Pattern forming method and wiring pattern forming method, and electro-optic device and electronic equipment

a technology of pattern forming and pattern forming, which is applied in the direction of diffusion transfer process, thermography, instruments, etc., can solve the problems of difficult patterning, high cost and large-scale device, and the above-mentioned related art, etc., to achieve low cost device structure, high precision, and efficient conversion into thermal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

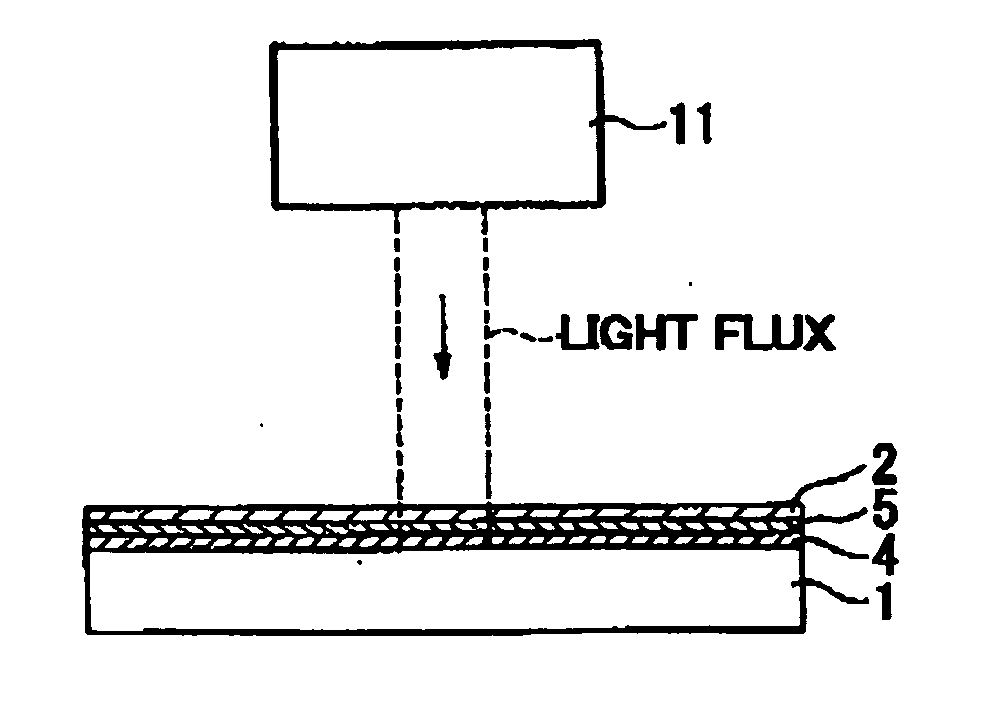

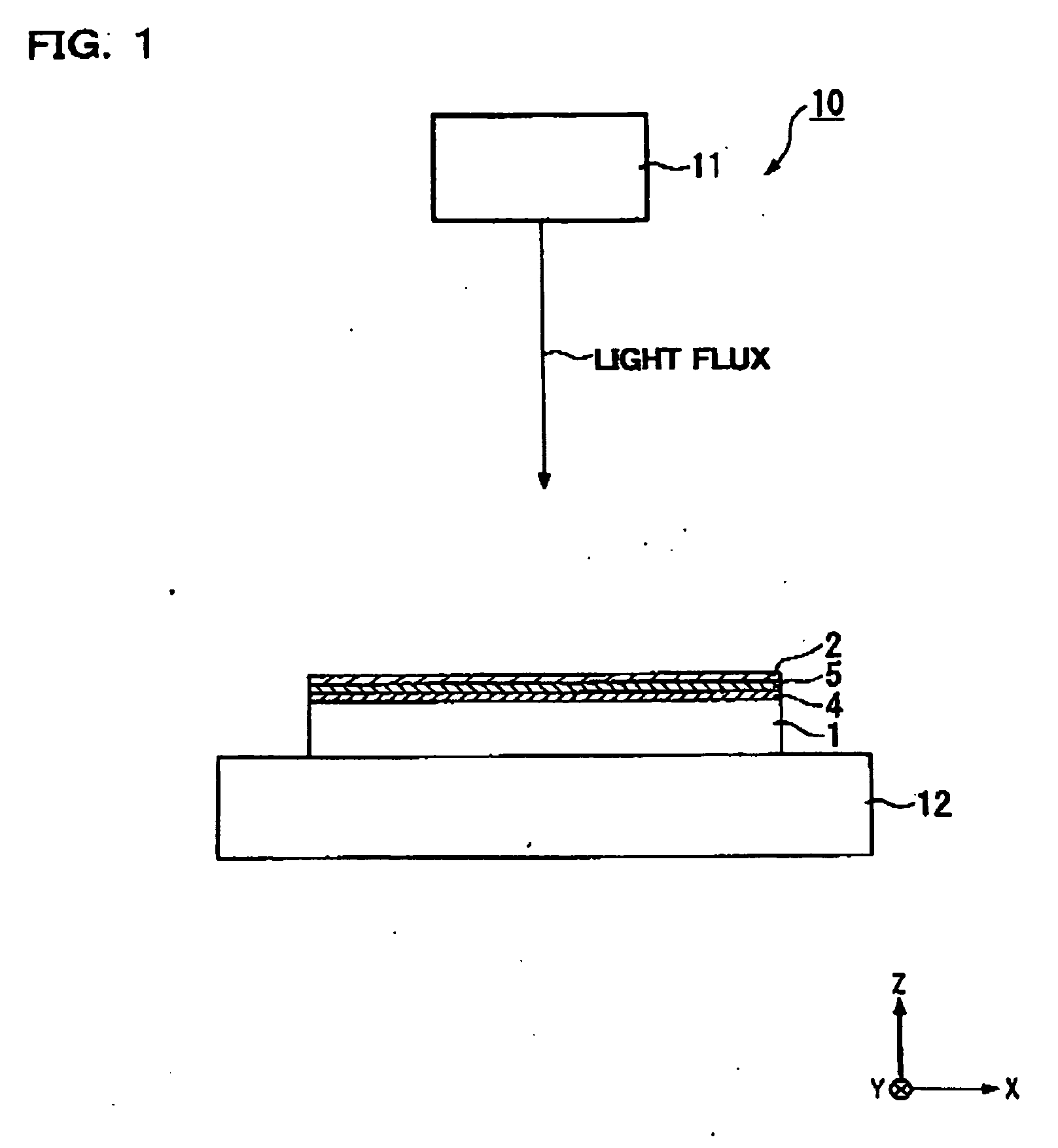

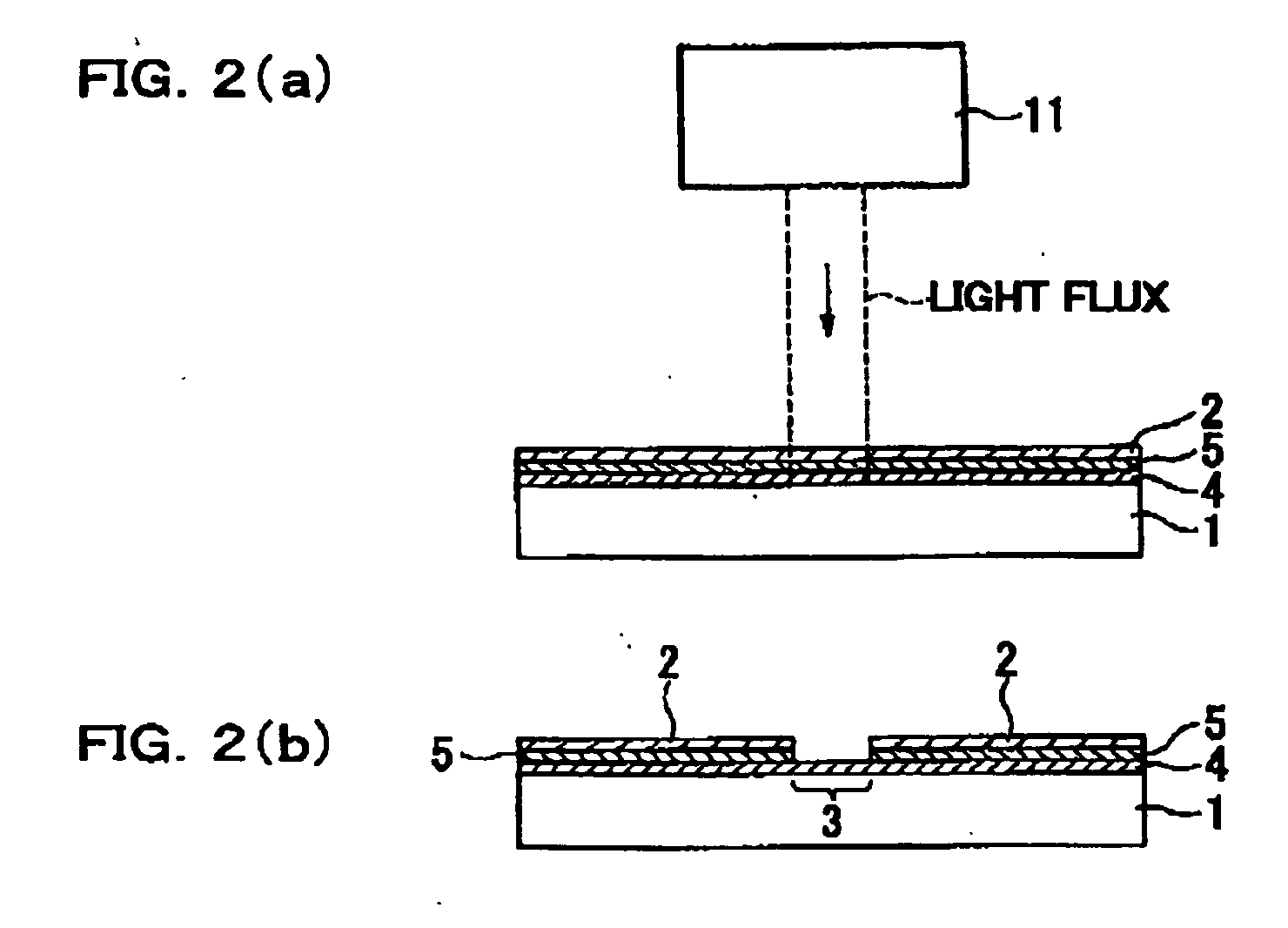

[0040] Hereinafter, a description of a pattern forming method of the present invention is given referring to the drawings. FIG. 1 is a schematic structural view showing one embodiment of a pattern forming device used for the thin film pattern forming method of the present invention. In FIG. 1, a pattern forming device 10 comprises a laser light source 111 emitting laser light flux having a predetermined wavelength, and a stage 12 supporting a base material 1 to be processed. On an upper surface of the base material 1, a photothermal conversion layer 4 is provided, on the photothermal conversion layer 4, a sublimable dyestuff layer 5 is provided, and on the sublimable dyestuff layer 5, a thin film 2 is provided. In this structure (the respective layers on the upper surface side) of the base material 1, it is also possible that the photothermal conversion layer 4 is omitted to provide the sublimable dyestuff 5 on the upper surface of the base material 1, and to provide the thin film 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com