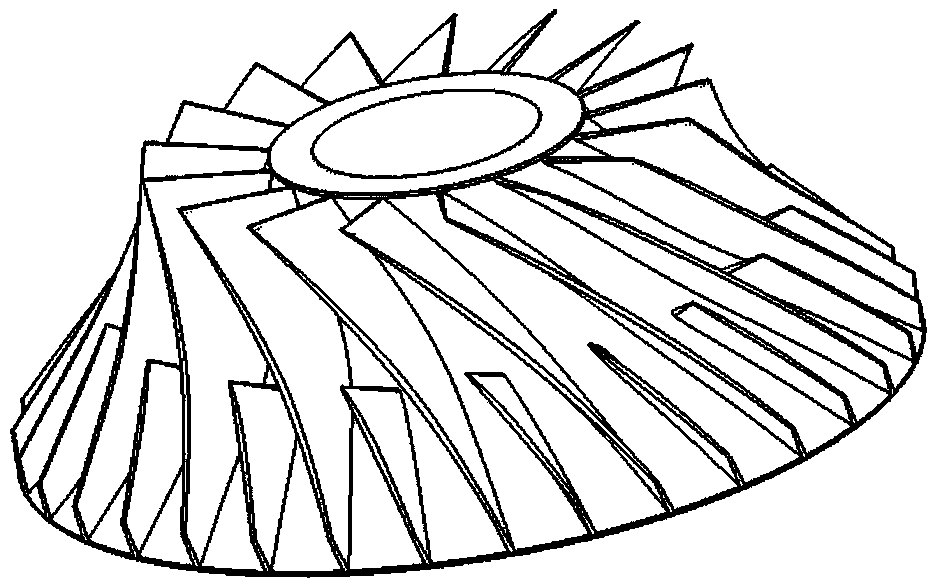

Quick replacement method and replacement error adjustment method for impeller part

A part and fast technology, applied in the field of tooling design, can solve the problems of low equipment utilization, long clamping alignment time, and long product manufacturing cycle, so as to improve clamping alignment and changing efficiency, and ensure repeatability. Clamping accuracy and the effect of shortening non-machining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and examples.

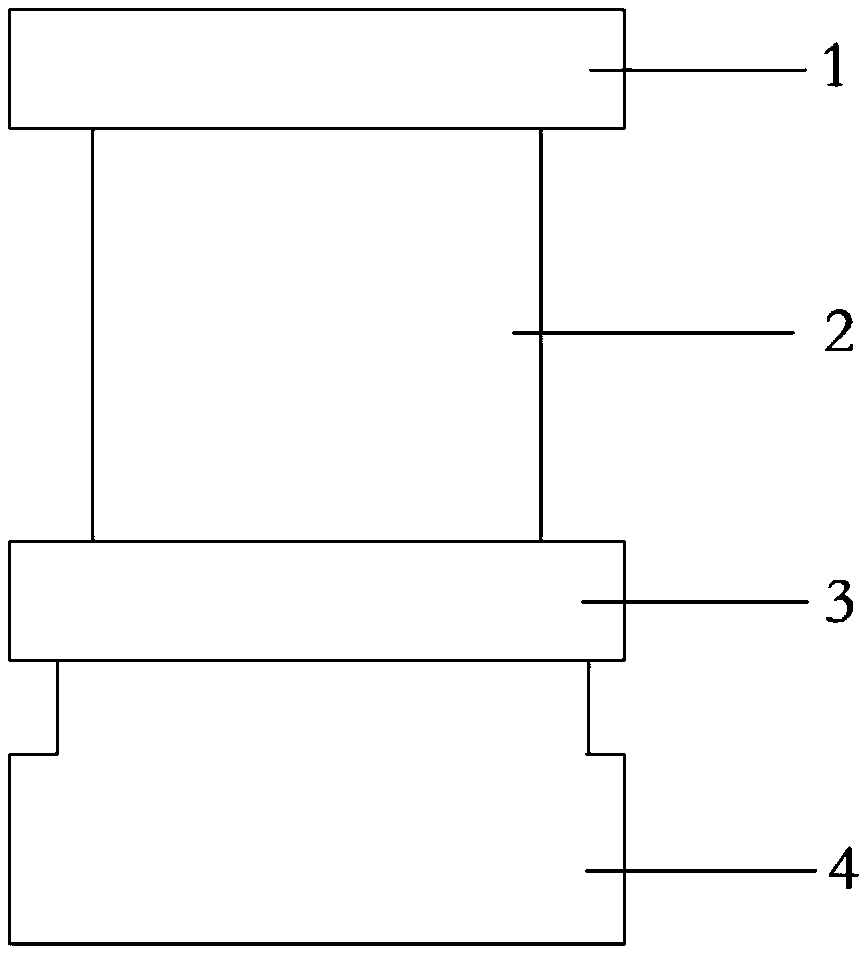

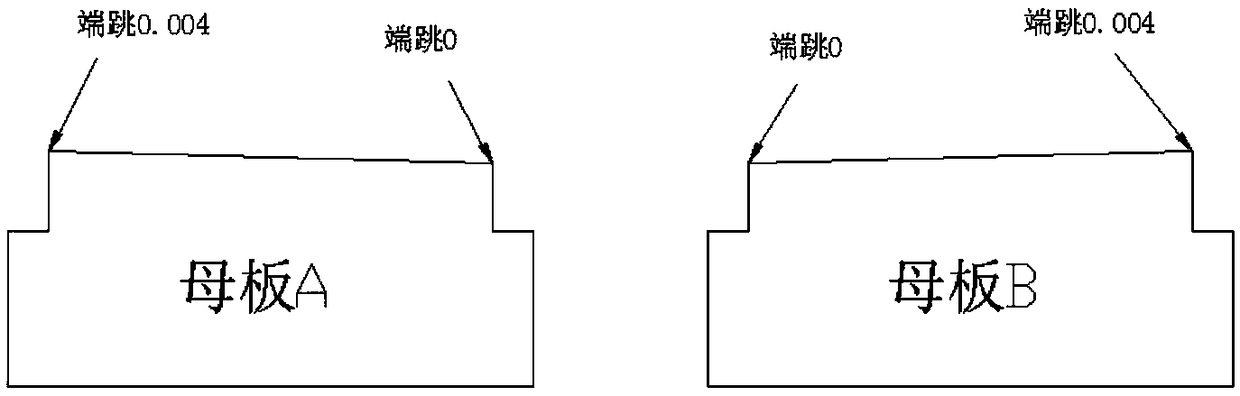

[0021] The invention provides a method for quick replacement of impeller parts and adjustment of replacement errors, as shown in the attached figure 2 As shown, the device used for quick replacement has two motherboards 4 with identical structures, a daughter board 3 and a set of tooling 2, wherein one motherboard 4 is arranged outside the machine, and the other motherboard 4 is arranged on the machine tool;

[0022] The part 1 is clamped by the tooling 2, and the sub-board 3 is connected with the tooling to form a part clamping assembly. The assembly is used as a carrier to perform the part clamping and alignment on the motherboard 4 outside the machine, and then the parts together with the sub-board 3. Send it directly to the motherboard on the machine tool for installation, realizing the whole process flow of parts from outside the machine to the machi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com