Liquid asphalt low-temperature storage device

A liquid asphalt, storage device technology, applied in liquid distribution, transportation or transfer devices, distribution devices, special distribution devices, etc., can solve the problems of easy oxidation or a large amount of volatilization, reduce quality characteristics, etc., to prevent oxidation or a large amount of volatilization. , The effect of improving asphalt quality and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

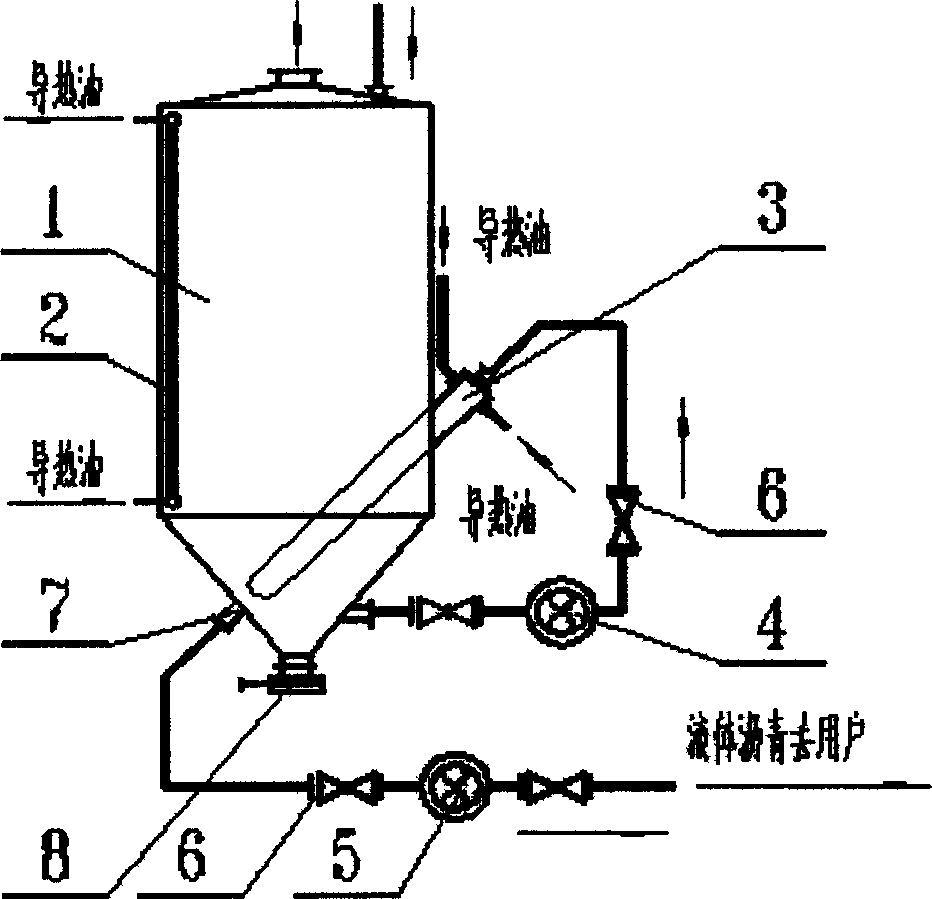

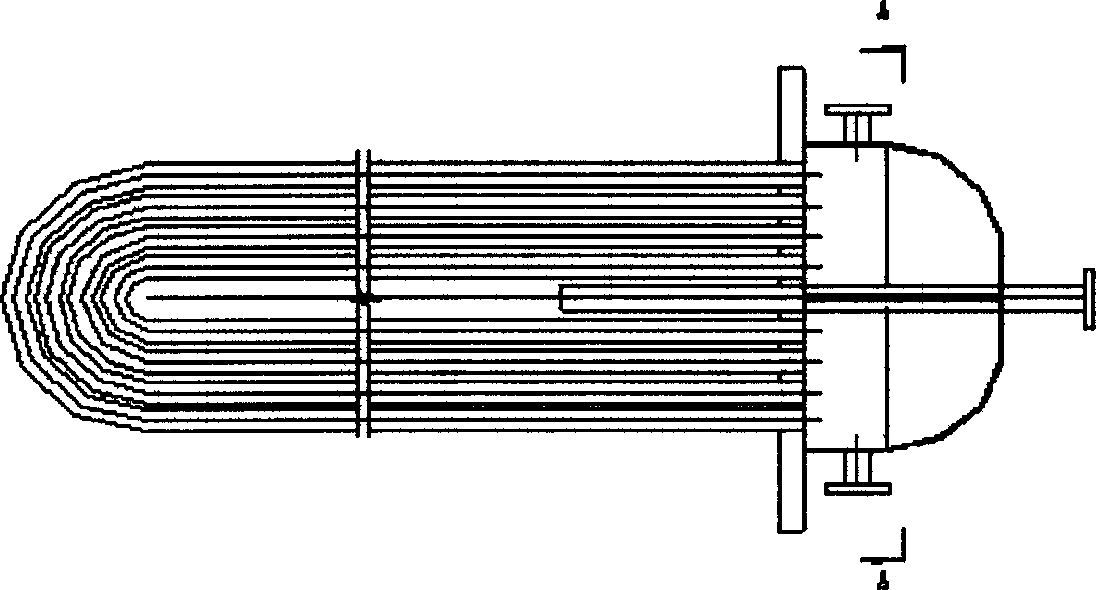

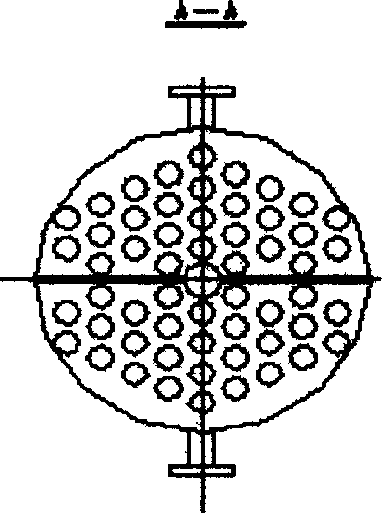

[0015] Embodiments of the present invention: The present invention is mainly equipped with an asphalt storage tank (1), a heat conduction oil pipe (2), a heater (3), an asphalt circulation pump (4), an asphalt delivery pump (5), and an asphalt valve (6). The heater (3) is mainly composed of heat-conducting oil tube bundles, and high-temperature heat-conducting oil can be introduced into the heat-conducting oil tubes to heat the asphalt. Electric heating is usually not used to avoid coking of the asphalt. The heater (3) is movably installed in the asphalt storage tank (1), and can be drawn out for cleaning when needed. The asphalt discharge port (7) to the user is generally set at the corresponding position of the lower end of the heater, so as to meet the requirements of the transportation or the user for the asphalt temperature. The heat-conducting oil pipes (2) usually contain 2-4, and are evenly distributed on the inner wall of the asphalt storage tank (1), so as to meet th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com