High-entropy alloy nitride cutter coating and preparation method thereof

A high-entropy alloy and nitride technology, applied in the field of metal coating, can solve problems such as inability to meet industrial needs, and achieve the effects of low cost, high hardness and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

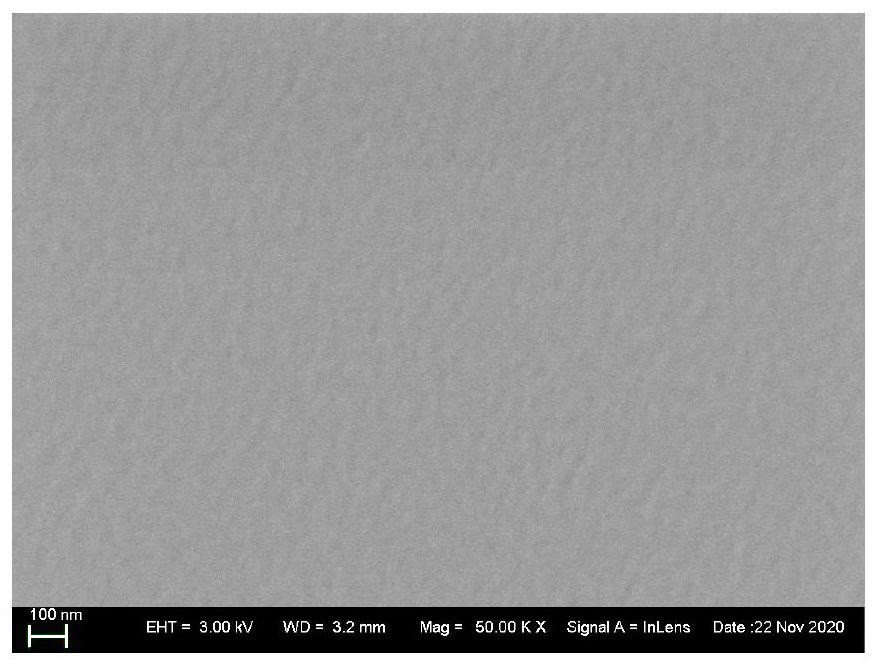

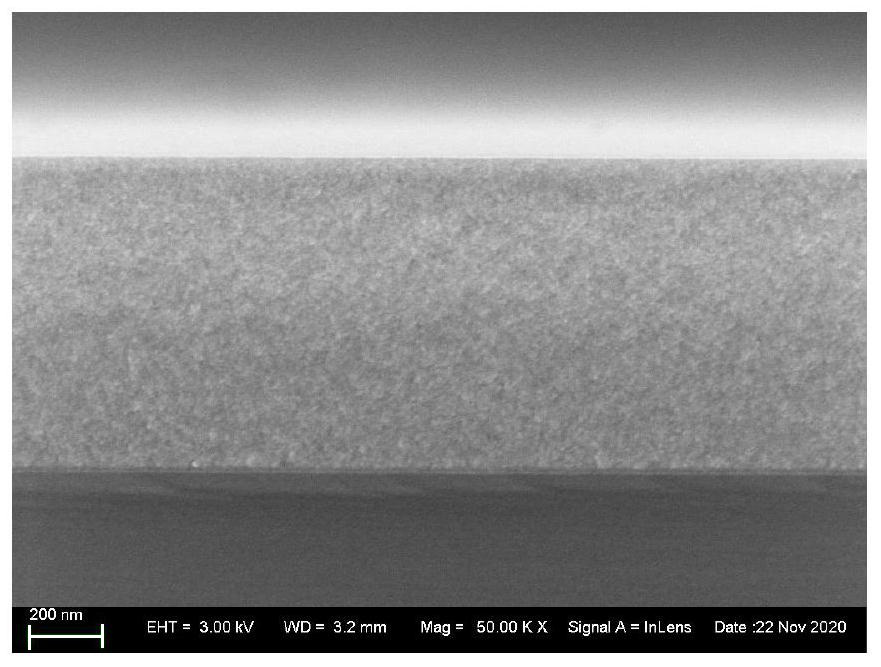

[0032] The invention discloses a preparation method of a high-entropy alloy nitride tool coating, which comprises the following steps:

[0033] The tool substrate is degreased and cleaned in sequence; the AlTiVNbCr high-entropy alloy target and B target are used as the sputtering source, and the mixed gas of argon and nitrogen is used as the working gas, and the combination of radio frequency magnetron sputtering and DC magnetron sputtering is adopted. The way to deposit (AlTiVNbCr) BN high-entropy alloy nitride coating on the cleaned tool substrate; wherein, during the deposition process, the temperature of the tool substrate is 350-450°C, the bias voltage of the tool substrate is 150-250V, and the workpiece holder The rotation speed is 5r / min, the base distance of the target is 65mm, the flow rate of argon gas is 6-7sccm, the flow rate of nitrogen gas is 1-2sccm, the AlTiVNbCr high-entropy alloy target is connected to the RF power supply, the power of the AlTiVNbCr high-entro...

Embodiment 1

[0045] Select silicon wafers and high-speed steel tools as substrates, and deposit (AlTiVNbCr) BN high-entropy alloy nitride coatings on silicon wafers and high-speed steel tool substrates. The specific steps are as follows:

[0046] Put the high-speed steel tool base into a degreasing solution with a concentration of 5%, and perform ultrasonic degreasing treatment at 50°C for 20 minutes; rinse the high-speed steel tool base after degreasing treatment with flowing deionized water, and then clean the silicon wafer and The finished high-speed steel cutter substrate was put into absolute ethanol and ultrasonically cleaned at room temperature for 3 times, each time for 15 minutes. After cleaning, the sample was blown dry with an air gun of an air compressor. Ultrasonic cleaning adopts KQ2200DE ultrasonic cleaning machine.

[0047] Send the cleaned silicon wafer and high-speed steel tool substrate into a vacuum chamber equipped with AlTiVNbCr high-entropy alloy targets and B target...

Embodiment 2

[0051] The difference between this embodiment and Embodiment 1 is the magnetron sputtering parameters, specifically: the flow rate of argon gas is 6 sccm, the flow rate of nitrogen gas is 2 sccm, the working air pressure is maintained at 0.86 Pa, the rotating speed of the workpiece holder is 5 r / min, and the target base distance is 65 mm. The AlTiVNbCr high-entropy alloy target power is 200W, the B target power is 50W, the substrate bias voltage is 250V, and the substrate temperature is 400°C.

[0052] Using the same test method as in Example 1, after testing, Al: 14.89at.%, Ti: 4.70at.%, V: 3.26at.%, Nb: 5.34at in the (AlTiVNbCr) BN high-entropy alloy nitride coating .%, Cr: 4.51at.%, N: 56.63at.%, B: 10.67at.%, the coating thickness is 0.78μm, the film-base bonding force is 72.20N, the hardness is 53.77GPa, and the friction coefficient is 0.69.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| mechanical properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com