Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Reduce non-processing time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

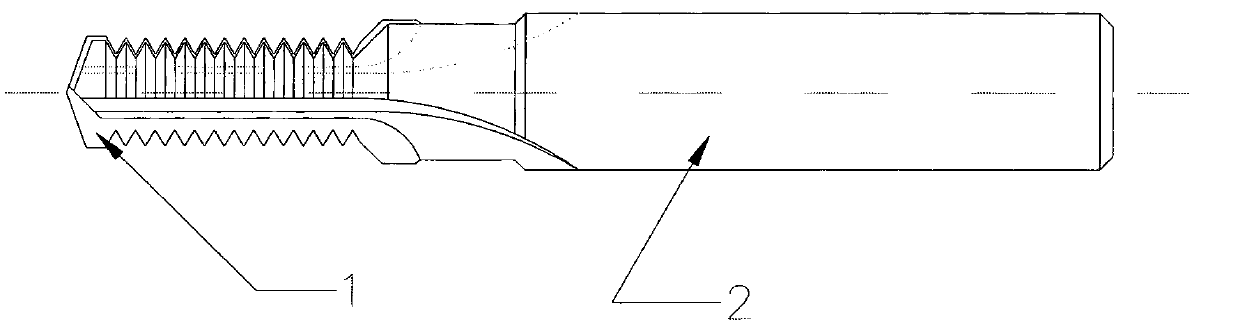

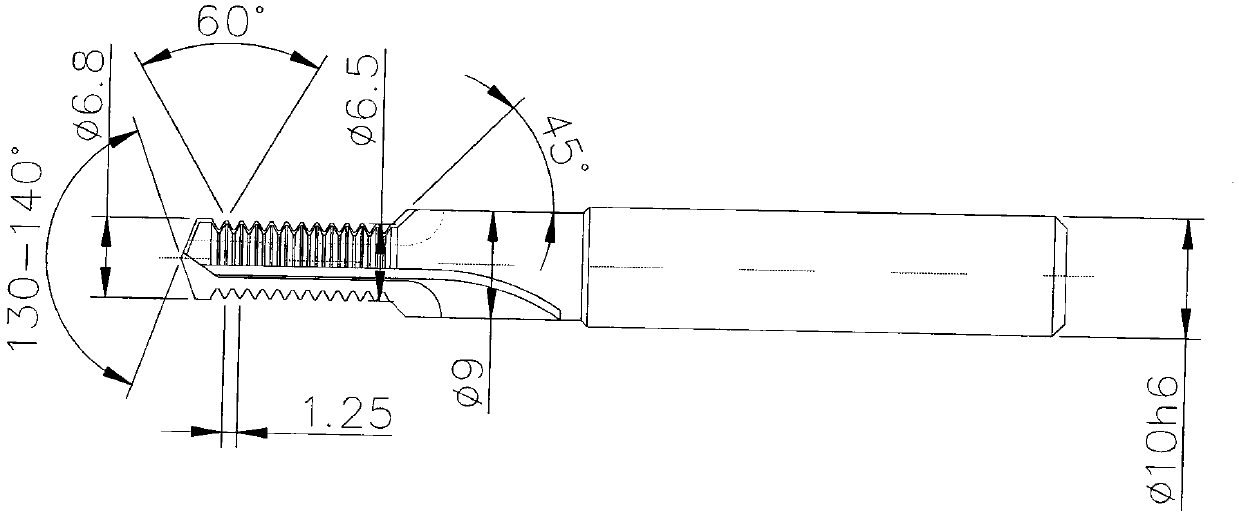

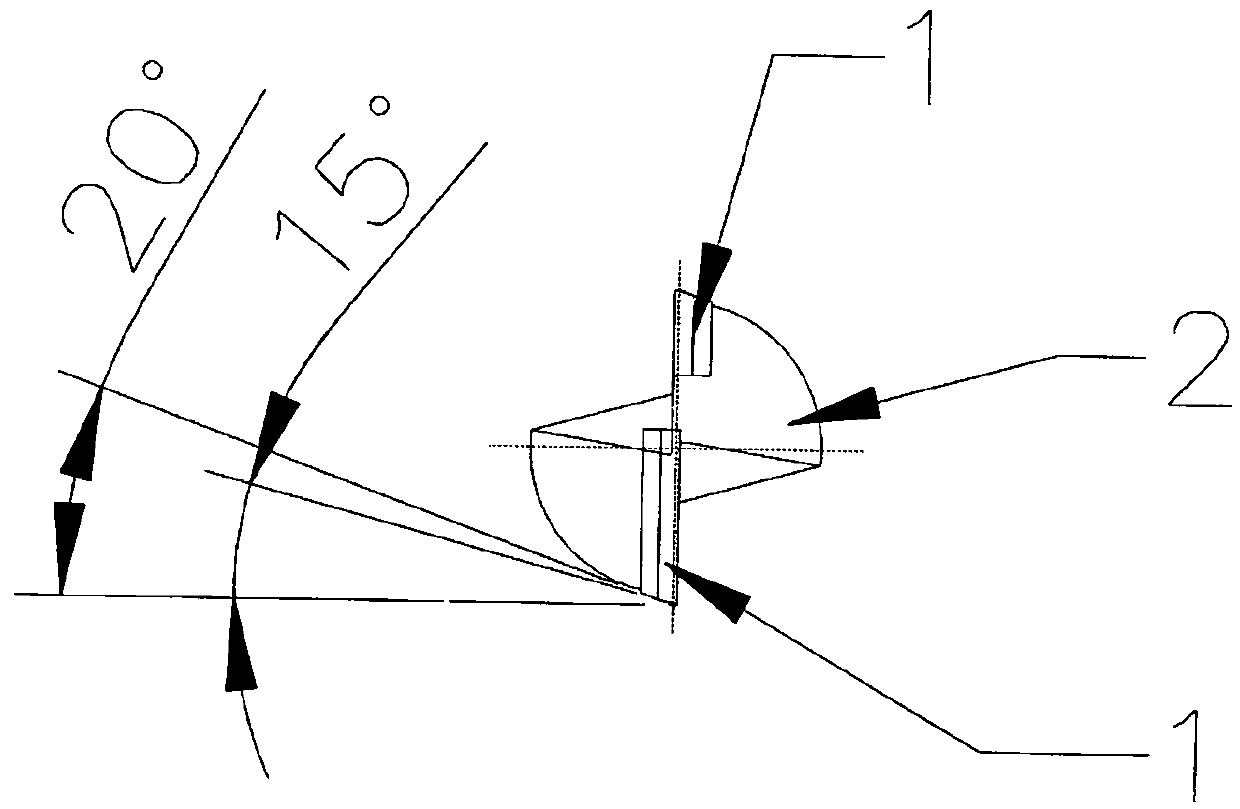

PCD (Poly Crystal Diamond) thread drilling and milling cutter

ActiveCN102990171AReduce tool positionsReduce non-processing timeThread cutting toolsMilling cutterEngineering

The invention discloses a PCD (Poly Crystal Diamond) thread drilling and milling cutter, wherein the cutter body is a milling cutter with a thread structure; the cutter body is made of hard alloy; a drill is arranged at the front end of the cutter body; the vertex angle of a drill tip is 130-140 degrees; a first rear angle is 120 degrees; the width is 0.5mm; the second rear angle is 25 degrees; an edge passes through the center; two chip spaces are arranged along the axis of the cutter body; the first rear angle in the radial direction of the middle thread milling cutter part is 15 degrees; the width is 0.5mm; the second rear angle is 20 degrees; a chamfering edge is formed at the rear end of the cutter body, and the edge part of the cutter body is made of a PCD material. The PCD thread drilling and milling cutter has the characteristics that tool positions are reduced; twice processing of two support cutters is merged into a whole; non-manufacturing time generated when the cutter is replaced is reduced, and the service life of the tool is prolonged.

Owner:博澳精密工业(大连)有限公司

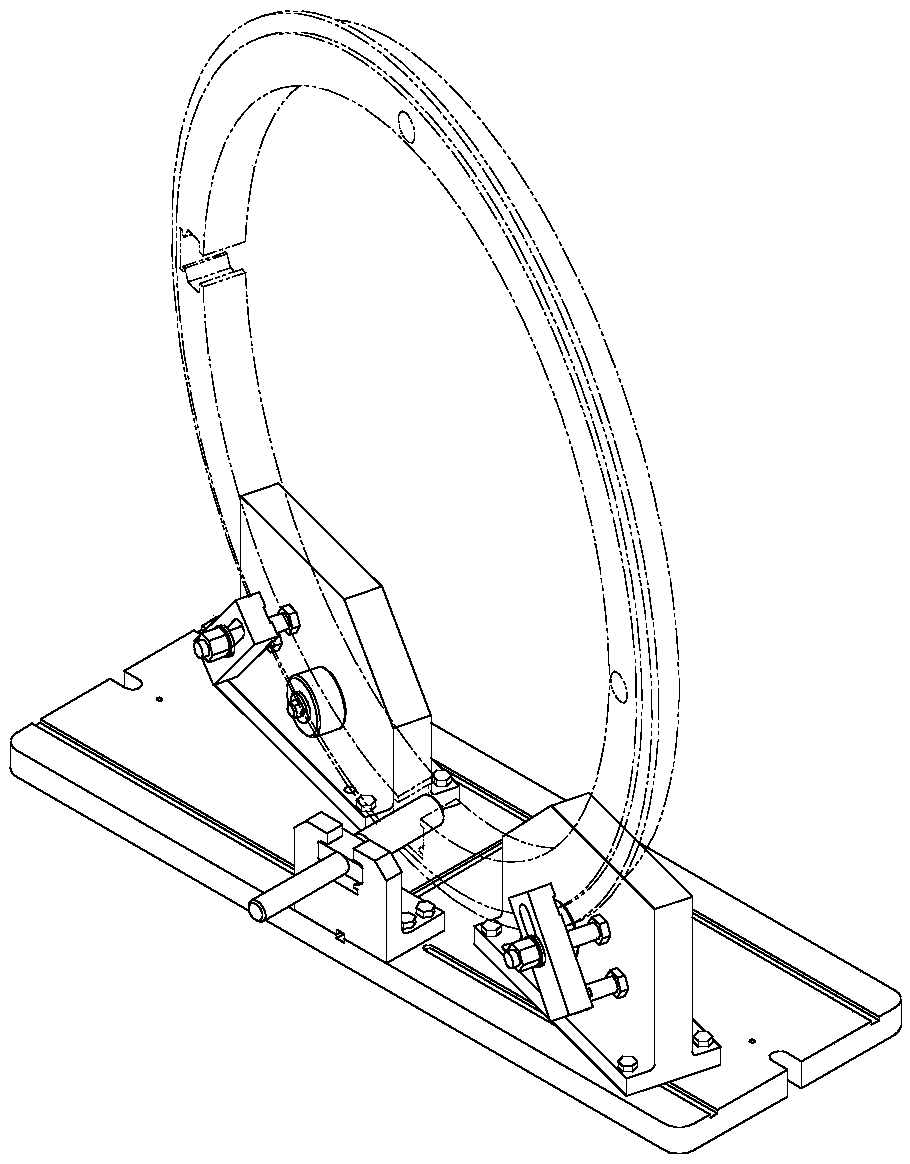

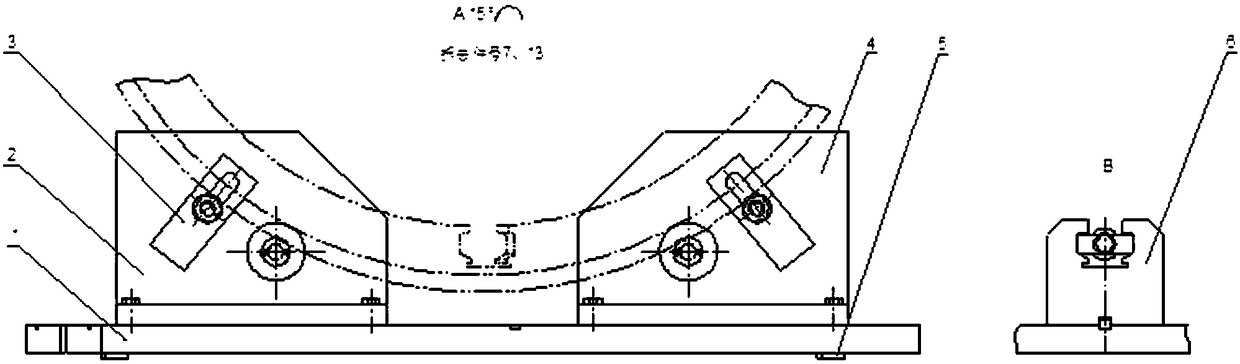

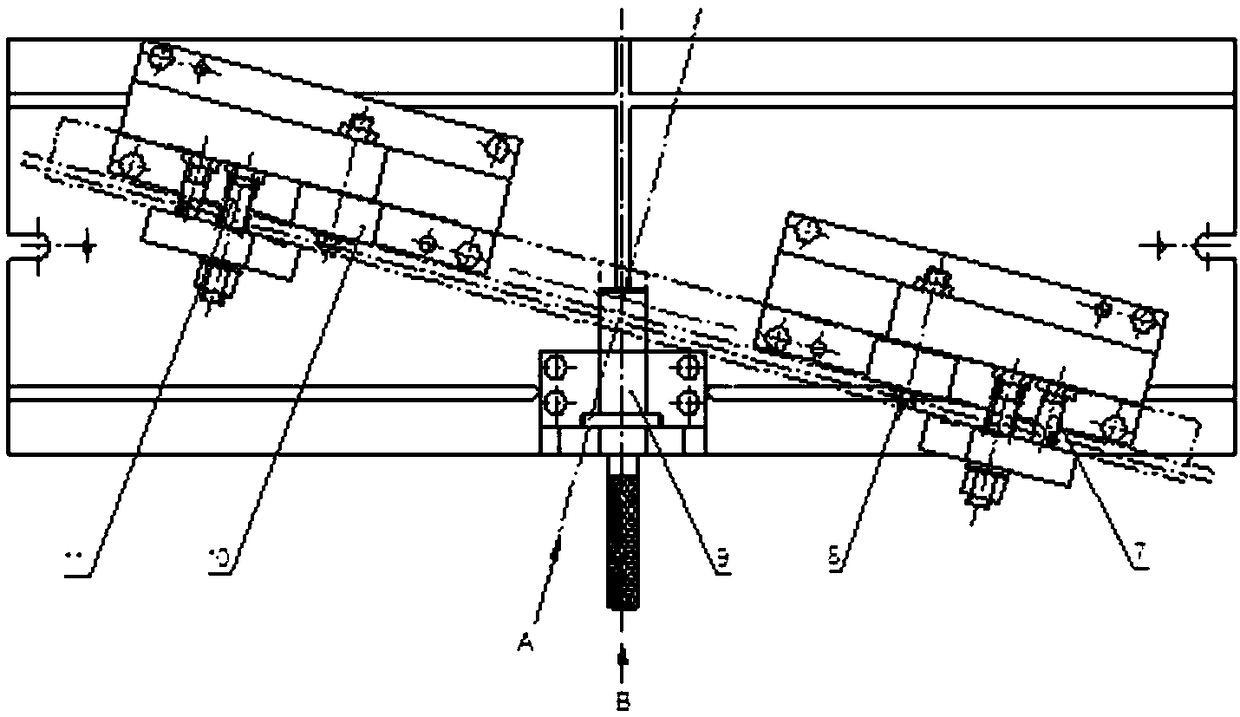

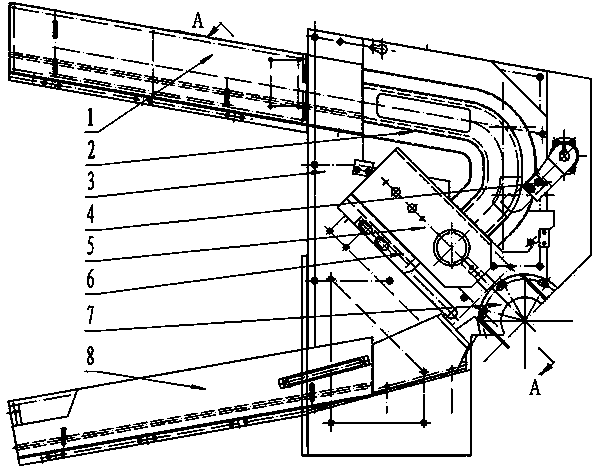

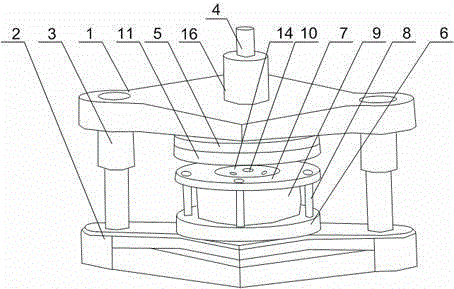

Milling machine fixture for machining internal chute of ring part and processing method

PendingCN109108688AEasy clampingEasy to operateMilling equipment detailsPositioning apparatusEngineeringMachining time

The invention relates to a milling machine fixture and for machining an internal chute of a ring part and a processing method. The milling machine fixture is composed of a bottom plate, support seats,a tool alignment block, a positioning pin, roller shafts, rollers, pressing plates, supports and positioning keys. By using the fixture, the machining of the internal chute of a medium-sized ring part can be completed on a common vertical milling machine X52K, and the machining of a plurality of chutes can be completed. Part clamping is convenient, and fixture alignment is performed during processing. Tool alignment is realized by the tool alignment block, so the operation is simple and convenient, and the production cost is low. The processing method overcomes the shortcoming that an original processing method is limited by equipment and production conditions. The processing method is simple, the fixture is convenient to use, and is suitable for single piece and batch production. Part clamping, alignment and tool alignment are convenient and quick, the non-machining time of the equipment is shortened and the production efficiency is improved. The method is used for machining multiplechutes or cavities with internal fixed indexing of medium ring parts, and realizing machining of chutes or cavities with different cross-sections of the parts by replacing tool alignment blocks and positioning pins.

Owner:XIAN KUNLUN IND GRP

Control mode for realizing high-efficiency dry running in numerical control system

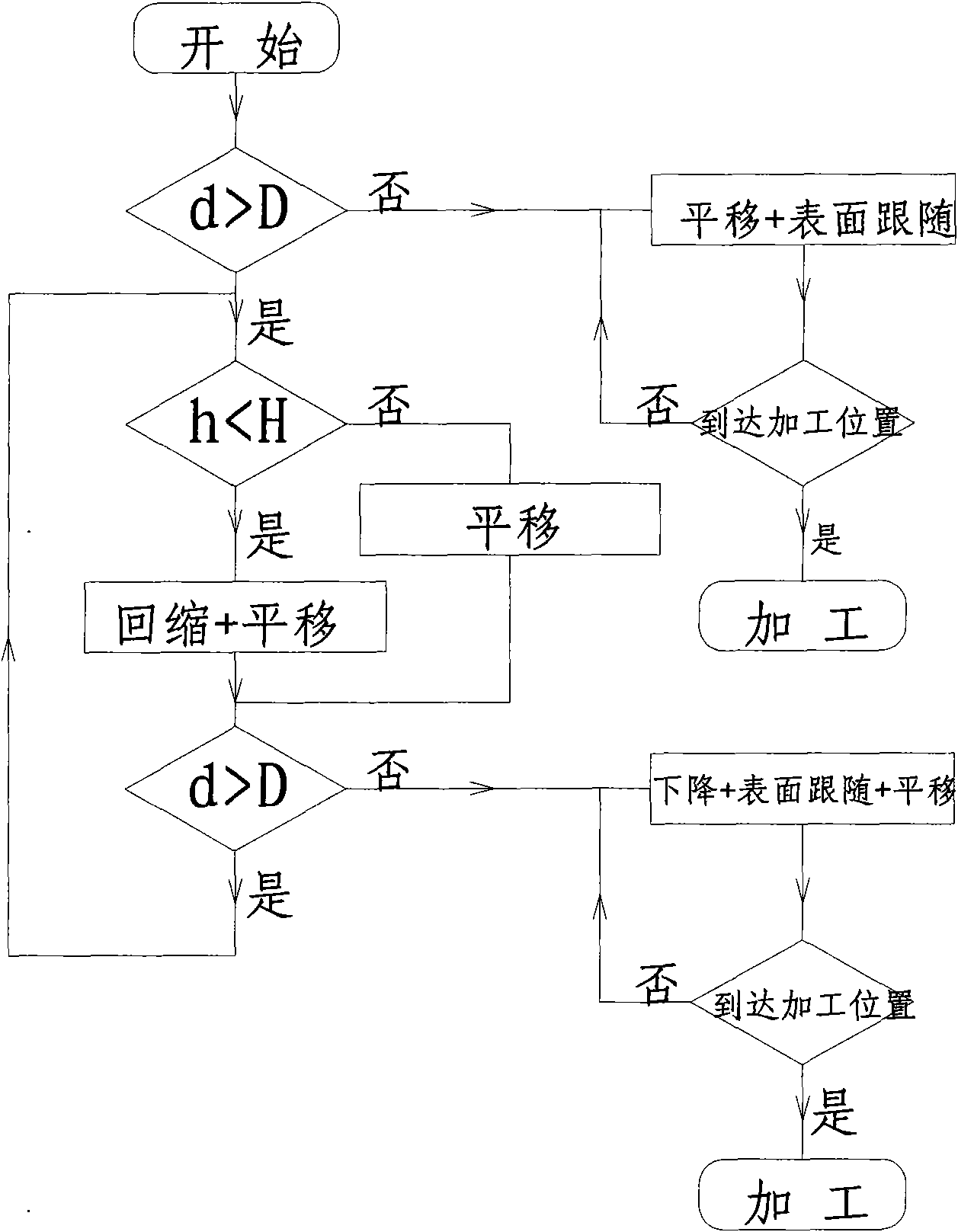

ActiveCN101937206AGuaranteed uptimeReduce non-processing timeNumerical controlLaser processingControl manner

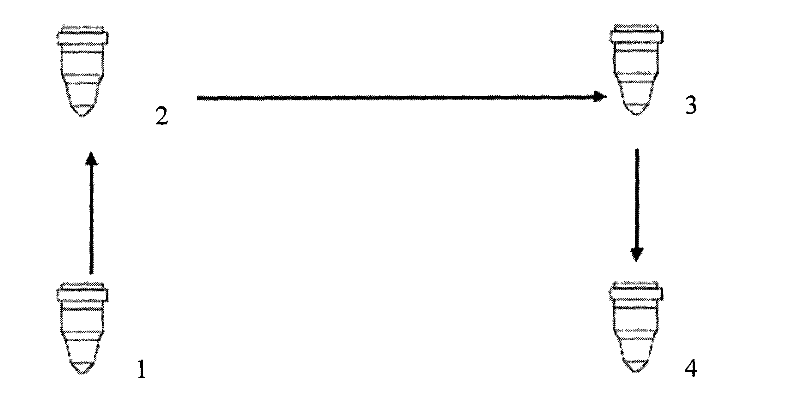

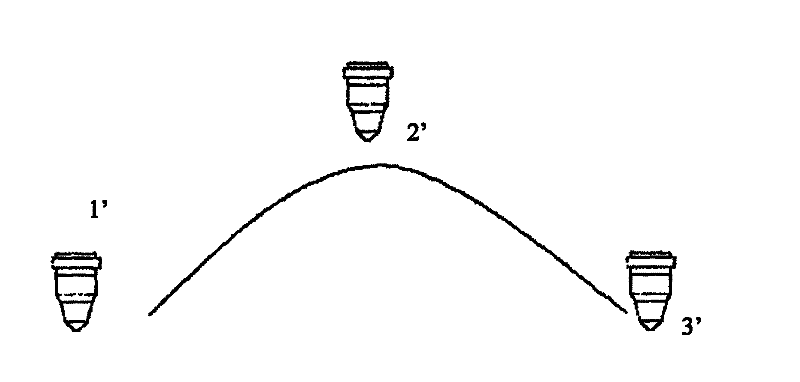

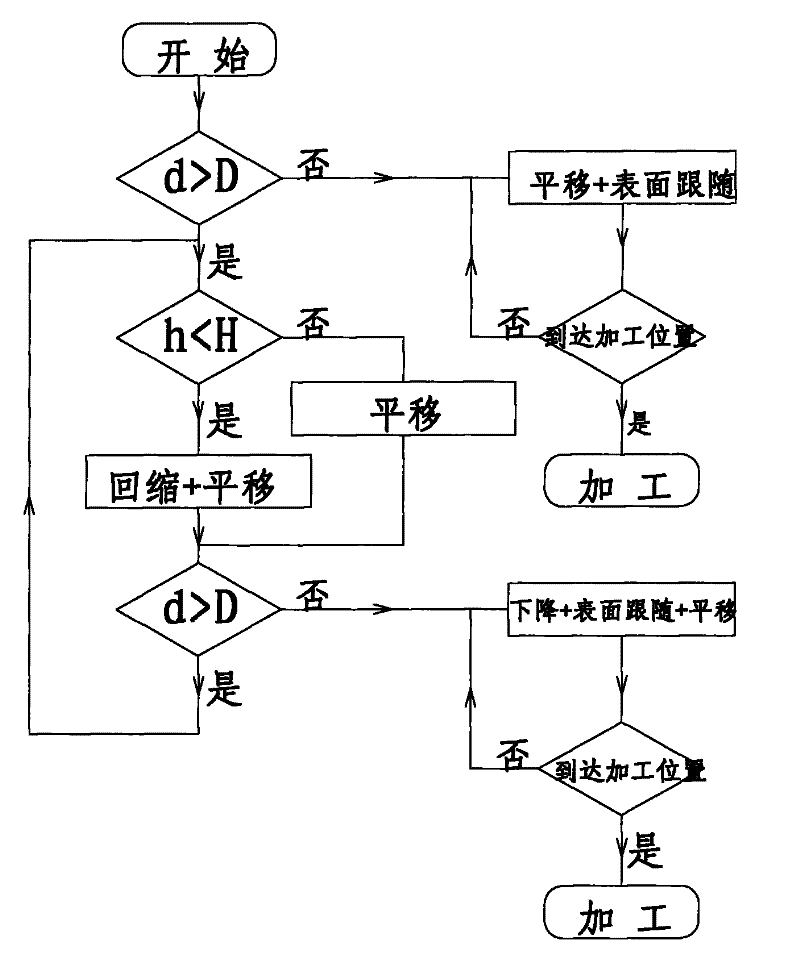

The invention discloses a control mode for realizing high-efficiency dry running in a numerical control system, which is based on the surface following function of a height sensor in the numerical control system to realize non processing time compression and cause laser processing to be efficient on the premise of ensuring that equipment is safe. The control mode comprises setting a retraction height H and a preset distance D before dry running ends, thus three actions of the existing laser processing are combined into one action to finish, i.e. a processing head quickly moves to the next processing position directly at dry running speed; in the process, the processing head retracts to the preset height H at the maximum speed and begins falling when the processing head does not reach the next processing point (distance D away from the next processing point), thus reducing non processing time of the equipment and greatly improving the using efficiency of the equipment.

Owner:HUAGONG TECHNOLOGY CO LTD

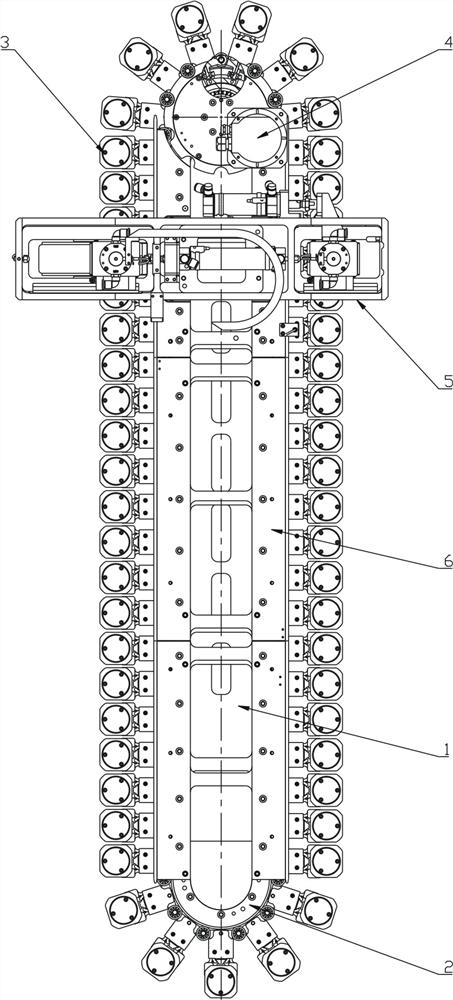

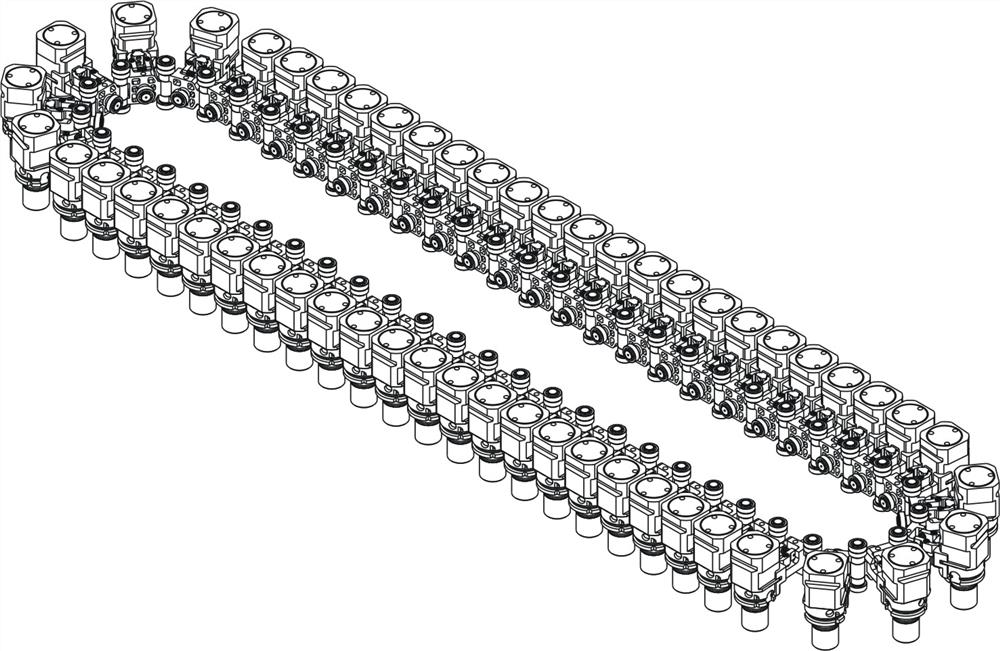

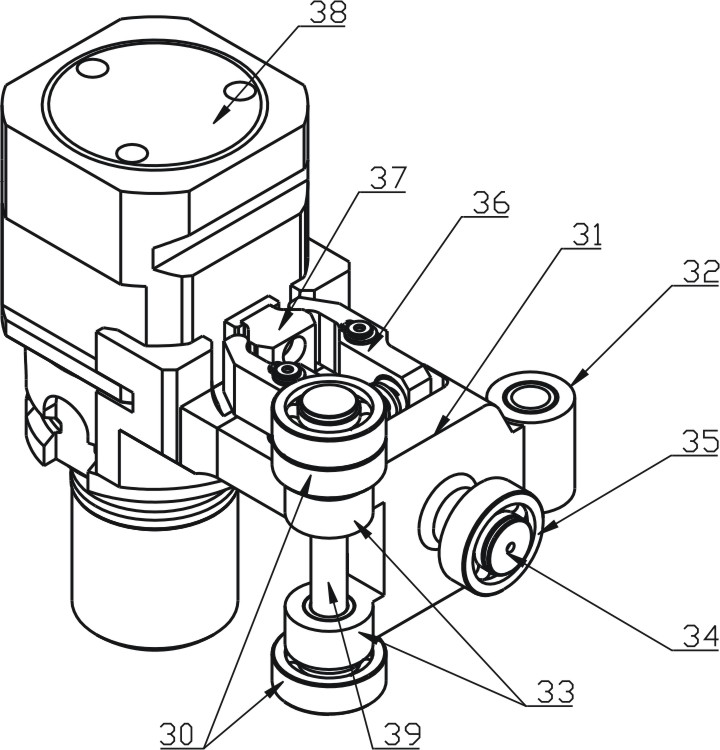

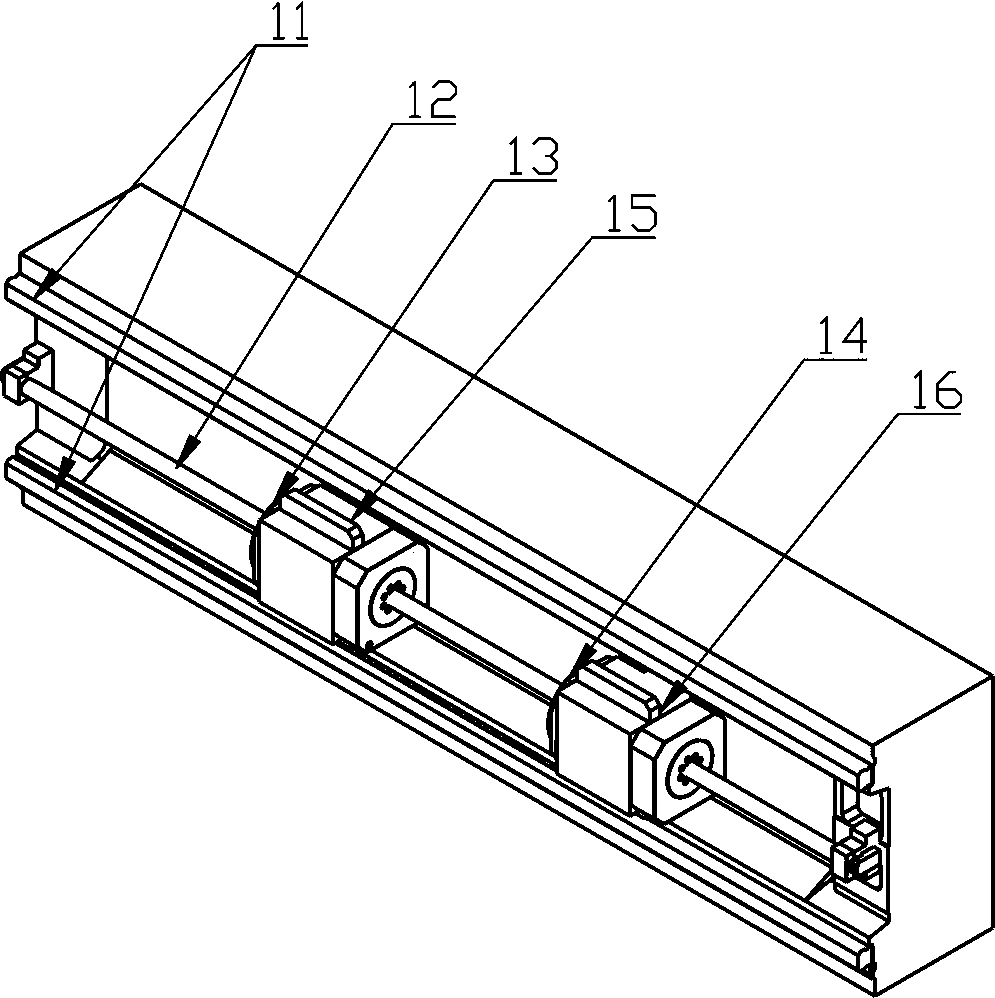

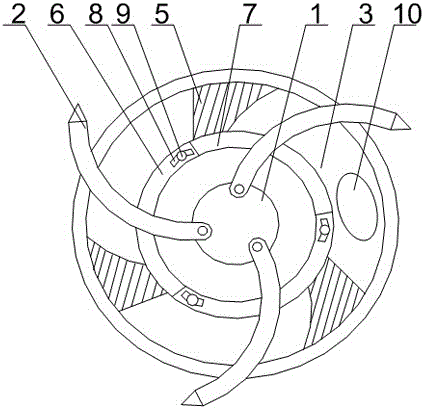

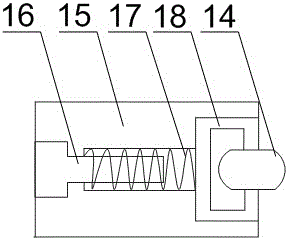

Knife pouch push-out type chain type tool magazine

PendingCN111843578AHigh precisionIncrease line speedPositioning apparatusMetal-working holdersChain typeChain link

The invention relates to a knife pouch push-out type chain type tool magazine, and aims to provide a chain type tool magazine structure which is simple in structure, small in structural space, high inmotion precision, high in tool changing speed, stable in operation, small in vibration, long in service life, low in use cost, convenient to adjust and flexible in application. The knife pouch push-out type chain type tool magazine comprises a base, an annular guide rail, a chain mechanism, a chain driving unit and a knife pouch push-out device. The base is connected with a machine tool, the annular guide rail is arranged on the base, and the chain mechanism comprising a plurality of knife pouches is arranged on the annular guide rail and can rotate along the annular guide rail under the action of the chain driving unit. The knife pouch push-out device is erected above the chain mechanism and installed on the base through a push-out installation plate, and the knife pouches can be pushedout of the chain mechanism to conduct automatic tool changing or manual tool installing.

Owner:北京精雕精密机械制造有限公司

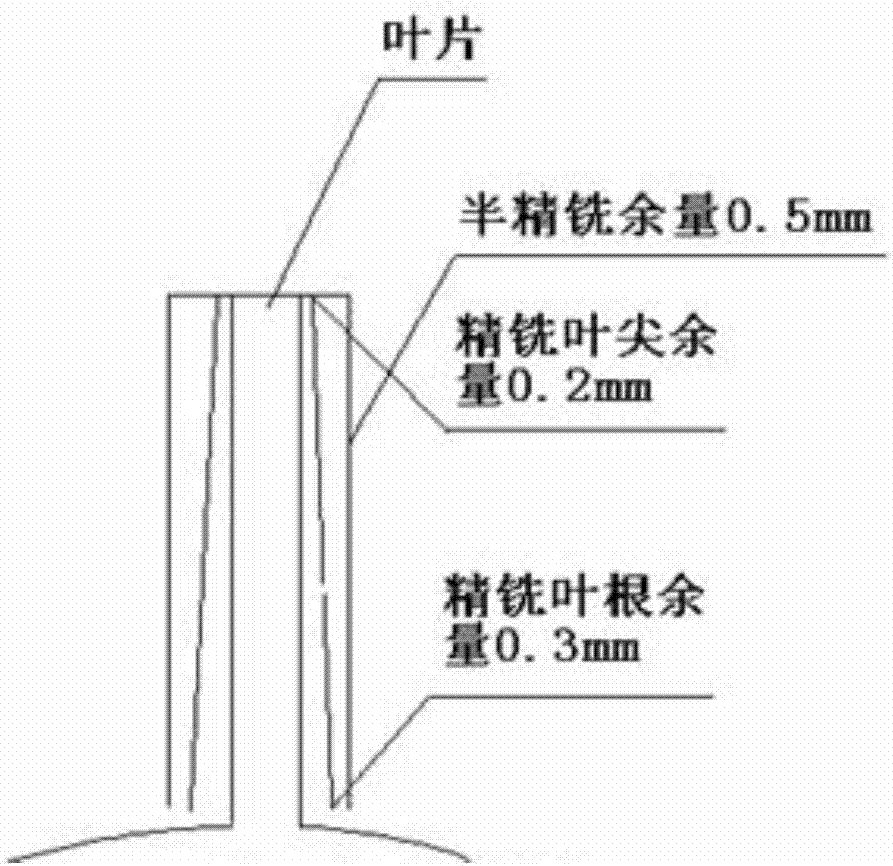

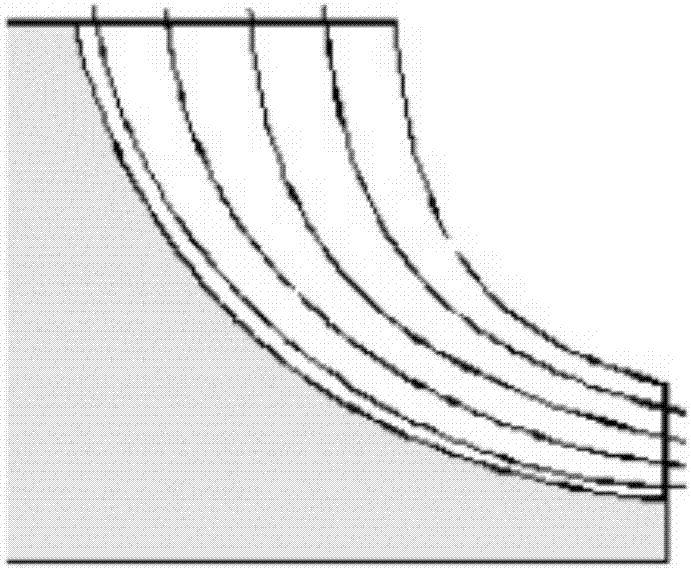

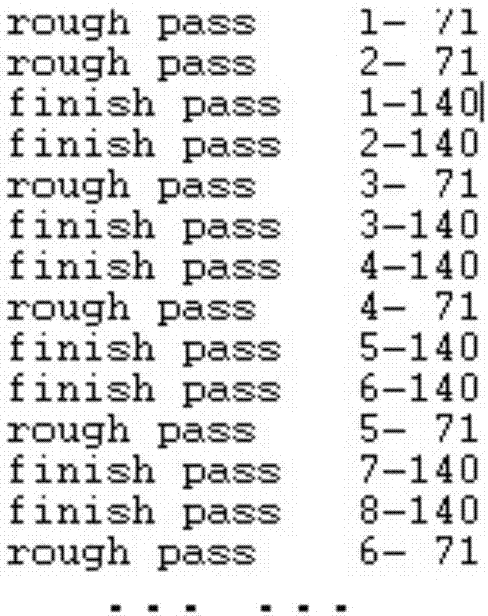

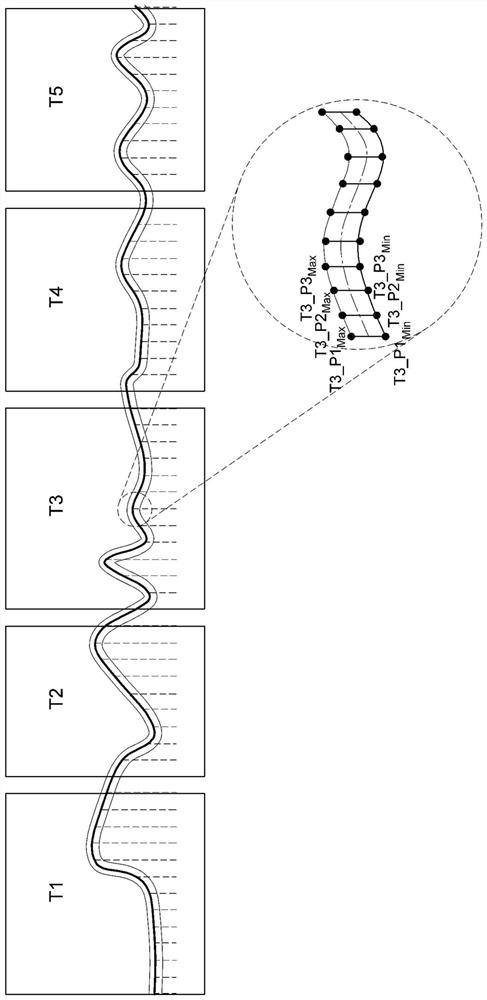

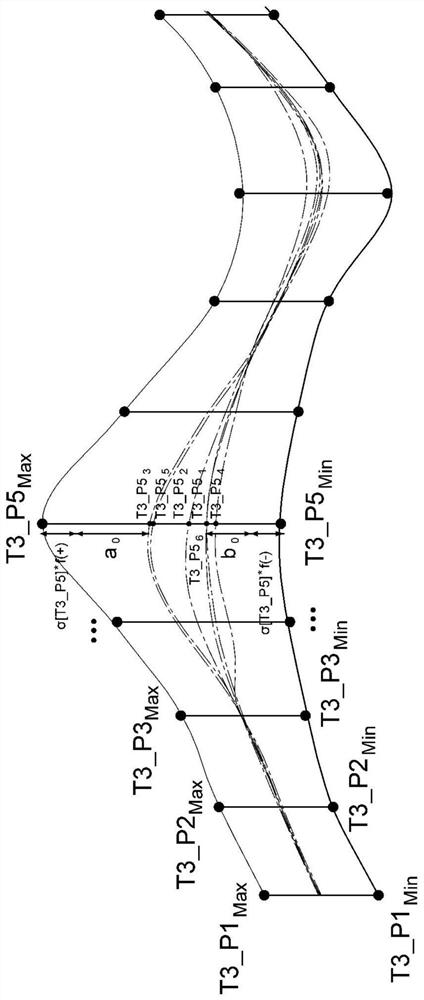

Blisk blade circulating milling rigidity reinforcing method

ActiveCN107159951AImprove machining efficiency and surface qualityImprove rigidityProgramme controlComputer controlEngineeringMachining process

The invention discloses a blisk blade circulating milling rigidity reinforcing method. According to the method, tool paths of semi-finish milling and finish milling in the machining process are combined circularly in combination with allowance distribution, the system rigidity can be improved, and tool marks are avoided; according to the rigidity of blade profiles, the finish milling allowance and the semi-finish milling allowance of the blade profiles are determined; according to the leafing length of the blade profiles and the maximum thickness of blade tips, the rigidity of the blade profiles is judged, generally, the finish milling allowance of the blade tips is set to be 0.2 mm, the finish milling allowance of blade roots is set to be 0.3 mm, and the allowances change in a gradient mode and can be adjusted according to actual conditions; and the semi-finish milling rigidity of the blade profiles needs to be guaranteed in the process, chattering is avoided during machining, and the semi-finish milling allowance is generally set to be 0.5 mm. The machining efficiency is improved, and good surface quality is achieved. Defects of other rigidity reinforcing methods are overcome, the non-machining time is not prolonged, the tool marks are avoided, no additional working procedure is needed, and the machining method is reliable, convenient and fast to implement.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

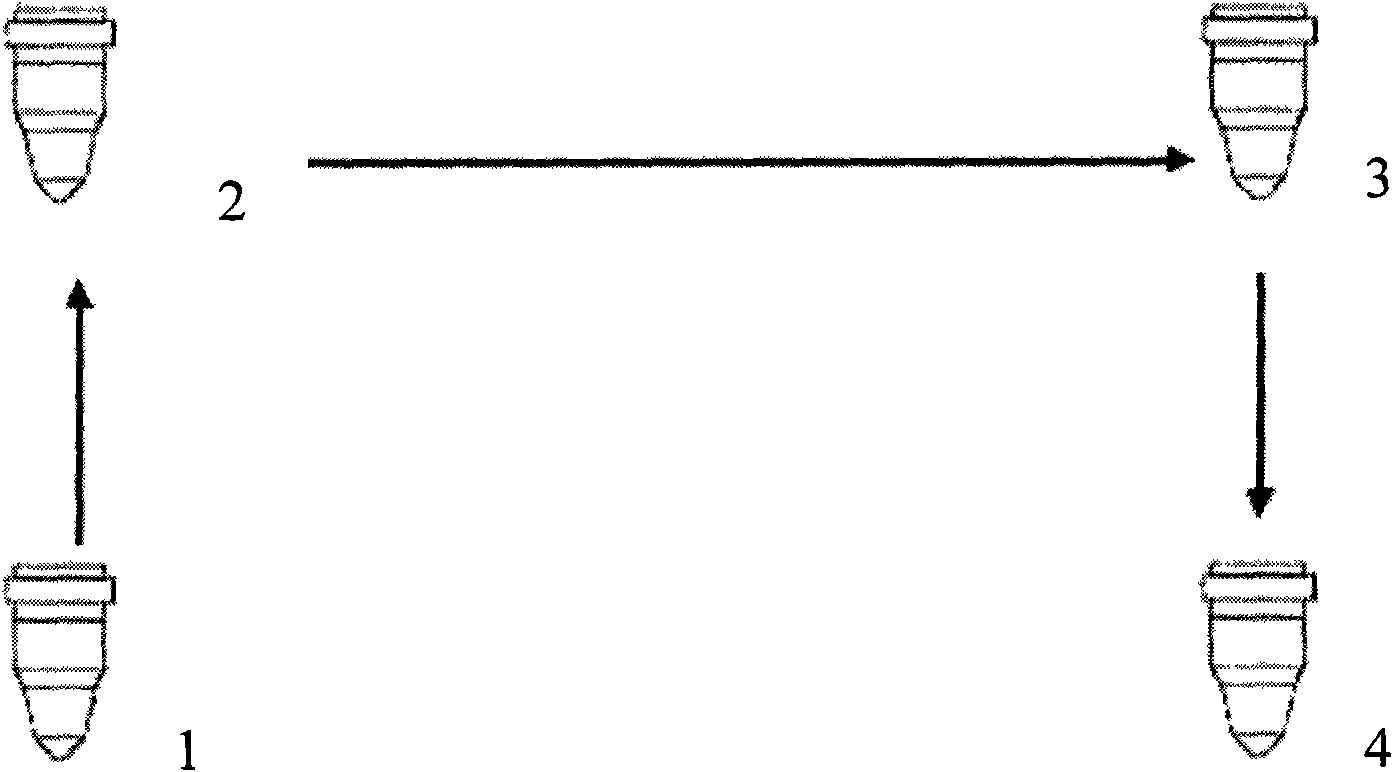

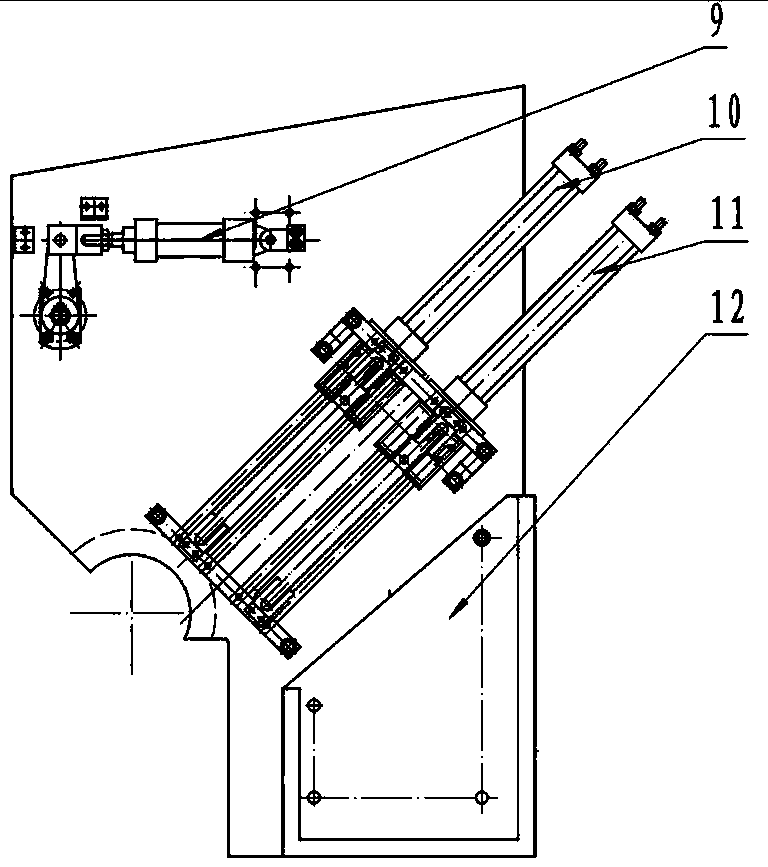

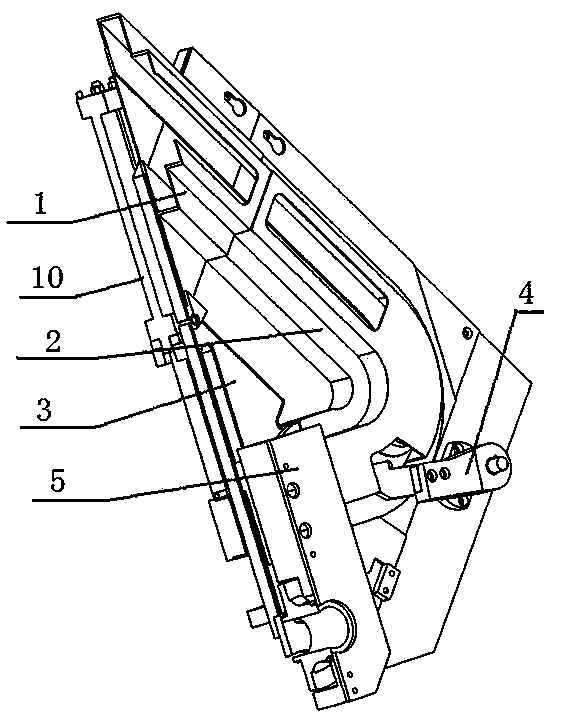

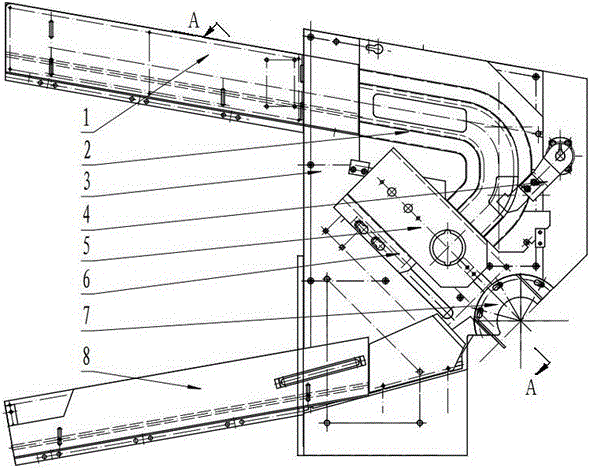

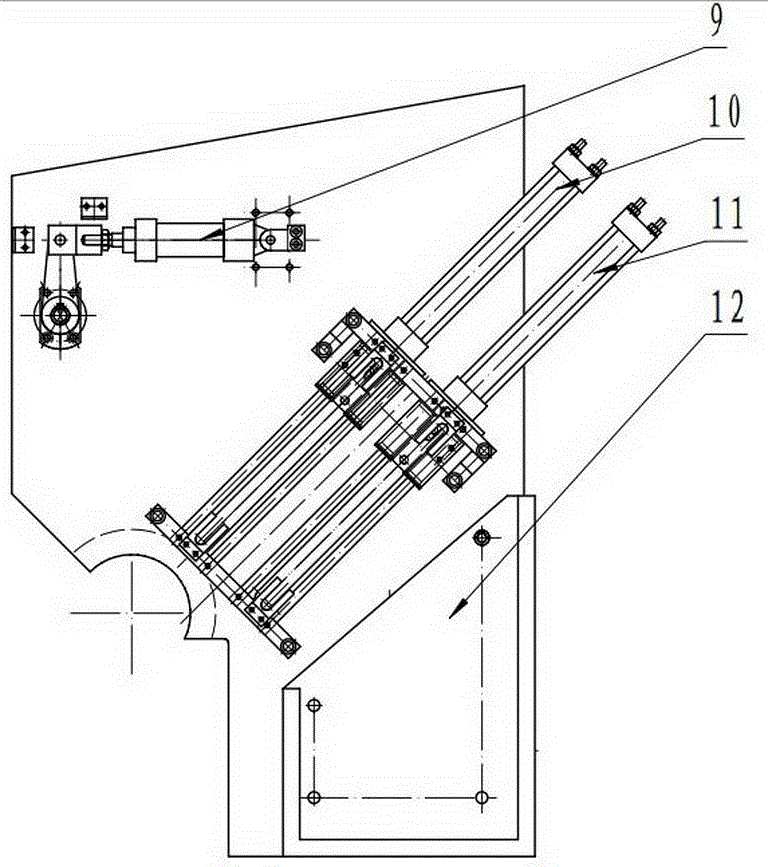

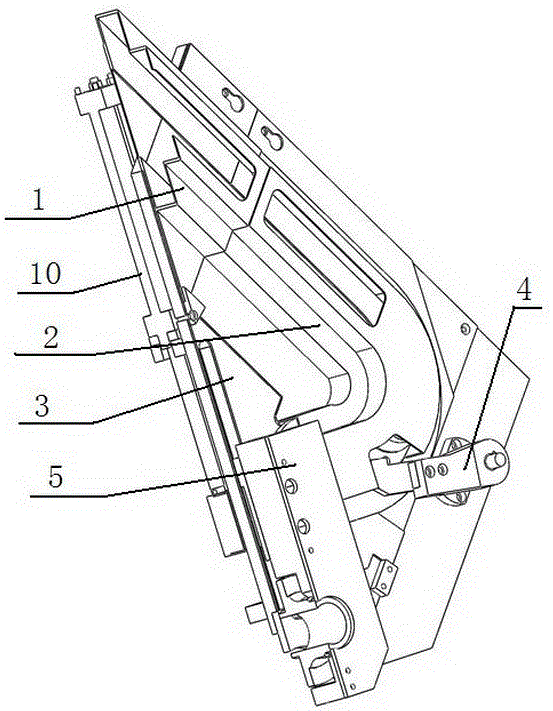

Charging and discharging device for outer circle groove grinder of automobile hub bearing unit, and application of device

ActiveCN103769977ALess mechanical actionFast loading and unloadingGrinding machinesGrinding feedersMachining timeBearing (mechanical)

The invention relates to a bearing grinder charging and discharging technology, in particular to a charging and discharging device for an outer circle groove grinder of an automobile hub bearing unit, and the application of the device. The charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit comprises a panel, wherein a charging channel, a transitional material channel, a discharging channel, a material separation oil cylinder, a main manipulator oil cylinder and an auxiliary manipulator oil cylinder are fixedly arranged on the panel; the charging channel is connected with the transitional material channel; a material separation manipulator is arranged on one side of the transitional material channel and is connected with the material separation oil cylinder; the main manipulator oil cylinder and the auxiliary manipulator oil cylinder are positioned at the tail end of the transitional material channel; a main manipulator is connected with the main manipulator oil cylinder; an auxiliary manipulator is connected with the auxiliary manipulator oil cylinder; a fan-shaped plate is arranged at a grinding station on the panel; the discharging channel is arranged at a position corresponding to the fan-shaped plate. Compared with a common charging and discharging device, the charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit has the advantages that waiting time for discharging and charging is not needed; the device is less in mechanical motion, high in charging and discharging speed and high in stability, the non-machining time is greatly shortened, and the efficiency is improved.

Owner:PUYANG BEAIN CNC MACHINERY & EQUIP

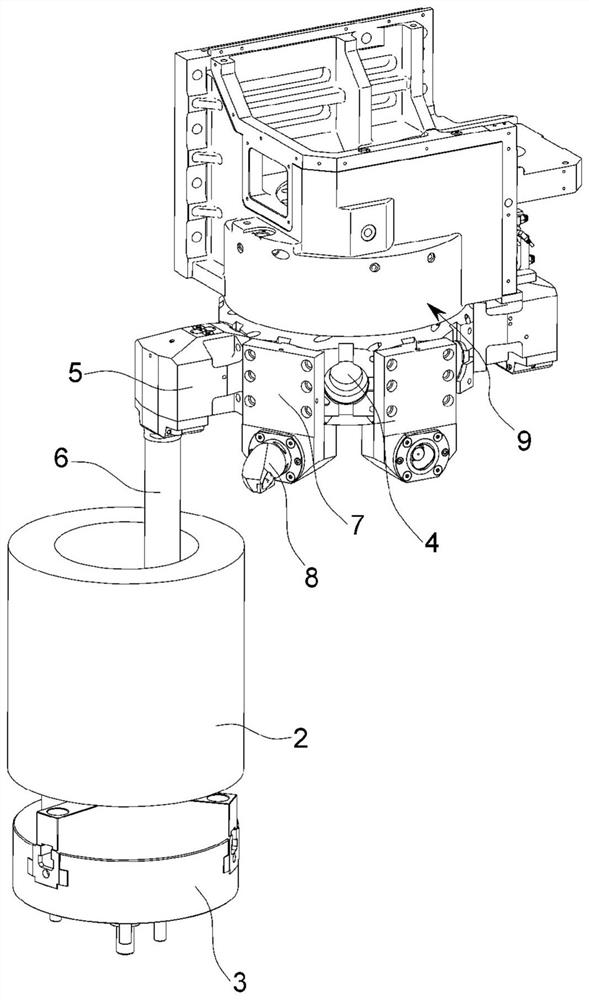

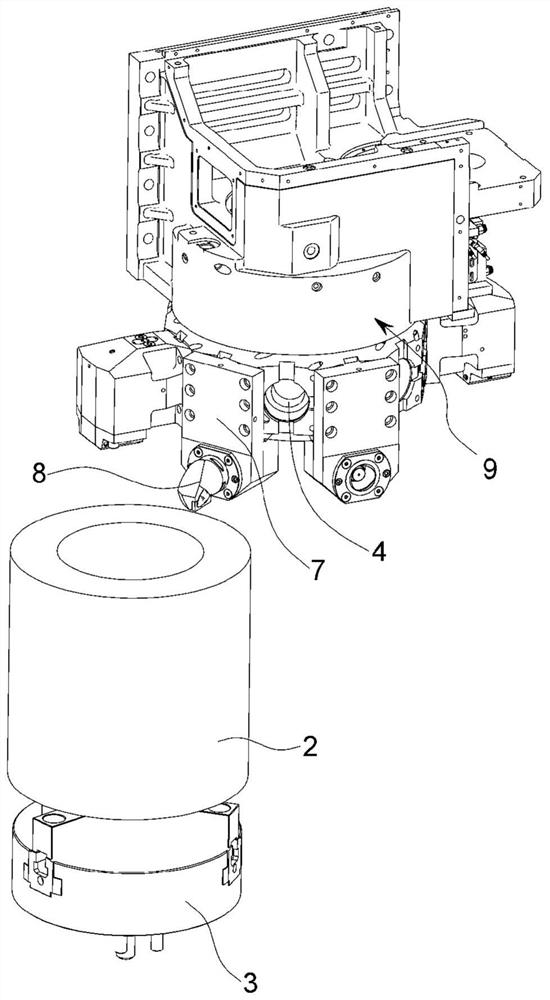

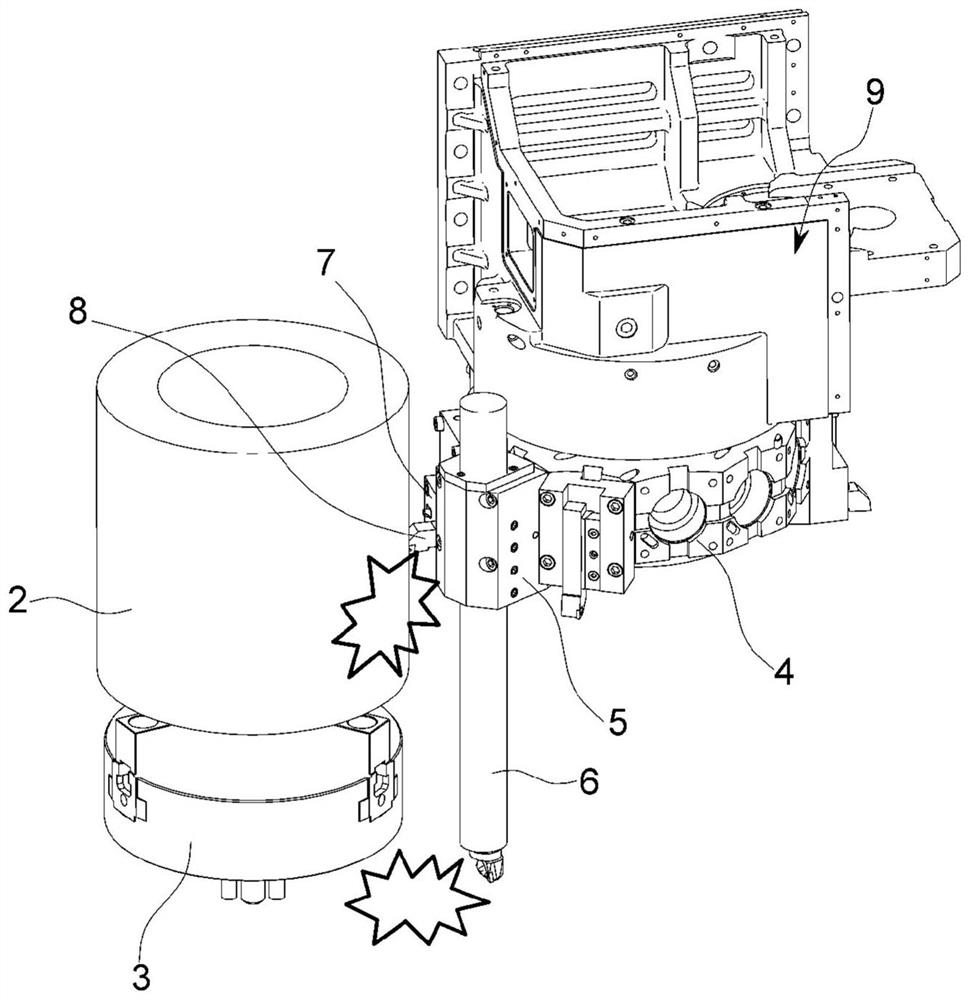

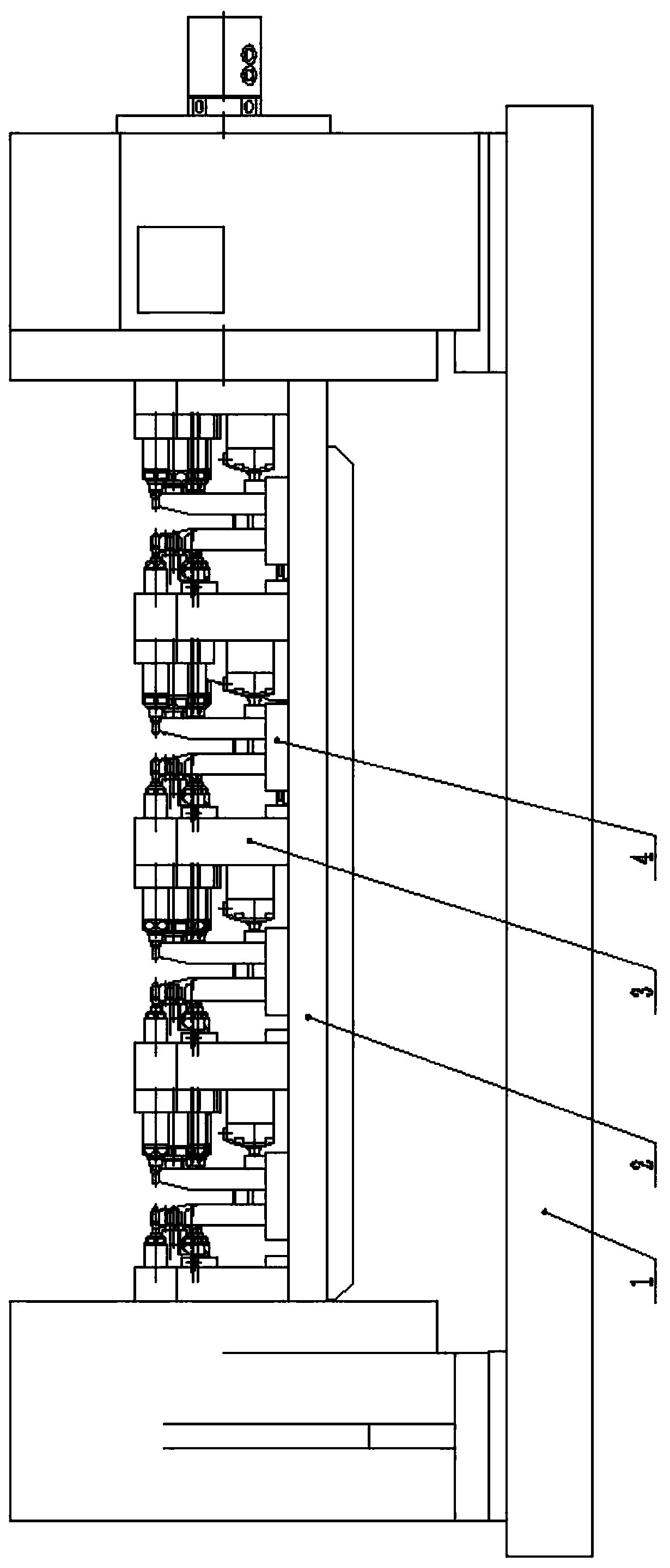

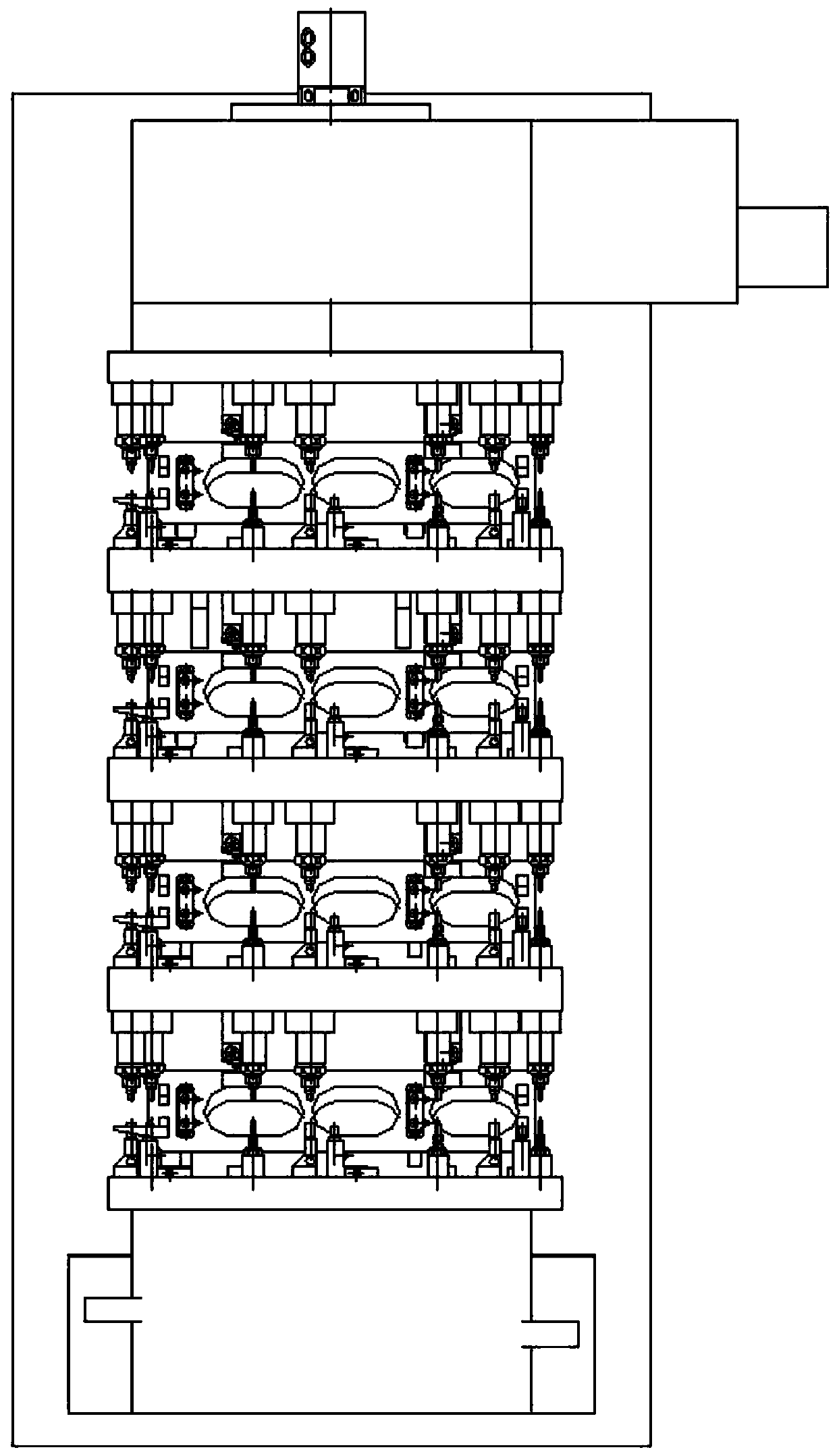

Five-axis multi-head polishing machine

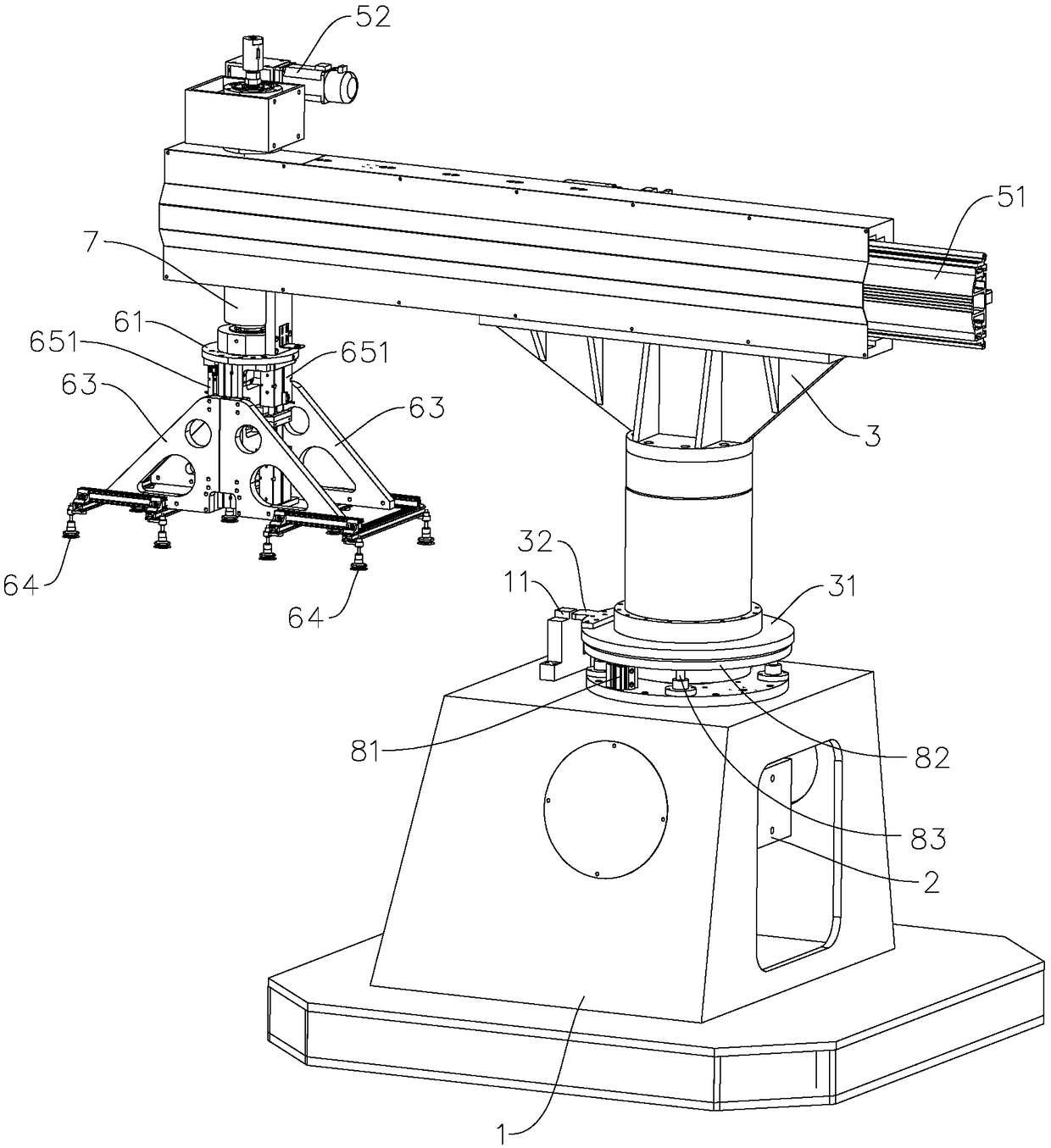

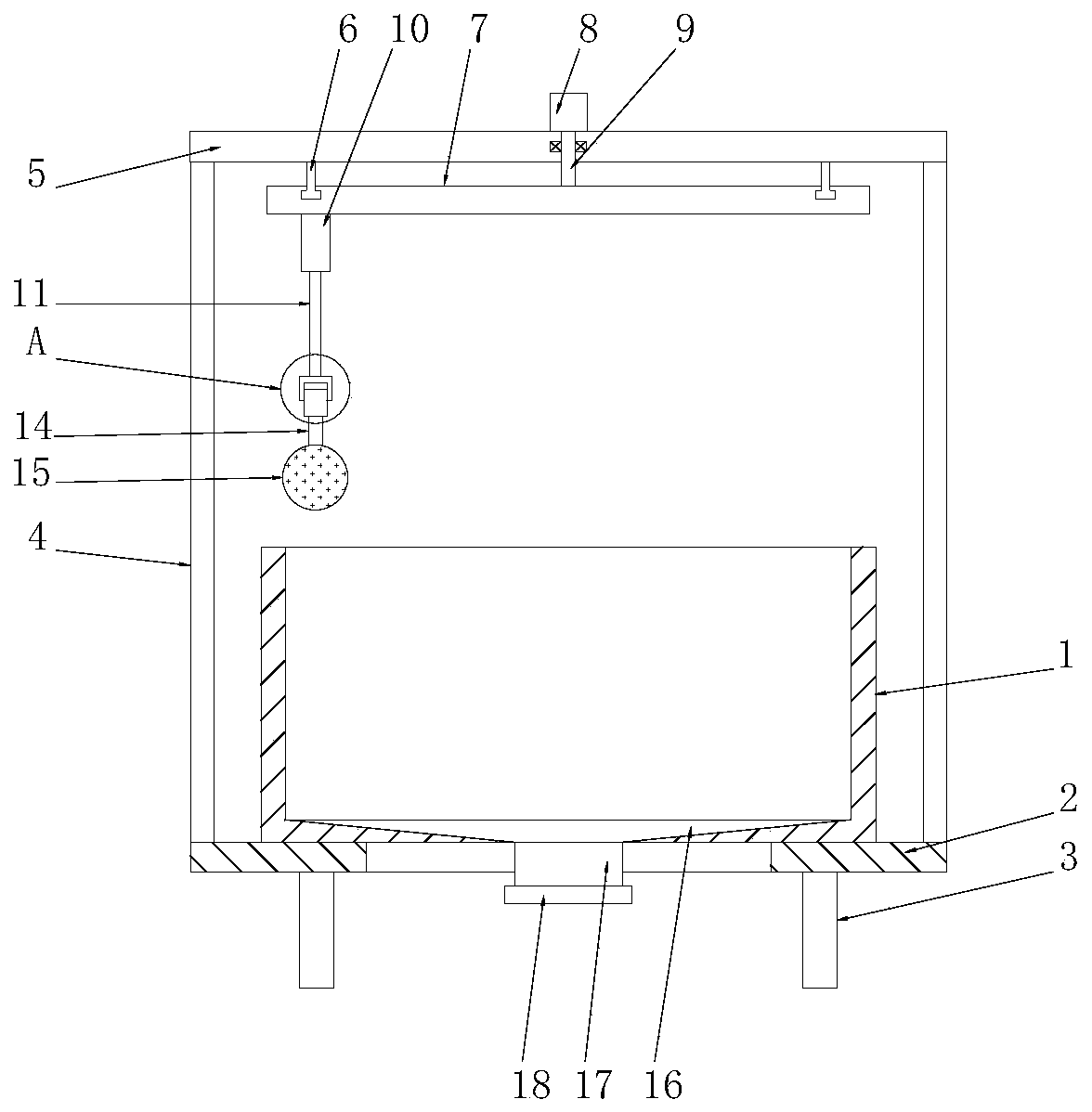

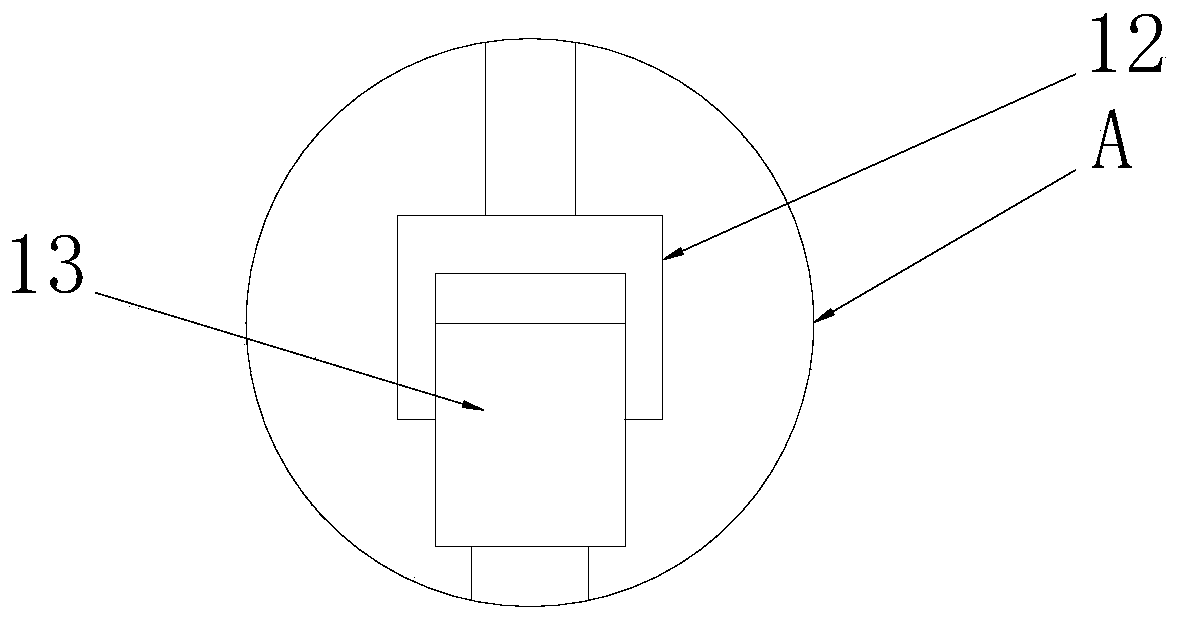

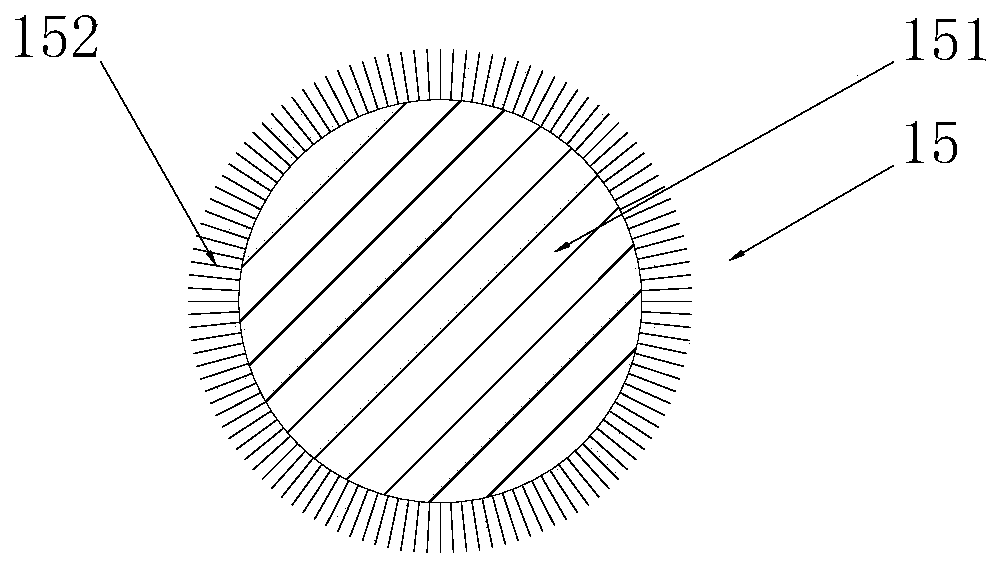

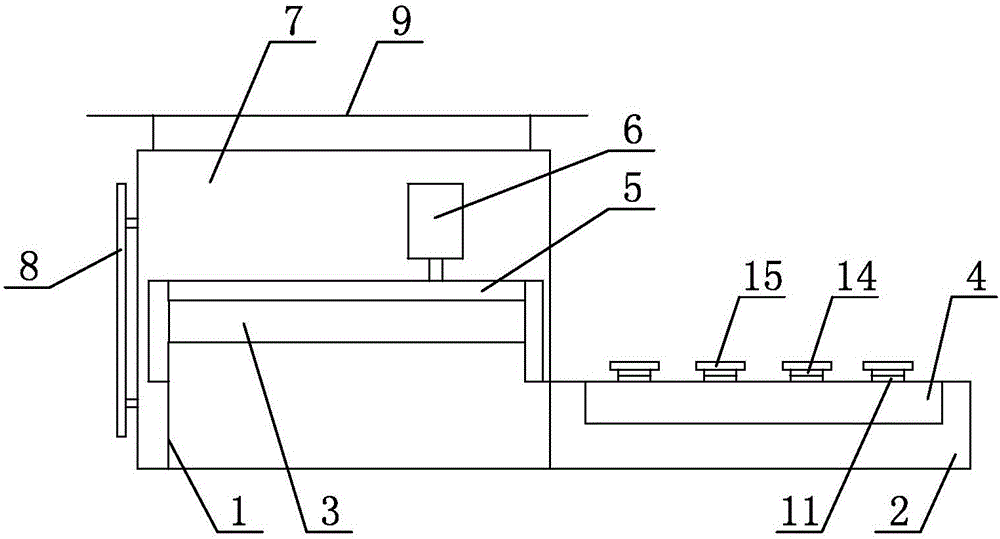

PendingCN109759935AImplement the rotation functionAchieve axial movementGrinding carriagesPolishing machinesEngineering

The invention discloses a five-axis multi-head polishing machine, which comprises a main frame, a base frame and a worktable. The base frame is fixedly connected to the lower part of the main frame. The five-axis multi-head polishing machine is characterized in that A-axis rotating modules are arranged on the worktable at intervals, a first linear rail sliding block is arranged at the bottom of the main frame, a first saddle is arranged at the position, corresponding to the first linear rail sliding block, of the bottom face of a sliding seat, the first saddle is slidably arranged on the firstlinear rail sliding block, two second saddles are arranged at the two ends of a gap bridge plate correspondingly, second linear rail sliding blocks are arranged at the positions, corresponding to thesecond saddles, of the upper parts of the two sides of the main frame, and the second saddles are slidably arranged on the second linear rail sliding blocks. The multiple sets of A-axis rotating modules and a plurality of sets of B-axis rotating modules are adopted, the rotating function of the A-axis rotating modules and the B-axis rotating modules is achieved, the linear rail sliding blocks andthe saddles are combined to achieve axial motion of the X axis and the Y axis, B-axis rotation and Z-axis axial motion of main shafts are achieved through connection of the gap bridge plates and theZ axes, and different angle machining requirements are met.

Owner:嘉泰数控科技股份公司

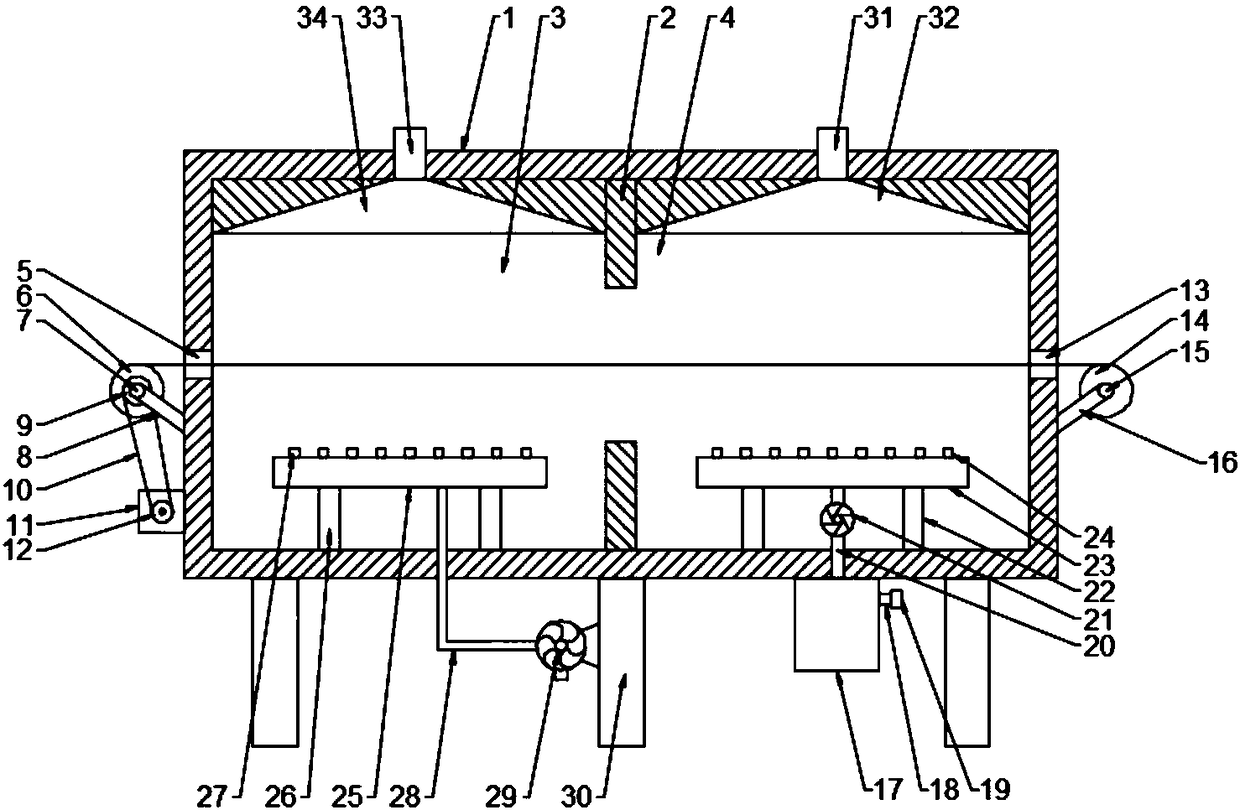

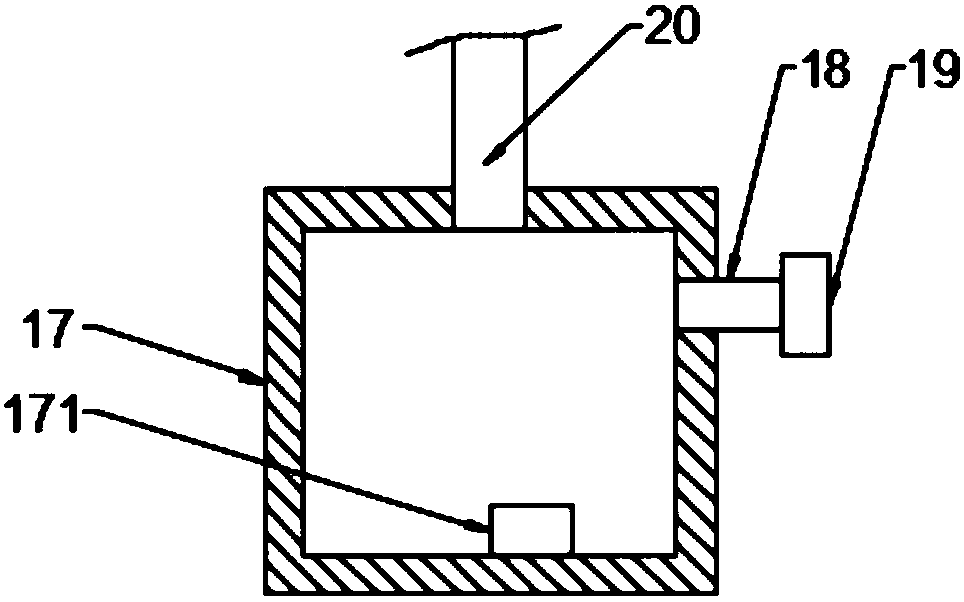

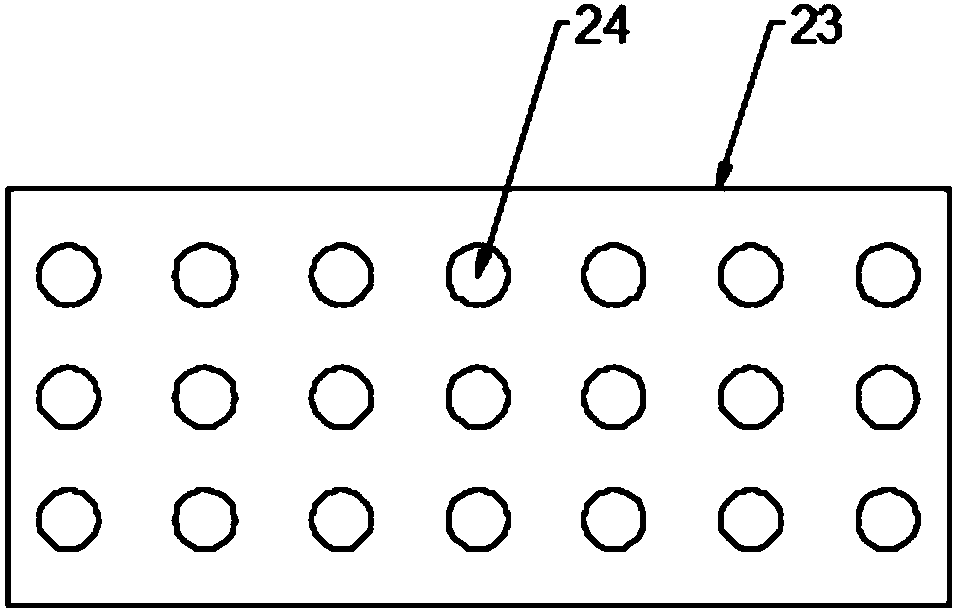

PCB welding table based on independent cooling technology

InactiveCN112059355AAvoid scatterAvoid pollutionWelding/cutting auxillary devicesAuxillary welding devicesMachining timePneumatic cylinder

The invention discloses a PCB welding table based on an independent cooling technology. The PCB welding table comprises a table frame; the top end of the table frame is connected with an overturning cavity in a communicating mode; a welding table plate is arranged in the overturning cavity; the welding table plate is rotationally connected to the inner cavity wall of the overturning cavity throughan overturning shaft; side supporting cavities are symmetrically formed in the left side end and the right side end of the table frame; supporting columns are arranged in the side supporting cavities; the supporting columns are rotationally connected to the side supporting cavities through rotating shafts; first protective nets, air cooling fans and pneumatic cylinders are sequentially arranged in inner cavities of air cooling holes from bottom to top; and supporting plate assemblies matched with the welding table plate are fixedly connected to the top ends of pneumatic rods on the pneumaticcylinders. External air is dragged by the air cooling fans to enter the air cooling holes and blows upwards along the air cooling holes, the rising airflow flows to the bottom end of the welding tableplate under the action of a flow guide cavity and obliquely blows the PCB on the welding table plate, thus the PCB can be rapidly cooled, the cooling time of the PCB can be greatly shortened, the non-machining time can be greatly shortened, and the machining efficiency can be greatly improved.

Owner:王文俊

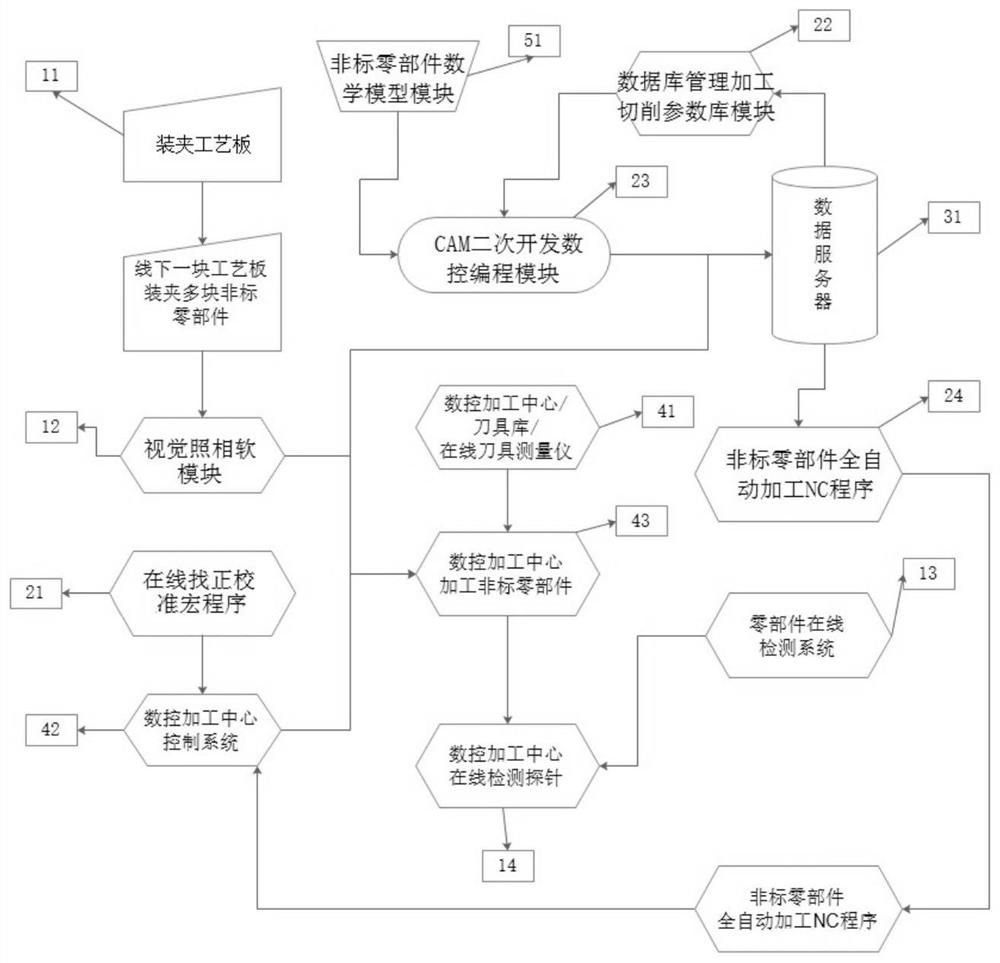

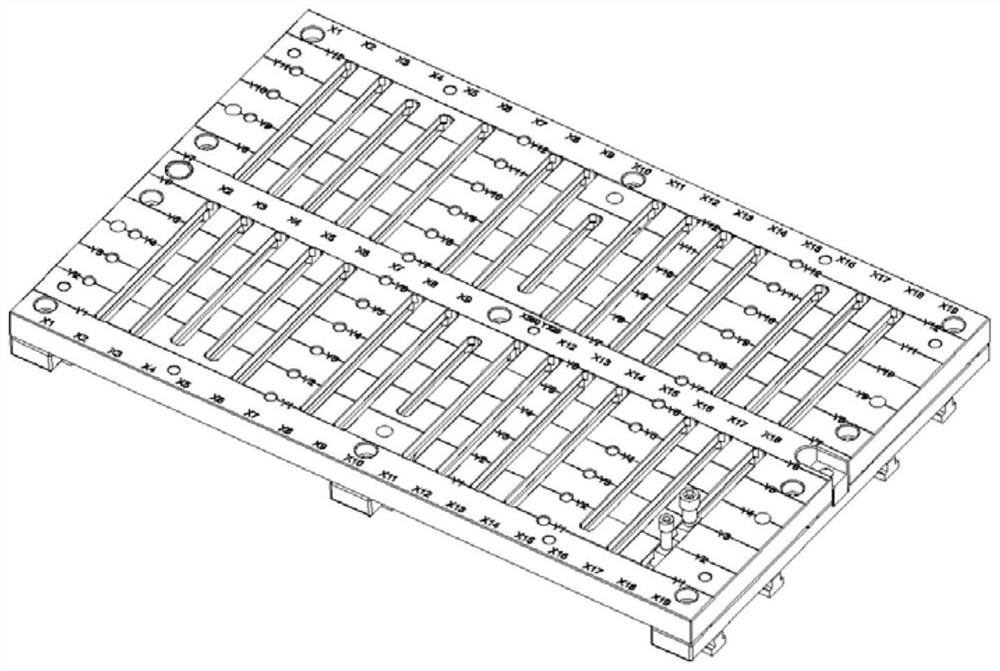

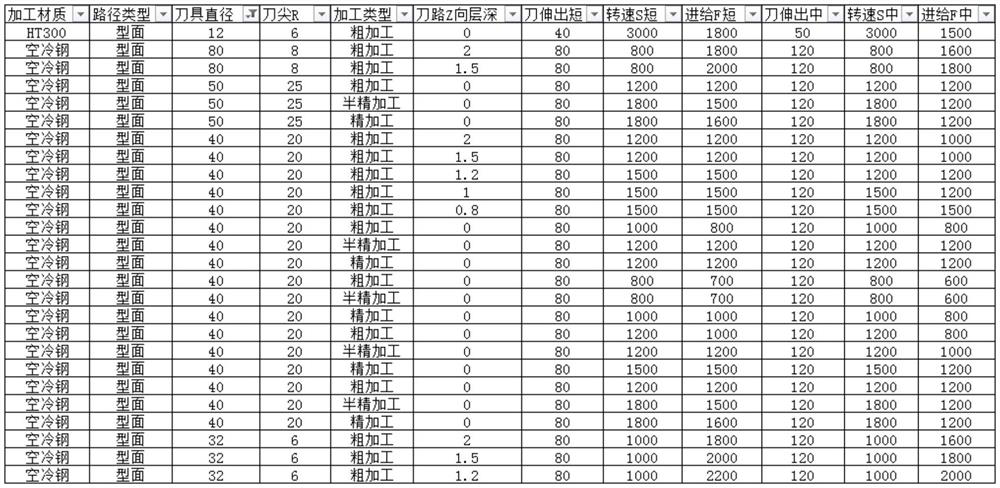

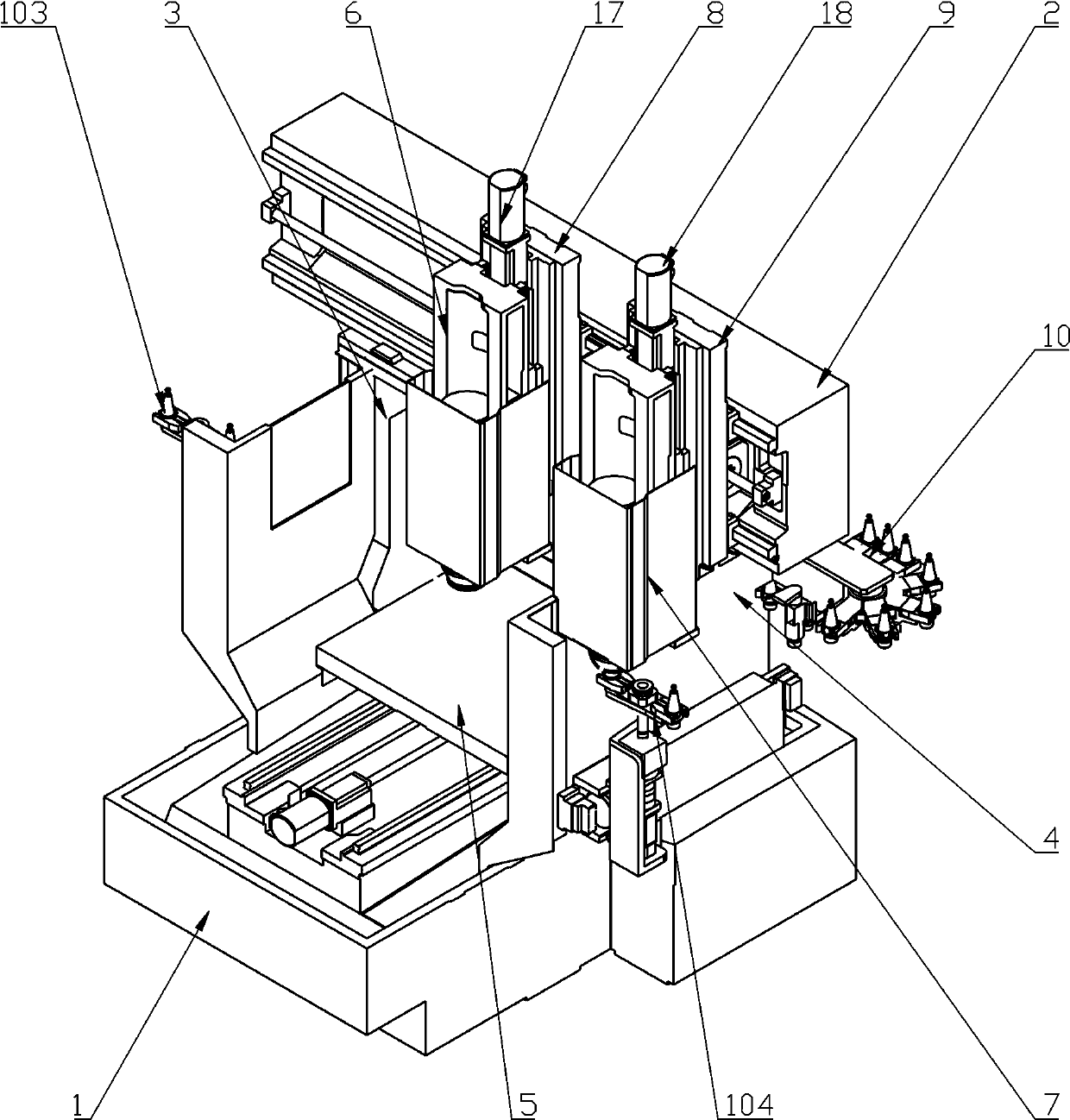

System and method for simultaneously machining non-standard parts based on numerical control machining center

ActiveCN111993161AGuaranteed utilityGuaranteed processing efficiencyProgramme controlComputer controlNumerical controlData acquisition

The invention provides a system and method for simultaneously machining non-standard parts based on a numerical control machining center. The system comprises a clamping process plate, a visual photographing soft module, a machining center online alignment and calibration module, a CAM secondary development numerical control programming module and a part online detection module. The clamping process plate is used for clamping a plurality of non-standard parts onto one process plate; the visual photographing soft module is used for carrying out workpiece primary alignment calibration on parts on a process plate through visual photographing, the machining center online alignment calibration module is used for detecting probe movement online, and the CAM secondary development numerical control programming module is used for compiling a non-standard part full-automatic machining NC program for a numerical control machining center. The system has the advantages that data of non-standard parts are collected and processed, it is guaranteed that the numerical control machining center can clamp multiple non-standard parts on one process plate at the same time for unattended full-automatic machining, the auxiliary time of the machining and manufacturing process of a numerical control machine is shortened, and the utilization rate of the numerical control machining center is guaranteed.

Owner:格致汽车科技股份有限公司

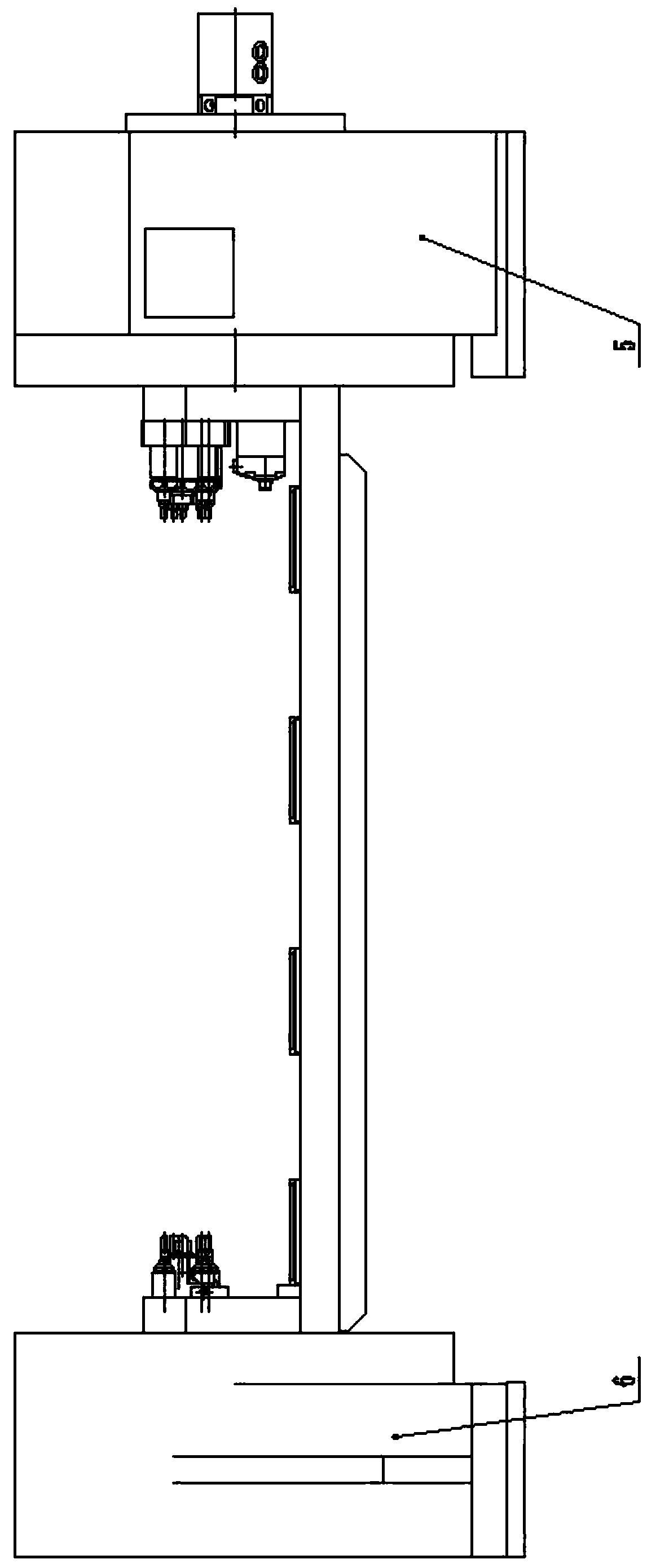

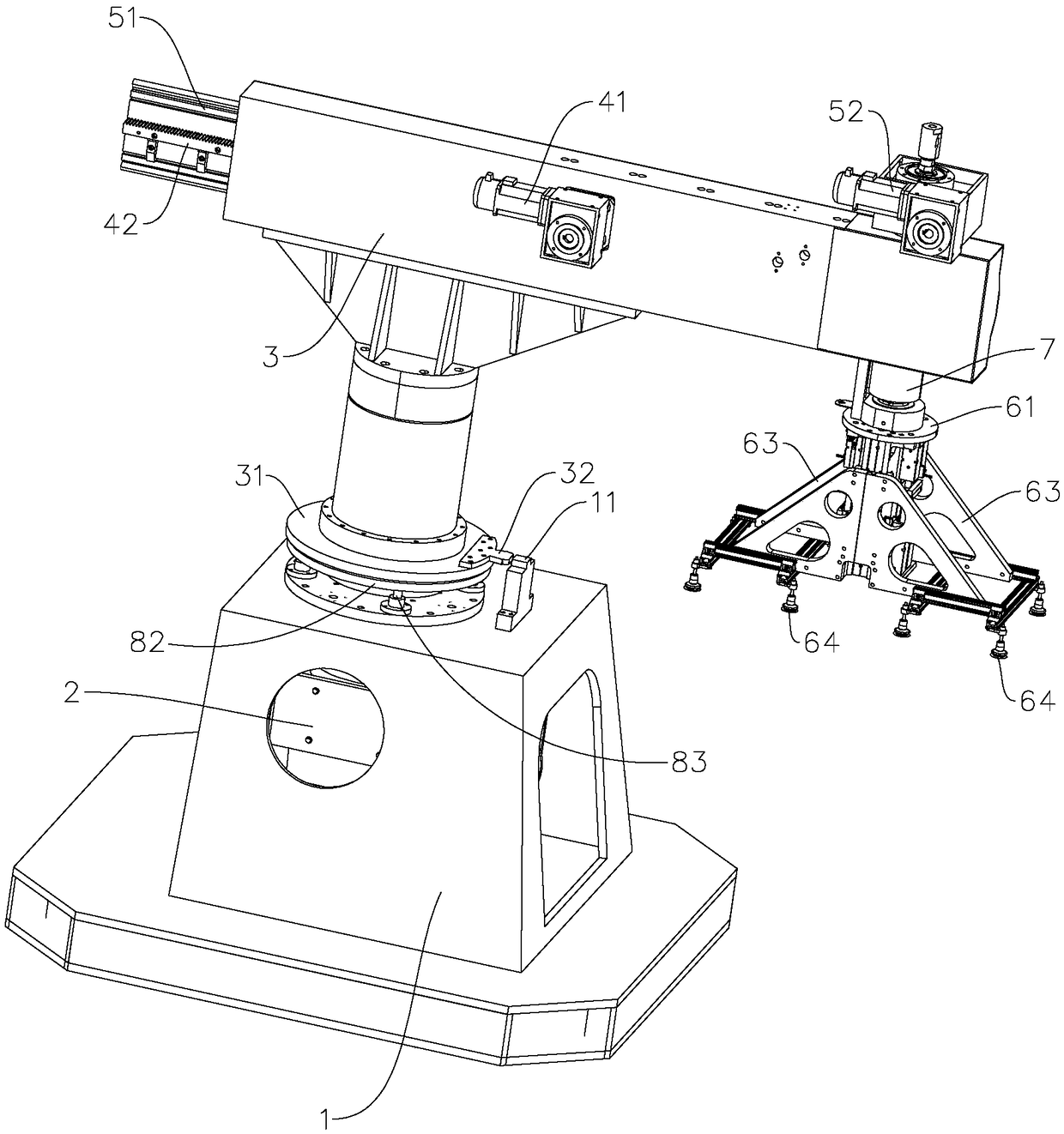

Gantry type numerical control machine tool capable of simultaneously performing tool changing and machining

PendingCN111376109AMove fastNo rotational jumpFeeding apparatusLarge fixed membersControl engineeringProcess engineering

The invention relates to a gantry type numerical control machine tool capable of simultaneously performing tool changing and machining, and aims to realize multi-process non-intermittent continuous machining, the tool changing of the machine tool does not occupy the machining time, and the production efficiency is greatly improved. The gantry type numerical control machine tool is composed of a left machine head, a right machine head, a first X sliding plate, a second X sliding plate, a first X-axis driving assembly, a second X-axis driving assembly, a left Z-axis driving assembly and a rightZ-axis driving assembly, wherein the left machine head and the right machine head are installed on a cross beam through the first X sliding plate and the second X sliding plate respectively, can independently reciprocate in the X direction under the action of the first X-axis driving assembly and the second X-axis driving assembly respectively, and meanwhile, independently reciprocate in the Z-axis direction under the action of the left Z-axis driving assembly and the right Z-axis driving assembly respectively; and a numerical control system can control the right machine head to execute the tool changing action while controlling the left machine head to execute the machining action, and can also control the left machine head to execute the tool changing action while controlling the right machine head to execute the machining action.

Owner:BEIJING JINGDIAO GRP CO LTD

Tool magazine of machine tool

ActiveCN113412175AReduce replacement timeIncrease production capacityLarge fixed membersPositioning apparatusMachine toolMachining

Owner:DN SOLUTIONS CO LTD

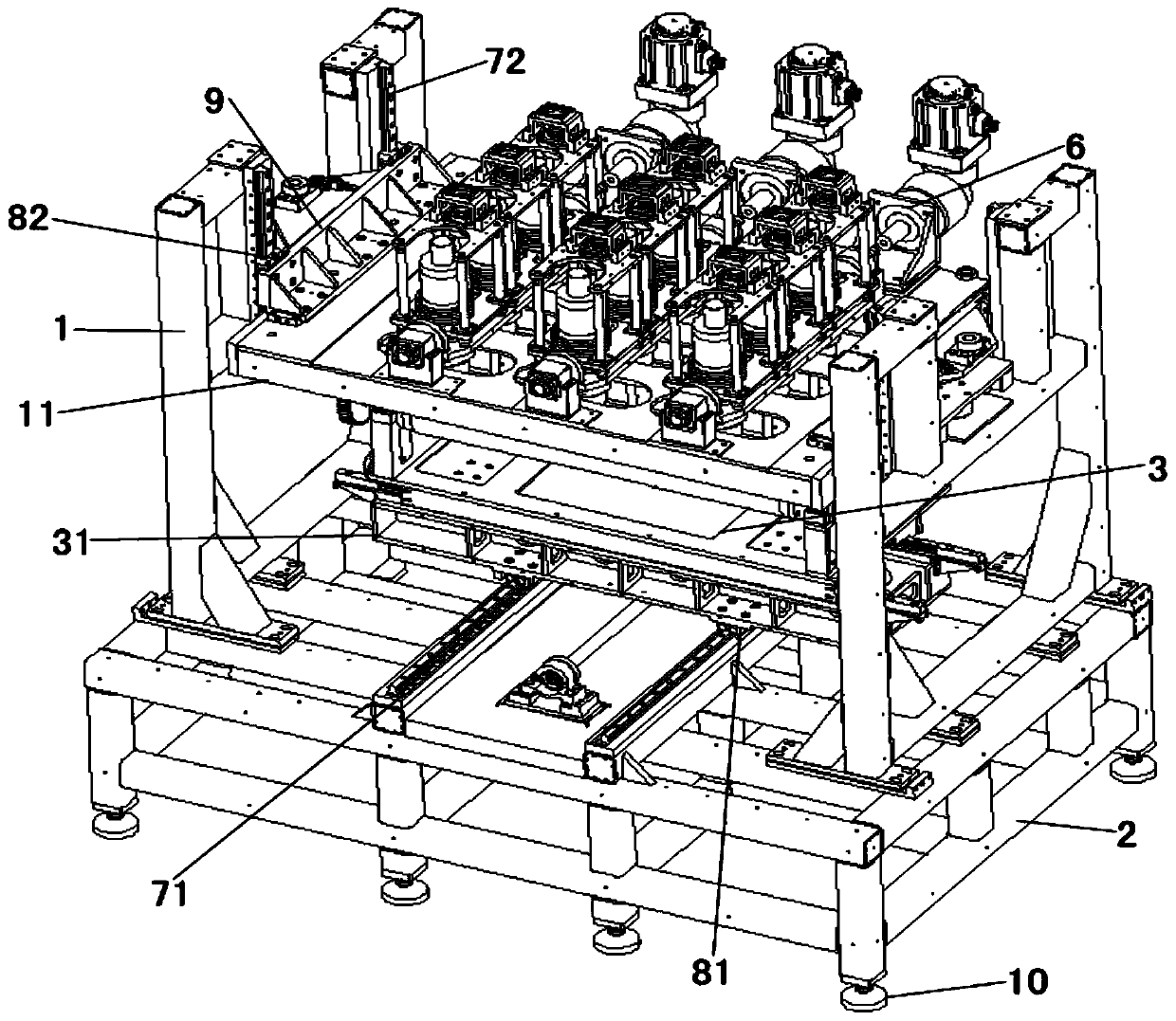

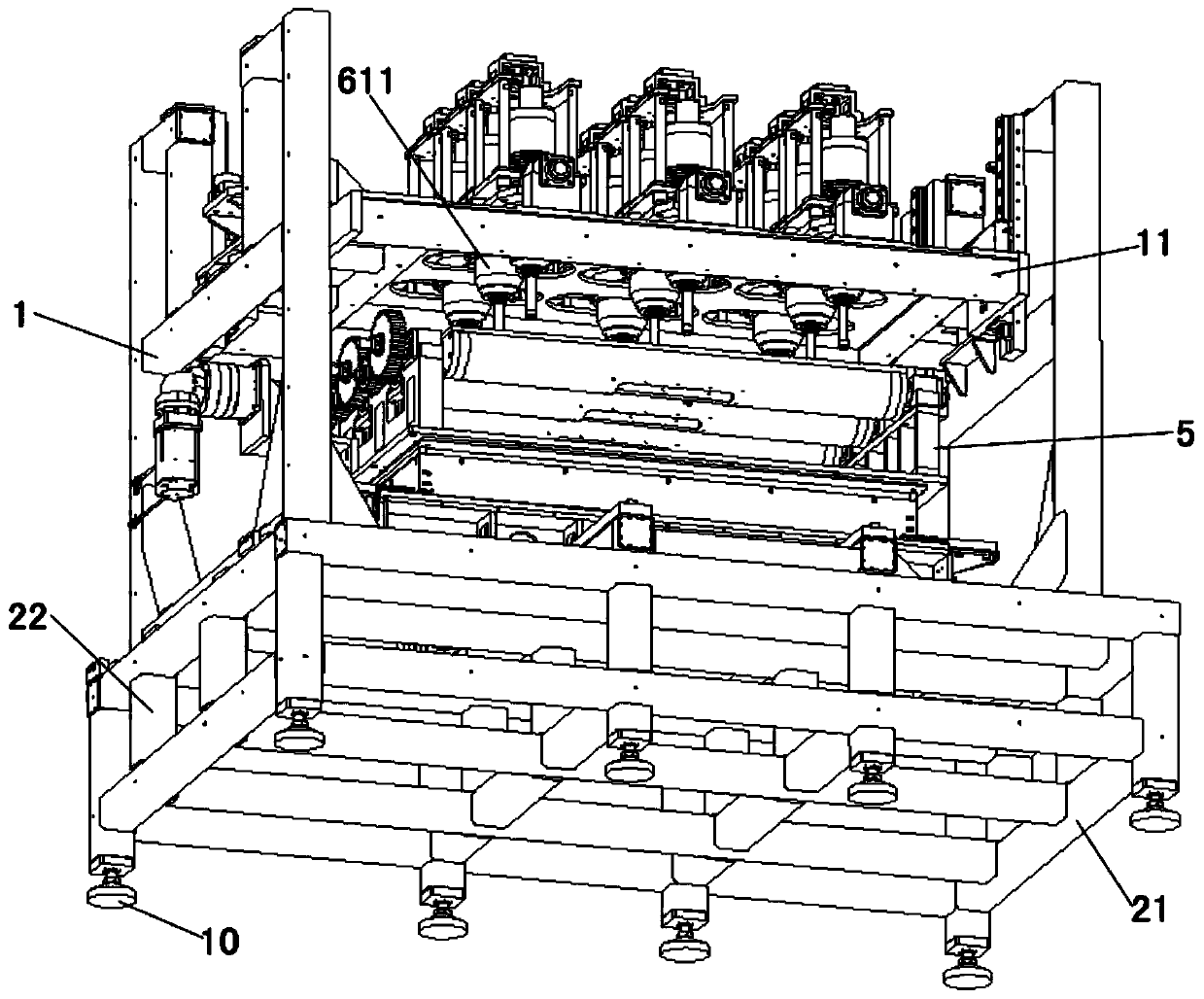

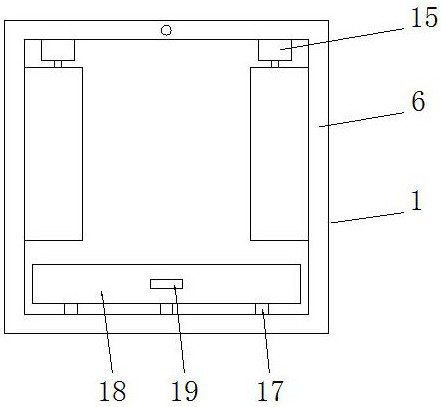

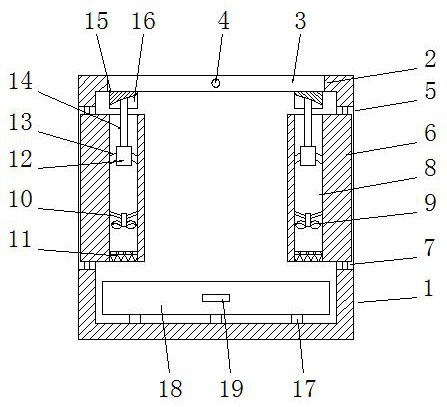

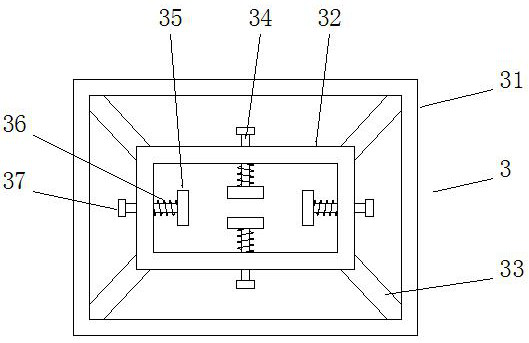

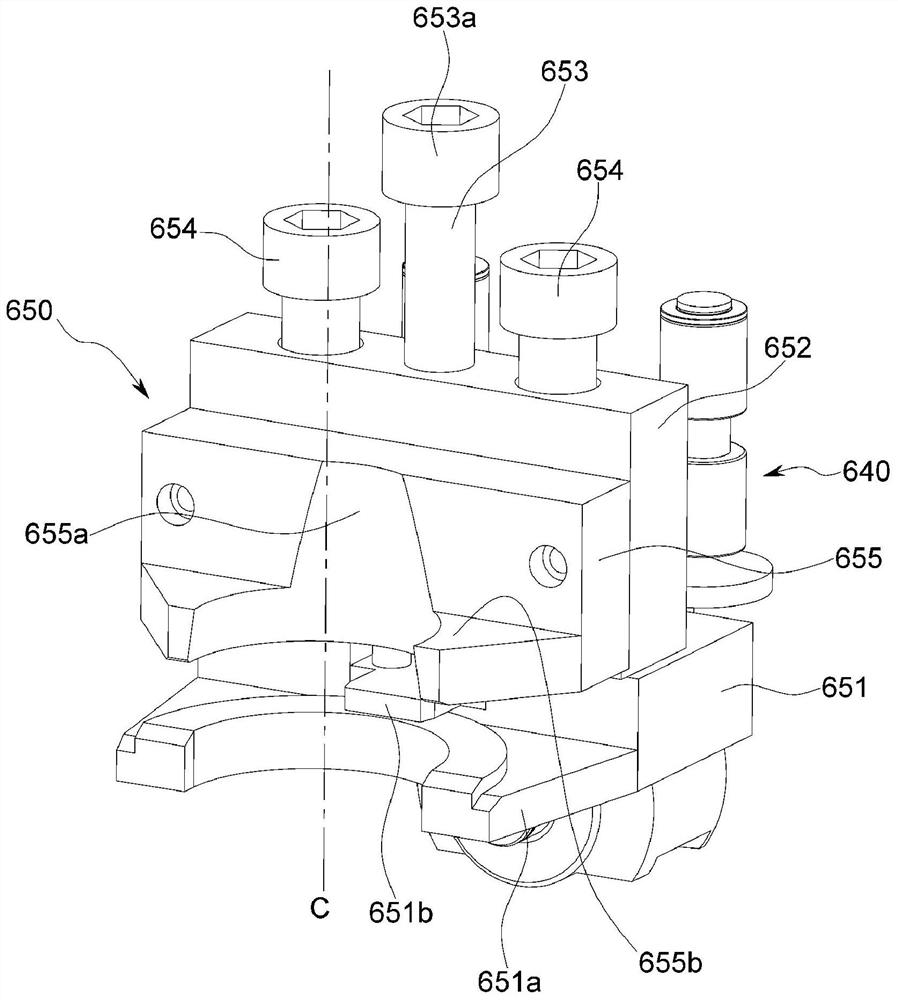

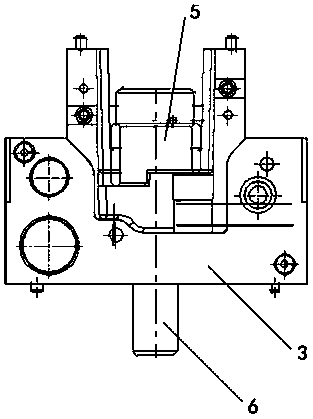

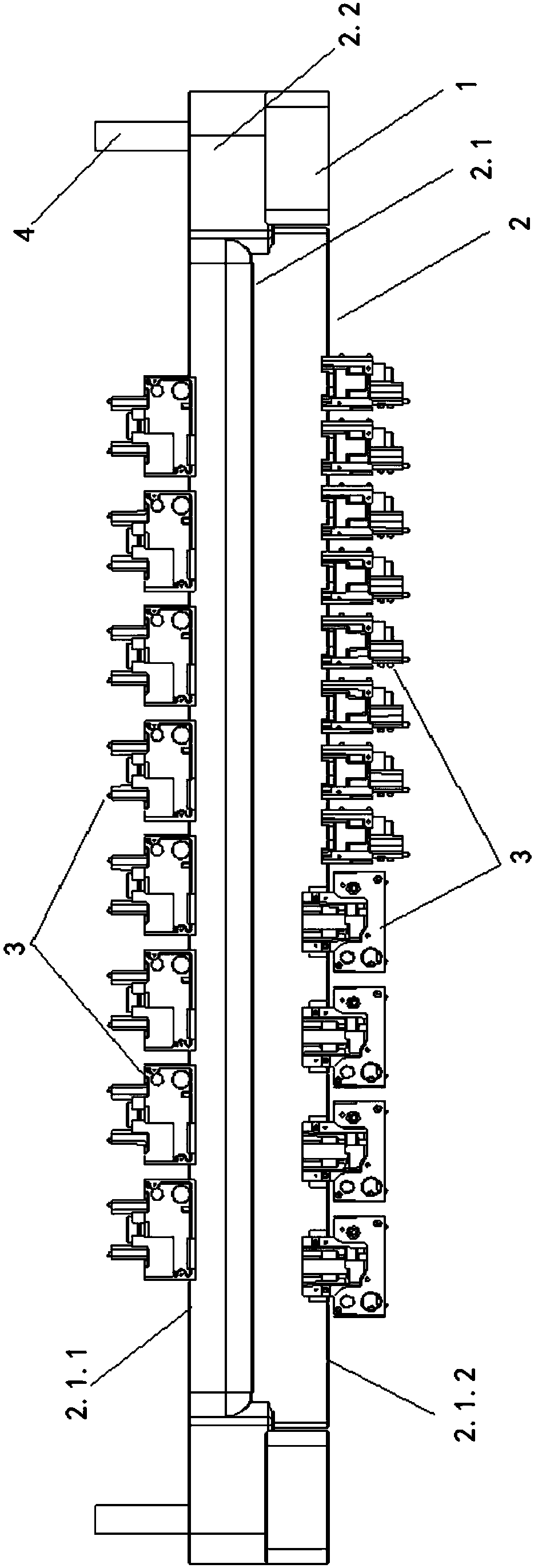

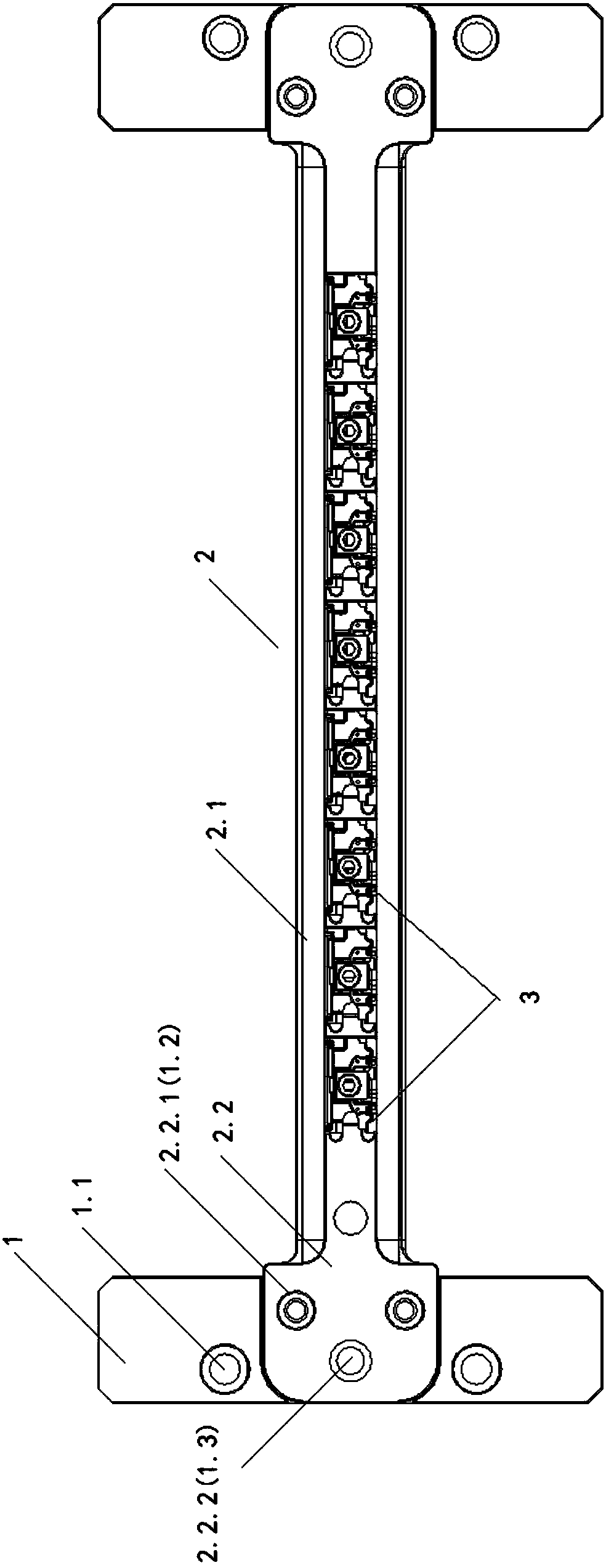

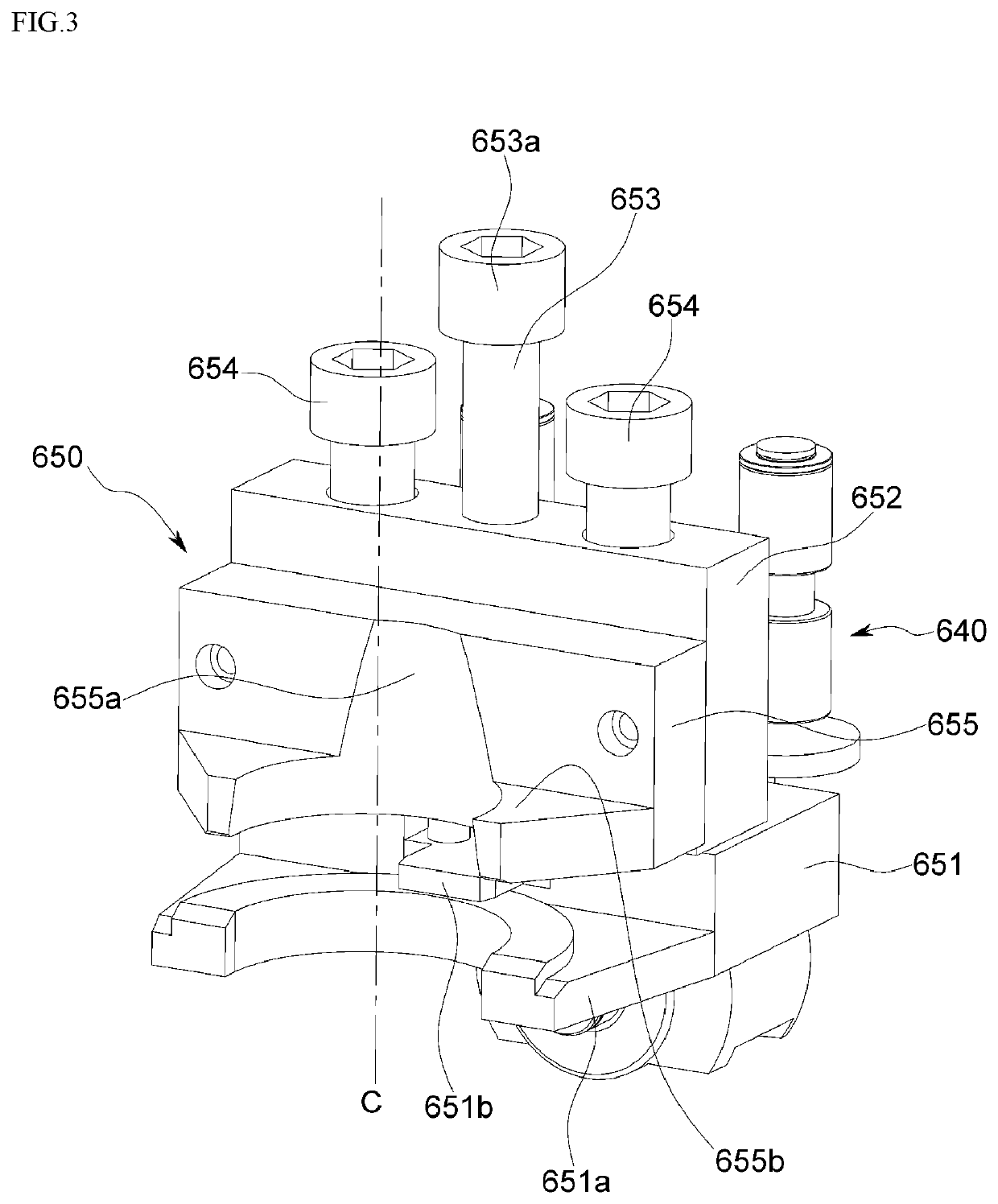

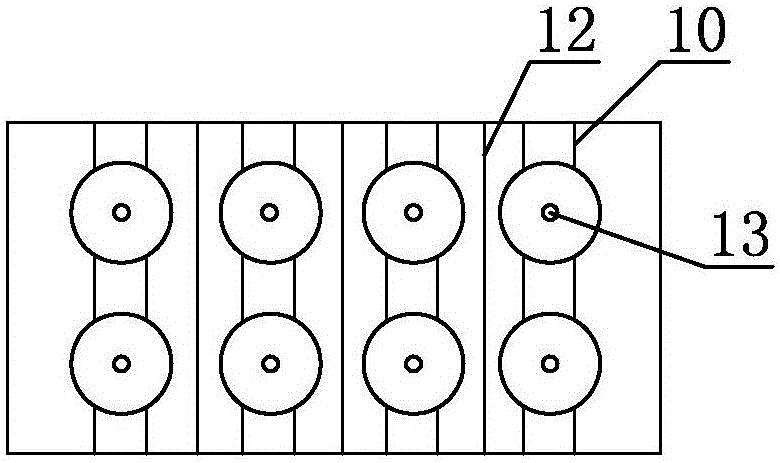

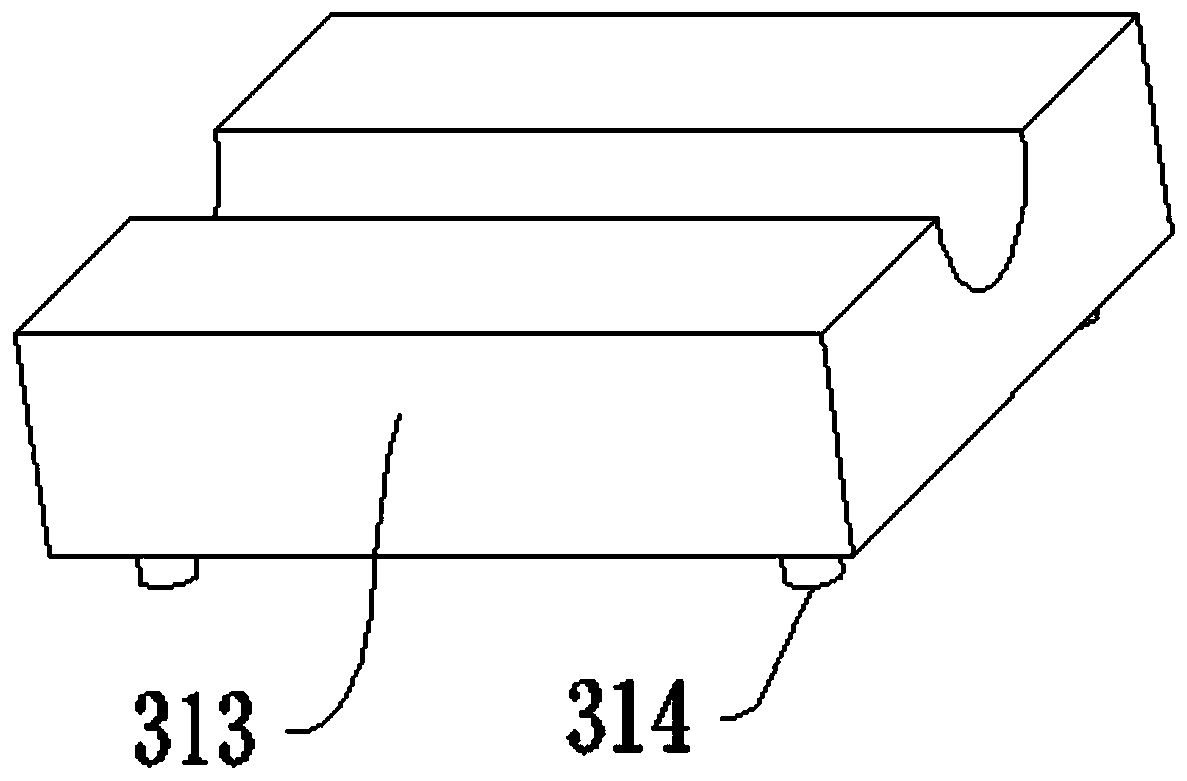

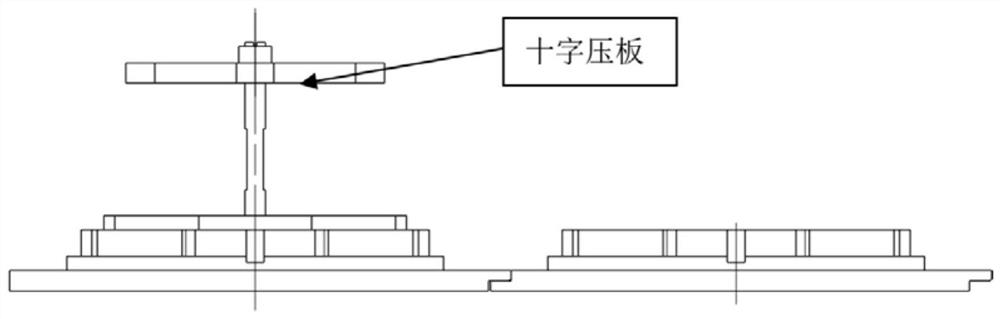

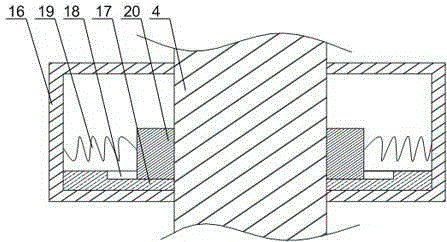

Multi-station rotary interchangeable clamp

InactiveCN108436514AEasy to replaceLower runPositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a multi-station rotary interchangeable clamp. The multi-station rotary interchangeable clamp comprises clamp bottom plates and a bridge plate, wherein the clamp bottom plates are arranged on the two sides of the bridge plate respectively, the clamp bottom plates are fixedly connected with a rotary table, and the bridge plate is fixedly connected with the clamp bottom plates; and a plurality of product positioning holes are formed in the upper end surface and the lower end surface of the bridge plate respectively, and products are arranged at the product positioning holes and are fixedly connected with the bridge plate. According to the multi-station rotary interchangeable clamp, the detachable bridge plate is arranged, the plurality of product positioning holes areformed in the upper end surface and the lower end surface of the bridge plate, and therefore the bridge plate can be conveniently replaced by an operator; meanwhile, the plurality of products can be machined by using a tool; and compared with an existing clamp which can clamp a single product, the multi-station rotary interchangeable clamp has the advantage that during operation, non-machining time for invalid operation of a machine tool, cyclical tool changing and rotation of the rotary table can be saved, and the machining efficiency of the products is improved.

Owner:沃热精密机械(上海)有限公司

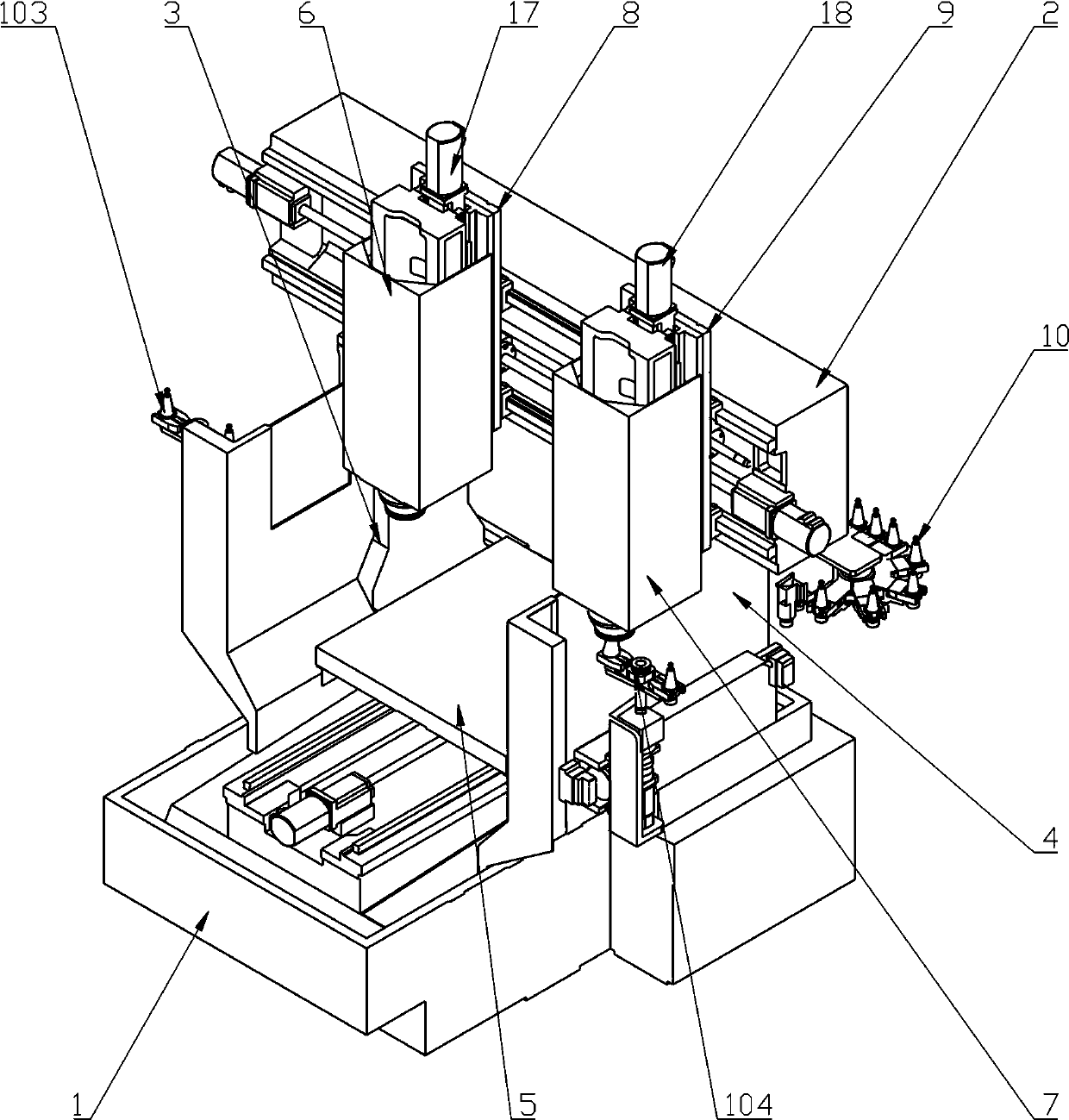

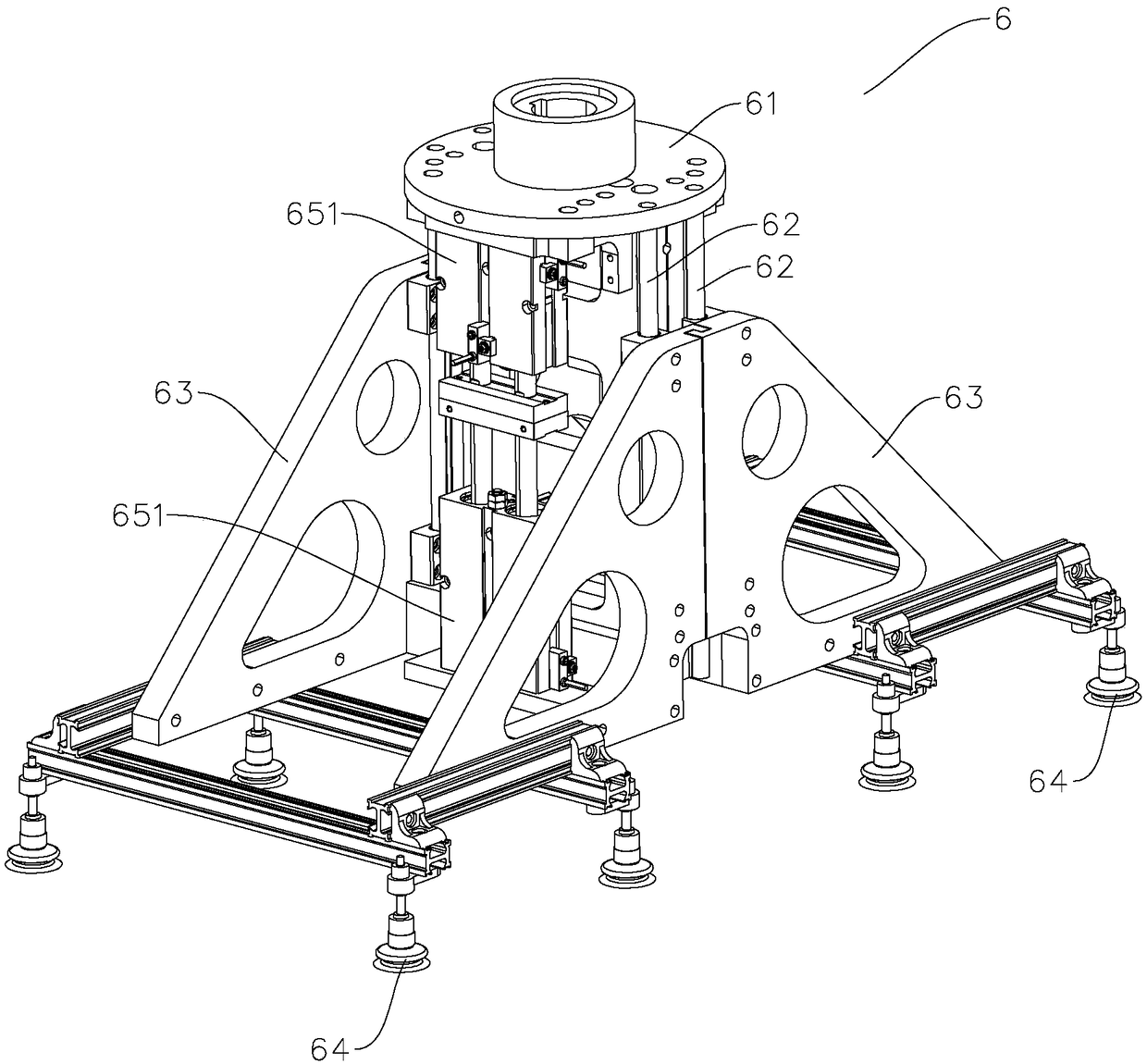

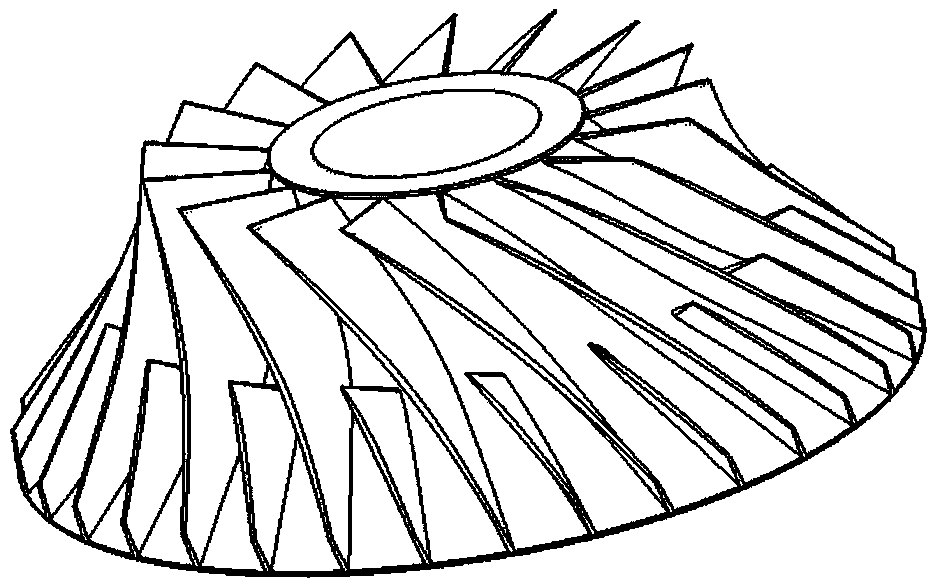

Tool magazine of machine tool

ActiveCN111655424AIncrease production capacityEasy to replaceTool changing apparatusPositioning apparatusRotational axisCentre of rotation

The present invention relates to a tool magazine of a machine tool, comprising: a base part installed in a part of a space in which a spindle head moves; a support part installed vertically with respect to the base part; a rotation shaft part rotatably installed to the support part; a first tool storage part rotatably installed to the rotation shaft part, and accommodating a plurality of tools radially from the center of rotation of the rotation shaft part; and a second tool storage part which is vertically above the first tool storage part and rotatably installed to the rotation shaft part, and accommodates a plurality of tools radially from the center of rotation of the rotation shaft part, wherein the tool magazine of a machine tool may be installed such that the tool storage directionof the second tool storage part is orthogonal to the tool storage direction of the first tool storage part. Moving in the horizontal and vertical directions, the spindle head easily replaces the inner-diameter tools in the first tool storage part and the outer-diameter tools in the second tool storage part, thereby minimizing non-processing time and enhancing the productivity of the machine tool.

Owner:DN SOLUTIONS CO LTD

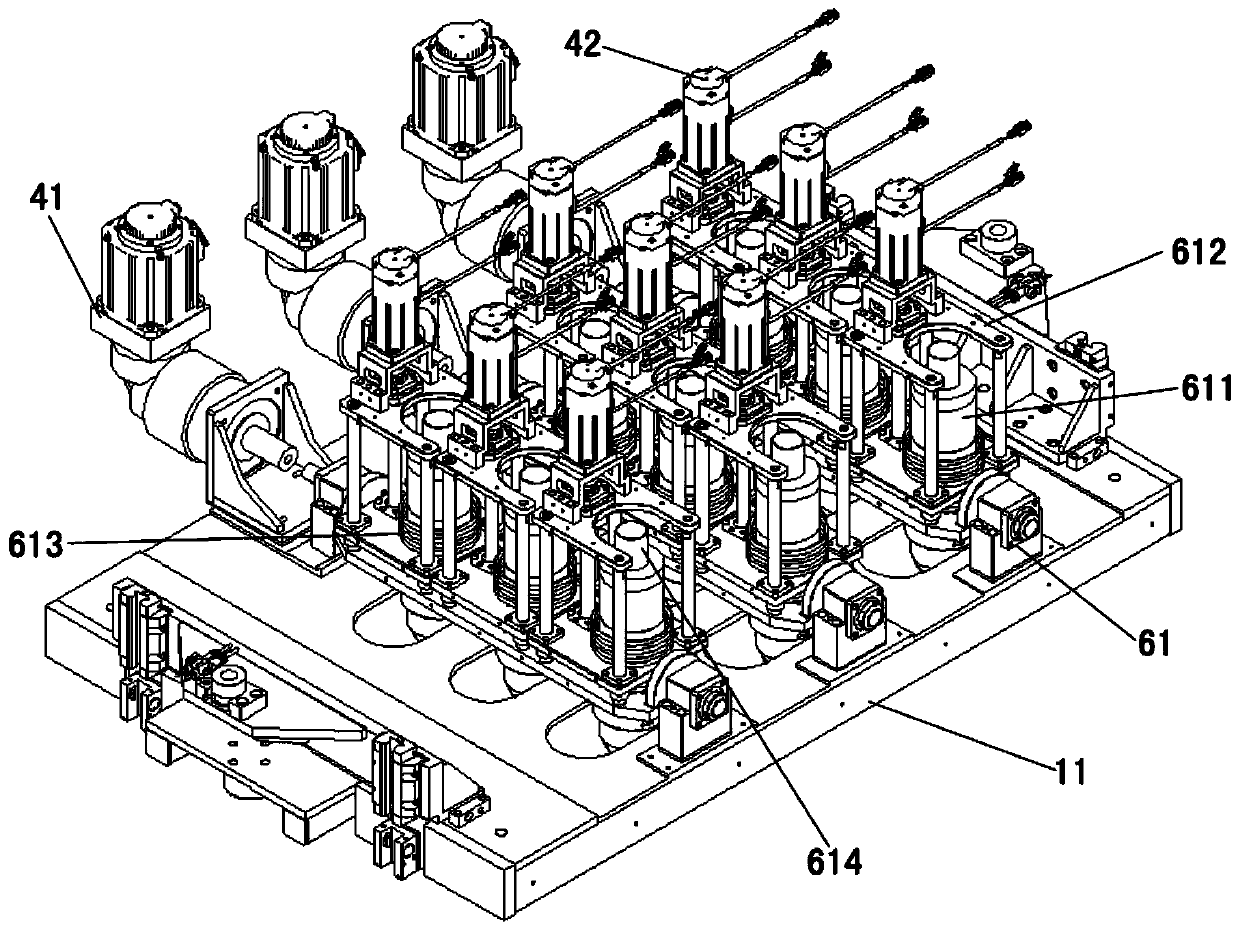

Multi-station vertical machining center four-axis hydraulic clamp

PendingCN110757213AReduce volumeReduce weightPositioning apparatusMetal-working holdersControl engineeringSupport point

The invention discloses a multi-station vertical machining center four-axis hydraulic clamp which comprises a rotary working table mounted on a machine tool working table, wherein positioning and clamping components and pre-positioning components are mounted on the rotary working table; and one pre-positioning component is connected between every two adjacent positioning and clamping components and is connected between the rotary working table and the adjacent positioning and clamping component. According to the multi-station vertical machining center four-axis hydraulic clamp, a workpiece isvertically placed, three points in a workpiece four-position technological positioning face are utilized to construct a Y-axis positioning face to realize limitation of six degrees of freedom; in addition, an auxiliary support is arranged to improve the processing stability; and a spring positioning pin component is adopted to determine the positions of the workpiece in X-axis and Z-axis, and clamps are arranged at corresponding positions of a positioning point and an auxiliary support point to clamp the workpiece.

Owner:YUN DONG LI INTELLIGENT MFG EQUIP CO LTD

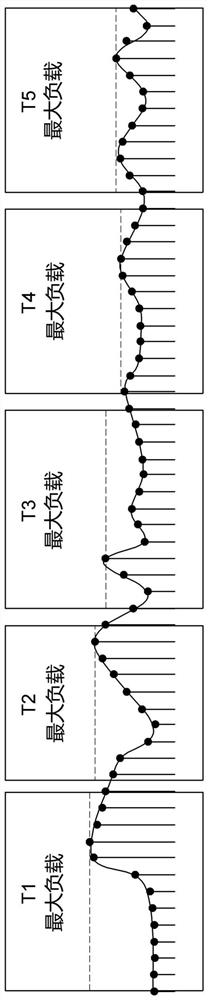

Detection apparatus and detection method for machine tool abnormality

ActiveCN111655426AMaximize reliabilityMaximize accuracyProgramme controlComputer controlControl engineeringMaterials processing

The present invention relates to a detection apparatus and a detection method for machine tool abnormality and, more specifically, to a correction apparatus and a correction method for a backlash of amachine tool which are capable of repeatedly measuring a load of a material transferring part or a material processing part, and automatically detecting an abnormality of a tool on the basis of a normal range of load data that is proportional to a standard deviation of the load data measured on the basis of either the mode value, the mean value, or the median value among repeatedly measured loaddata.

Owner:DN SOLUTIONS CO LTD

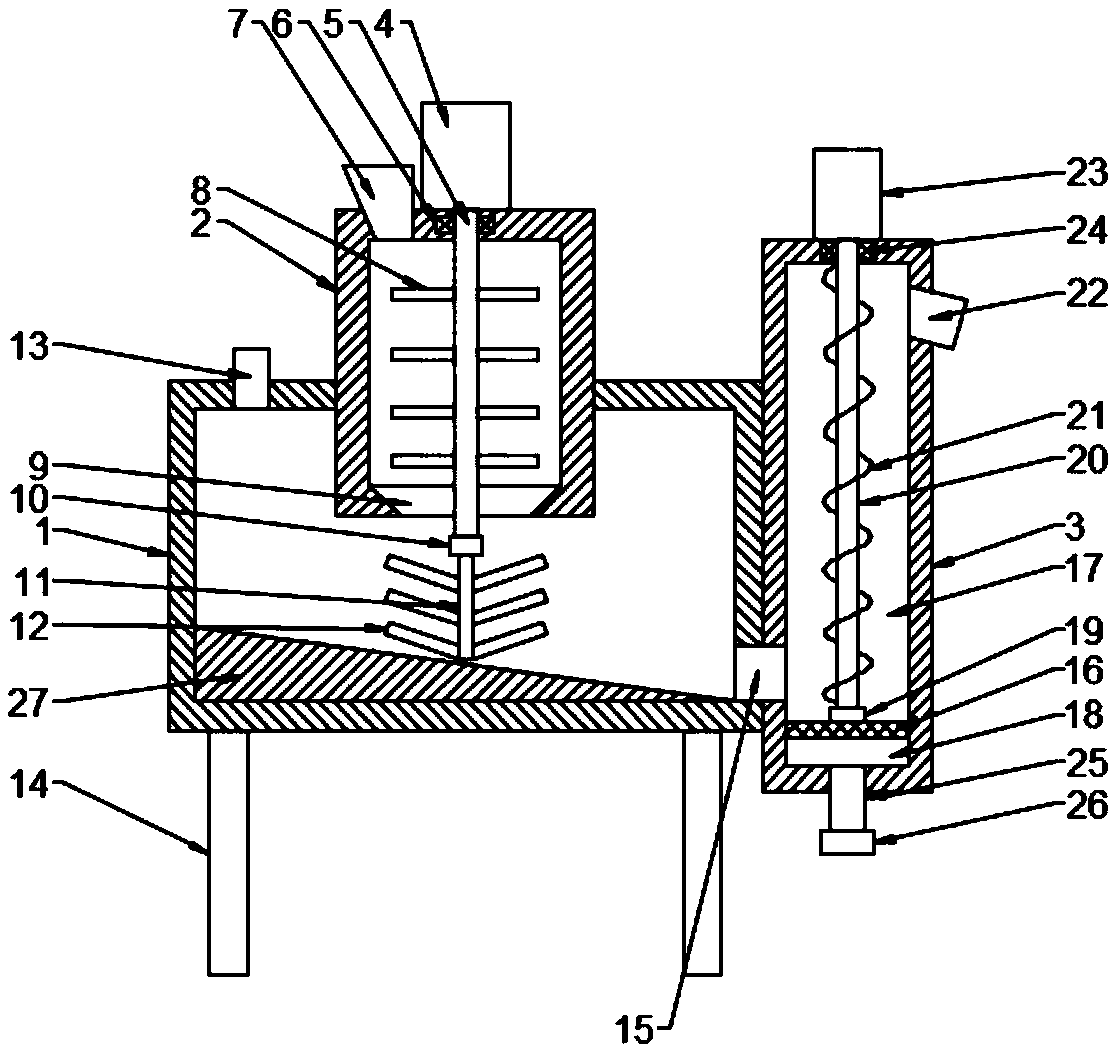

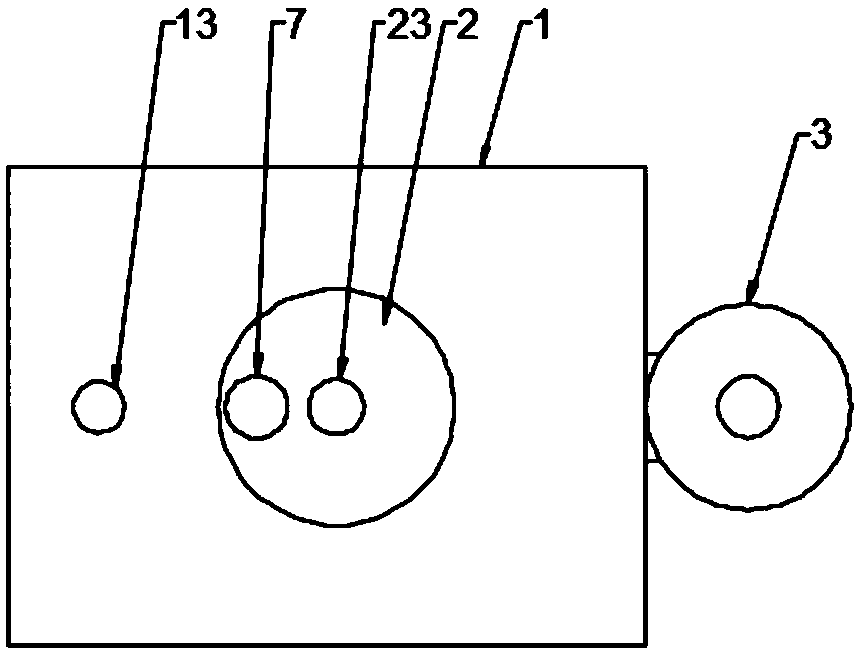

Agricultural machinery straw crushing device based on water-washing silt removal technology

InactiveCN108617291AImprove cleanlinessImprove convenienceCuttersCleaning using liquidsAgricultural engineeringMachining time

The invention discloses an agricultural machinery straw crushing device based on a water-washing silt removal technology. The agricultural machinery straw crushing device comprises a cleaning box, a crushing box and a separating box, wherein the top end of the cleaning box is embedded with the crushing box; the bottom end of the crushing box is provided with a communicating hole; the center of thetop end surface of the crushing box is provided with a first motor; the inner cavity of the crushing box is provided with a crushing shaft; the bottom end of the crushing shaft penetrates through thecommunicating hole and is fixedly connected with a stirring rod through a connecting sleeve; the right side end of the cleaning box is fixedly connected with the separating box; the bottom part of the inner cavity of the separating box is provided with a separating net which separates the inner cavity of the separating box into a discharge chamber and a drainage chamber; and the interior of the discharge chamber is provided with a rotating shaft which is sleeved by an auger. According to the invention, through embedding of the crushing box on the cleaning box, two processes of crushing and cleaning are integrated together, and convenience in processing is greatly improved, so non-processing time is reduced, and processing efficiency is improved; and water stirred in the cleaning box is utilized to completely clean silts in crushed straw, and cleanness of straw can be effectively guaranteed, so the difficulty of subsequent processing is reduced, and the quality of processing is improved.

Owner:汪培杰

A Control Method for Realizing Efficient Dry Running in Numerical Control System

ActiveCN101937206BGuaranteed uptimeReduce non-processing timeNumerical controlLaser processingEngineering

The invention discloses a control method for realizing high-efficiency dry running in a numerical control system. The control method is based on the surface following function of the height sensor in the numerical control system, realizes the compression of non-processing time, and makes laser processing more efficient under the premise of ensuring equipment safety. efficient. The control method includes setting a predetermined retraction height H and a predetermined distance D before the end of the dry run, which can be completed by combining the three actions in the existing laser processing into one action, that is, the processing head directly runs in dry mode. The speed quickly moves to the next processing position. During this process, the processing head first retracts to the predetermined height H at the highest speed. Before reaching the next processing point (distance D from the next processing point), it starts to descend. , which reduces the non-processing time of the equipment and greatly improves the efficiency of the equipment.

Owner:HUAGONG TECHNOLOGY CO LTD

Rotary sheet feeding manipulator

PendingCN108818513AEasy to moveShorten the timeProgramme-controlled manipulatorGripping headsManipulatorMachining time

The invention discloses a rotary sheet feeding manipulator. The rotary sheet feeding manipulator comprises a base, a first rotary support, a transverse moving support and a grabbing device. A first rotary drive device is arranged on the base. The first rotary support is connected with an output shaft of the first rotary drive device. The transverse moving support is movably arranged on the first rotary support and connected with a transverse moving drive device arranged on the first rotary support. The grabbing device is pivotally arranged on the transverse moving support and connected with asecond rotary drive device arranged on the transverse moving support. The first rotary support and the transverse moving support can rotate relative to the base, and the grabbing device can also rotate relative to the transverse moving support, so that the grabbing device moves to a position in front of any glass support conveniently to perform sheet feeding operation; and in addition, the glass transfer time is short, the non-machining time is shortened, and the working efficiency is improved. Furthermore, the rotary sheet feeding manipulator is compact in structure, no large operating spaceneeds to be occupied, and the occupied area and the space required for work can be effectively reduced.

Owner:ZHONGSHAN DIWEI GLASS MACHINERY MFG CO LTD

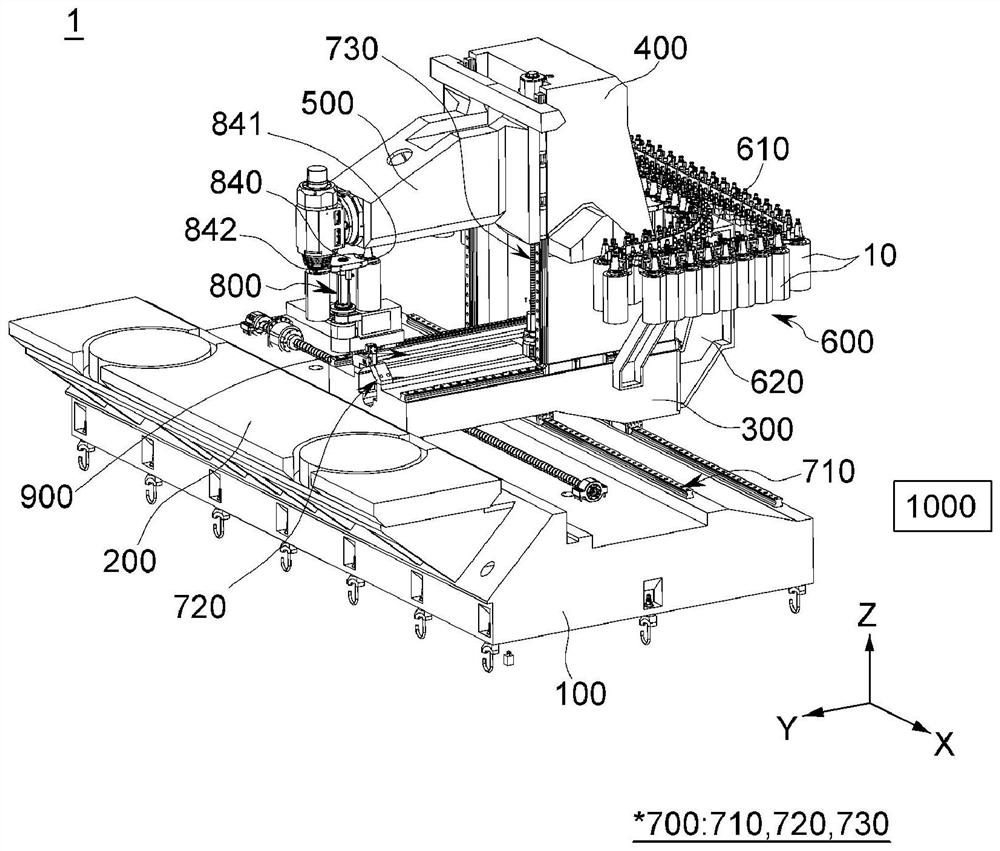

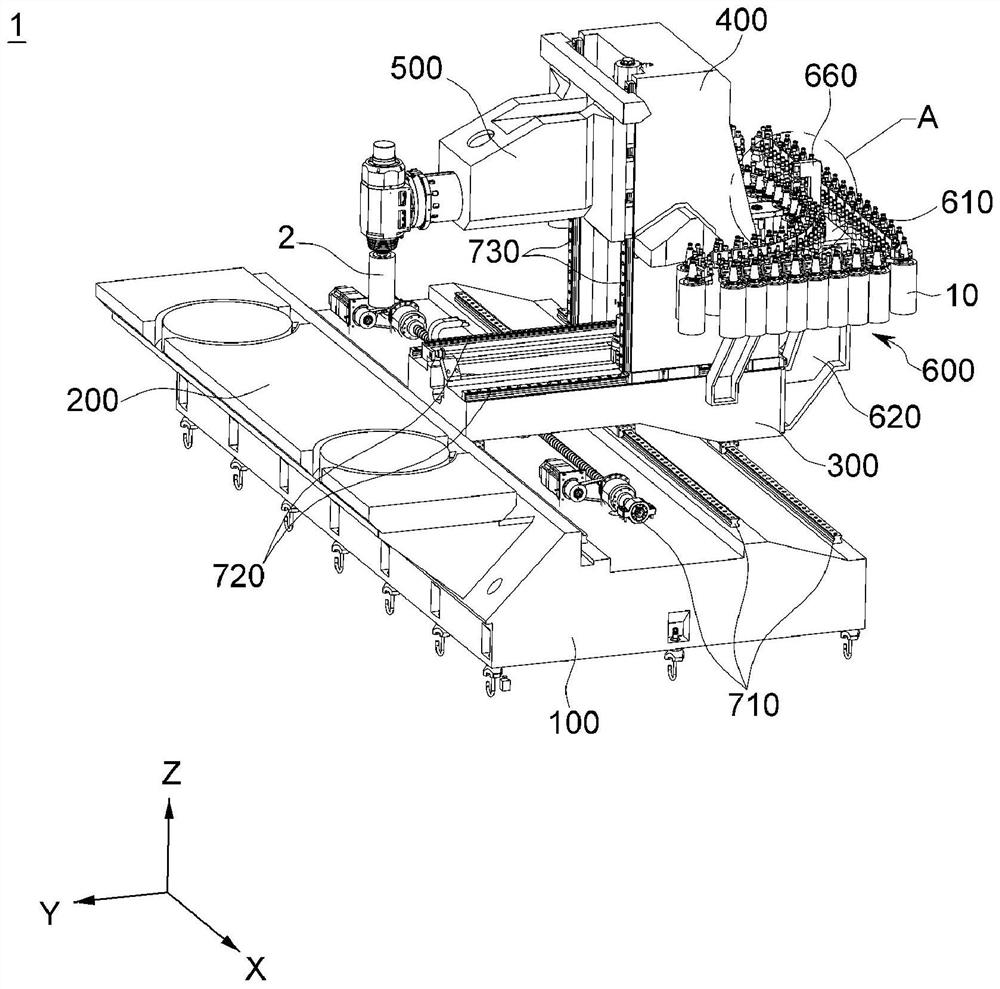

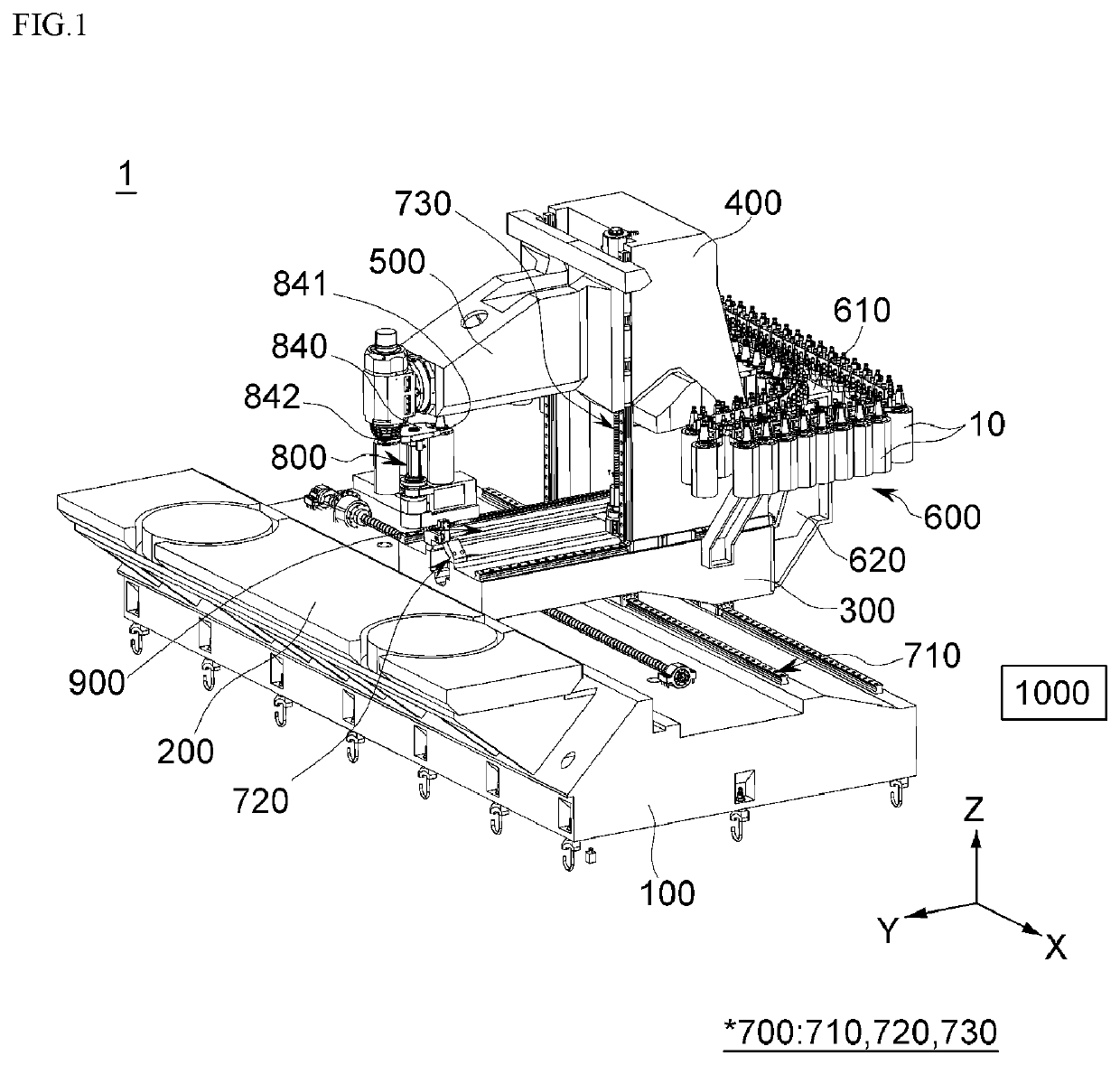

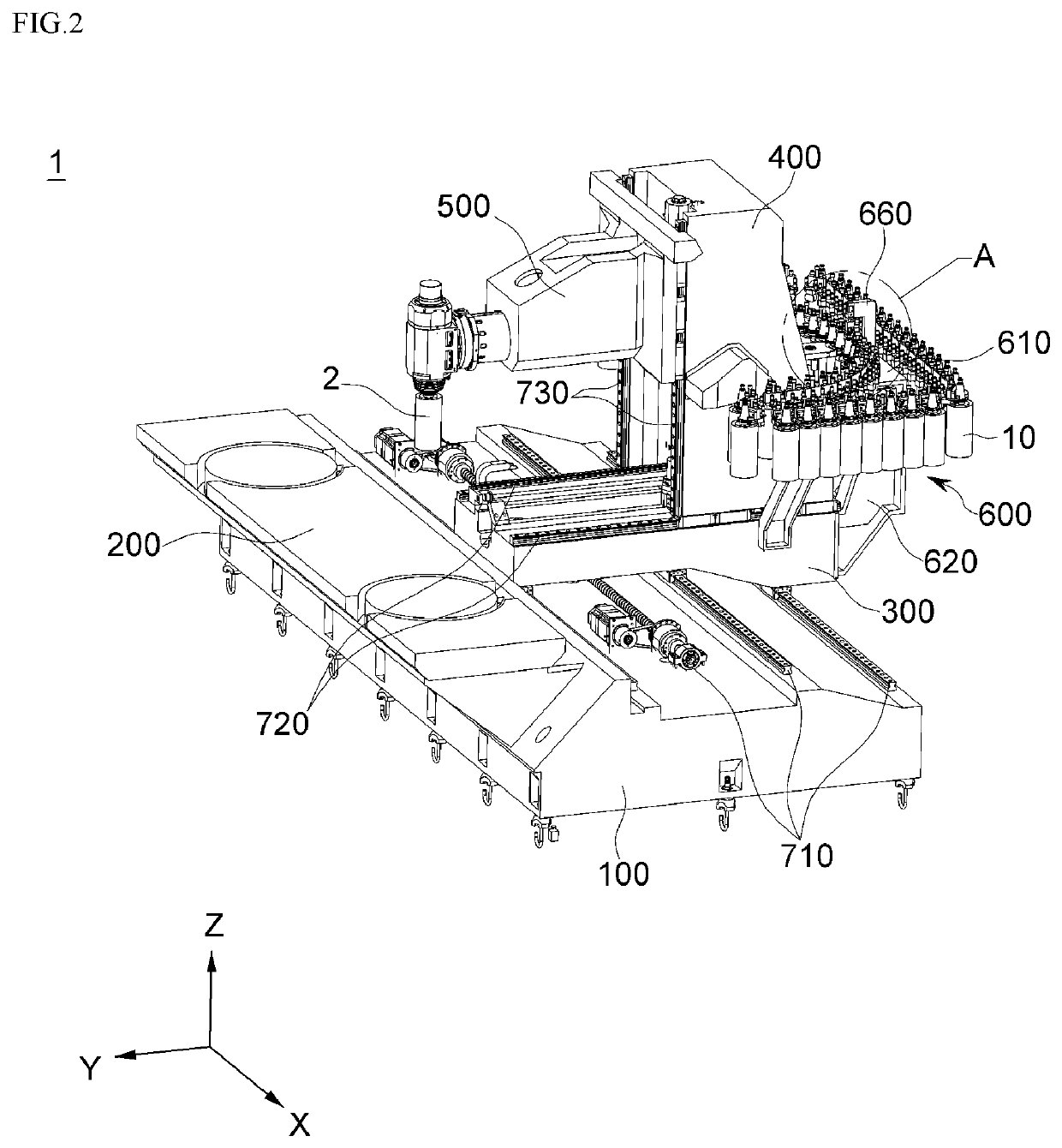

Tool magazine of machine tool

PendingUS20220105596A1Reduce tool change timeMaximize productivityLarge fixed membersPositioning apparatusPinch gripMachine tool

The present disclosure relates to a tool magazine of a machine tool such as a moving column-type machining center, in which a magazine unit is installed on a saddle, a tool accommodated in a gripper part of the magazine unit is loaded or unloaded in a direction perpendicular to a tool axis, and a gripping part of a change arm directly grips a flange portion of the tool at the time of changing the tools by means of a tool changing part movably installed on the saddle and a tool changing part transfer part configured to move the tool changing part independently of a column, thereby reducing tool change time, improving productivity, minimizing a collision or mechanical interference, and improving stability and reliability in the medium-sized or large-sized machine tool having a length in a width direction.

Owner:DN SOLUTIONS CO LTD

Transpiration disinfection technology based textile disinfection and drying device

InactiveCN108532181AMeet long-time processing needsReduce non-processing timeLiquid/gas/vapor removal by gas jetsChemicalsDisinfectantEngineering

The invention discloses a transpiration disinfection technology based textile disinfection and drying device which comprises a casing; a feeding hole is formed in the middle part of the right side endof the casing; a discharge hole is formed in the middle part of the left side end of the casing; partition plates are symmetrically arranged in an inner cavity of the casing up and down and divide the inner cavity of the casing into a drying cavity and a disinfection cavity; the top wall of the disinfection cavity is connected with a fog discharge pipe in a penetrating manner; the bottom of the disinfection cavity is provided with an atomization device matched with the feeding hole; the top wall of the drying cavity is connected with an exhaust pipe in the penetrating manner; and the bottom of the drying cavity is provided with an air injection device matched with the discharge hole. By adopting the transpiration disinfection technology based textile disinfection and drying device provided by the invention, smoking disinfection is performed on a textile with a foggy disinfectant sprayed by the atomization device in the disinfection cavity, so that the textile can be disinfected all around without four-corner disinfection; and the textile after being disinfected enters the drying cavity and is subjected to drying treatment under the effect of high-temperature gas sprayed by the airinjection device, the whole processing process is strong in continuity, sequential loading meets the long-time processing demand, the non-processing time is lowered, and the production efficiency isimproved.

Owner:绍兴柯桥永豪纺织有限公司

Slagging dedusting equipment for boiler in power plant

InactiveCN110195873AImprove work efficiencyReduce non-processing timeHollow article cleaningSolid removalPower stationWater flow

The invention discloses slagging dedusting equipment for a boiler in a power plant. The equipment comprises a boiler body, a sitting plate is installed at the bottom of the boiler body, and multiple supporting legs are evenly installed at the bottom of the sitting plate; a slagging pipe penetrates through the bottom of the boiler body and is connected to the bottom of the boiler body, multiple columns are evenly installed at the top of the sitting plate, and a top plate is fixedly installed at the tops of all the columns and provided with a feeding mechanism; the feeding mechanism is providedwith a retractable mechanism, and a brushing mechanism matched with the boiler body is installed on the retractable mechanism. According to the slagging dedusting equipment, the whole process of cleaning the side wall of an inner cavity of the boiler body is automatically completed, the working efficiency is greatly improved, a worker does not need to enter the boiler body for cleaning, cleaning can be completed when the boiler body keeps a high temperature state, the non-processing time is greatly shortened, and the processing efficiency is improved; in cooperation with a spray-cleaning device, the high-speed water flow is sprayed out and used for washing the side wall of the boiler body, and in assistance with a ball brush, the effect of cleaning the inner cavity of the boiler body is greatly improved.

Owner:黄明佳

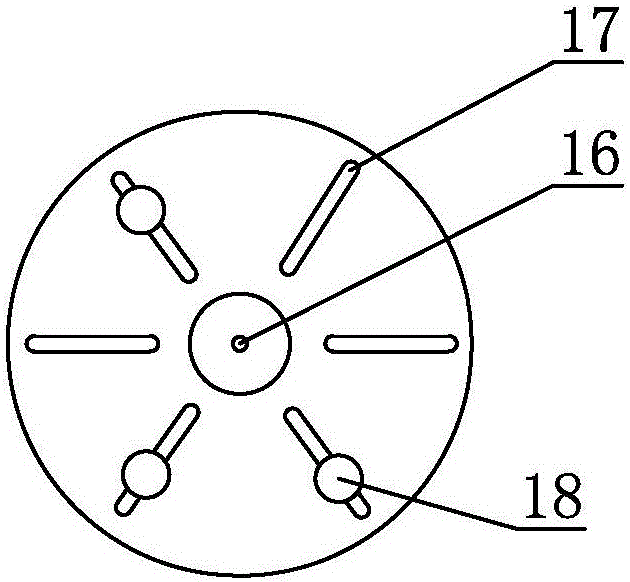

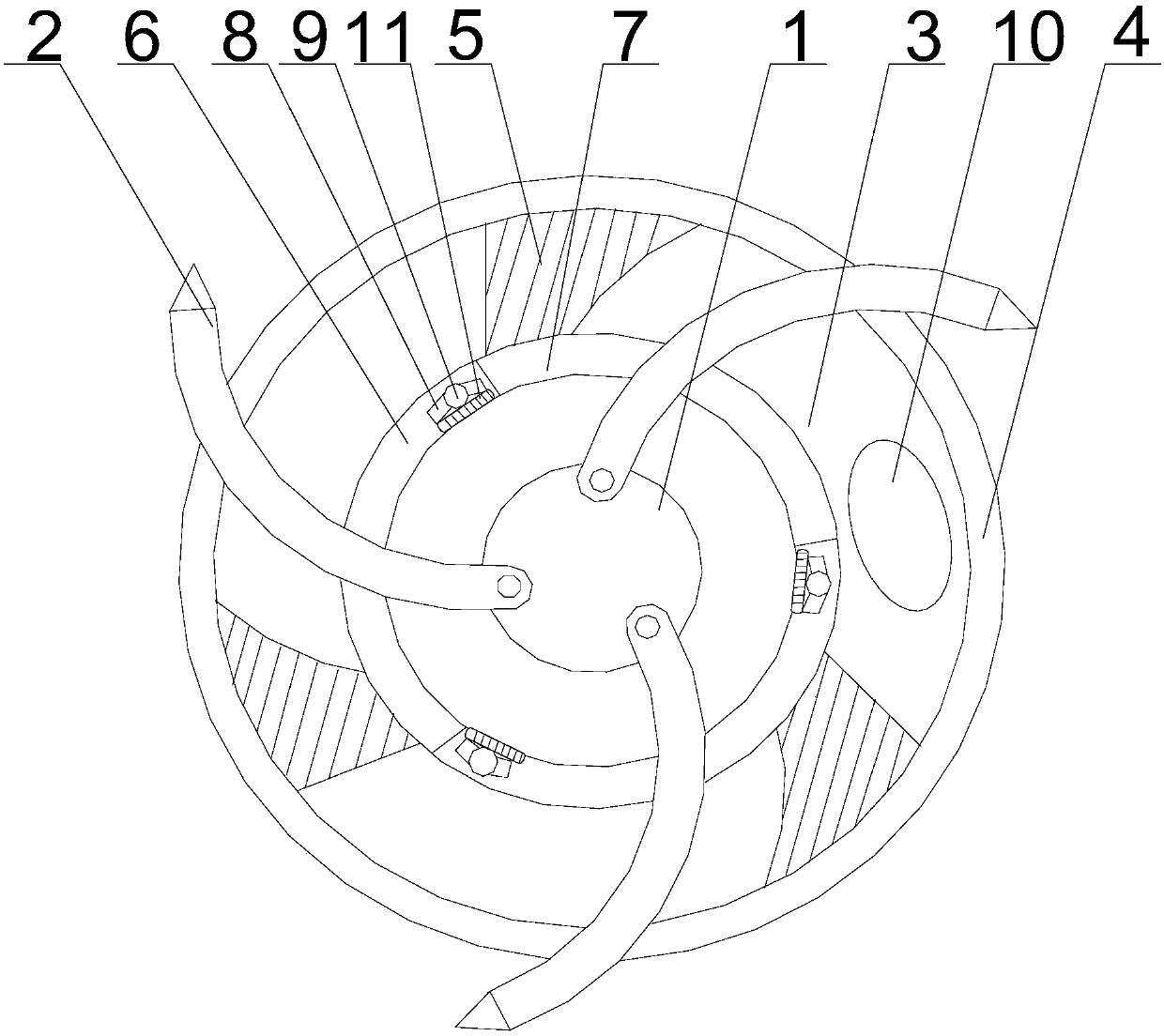

Laser cutting device for saw web base body

ActiveCN105965166ANo displacementImprove pass rateMetal sawing tool makingWelding/cutting auxillary devicesEngineeringLaser cutting

The invention provides a laser cutting device for a saw web base body to solve the technical problems that an existing laser cutting device for the saw web base body is relatively low in product percent of pass and production efficiency. The laser cutting device is provided with a first base; a first workbench and a laser cutting machine are arranged on the first base; fixed tools are arranged on the first workbench and provided with mandrel holes correspondingly; strip-shaped holes are evenly formed in the fixed tools in the circumferential direction correspondingly; and magnetic posts are arranged on the strip-shaped holes. The laser cutting device for the saw web base body can be widely used for manufacturing of the saw web base body.

Owner:SHANDONG HEIXUANFENG SAW IND

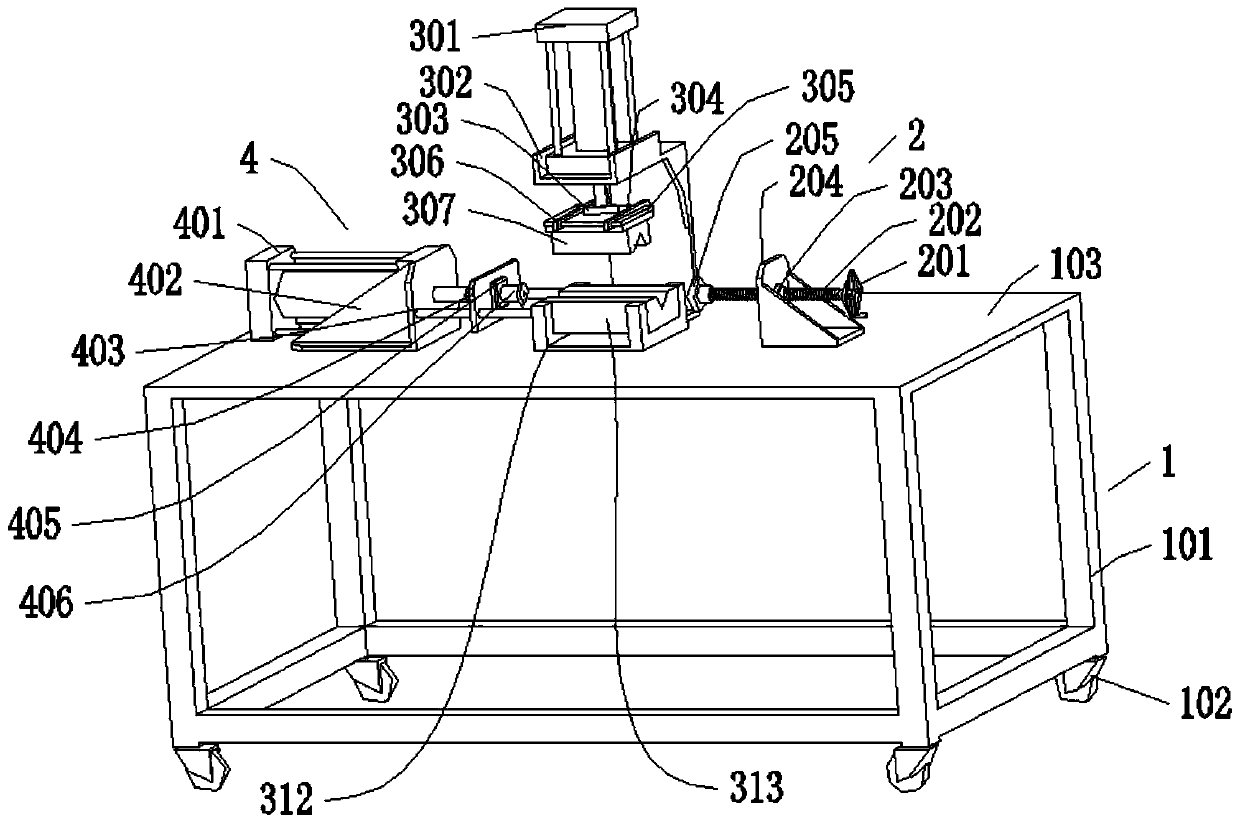

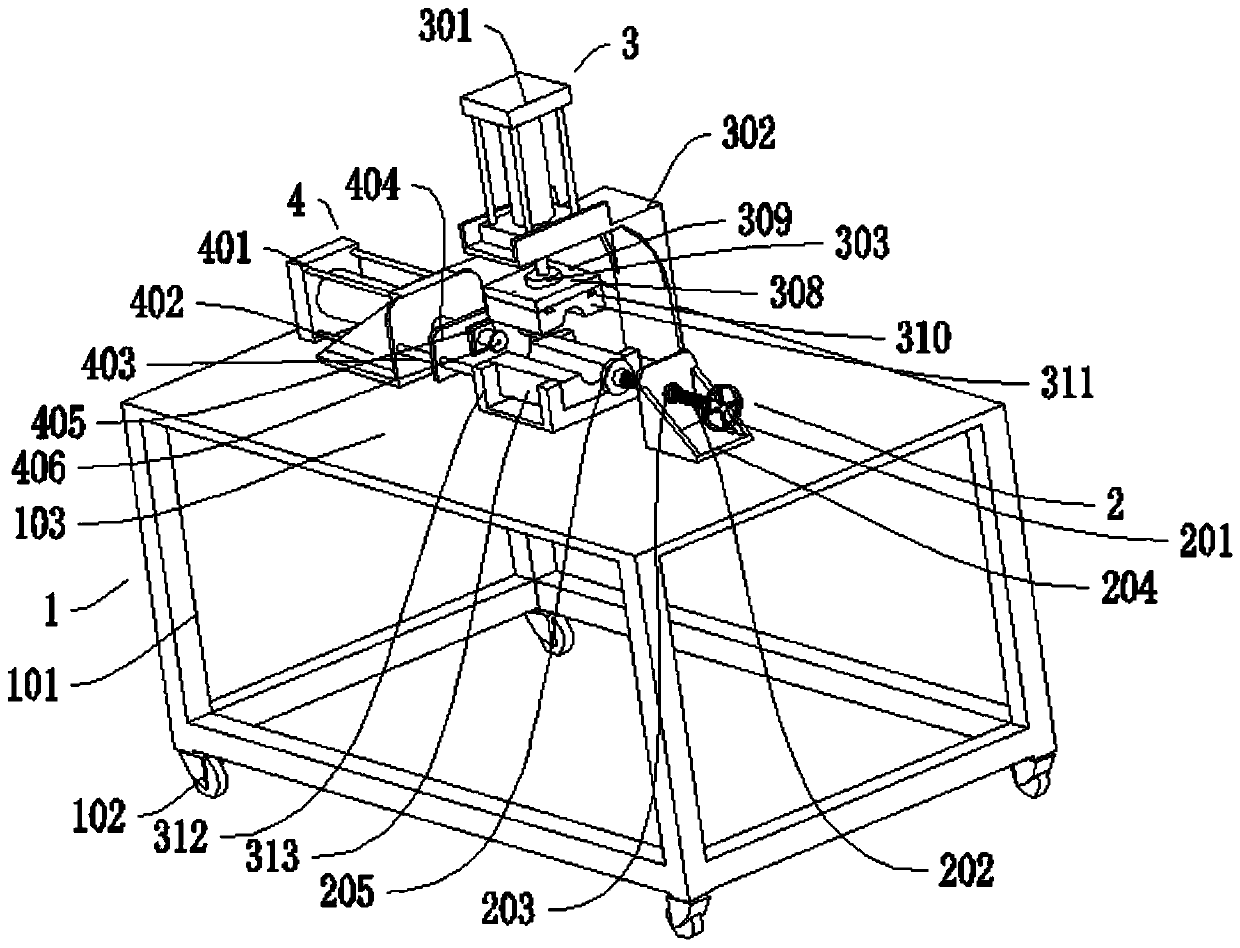

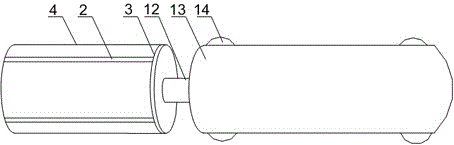

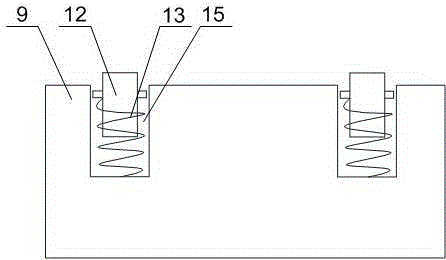

Pipe compression and shrinkage device for condenser manufacturing and use method of device

PendingCN111001718AFast clampingQuick disassembly and replacementMetal-working feeding devicesHeat exchange apparatusStructural engineeringMachining process

The invention discloses a pipe compression and shrinkage device for condenser manufacturing and a use method of the device. The device comprises a fixing mechanism, a jacking mechanism, a pipe shrinkage mechanism and a clamping mechanism; the jacking mechanism is mounted at the upper end of the fixing mechanism and is used for jacking one end of a to-be-machined copper pipe to prevent the to-be-machined copper pipe from sliding in a machining process; the pipe shrinkage mechanism is used for providing power for the to-be-machined copper pipe; the clamping mechanism is used for clamping the to-be-machined copper pipe so that the pipe shrinkage mechanism can act conveniently; the clamping mechanism, the pipe shrinkage mechanism and the jacking mechanism are all connected to the fixing mechanism; and the clamping mechanism is connected to the pipe shrinkage mechanism. According to the pipe compression and shrinkage device for condenser manufacturing and the use method of the device of the invention, a copper pipe for a condenser can be rapidly clamped and fixed through the clamping mechanism; the upper clamping die and lower clamping die of the clamping mechanism can be rapidly disassembled, assembled and replaced, so that copper pipes with different diameters can be machined; and therefore, the waste of non-machining time is reduced, and machining efficiency and the practicability of the device are improved.

Owner:东莞市泰丰空调制冷设备有限公司

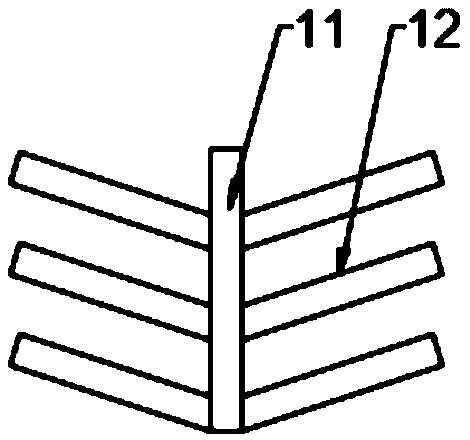

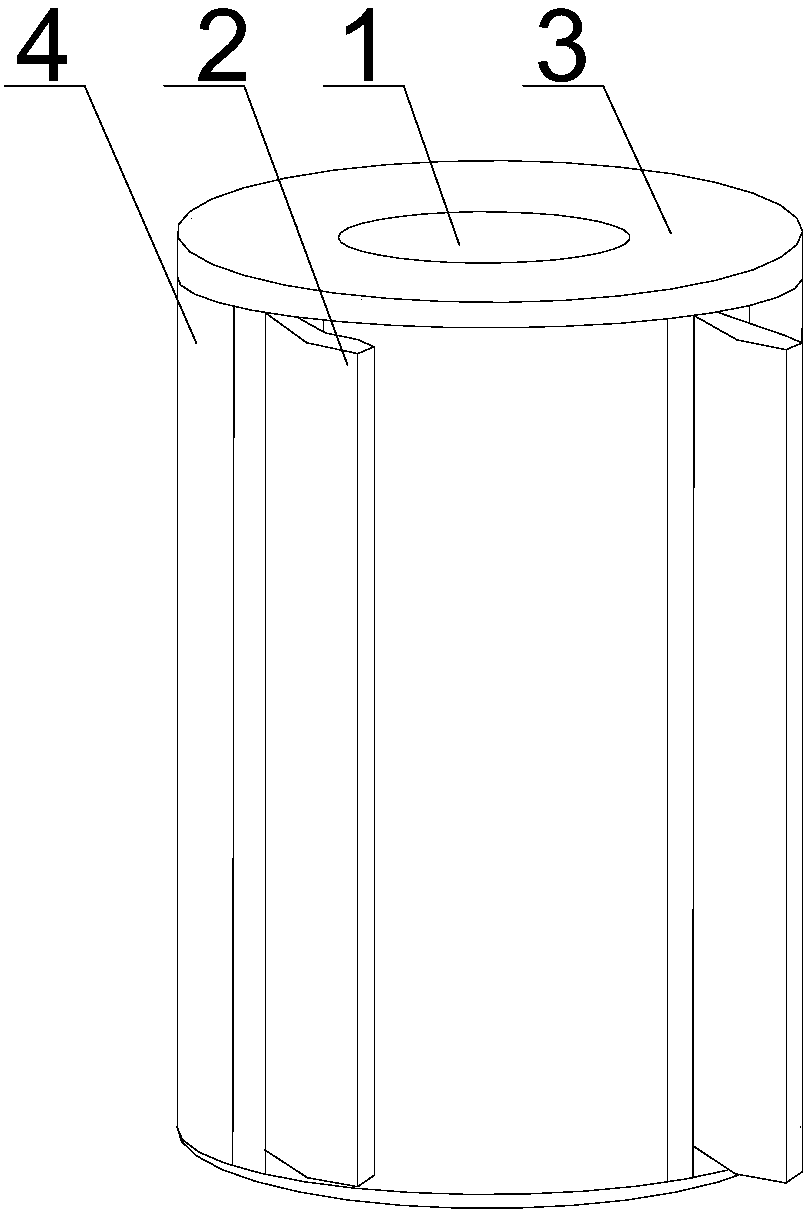

Internal burr removal mechanism for straight seam steel pipe

ActiveCN103920935BEasy to useIncrease or decrease the clearing rangeStructural engineeringDrive motor

The invention discloses a removing mechanism for burrs in straight welded steel pipes. The removing mechanism comprises a support barrel and blade angle adjusting mechanisms. An end of the support barrel is connected with an external core rod, a plurality of rollers are arranged on the support barrel, a driving motor is arranged in the support barrel, an output end of the driving motor is connected with a cutter, the cutter comprises a center shaft, a plurality of arc-shaped blades are arranged on the center shaft, are hinged to the center shaft and are annularly arrayed and distributed on the outer wall of the center shaft, fixing plates are mounted at the upper end and the lower end of the center shaft, the arc-shaped blades are arranged between the two fixing plates, and the blade angle adjusting mechanisms are arranged among the arc-shaped blades. The removing mechanism has the advantages that the blade angle adjusting mechanisms are flexible in connection mode and simple in structure, accordingly, included angles among the arc-shaped blades and the center shaft can be quickly adjusted while the arc-shaped blades are assuredly firmly fixed, the abnormal machining time can be shortened, the efficiency can be improved when welding flux residues and protrusions on the inner walls of the steel pipes are cleaned, and the service performance of the steel pipes can be guaranteed.

Owner:JIANGSU LIWEI SHEARING & BENDING MACHINE

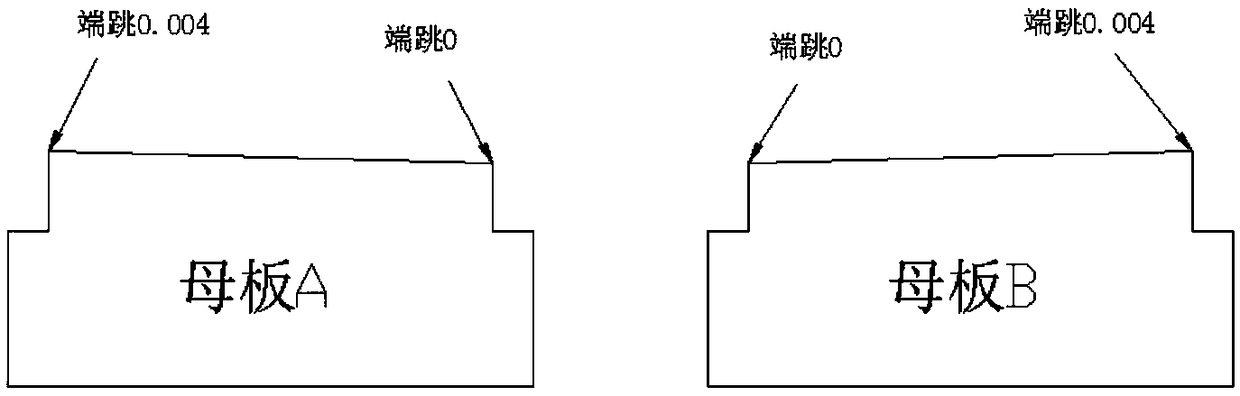

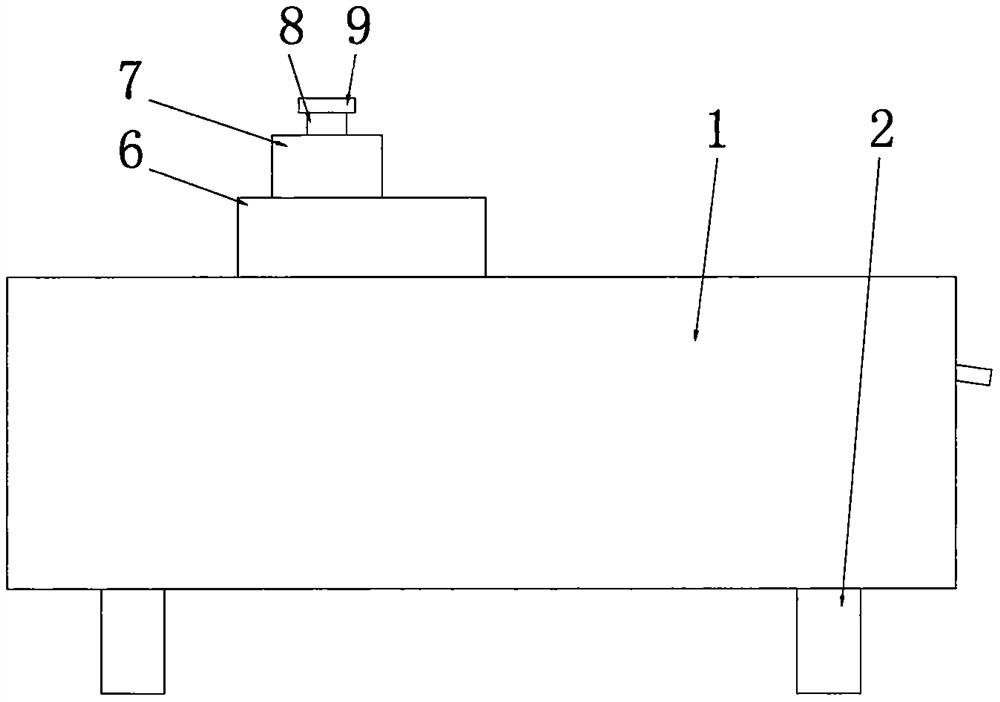

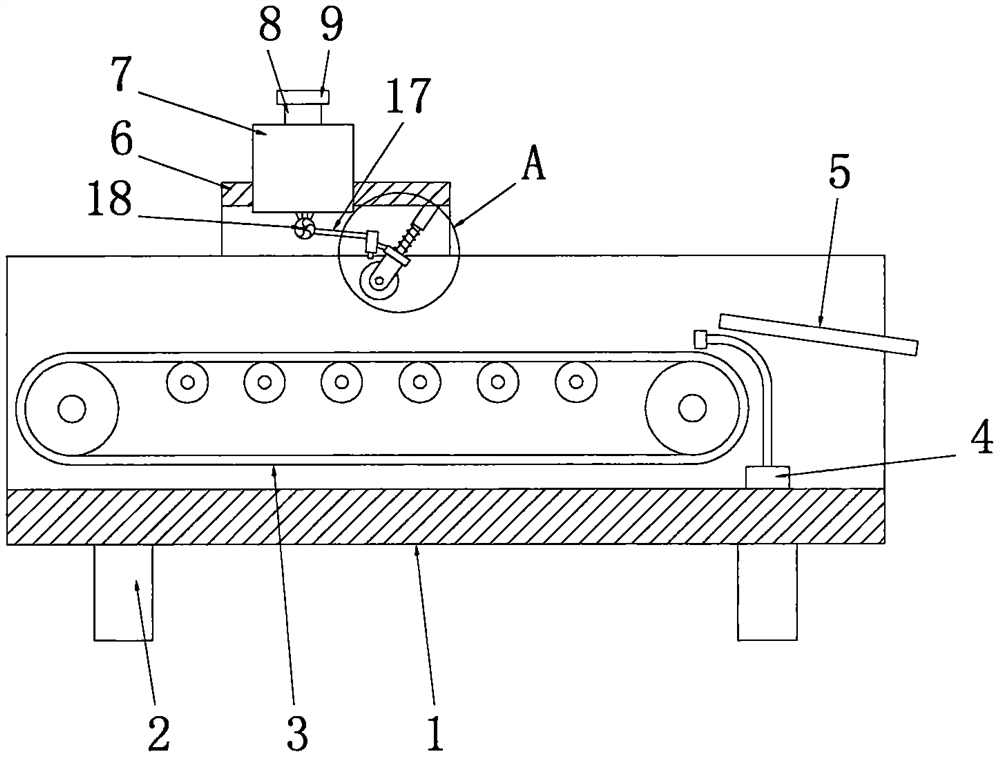

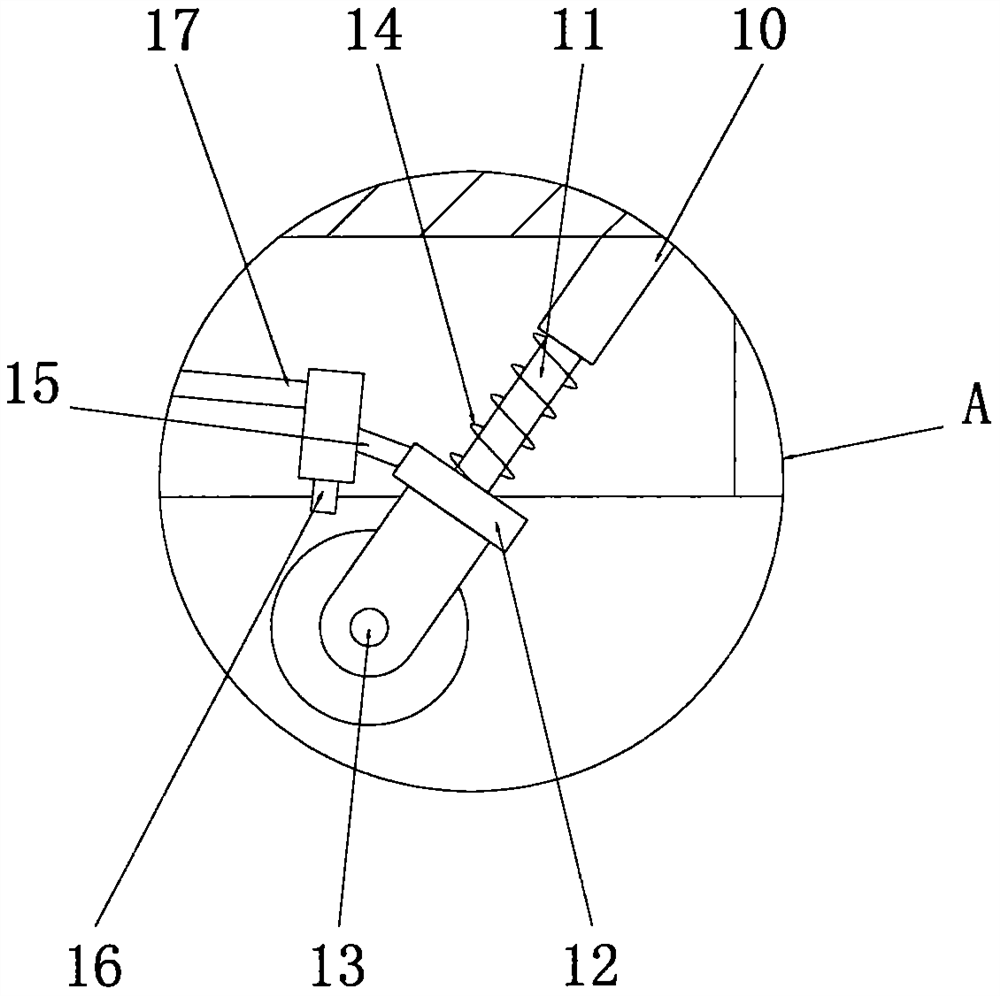

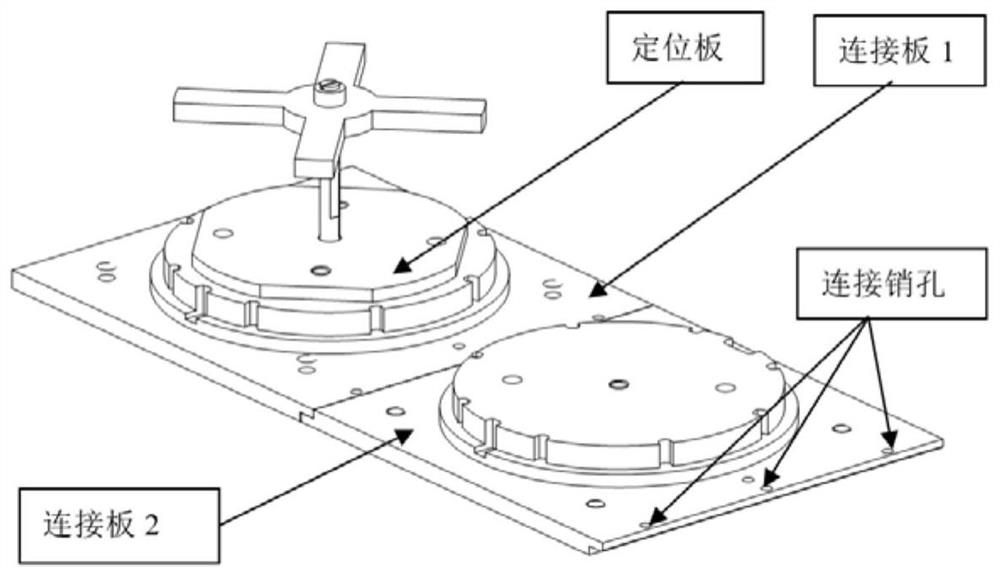

Quick replacement method and replacement error adjustment method for impeller part

InactiveCN108907769AImprove clamping alignmentImprove efficiencyAutomatic control devicesFeeding apparatusImpellerBoard structure

The invention discloses a quick replacement method and a replacement error adjustment method for an impeller part. In the quick replacement method, a universal sub-board structure is adopted and connected with different tools to form a combination for clamping different parts, the combination as a carrier is first subjected to part clamping and alignment outside a machine, and then all-process transfer of the parts from the outside of the machine to a machine tool is achieved through quick replacement of a sub-board and a mother board. The replacement error adjustment method compensates for aninfluence value of the end face runout on the circumferential runout by adjusting the circumferential runout of a single mother board. According to the quick replacement method and the replacement error adjustment method for the impeller part, high-precision, fast and automatic clamping positioning of the impeller part can be achieved, the replacement efficiency is improved, and the device utilization rate is improved.

Owner:BEIJING POWER MACHINERY INST

Electronic commerce product logistics sending and packaging auxiliary system

PendingCN112141459AReduce non-processing timeImprove the working efficiency of gluingLabelling machinesManufacturing engineeringMechanical engineering

The invention discloses an electronic commerce product logistics sending and packaging auxiliary system. The electronic commerce product logistics sending and packaging auxiliary system comprises a rack, a conveying mechanism is arranged in an inner cavity of the rack, a seal mechanism matched with the conveying mechanism is arranged on the right side of the bottom wall of the inner cavity of therack, and a discharging plate matched with the conveying mechanism and the seal mechanism is arranged in the inner cavity of the rack; a gluing frame is arranged on the left side of the top end of therack in a sleeving manner, the top wall of an inner cavity of the gluing frame is fixedly connected with a supporting cylinder, a telescopic sliding rod is in sliding connection in the supporting cylinder, one end, far away from the supporting cylinder, of the telescopic sliding rod is suspended and extends to the outside and is fixedly connected with a baffle, the outer side of the telescopic sliding rod is sleeved with a pre-tightening spring, and a gluing wheel is fixedly connected to the baffle. In the whole working device running process, the conveying mechanism conveys packages, the packages are sequentially fed into the gluing frame and the seal mechanism, the packages are subject to gluing work and seal marking work, in the whole working process, the packages are subject to gluingwork and seal marking work in the moving process, and the working efficiency is greatly improved.

Owner:WENZHOU UNIVERSITY

Small thin-wall shell batch production tooling

PendingCN112658722AReduce non-processing timeImprove processing efficiencyPositioning apparatusMetal-working holdersThin walledBatch production

The invention discloses a small thin-wall shell batch production tooling, which comprises a plurality of tooling units spliced in sequence, and each tooling unit comprises a connecting plate and a positioning plate; a boss is arranged on the connecting plate and is matched with a part seam allowance; the positioning plate is arranged on the connecting plate and used for positioning an inner cavity of a thin-wall shell; and splicing steps are arranged on the end faces of the two sides of each connecting plate, when the two connecting plates are spliced, the opposite splicing steps are in butt joint, and the two connecting plates are in butt joint to form a whole plate-shaped structure. The requirement for large-batch production of parts is met, and machining of multiple parts can be achieved through one-time clamping; and meanwhile, the tooling is used for quickly clamping and positioning, so that the non-machining time is saved, and the machining efficiency is improved.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

The loading and unloading device and application of the groove grinding machine for the outer ring of the automobile hub bearing unit

ActiveCN103769977BLess mechanical actionFast loading and unloadingGrinding machinesGrinding feedersManipulatorMachining time

The invention relates to a bearing grinder charging and discharging technology, in particular to a charging and discharging device for an outer circle groove grinder of an automobile hub bearing unit, and the application of the device. The charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit comprises a panel, wherein a charging channel, a transitional material channel, a discharging channel, a material separation oil cylinder, a main manipulator oil cylinder and an auxiliary manipulator oil cylinder are fixedly arranged on the panel; the charging channel is connected with the transitional material channel; a material separation manipulator is arranged on one side of the transitional material channel and is connected with the material separation oil cylinder; the main manipulator oil cylinder and the auxiliary manipulator oil cylinder are positioned at the tail end of the transitional material channel; a main manipulator is connected with the main manipulator oil cylinder; an auxiliary manipulator is connected with the auxiliary manipulator oil cylinder; a fan-shaped plate is arranged at a grinding station on the panel; the discharging channel is arranged at a position corresponding to the fan-shaped plate. Compared with a common charging and discharging device, the charging and discharging device for the outer circle groove grinder of the automobile hub bearing unit has the advantages that waiting time for discharging and charging is not needed; the device is less in mechanical motion, high in charging and discharging speed and high in stability, the non-machining time is greatly shortened, and the efficiency is improved.

Owner:PUYANG BEAIN CNC MACHINERY & EQUIP

Sheet metal stamping device

ActiveCN103909136BGuaranteed uptimeQuick contactMetal-working feeding devicesStripping-off devicesPunchingEngineering

Owner:江门市广润轨道交通实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com