Preparation method of silicon-phosphorus alloy

A technology of silicon-phosphorus alloy and red phosphorus, which is applied in the field of preparation of silicon-phosphorus alloy, can solve the problems of low alloy purity and low phosphorus content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

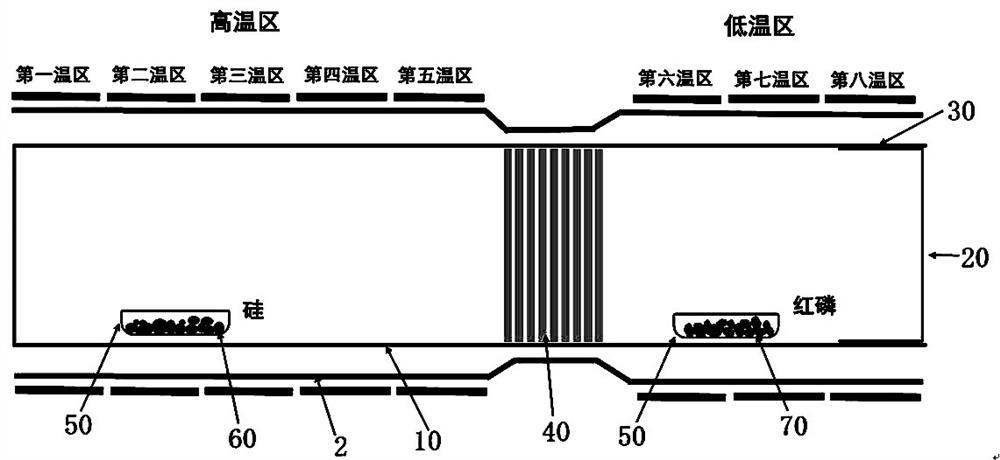

[0053] A method for preparing a silicon-phosphorus alloy, comprising the steps of:

[0054] 1) Prepare 1 quartz tube 10, 2 quartz boats 50, 8-9 quartz blocks 40 and 1 quartz cap 20, soak all the above-mentioned quartz products in aqua regia, rinse them with deionized water and ventilate them. Dry in the cupboard.

[0055] 2) Weigh 400 g of the high-purity silicon element 60 and 430 g of the high-purity red phosphorus element 70.

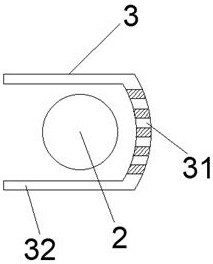

[0056] 3) The silicon element 60 and the red phosphorus element 70 weighed are respectively placed in two cleaned and dried quartz boats 50, and the quartz boat 50 equipped with the silicon element 60 is placed in the quartz tube 10 near the closed end. 8 pieces of quartz blocks 40 are placed in the middle of the quartz tube 10 in sequence, and then the quartz boat 50 containing the red phosphorus element 70 is placed in the quartz tube 10 and close to the opening end, and then the quartz sealing cap 20 is placed at the opening end of the quartz tub...

Embodiment 2

[0074] A method for preparing a silicon-phosphorus alloy, the preparation steps of which are the same as steps 1-5, 7-8 in Example 1, wherein the difference in step 6 is: the heating stage of the high-temperature zone: the temperatures of the five temperature zones in the high-temperature zone are respectively From room temperature to 1000°C, the temperature of the three temperature zones in the low temperature zone rose from room temperature to 400°C respectively. Other conditions in step 6 were also the same as in Example 1. No alloy material was prepared in this example.

Embodiment 3

[0076] A method for preparing a silicon-phosphorus alloy, the preparation steps of which are the same as steps 1-5, 7-8 in Example 1, wherein the difference in step 6 is: the heating stage of the high-temperature zone: the temperatures of the five temperature zones in the high-temperature zone are respectively From room temperature to 1130°C, the temperature of the three temperature zones in the low temperature zone rose from room temperature to 420°C respectively, and other conditions in step 6 were also the same as in Example 1.

[0077] According to this embodiment, the phosphorus content in the prepared silicon-phosphorus alloy is 44.87%, the silicon content is 54.99%, the sulfur content is 0.04%, the magnesium content is 0.05%, and the sodium content is 0.05%.

[0078]See Table 2 for the phosphorus content, silicon content, sulfur content, magnesium content, and sodium content of a silicon-phosphorus alloy prepared in Examples 1-3.

[0079] Table 2: Comparison of phosphor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com