Ink jet recording head, producing method therefor and composition for ink jet recording head

a technology of ink jet recording head and producing method, which is applied in the direction of recording apparatus, photomechanical apparatus, instruments, etc., can solve the problems of insufficient resolution, inability to meet the needs of recording, etc., to achieve high quality image recording, high durability, and high ink resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

[0095]A hydrolysable condensate was synthesized by a following process. With hydrochloric acid as a catalyst, 55.6 g (0.2 mol) of glycidoxypropyl triethoxysilane, 48.1 g (0.2 mol) of phenyl triethoxysilane and 21.6 g of water were stirred at the room temperature and then refluxed under heating for 24 hours to obtain a solution of a hydrolysable condensate. The degree of condensation of silane, measured by 29Si-NMR, was about 69%.

example 1

[0096]The compound of Synthesis Example 1 was used for preparing a composition shown in Table 1, thereby obtaining a coating solution.

TABLE 1(coating composition)hydrolyxablehydrolysable230parts by weightcondensatecondensate solutionof SyntheticExample 1epoxy resinEHPE-3150 (Daicel100parts by weightChemical)cationic photopoly-SP172 (Asahi Denka)5parts by weightmerizationinitiatorreducing agentcopper (II)0.5parts by weighttrifluoromethane-sulfonatesolventethanol10parts by weight

[0097]The coating solution of the above-mentioned composition was spin coated on a silicon substrate to form a coated layer, which was prebaked for 4 minutes at 90° C. A thickness of the coated film was 20 μm. Then it was exposed with a Canon mask aligner (MPA600 Super), then heated for 4 minutes at 90° C., developed with methyl isobutyl ketone and rinsed with isopropyl alcohol to form an evaluation pattern. Thereafter it was heated for 1 hour at 200° C. to obtain a cured substance.

example 12

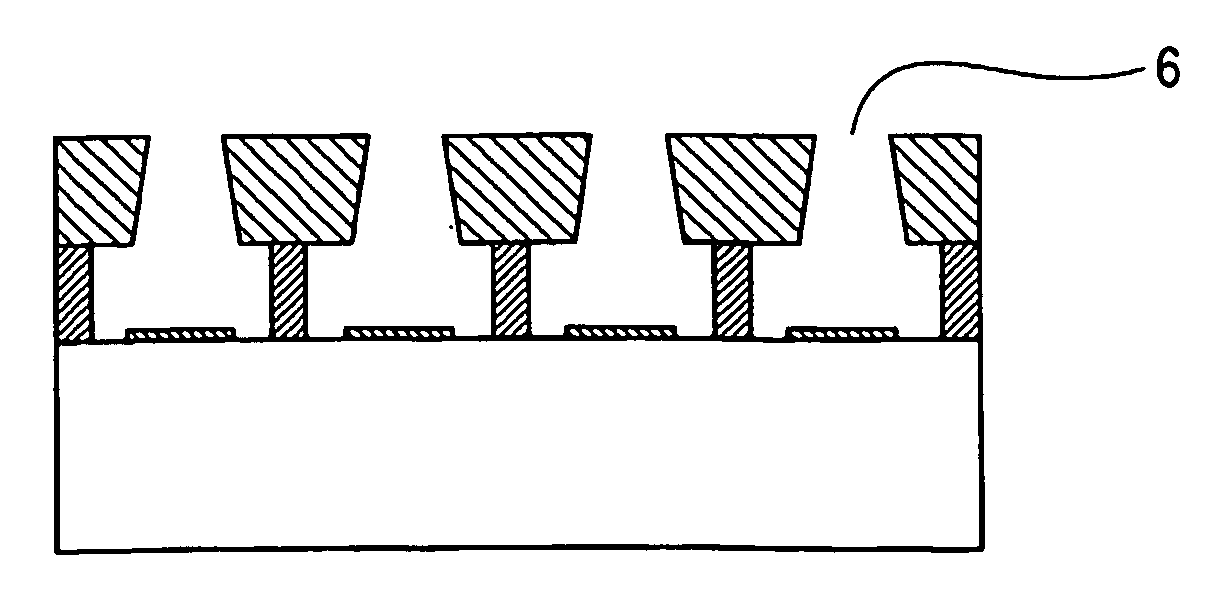

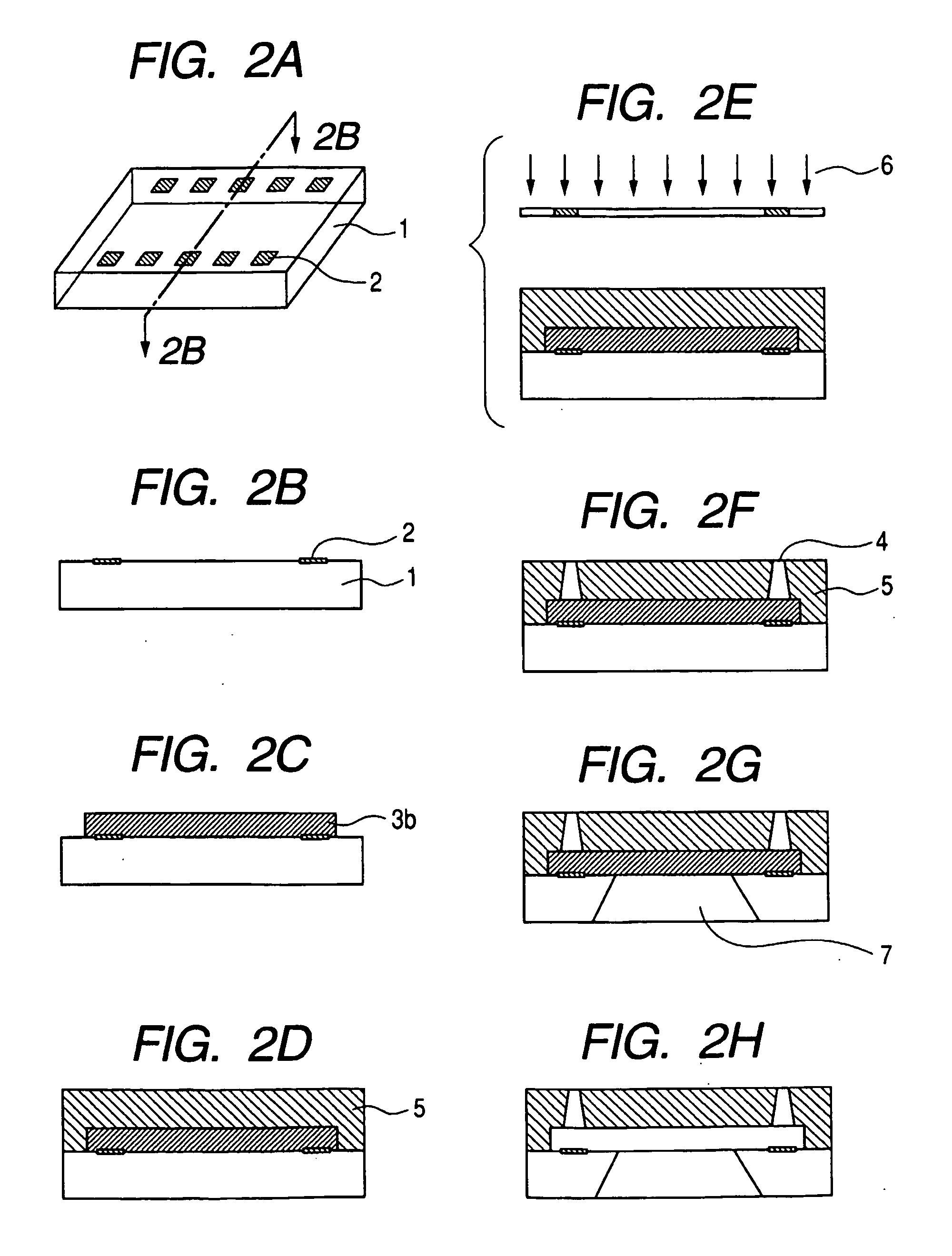

[0104]An ink jet recording head was prepared with the composition of Example 1 according to the procedure shown in FIGS. 2A to 2H. At first, on a silicon substrate on which electric-heat conversion elements were formed as ink discharge energy generating elements, polymethyl isopropenyl ketone (ODUR-1010, manufactured by TOKYO OHKA KOGYO Co.) was spin coated as a soluble resin layer. It was then prebaked for 6 minutes at 120° C. and subjected to a pattern exposure with a mask aligner UX3000 manufactured by Ushio Inc. The exposure was executed for 3 minutes, and development was executed with methyl isobutyl ketone / xylene=2 / 1 followed by rinsing with xylene. Polymethyl isopropenyl ketone is so-called positive resist which is decomposed by a UV irradiation and becomes soluble in an organic solvent. The pattern of such soluble resin is formed in a non-exposed portion at the pattern exposure, for securing an ink supplying flow path (FIG. 2C). The soluble resin had a thickness of 20 μm aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| discharging energy | aaaaa | aaaaa |

| photocurable | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com