Chemical Disposal Methods of Waste Lead-acid Batteries

A technology for waste lead-acid batteries and disposal methods, applied in battery recycling, waste collector recycling, solid waste removal, etc. The effect of high generation efficiency, fast reaction speed and high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The following is further described in detail through specific implementation methods:

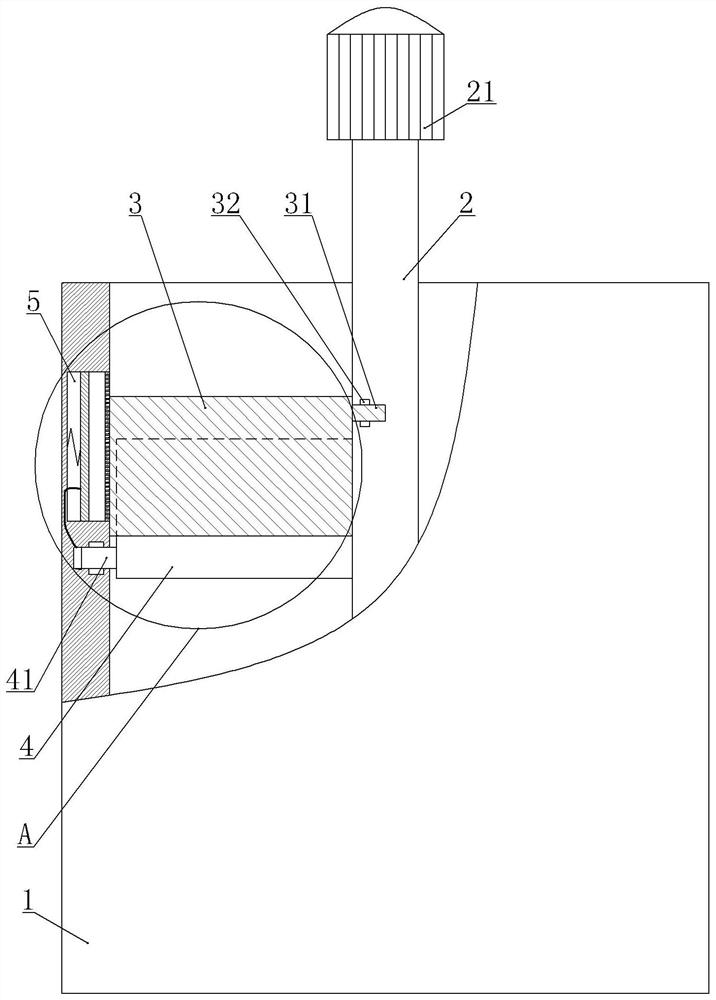

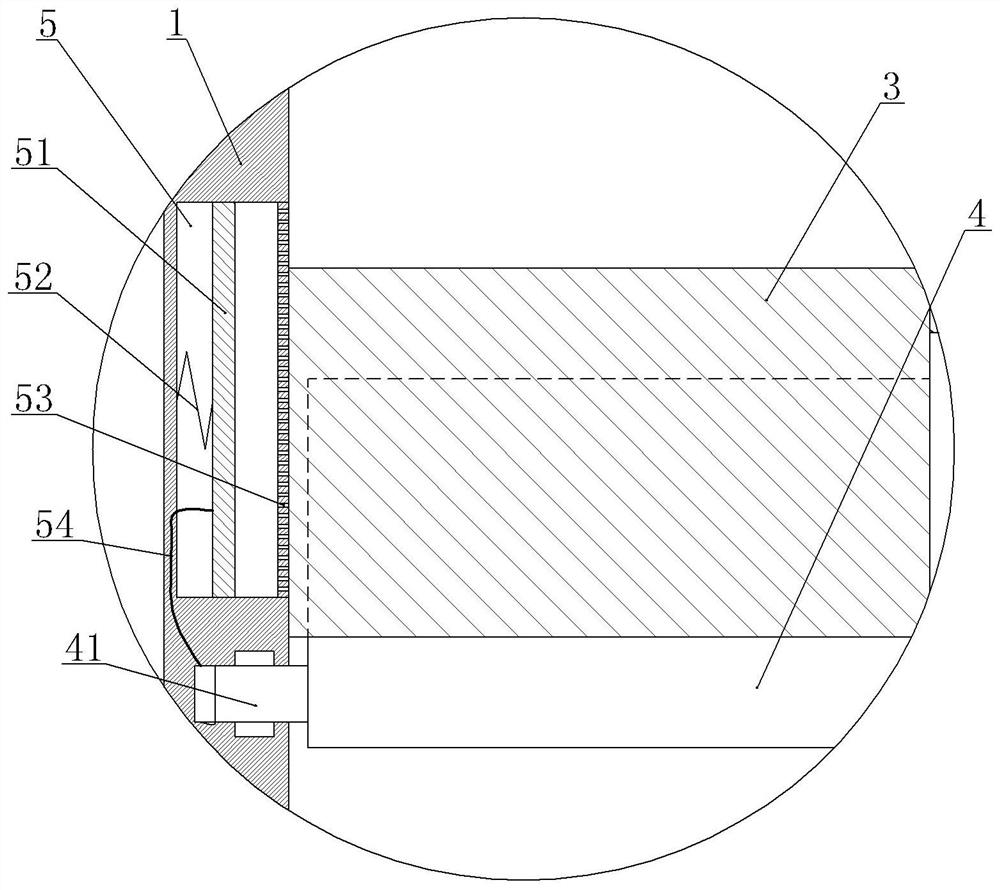

[0034] The reference signs in the drawings of the description include: reaction barrel 1, stirring shaft 2, rotating drive member 21, first blade 3, first rotating shaft 31, torsion spring 32, second blade 4, second rotating shaft 41, sliding chamber 5 , Piston 51, elastic member 52, through hole 53, stay cord 54.

[0035] A chemical disposal method for waste lead-acid batteries, comprising the following steps:

[0036] Step (1) crushing, using distilled water to clean the lead plaster in the waste lead-acid battery, and then crushing the lead plaster until the particle size of the lead plaster is less than 100 mesh to obtain crushed material;

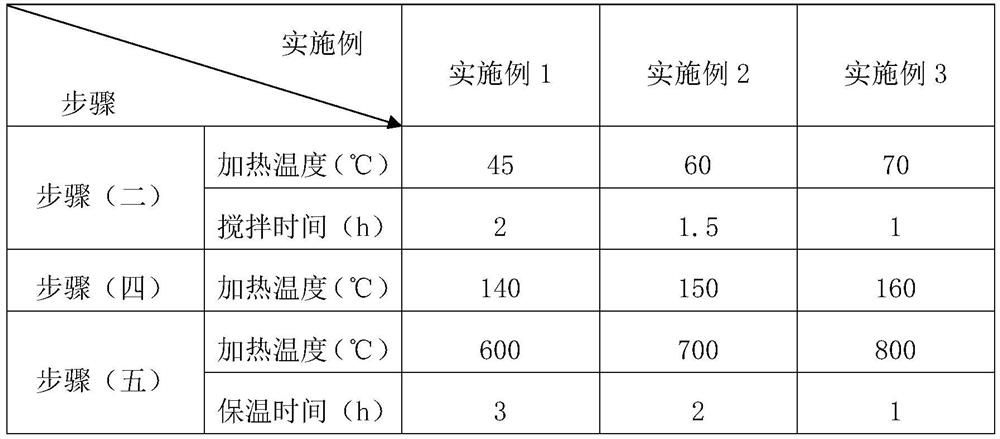

[0037] Step (2) precipitation, NH 4 HCO 3 The solid is added to the reaction device to prepare saturated NH 4 HCO 3 solution, and use a reaction device to mix the pulverized material with saturated NH 4 HCO 3 Mix the solutions, heat to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com