Compound sealed vacuum glass insulation panel and preparation method thereof

A vacuum glass and glass technology, applied in glass manufacturing equipment, glass production, glass molding, etc., can solve the problems of low production capacity, affecting bonding strength and air tightness, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

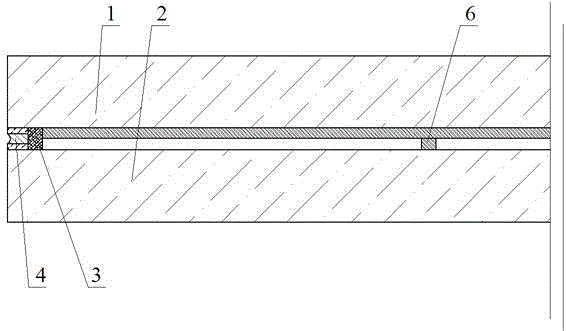

[0061] Embodiment 1: see figure 1 , a composite sealed vacuum glass, two pieces of glass are toughened glass, one of which is low-emissivity glass, the production method is as follows: firstly cut a piece of flat glass and a piece of low-emission glass according to the shape and size of the vacuum glass to be produced glass, and carry out edging, chamfering, cleaning, and drying; secondly, on the upper glass 1 or the lower glass 2, use tempered glass ink and a dispensing machine to prepare the support 6, the support 6 is cylindrical, and then separate the two pieces of glass Send it into a tempering furnace for tempering treatment, and the prepared support 6 is also sintered on the glass; the sintered support 6 is mechanically ground again so that the top is in a plane, and the top edge after grinding is rounded Corner treatment to further eliminate the influence of stress; apply a low-temperature glass solder 4 and two silicone adhesives evenly on the periphery of one piece o...

Embodiment 2

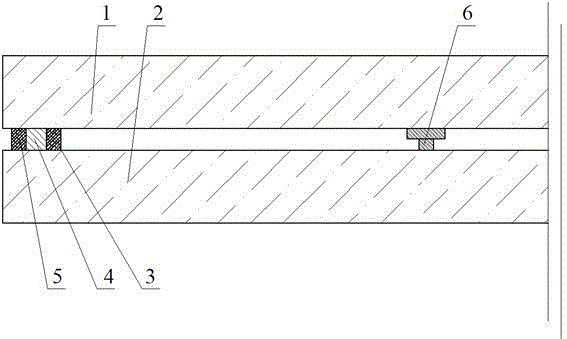

[0065] Example 2: see figure 2 , a flat vacuum glass with two seals, the two glasses are tempered glass, one of which is low-emissivity glass; the vacuum glass is composed of upper glass 1 and lower glass 2, and the periphery of the two glasses is sealed by the first 3 polyamide The imide adhesive and the second seal 4 metal solder are welded together with a vacuum layer in between. The production method is as follows: first, cut two pieces of flat glass of the required size according to the shape and size of the vacuum glass to be produced, and perform edge grinding, chamfering, cleaning and drying; secondly, apply Coat silver paste, and then send the two pieces of glass into the tempering furnace for tempering treatment, and the coated silver paste is also sintered on the glass; and then prepare the support on the two pieces of glass with polyimide adhesive and glue coating machine Object 6, the support object 6 is a line shape, and the upper and lower support objects 6 cr...

Embodiment 3

[0067] Embodiment 3: see image 3 , a three-way sealed planar vacuum glass, two pieces of glass are tempered glass, one of which is still low-emissivity glass, and its production method is as follows: First, cut a piece of flat glass and a piece of required size according to the shape and size of the vacuum glass to be produced. Low-emissivity glass, and carry out edging, chamfering, cleaning, and drying; secondly, on the two pieces of glass, use tempered glass ink and a glue dispenser to prepare the support 6, the support 6 is a long strip, and after the two pieces of glass are combined The upper and lower supports are intersected together, and then the two pieces of glass are respectively sent into the tempering furnace for tempering treatment, and the prepared support 6 is also sintered on the glass; the sintered support 6 is mechanically ground again, so that the top is in the In one plane, round the top edge after grinding to further eliminate the influence of stress; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com