Method for improving LTCC interlayer alignment precision and preparation method of LTCC chip device

A technology of alignment accuracy and green ceramic sheet, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of size asymmetry, ceramic block expansion, etc. The effect of small size changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

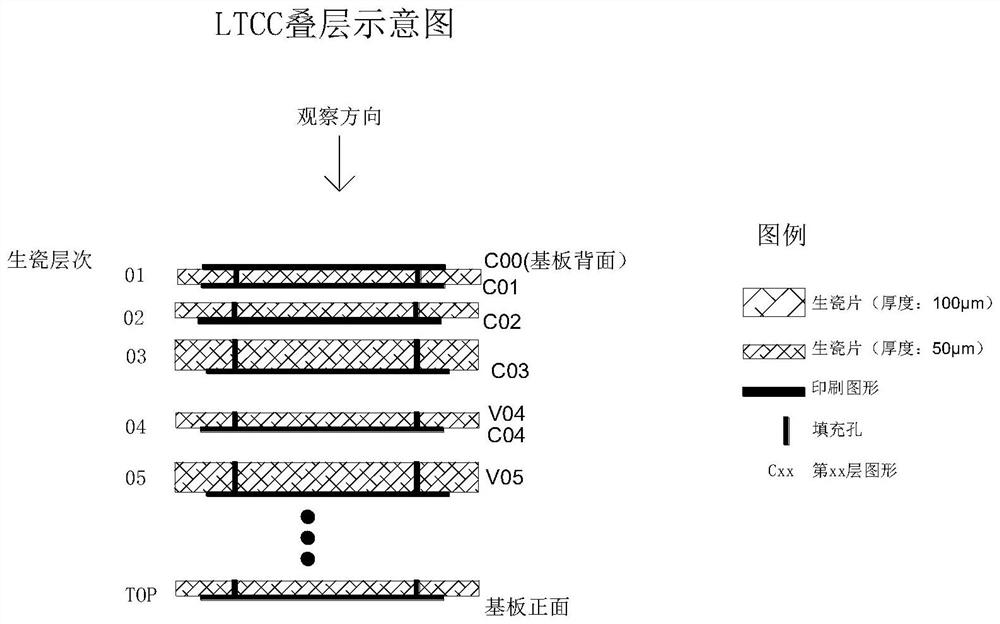

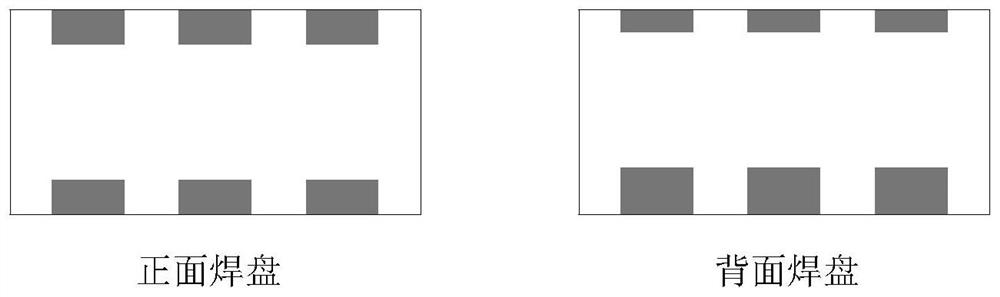

[0037] The invention provides a method for improving the alignment accuracy between layers of LTCC. The graphics with higher alignment accuracy requirements on two adjacent layers are printed on the front and back sides of the same piece of green porcelain, and the same printing is used for the front and back printing. Alignment marks to eliminate the influence of positioning pins and punching accuracy on the alignment accuracy between layers.

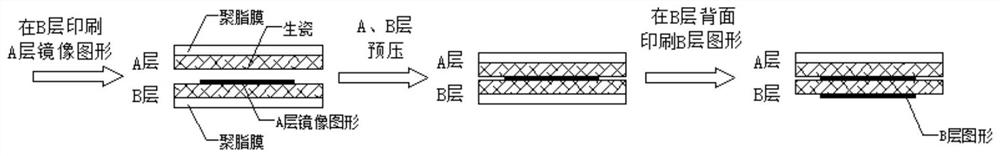

[0038] see image 3 , defining layers A and B as two adjacent layers, a method to improve the alignment accuracy between LTCC layers The specific implementation process is as follows:

[0039] 1) Use 4 sets of through holes to make Mark points in the non-graphic area of the four corners of the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com