductivity

The present disclosure provides a conductive pattern formed body with a conductive pattern formed efficiently and highly precisely in a simple process, a conductivity variable laminated body used for formation of the conductive pattern, and the like. The disclosure provides a conductivity variable composition characterized by containing insulating particle including a conductive inorganic material and an organic material adhered on the circumference of the conductive inorganic material, and a photocatalyst.

Owner:DAI NIPPON PRINTING CO LTD

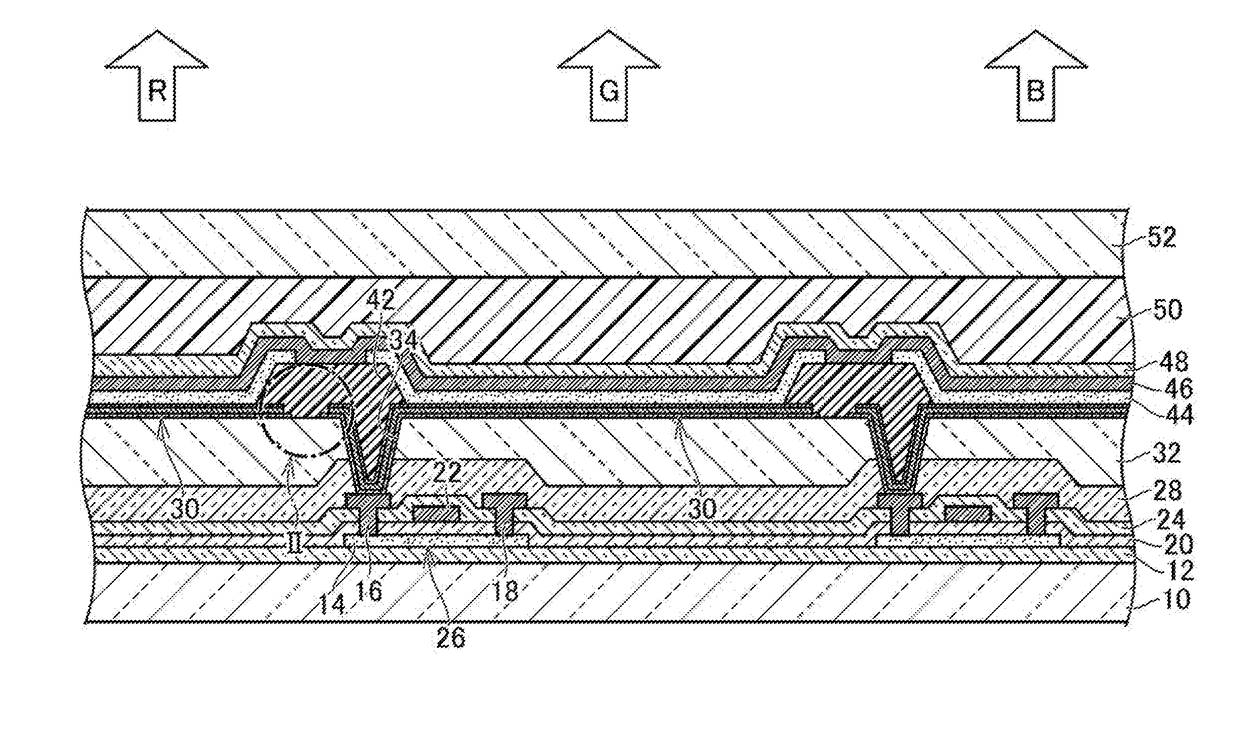

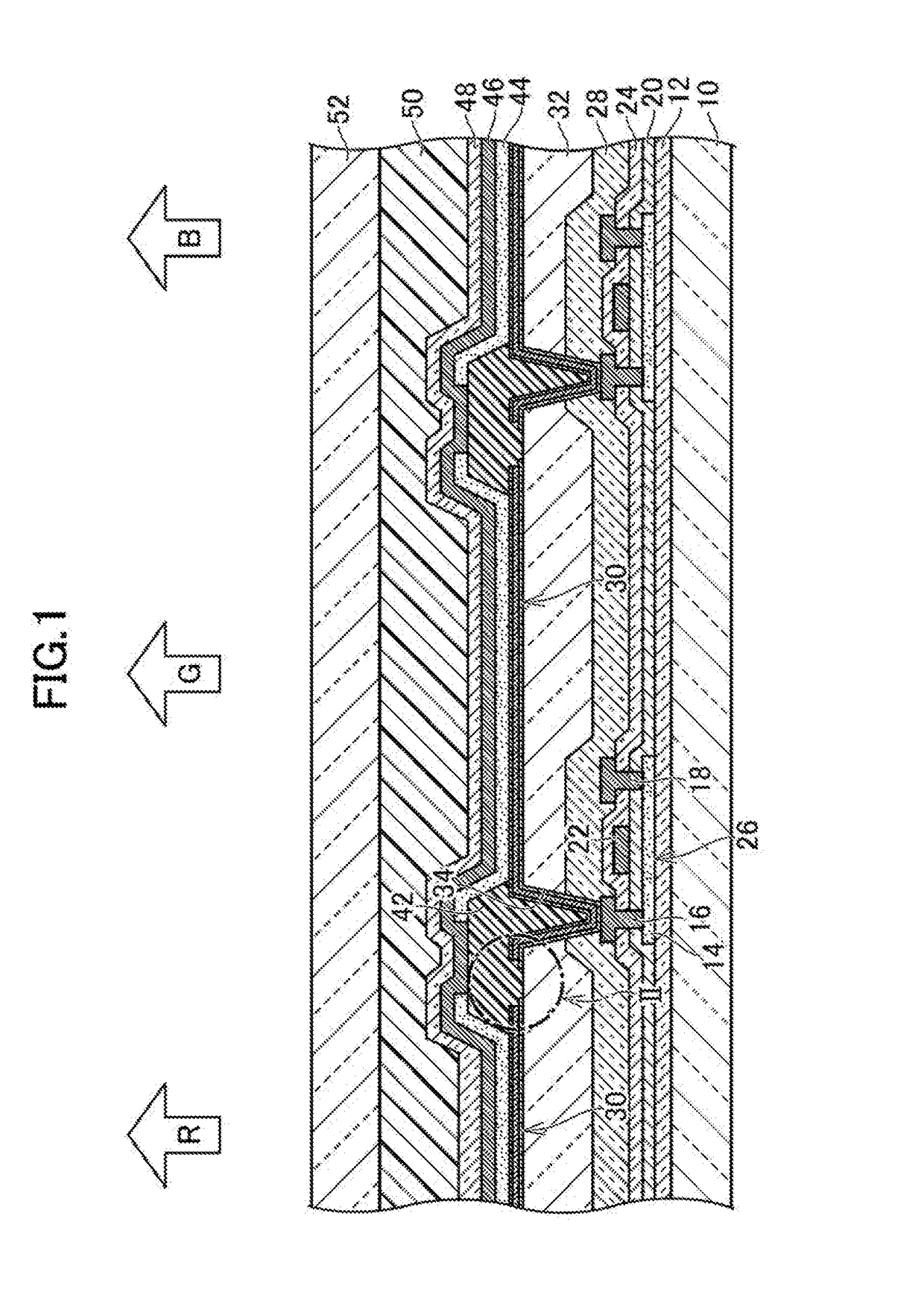

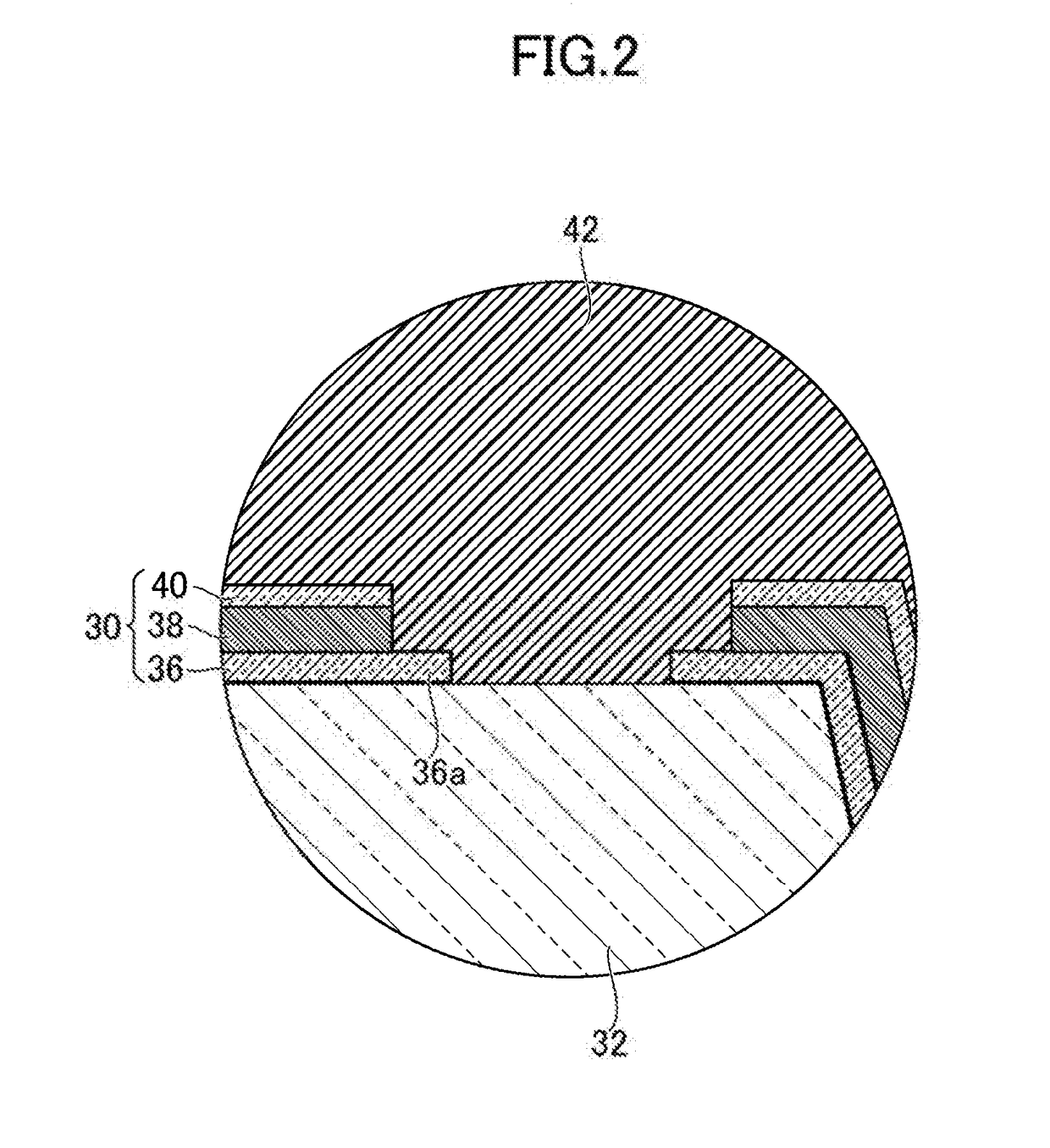

Display device and method for manufacturing the same

ActiveUS20170221923A1Improve accuracyHigh-precision patternSolid-state devicesSemiconductor devicesDisplay deviceOptoelectronics

A display device includes: a base layer; pixel electrodes laminated on the base layer; a light emitting element layer laminated on the pixel electrodes; and a common electrode laminated on the light emitting element layer. Each of the pixel electrodes includes a first oxide conductive layer that is in direct contact with the base layer, a metal conductive layer that is in direct contact with the first oxide conductive layer, and a second oxide conductive layer that is in direct contact with the metal conductive layer. The base layer has an adhesion to the first oxide conductive layer that is higher than that of the metal conductive layer. The first oxide conductive layer includes a protrusion part that is extended farther than the metal conductive layer and the second oxide conductive layer in a direction, adjacent two of the pixel electrodes facing each other in the direction.

Owner:JAPAN DISPLAY INC

Magnetic head having toroidal coil layer and manufacturing method thereof

ActiveUS7667927B2Improve accuracyShorten the lengthConstruction of head windingsRecord information storageEngineeringToroidal coil

First and second magnetic layers of a magnetic head face each other. A toroidal coil layer having upper and lower layer coil pieces (ULCP and LLCP) is wound around one of the magnetic layers. The ULCP extend from a first insulating layer by downward steps to a top of a second insulating layer which is widened at ends of the first insulating layer. Side ends of the first insulating layer extend parallel to a height direction. The ULCP are orthogonal to the side ends. Each of the LLCP is formed on a third insulating layer and has a straight region extending in the same direction as the upper layer coil pieces and a curved region curved toward a facing surface or in a height direction on one end in the track width direction. An end of each of the straight and curved region is connected to an ULCP.

Owner:TDK CORPARATION

Ink jet recording head, producing method therefor and composition for ink jet recording head

InactiveUS20090284567A1Increased durabilityIncrease resistanceRecording apparatusInksSilane compoundsImage recording

The invention provides a method for producing an ink jet recording head having a high durability and a high ink resistance and enabling a high-quality image recording by employing a material capable of reducing the internal stress and having satisfactory patterning characteristics. It also provides a method of producing such ink jet recording head with a high precision. A cationically photopolymerizable resin composition containing a condensate of a hydrolysable organosilane compound, employed as a material for forming a flow path forming member, enables a reduction of internal stress and a highly precise pattern in the flow path forming member thereby providing an ink jet recording head having a high durability and a high ink resistance and capable of high-quality printing over a prolonged time, and a producing method therefor.

Owner:CANON KK

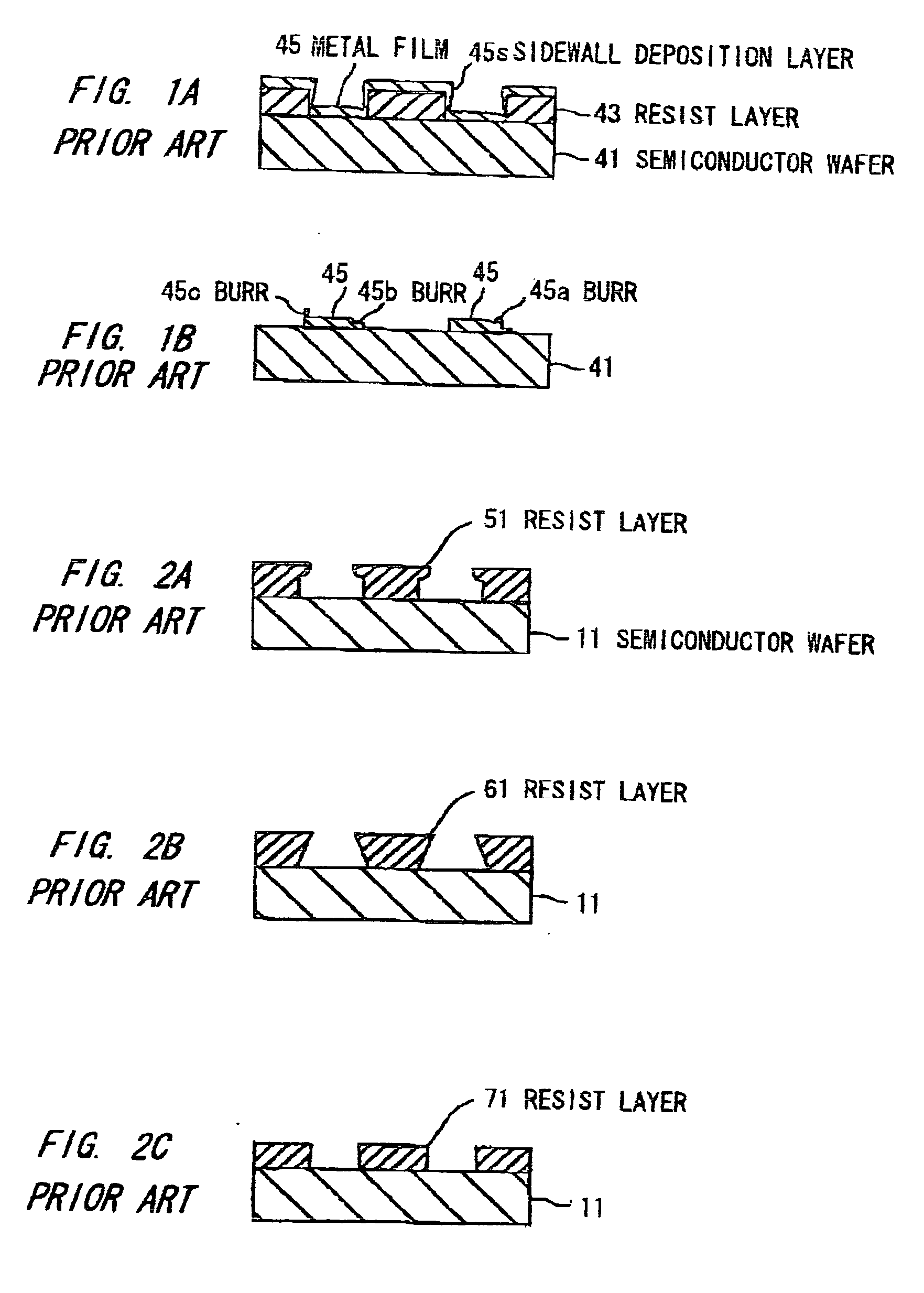

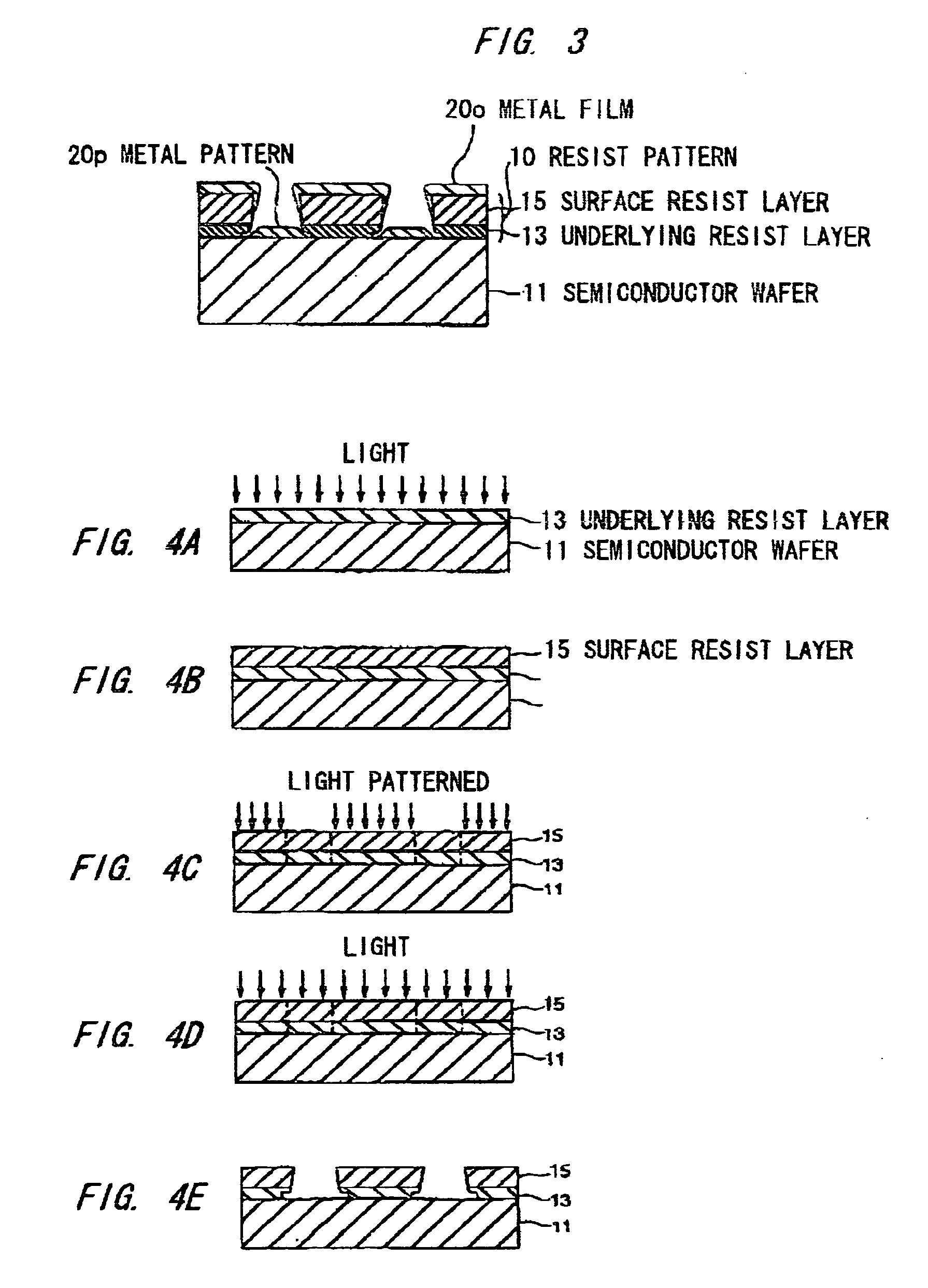

Semiconductor device fabrication method

InactiveUS20060138078A1Shorten the length of timeHigh-precision patternDecorative surface effectsSemiconductor/solid-state device manufacturingResistLight exposure

A semiconductor device fabrication method applies a diazo novolac photoresist to a semiconductor wafer, followed by light exposure of its entire surface to form an underlying resist layer; forms a surface resist layer thereover; performs patterned-light exposure and heat treatment to the photoresist film consisting of the two resist layers formed; and exposes its entire surface to light, followed by development to process the photoresist film into a resist pattern, where the surface resist layer is in an inverse tapered shape, while the underlying resist layer is in an undercut shape relative to the surface resist layer.

Owner:HITACHI CABLE

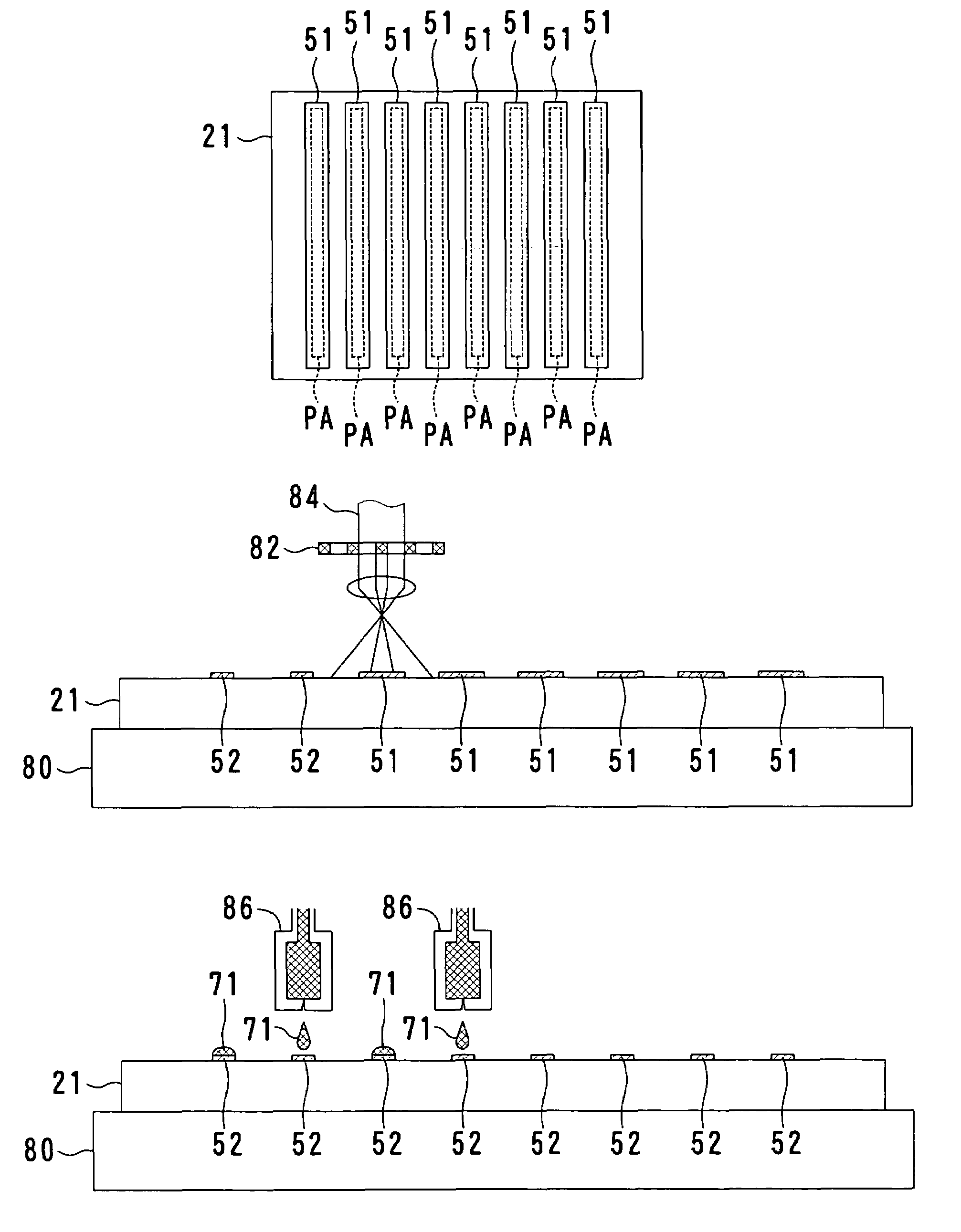

Organic electroluminescent device and manufacturing method thereof

InactiveUS7821199B2Improve accuracyImprove display qualityDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceLight-emitting diode

A highly fine organic electroluminescent device is provided. A method for manufacturing the organic electroluminescent device is provided for patterning a very fine light emitting layer, and a deposition mask is provided to be used in the patterning. For deposition of the light emitting layer, a mask member is provided with apertures (effective apertures) for forming the light emitting layer to be used for light emitting pixel and apertures (dummy apertures) not to be used for forming the light emitting pixel around an area (effective aperture area) separated by the outer edge of a group of the apertures. The light emitting layer is deposited by using the deposition mask.

Owner:TORAY IND INC

Conductivity variable composition, conductivity variable laminated body, and conductive pattern formed body

InactiveUS20060222889A1Easy to changeProvides insulating propertiesPhotosensitive materialsElectroluminescent light sourcesElectrical conductorInorganic materials

The main object of the present invention is to provide a conductive pattern formed body with a conductive pattern formed efficiently and highly precisely in a simple process, a conductivity variable laminated body used for formation of the conductive pattern, and the like. To attain the object, the invention provides a conductivity variable composition characterized by containing insulating particle including a conductive inorganic material and an organic material adhered on the circumference of the conductive inorganic material, and a photocatalyst.

Owner:DAI NIPPON PRINTING CO LTD

Pellicle frame, pellicle containing same, method for producing pellicle frame, and method for producing pellicle

ActiveUS20180239242A1High-precision patternHighly precise patterningSurface reaction electrolytic coatingOriginals for photomechanical treatmentPolyimideForeign matter

The purpose of the present invention is to provide: a pellicle frame which is not susceptible to deterioration even if irradiated with short-wavelength light such as excimer light, and which is not susceptible to generation of an outgas or foreign substance; and a pellicle which uses this pellicle frame. In order to achieve the above-described purpose, this pellicle frame for supporting the outer periphery of a pellicle film is configured to comprise a frame and a film that is formed on the surface of the frame and contains a polyimide resin.

Owner:MITSUI CHEM INC

Thin metal layers-having ceramic green sheet and method for producing ceramic capacitor

InactiveUS20050030696A1Shrink evenlyNon-uniform contractionFixed capacitor dielectricStacked capacitorsThin metalCeramic capacitor

The invention provides a thin metal layers-having ceramic green sheet comprising: a base film; a first thin metal layer formed on the whole surface of the base film; a second thin metal layer formed on the first thin metal layer in the form of predetermined pattern; and a ceramic powder-dispersed layer which comprises a binder and a ceramic powder dispersed therein and which is formed on the metal films including the first thin metal layer and said second thin metal layer. Also disclosed is a method for producing a ceramic capacitor using a plurality of the thin metal layers-having ceramic green sheets.

Owner:NITTO DENKO CORP

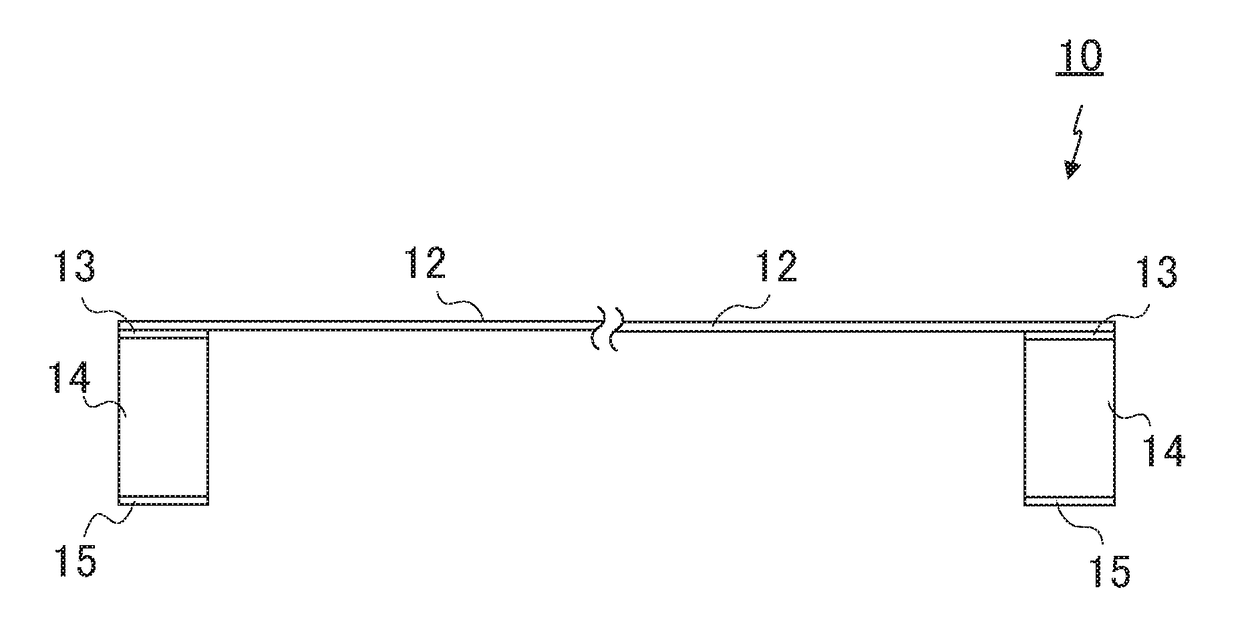

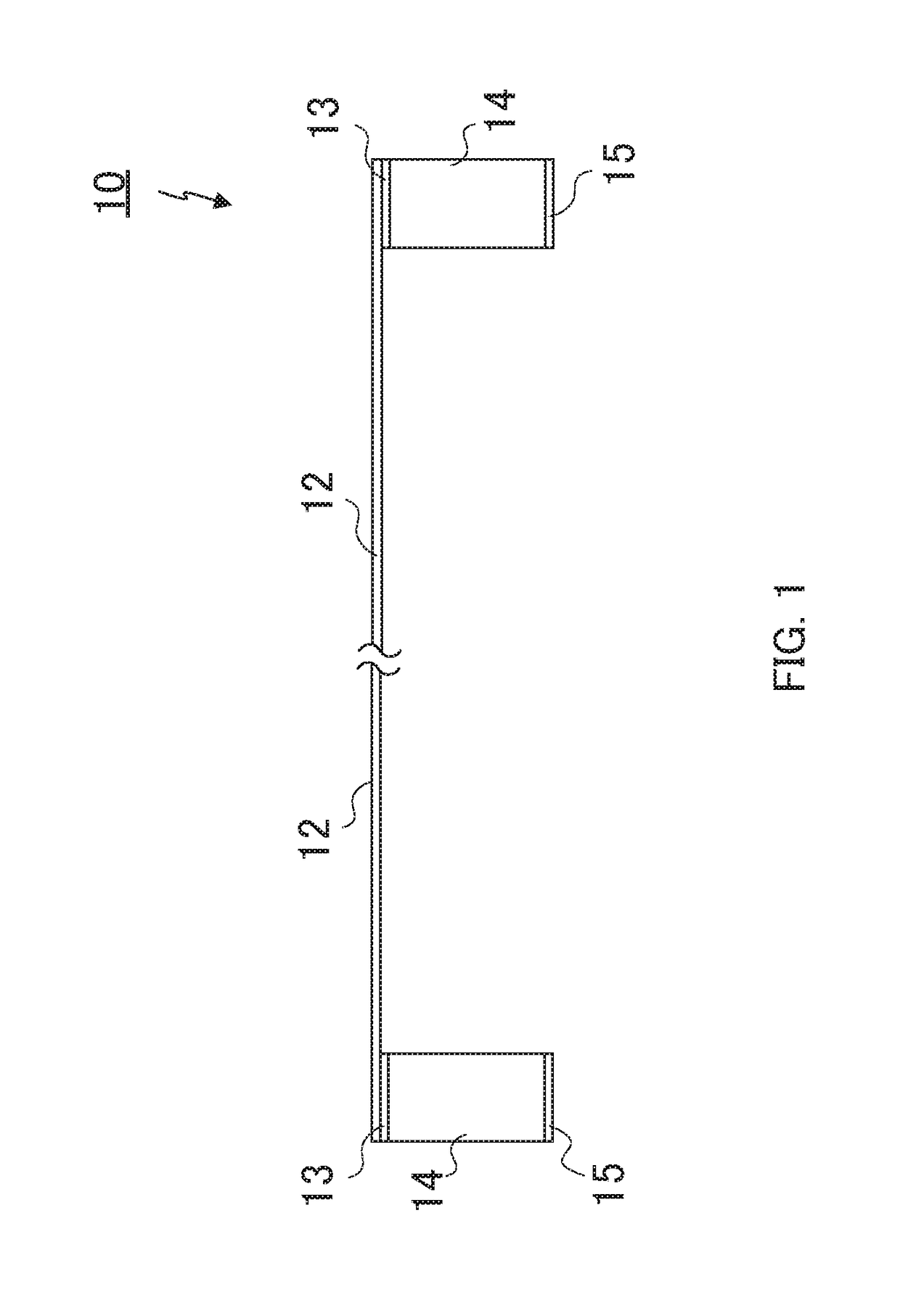

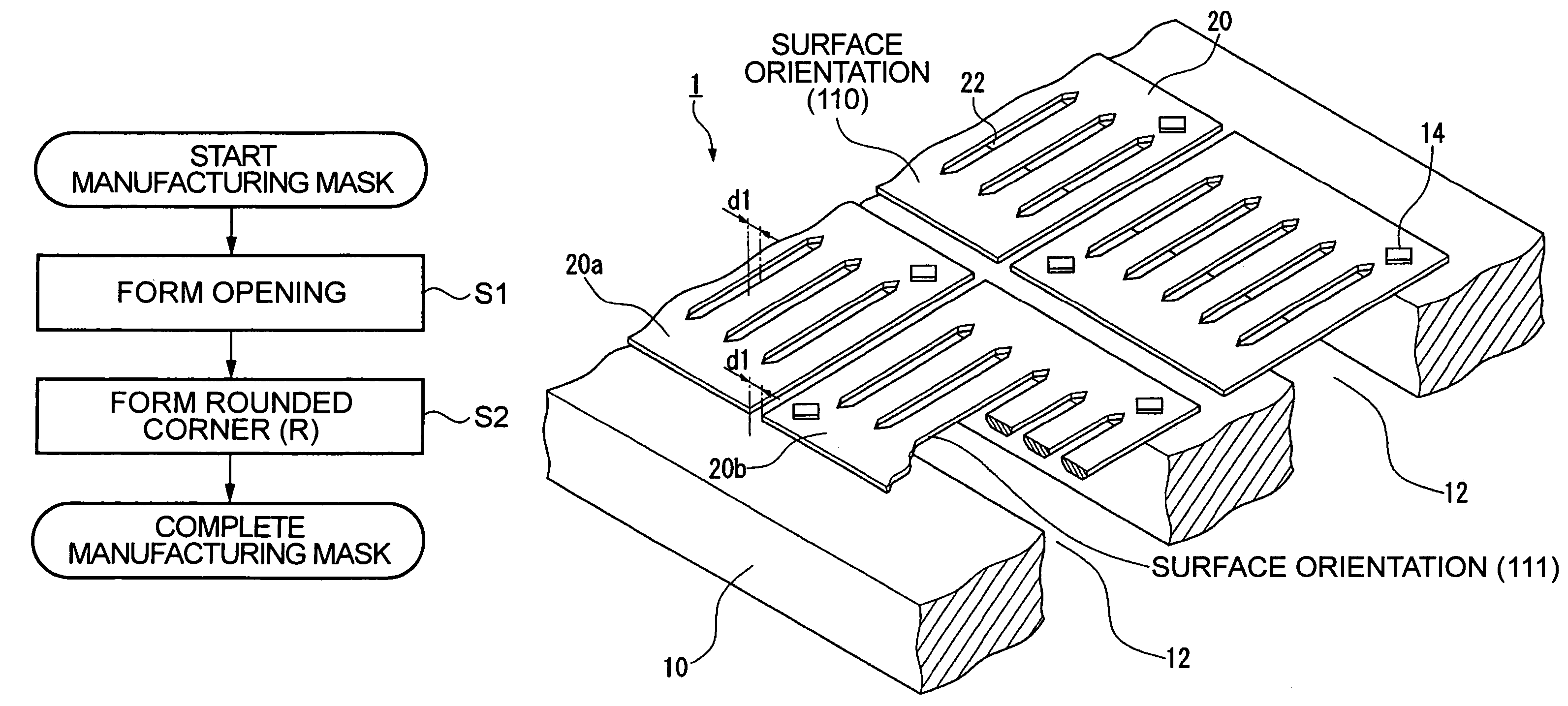

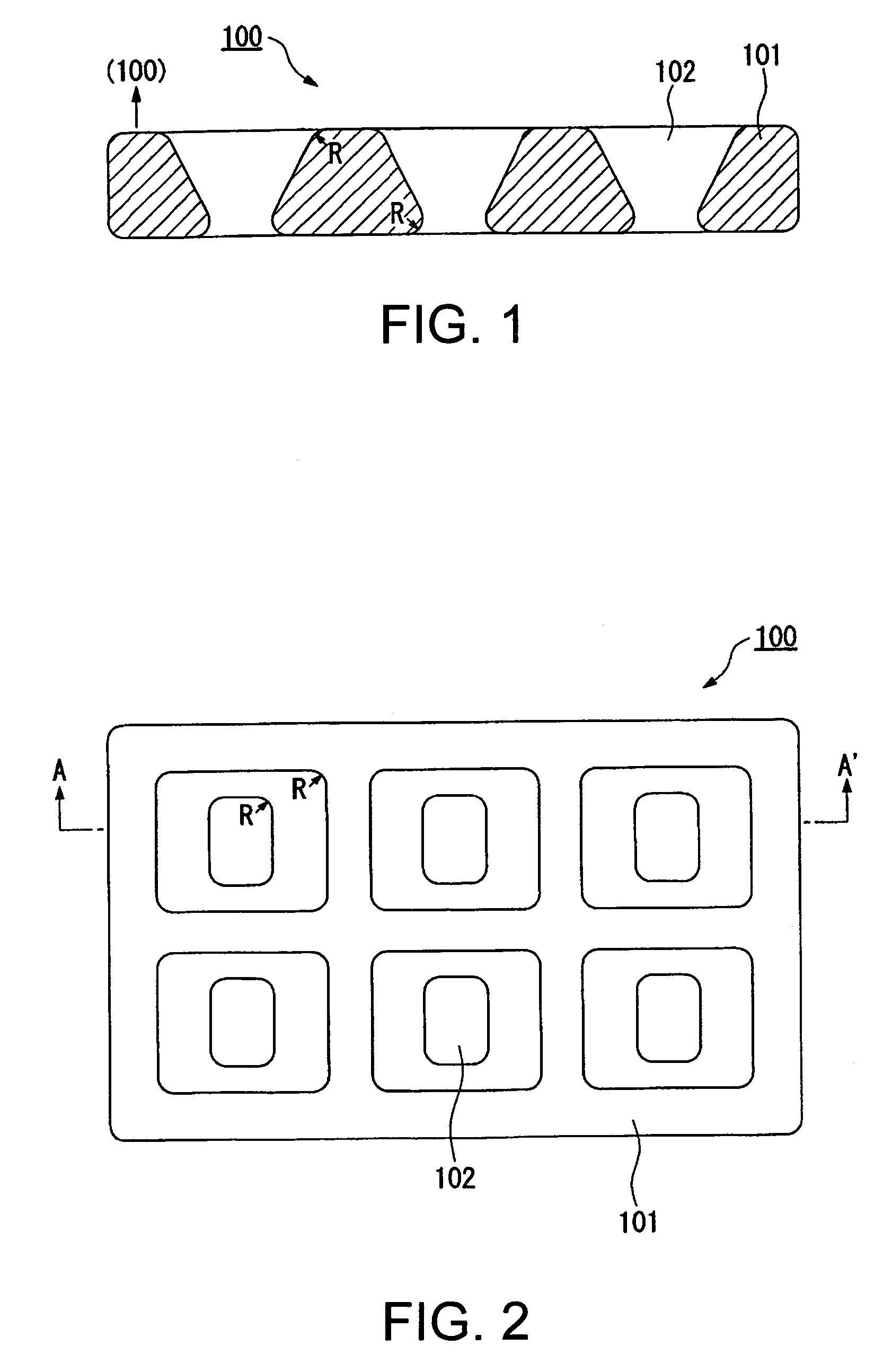

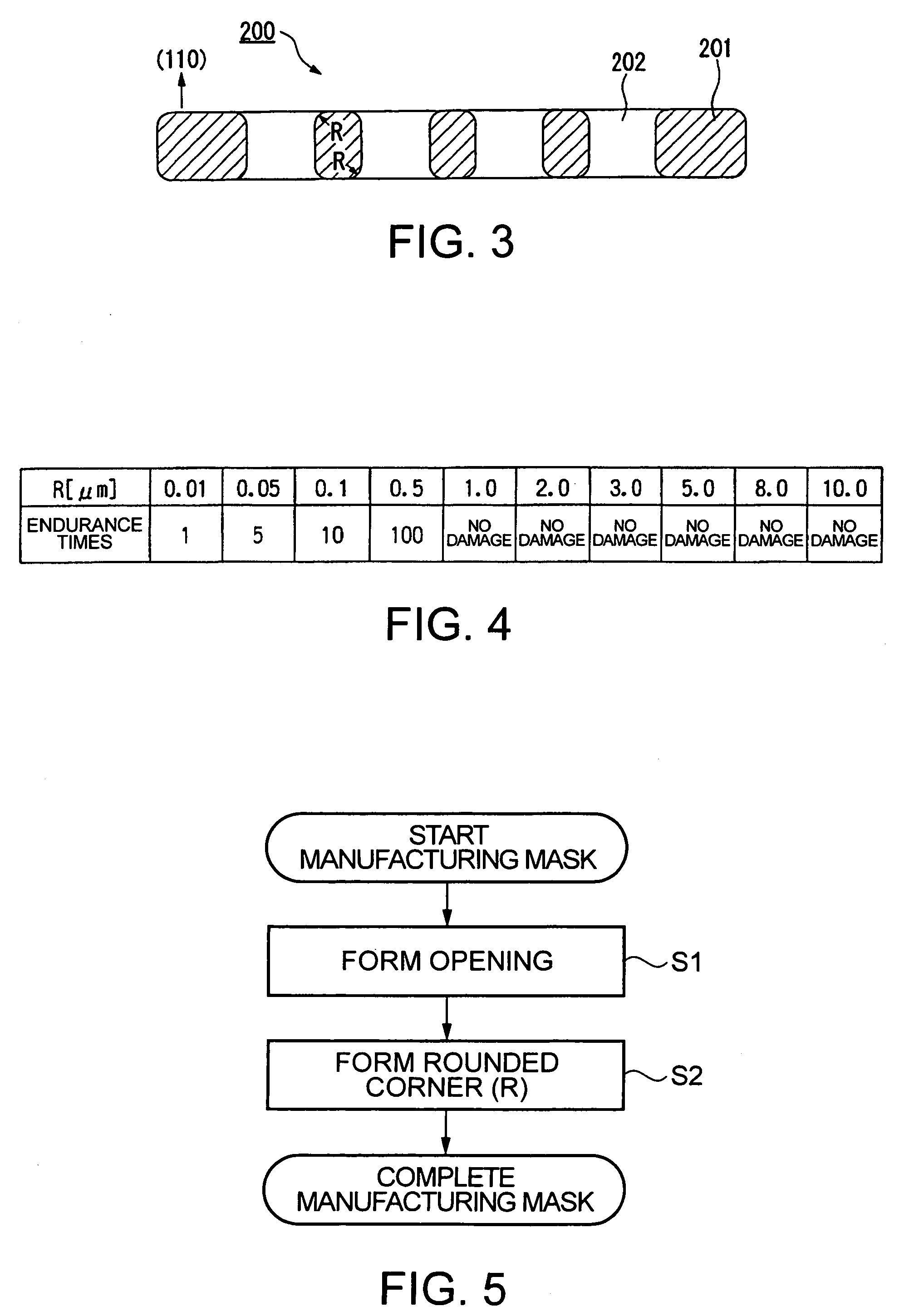

Mask, method for manufacturing a mask, method for manufacturing an electro-optical device, and electronic equipment

InactiveUS7285497B2Reduce size changeImprove machining accuracySewerage structuresPipesEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

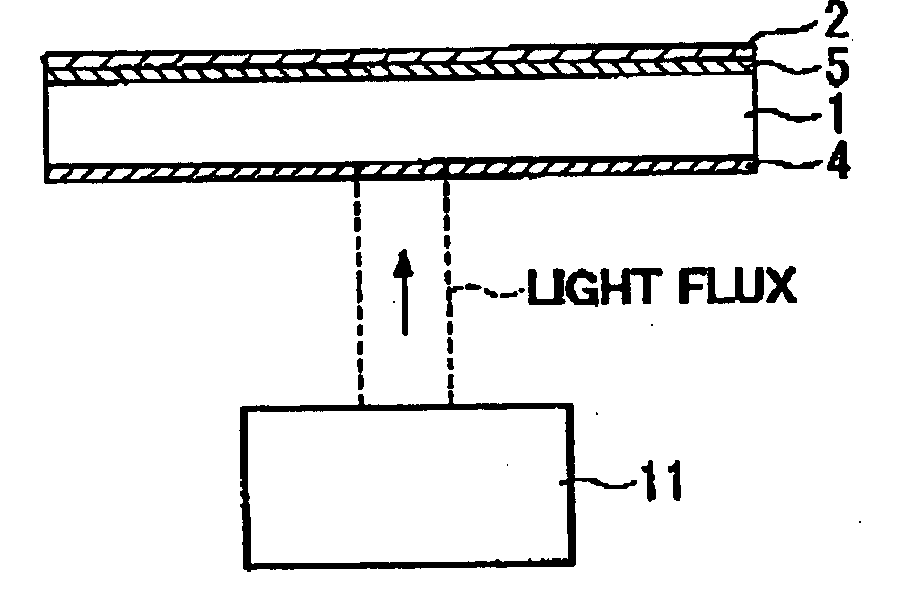

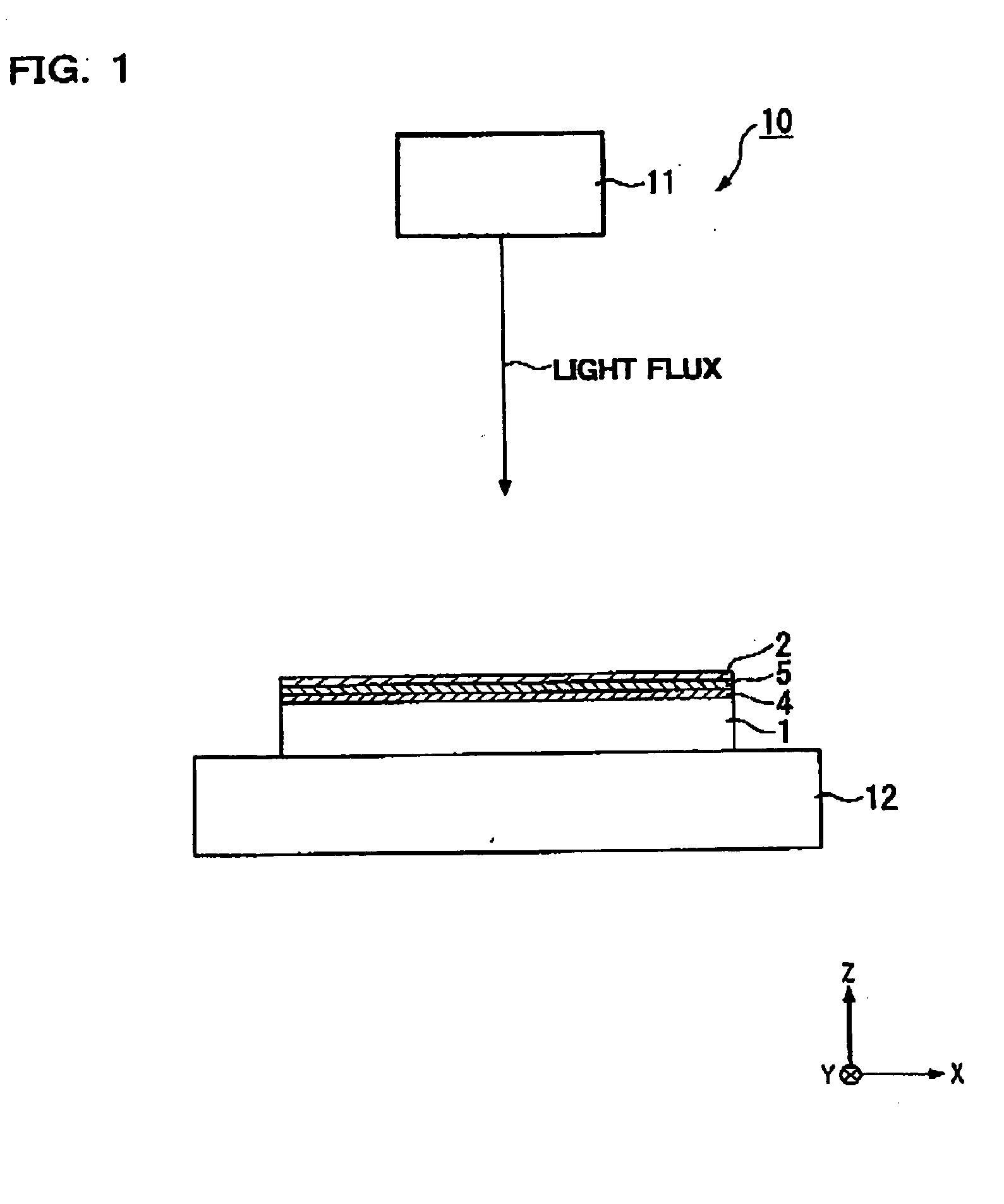

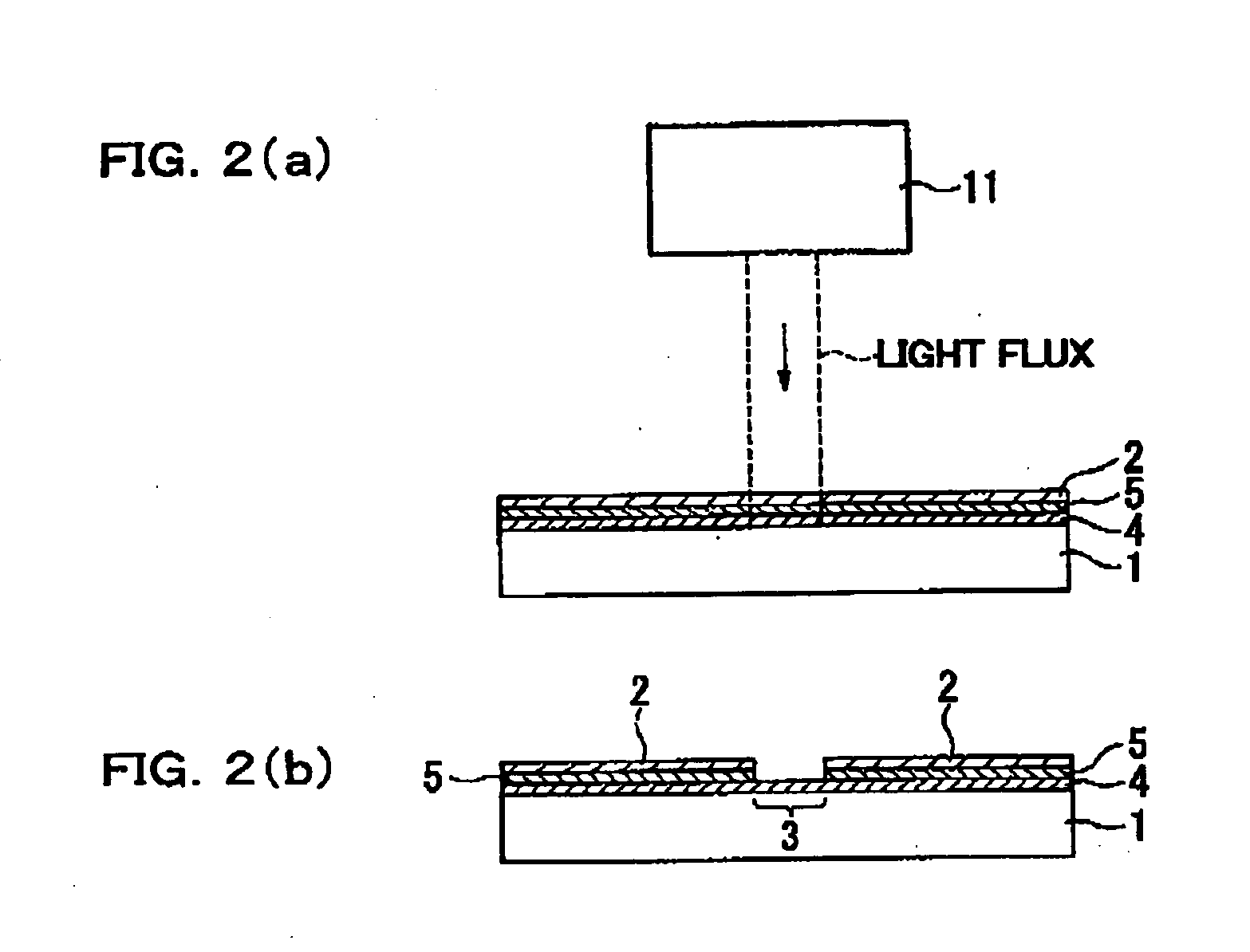

Pattern forming method and wiring pattern forming method, and electro-optic device and electronic equipment

ActiveUS20050037275A1Efficiently converted into thermal energyLow costMaterial nanotechnologyDiffusion transfer processesLight irradiationEngineering

To provide a pattern forming method enabling a thin film to be patterned with high precision by easy and low cost techniques. A thin film 2 is provided on a base material 1 containing a sublimable dyestuff, light is irradiated to the base material 1, and heat generated by the light irradiation sublimates the sublimable dyestuff in a desired region, thereby removing the thin film 2 corresponding to an irradiation region where the light is irradiated to thereby pattern this thin film 2.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Glass ceramic material for plasma display

InactiveUS7910507B2Improve accuracyHigh-precision patternGas discharge electrodesGas discharge vessels/containersGlass fiberRefractive index

There is provided a glass ceramic material for plasma display, in which glass fine grains (A) having a softening point of 570-640° C. are in 40-70 wt %, and glass fine grains (B) having a softening point of 480-540° C. are in 30-60 wt %, the glass ceramic material for plasma display being characterized in that the glass fine grains (A) comprise 2-12 wt % of SiO2, 50-58 wt % of B2O3, 10-20 wt % of Al2O3, 0-6 wt % of ZnO, 0-2.8 wt % of Li2O, and 10-22 wt % of at least one selected from MgO, CaO, SrO and BaO and that refractive index of the glass fine grains (A) is 1.53-1.56.

Owner:CENT GLASS CO LTD

Patterned material layer, method of forming the same, microdevice, and method of manufacturing the same

InactiveUS20060228877A1High saturate magnetic flux densityTurn easilySemiconductor/solid-state device manufacturingRecord information storageResistChemistry

A method of forming a patterned material layer, the method comprising: a resist layer forming step of forming a resist layer on a substrate, the resist layer including a first photosensitive resin layer, an intermediate resin layer, and a second photosensitive resin layer; an exposing step; a developing step of partly removing the resist layer so as to form a trench exposing the substrate and partly removing the intermediate resin layer so as to form a groove on a side face of the trench, thereby forming a resist frame; a vacuum coating step of forming a vacuum coating layer having a material pattern part covering the exposed part of the substrate and a part to lift off covering the resist frame; and a liftoff step of removing the part to lift off in the vacuum coating layer together with the resist frame, so as to yield a patterned material layer.

Owner:TDK CORPARATION

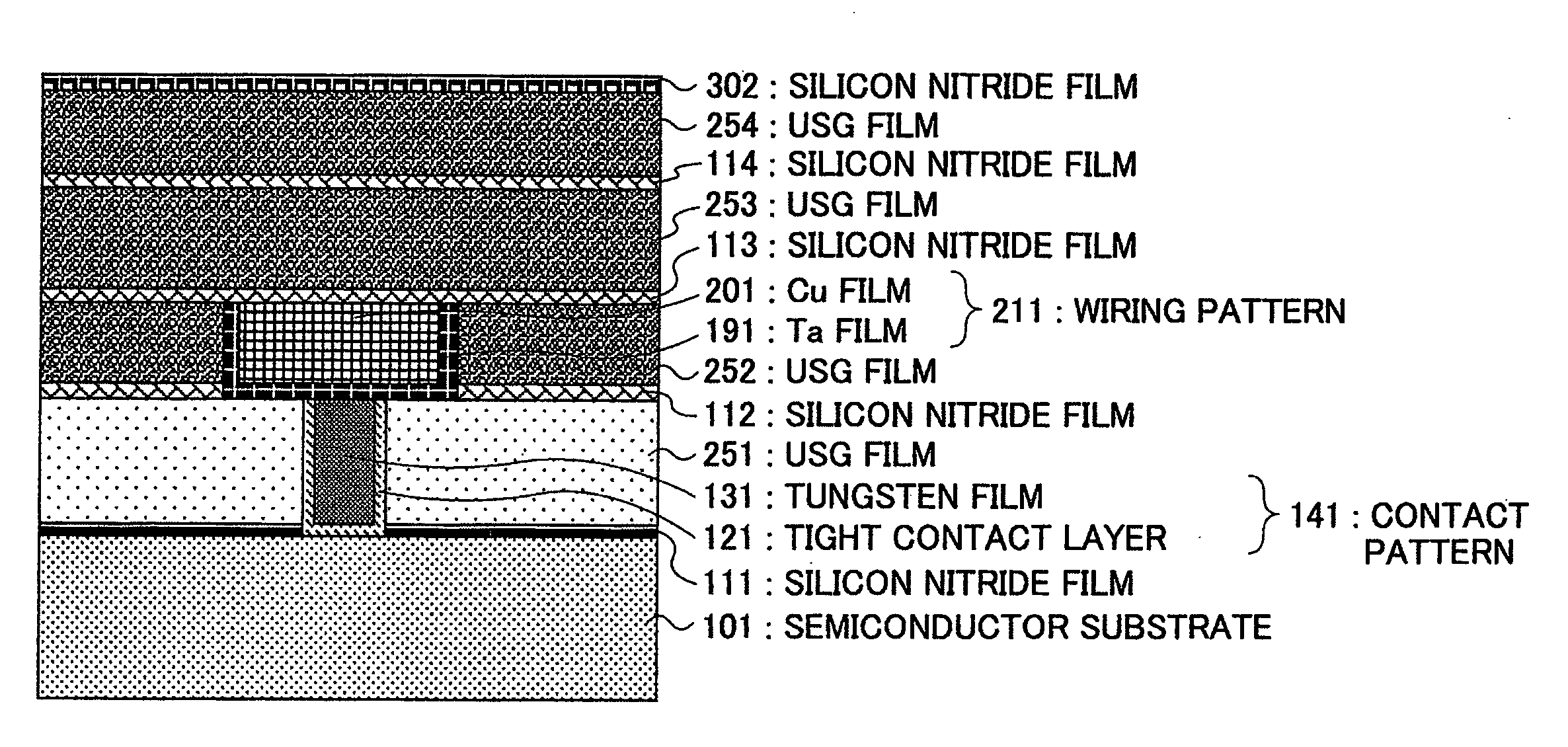

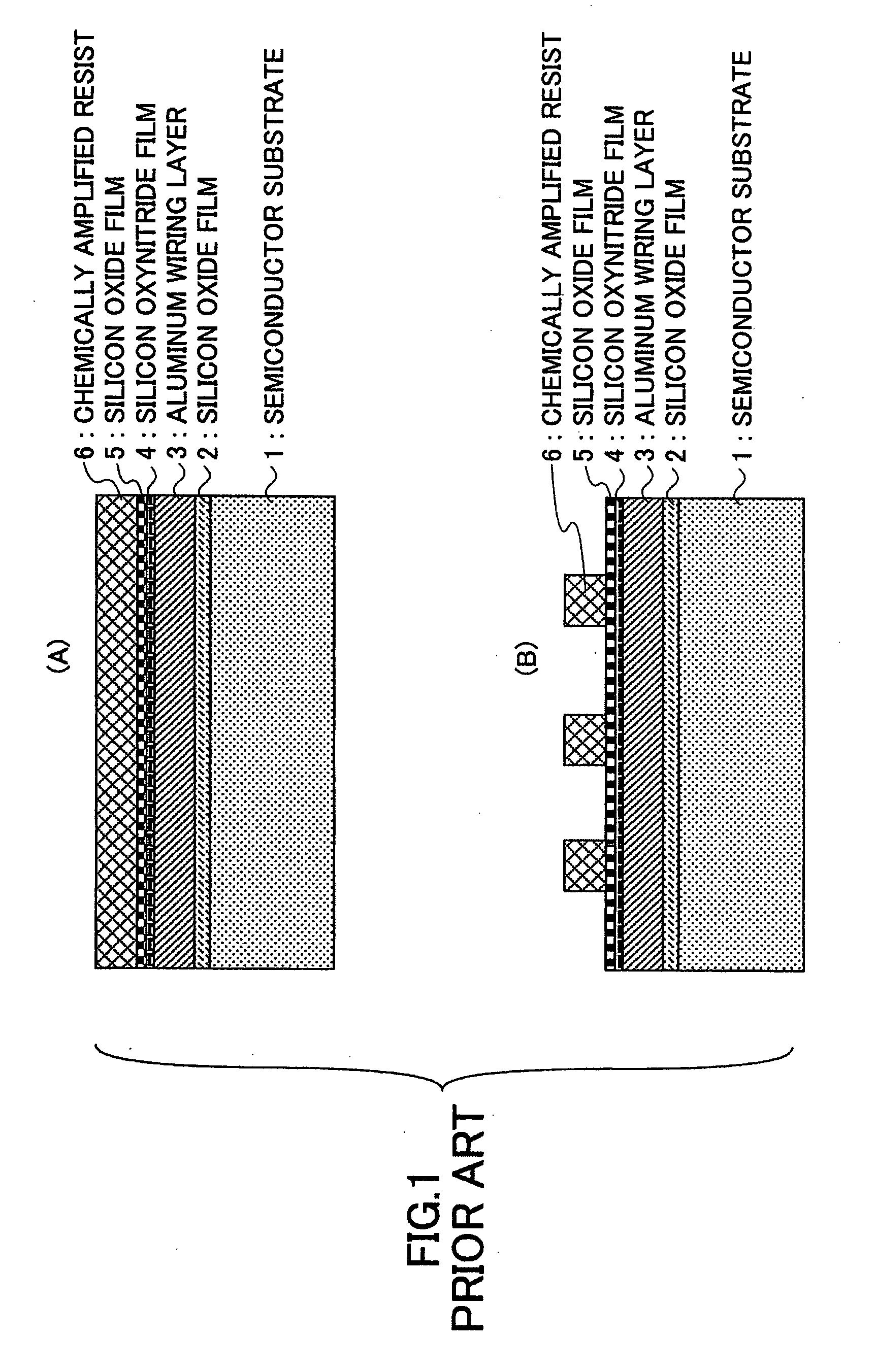

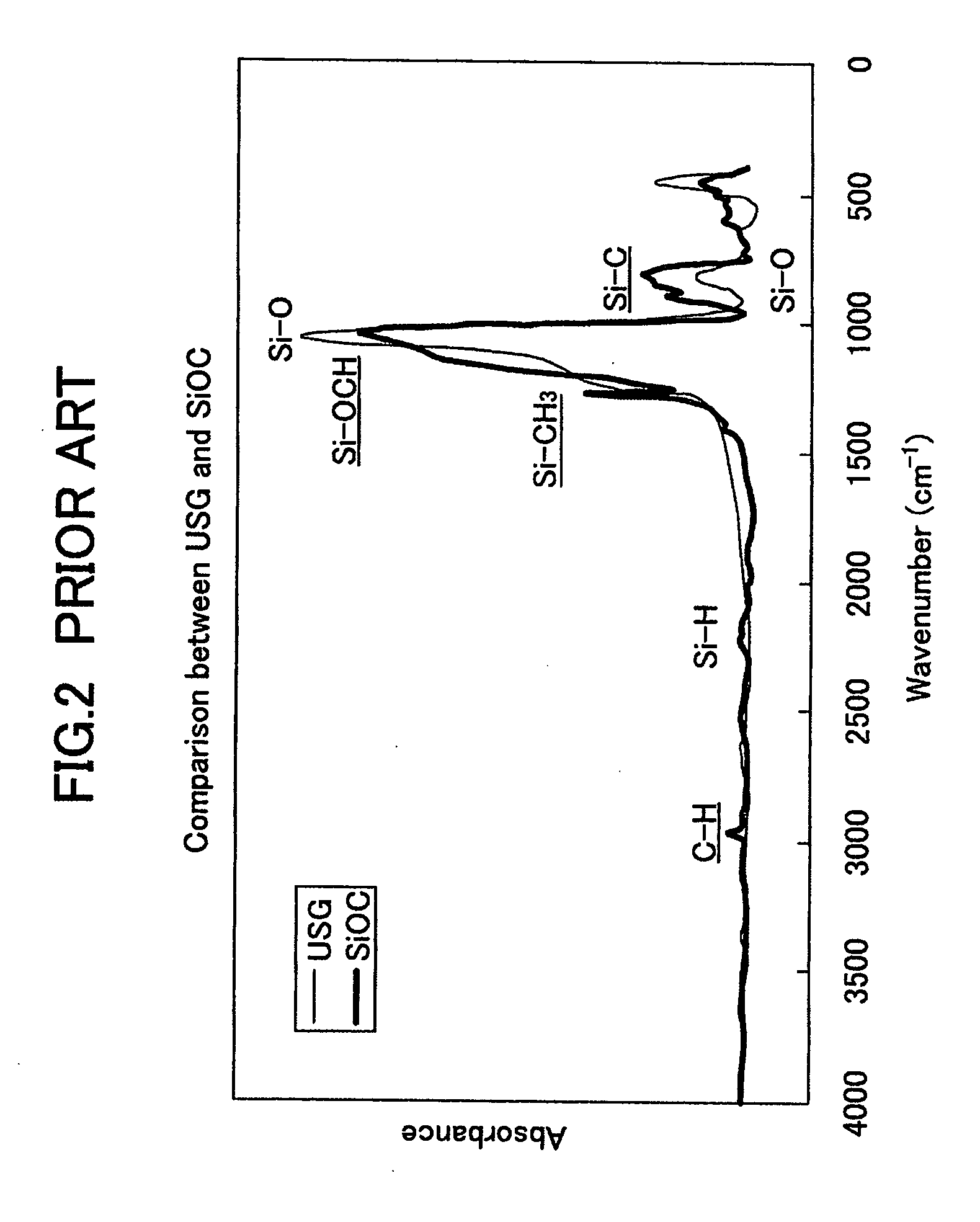

Method of making a semiconductor device with residual amine group free multilayer interconnection

InactiveUS20090149031A1Prevents dissolution hindering effectHigh-precision patternSemiconductor/solid-state device detailsSolid-state devicesResistDissolution

The present invention provides a semiconductor device that can restrict the dissolution hindering phenomenon in a chemically amplified resist film. More specifically, after the formation of a contact pattern on a semiconductor substrate, a wiring pattern is formed on the contact pattern. A SiC film, a first SiOC film, a SiC film, a second SiOC film, a USG film as a diffusion preventing film, and a silicon nitride film as a reflection preventing film, are formed on the wiring pattern. A dual damascene structure is then formed using the chemically amplified resist film and another chemically amplified resist film. In this manner, the N2 gas generated during the formation of the silicon nitride film as a reflection preventing film can be prevented from diffusing into the second SiOC film formed under the silicon nitride film. Accordingly, the reaction of the N2 gas with the H group contained in the second SiOC film and the generation of an amine group such as NH in the second SiOC film can be prevented. Thus, the dissolution hindering phenomenon in the chemically amplified resist film can be avoided.

Owner:FUJITSU MICROELECTRONICS LTD

Graphene structure, method for producing the same, electronic device element and electronic device

InactiveUS9607725B2Reduce manufacturing costHigh-precision patternMaterial nanotechnologyDecorative surface effectsResistManufacturing cost reduction

Provided are a graphene structure and a method for producing the same in which graphene can be patterned with high precision, and thereby microfabrication of electronic device elements and electronic devices using graphene is possible and the manufacturing cost can be notably reduced. A resist film is precisely patterned on a substrate, hydrophilized films are formed in openings of the resist film, and then GO is selectively fixed on the portions of the hydrophilized films by a chemical bond utilizing the hydrophilicity of the GO, and the GO is reduced to obtain a graphene structure in which graphene is selectively fixed to only the portions of the hydrophilized films. Thus, the graphene structure is constituted by disposing graphene on a substrate and forming a bond, by hydrophilization treatment, between the hydrophilized portion of the substrate and the graphene and / or between the unhydrophobized portion of the substrate and the graphene.

Owner:EMPIRE TECH DEV LLC

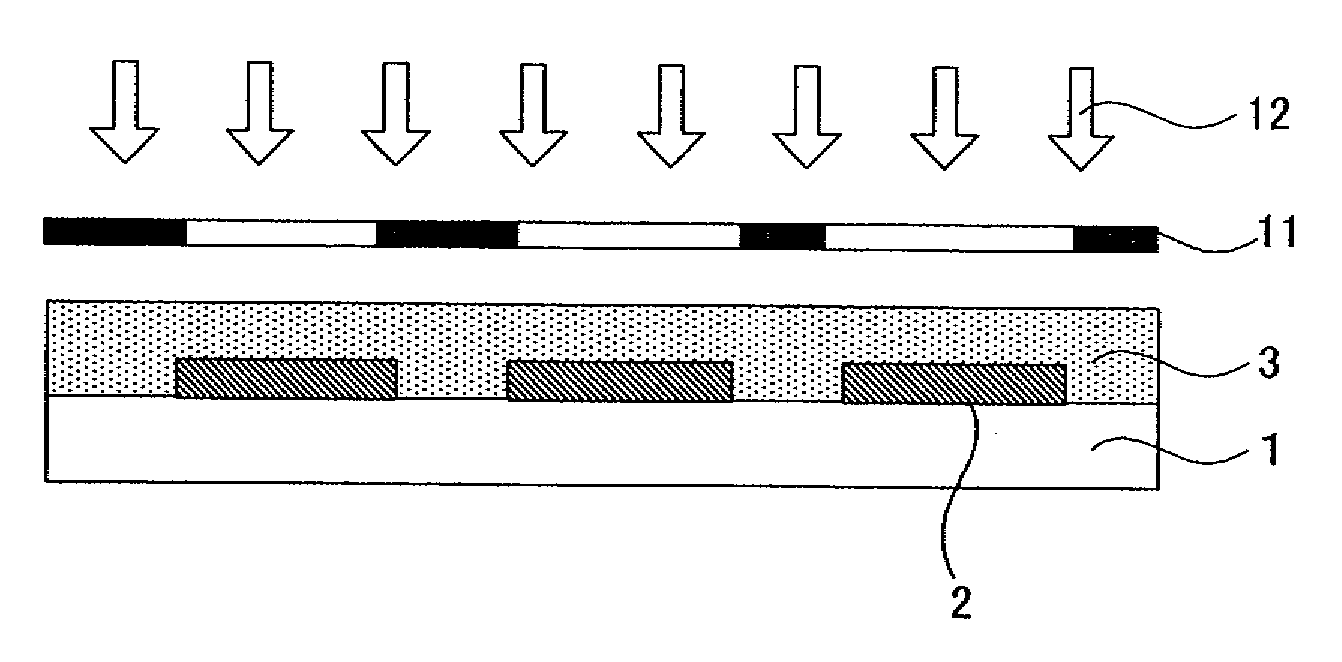

Substrate for organic electroluminescent element, and organic electroluminescent element

InactiveUS20100127706A1High-precision patternShort timeSolid-state devicesMeasurements using electron paramagnetic resonanceUltravioletOrganic electroluminescence

The object of the present invention is to provide a substrate for an organic EL element capable of forming an organic EL layer efficiently in a highly precise pattern in a short period of time, and an organic EL element having the preferable electric characteristics.To attain the object, the invention provides a substrate for an organic electroluminescent element comprising a base material, an electrode layer formed in a pattern on the base material, and a photocatalyst containing layer formed to cover the electrode layer and contains a photocatalyst and a binder so as to show the wettability change by the action of the photocatalyst accompanied by the energy irradiation, wherein the photocatalyst containing layer contains a portion with the signal intensity of the electron spin resonance spectrum derived from the hydroxy radical increased to 1,000 times or more in 1 second within 600 seconds of the start of the irradiation of the ultraviolet ray at the time of measuring the electron spin resonance spectrum while irradiating the ultraviolet ray.

Owner:DAI NIPPON PRINTING CO LTD

Method of manufacturing flat panel displays utilizing a surface treating layer

InactiveUS7037161B2Improve wettabilityReduce the amount requiredAddress electrodesGas discharge vessels/containersDisplay deviceEngineering

To enable formation of a pattern of constituent elements, arranged in correspondence with an arrangement of cells in a display region, as desired or required with a minimized quantity of the film material, a method of manufacturing a flat panel display is provided which includes printing on a substrate a surface treating material capable of partially enhancing the wettability of the substrate, in a predetermined pattern sufficient to encompass the eventually formed pattern of constituent elements of the flat panel display. Undercoats made of the surface treating material so printed is then patterned by irradiation of light. Thereafter, utilizing the undercoats, a film material is thereafter selectively deposited on the substrate to thereby complete the predetermined pattern of the constituent elements.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

Method of manufacturing flat panel displays

InactiveUS20050032454A1Cost reductionImprove wettabilityAddress electrodesGas discharge vessels/containersFilm materialEngineering

To enable formation of a pattern of constituent elements, arranged in correspondence with an arrangement of cells in a display region, as desired or required with a minimized quantity of the film material, a method of manufacturing a flat panel display is provided which includes printing on a substrate a surface treating material capable of partially enhancing the wettability of the substrate, in a predetermined pattern sufficient to encompass the eventually formed pattern of constituent elements of the flat panel display. Undercoats made of the surface treating material so printed is then patterned by irradiation of light. Thereafter, utilizing the undercoats, a film material is thereafter selectively deposited on the substrate to thereby complete the predetermined pattern of the constituent elements.

Owner:FUJITSU HITACHI PLASMA DISPLAY LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com