Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Reduce self-explosion rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum-glass heat-insulating board and manufacturing method thereof

InactiveCN105669007ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAir tightness

The invention relates to a vacuum-glass heat-insulating board. The vacuum-glass heat-insulating board comprises upper glass and lower glass, wherein the periphery of the upper glass and the periphery of the lower glass are connected together through a sealing material in a sealing manner, a closed vacuum layer is formed between the upper glass and the lower glass and contains a low-melting-point or volatile or highly-inspiratory metal, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces to the outer side. A manufacturing method for the vacuum-glass heat-insulating board disclosed by the invention is simple in process, the sealing effect is good, the air tightness and service life of the vacuum-glass heat-insulating board can be effectively guaranteed, and mechanized, automated and large-scale production can be achieved.

Owner:戴长虹

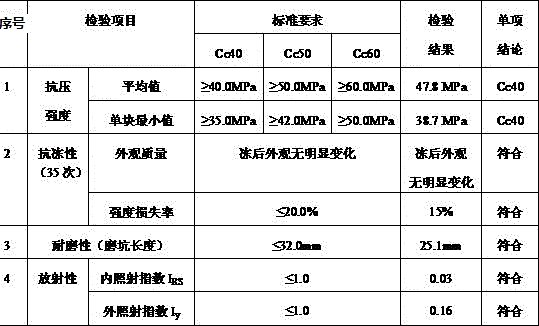

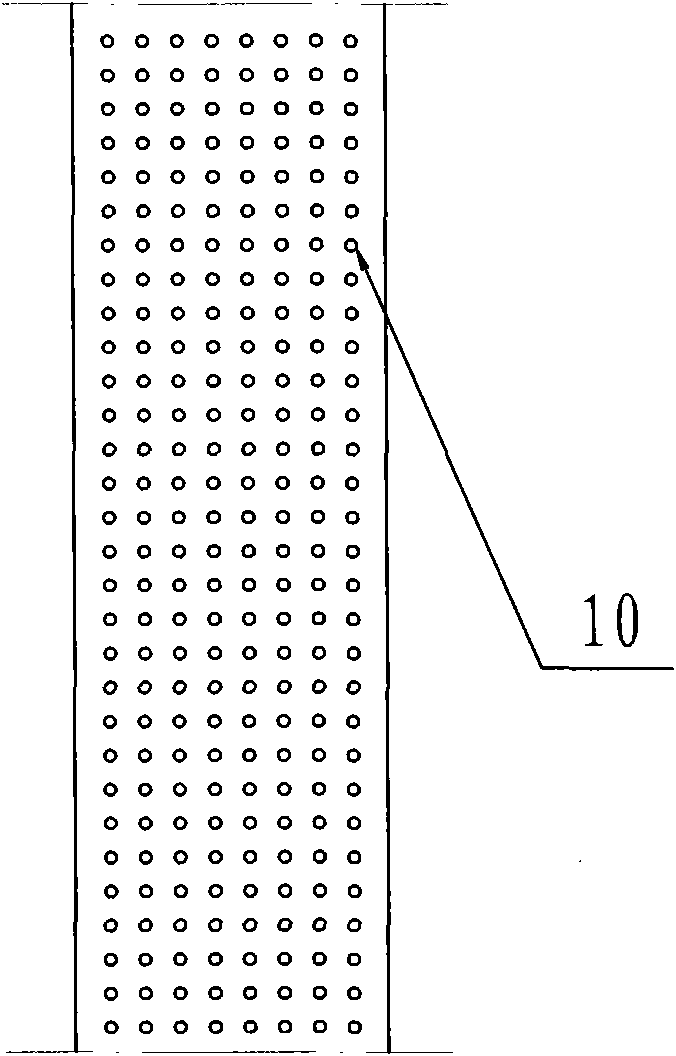

Outdoor energy-storage luminescent crystal floor tile

InactiveCN106758686AGood acid and alkali resistanceNot easily oxidizedSidewalk pavingsPavement lightsBrickAcrylic resin

The invention discloses an outdoor energy-storage luminescent crystal floor tile and belongs to the technical field of energy conservation construction materials. The outdoor energy-storage luminescent crystal floor tile is prepared from a substrate, a luminescent coating arranged on the substrate and a protection layer arranged on the luminescent coating, wherein the substrate is natural marble or acid-proof brick; the luminescent coating is energy-storage luminescent resin adhesive, and the luminescent resin adhesive is prepared from materials in parts by weight: 20 to 40 parts of luminescent powder, 50 to 70 parts of acrylic resin adhesive and 5 to 15 parts of addition agent without heavy metal compound; the protection layer is any one of silicate glass sand with thickness of 1mm to 2mm, high-transmittance glass bead with size of 1mm to 6mm or ultra clear glass face with thickness of 2mm to 8mm, wherein the particle size of the silicate glass sand is 2 to 120 meshes. The floor tile prepared by the invention has a good luminescent effect, avoids power consumption and has low cost; furthermore, the luminescent material of the floor tile is safe and free of harm.

Owner:天津众升自发光材料科技有限公司

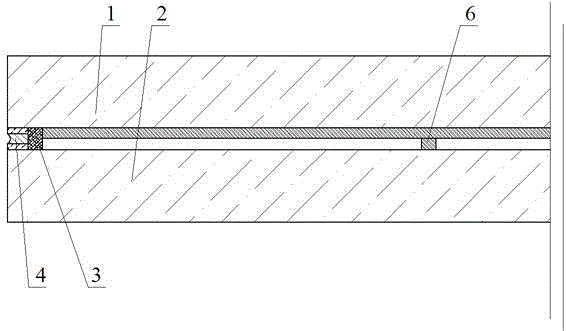

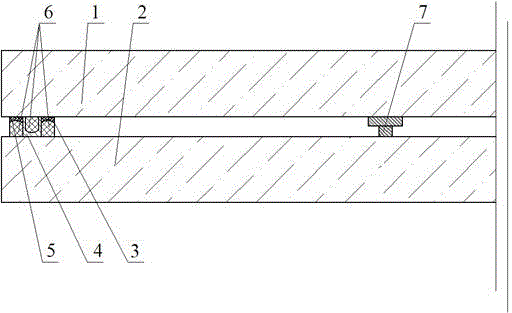

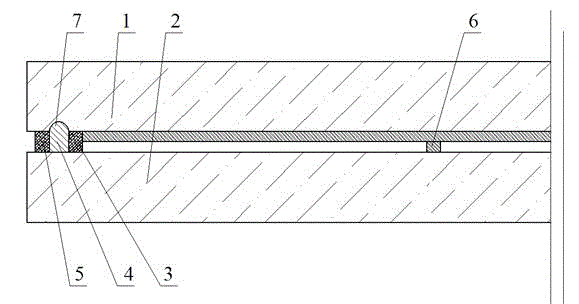

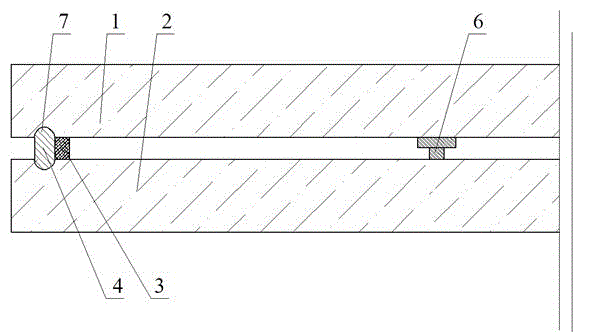

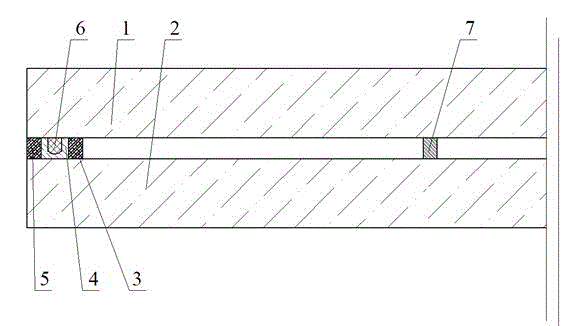

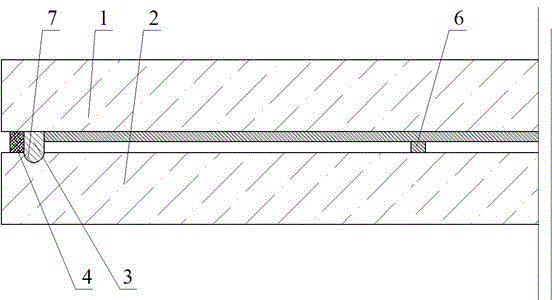

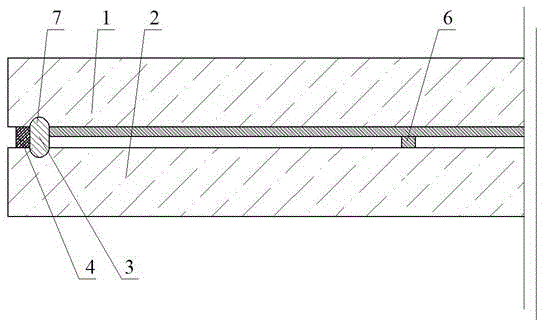

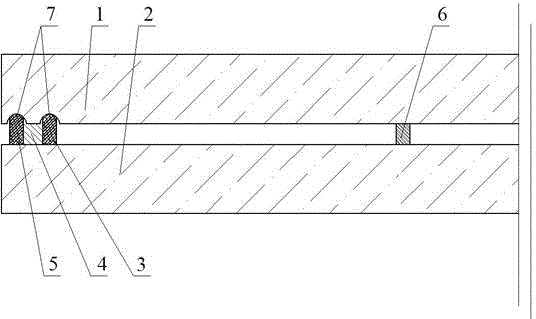

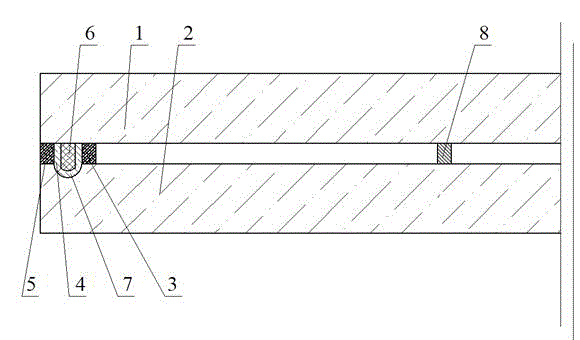

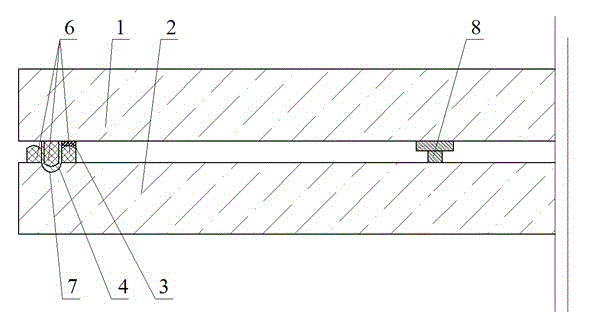

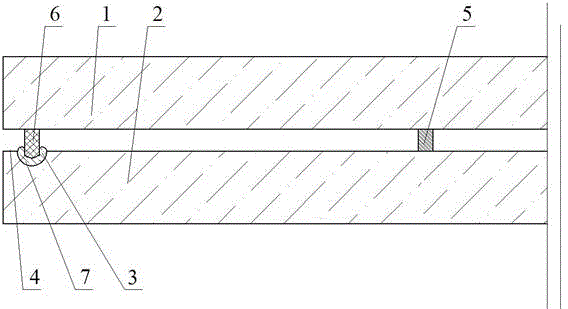

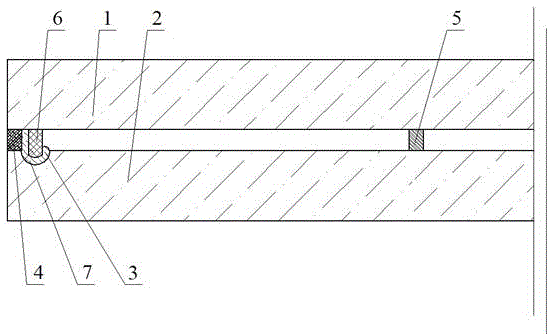

Endothermic solar photovoltaic hollow glass

ActiveCN101881070AGuaranteed power generation efficiencyReduce the temperatureRoof covering using slabs/sheetsRoof covering using tiles/slatesMolecular sieveAluminium

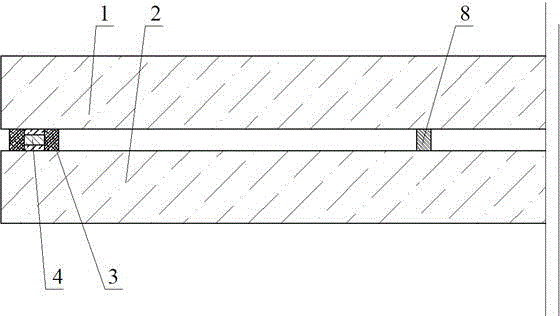

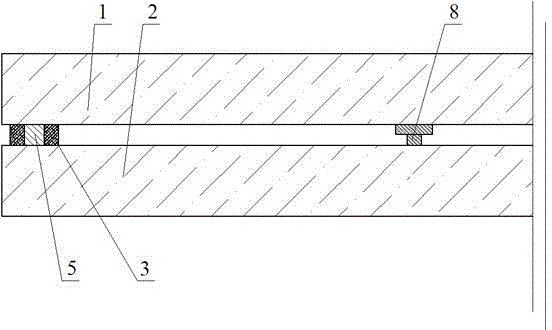

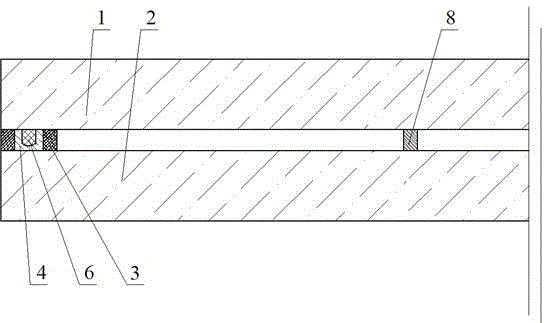

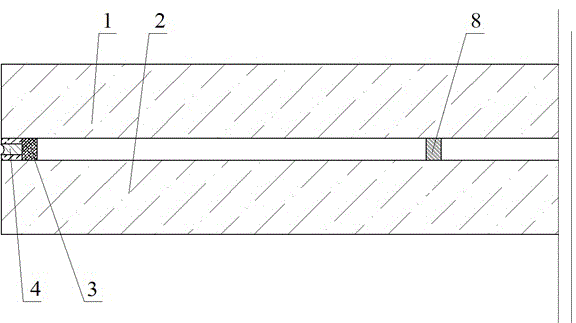

The invention relates to endothermic solar photovoltaic hollow glass in a building integrated photovoltaic generating system, comprising laminated glass (2) including a photovoltaic battery bank piece (6), hollow aluminum (3) with a groove and a glass unit (1), wherein the hollow aluminum (3) with the groove is fixed between the laminated glass (2) and the glass unit (1); the laminated glass (2) comprises first toughened glass (4), second toughened glass (5) and the photovoltaic battery bank piece (6) between the first toughened glass (4) and the second toughened glass (5); the hollow aluminum (3) with the groove adopts the double-cavity structure; and one cavity is filled with molecular sieves and the other cavity is filled with heat absorbents. The hollow glass has high generating efficiency, obvious heat preservation and energy conservation effects, good safety and high reliability.

Owner:沈阳金都铝业装饰工程有限公司

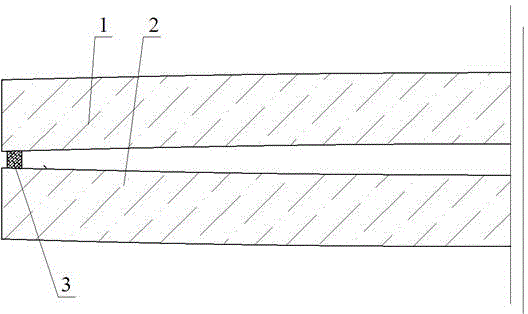

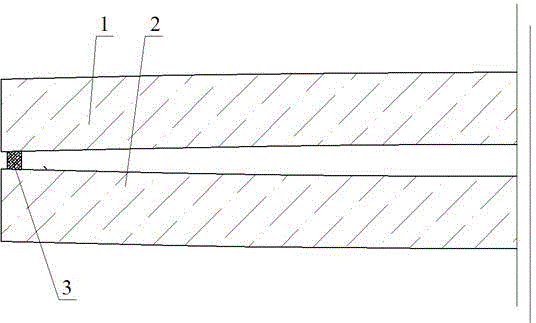

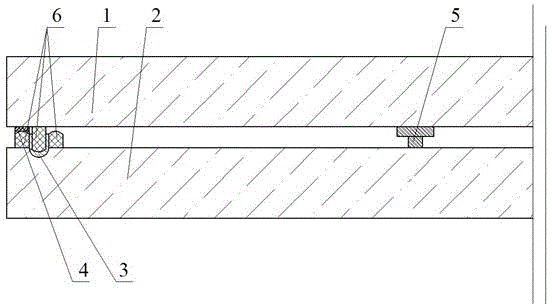

Adhesive sealed vacuum glass and preparation method thereof

InactiveCN105601092AHigh bonding strengthEasy to operateGlass reforming apparatusGlass productionAdhesiveEngineering

The invention relates to an adhesive sealed vacuum glass, which comprises an upper glass and a lower glass, wherein the peripheries of the upper glass and the lower glass are sealed and connected through an adhesive, the adhesive has two parts, a metal or glass welding material is arranged between the two adhesive parts, a closed vacuum layer is formed between the upper glass and the lower glass, the upper glass and the lower glass are convex glasses or flat glasses, and the convex surface of the convex glass is toward the outer side. According to the present invention, the vacuum glass production method is simple, the prepared vacuum glass and the prepared tempered vacuum glass can overcome the defects in the prior art, the tightness and the service life of the vacuum glass can be effectively ensured, and mechanization, automation and large-scale production can be achieved.

Owner:戴长虹

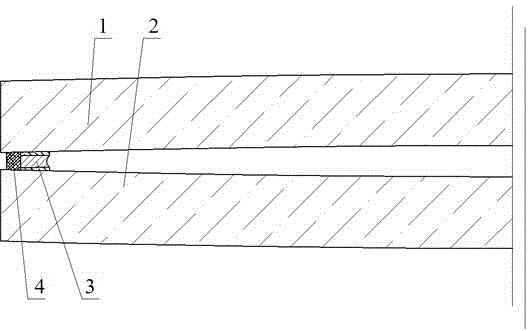

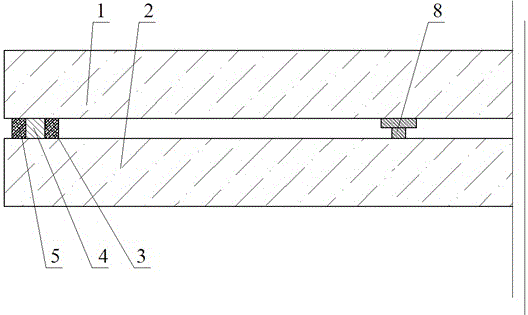

Vacuum glass with two or a plurality of paths of sealing and a preparing method thereof

InactiveCN105645743AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionAdhesiveAir tightness

Vacuum glass with two or a plurality of paths of sealing is provided. The vacuum glass comprises upper glass and lower glass. The periphery of the upper glass and the periphery of the lower glass are sealed through two or a plurality of paths of sealing materials. The sealing materials comprise glass solder, metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or plain glass. The convex surface of the convex glass faces the outside. A preparing method of the vacuum glass is simple. The prepared vacuum glass and tempered vacuum glass can overcome disadvantages of the prior art. Air impermeability and service lifetime of the vacuum glass can be ensured effectively. Mechanized, automatic and large-scale production can be achieved.

Owner:戴长虹

Vacuum glass insulation panel and preparation method thereof

InactiveCN105669003ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

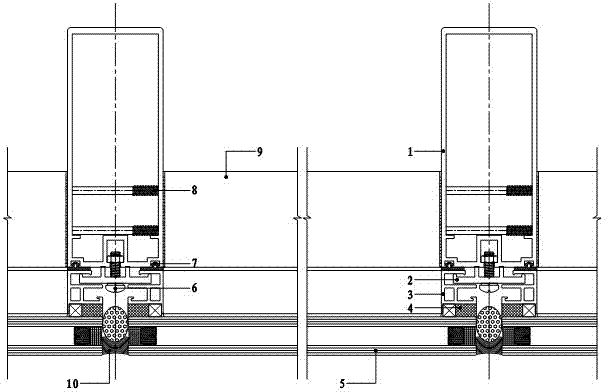

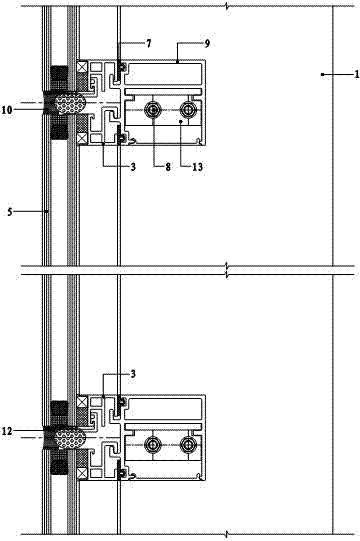

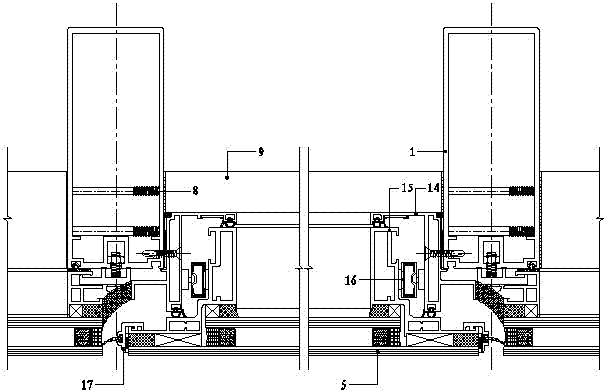

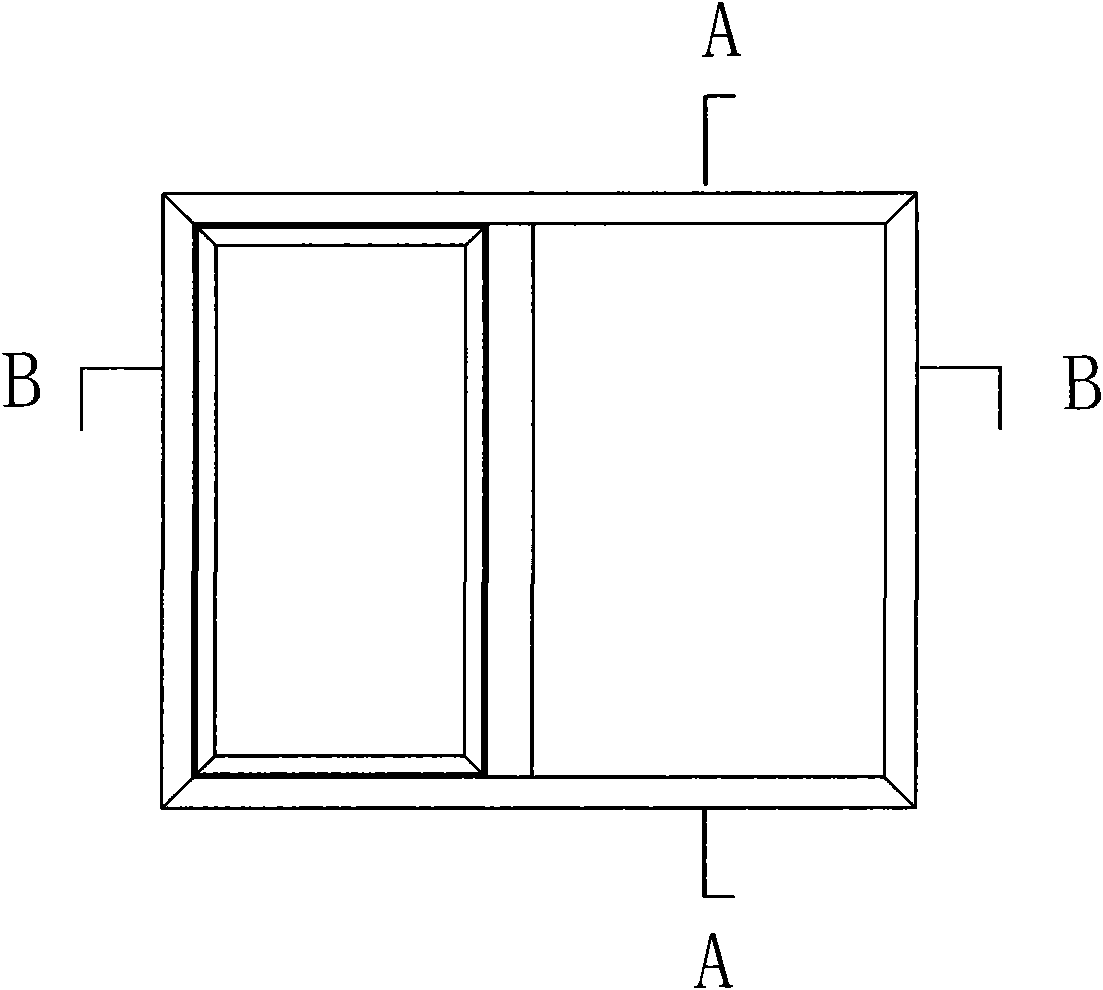

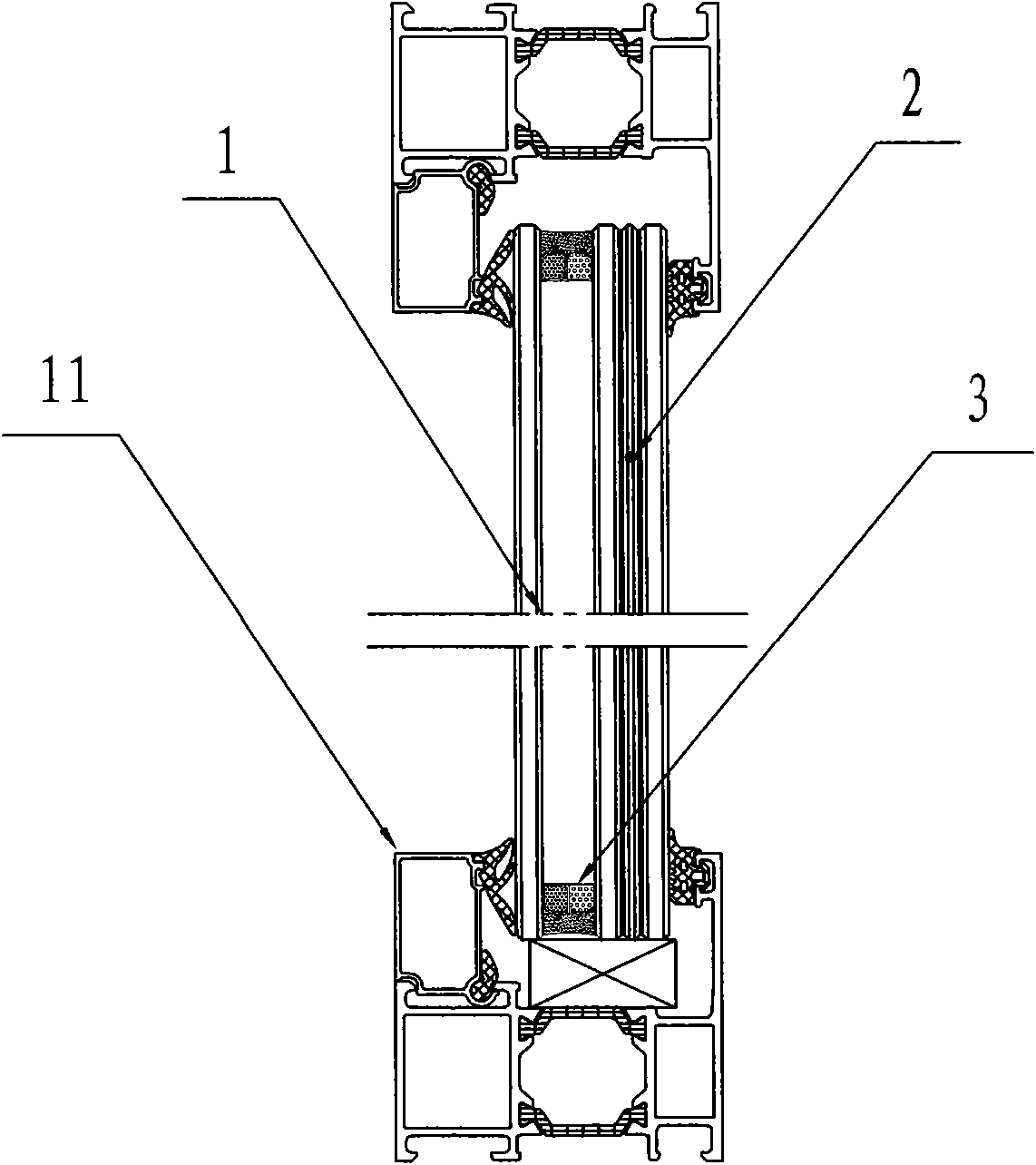

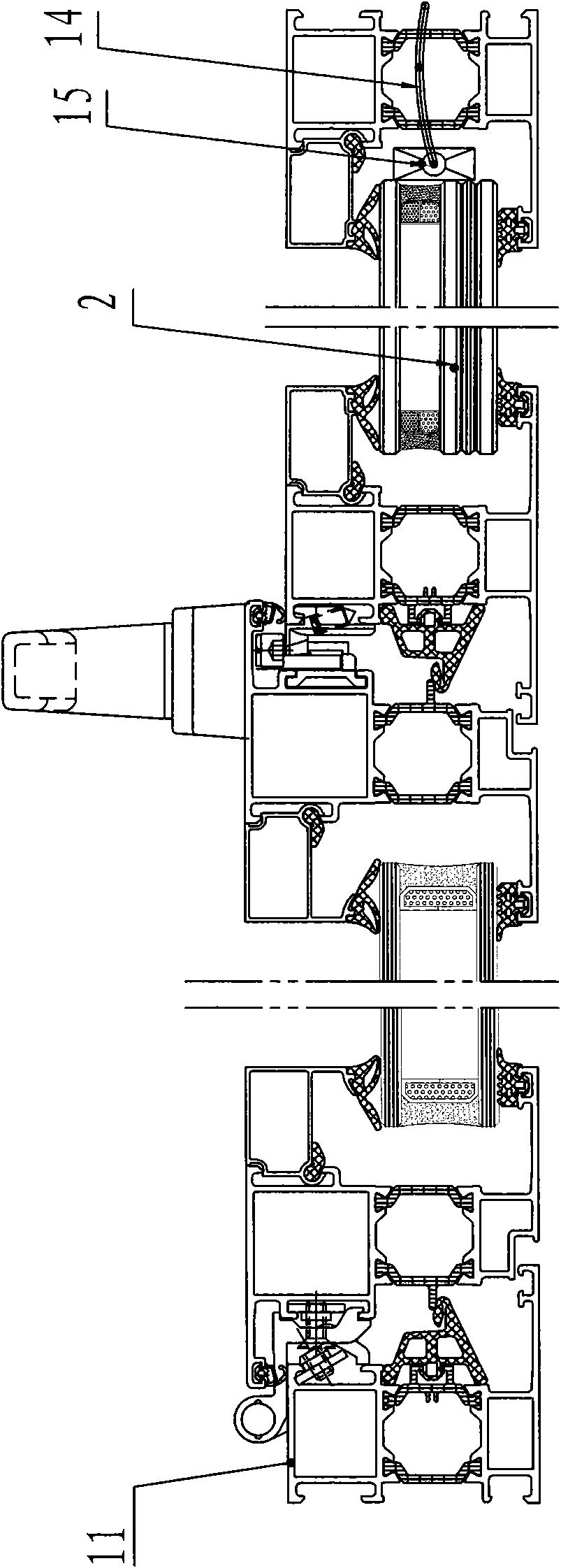

Hitching hidden-frame glass curtain wall

InactiveCN103397724ARapid positioningImprove on-site installation efficiencyWallsAdhesiveEngineering

The invention provides a hitching hidden-frame glass curtain wall comprising a main frame, an auxiliary frame, a cross beam, an opening frame, an opening sash and glass. Left and right vertical sides in the main and auxiliary frames are connected through pressure plates, and top and bottom horizontal sides in the main and auxiliary frames are connected through hooks. The cross beam is fixed on the main frame. The auxiliary frame is hitched to the cross beam, and a carrier strip is disposed at the lower end of the auxiliary frame. The glass is adhered to the auxiliary frame through silicone structural adhesive. The upper end of the opening frame is hitched to the cross beam. The opening frame is connected with the opening sash in a hitched structure. A channeled carrier strip is disposed at the upper end of the opening sash. The hitching hidden-frame glass curtain wall has the advantages that small-unit glass plates are positioned fast, field installation efficiency is improved, and the problems such as shedding of corners of the opening sash and frame-sash scratching are prevented effectively.

Owner:秦皇岛市中贤幕墙装饰工程有限公司

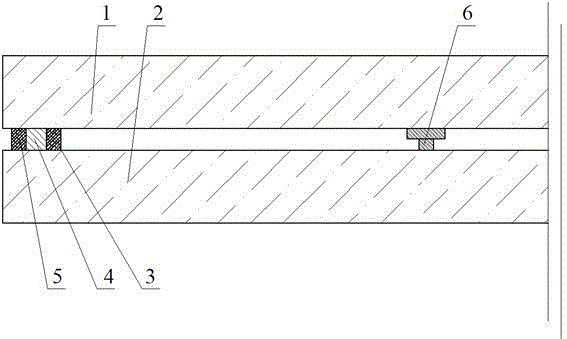

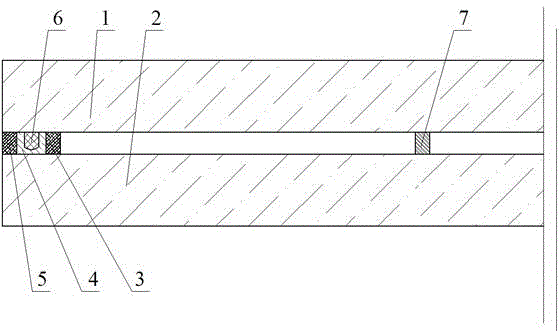

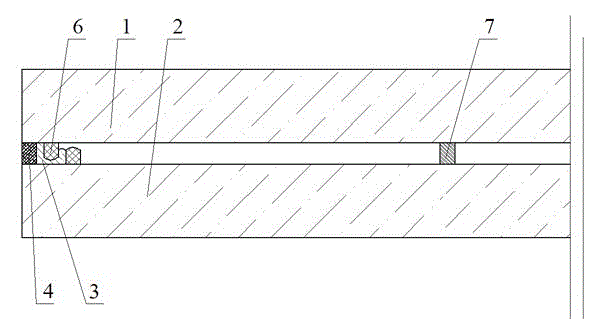

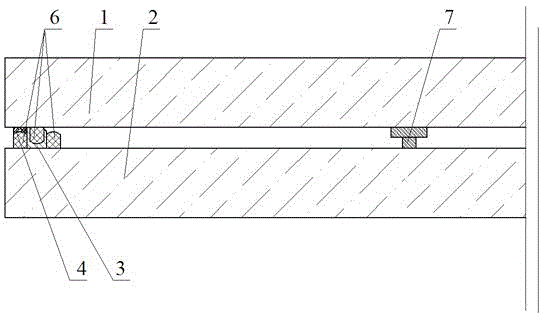

Solar photovoltaic high heat insulating window

ActiveCN101881123AImprove power generation efficiencyImprove reliabilityDoor/window applicationsUnits with parallel planesBuilding integrationEngineering

The invention relates to a solar photovoltaic high heat insulating window in a building integrated photovoltaic generating system, comprising a body and a control module, wherein the body comprises a window frame (11) and solar photovoltaic hollow glass; the solar photovoltaic hollow glass comprises laminated glass (2), a glass unit (1) and aluminum (3) with a groove; the aluminum (3) with the groove is fixed between the laminated glass (2) and the glass unit (1); an outgoing cable (14) of the solar photovoltaic hollow glass is connected to a signal transmission port of the control module; the laminated glass (2) comprises first toughened glass (4), second toughened glass (5) and a photovoltaic battery bank piece (6) between the first toughened glass (4) and the second toughened glass (5); the aluminum (3) with the groove adopts the double-cavity structure; and one cavity is filled with molecular sieves and the other cavity is filled with heat absorbents. The window has high generating efficiency, obvious heat preservation and energy conservation effects, good safety and high reliability.

Owner:沈阳金都铝业装饰工程有限公司

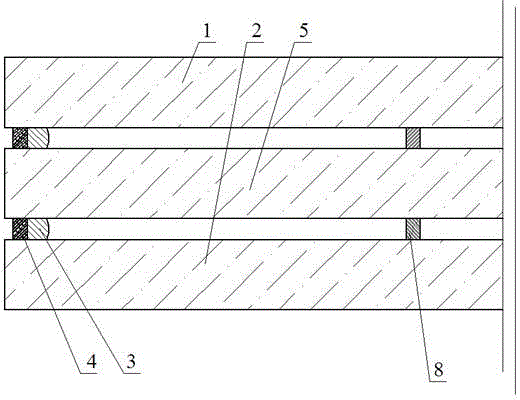

Compound sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669006ABroaden your optionsAvoid a lot of volatilizationGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a compound sealed vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

Manufacturing process of mobile phone camera lens

InactiveCN111683167ASave manual processSave manpowerCoatingsGlass severing apparatusScreen printingManufacturing technology

The invention discloses a manufacturing process of a mobile phone camera lens. The manufacturing process comprises the steps of cutting, laser cutting, ultrasonic cleaning, etching, tempering, tertiary silk-screen printing, NCVM electroplating, deplating, AR plating, AF plating, splitting, film coating and inspection. Compared with a small piece CNC technological process, the technological processhas the advantages that manual processes such as piece placing and dispensing after cutting are omitted, manual processes such as tempered frame inserting and frame taking are omitted, and manual stations such as piece placing in silk-screen printing are omitted; the appearance precision of the product is improved; the laser cutting process is used for scribing the outer contour, so that the boundary dimension precision of the product is improved and appearance, size and precision of the product are improved; a secondary tempering process is adopted, so that the impact strength of the cameralens is improved, and the spontaneous explosion rate is reduced; and the yield is improved: the comprehensive yield of the product is averagely improved by more than 10%.

Owner:SHENZHEN RUI EURO OPTICAL ELECTRONICS CO LTD

Bar frame sealed vacuum glass and manufacturing method thereof

InactiveCN105669052AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionFlat glassAdhesive

The invention relates to bar frame sealed vacuum glass. The bar frame sealed vacuum glass comprises upper glass and lower glass, wherein the periphery of the upper glass and the periphery of the lower glass are connected together through an edge banding bar frame and two or multiple sealing materials in a sealing manner, each sealing material comprises glass solder, metal solder and an adhesive, a closed vacuum layer is formed between the upper glass and the lower glass, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces to the outer side. A manufacturing method for the vacuum glass disclosed by the invention is simple in process, the manufactured vacuum glass and tempered vacuum glass can overcome the shortages in the prior art, the air tightness and service life of the vacuum glass can be effectively guaranteed, and mechanized, automated and large-scale production can be achieved.

Owner:戴长虹

Groove sealed vacuum glass and preparing method thereof

InactiveCN105645742AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionAdhesiveAir tightness

Groove sealed vacuum glass is provided and comprises upper glass and lower glass. The periphery of the upper glass and the periphery of the lower glass are sealed through an edge sealing groove and two or a plurality of paths of sealing materials. The sealing materials comprise glass solder, metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or plain glass. The convex surface of the convex glass faces the outside. A preparing method of the vacuum glass is simple. The prepared vacuum glass and tempered vacuum glass can overcome disadvantages of the prior art. Air impermeability and service lifetime of the vacuum glass can be ensured effectively. Mechanized, automatic and large-scale production can be achieved.

Owner:戴长虹

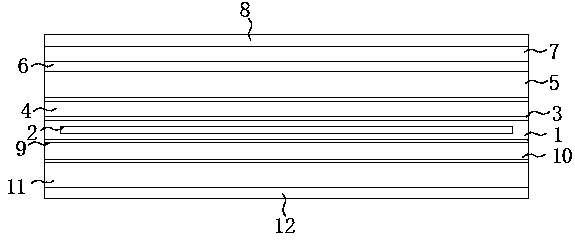

Novel multifunctional toughened glass

PendingCN108515767AReduce self-explosion rateImprove securitySynthetic resin layered productsGlass/slag layered productsPolyesterOrganic glass

The invention discloses novel multifunctional toughened glass. The glass comprises an organic glass base layer, a vacuum cavity is formed in the middle of the organic glass base layer, and a first polyester buffer layer fixedly adheres to the upper end of the organic glass base layer; a first toughened glass base layer fixedly adheres to the upper end of the first polyester buffer layer, and the upper end of the first toughened glass base layer is coated with a colored glaze coating. According to the multifunctional toughened glass, the first polyester buffer layer, an explosion-proof membranelayer and a second polyester buffer layer are arranged, so that the self-explosion rate of the toughened glass is reduced, and the safety of the toughened glass is improved; by arranging the organicglass base layer and the vacuum cavity, the weight of the toughened glass is reduced, and the sound insulation and heat preservation effects of the organic glass are improved; by arranging the coloredglaze coating, the number of styles of the toughened glass is increased, and the attractiveness is improved; by arranging a hydrophobic coating, a second toughened glass base layer is not likely to be stained by dust and water, and the toughened glass can be cleaned conveniently.

Owner:荆门市欣安泰钢化玻璃有限公司

Bar-frame sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669005ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a bar-frame vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

Groove sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669004ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionAdhesiveFlat glass

The present invention discloses a groove vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

Vacuum glass with sealed strip frame and groove as well as preparation method thereof

InactiveCN105621868AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionFlat glassAdhesive

The invention relates to a vacuum glass with a sealed strip frame and a groove. The vacuum glass comprises upper glass and lower glass which adopt convex glass or plain glass, wherein an air extraction opening is formed in the upper glass; the sealing strips are arranged on the peripheries of the upper glass and the air extraction opening; the sealed materials comprises a glass solder, a metal solder and an adhesive, a closed vacuum layer is formed between the upper glass and the lower glass, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces outwards. The preparation method of the vacuum glass is simple, the prepared vacuum glass and toughened vacuum glass can overcome insufficiency in the prior art, air tightness and service life of the vacuum glass are effectively guaranteed, and mechanization, automation, and large-scale production can be realized.

Owner:戴长虹

Processing technology for reducing spontaneous explosion rate of tempered glass

PendingCN113912306AUniform stressIt is not easy to cause fracture due to uneven stressSynthetic resin layered productsLaminationToughened glassGlass material

The invention relates to the technical field of glass materials, in particular to a processing technology for reducing the spontaneous explosion rate of tempered glass, which comprises the following steps: pretreating a glass substrate; carrying out tempering treatment; carrying out hot dipping treatment; and performing explosion-proof treatment. The problem that in the prior art, the spontaneous explosion rate of tempered glass is high is solved. According to the processing technology, through preheating, the problem that the glass substrate is curled and broken due to uneven stress distribution in the tempering process can be avoided. Hot dipping treatment and anti-explosion treatment are performed after tempering treatment, so that the possibility of spontaneous explosion of a finished product is reduced. The finally prepared tempered glass has the advantages of high strength, uniform stress distribution and low spontaneous explosion possibility.

Owner:张家港市强达玻璃有限公司

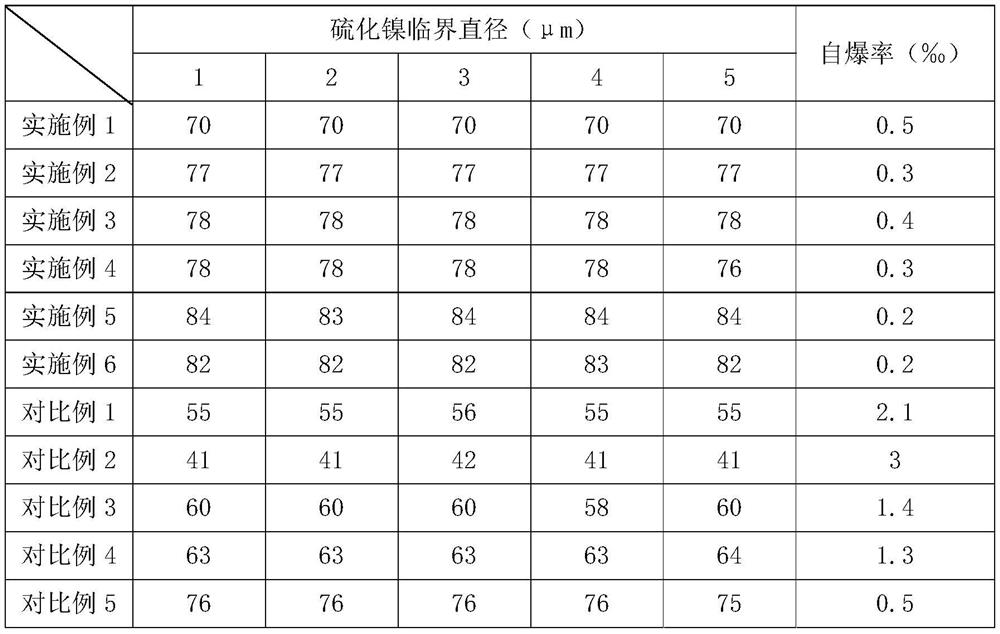

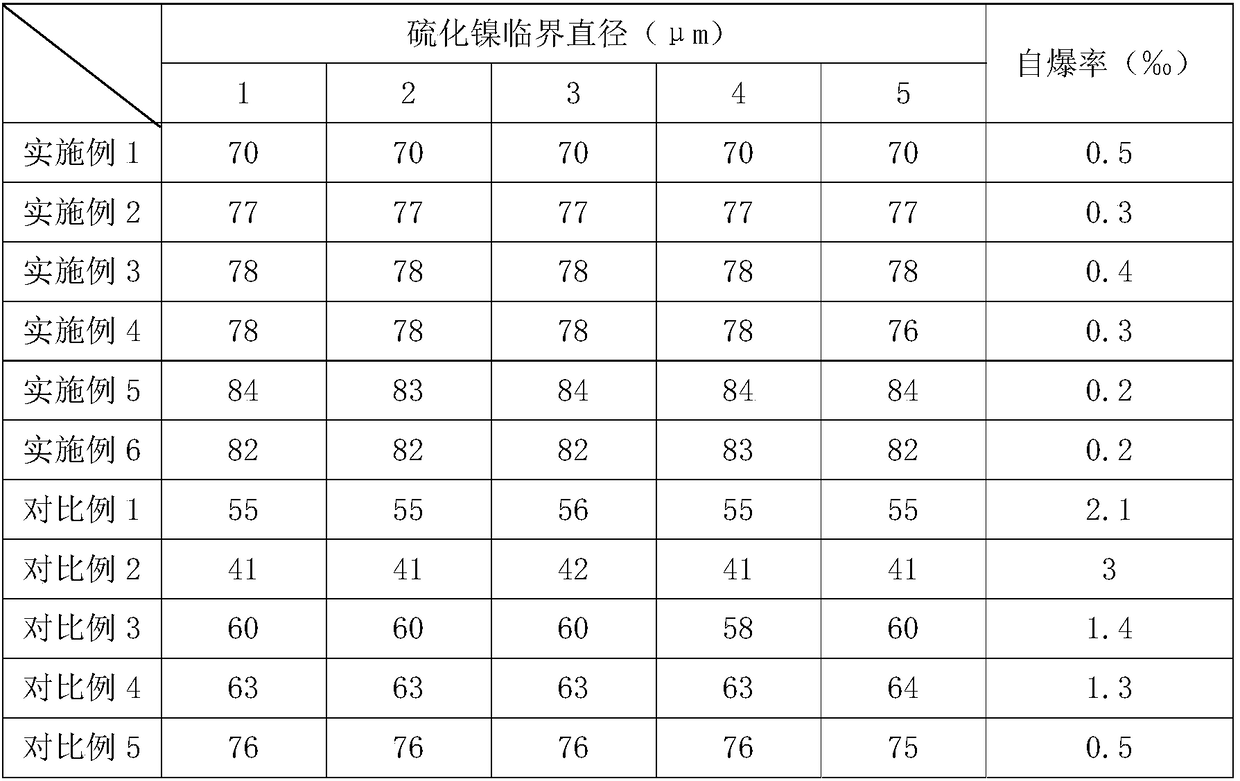

Processing technology of tempered glass

ActiveCN108585457BPromote self-destructionReduce self-explosion rateGlass tempering apparatusFlat glassPhysical chemistry

The invention discloses a processing technology of tempered glass, which comprises the following steps: step 1, heating, taking flat glass, and heating at 650°C-750°C for 3-10min; step 2, cooling, taking out the glass, and spraying evenly on both sides of the glass Blow air to cool the glass uniformly to 200-250°C; step 3, slowly heat the glass to 270-280°C, and keep it warm for 10-25min; step 4, cool the glass in step 3 to room temperature to obtain tempered glass. The present invention has the following advantages and effects: gamma ray irradiation is used in the cooling process to promote the transformation of nickel sulfide in the glass from the high-temperature phase α-NiS to the low-temperature phase β-NiS, reducing the self-explosion of the prepared tempered glass; secondly, step 3 In the process, the glass is slowly heated to 270-280°C, and under the irradiation of gamma rays, it can further promote the transformation of nickel sulfide from the high-temperature phase α-NiS to the low-temperature phase β-NiS, further reducing the self-explosion of the tempered glass and reaching the strength High, low self-explosion rate of tempered glass, safe to use.

Owner:四川雄港玻璃有限公司

Toughened glass processing technology

ActiveCN108585457APromote self-destructionReduce self-explosion rateGlass tempering apparatusFlat glassCombustion

The invention discloses a toughened glass processing technology. The method comprises the following steps: 1) heating: taking a flat glass, heating the flat glass at the temperature of 650-750 DEG C for 3-10 min; 2) cooling: taking the glass out, and uniformly blowing air to two surfaces of the glass until the glass is uniformly cooled to 200-250 DEG C; 3) slow heating: slowly heating the glass tothe temperature of 270-280 DEG C, and performing insulation for 10-25 min; and 4) cooling the glass in the step 3) to room temperature to obtain the toughened glass. The method has the following advantages and effects that during a cooling process, gamma-ray is employed for irradiation, nickel sulfide in the glass is changed from a high-temperature phase alpha-NiS to a low-temperature phase beta-NiS, self-combustion of the toughened glass can be reduced, in the step 3), the glass is slowly heated to 270-280 DEG C, under gamma-ray irradiation, nickel sulfide in the glass changed from the high-temperature phase alpha-NiS to the low-temperature phase beta-NiS is subjected to further promotion, self-combustion of the toughened glass can be reduced, and the toughened glass has the advantages of high intensity, low self-combustion rate, and safe usage.

Owner:四川雄港玻璃有限公司

Processing technology for tempered glass

InactiveCN108069587AAdvantages of processing technologyReduce self-explosion rateGlass tempering apparatusFree coolingSlow cooling

The invention provides a processing technology for tempered glass, belonging to the field of glass manufacturing. The processing technology comprises the following steps: heating, cooling, slow heating, slow cooling, natural cooling, spray cleaning, cleaning, drying and the like. Through slow heating and slow cooling of the glass and conversion of high-temperature nickel sulfide, the self-explosion rate of the tempered glass is lowered; and aqua regia is employed for jet scrubbing of the surface of the tempered glass so as to dissolve nickel sulfide on glass surfaces in the aqua regia, so theself-explosion rate is further lowered. This processing technology has the advantage of capacity of greatly reducing the self-explosion rate of the tempered glass.

Owner:刘书刚

Bar-frame and groove sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669002ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a bar-frame and groove sealed vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

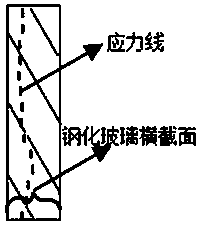

Method used for detecting tempered glass tableware spontaneous explosion hidden troubles, and applications thereof

ActiveCN107632020ASimplify testing proceduresEasy to operatePreparing sample for investigationMaterial analysis by optical meansQuality controlToughened glass

The invention discloses a method used for detecting tempered glass tableware spontaneous explosion hidden troubles. According to the method, the stress lines of tempered glass tableware are detected,if the stress lines are close to the center lines of cross sections of the tempered glass, the probability of spontaneous explosion is low; if the stress lines are far away from the center lines of cross sections of the tempered glass, the probability of spontaneous explosion is high. The stress lines of tempered glass formed at the interaction of internal stress and external stress are used for evaluating the probability of spontaneous explosion for the first time. In practical production, the method can be used for accurate prediction of tempered glass spontaneous explosion, and ahead quality control, so that the spontaneous explosion rate of outgoing tempered glass tableware is reduced further. Operation of the method is simple, rapid, low in cost, and high in efficiency and accurate. The method can be used for accurate prediction of tempered glass product spontaneous explosion situations; the method can be used for detecting a zone of 5cm*5cm; the application range is wider; the limitation is low; and the practicability is high.

Owner:山东孟友新材料科技有限责任公司

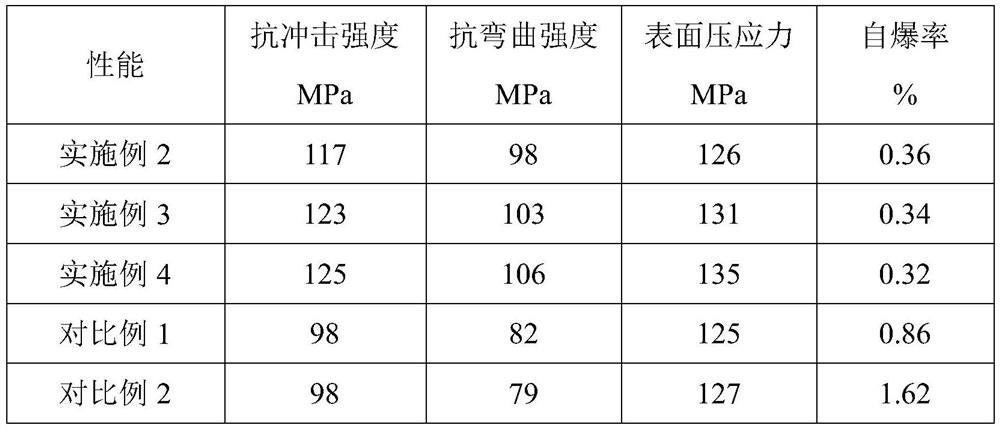

High-strength explosion-proof tempered glass and manufacturing process thereof

PendingCN114133138AHigh impact strengthImprove bending strengthGlass tempering apparatusFiberLead nitrate

The invention discloses high-strength explosion-proof tempered glass and a manufacturing process thereof. The high-strength explosion-proof tempered glass is prepared from the following raw materials in parts by weight: 48-55 parts of silicon dioxide, 15-20 parts of wollastonite, 10-14 parts of albite, 7-11 parts of silicon-aluminum-magnesium high-strength fibers, 5-9 parts of silicon nitride fibers, 12-15 parts of aluminum oxide fibers, 11-13 parts of zirconium dioxide, 5-8 parts of germanium dioxide and 2.5-4 parts of lead nitrate. Compared with common tempered glass, the high-strength explosion-proof tempered glass has high impact strength and bending strength, is good in mechanical property and is not easy to damage; and the surface compressive stress is large, the self-explosion rate is low, and safety and durability are achieved.

Owner:福建新天龙玻璃科技有限公司

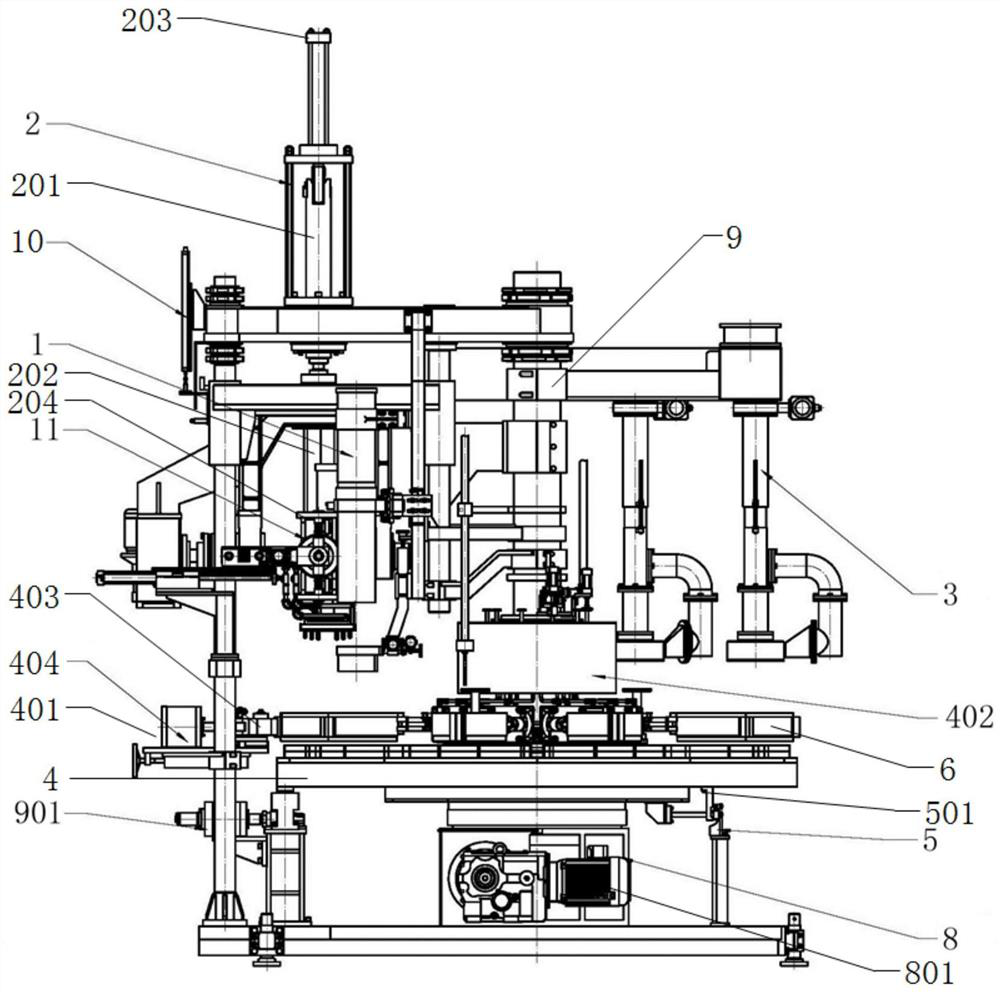

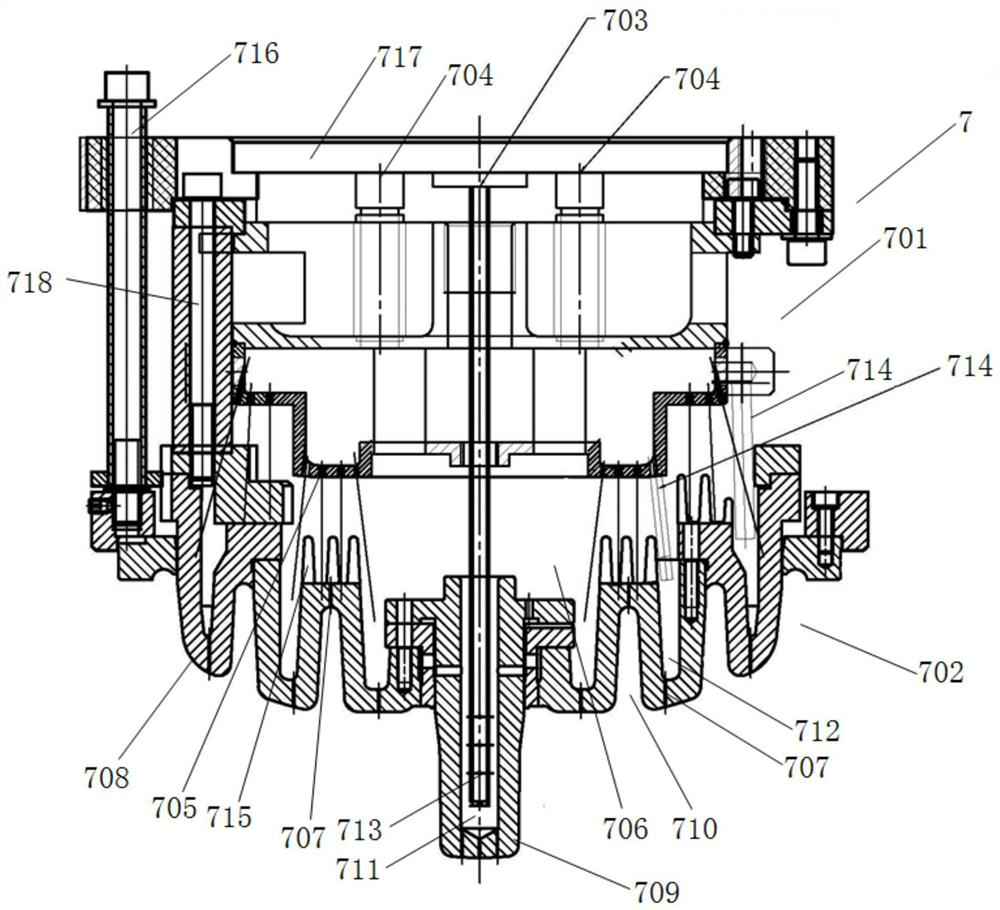

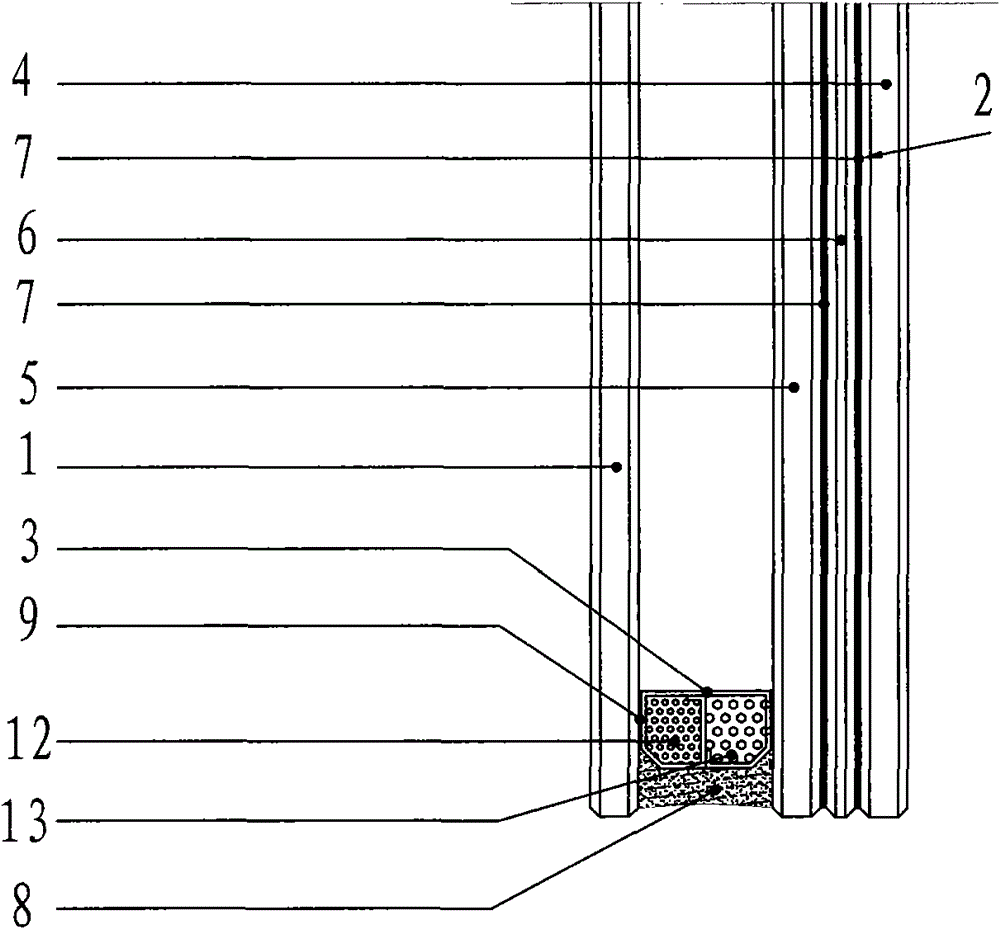

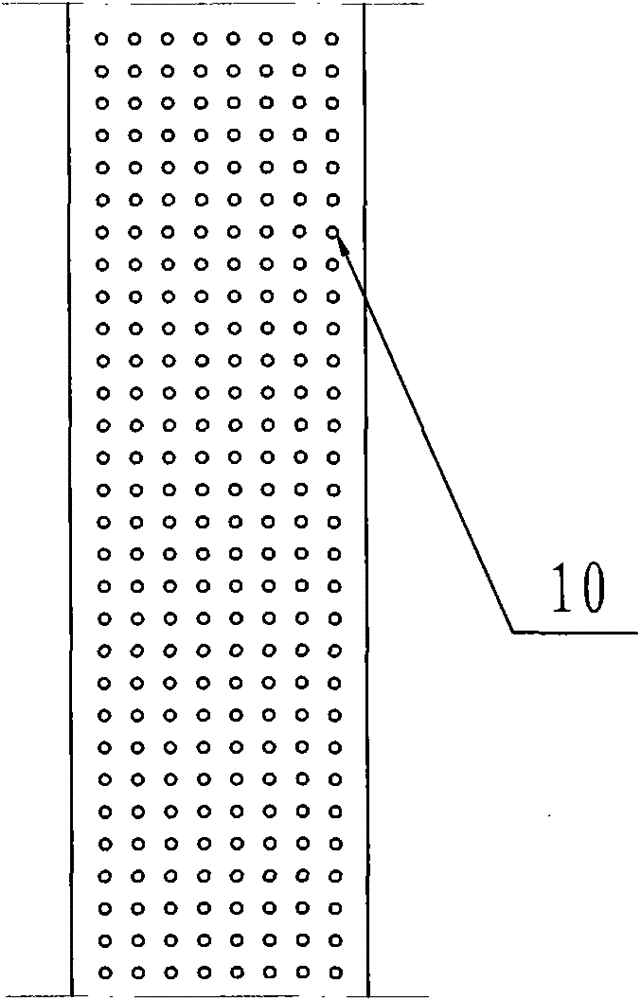

Glass insulator compression molding device

PendingCN113772925AEfficient dischargeIncrease dry arc distanceGlass pressing apparatusCompression moldingEngineering

The invention provides a glass insulator compression molding device, which comprises a material guide mechanism, a stamping device, a cold blowing device, a turntable and a turntable air inlet mechanism, the turntable is provided with a plurality of lower dies distributed circumferentially, the lower end of the stamping device is connected with an upper die, the material guide mechanism, the stamping device and the cold blowing device are arranged above the turntable, and an air outlet of the turntable air inlet mechanism is arranged below the turntable. A mold cooling system in compression molding is improved, heat can be effectively discharged, the temperature difference of the improved mold is smaller than 50 K, the dry arc distance can be effectively increased, the electromechanical performance of a product is more stable and excellent, and the spontaneous explosion rate of the product is effectively reduced. And the lower die is periodically moved by using the turntable, so that the compression molding, glass piece conveying and demolding operations are continuously carried out, and the working efficiency is greatly improved.

Owner:江西泉新电气有限公司

A kind of high-toughness tempered glass and preparation method thereof

ActiveCN109574499BImprove toughnessHigh impact strengthGlass pressing apparatusGlass tempering apparatusSodium bismuth titanateSic fiber

The invention discloses a high-toughness toughened glass and a preparation method thereof, comprising the following raw materials in parts by weight: 600-700 parts of quartz sand, 125-165 parts of fluorite, 90-115 parts of potassium feldspar, iron-containing compound 75-90 parts of fiber, 50-65 parts of silicon carbide fiber, 95-110 parts of alumina fiber, 35-45 parts of zinc oxide, 40-55 parts of zirconium boride, and 40-60 parts of sodium bismuth titanate. The present invention selects the constituent raw materials of high-toughness tempered glass and optimizes the ratio of the constituent raw materials of high-toughness tempered glass. Glass has high impact strength and bending strength, good toughness, good mechanical properties, and is not easy to damage; the surface compressive stress is large, and the self-explosion rate is low.

Owner:福建南平荣坤钢化玻璃有限公司

A kind of tempered glass and its manufacturing process

ActiveCN105818494BReduce self-explosionReduced UV protectionLamination ancillary operationsSynthetic resin layered productsCalcium silicateLithium oxide

The invention belongs to the technical field of materials and particularly discloses tempered glass and a manufacturing process thereof. The tempered glass comprises a tempered glass substrate and an explosion-proof layer. The tempered glass substrate comprises, by weight, 20-60 parts of silicon dioxide, 10-15 parts of limestone, 3-5 parts of borax, 5-8 parts of calcium carbonate, 10-16 parts of feldspar, 3-8 parts of bauxite, 5-13 parts of calcium silicate, 2-5 parts of sodium oxide, 2-4 parts of lithium oxide, 4-8 parts of bismuth oxide, 7-9 parts of aluminium sesquioxide, 1.5-2.5 parts of macrogol ester, 3-7 parts of copper sulfate pentahydrate, 5-11 parts of potassium permanganate, 3-6 parts of sodium hydroxide and 2-6 parts of a clarifying agent; the explosion-proof layer is composed of, by weight, 15-30 parts of polyvinyl alcohol, 30-60 parts of butyraldehyde, 15-30 parts of hydrochloric acid, 8-12 parts of plasticizer and 6-9 parts of an additive. According to the tempered glass and the manufacturing process thereof, a PVB middle membrane is additionally arranged between two layers of tempered glass, good binding power is achieved for inorganic glass, possibility of spontaneous explosion of the tempered glass can be effectively reduced, and the performance of the prepared tempered glass is far superior to conventional tempered glass.

Owner:DONGGUAN YINTAIFENG OPTICAL TECH CO LTD

Endothermic solar photovoltaic hollow glass

ActiveCN101881070BGuaranteed power generation efficiencyReduce self-explosion rateRoof covering using slabs/sheetsRoof covering using tiles/slatesMolecular sieveBuilding integration

The invention relates to endothermic solar photovoltaic hollow glass in a building integrated photovoltaic generating system, comprising laminated glass (2) including a photovoltaic battery bank piece (6), hollow aluminum (3) with a groove and a glass unit (1), wherein the hollow aluminum (3) with the groove is fixed between the laminated glass (2) and the glass unit (1); the laminated glass (2) comprises first toughened glass (4), second toughened glass (5) and the photovoltaic battery bank piece (6) between the first toughened glass (4) and the second toughened glass (5); the hollow aluminum (3) with the groove adopts the double-cavity structure; and one cavity is filled with molecular sieves and the other cavity is filled with heat absorbents. The hollow glass has high generating efficiency, obvious heat preservation and energy conservation effects, good safety and high reliability.

Owner:沈阳金都铝业装饰工程有限公司

Tempering process for reducing self-explosion rate of glass

The invention relates to a tempering process for reducing the spontaneous explosion rate of glass, and the process is characterized in that the process comprises the following steps: pretreating a glass sheet, sequentially carrying out hydro-thermal treatment in a KMnO4 solution and a K2Cr2O7 solution, then carrying out microwave heating treatment in a potassium hydroxide aqueous solution with the mass concentration of 0.2-0.4%, preheating the treated glass sheet at the high temperature of 420-450 DEG C for 20-30 minutes, putting the glass sheet in potassium nitrate fused salt, carrying out ion exchange at the temperature of 350-390 DEG C for 1-4 hours; performing cooling to 200-230 DEG C at the speed of 1-2 DEG C / min, and then performing cooling along with the furnace. According to the invention, glass tempering is completed at a low temperature in a short time, so that the tempering efficiency is greatly improved, and meanwhile, the energy consumption is reduced; in addition, the self-destruction rate of the tempered glass is as low as 0.04%, the Na+ exchange capacity reaches 82.4-85.6%, and the ion exchange depth reaches 139-155 [mu]m; and the bending strength reaches 607-641 MPa.

Owner:ANHUI SCI & TECH UNIV

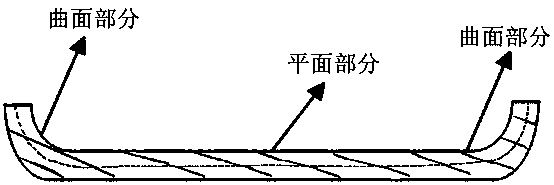

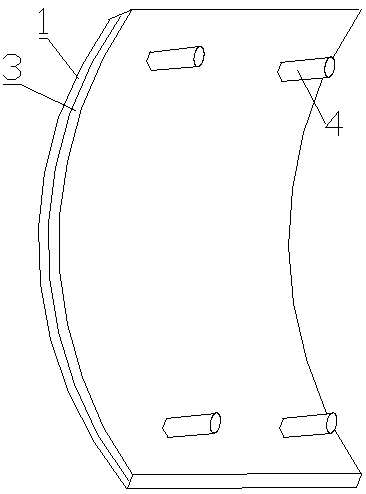

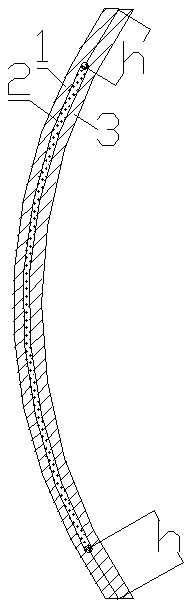

A solid mold for tempered glass molding

ActiveCN104803588BLow costTechnological innovationGlass reforming apparatusGlass fiberRoom temperature

The invention discloses a solid mold for tempering glass molding, and particularly relates to a solid mold for curved tempered glass molding. The invention aims to solve the technical problems of difficult molding, low yield and poor appearance quality of curved tempering glass. The mold is prepared through the following steps: 1, covering at least one layer of glass fiber on the inner surface of the curved glass as a convex glass wool cloth; 2, adding a lap of steel bar on the inner surface of the convex glass wool cloth; 3, paving at least one layer of glass wool cloth on the steel bar as a concave glass wool cloth; and 4, coating a fixing liquid on the inner surface of the concave glass wool cloth and drying at room temperature for 25-35 min. Adopting the technical scheme, the self-destruction rate of the curved tempering glass is reduced from 1% to 0.3%.

Owner:HENAN HUANYU GLASS TECH CO LTD

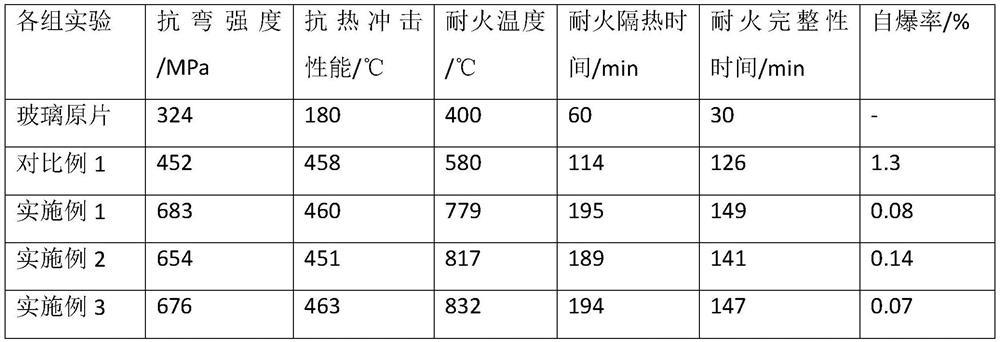

High borosilicate fireproof tempered glass and tempering method thereof

ActiveCN112939486AReduce self-explosion rateExcellent Tempering StrengthFlexible article cleaningCleaning using liquidsPotassium nitrateIon exchange

The invention relates to a tempering method of high borosilicate fireproof tempered glass, which comprises the following steps: sequentially carrying out three-stage surface pretreatment on a high borosilicate 4.0 glass sheet, drying to obtain an ultra-pure glass sheet, preheating the ultra-pure glass sheet in a medium-temperature furnace, putting the ultra-pure glass sheet into potassium nitrate molten salt, carrying out ion exchange at 340-380 DEG C for 0.5-5 h, and cooling the ultra-pure glass sheet to room temperature along with the furnace; wherein the three-section type surface pretreatment specifically adopts K2Cr2O7 hydro-thermal treatment, KMnO4 hydro-thermal treatment and high-purity water hydro-thermal treatment in sequence. According to the high borosilicate 4.0 fireproof glass tempered through a chemical tempering method, the Na < + > exchange capacity reaches 80% or above, the ion exchange depth reaches 152 microns, the excellent tempering strength is achieved, meanwhile, the spontaneous explosion rate of the glass is reduced to 0.06%, the excellent fireproof performance is achieved, the fireproof temperature reaches 832 DEG C, and the fireproof time reaches about 190 min.

Owner:ANHUI SCI & TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com