Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Avoid a lot of volatilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

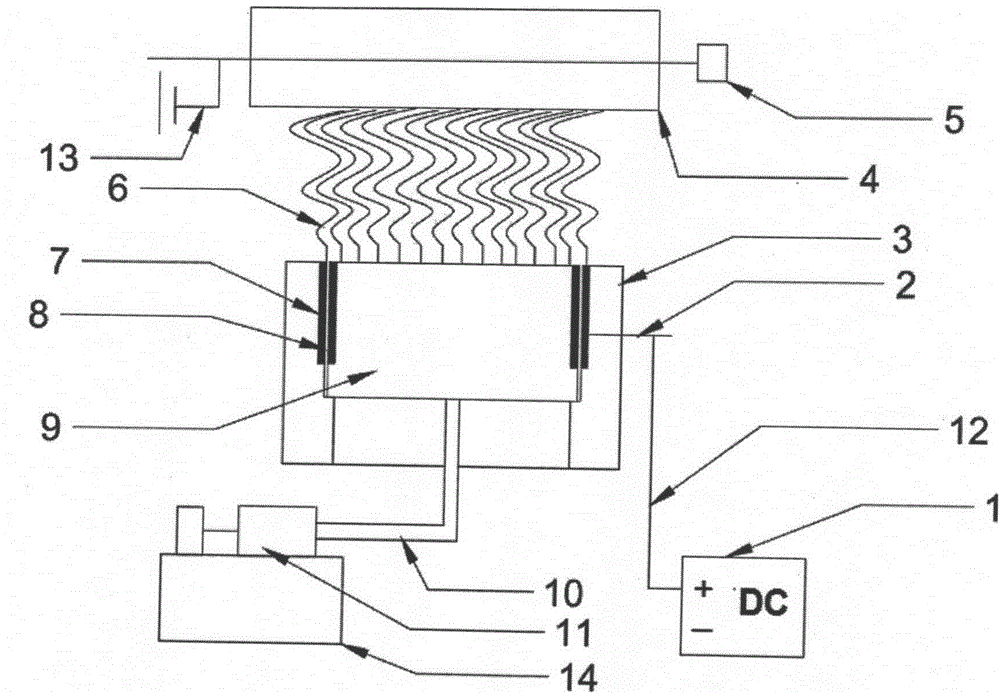

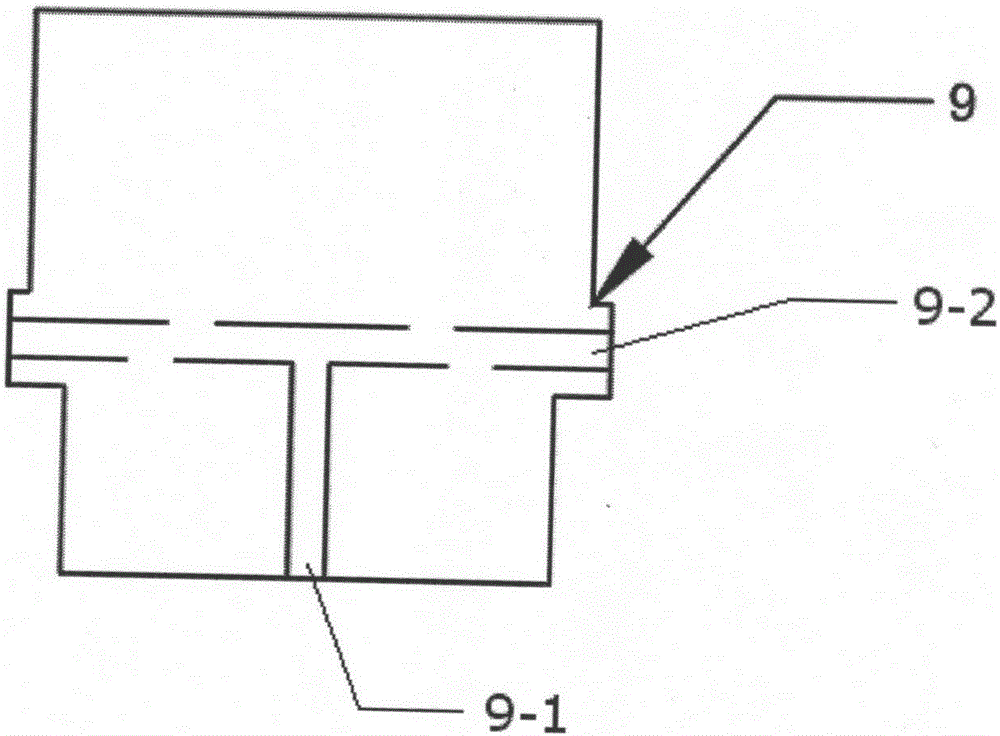

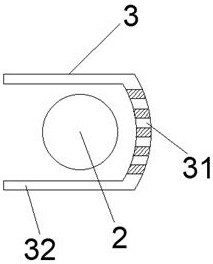

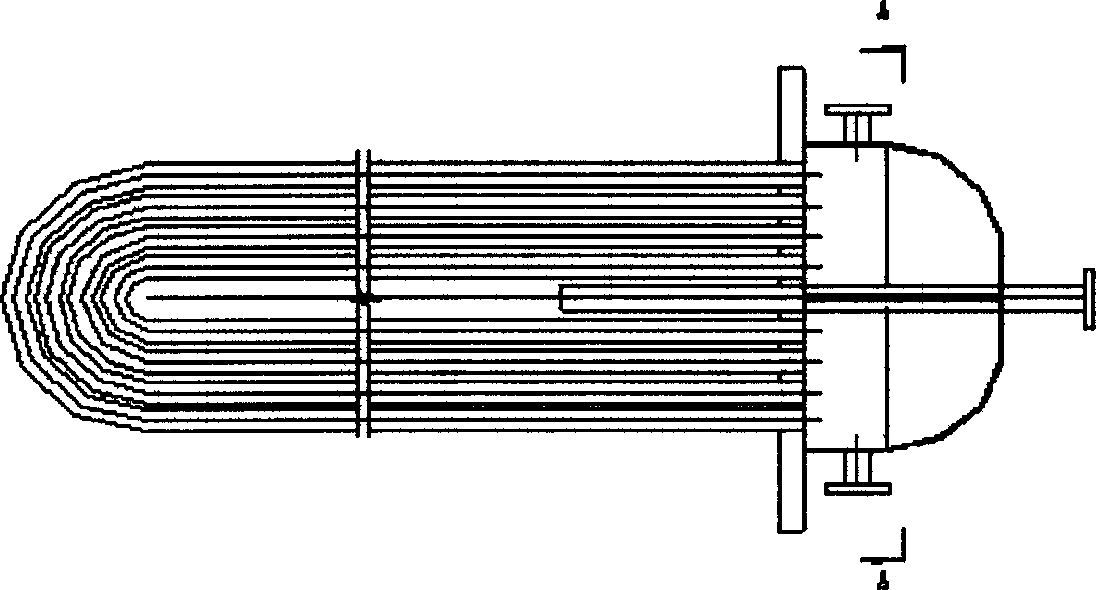

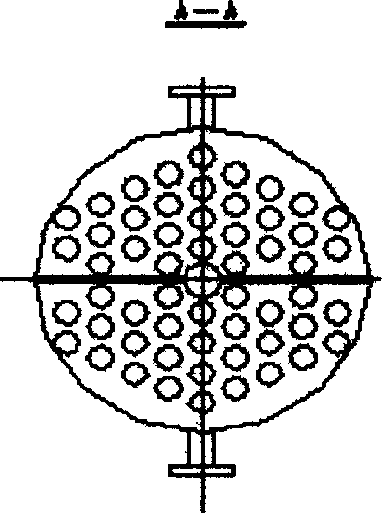

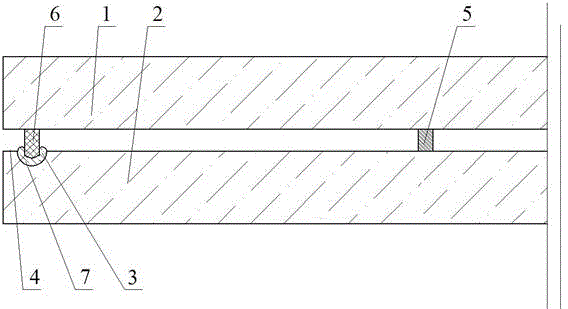

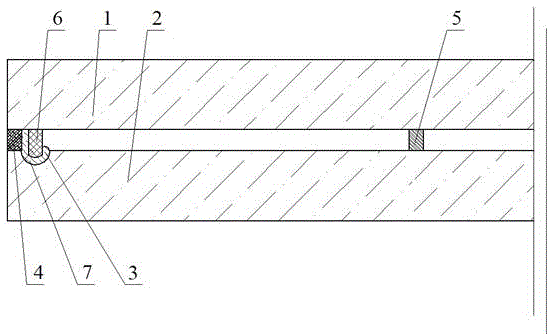

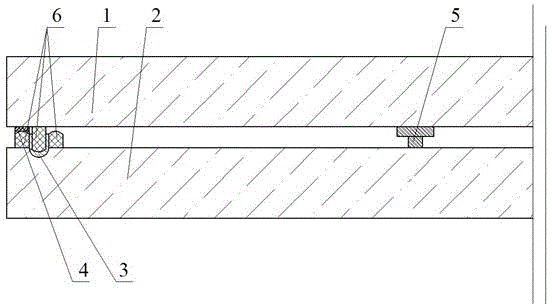

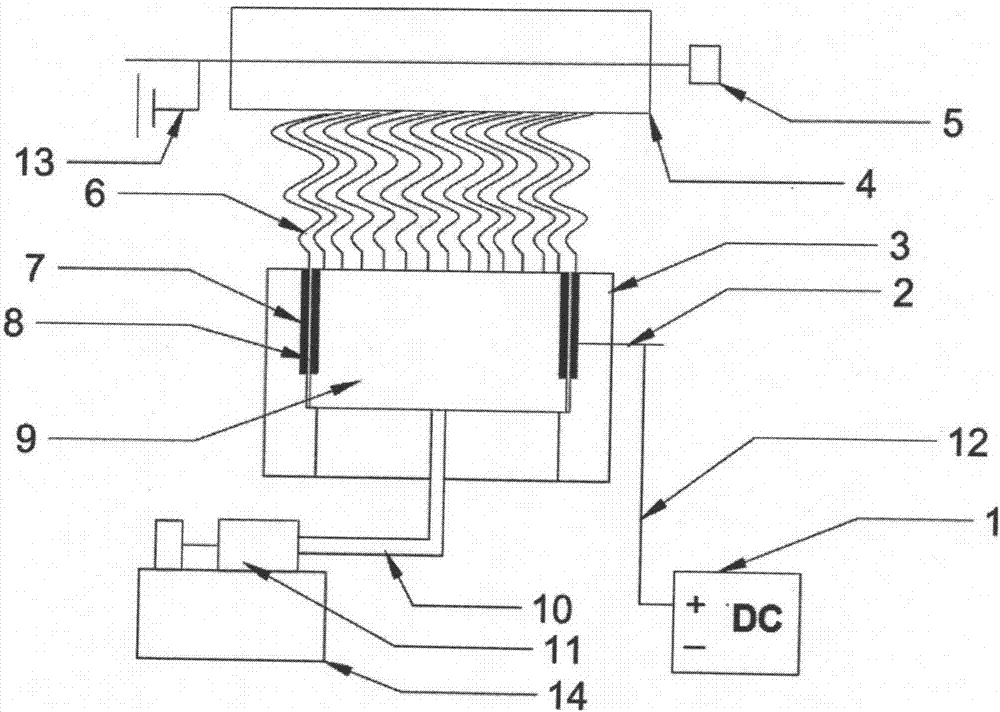

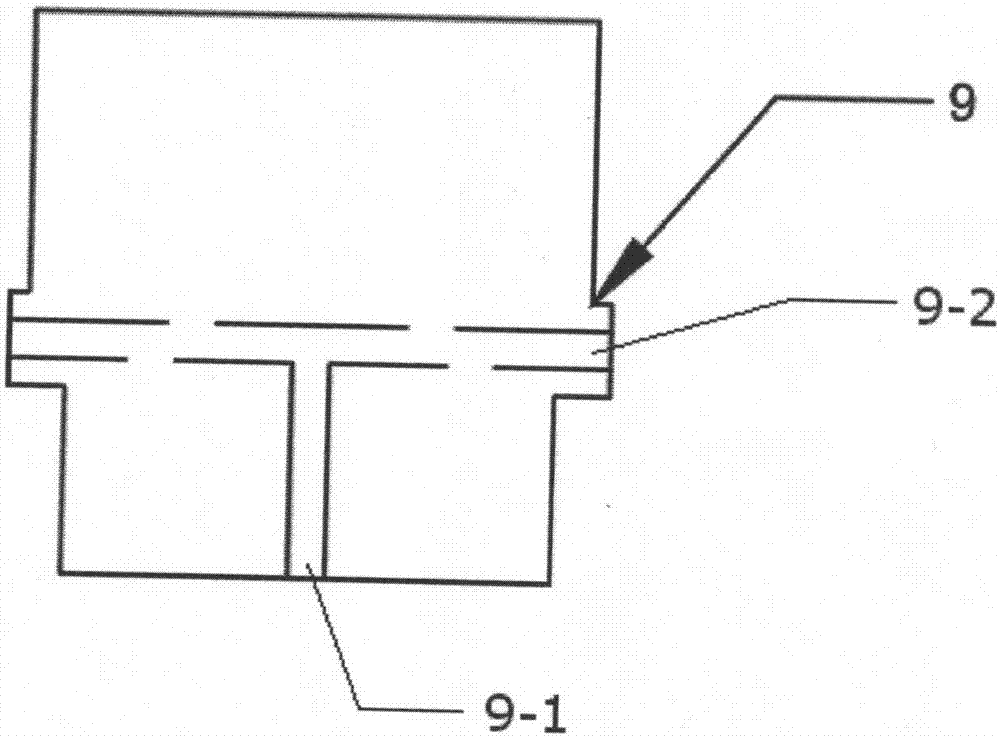

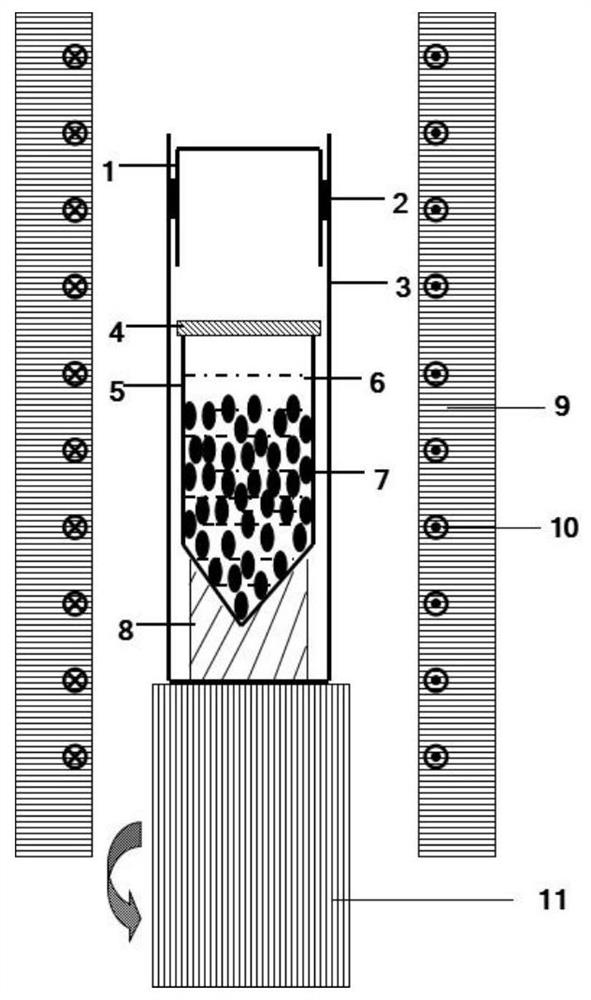

Double-circular-ring-shaped slit type electrostatic spinning device and method

InactiveCN105821497ARealize automatic and precise supplyRealize industrial preparationFilament/thread formingFiberCollection system

The invention discloses a double-circular-ring-shaped slit type electrostatic spinning device and method. The electrostatic spinning device comprises a liquid supply system, a double-circular-ring-shaped slit type nozzle system and a nano fiber collection system. The electrostatic spinning method comprises the following steps of: starting a microinjection pump to enable a solution to flow into a slit between an inner ring and an outer ring through a micro-channel in an inner core; adjusting the flow of the solution to enable a liquid surface of the solution to fully overflow in the slit, but not flow out; starting a speed regulating motor to enable a metal roller to rotate normally; starting a high-voltage electrostatic generator and slowly increasing voltage; when the voltage exceeds a certain value, forming a plurality of jet flows in the slit; in a process that the jet flows fly to the metal roller, volatilizing a solvent and curing a high polymer to form nano fibers which are deposited on the metal roller; and rotating the metal roller to collect the nano fibers. By adopting the microinjection pump and the liquid supply system, a high polymer solution can be automatically and accurately supplied, and the solution is sufficiently and efficiently utilized, so that the yield of the nano fibers is improved and continuous preparation of the nano fibers is realized.

Owner:DONGHUA UNIV

Method for preparing concentrated cheese powder by accelerated fermentation

ActiveCN101326937AShorten the production cycleReduce cost inputCheese manufactureFlavorRoom temperature

The invention relates to a method for preparing condensed cheese powder by rapid fermentation. The preparation steps include that (1) milk powder is taken as the raw material, and cooled to room temperature after sterilization; (2) microbiological culture is put into the milk powder; (3) enzyme preparation and supplementary materials are added; (4) the zymolyte product is embedded by embedding materials and emulsifier; (5) the embedded product is dried to make flour, thereby, the condensed cheese powder is achieved. The invention has the advantages of reasonable production process and easy operation; the production process is simplified and the production cycle is shortened, the flavor of cheese powder is enhanced, and high quality is ensured. The invention is a production method applicable to the modern large-scale production of novel cheese powder products.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

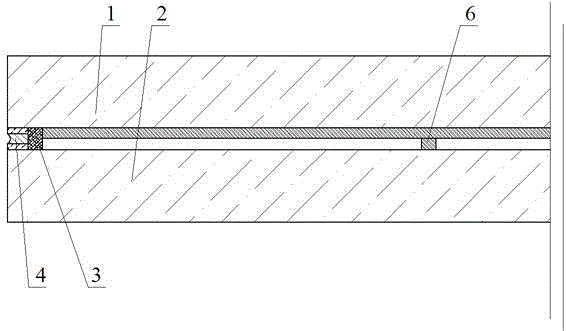

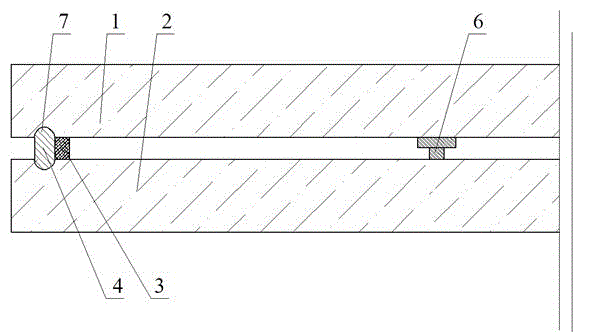

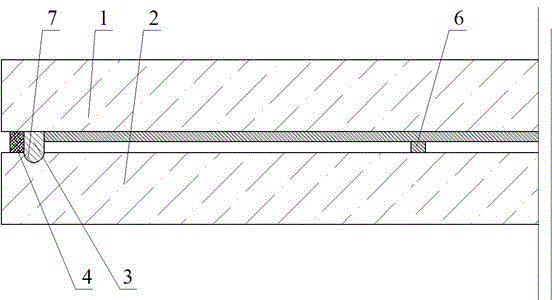

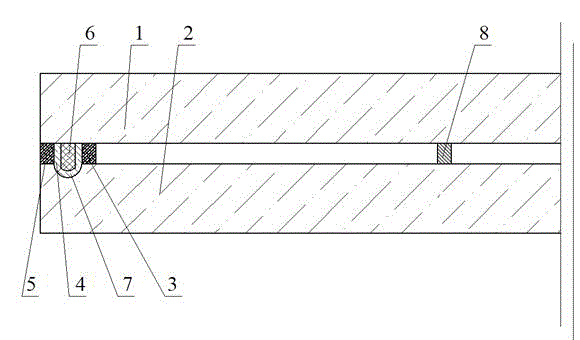

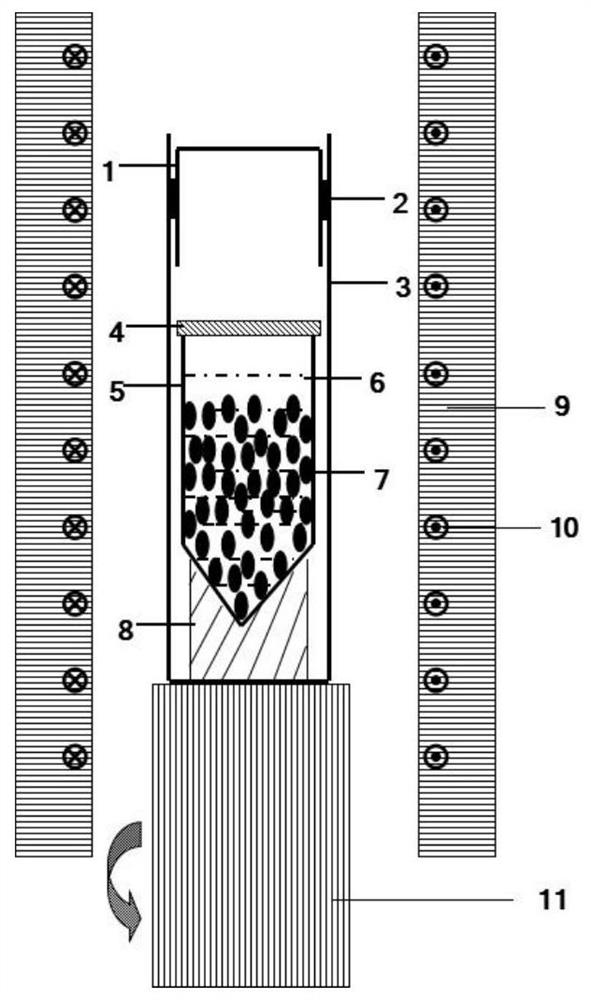

Vacuum-glass heat-insulating board and manufacturing method thereof

InactiveCN105669007ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAir tightness

The invention relates to a vacuum-glass heat-insulating board. The vacuum-glass heat-insulating board comprises upper glass and lower glass, wherein the periphery of the upper glass and the periphery of the lower glass are connected together through a sealing material in a sealing manner, a closed vacuum layer is formed between the upper glass and the lower glass and contains a low-melting-point or volatile or highly-inspiratory metal, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces to the outer side. A manufacturing method for the vacuum-glass heat-insulating board disclosed by the invention is simple in process, the sealing effect is good, the air tightness and service life of the vacuum-glass heat-insulating board can be effectively guaranteed, and mechanized, automated and large-scale production can be achieved.

Owner:戴长虹

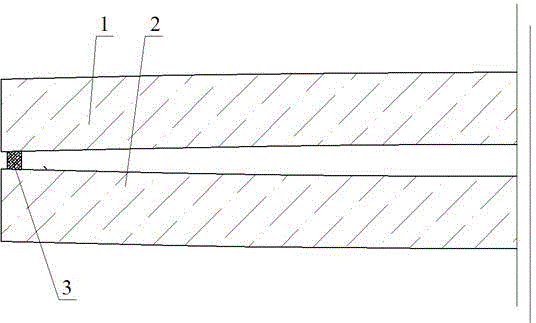

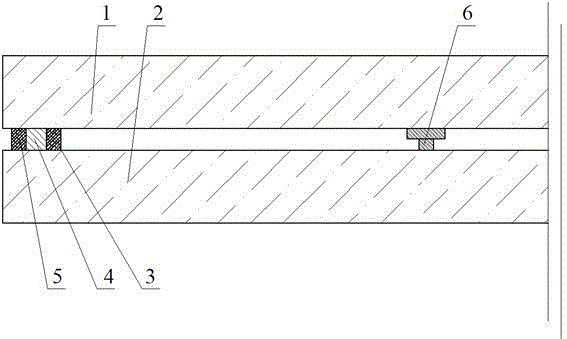

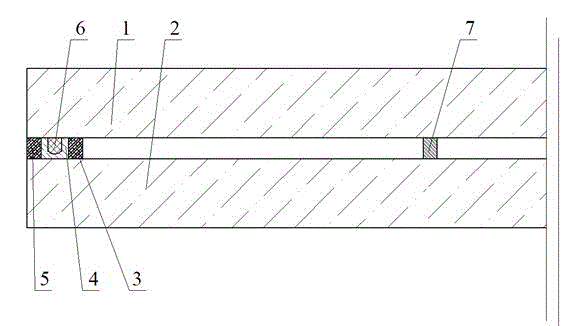

Adhesive sealed vacuum glass and preparation method thereof

InactiveCN105601092AHigh bonding strengthEasy to operateGlass reforming apparatusGlass productionAdhesiveEngineering

The invention relates to an adhesive sealed vacuum glass, which comprises an upper glass and a lower glass, wherein the peripheries of the upper glass and the lower glass are sealed and connected through an adhesive, the adhesive has two parts, a metal or glass welding material is arranged between the two adhesive parts, a closed vacuum layer is formed between the upper glass and the lower glass, the upper glass and the lower glass are convex glasses or flat glasses, and the convex surface of the convex glass is toward the outer side. According to the present invention, the vacuum glass production method is simple, the prepared vacuum glass and the prepared tempered vacuum glass can overcome the defects in the prior art, the tightness and the service life of the vacuum glass can be effectively ensured, and mechanization, automation and large-scale production can be achieved.

Owner:戴长虹

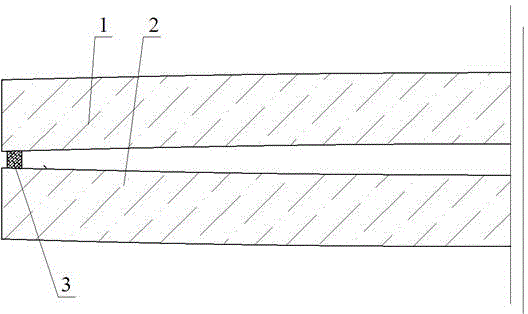

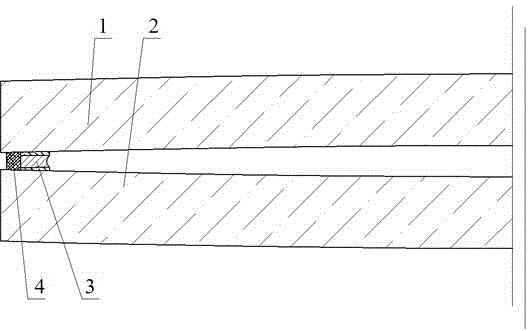

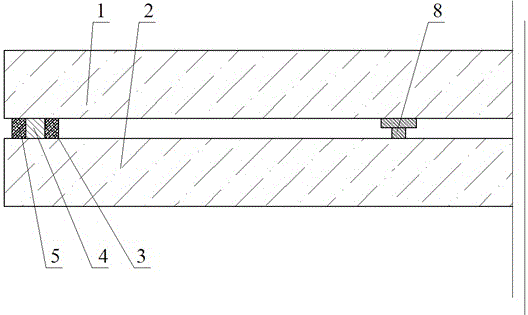

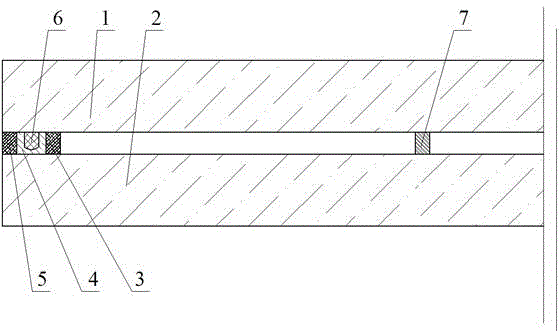

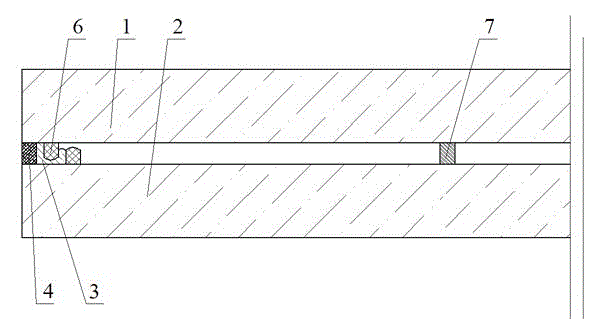

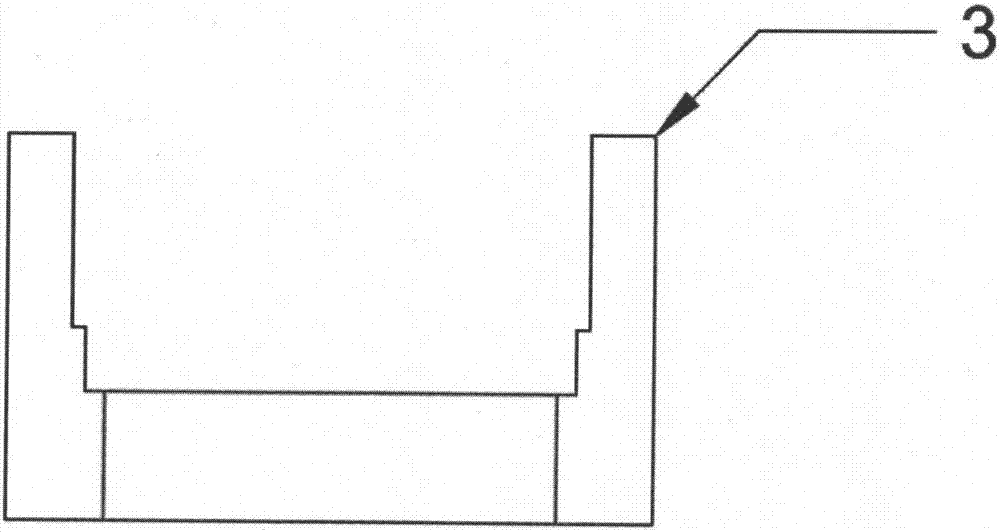

Vacuum glass with two or a plurality of paths of sealing and a preparing method thereof

InactiveCN105645743AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionAdhesiveAir tightness

Vacuum glass with two or a plurality of paths of sealing is provided. The vacuum glass comprises upper glass and lower glass. The periphery of the upper glass and the periphery of the lower glass are sealed through two or a plurality of paths of sealing materials. The sealing materials comprise glass solder, metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or plain glass. The convex surface of the convex glass faces the outside. A preparing method of the vacuum glass is simple. The prepared vacuum glass and tempered vacuum glass can overcome disadvantages of the prior art. Air impermeability and service lifetime of the vacuum glass can be ensured effectively. Mechanized, automatic and large-scale production can be achieved.

Owner:戴长虹

Vacuum glass insulation panel and preparation method thereof

InactiveCN105669003ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

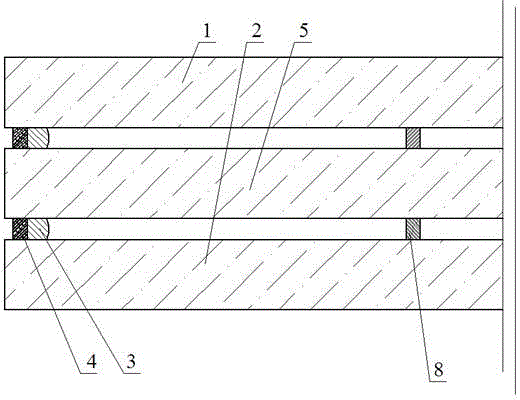

Compound sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669006ABroaden your optionsAvoid a lot of volatilizationGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a compound sealed vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

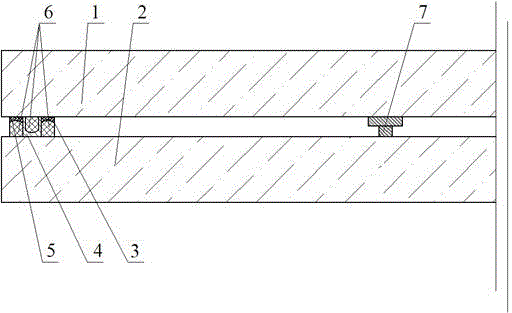

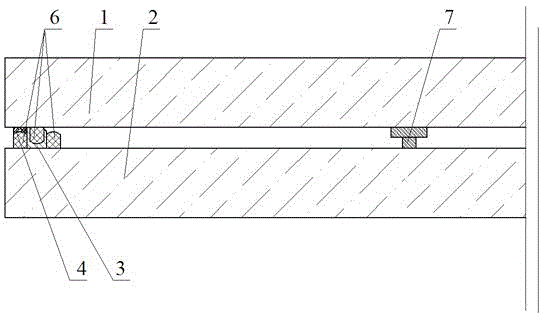

Bar frame sealed vacuum glass and manufacturing method thereof

InactiveCN105669052AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionFlat glassAdhesive

The invention relates to bar frame sealed vacuum glass. The bar frame sealed vacuum glass comprises upper glass and lower glass, wherein the periphery of the upper glass and the periphery of the lower glass are connected together through an edge banding bar frame and two or multiple sealing materials in a sealing manner, each sealing material comprises glass solder, metal solder and an adhesive, a closed vacuum layer is formed between the upper glass and the lower glass, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces to the outer side. A manufacturing method for the vacuum glass disclosed by the invention is simple in process, the manufactured vacuum glass and tempered vacuum glass can overcome the shortages in the prior art, the air tightness and service life of the vacuum glass can be effectively guaranteed, and mechanized, automated and large-scale production can be achieved.

Owner:戴长虹

Groove sealed vacuum glass and preparing method thereof

InactiveCN105645742AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionAdhesiveAir tightness

Groove sealed vacuum glass is provided and comprises upper glass and lower glass. The periphery of the upper glass and the periphery of the lower glass are sealed through an edge sealing groove and two or a plurality of paths of sealing materials. The sealing materials comprise glass solder, metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or plain glass. The convex surface of the convex glass faces the outside. A preparing method of the vacuum glass is simple. The prepared vacuum glass and tempered vacuum glass can overcome disadvantages of the prior art. Air impermeability and service lifetime of the vacuum glass can be ensured effectively. Mechanized, automatic and large-scale production can be achieved.

Owner:戴长虹

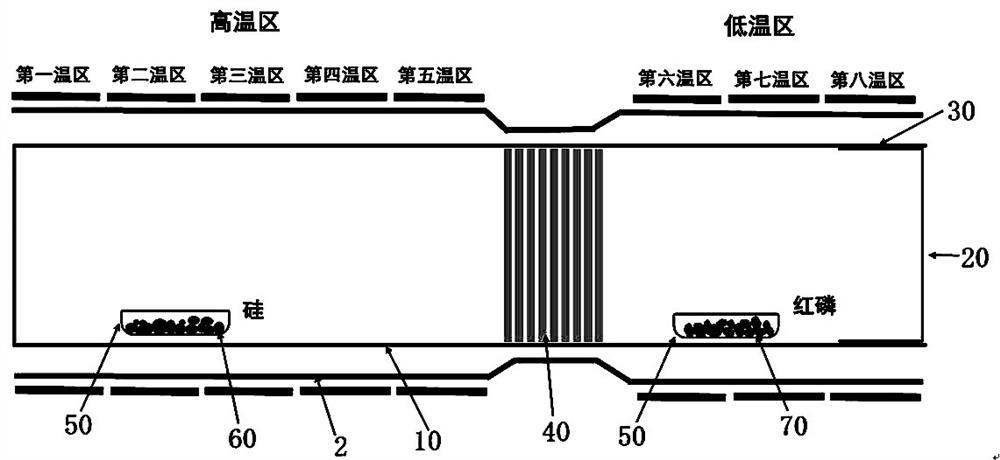

Preparation method of silicon-phosphorus alloy

PendingCN113371714AHigh purityAvoid pollutionAfter-treatment apparatusPolycrystalline material growthDirectional solidificationTemperature treatment

The invention discloses a preparation method of a silicon-phosphorus alloy, and relates to the technical field of semiconductor materials. The method comprises the following specific steps: cleaning and drying an appliance; respectively weighing a silicon elementary substance and a red phosphorus elementary substance according to the weight percentage; putting the silicon elementary substance and the red phosphorus elementary substance into the appliance, vacuumizing a quartz tube by using vacuumizing equipment, and then performing vacuum tube sealing on the quartz tube; putting the quartz tube into a high-pressure horizontal furnace, enabling the silicon elementary substance to be positioned in a high-temperature area of the high-pressure horizontal furnace, enabling the red phosphorus elementary substance to be positioned in the low-temperature area of the high-pressure horizontal furnace, and enabling the quartz block to be positioned between the high-temperature area and the low-temperature area of the high-pressure horizontal furnace; placing temperature thermocouples at two ends of the quartz boat respectively; performing variable-temperature treatment on the quartz tube; controlling internal and external pressure balance of the quartz tube; and synthesizing alloy, cutting the quartz tube, and taking out the alloy material. The method has the advantages that alloy preparation is carried out in the closed quartz tube so as to avoid external pollution, further material purification is carried out by using a directional solidification technology, and the purity of the synthesized silicon-phosphorus alloy is high.

Owner:如皋市化合物半导体产业研究所

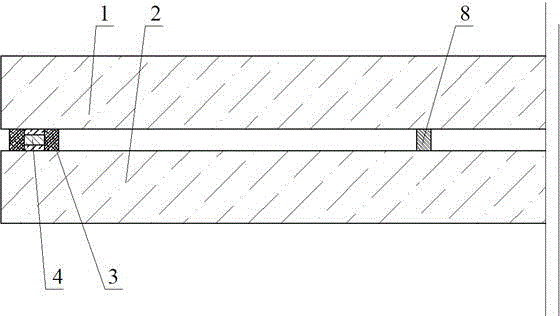

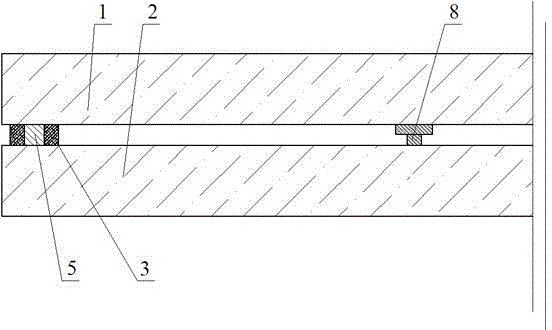

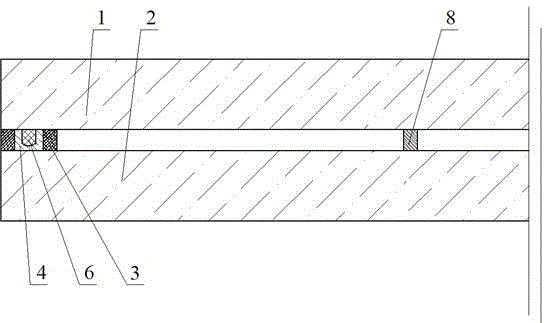

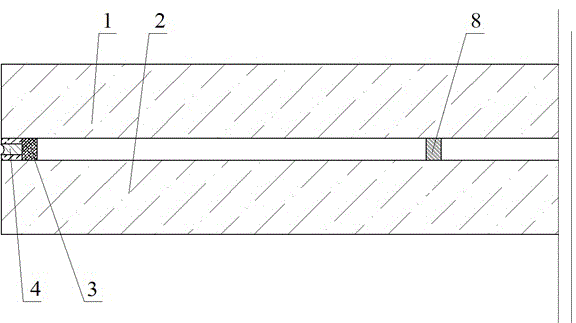

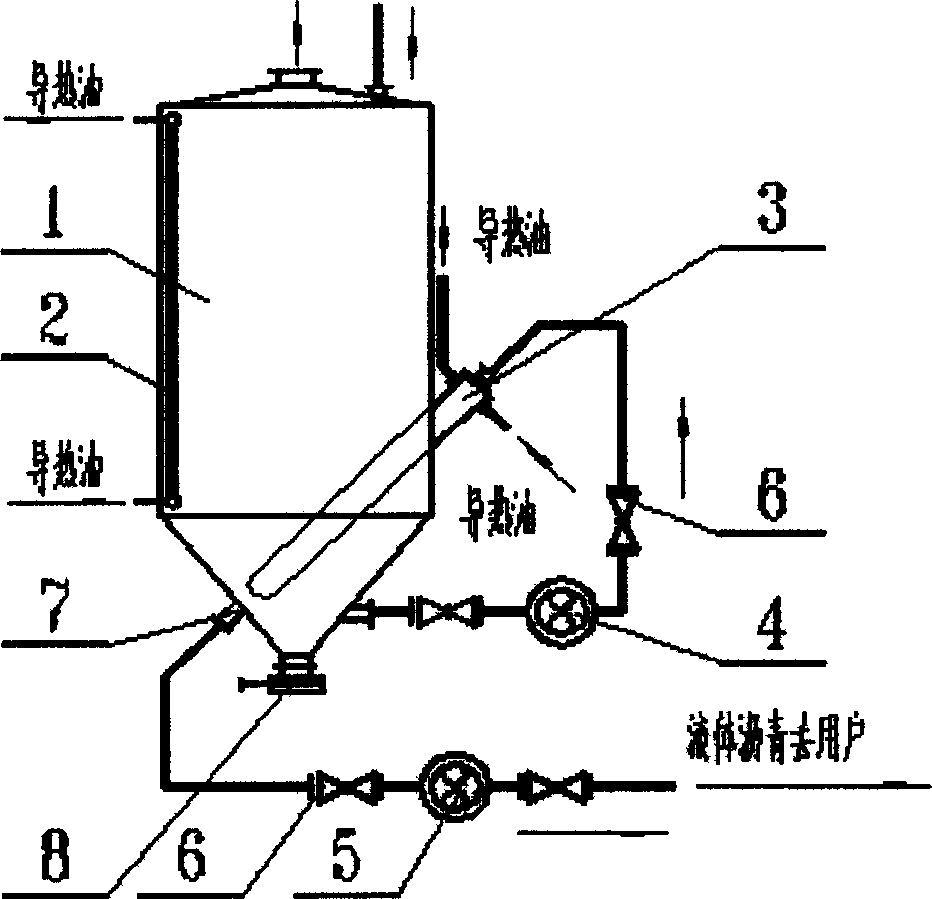

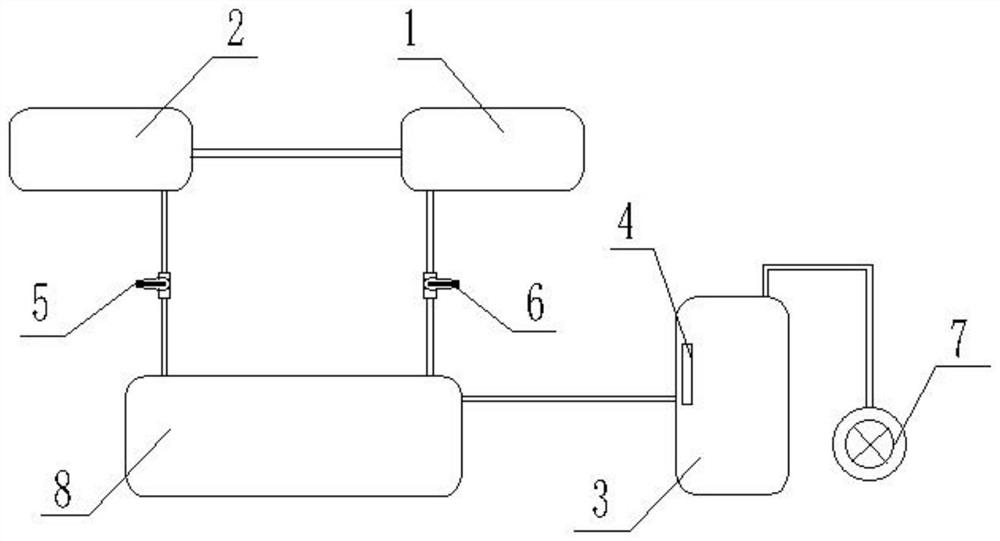

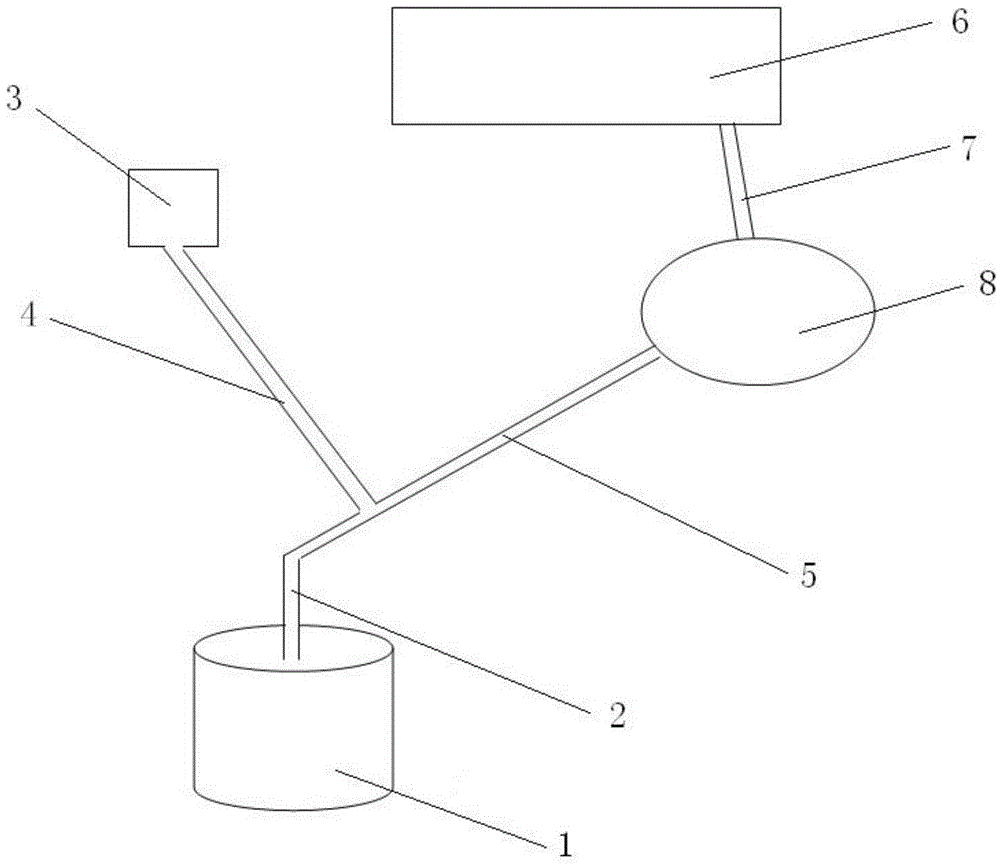

Liquid asphalt low-temperature storage device

InactiveCN1803576AImprove heat transfer efficiencyMeet the use requirementsLiquid transferring devicesTarEngineering

The invention discloses a low-temperature storage technique of liquid tar, which comprises the following parts: tar storage groove (1), heat conductivity oil pipe (2), heater (3), tar circulating pump (4), tar transmission pump (5) and tar valve (6), wherein the heater is set on the bottom of tar storage groove to heat bottom tar, which keeps most of tar at low-temperature state; several heat conductivity oil pipes are set in the tar storage groove from up to down, which drains water outsides and avoids overflow accident of tar. The invention can stew liquid tar for a long time, which prevents tar from oxygenizing and volatilizing effectively.

Owner:GUIYANG AL-MG DESIGN & RES INST

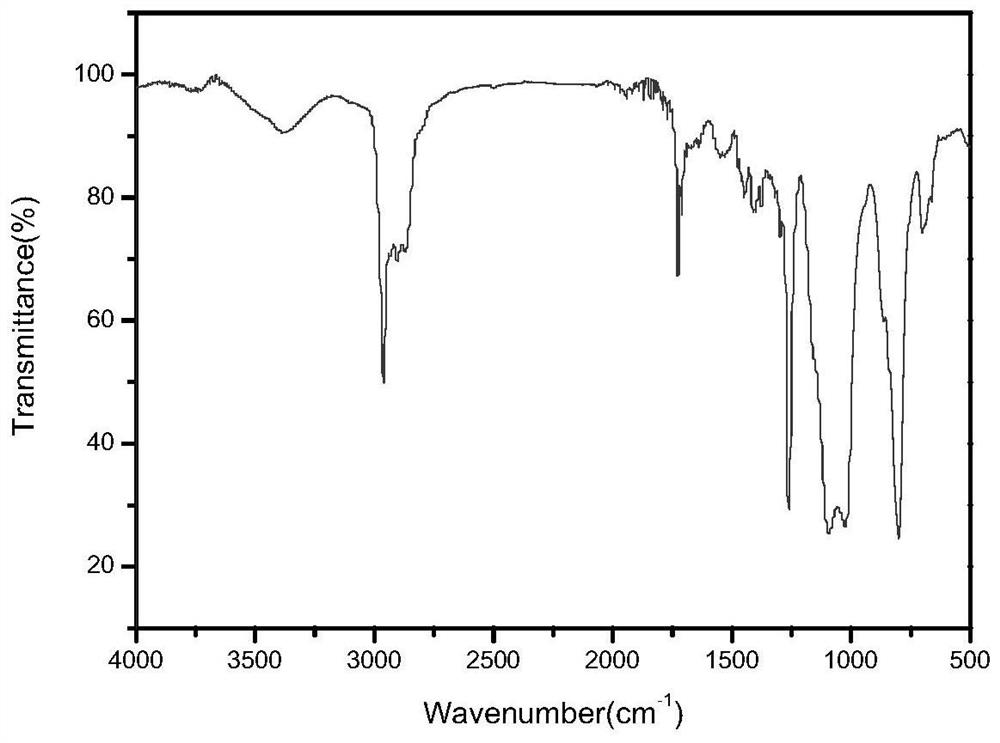

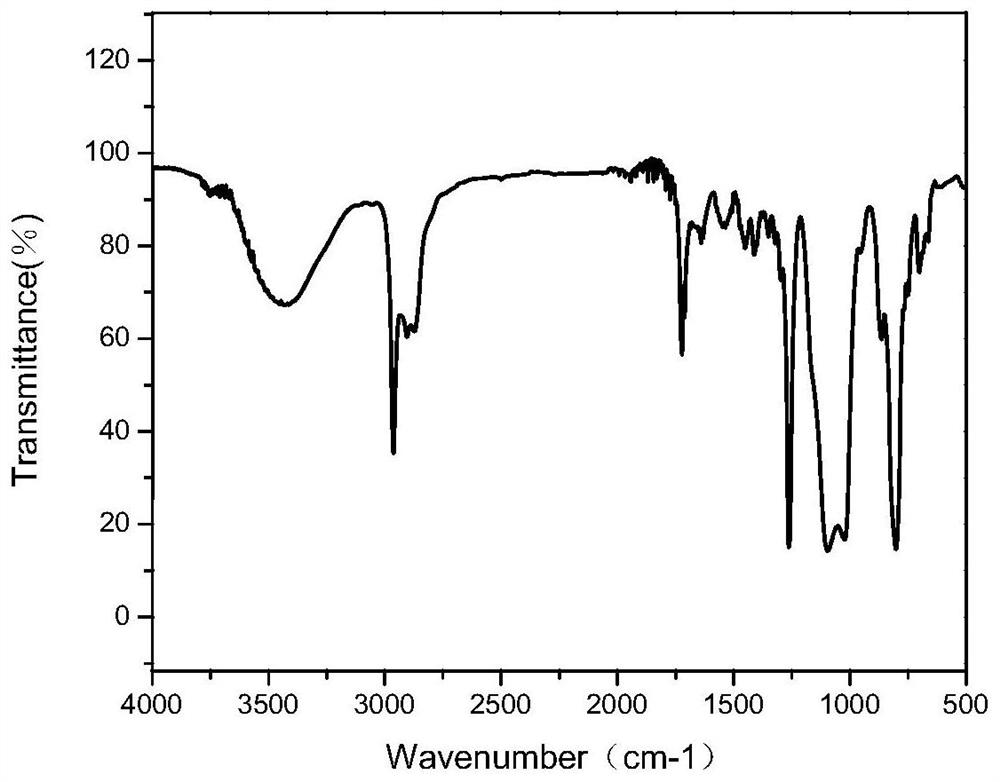

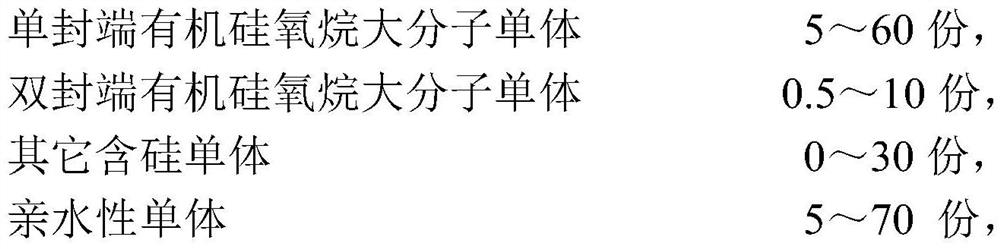

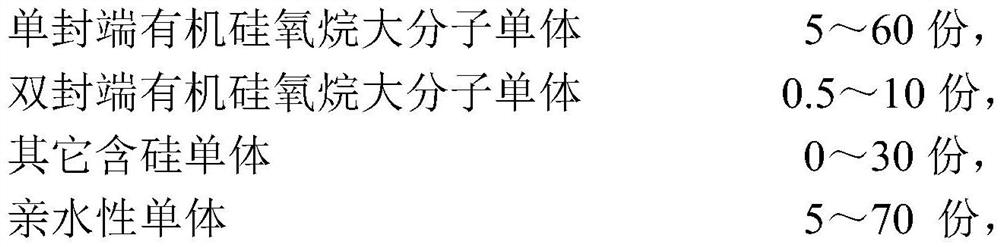

Silicone hydrogel with high oxygen permeability and corneal contact lens

The invention discloses a silicon hydrogel, which is prepared from the following components in parts by mass through polymerization reaction: 5 to 60 parts of single-end-capped organosiloxane macromonomer, 0.5 to 10 parts of double-end-capped organosiloxane macromonomer, 0 to 30 parts of other silicon-containing monomers, 5 to 70 parts of hydrophilic monomer, an initiator and a cross-linking agent. According to the invention, the single-end-capped organosiloxane macromonomer is taken as a main component and compounded with the double-terminated organosiloxane macromonomer, and the single-end-capped organosiloxane macromonomer and the double-terminated organosiloxane macromonomer are compounded to generate an obvious synergistic effect, so that the oxygen permeability, the mechanical property and the hydrophilic property of the silicon hydrogel can be better improved. The invention also discloses a corneal contact lens prepared from the silicone hydrogel material, and the corneal contact lens has the advantages of high oxygen permeability, good light transmission, strong hydrophilicity, good mechanical properties and comfortable wearing, does not contain a solvent, and is beneficial to large-scale industrial production.

Owner:JIANGSU HORIEN CONTACT LENS +1

Bar-frame sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669005ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a bar-frame vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

Traditional Chinese medicine tablet and preparation method thereof

InactiveCN110772426AReduce usageEvenly bondedInorganic non-active ingredientsPharmaceutical product form changeIcing sugarEngineering

The invention discloses a traditional Chinese medicine tablet and a preparation method thereof. The traditional Chinese medicine tablet is prepared by processing the following raw materials in parts by weight: 3-5 parts of cyclodextrine, 0.5-1 part of glycerol, 0.2-1 part of microcrystalline cellulose, 1-7 parts of attapulgite, 0.1-5 parts of malt syrup, 0.1-0.15 part of aluminum hydroxide, 10-40parts of traditional Chinese medicine extract, 0.1-5 parts of powdered sugar and 20-30 parts of corn starch. The traditional Chinese medicine tablet is processed by an automatic traditional Chinese medicine tablet processing device. When the formed traditional Chinese medicine tablets are unloaded; contact with the formed traditional Chinese medicine tablets is avoided in the whole process, the damage probability of the traditional Chinese medicine tablets is reduced, and the rate of finished products is increased; and in the processing process, defective traditional Chinese medicine tablets can be crushed and transferred in time, the defective traditional Chinese medicine tablets are prevented from entering into a downward moving procedure, meanwhile, due to the fact that the defective traditional Chinese medicine tablets are easy to crush, mixed raw materials in movable processing parts can be more completely removed through a detection device structure, and subsequent traditional Chinese medicine tablets are prevented from being polluted.

Owner:合肥一枫医药有限公司

Groove sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669004ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionAdhesiveFlat glass

The present invention discloses a groove vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

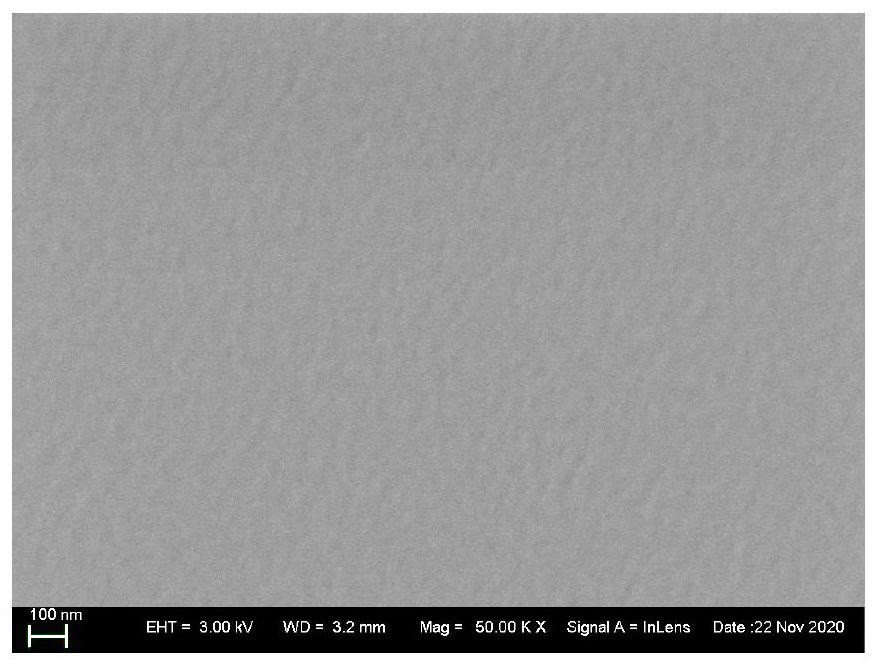

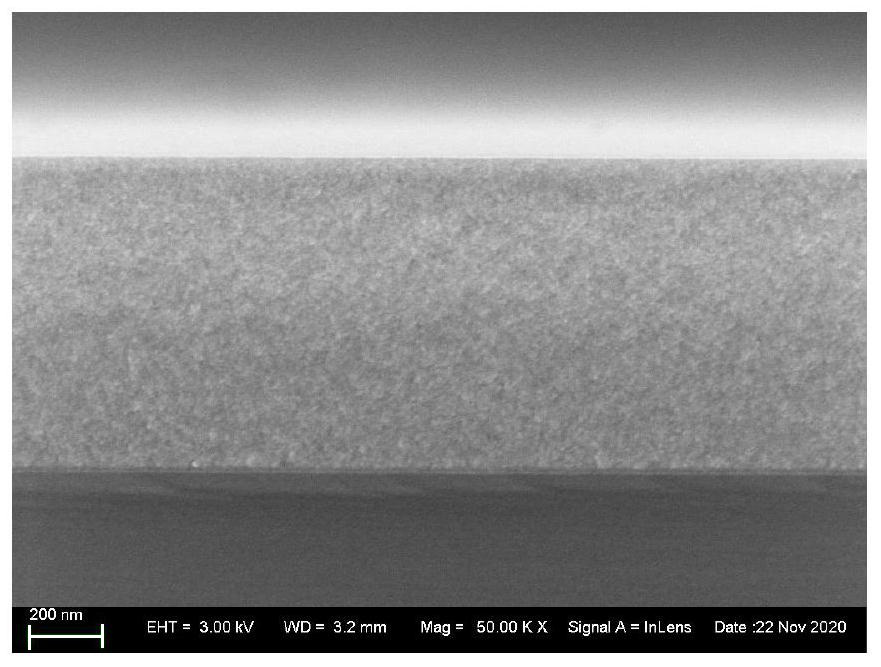

High-entropy alloy nitride cutter coating and preparation method thereof

ActiveCN113308675AHigh hardnessSmall grain sizeVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringHigh entropy alloys

The invention discloses a high-entropy alloy nitride cutter coating and a preparation method thereof. The preparation method comprises the steps that a cutter base body is sequentially subjected to oil removal treatment and cleaning; and an AlTiVNbCr high-entropy alloy target and a B target are used as sputtering sources, mixed gas of argon and nitrogen is used as working gas, and the (AlTiVNbCr)BN high-entropy alloy nitride coating is deposited on the cleaned cutter base body in the mode that radio frequency magnetron sputtering and direct current magnetron sputtering are combined. According to the high-entropy alloy nitride cutter coating and the preparation method thereof, the B-containing high-entropy alloy nitride cutter coating is prepared in a double-target co-sputtering mode, the content of the B element can be accurately controlled, a large amount of volatilization of the B element during preparation of the B-containing high-entropy alloy target material is avoided, the process is simple, and the cost is low; the coating prepared in the mode of combining radio frequency magnetron sputtering and direct current magnetron sputtering is high in hardness, small in grain size, compact in structure and uniform in component; and the thickness of the coating can be adjusted by adjusting the power, so that the hardness and the wear resistance of the superhard high-entropy alloy nitride coating are improved, and the application range is expanded.

Owner:XIAN TECH UNIV +1

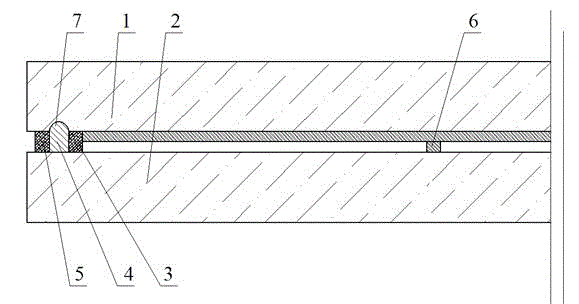

Vacuum glass with sealed strip frame and groove as well as preparation method thereof

InactiveCN105621868AAvoid a lot of volatilizationBroaden your optionsGlass reforming apparatusGlass productionFlat glassAdhesive

The invention relates to a vacuum glass with a sealed strip frame and a groove. The vacuum glass comprises upper glass and lower glass which adopt convex glass or plain glass, wherein an air extraction opening is formed in the upper glass; the sealing strips are arranged on the peripheries of the upper glass and the air extraction opening; the sealed materials comprises a glass solder, a metal solder and an adhesive, a closed vacuum layer is formed between the upper glass and the lower glass, the upper glass and the lower glass are convex glass or flat glass, and the convex surface of the convex glass faces outwards. The preparation method of the vacuum glass is simple, the prepared vacuum glass and toughened vacuum glass can overcome insufficiency in the prior art, air tightness and service life of the vacuum glass are effectively guaranteed, and mechanization, automation, and large-scale production can be realized.

Owner:戴长虹

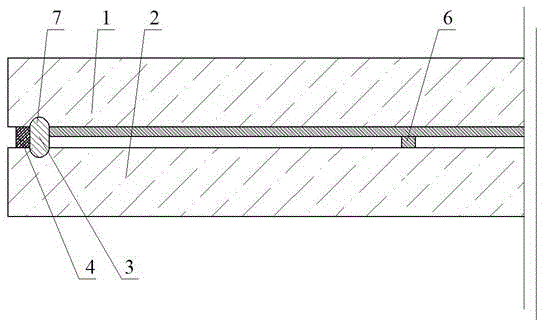

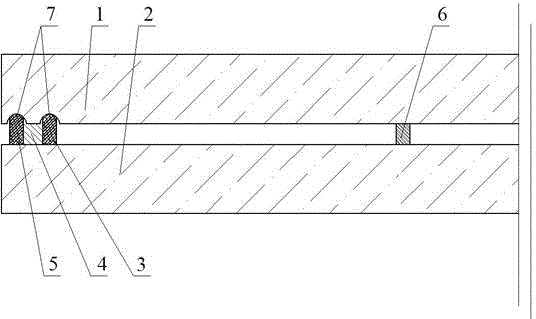

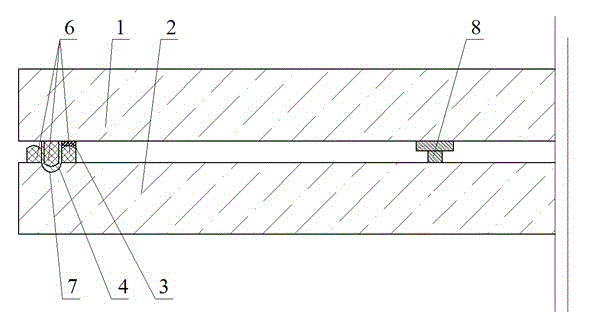

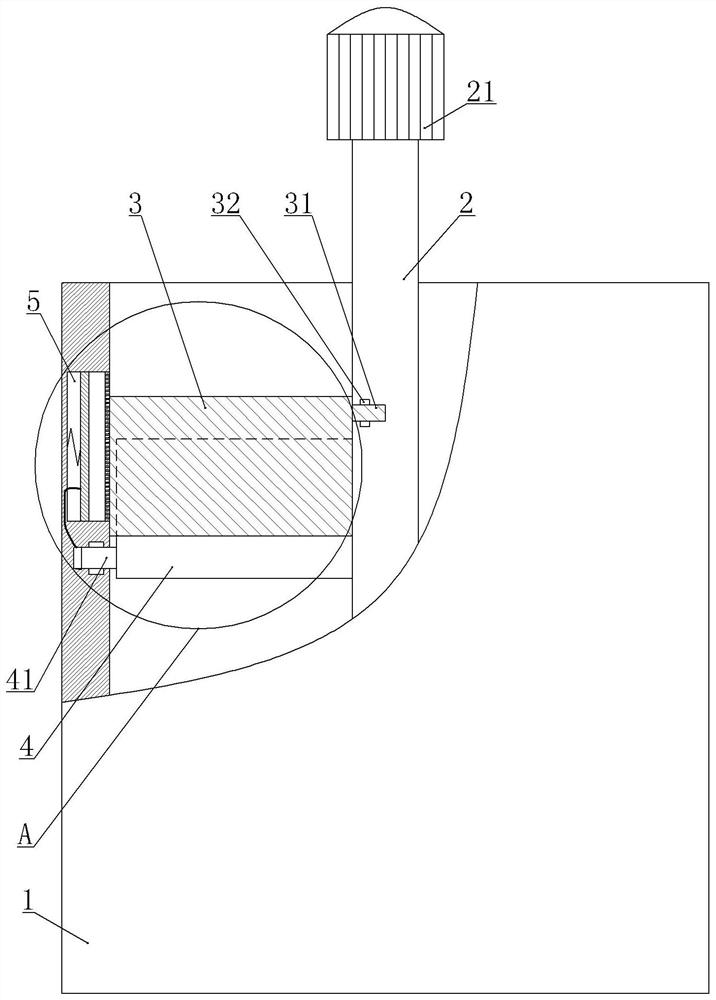

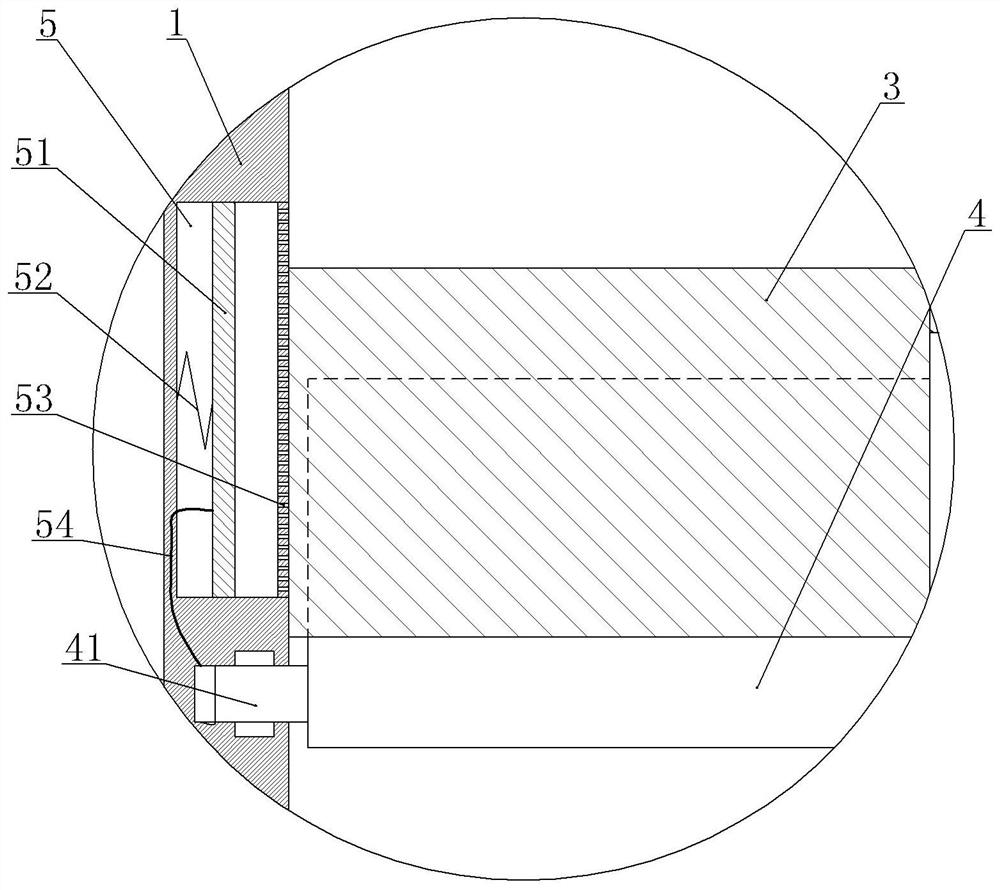

Synthesis device and method of gallium antimonide polycrystalline raw material

ActiveCN111647947AAvoid a lot of volatilizationGood process repeatabilityPolycrystalline material growthSingle crystal growth detailsGallium antimonideProcess design

The invention relates to a synthesis device and method of a gallium antimonide polycrystalline raw material. According to the device, the sealed ampoule bottle is adopted, and the unique quartz crucible structure and process design are combined, so that a large amount of elemental antimony is prevented from being volatilized at high temperature, the gallium antimonide polycrystalline raw materialwith the stoichiometric ratio close to 1: 1 is successfully obtained, and the device has excellent process repeatability.

Owner:苏州燎塬半导体有限公司

Bar-frame and groove sealed vacuum glass insulation panel and preparation method thereof

InactiveCN105669002ASolve the sealing problemSolve the vacuum problemGlass reforming apparatusGlass productionFlat glassAdhesive

The present invention discloses a bar-frame and groove sealed vacuum glass insulation panel. The vacuum glass insulation panel includes an upper glass and a lower glass. The peripheries of the upper glass and the lower glass are sealed and connected together through one, two or multiple sealing materials. The sealing materials comprises a glass solder, a metal solder and an adhesive. A sealed vacuum layer is formed between the upper glass and the lower glass. The upper glass and the lower glass are convex glass or flat glass. The convex surface of the convex glass faces towards the outside. The vacuum glass insulation panel preparation method is simple in processes. The prepared vacuum glass insulation panel and tempered vacuum glass insulation panel overcome the deficiencies in the prior art. The preparation method can effectively ensure the tightness and service life of the vacuum glass insulation panel, and can realize mechanized, automatic and mass productions.

Owner:戴长虹

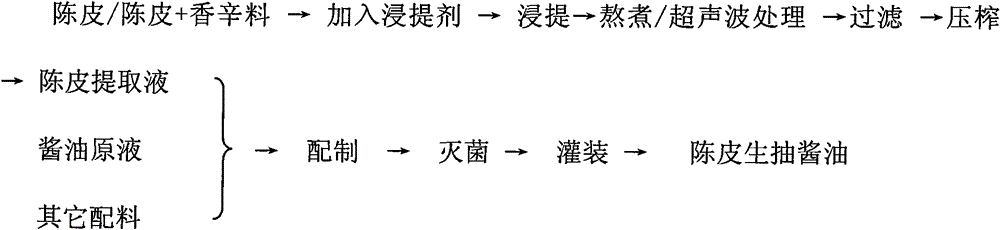

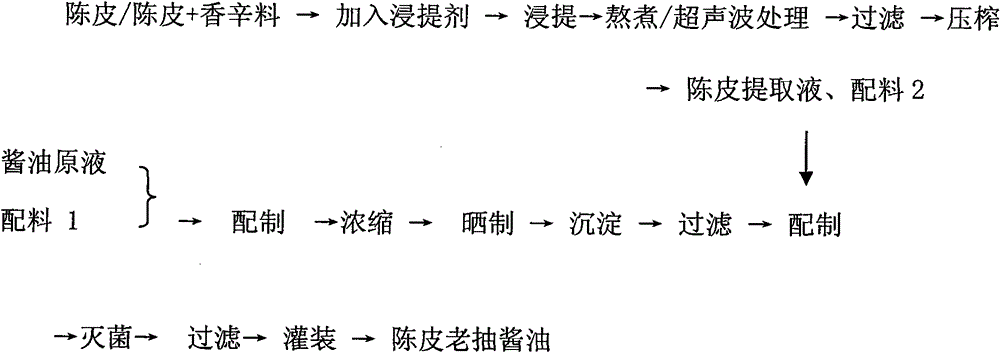

Preparation method of dried orange peel soy sauce

ActiveCN101653235BImprove sexual functionIncrease health functionFood preparationChinese traditionalFood flavor

The invention relates to a preparation method of dried orange peel soy sauce, comprising the following steps: (1) processing dried orange peels or the dried orange peels and spices by a lixiviation and boiling technology to prepare a dried orange peel soy extracting solution; (2) mixing, the dried orange peel extracting solution a fermented soy sauce stock solution, a sweetener, a flavoring agent, and the like together, and then boiling, filtering and caning the prepared dried orange peel light soy sauce; and (3) or mixing the dried orange peel extracting solution, a concentrated and sun-cured soy sauce concentrated solution and a flavouring agent together, and then boiling, filtering and caning the dried orange peel extracting solution. The preparation method of the dried orange peel soysauce prepares the dried orange peel flavor soy sauce by adding a dried orange peel food with Chinese traditional characteristics on the basis of retaining the original flavor of general soy sauce; in addition, the dried orange peels can not only provide the unique flavor to the soy sauce and enhance the fragrance but also enable the soy sauce to have a certain health-care function.

Owner:LEE KUM KEE XIN HUI FOOD

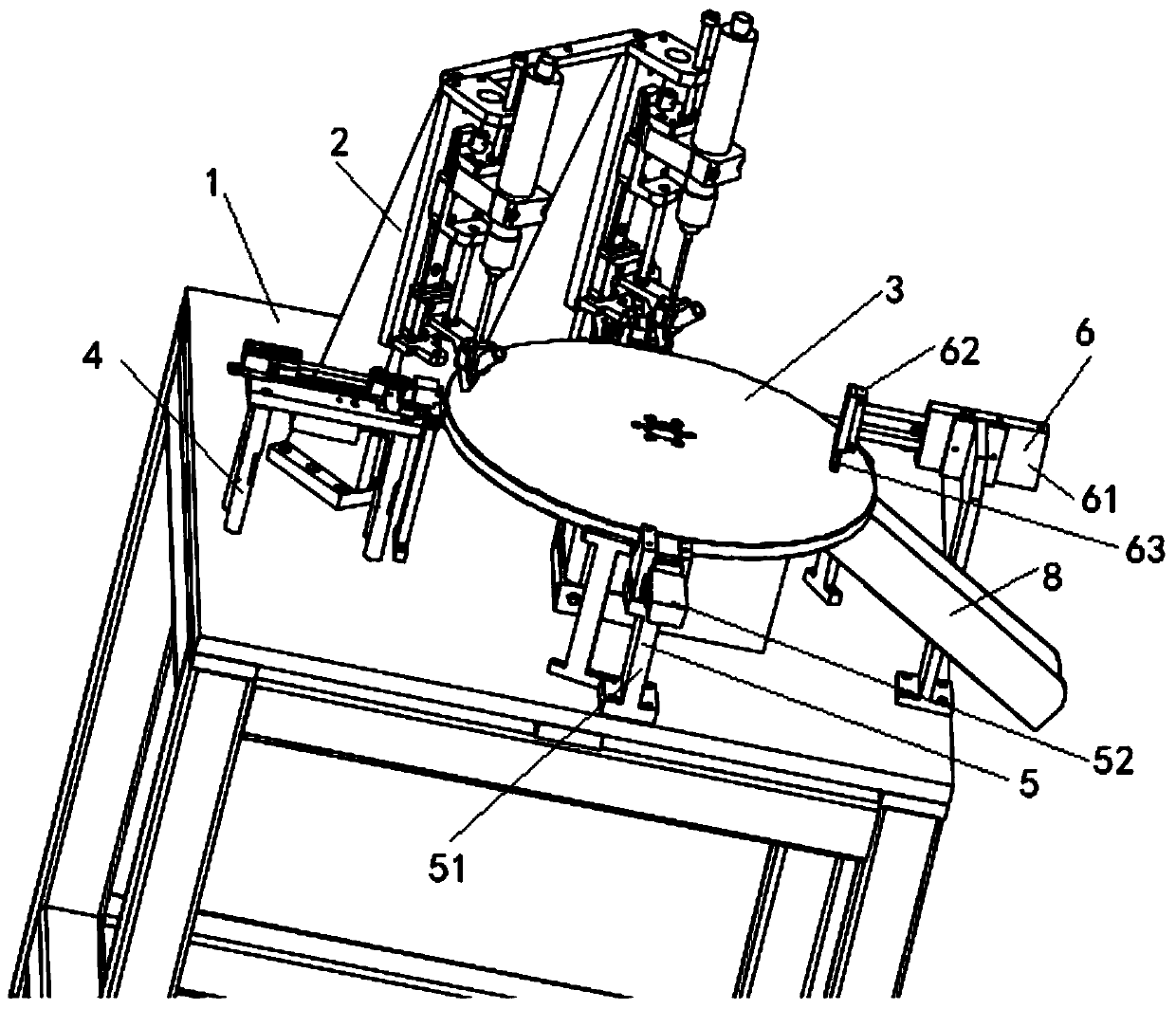

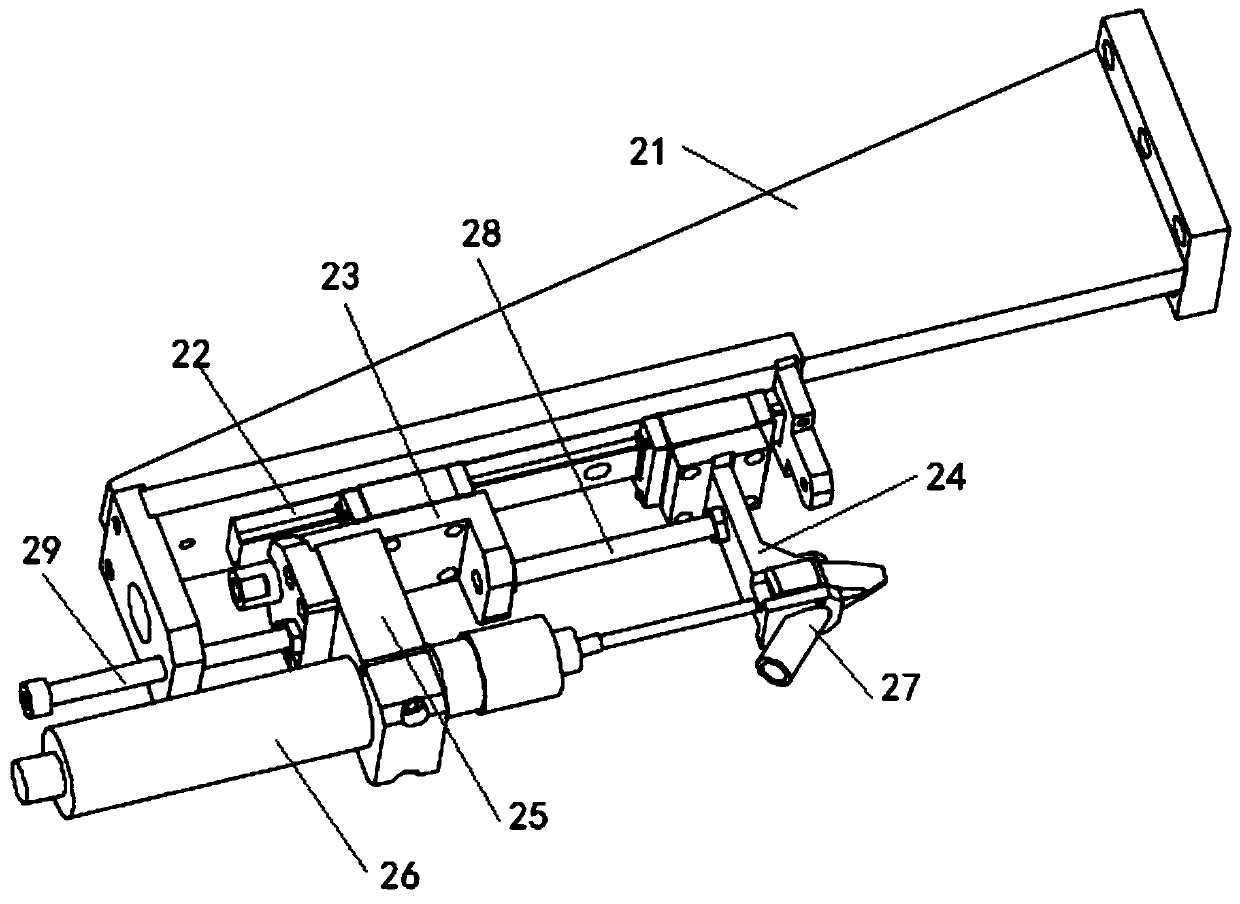

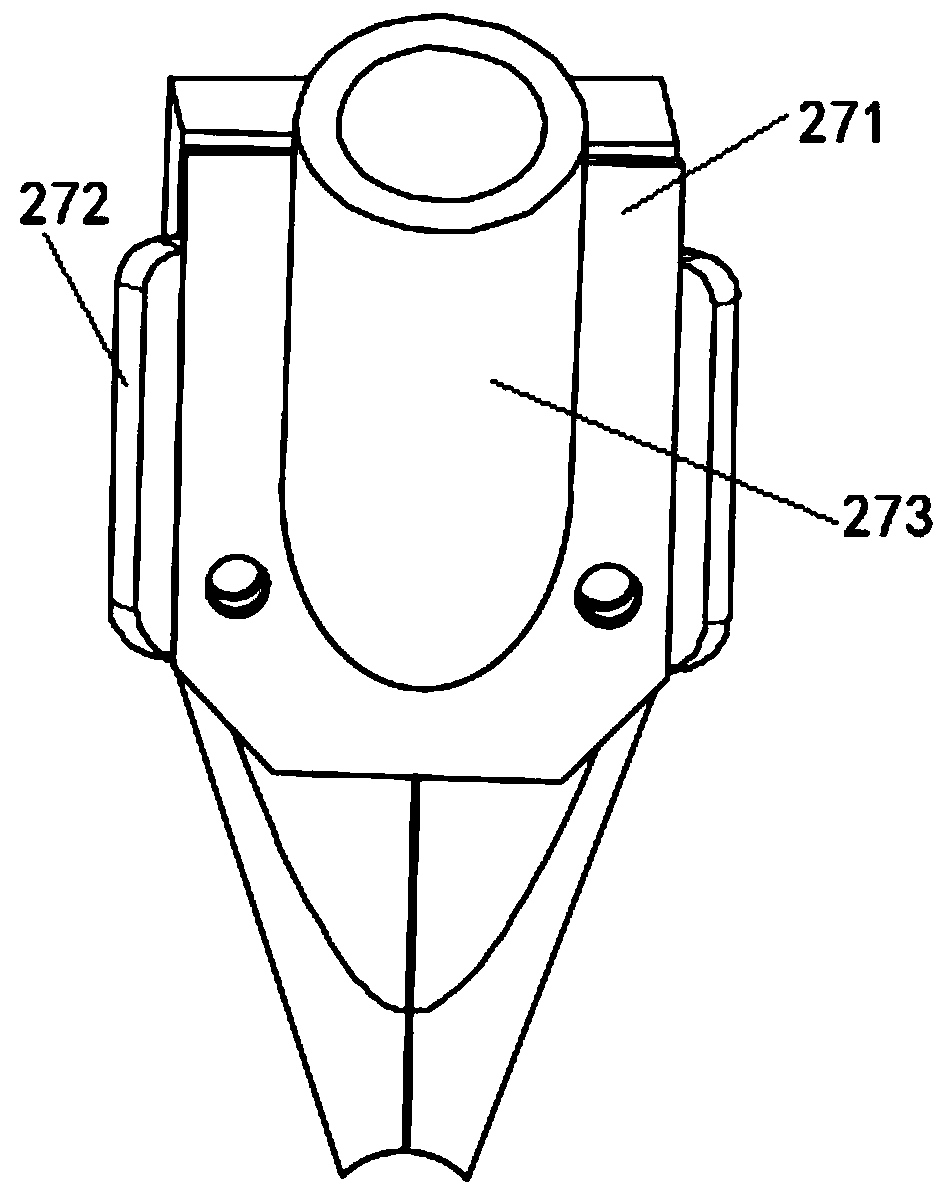

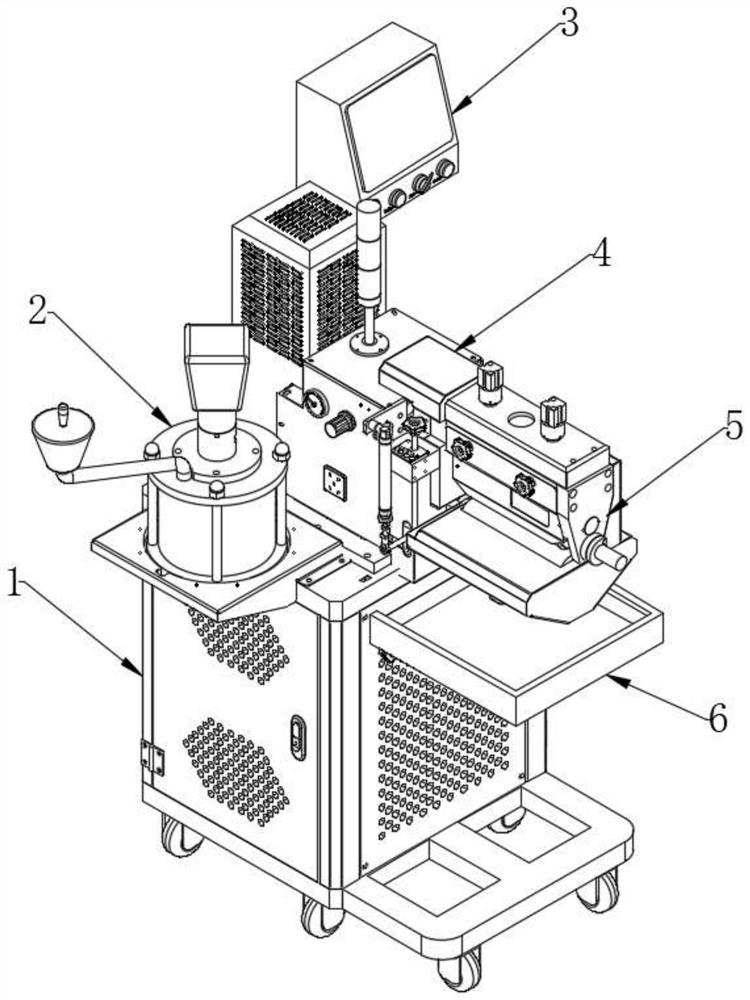

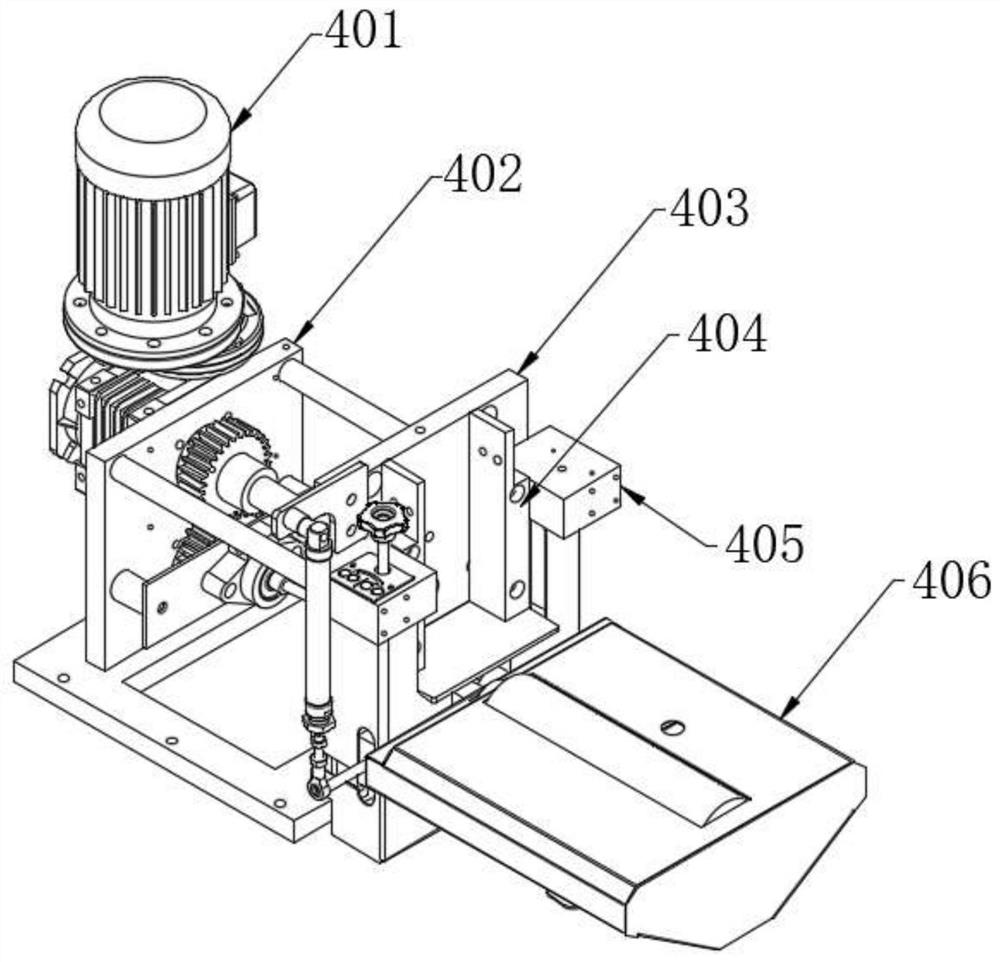

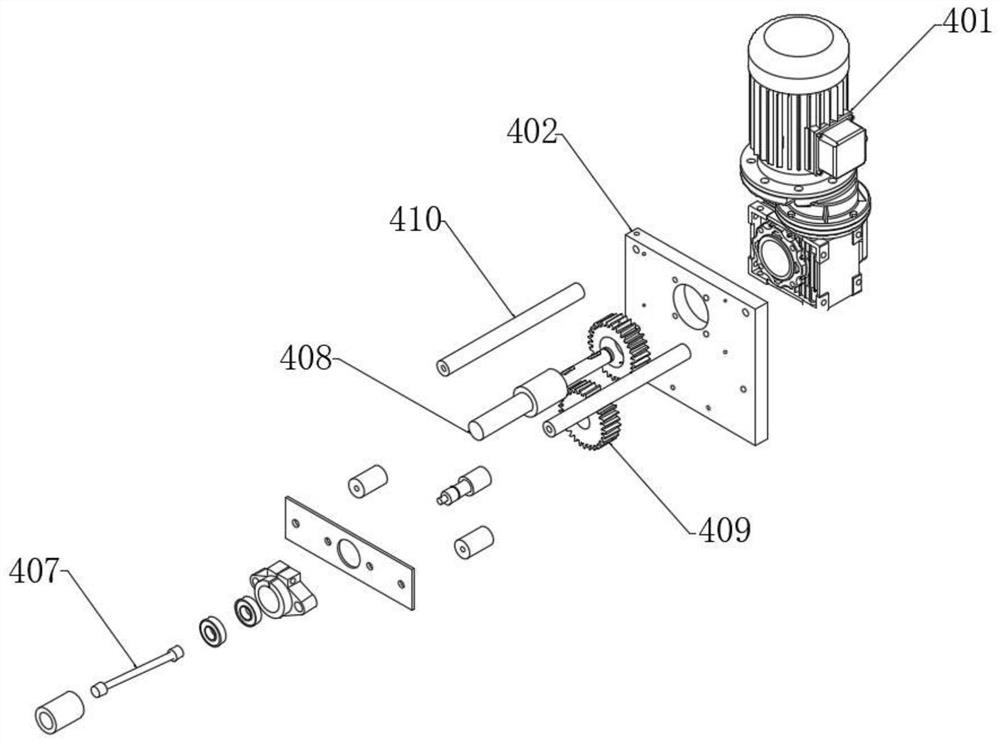

Novel upper wheel liquid medicine coating machine

PendingCN112774927ANovel structural designEasy to operateLiquid surface applicatorsCoatingsEngineeringPhysics

The invention belongs to the technical field of liquid medicine coating equipment, and particularly relates to a novel upper wheel liquid medicine coating machine. The novel upper wheel liquid medicine coating machine comprises a machine base, a liquid medicine box, a rack and a coating mechanism; a display screen is installed on the machine base; the liquid medicine box is fixedly arranged on the machine base; the rack is mounted on one side of the liquid medicine box and comprises a driving assembly, a feeding assembly and a height-adjustable lower roller; the coating mechanism is fixedly mounted at the front end of the rack and comprises a liquid medicine tank communicating with the liquid medicine box and a medicine conveying assembly arranged below the liquid medicine tank, wherein the medicine conveying assembly comprises a turbine line roller and a coating wheel which are driven by the driving assembly, and the coating wheel is located under the turbine line roller. According to the novel upper wheel liquid medicine coating machine, the defects in the prior art are overcome, and liquid medicine is transferred to a material in a transfer printing mode through upper roller coating, therefore, the defect of non-uniform liquid medicine coating is overcome, the quality is guaranteed, and the production efficiency is improved.

Owner:莆田市驰胜机械科技有限公司

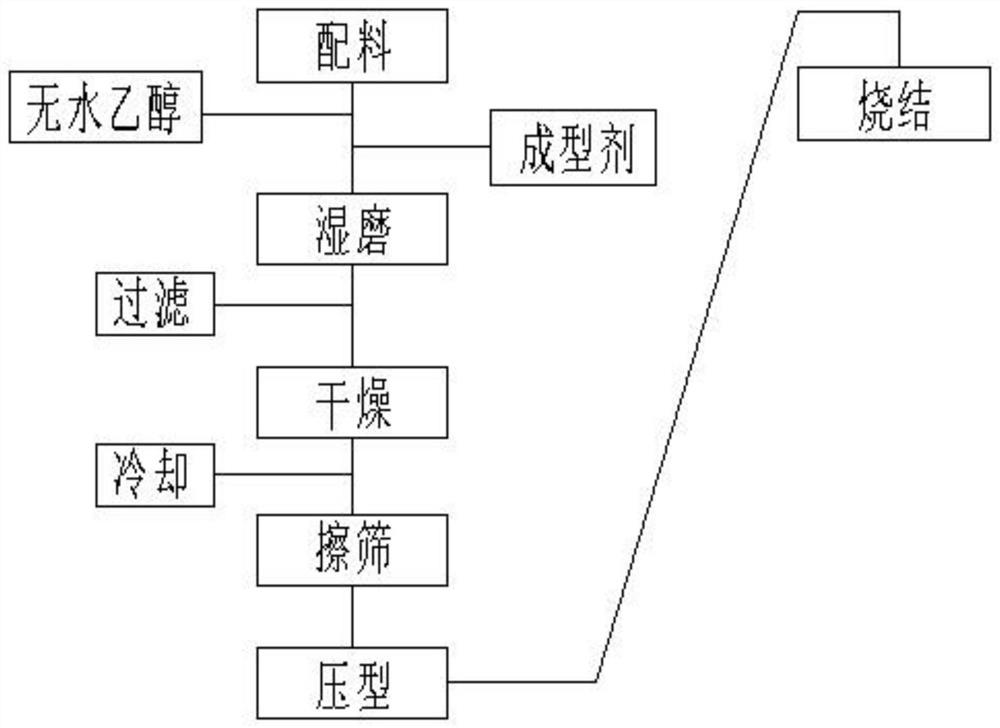

A production process that effectively improves the pass rate of cemented carbide round knife blanks

ActiveCN109604607BGuaranteed moldingGuaranteed compactnessTurbinesOther manufacturing equipments/toolsProcess engineeringMixed materials

Owner:技锋精密刀具(马鞍山)有限公司

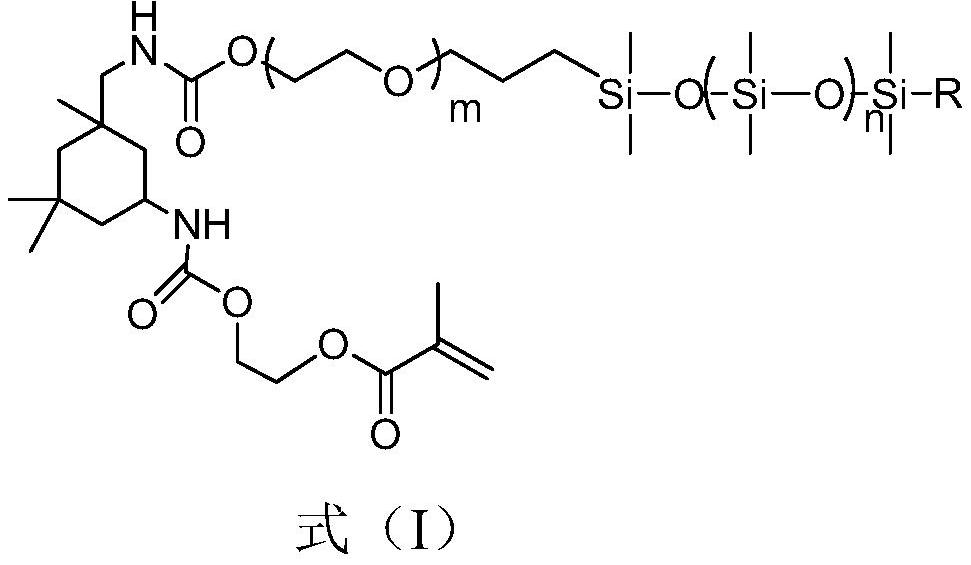

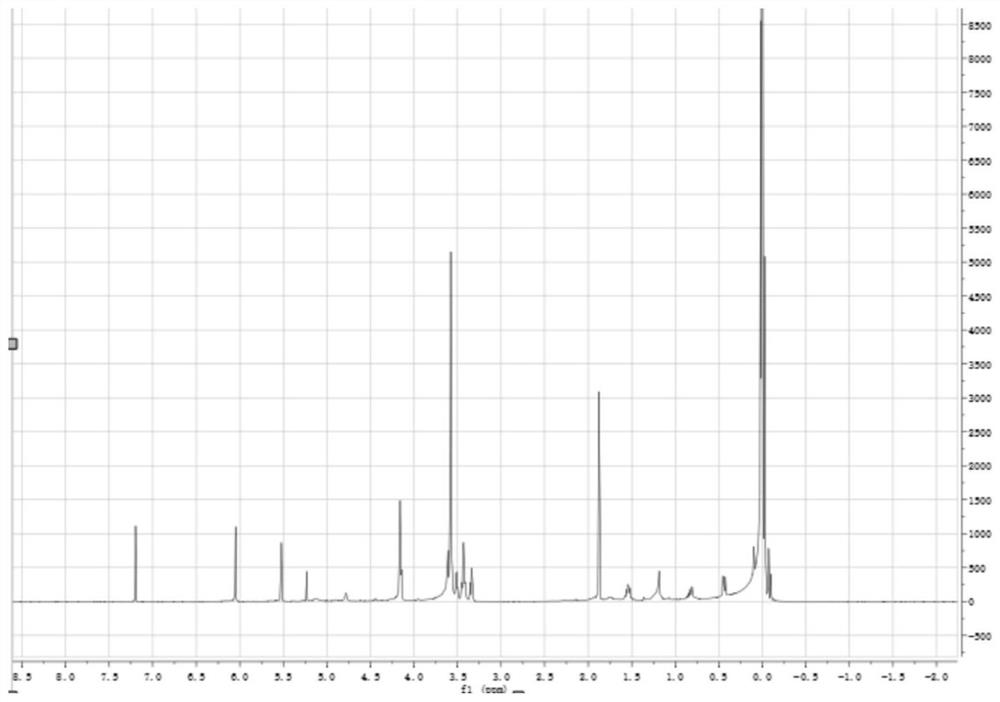

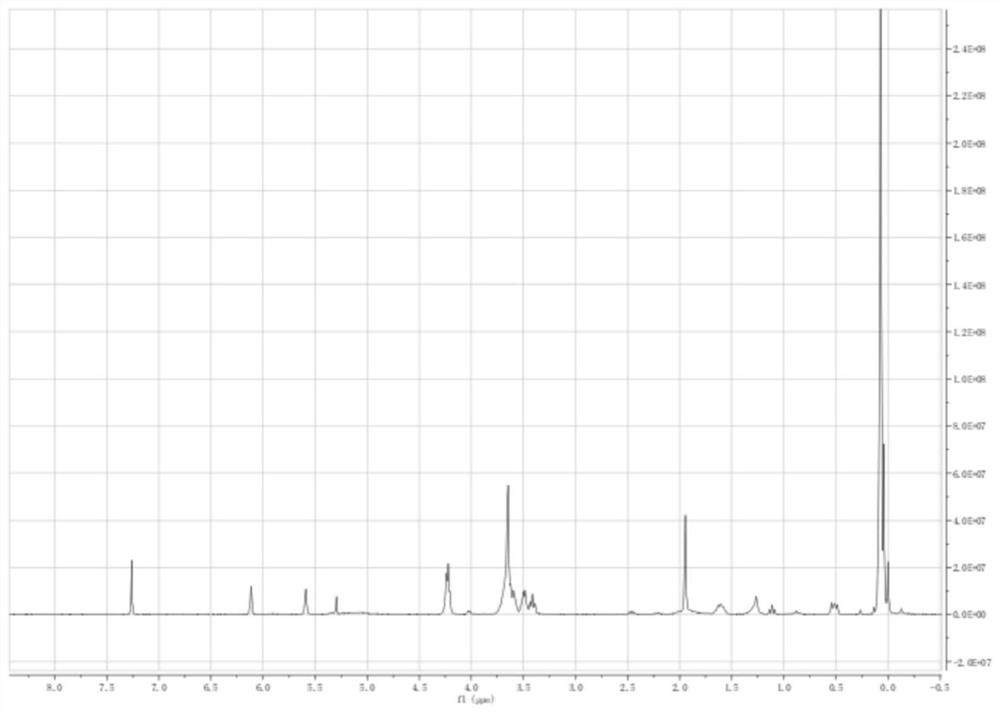

Single-end-capped organosiloxane oligomer, silicone hydrogel, corneal contact lens and preparation methods of single-end-capped organosiloxane oligomer, and corneal contact lens

ActiveCN113248719AImprove hydrophilicityIncrease the amount addedOptical partsHydrophilic monomerPolymer science

The invention discloses a single-end-capped organosiloxane oligomer. The single-end-capped organosiloxane oligome can be well mixed with various hydrophilic monomers under the condition of no hydrotropy of a solvent, overcomes the problem of difficult mutual dissolution of the organosiloxane oligomer and hydrophilic monomers, and can be used for preparing a silicon hydrogel material with high oxygen permeability and high hydrophilicity. Meanwhile, the invention further provides the silicon hydrogel which is formed by polymerizing the single-end-capped organosiloxane oligomer, hydrophilic monomers and the like. No solvent is added in the formula of the silicon hydrogel, so large-scale industrial production of the silicon hydrogel is facilitated. The addition proportion of the organosiloxane oligomer in the silicon hydrogel is large, so the silicon hydrogel has high oxygen permeability, and meanwhile, the high hydrophilicity and flexibility of the gel are also maintained. The invention also provides a corneal contact lens. The corneal contact lens is prepared from the silicone hydrogel material and has the advantages of high oxygen permeability, strong hydrophilicity, good light transmission, less lipid precipitation, good flexibility, comfort in wearing and the like.

Owner:JIANGSU HORIEN CONTACT LENS +2

Method for processing rhizoma corydalis

InactiveCN109350651ASave active ingredientsIncrease total alkaloidsNervous disorderAntipyreticSaline waterMedicine

The invention provides a method for processing rhizoma corydalis. The method includes (1), washing the fresh rhizoma corydalis, adding a mixture of local vinegar and oxalic acid before uniform stirring, and standing the rhizoma corydalis in a closed container for 1-3 hours; (2), adding mixed liquid of yellow rice wine and baijiu into the rhizoma corydalis treated in the step (1), and standing therhizoma corydalis in the closed container for 2-4 hours after uniform stirring; (3), taking out the rhizoma corydalis treated in the step (2), adding water, and fishing out and air-drying the rhizomacorydalis after 0.5-1.5 hours of cooking; (4), evenly blending the rhizoma corydalis obtained in the step (3) with saline water, standing the rhizoma corydalis in the closed container for 1 hour, andtaking out, drying and slicing the rhizoma corydalis to obtain the processed rhizoma corydalis. The method has the advantages that evaporation of a large amount of the solvent vinegar and the wine during processing is avoided; through selection of the local vinegar, the dissolution rate of total alkaloids and corydaline in the rhizoma corydalis is increased; important components of the rhizoma corydalis are effectively preserved after processing, and products prepared from the rhizoma corydalis can effectively develop their pharmacological effects.

Owner:张瑶

Method for preparing concentrated cheese powder by accelerated fermentation

ActiveCN101326937BShorten the production cycleReduce cost inputCheese manufactureFlavorRoom temperature

The invention relates to a method for preparing condensed cheese powder by rapid fermentation. The preparation steps include that (1) milk powder is taken as the raw material, and cooled to room temperature after sterilization; (2) microbiological culture is put into the milk powder; (3) enzyme preparation and supplementary materials are added; (4) the zymolyte product is embedded by embedding materials and emulsifier; (5) the embedded product is dried to make flour, thereby, the condensed cheese powder is achieved. The invention has the advantages of reasonable production process and easy operation; the production process is simplified and the production cycle is shortened, the flavor of cheese powder is enhanced, and high quality is ensured. The invention is a production method applicable to the modern large-scale production of novel cheese powder products.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

A double annular slit electrospinning device and method

InactiveCN105821497BRealize automatic and precise supplyRealize industrial preparationFilament/thread formingFiberCollection system

The invention discloses a double-circular-ring-shaped slit type electrostatic spinning device and method. The electrostatic spinning device comprises a liquid supply system, a double-circular-ring-shaped slit type nozzle system and a nano fiber collection system. The electrostatic spinning method comprises the following steps of: starting a microinjection pump to enable a solution to flow into a slit between an inner ring and an outer ring through a micro-channel in an inner core; adjusting the flow of the solution to enable a liquid surface of the solution to fully overflow in the slit, but not flow out; starting a speed regulating motor to enable a metal roller to rotate normally; starting a high-voltage electrostatic generator and slowly increasing voltage; when the voltage exceeds a certain value, forming a plurality of jet flows in the slit; in a process that the jet flows fly to the metal roller, volatilizing a solvent and curing a high polymer to form nano fibers which are deposited on the metal roller; and rotating the metal roller to collect the nano fibers. By adopting the microinjection pump and the liquid supply system, a high polymer solution can be automatically and accurately supplied, and the solution is sufficiently and efficiently utilized, so that the yield of the nano fibers is improved and continuous preparation of the nano fibers is realized.

Owner:DONGHUA UNIV

A kind of synthesis device and method of gallium antimonide polycrystalline raw material

ActiveCN111647947BAvoid a lot of volatilizationGood process repeatabilityPolycrystalline material growthSingle crystal growth detailsGallium antimonideProcess design

The invention relates to a device and method for synthesizing gallium antimonide polycrystalline raw materials. The device adopts a closed ampoule bottle and combines a unique quartz crucible structure and process design, thereby avoiding a large amount of volatilization of antimony simple substance at high temperature and successfully obtaining The gallium antimonide polycrystalline raw material with a stoichiometric ratio close to 1:1 has been obtained, and has excellent process repeatability.

Owner:苏州燎塬半导体有限公司

Chemical Disposal Methods of Waste Lead-acid Batteries

ActiveCN109713392BQuick responseImprove recycling efficiencySolid waste disposalWaste accumulators reclaimingChemical treatmentDistilled water

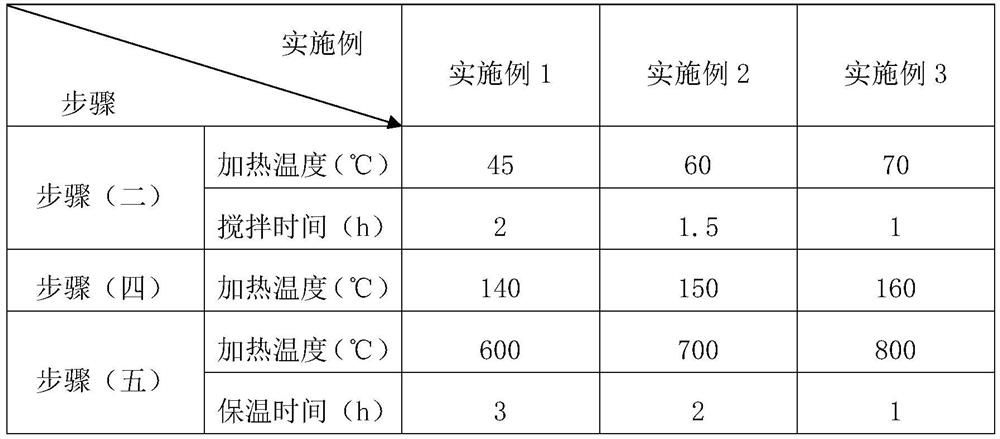

The invention relates to the field of lead-acid storage battery recovery, and particularly discloses a waste lead-acid storage battery chemical treatment method which comprises the following steps: (1) crushing: crushing lead paste in a waste lead-acid storage battery until the particle size of the lead paste is less than 100 meshes to obtain a crushed material; (2) precipitation: mixing the crushed material with NH4HCO3 solution by adopting a reaction device, stirring the mixture for 1-2 hours, and filtering the mixture to obtain a precipitate; (3) cleaning: repeatedly cleaning the precipitate with distilled water until the cleaned water is neutral at normal temperature to obtain a wet product; (4) heating: heating the wet product to 140-160 DEG C, and drying the product to obtain a sample; (5) preparing of red lead: heating the sample to 600-800 DEG C, and preserving heat for 1-3 hours to obtain the red lead. The treatment method is low in pollution and low in energy consumption.

Owner:重庆煌达环保科技有限公司

Connecting device of solvent dripping box and double-partition pump

The invention relates to a connecting device, and particularly relates to a connecting device of a solvent dripping box and a double-partition pump, and belongs to the technical field of packaging materials. The connecting device comprises a glue barrel, the solvent dripping box, a glue box and the double-partition pump, wherein the glue barrel is connected with a glue taking tube, the other end of the glue taking tube is connected with a mixing tube through a three-way joint, the solvent dripping box is connected with a solvent tube which is connected with the mixing tube through the three-way joint, the mixing tube is connected with the double-partition pump which is connected with a glue feed tube, and the other end of the glue feed tube is connected with the glue box. The connecting device has a simple, compact and reasonable structure, is relatively low in cost, is convenient and reliable to use, can fully mix glue with a solvent, prevents the glue solvent from volatilizing by a large amount, and guarantees the viscosity of the glue.

Owner:JIANGSU SUNKEY PACKAGING

Silicone hydrogel with high oxygen permeability, corneal contact lens and preparation method of corneal contact lens

The invention discloses a silicon hydrogel. The silicon hydrogel is prepared from the following components in parts by mass through a polymerization reaction: 5 to 60 parts of a single-terminated organosiloxane macromonomer, 0.5 to 10 parts of a double-terminated organosiloxane macromonomer, 0 to 30 parts of other silicon-containing monomers, 5 to 70 parts of a hydrophilic monomer, an initiator and a cross-linking agent. According to the invention, the single-terminated organosiloxane macromonomer is taken as a main component and compounded with the double-terminated organosiloxane macromonomer, and the single-terminated organosiloxane macromonomer and the double-terminated organosiloxane macromonomer are compounded to generate an obvious synergistic effect, so the oxygen permeability, the mechanical property and the hydrophilic property of the silicon hydrogel can be better improved. The invention also discloses a corneal contact lens prepared from the silicone hydrogel. The corneal contact lens has the advantages of high oxygen permeability, good light transmission, strong hydrophilicity, good mechanical properties and comfortable wearing, does not contain a solvent, and is beneficial to large-scale industrial production.

Owner:JIANGSU HORIEN CONTACT LENS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com