Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141results about How to "Fast clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

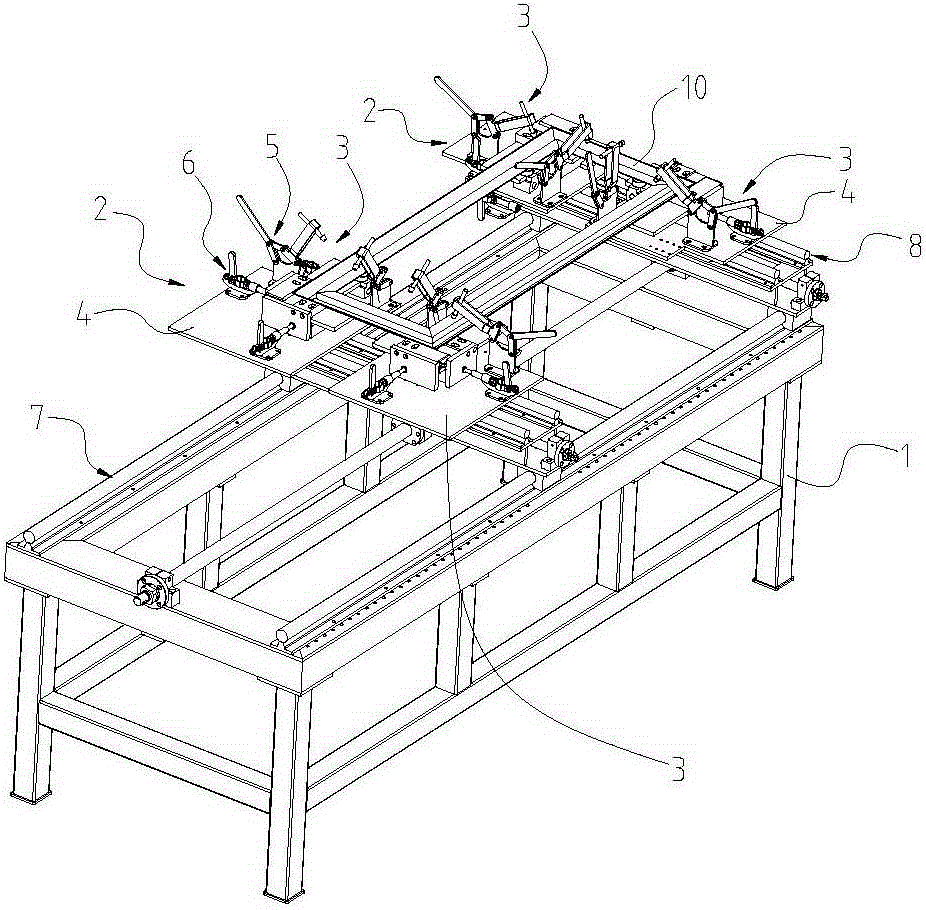

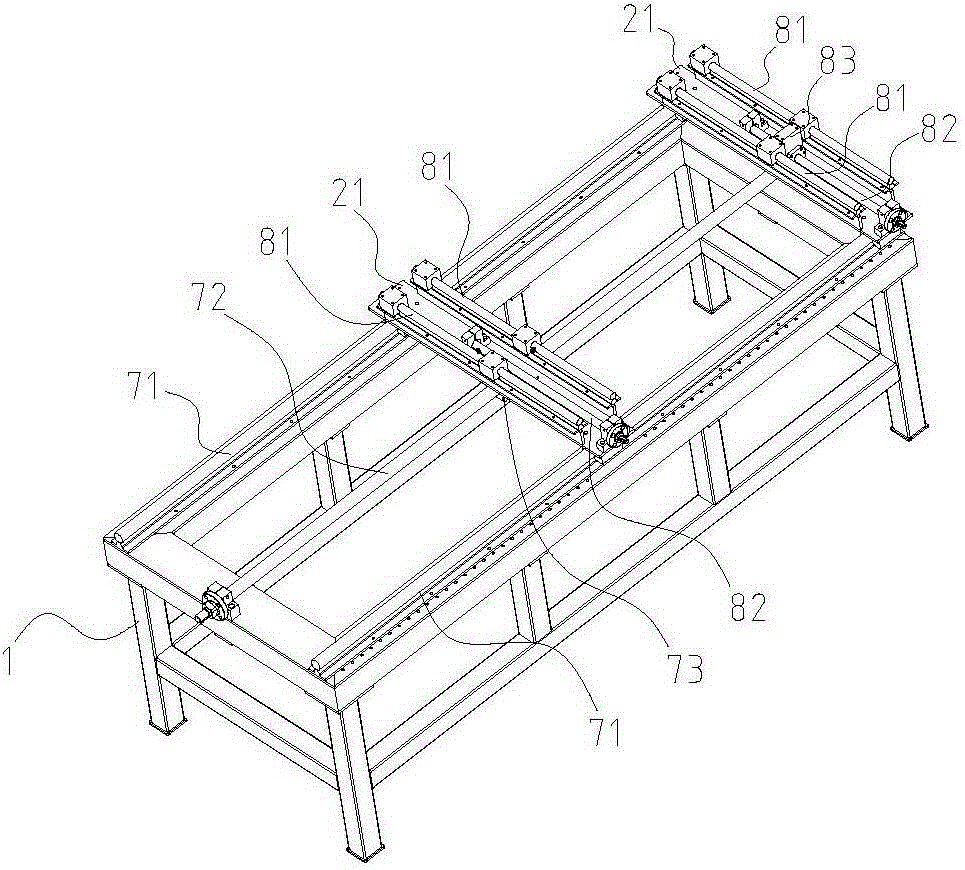

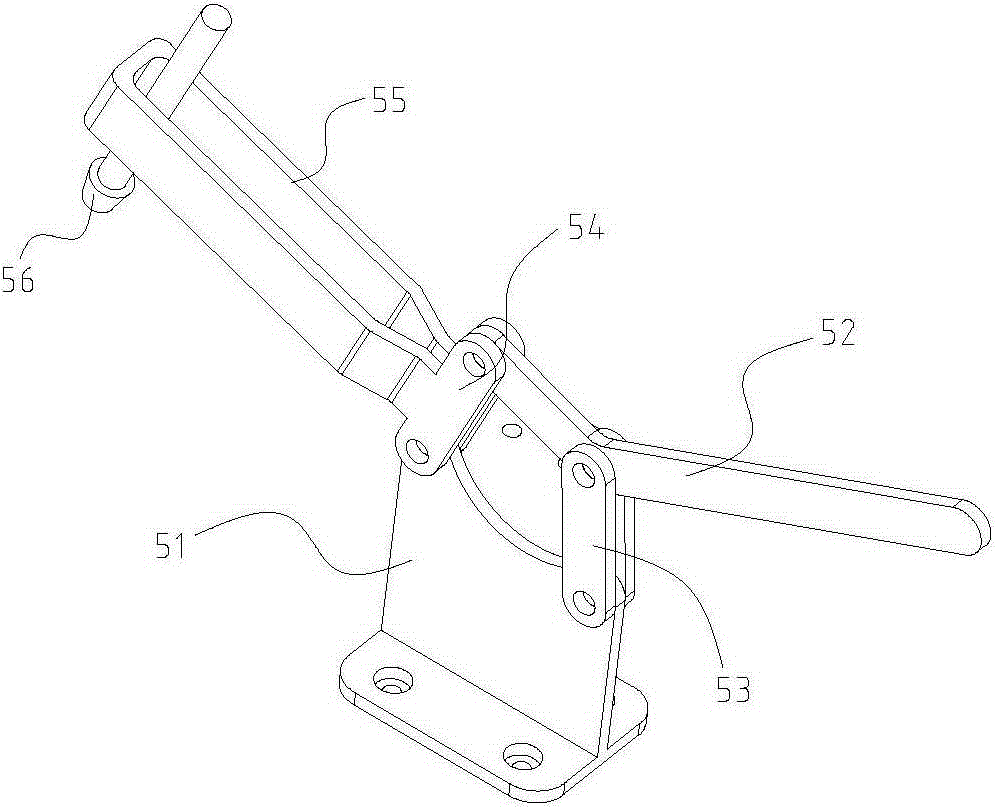

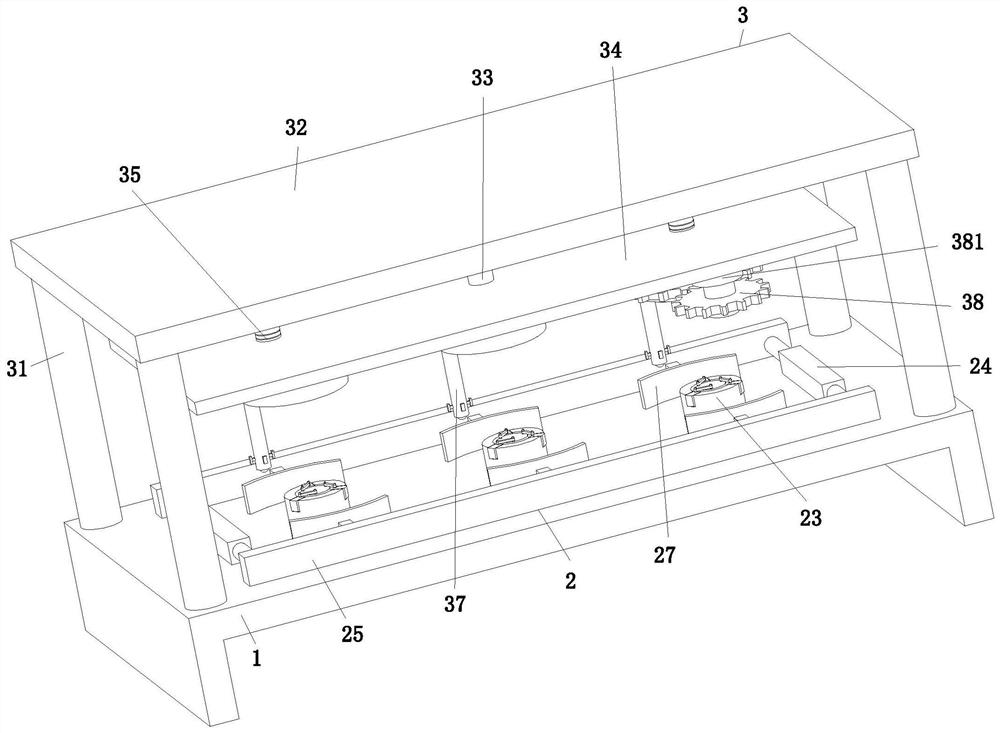

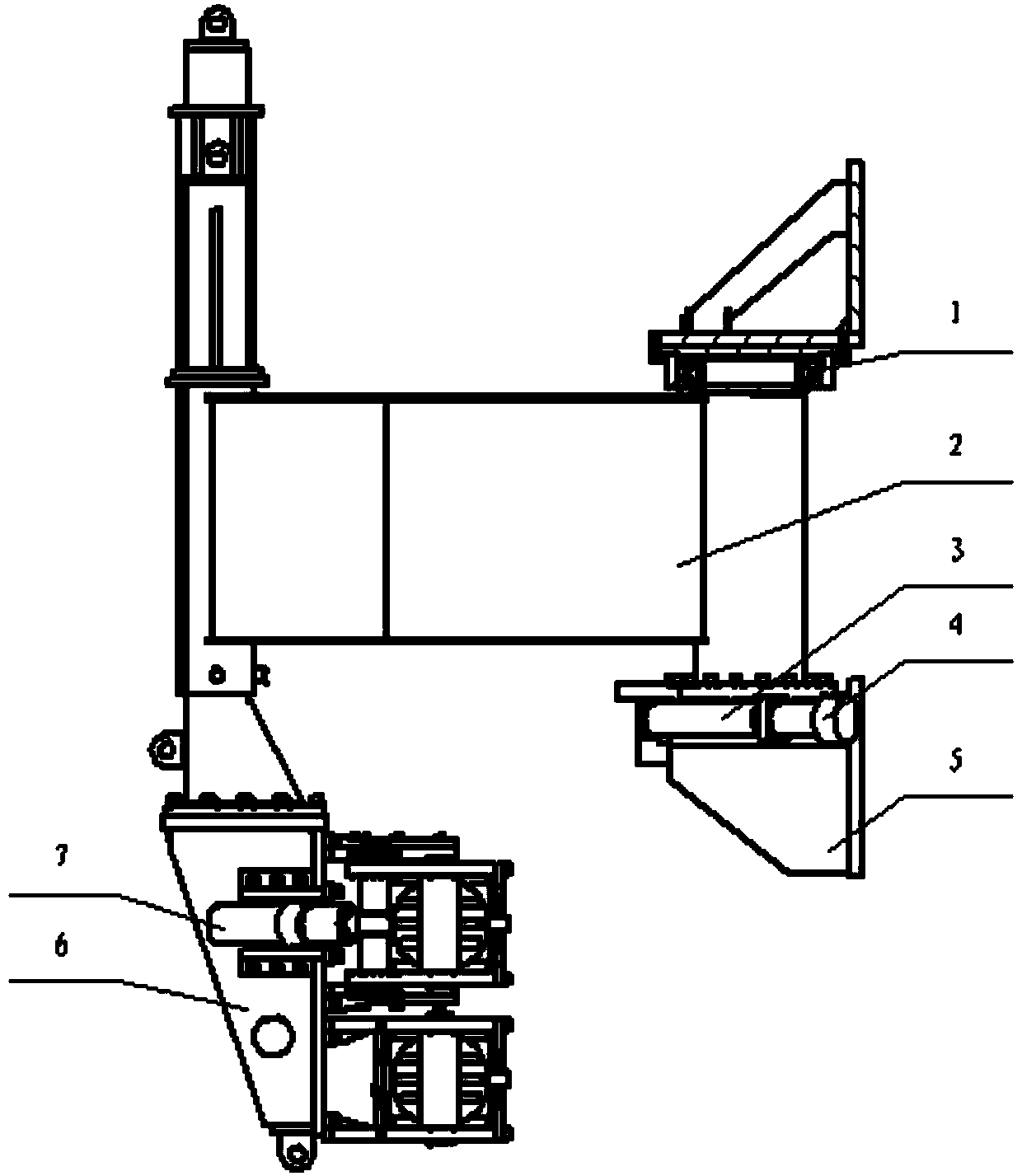

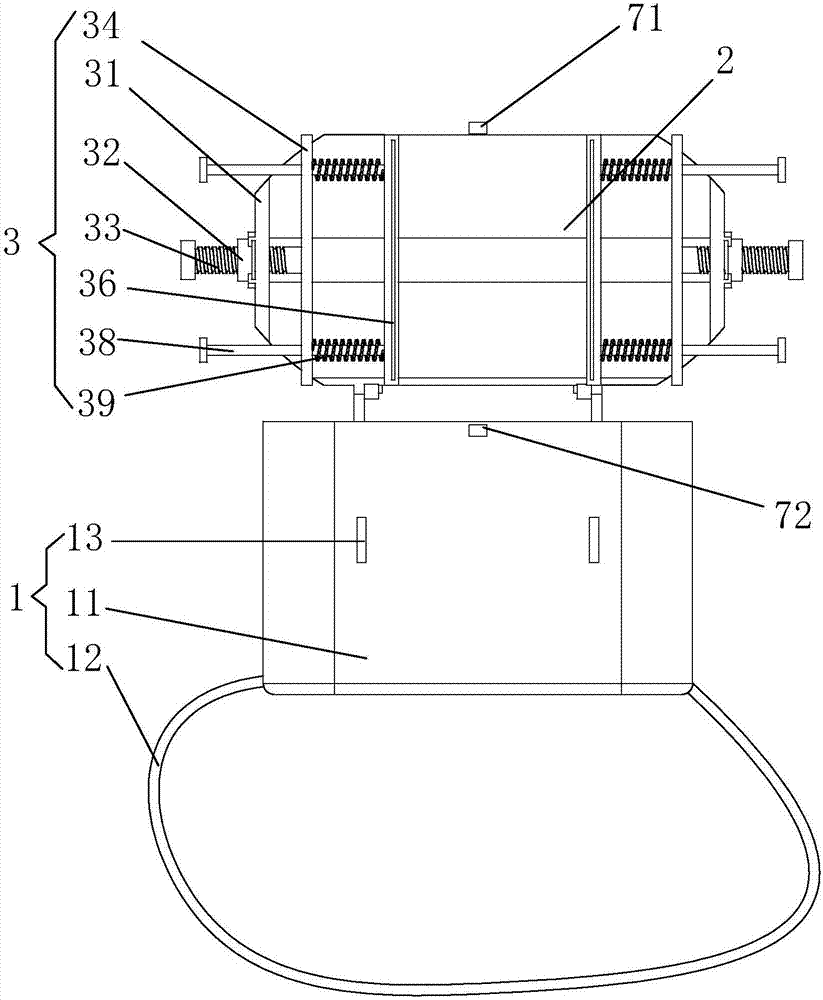

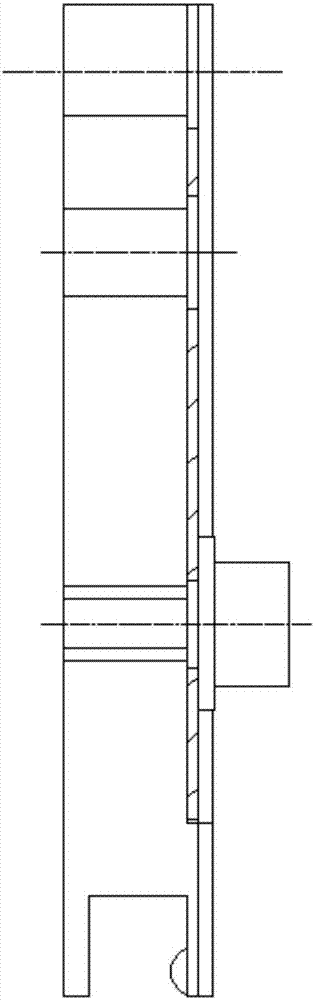

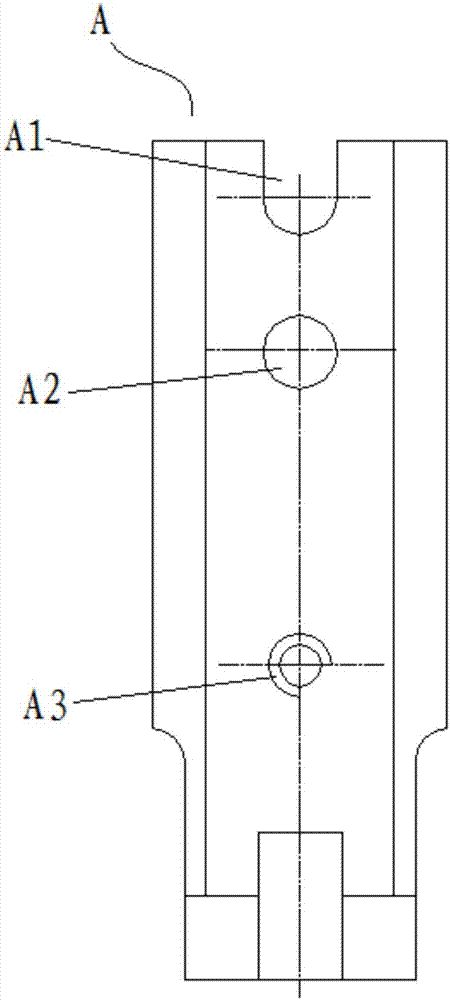

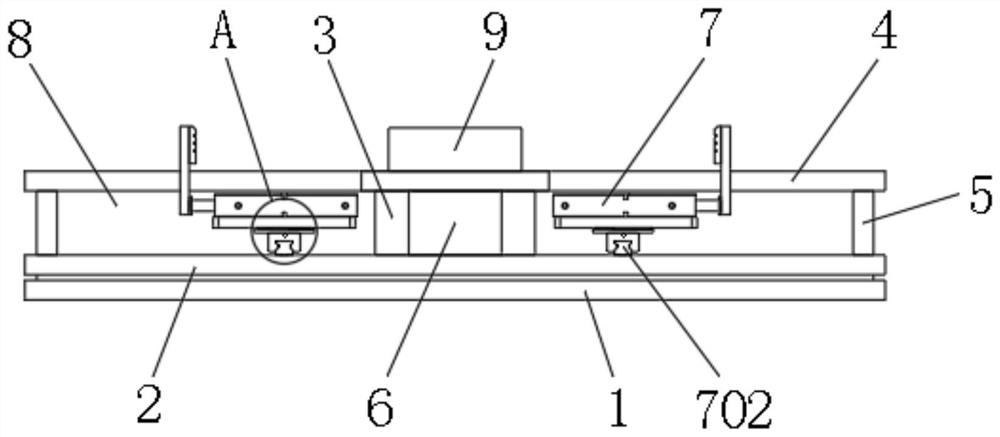

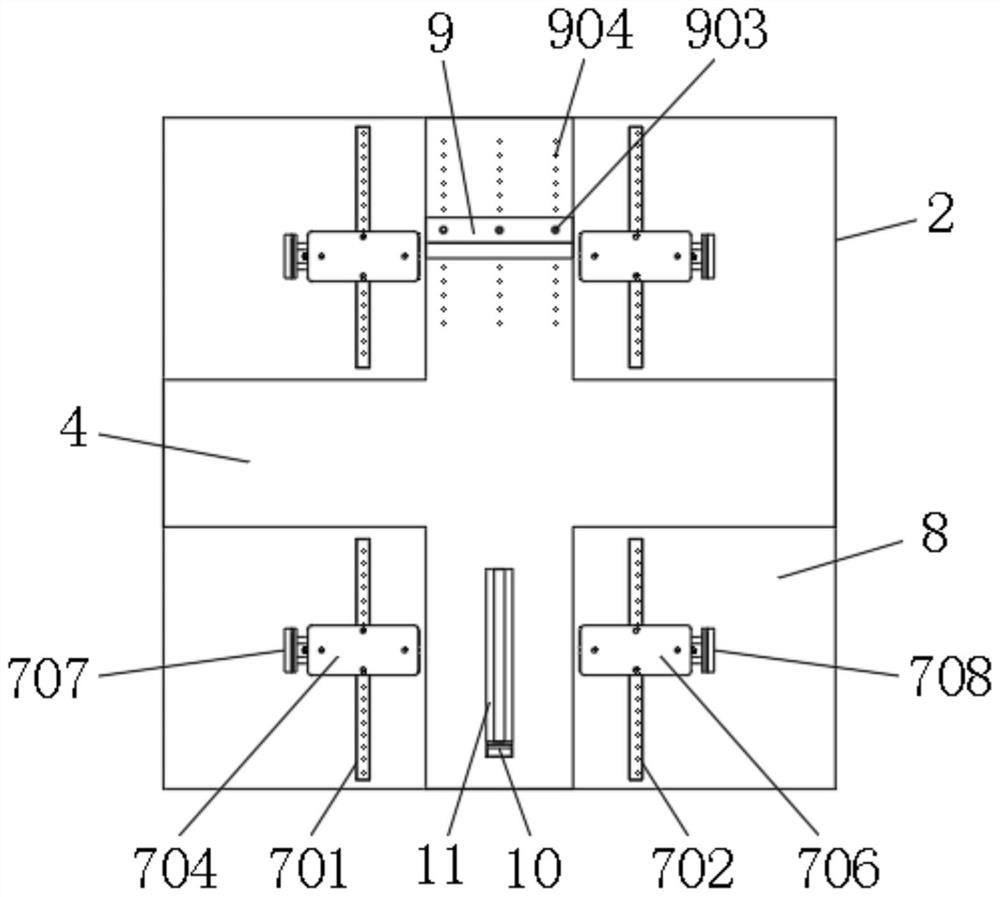

Welding and positioning tool for air conditioner air return net frame

InactiveCN105345379ACooperate accuratelyMeet welding requirementsWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineering

A welding and positioning tool for an air conditioner air return net frame comprises a rack, two clamping devices arranged on the rack and a first drive device driving one clamping device to be far away from or get close to the other clamping device, wherein each clamping device comprises a base, two corner clamping mechanisms arranged on the base and a second drive device driving one corner clamping mechanism to be far away from or get close to the other corner clamping mechanism; each corner clamping mechanism comprises a mounting plate, a side edge positioning mechanism fixed on the mounting plate and a top pressing mechanism fixed on the mounting plate; four corner clamping mechanisms can be reasonably distributed at four corners of the frame through horizontal movement of the clamping devices and longitudinal movement of the corner clamping mechanisms, the side edge positioning mechanisms and the top pressing mechanisms tightly press two side bars at the corners, and the 45-degree notches in the end parts of the side bars can be accurately matched and meet the welding requirement.

Owner:GUANGZHOU JINGYI AUTOMOBILE AIR CONDITIONER

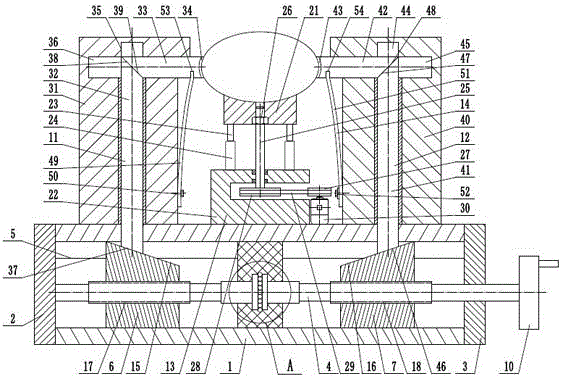

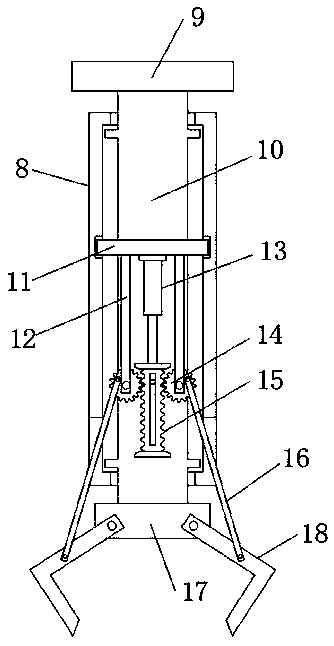

Centering clamping apparatus of ellipsoidal workpiece

PendingCN106826294APrevent axial slippageAchieve peace of mindPositioning apparatusMetal-working holdersLever pressingScrew thread

The invention provides a centering clamping apparatus of an ellipsoidal workpiece, which belongs to the technical field of a clamping device. The centering clamping apparatus comprises a screw, a left slide block, a right slide block, a left centering clamping assembly, a right centering clamping assembly, a height adjusting assembly and a return assembly, wherein both the left slide block and the right slide block can be arranged on a guiding seat in a sliding manner, a left threaded section of the screw is connected with the left slide block in a threading manner, a right threaded section of the screw is connected with the right slide block in a threading manner, a carrier frame of the height adjusting assembly is arranged on a fixed seat in an up-down sliding manner by virtue of a guide rod and a guide column, a left centering clamping assembly and a right centering clamping assembly are symmetrically arranged at the left side and the right side of the height adjusting assembly, the lower end of a left leaf spring of the return assembly is installed on a left supporting frame by virtue of a left nail, and the upper end of a right leaf spring is inserted into a right clamping groove of a right centering pressure rod. The centering clamping apparatus not only rapidly centers and clamps the ellipsoidal workpiece and is reasonable in structure, but also can be suitable for various models of ellipsoidal workpieces, and is high in universality.

Owner:全彬强

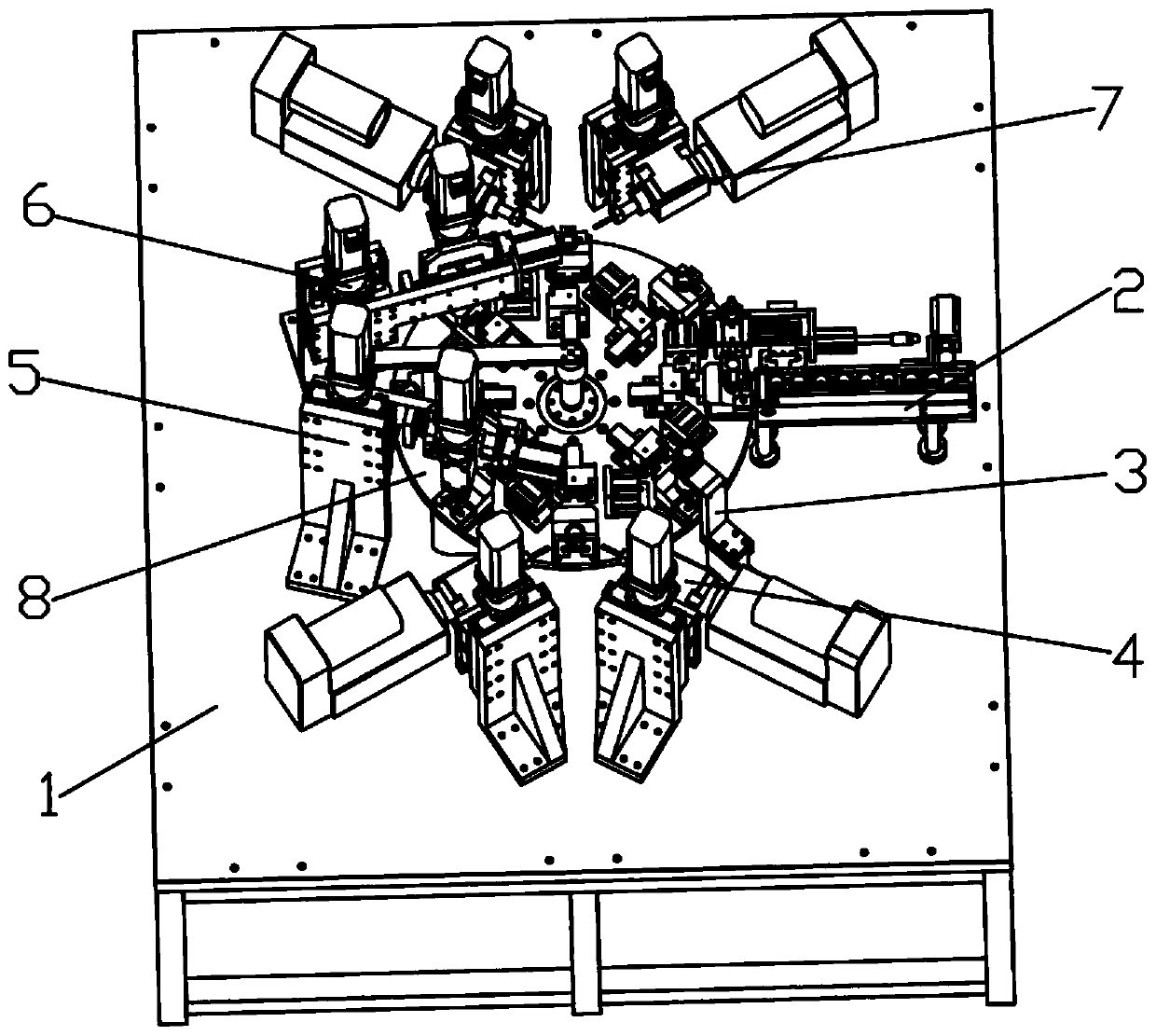

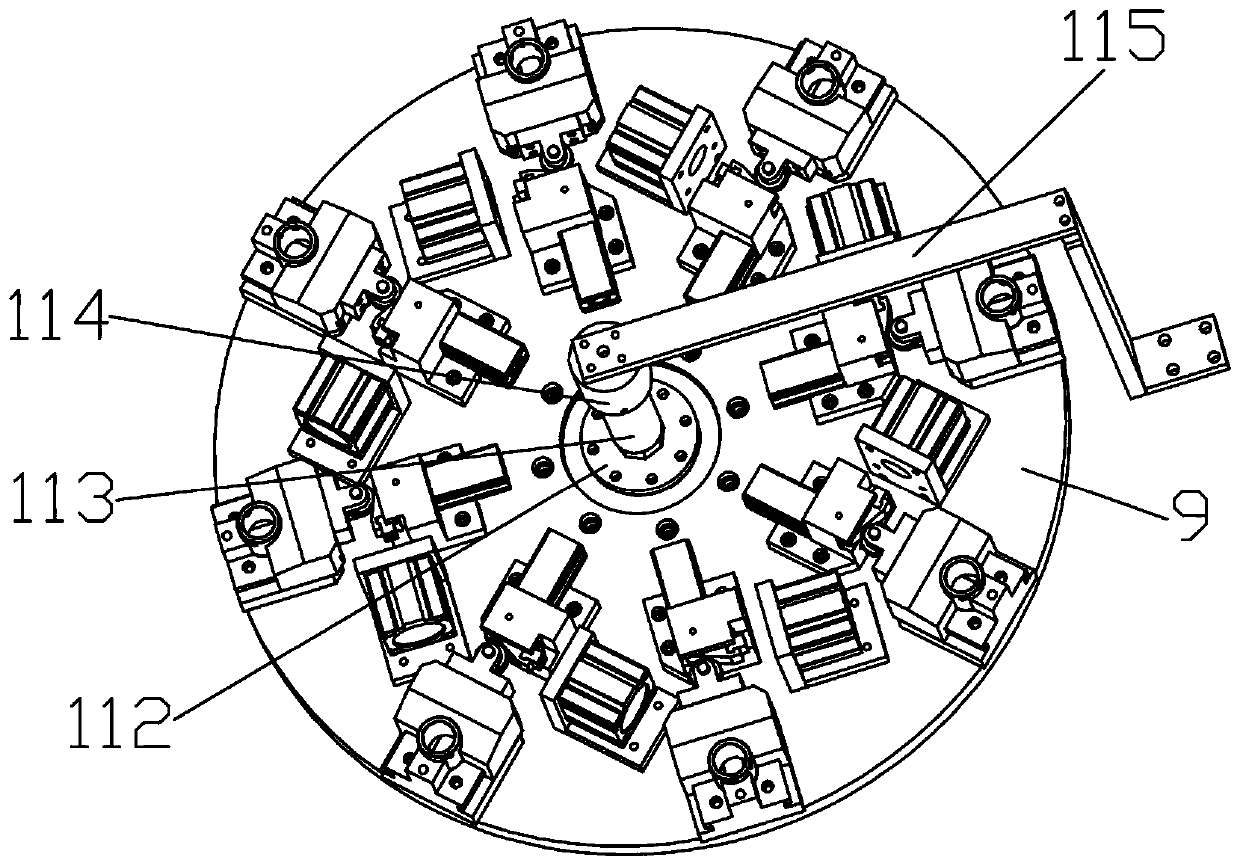

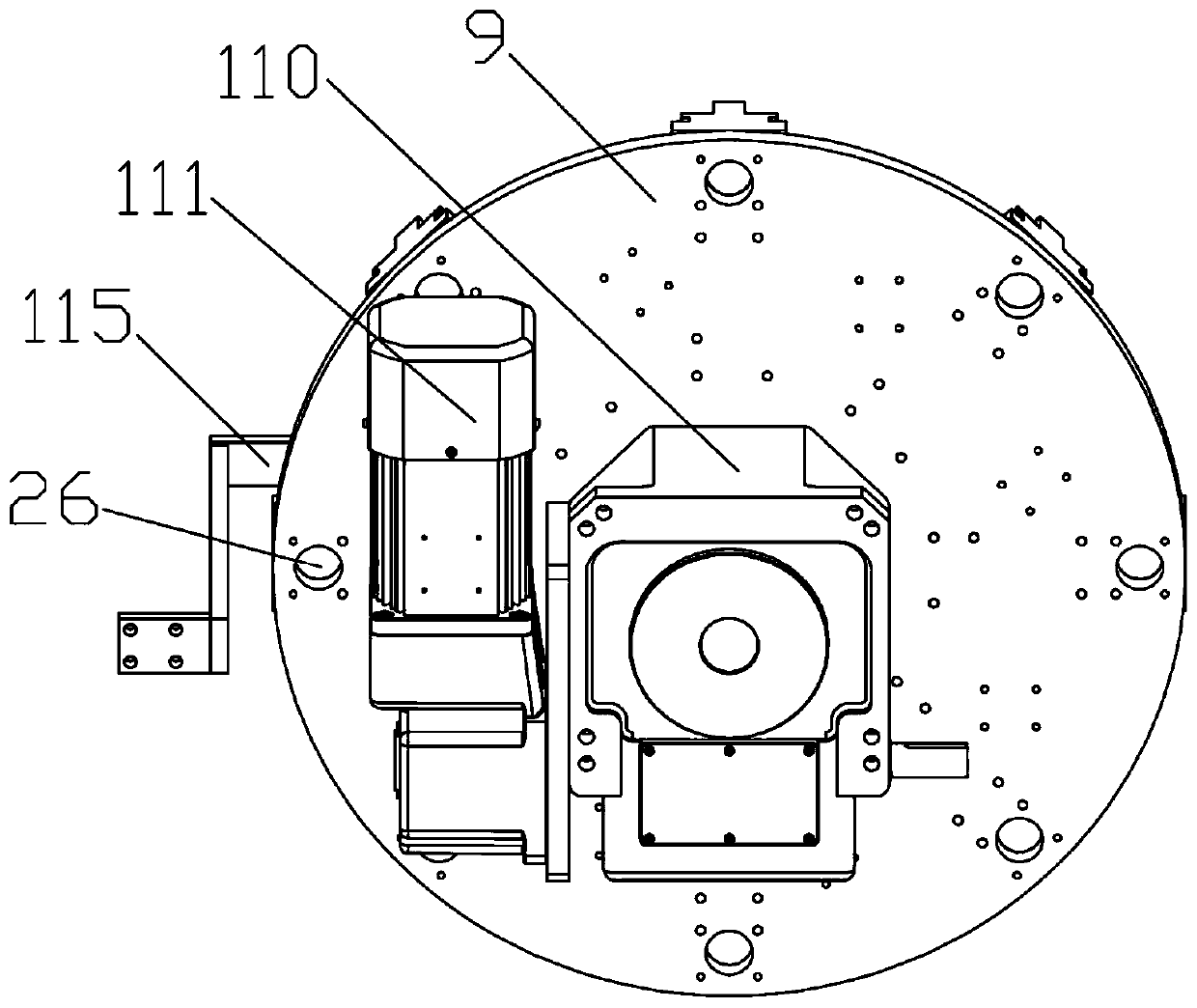

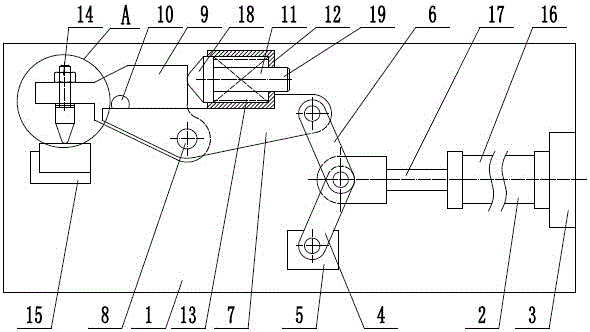

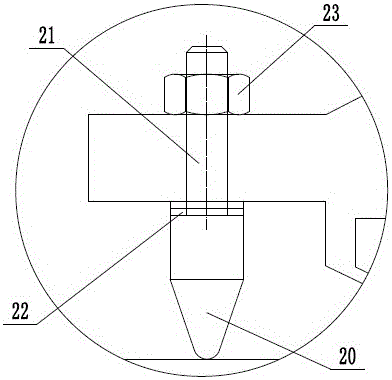

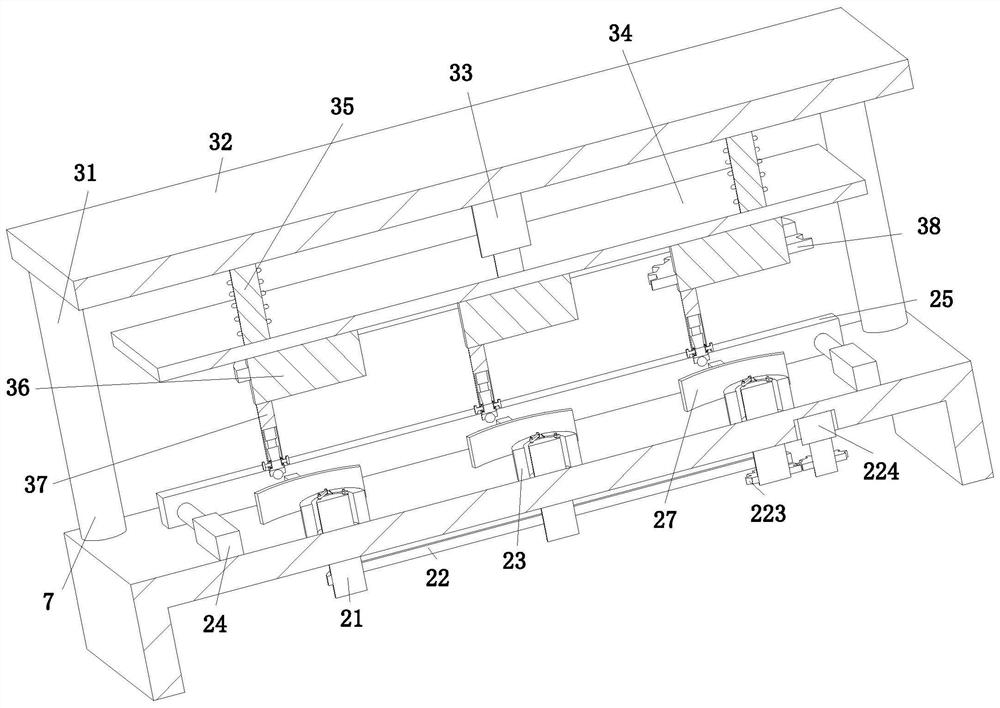

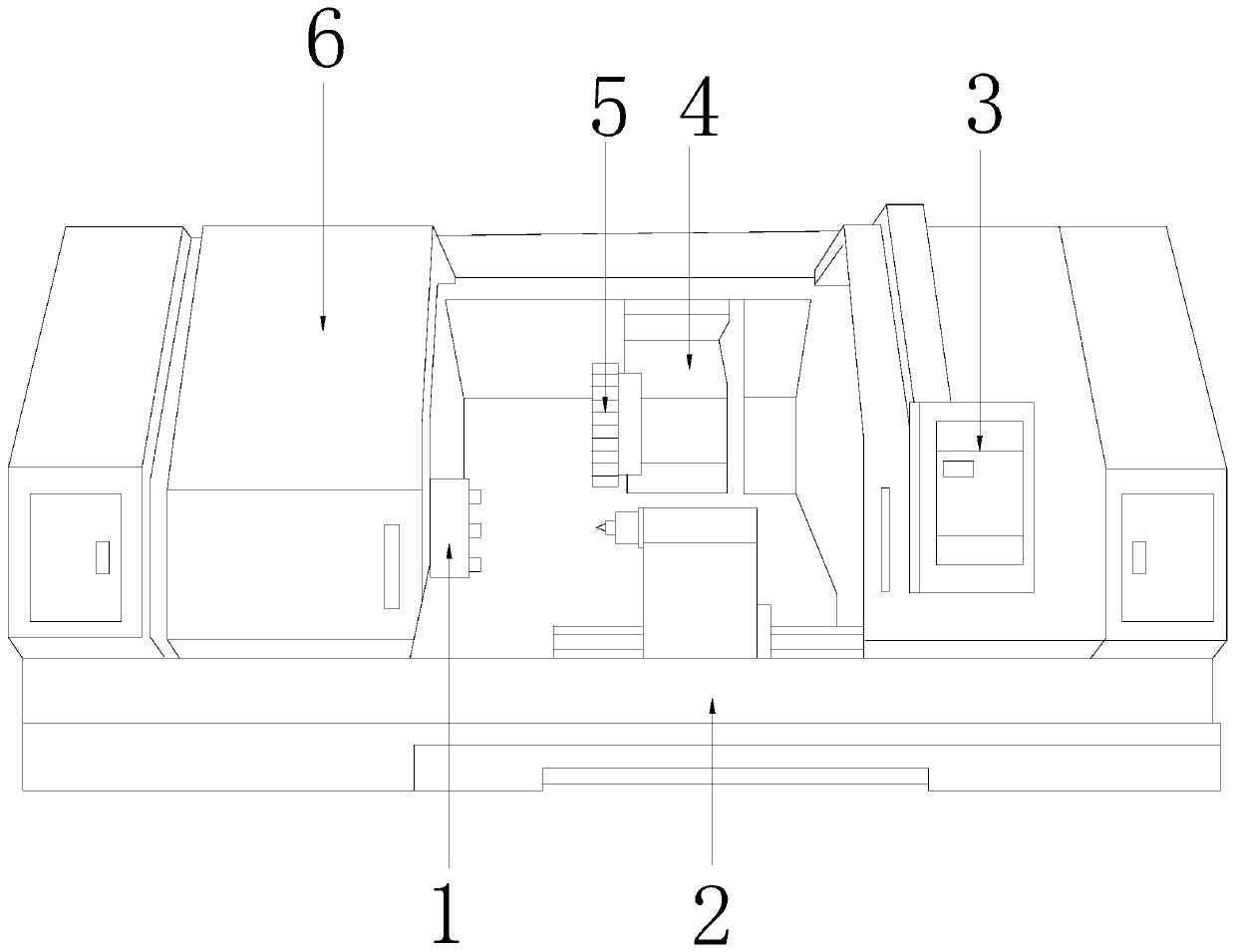

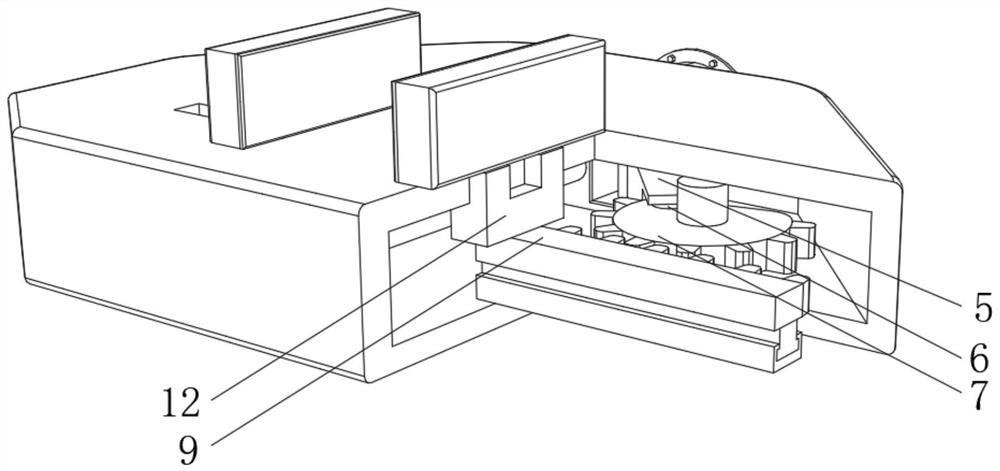

Full-automatic bearing spherical surface drilling, chamfering, tapping all-in-one machine and use method thereof

PendingCN109746683AIncrease the number ofReduce processing timeOther manufacturing equipments/toolsPositioning apparatusEngineeringCam

The invention discloses a full-automatic bearing spherical surface drilling, chamfering, tapping all-in-one machine and a use method thereof, and belongs to the technical field of bearing machining. The full-automatic bearing spherical surface drilling, chamfering, tapping all-in-one machine comprises a rack, a feeding mechanism, a pressing mechanism, a drilling mechanism, a first inner chamferingmechanism, a second inner chamfering mechanism, a tapping mechanism and a rotary disc mechanism. The rotary disc mechanism comprises a rotary disc and eight clamping modules, and the eight clamping modules form a circumferential array around the circle center of the rotary disc. The feeding mechanism, the pressing mechanism, the drilling mechanism, the first inner chamfering mechanism, the secondinner chamfering mechanism and the tapping mechanism are located on the periphery of the rotary disc and correspond to six clamping modules so that a bearing clamped by the clamping modules can be machined. According to the full-automatic bearing spherical surface drilling, chamfering, tapping all-in-one machine, the machining processes of feeding, pressing, drilling, inner chamfering, tapping, returning and the like are completed through full-automatic operation, and the automation degree is high; and a cam separator controls the rotary disc to cyclically rotate on eight stations, the bearing is moved to the station needing to be machined, and continuous production is achieved in the whole process.

Owner:浙江勇峰智能科技有限公司

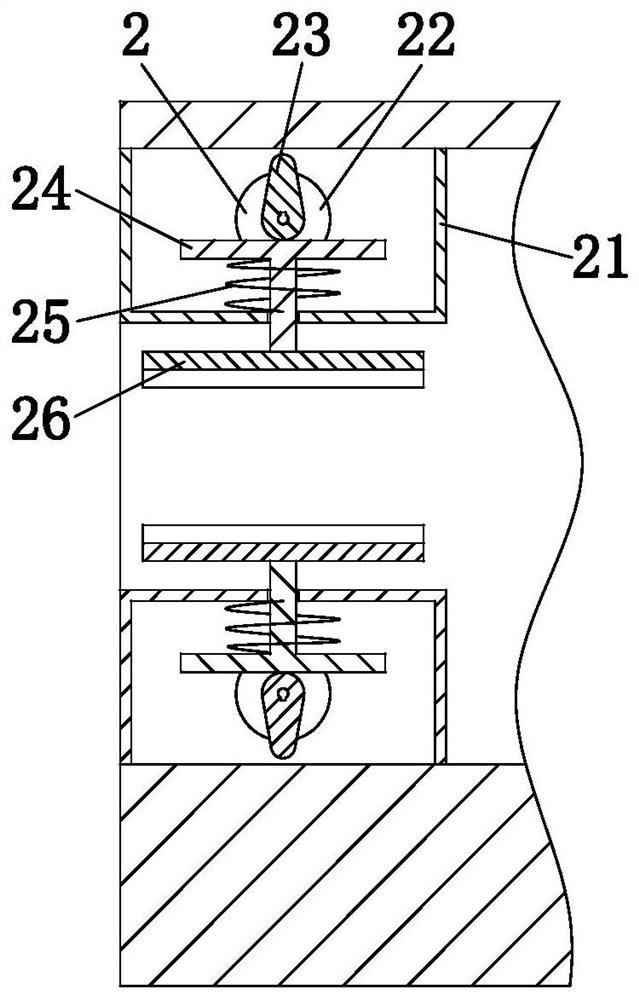

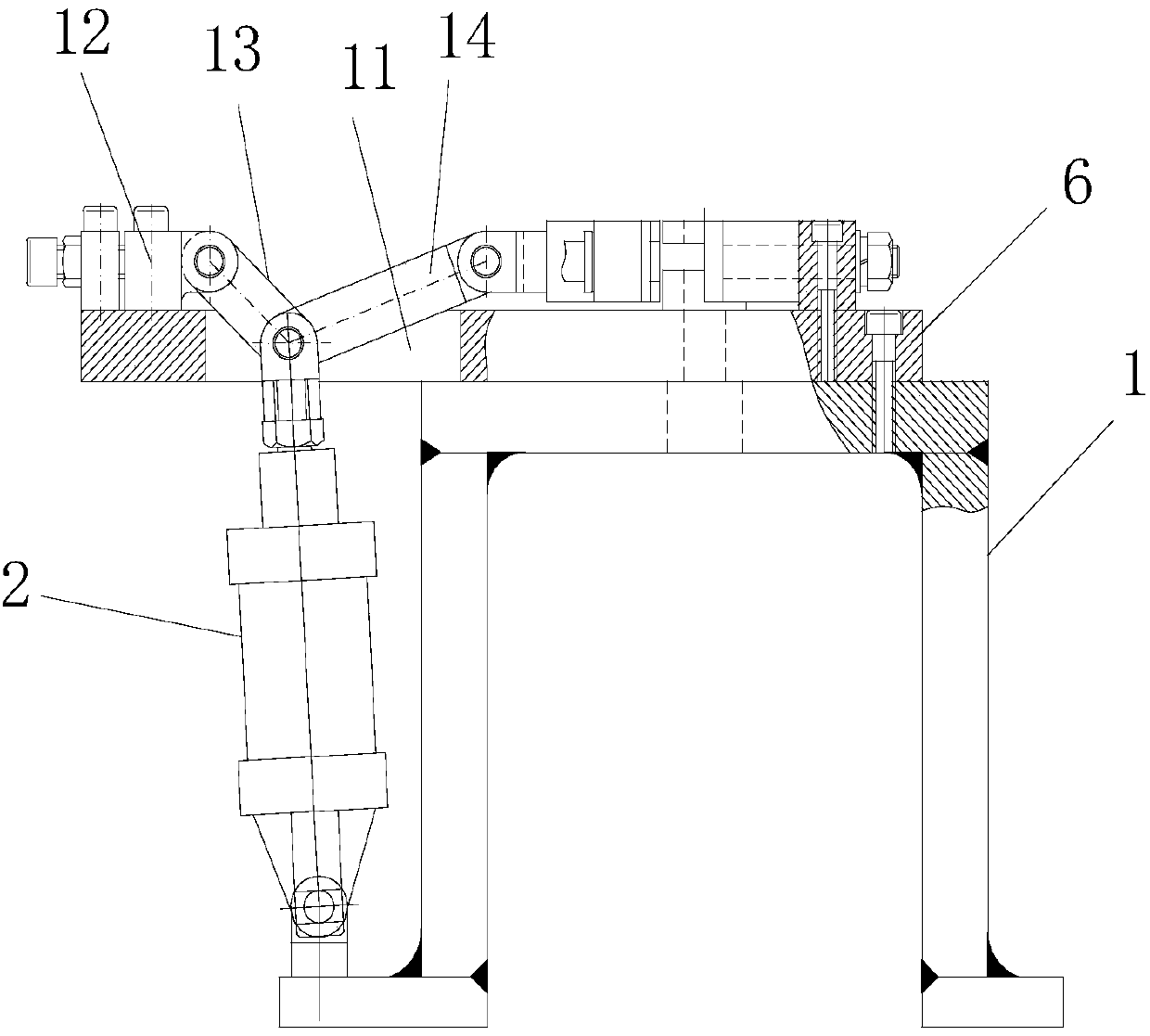

Swing type clamping device

InactiveCN106624926ASmooth movementAchieve clampingWork clamping meansPositioning apparatusEngineeringMachining

The invention provides a swing type clamping device and belongs to the technical field of machining. The swing type clamping device comprises a rocking rod, a connecting rod, a lever, a pressing plate, a pressure spring and a clamping assembly. The lower end of the rocking rod is hinged to a rocking rod supporting base. The middle end of the lever is hinged to a rack through a supporting hinge pin. The right end of the lever is hinged to the upper end of the connecting rod. The left end of a piston rod of a drive air cylinder is hinged to the lower end of the connecting rod and the upper end of the rocking rod. The lower right end of the pressing plate is also hinged to the supporting hinge pin. The pressing plate is provided with a stop pin. A top block is coaxially fixed to the left end of the sliding rod and arranged in a sliding column support in the manner of being capable of sliding left and right. The right end of the pressure spring is attached to the sliding column support. The left end of the pressure spring is attached to the pressing plate. The upper end of a supporting rod of a clamping assembly penetrates the pressing plate and is locked through a locking nut. An adjusting gasket is arranged between a chuck and the pressing plate. The swing type clamping device can clamp or loosen workpieces fast, can also effectively prevent clamping force from being too large, and is reasonable in structure and good in reliability.

Owner:魏俊杰

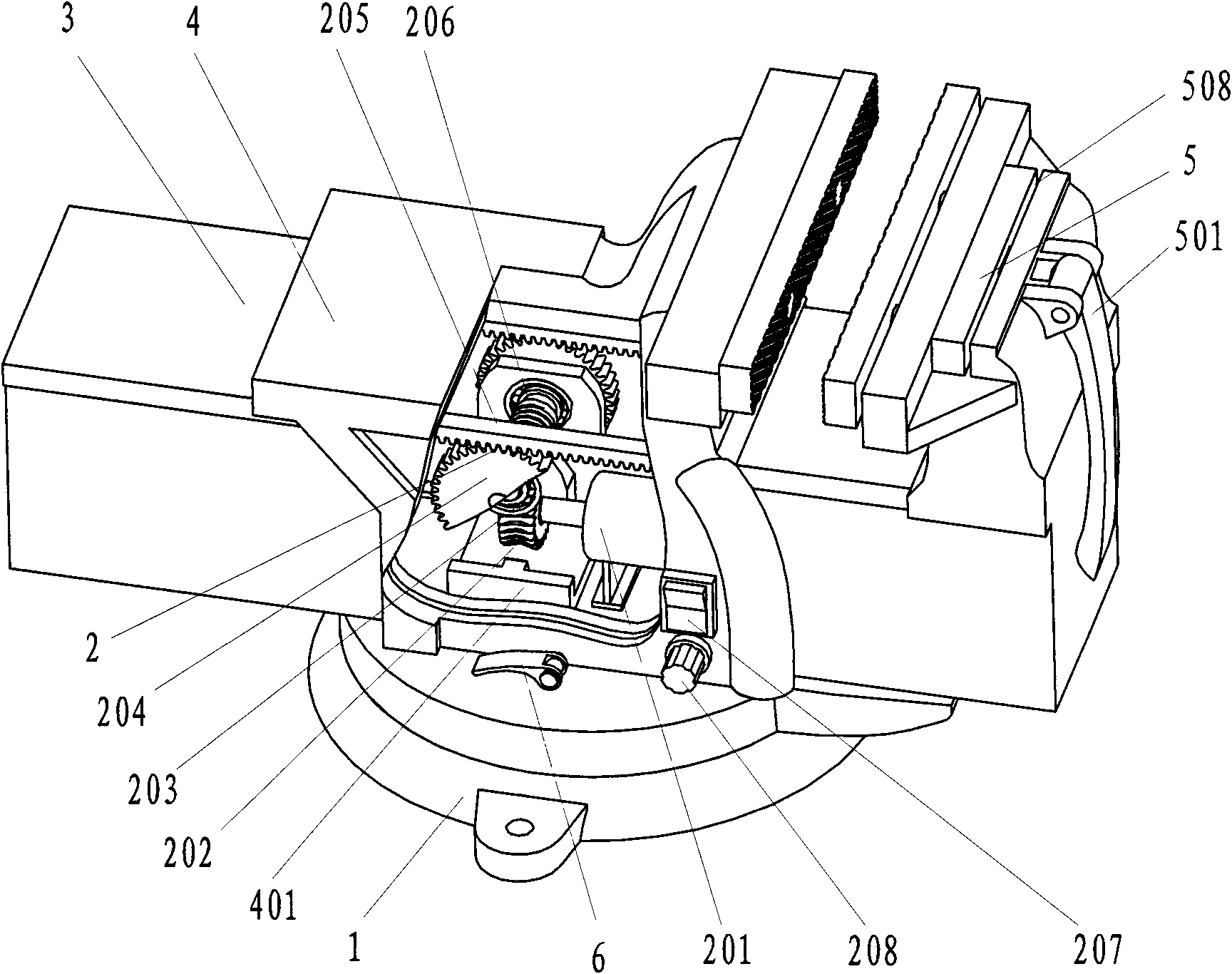

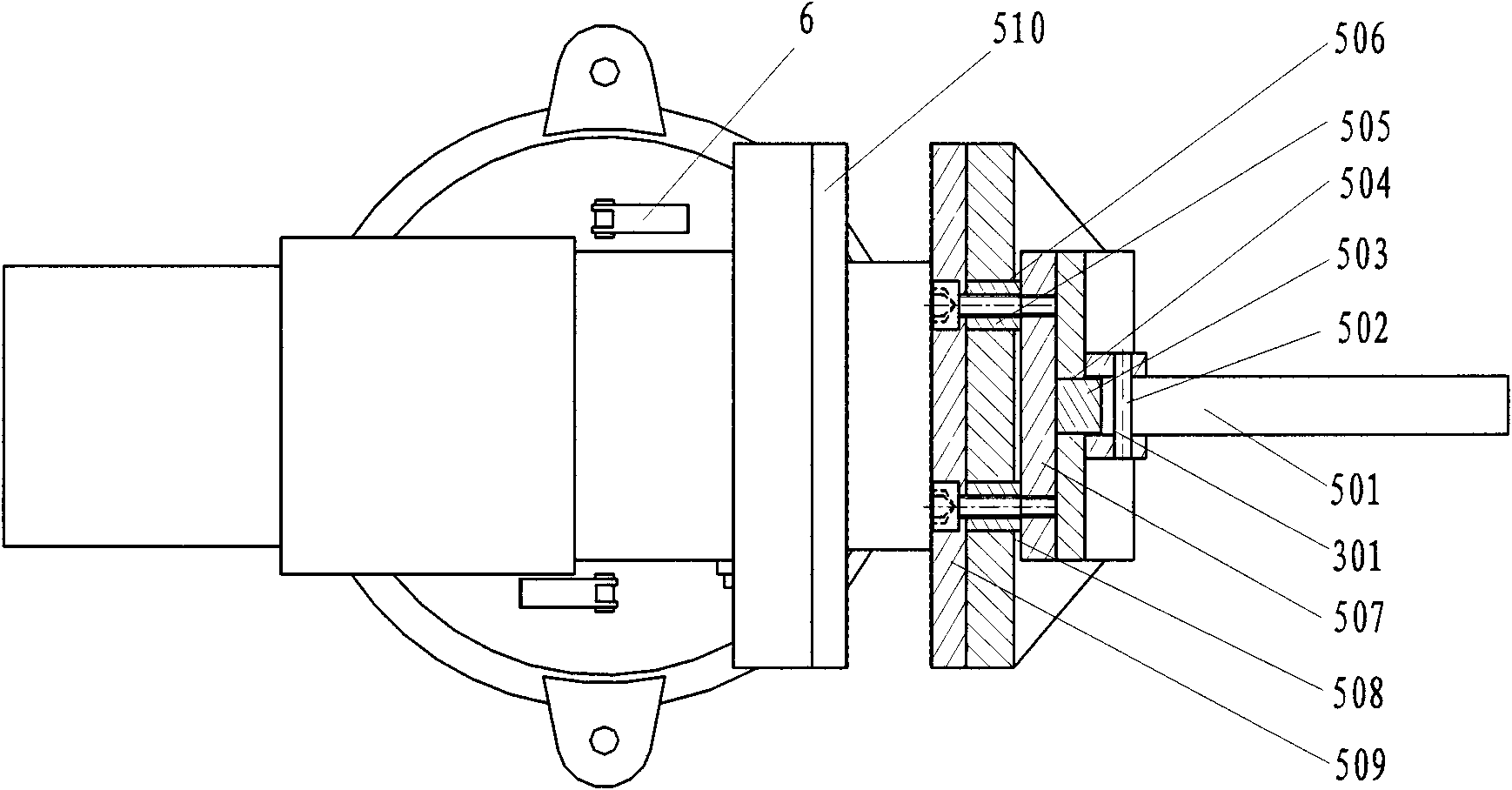

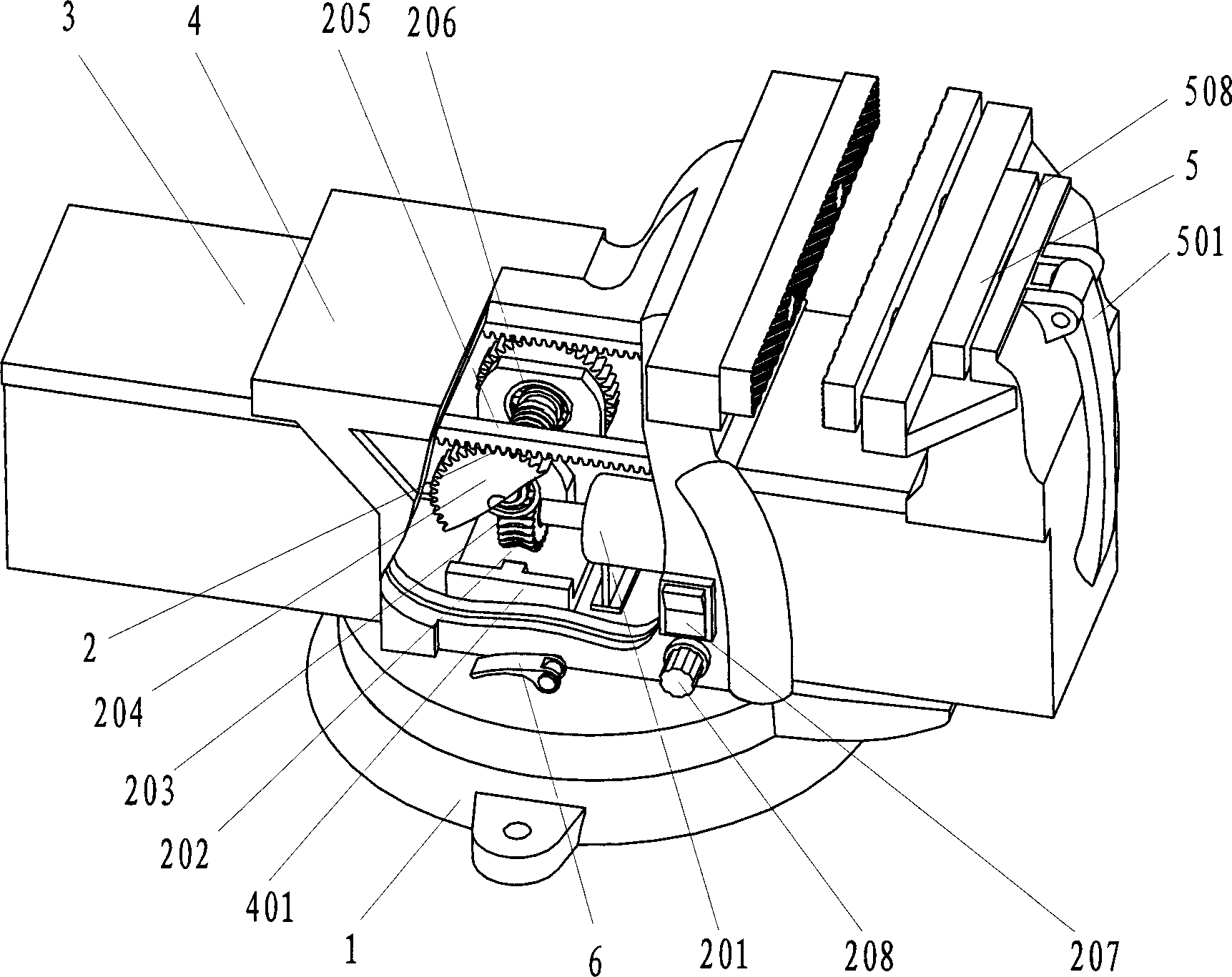

Motor-driven quick bench clamp

The invention relates to a motor-driven quick bench clamp, which belongs to the field of fixtures. The motor-driven quick bench clamp is composed of a base, a fixed pliers body, a locking handle, a transmission system and a clamping device, wherein the base and the fixed pliers body are connected by the locking handle; a movable pliers body is connected with the fixed pliers body by the transmission system; the transmission system is meshed with gears and racks by a worm-and-gear transmission mechanism to move to drive the movable pliers body to move; the clamping device is installed on the upper end of the movable pliers body; the transmission system is used for regulating distance between a first locating block and a second locating block to quickly move the movable pliers body; the worm-and-gear transmission mechanism is used for realizing the self-locking function of a workpiece after the workpiece is quickly and tightly clamped between the first locating block and the second locating block; and the clamping device is used for further quickly clamping the workpiece. The motor-driven quick bench clamp has the advantages that the structure is compact, the design is smart, the movable pliers body can be moved quickly, the operation is convenient and the like, time and effort are saved, the labor intensity can be effectively lowered, and the working efficiency is improved.

Owner:NANTONG ZHONGYI BOILER EQUIP

Intelligent polishing machine for manufacturing inner ring and outer ring of bearing

InactiveCN113664697AImprove work efficiencyCause workloadPolishing machinesGrinding drivesPolishingEngineering

The invention relates to an intelligent polishing machine for manufacturing the inner ring and the outer ring of a bearing. The intelligent polishing machine comprises a workbench, a fixing device and a moving device. The workbench is a C-shaped plate with a downward opening, and the fixing device and the moving device are arranged on the upper end face of the workbench. The fixing device comprises cylindrical rods, a moving frame, clamping frames, bidirectional electric push rods, square plates, extension rods and first arc-shaped plates. According to the intelligent polishing machine, the inner ring and the outer ring of the bearing can be polished at the same time, so that the working efficiency during polishing of the inner ring and the outer ring of the bearing is greatly improved. According to the intelligent polishing machine, the inner ring and the outer ring of the bearing needing to be polished can be subjected to batch polishing, and the problems that the workload of operators is increased and the polishing efficiency is reduced due to traditional repeated taking are solved.

Owner:溧阳市超强链条制造有限公司

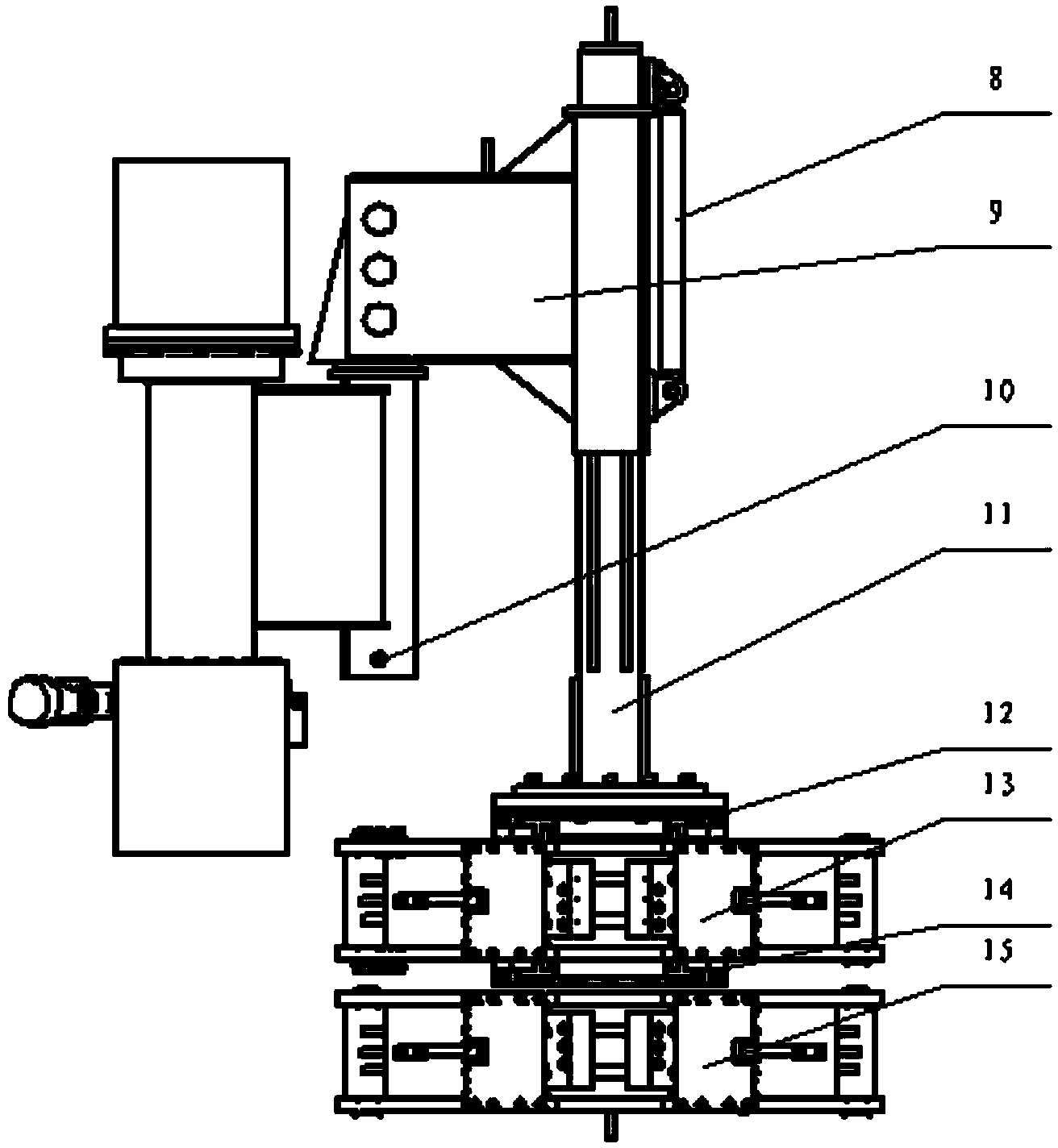

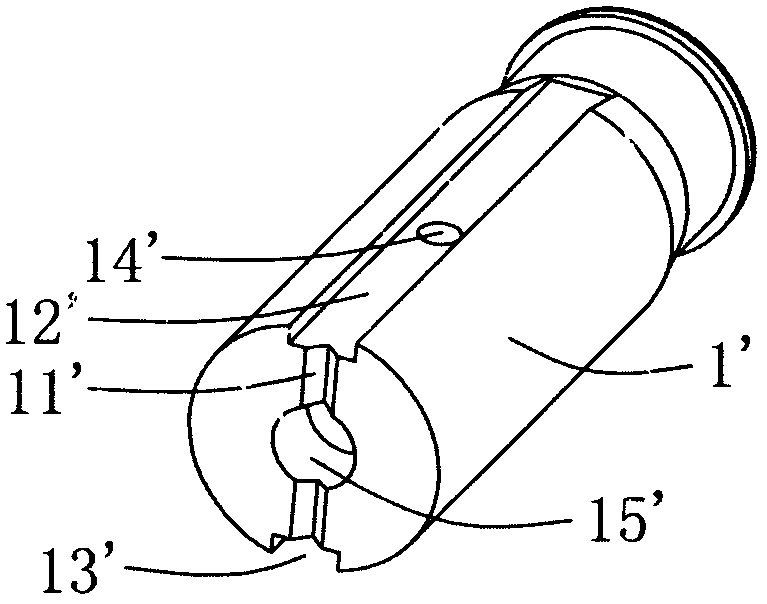

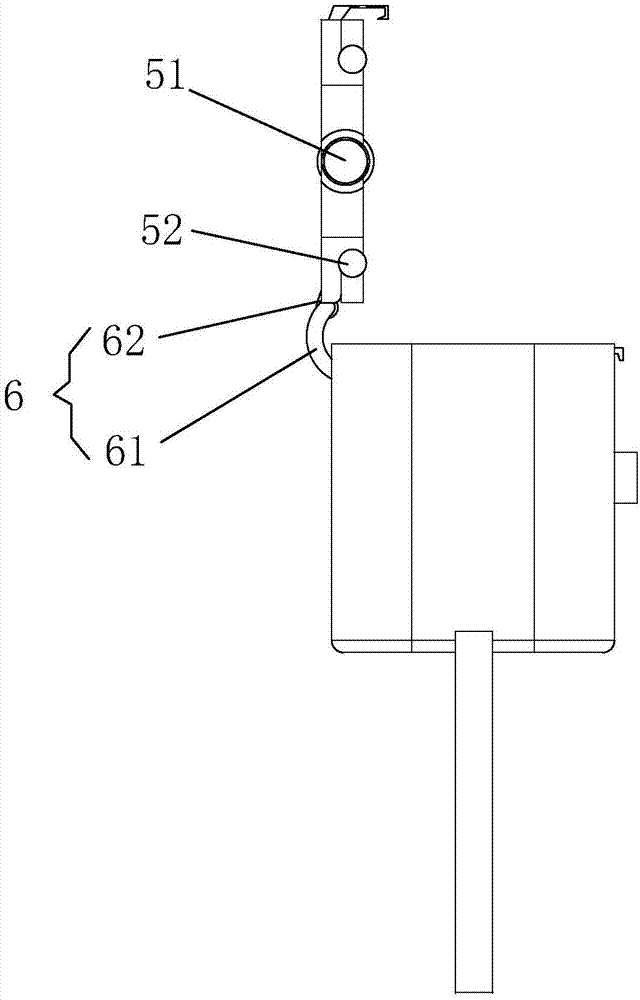

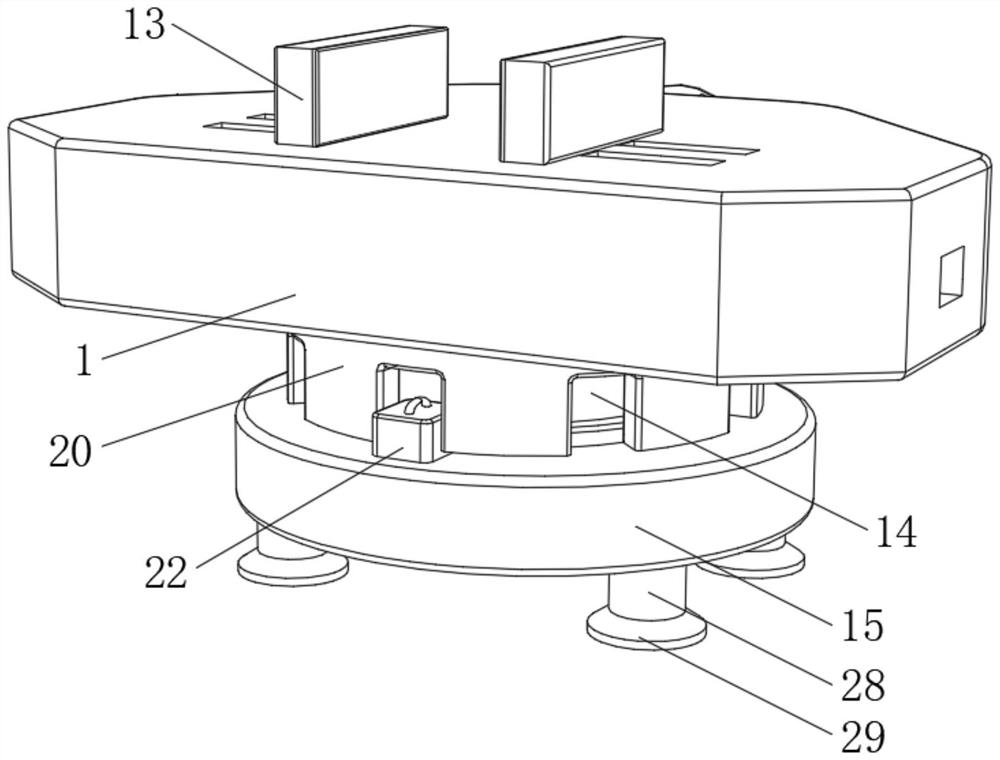

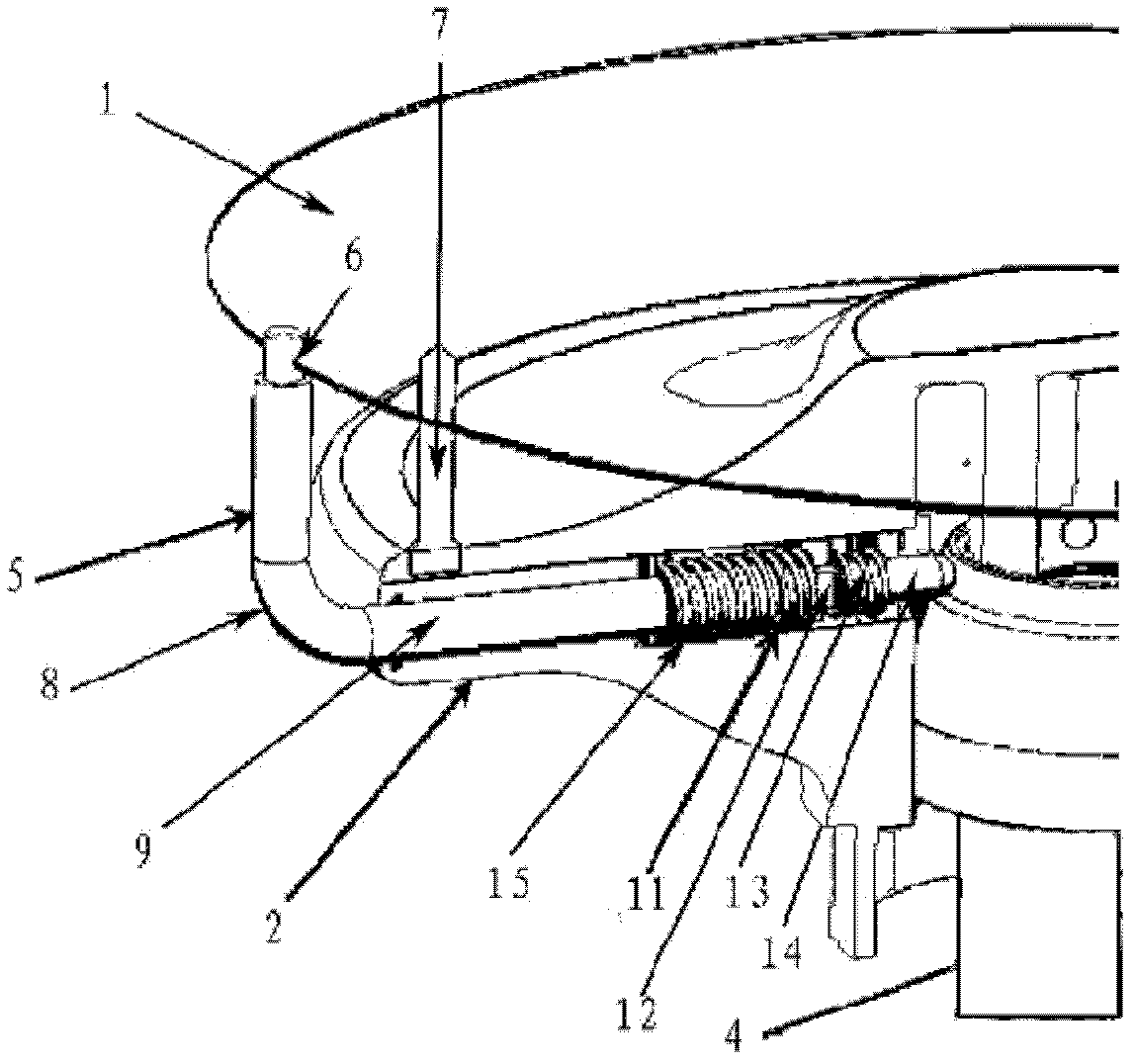

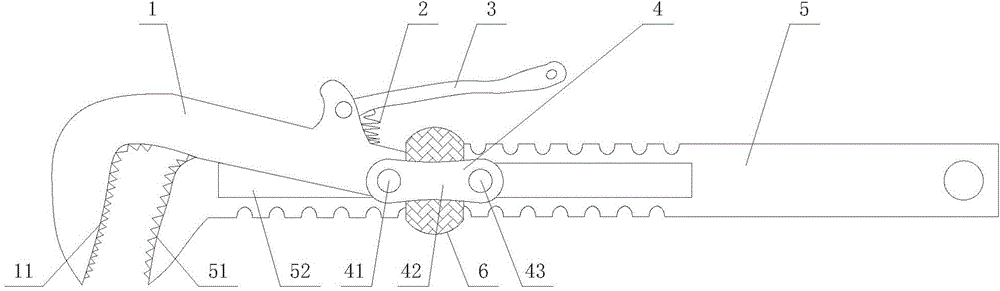

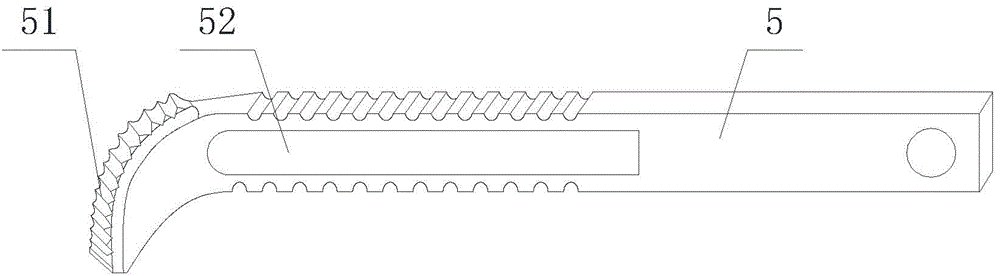

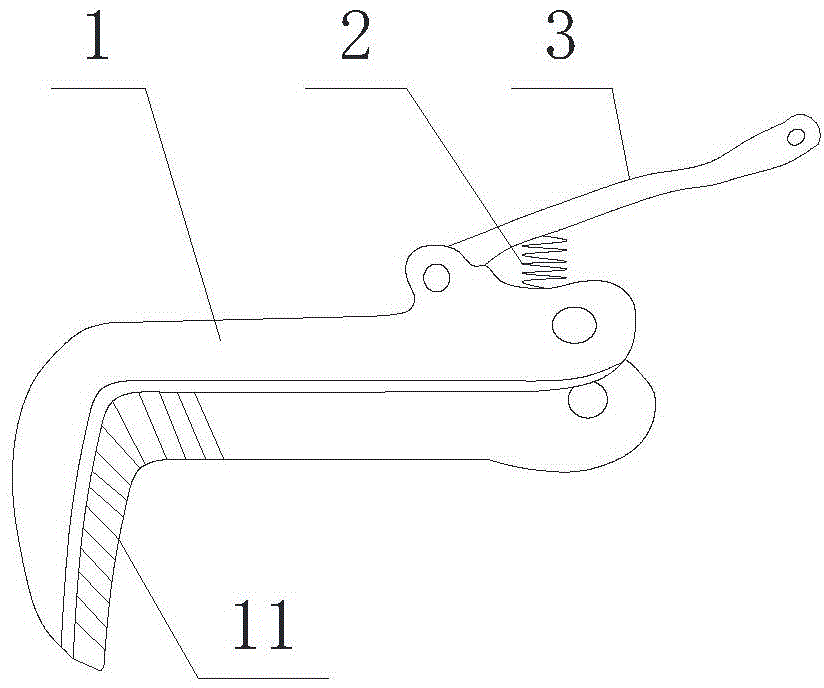

Hydraulic break-out tongs with screw thread protection function

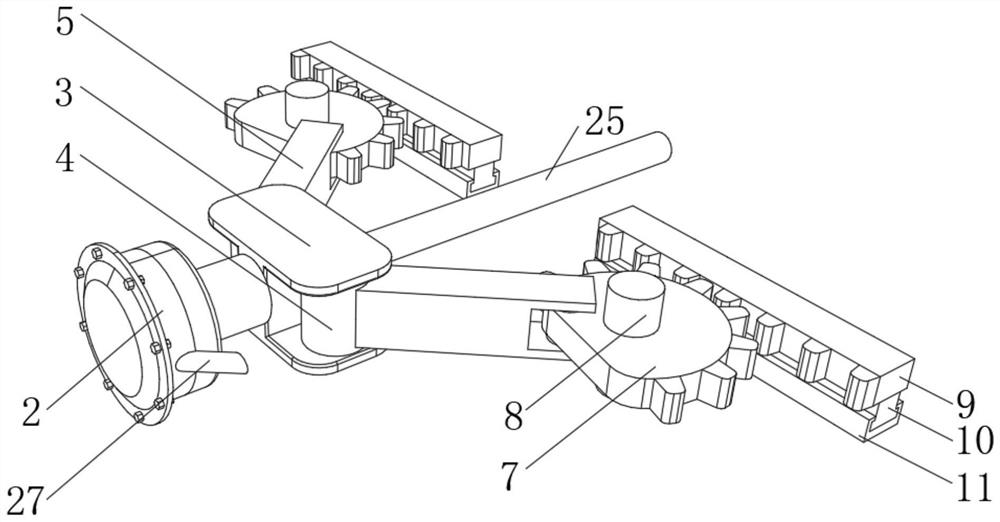

ActiveCN103643908AHigh degree of automationEasy to assemble and disassembleDrilling rodsDrilling casingsEngineeringScrew thread

The invention discloses a pair of hydraulic break-out tongs with a screw thread protection function, which comprises a bearing 1, a swing arm 2, a slewing support 3, a motor 4, a pedestal 5, a bracing seat 6, a break-out oil cylinder 7, a lifting oil cylinder 8, a bracing arm 9, a pin shaft 10, a hoisting frame 11, an upper rotary rail 12, a break-out tong part 13, a lower rotary rail 14 and a clamping tong part 15. The pair of break-out tongs is high in automation degree, convenient to mount and dismount and strong in break-out capability, can quickly realize actions of swing, lifting, clamping, as well as drilling rod screwing and dismounting, and has the drilling rod screw thread protection function during break-out.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

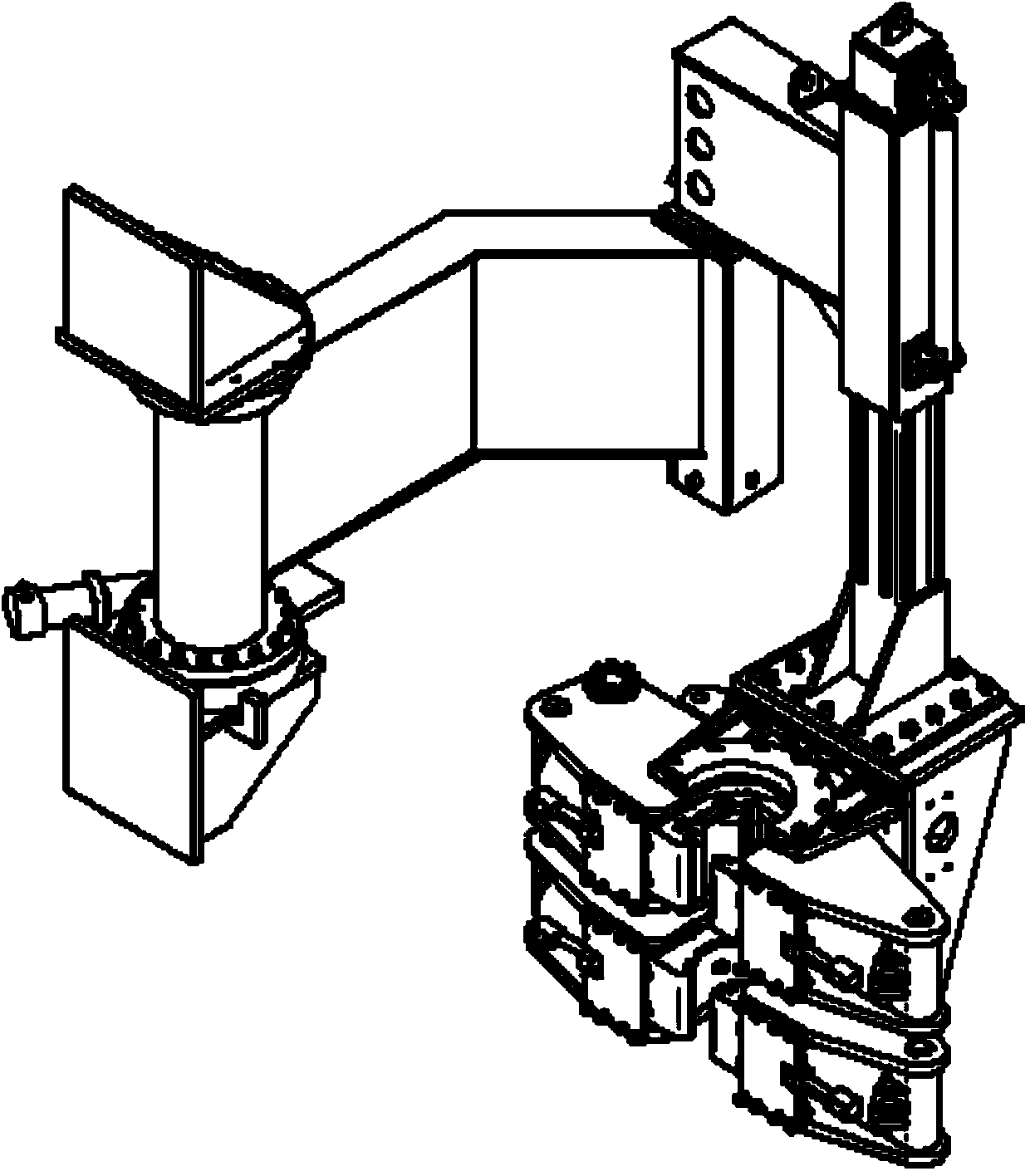

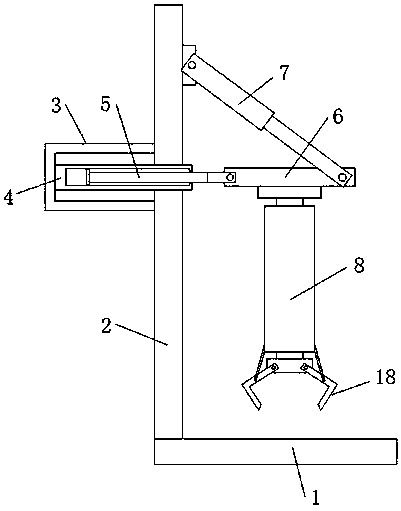

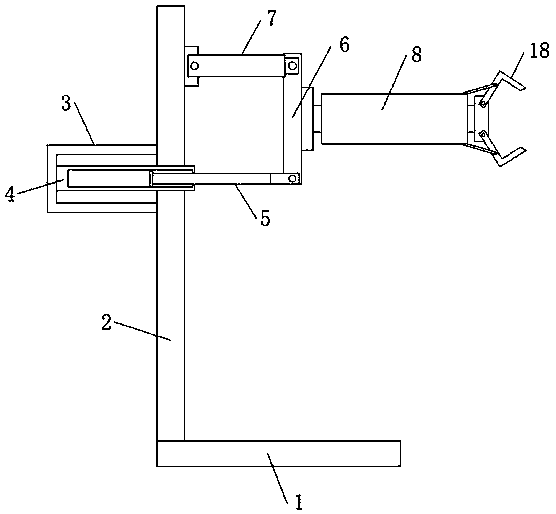

Loading and unloading device capable of converting tool bit direction

ActiveCN107585564AImprove loading and unloading efficiencyReduce transmission timeStacking articlesDe-stacking articlesHydraulic cylinderMechanical engineering

The invention discloses a loading and unloading device capable of converting the tool bit direction. The device comprises a fixing base and a supporting plate. The supporting plate is perpendicularlyinstalled on one side of the top of the fixing base. The device further comprises a steering mechanism and a loading and unloading mechanism at the bottom of the steering mechanism, wherein the steering mechanism installed on the supporting plate comprises a fixing support and a hydraulic cylinder, the fixing support is welded to the side, away from the fixing base, of the supporting plate, a horizontally-arranged fixing plate is welded to the interior of the fixing support, a stretchable plate on the same horizontal plane with the fixing plate is movably installed on one side of the fixing plate, one end of the stretchable plate is rotationally connected with one end of a steering plate, the steering plate is located over the fixing base, the hydraulic cylinder is rotationally installed on the side, close to the fixing base, of the supporting plate, and a piston rod of the hydraulic cylinder is rotationally connected with the other end of the steering plate. The device is reasonable in design, easy to operate and capable of conveniently converting the goods loading and unloading direction, meeting the requirement for clamping and fixing goods of different specifications and sizes,lowering the cost and improving the goods loading and unloading efficiency.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

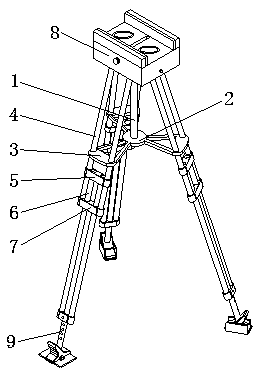

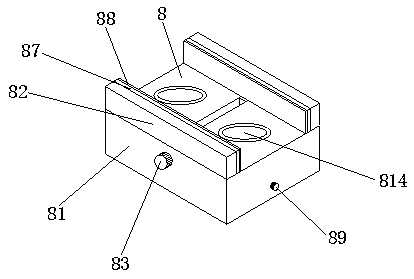

Novel pan-tilt camera mounting device

InactiveCN111022858AImprove the effectEasy to installStands/trestlesSuction cupsStructural engineeringMechanical engineering

The invention discloses a novel pan-tilt camera mounting device comprising a supporting column; a quick mounting mechanism is arranged at the upper end of the supporting column; two sides of cameras with different sizes can be quickly clamped and fixed through clamping plates and sponge pads on the quick mounting mechanism; the outer surfaces of the cameras are protected; the front ends and the rear ends of the bottoms of the cameras can be firmly sucked through air pressure suckers, and the mounting and fixing effects are improved; the installation process is more convenient, a stable adjusting supporting mechanism is arranged at the lower ends of second supporting rods, three second supporting rods can be finely adjusted through a stable adjusting supporting machine, it is guaranteed that the installation device is kept stable, the stress area of a supporting plate can be increased through hinges and side display plates, and the installation device and the ground are more stable.

Owner:TIANJIN ZHONGAN SHITONG TECH CO LTD

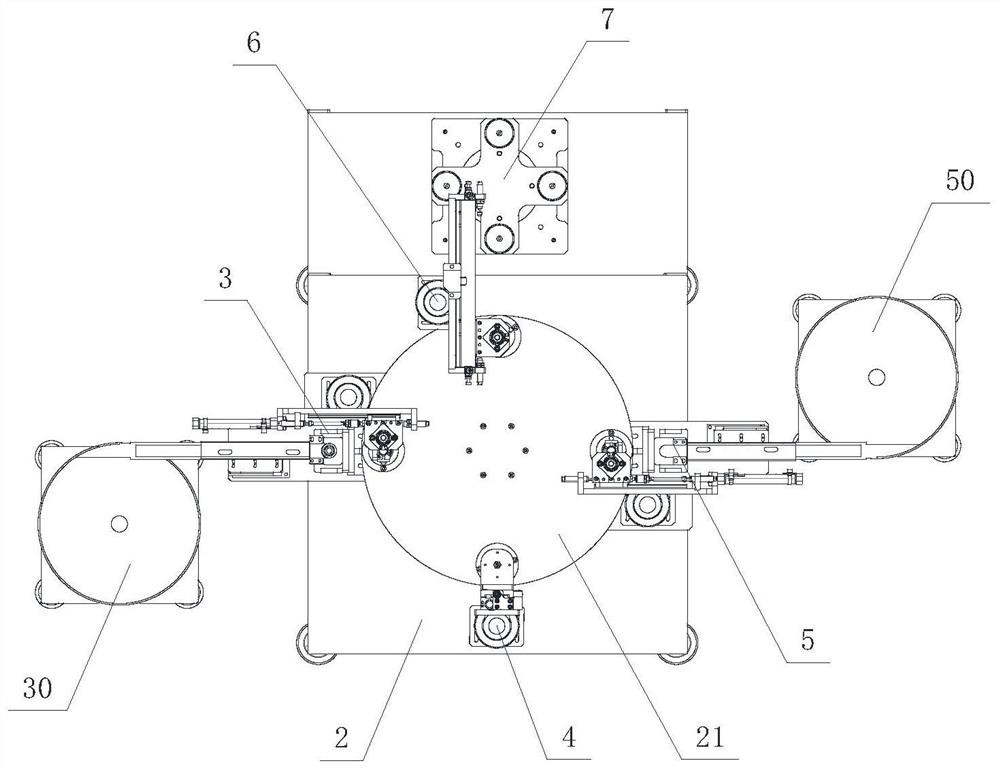

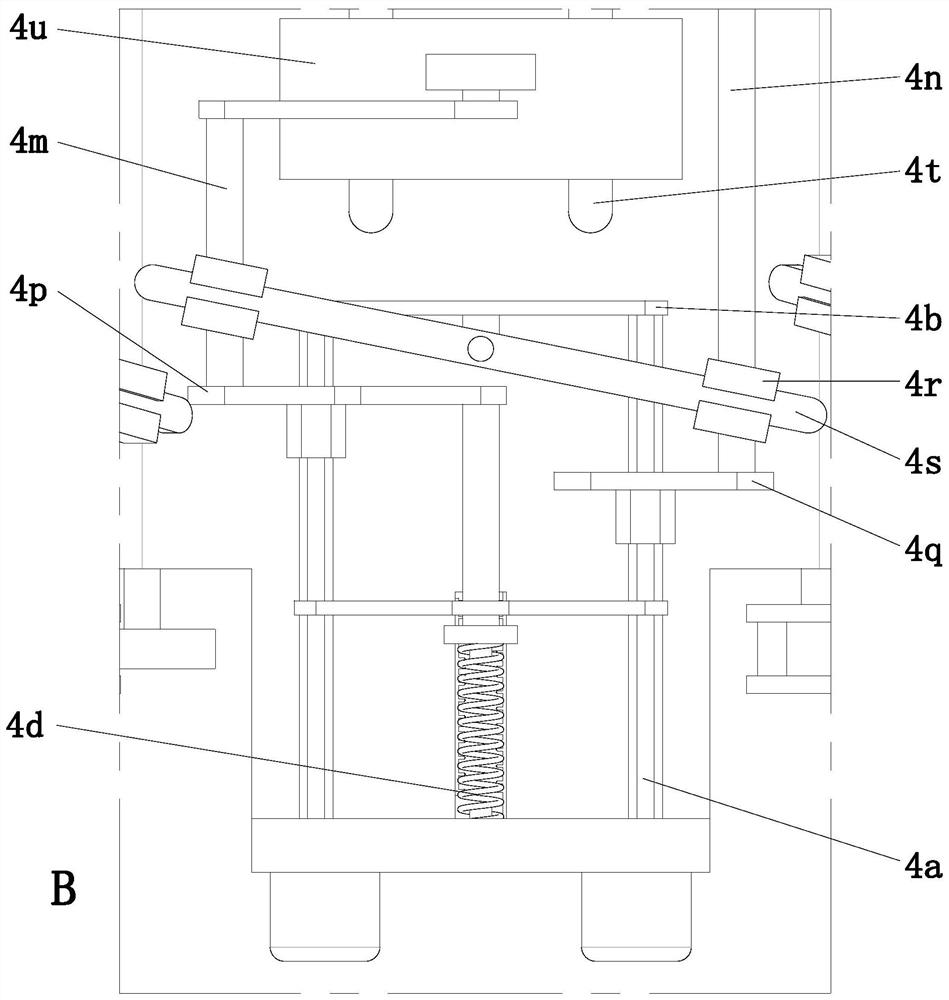

Full-automatic slurry pump framework oil seal four-station assembling system

ActiveCN111890019AEasy to adjustQuick RetrievalMetal working apparatusControl engineeringProcess engineering

The invention provides a full-automatic slurry pump framework oil seal four-station assembling system which comprises a mounting table, an oil seal feeding device, a pressing device 4 and a discharging device; a rotary disc is mounted on the mounting table; four clamps are uniformly distributed on the rotary disc in the circumferential direction; four stations are arranged on the mounting table; the oil seal feeding device is used for feeding a framework oil seal body into the clamp on the first station; the pressing device is used for completely pressing the framework oil seal body in the clamp on the second station into the clamp to realize precise positioning; a spring feeding device is used for grabbing a spring at the discharging end of a second vibrating disc and mounting the springon the framework oil seal body in the clamp on the third station; and the discharging device comprises a third walking mechanism and a discharging manipulator. The full-automatic slurry pump frameworkoil seal four-station assembling system can realize automatic feeding, pressing, assembling and discharging, is high in degree of automation, greatly lowers the production cost and improves the production efficiency.

Owner:LONGKOU FLYING WHEEL CAR ACCESSORIES

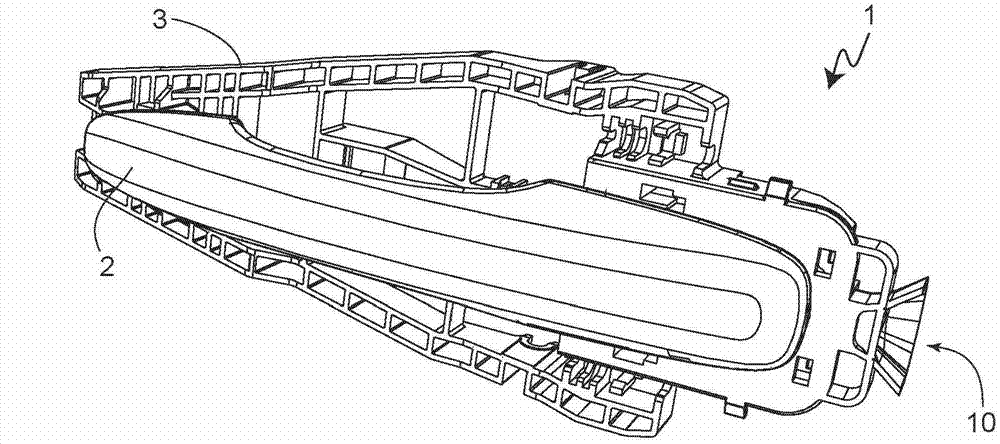

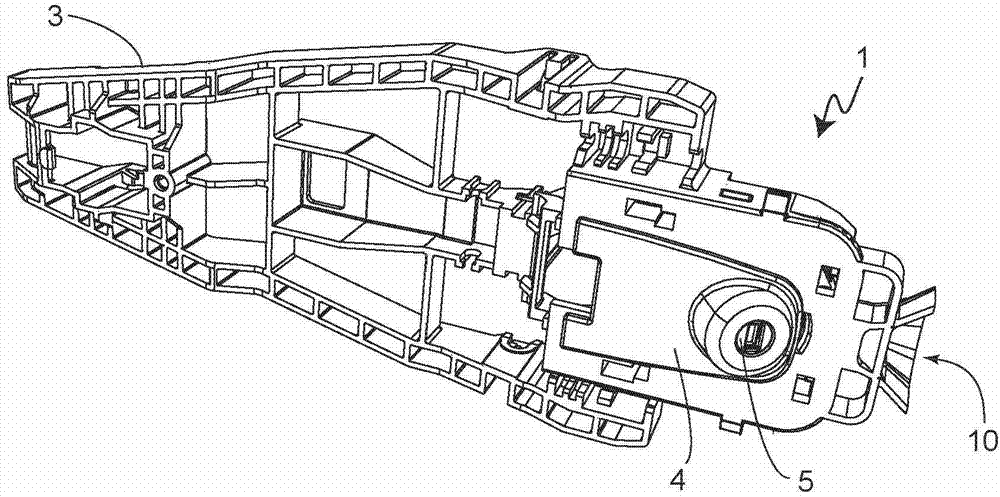

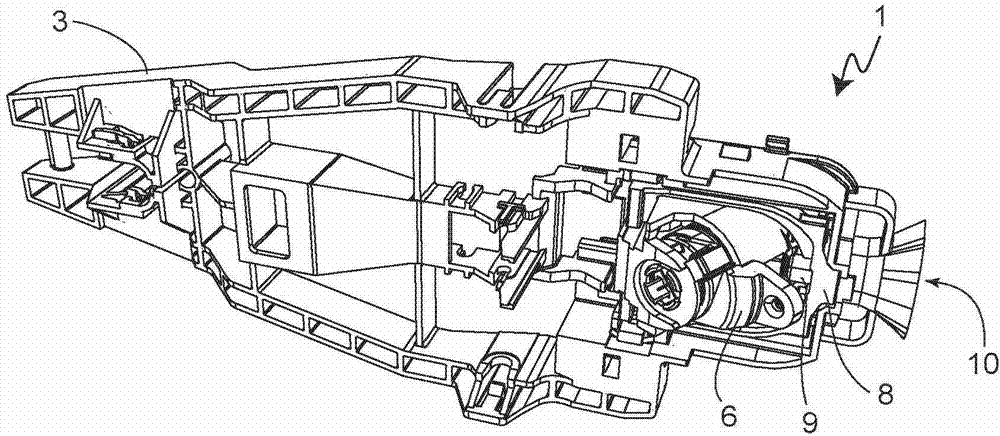

Door handle assembly of a motor vehicle

ActiveCN102953583ADoes not interfere with ease of assemblySimple structureVehicle locksWing handlesEngineeringMechanical engineering

The door handle assembly (1) comprises a lock cylinder (5), and a bearing bracket (3) for receiving the door handle components, which is coupled with a lock cylinder housing (4). The bearing bracket has a receptacle for accommodating the housing. The outer contour of housing is coordinated on the inner contour of receptacle so that at least one region of contact between the housing and receptacle forms a slide-gate which enables movement of housing during insertion into receptacle along a spatial direction which is oblique to other spatial direction.

Owner:HUF HULSBECK & FURST GMBH & CO KG

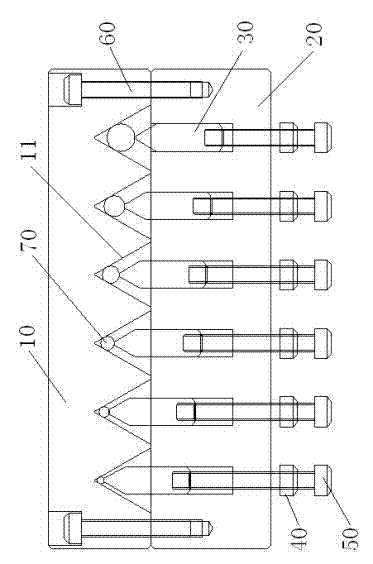

Length processing tool of round bar member

InactiveCN102806519AReduce labor intensityImprove the clamping methodWork carriersEngineeringRound bar

The invention discloses a length processing tool of a round bar member, which comprises a main body block, a supporting block, clamping blocks and locking nuts, wherein a plurality of V-shaped slots are uniformly distributed at the lower end of the main body block, the main body block is oppositely jointed with the supporting block and fixed through nuts, a plurality of grooves are formed in the supporting block and in the position corresponding to the V-shaped slots, the clamping blocks are arranged in the grooves, the head of each clamping block is tapered, and the round bar member is fixed in the V-shaped slots through the locking nuts under the action of engagement of the clamping blocks and the V-shaped slots. Accordingly, the length processing tool can rapidly clamp and load the round bar member, reduce the error frequency, save support time, reduce the labor intensity of technical staff, achieve the effect of batch process and increase the production efficiency.

Owner:昆山旭虹精密零组件有限公司

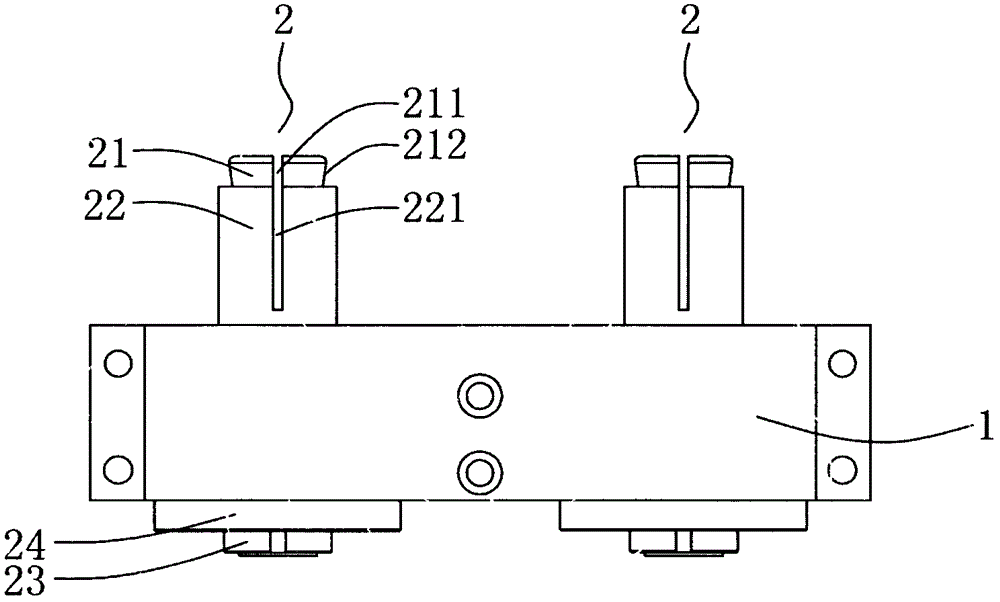

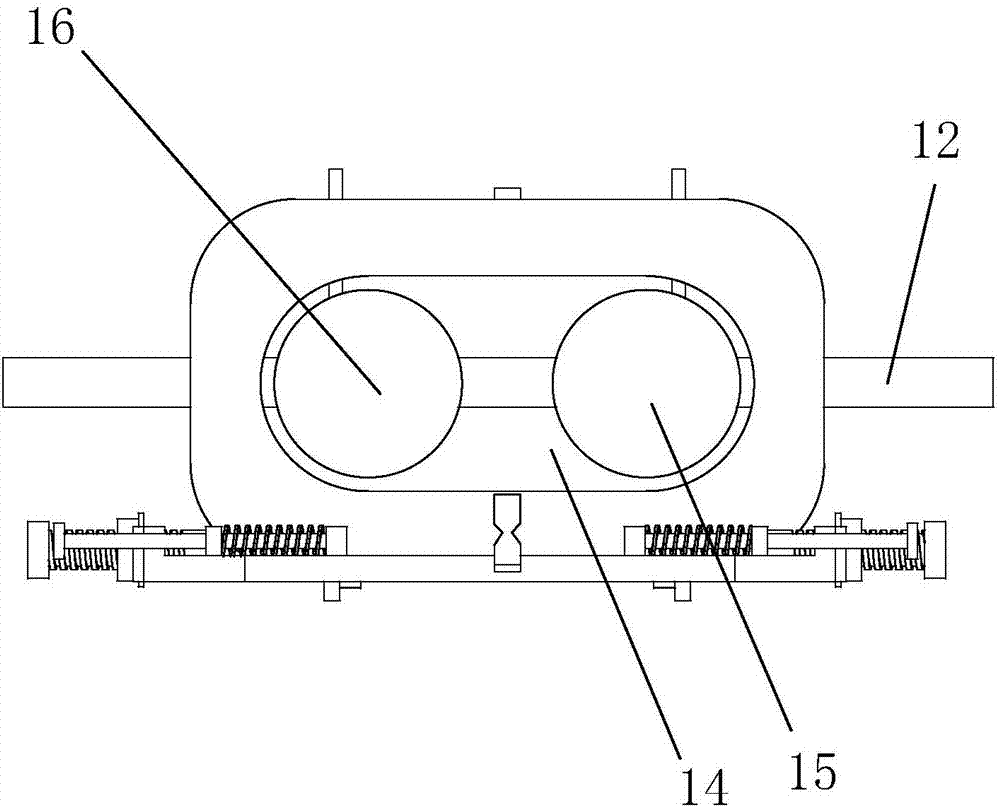

High-efficiency hydraulic clamp

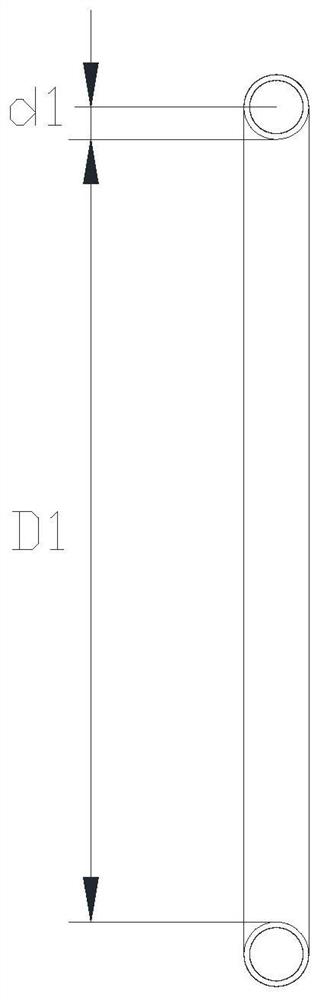

InactiveCN105945610AFast clampingSmall aperturePositioning apparatusMetal-working holdersEngineeringPiston

The invention discloses a high-efficiency hydraulic clamp. The high-efficiency hydraulic clamp comprises a clamp base and two clamp units which are arranged on the clamp base. Each clamp unit comprises a collet chuck and a piston sleeve, wherein the collet chuck is arranged in the clamp base in a penetrating mode, and the piston sleeve is arranged between the clamp base and the collet chuck in a sleeving mode; the front end of the piston sleeve stretches out of the clamp base; a plurality of contracting notches are formed in the front end of the collet chuck in the axial direction, and receding notches corresponding to the contracting notches are formed in the front end of the piston sleeve in the axial direction; and a first conical face is arranged on the outer wall of the front end of the collet chuck, and a second conical face attached to the first conical face is arranged on the inner wall of the front end of the piston sleeve. A first oil port and a second oil port which are matched with the piston sleeves correspondingly are formed in the clamp base. The high-efficiency hydraulic clamp is simple and reasonable in structure arrangement, convenient to use and high in stability; and two workpieces can be clamped at the same time, multiple procedures for machining the workpieces can be completed through one-time clamping of each clamp unit, the workload can be reduced easily, and the machining efficiency and machining precision are improved.

Owner:宁波市欧特瑞智能科技有限公司

VR glasses with adjustable mobile phone receiving groove

InactiveCN107357043AFast clampingNot easy to touchOptical elementsEngineeringElectrical and Electronics engineering

The invention discloses VR glasses with an adjustable mobile phone receiving groove. The pair of VR glasses includes a VR glasses body, a mobile phone holding plate is arranged in front of the VR glasses body, the pair of VR glasses is characterized in that symmetrical mobile phone clamping devices are arranged at the two sides of the inner wall of the mobile phone holding plate, and the VR glasses body and the mobile phone holding plate are connected through a rotation mechanism. By arranging the mobile phone clamping devices, the clamping of the mobile phone can be reinforced, and meanwhile, the buttons of the mobile phone cannot be easily touched during the clamping, the use quality is increased, people feel convenient, and the structure is simple and the use is convenient.

Owner:ZHONGSHAN NUODUN SCI RES TECH SERVICE CO LTD

Novel high-stability machining numerical control lathe

ActiveCN110449605AQuick loading and unloadingPrevent looseningAutomatic/semiautomatic turning machinesChucksNumerical controlClockwork

The invention discloses a novel high-stability machining numerical control lathe, and the structure of the novel high-stability machining numerical control lathe comprises a chuck, a base, a controller, a reciprocating table, a turret and a lathe body, wherein the base is connected to the bottom of the lathe body, and the controller is installed on one side of the lathe body. Compared with the prior art, the novel high-stability machining numerical control lathe has the beneficial effects that: the numerical control lathe adopts the chuck with a novel structure, which not only can be suitablefor workpieces with round clamped parts, but also can be suitable for workpieces with square clamped parts, and can be suitable for workpieces with different specifications, and the application rangeis wide, by controlling a motor, the clamping is more accurate, the clamping degree is firmer, the processing is more facilitated, the processing is more stable, the processing quality of the workpiece is improved, manual adjustment and a spanner are not needed, the operation is safe and simple and convenient, and through the matching of a winding wheel, a gear, arack plate and a clockwork spring,the rack plate can synchronously apply force to the clockwork spring with the winding wheel, which is helpful for improving the clamping speed of the workpiece, thereby realizing the clamping or loosening of the workpiece quickly.

Owner:广州通发智能装备股份有限公司

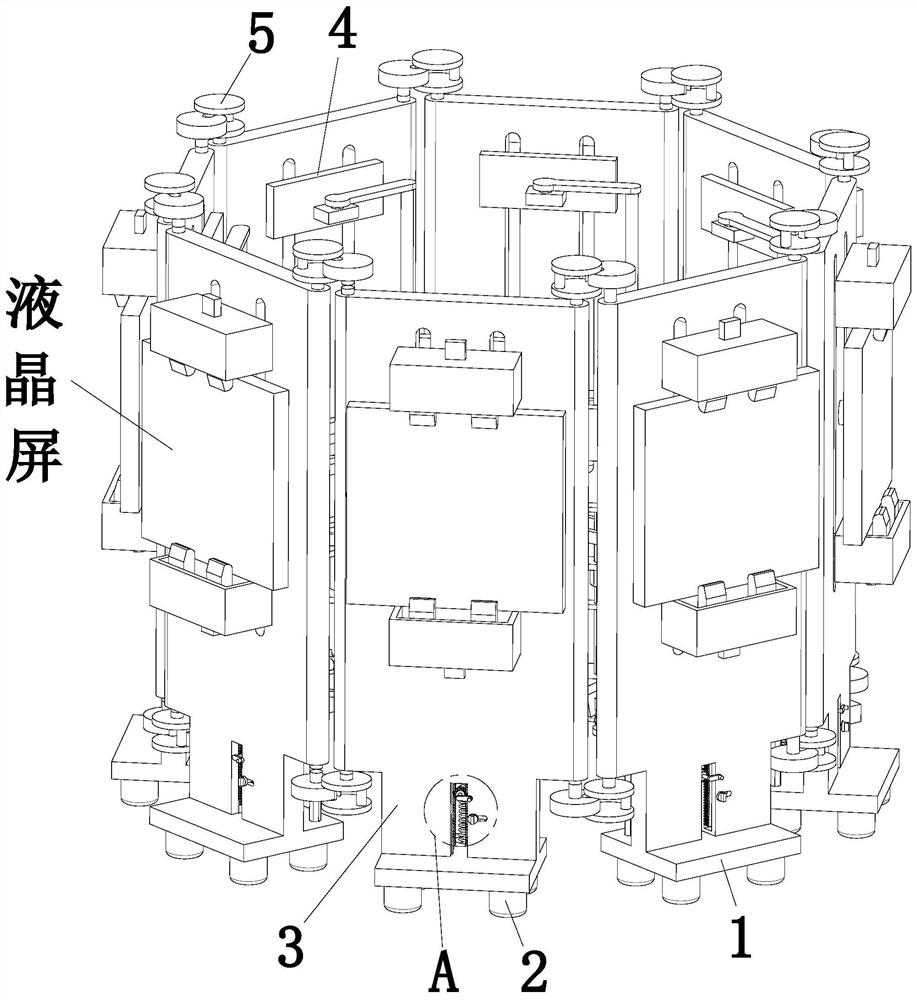

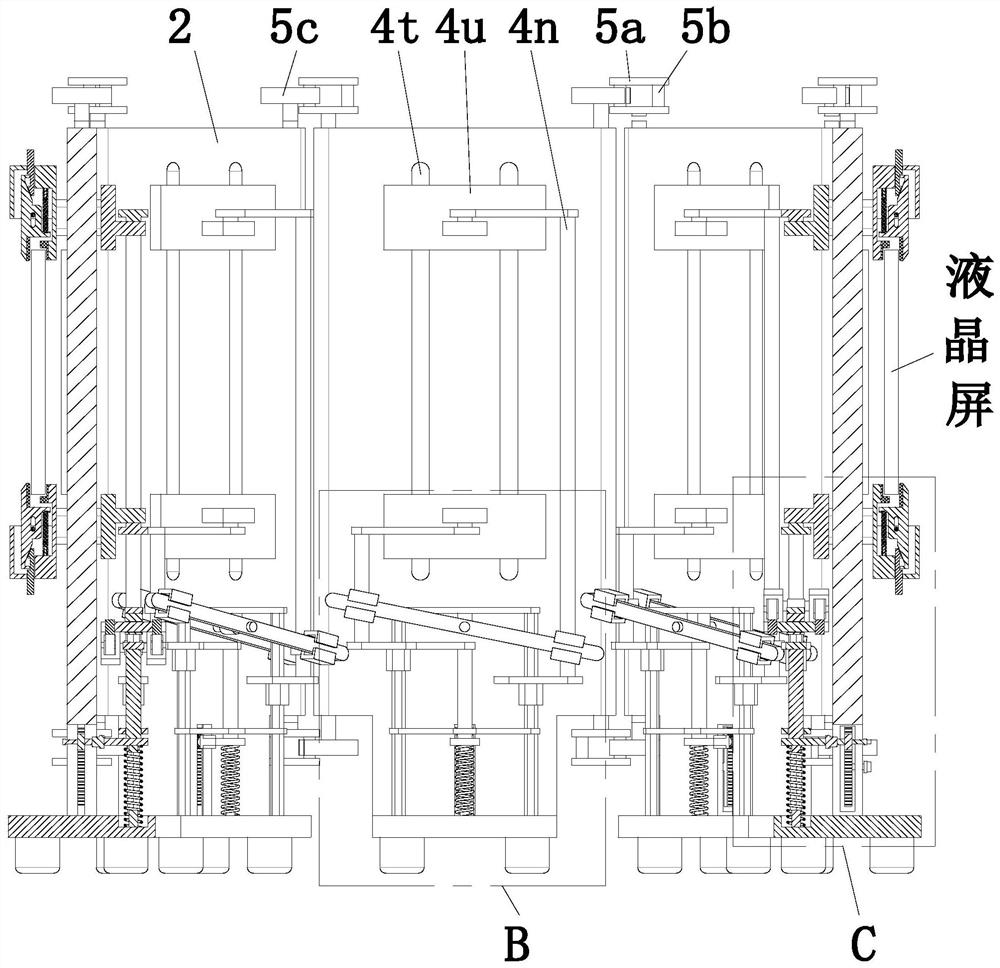

Assembled type liquid crystal display screen

InactiveCN112628538APrevent free fallRealize clamping workStands/trestlesIdentification meansLiquid-crystal displayEngineering

The invention provides an assembled type liquid crystal display screen. The assembled type liquid crystal display screen comprises a mounting bottom plate, a supporting seat, a supporting plate, a clamping mechanism and a splicing mechanism. The problems are solved that most existing liquid crystal display screens are fixedly mounted, specification and size differences of the liquid crystal display screens used in different occasions are large, in actual mounting and clamping operation, the clamping direction of a mounting clamp is difficult to adjust in real time according to the required sizes of the liquid crystal display screens, a stable and firm clamping effect is difficult to provide for the liquid crystal display screens, the mounting number and orientation direction of the liquid crystal screens are difficult to adjust in real time according to the occasion size and shape of a placement position, quick clamping and dismounting operation during mounting of the liquid crystal screens is more difficult to realize, consequently, the operation efficiency of liquid crystal screen assembling operation cannot be improved, and the use requirements of different occasions are not met.

Owner:黄浩

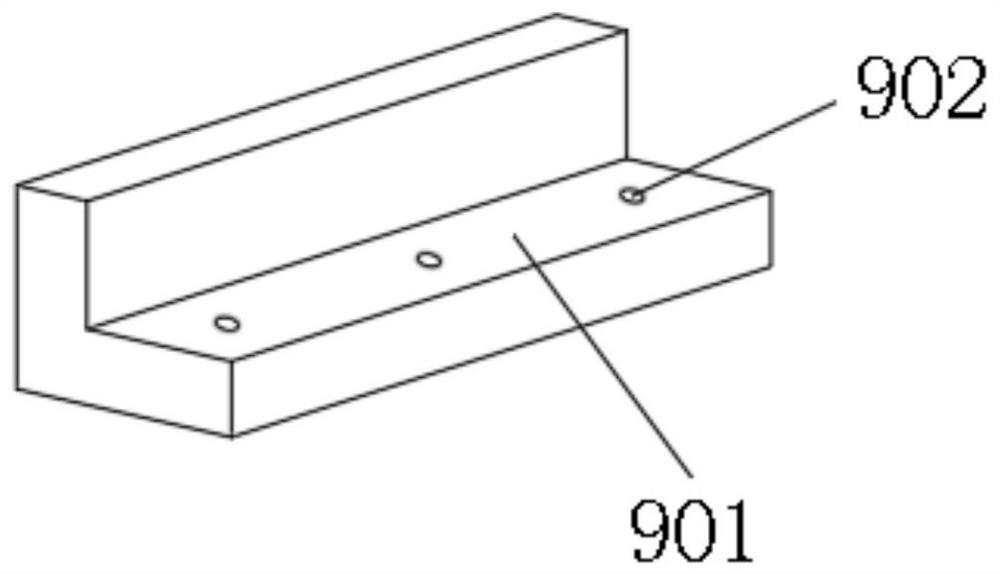

Welding forming auxiliary tool system for building construction PC embedded parts

InactiveCN113231767AGood fixed effectReduce manpower inputWelding/cutting auxillary devicesAuxillary welding devicesProcess engineeringManufacturing engineering

The invention relates to a welding forming auxiliary tool system for building construction PC embedded parts. The auxiliary tool system comprises a workbench, a conveying device and an alignment device. The system can solve the following problems possibly occurring in the welding process of existing building construction PC embedded parts: a, embedded part components are manually supported and fixed so as to complete the welding process between the embedded part components, the mode can be carried out only through cooperation of multiple persons, the welding efficiency is low, the production efficiency of enterprises is low, and thus the income of an enterprise is reduced; and b, the number of the embedded part components which are manually supported at a time is small, the fixing effect is poor, and the embedded part components are prone to shaking due to manual reasons in the welding process, so that the welding quality is affected, and the finished product quality of the building construction PC embedded parts is reduced.

Owner:武汉星润装饰工程有限公司

Clamping and fixing device for communication equipment machining

InactiveCN112091683AFast clampingSmooth rotationMetal working apparatusPositioning apparatusHydraulic cylinderBall bearing

The invention relates to the technical field of clamping and fixing devices, and discloses a clamping and fixing device for communication equipment machining. The device comprises a fixing plate, a working cavity is formed in the fixing plate, and a hydraulic cylinder is fixedly connected to the middle part of the rear side surface of the fixing plate. The output end of the hydraulic cylinder penetrates through the middle of the rear side face of the fixing plate and extends into the fixing plate to be fixedly connected with an auxiliary plate, and auxiliary shafts are rotatably connected intothe left end and the right end of the auxiliary plate. According to the clamping and fixing device for communication equipment machining, through the cooperation of the hydraulic cylinder, the auxiliary plate, the auxiliary shafts, a rotating plate, a control shaft, half gears, a stabilizing shaft, a rack, a sliding strip, a sliding rail, a limiting block and clamping plates, a communication equipment structural part can be clamped and fixed quickly, and time and labor are saved; and through the cooperation of a servo motor, a rotating shaft, a supporting shaft and ball bearings, the angle ofthe communication equipment structural part can be adjusted.

Owner:南京市旗心电子科技有限公司

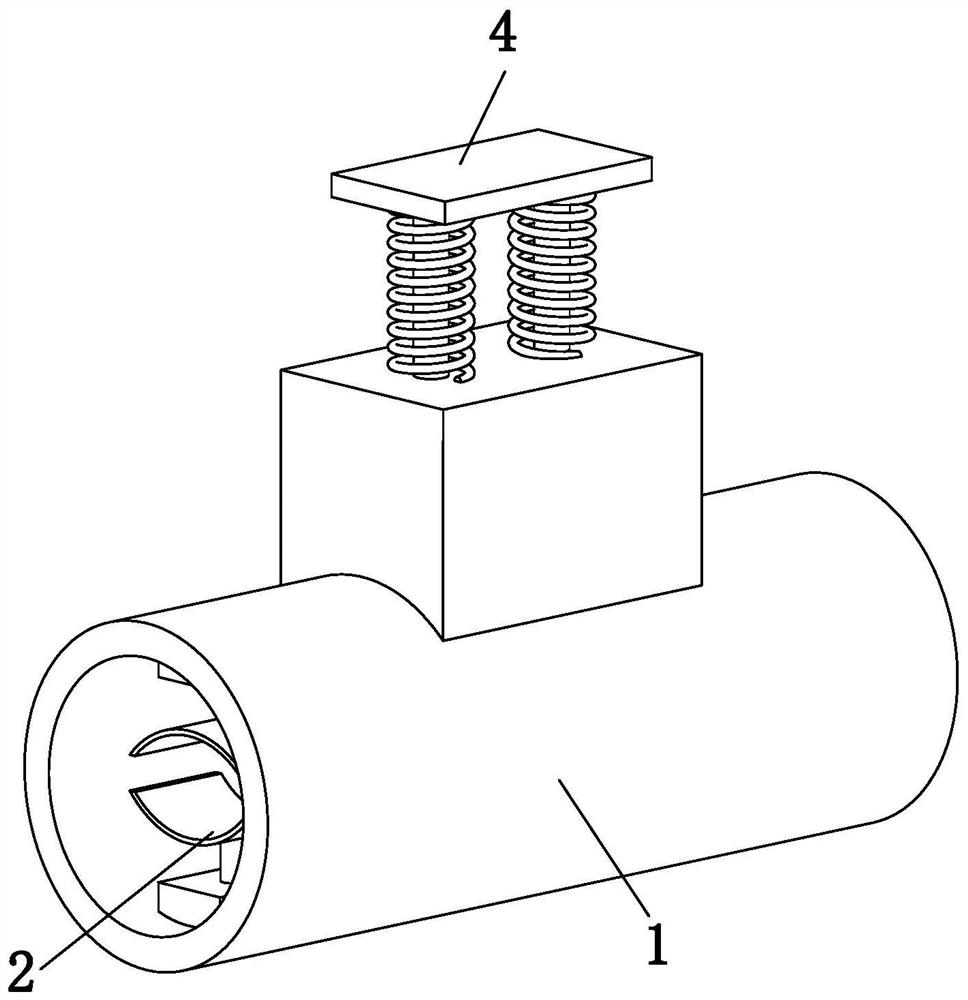

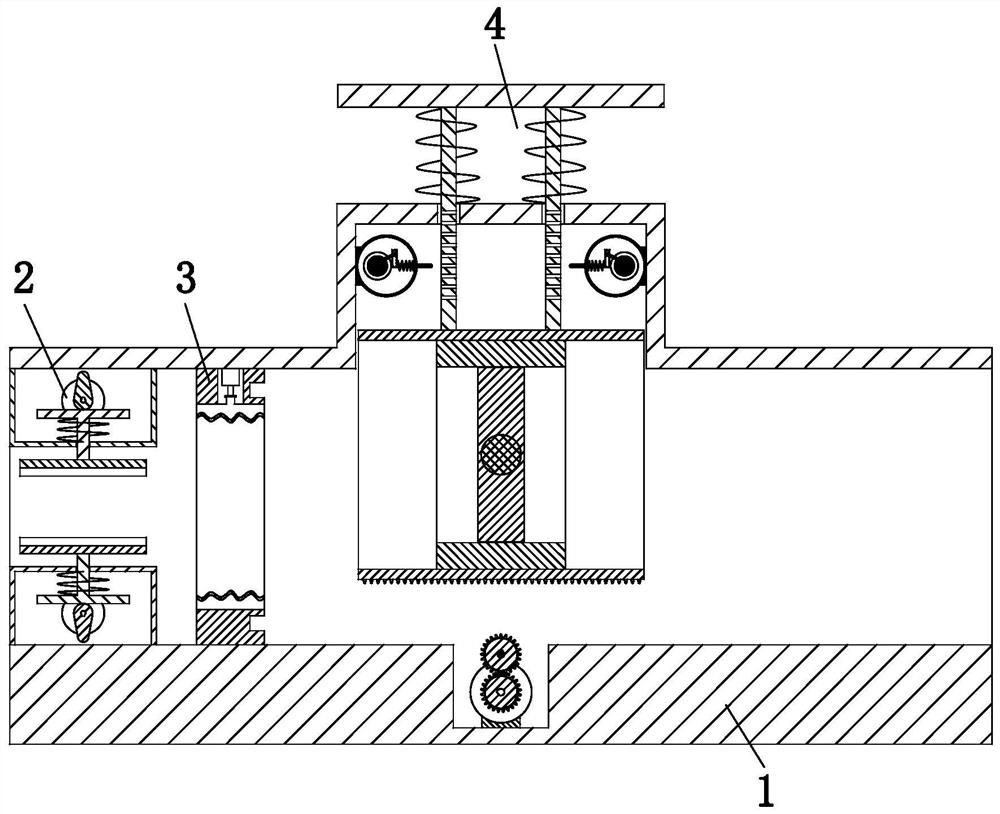

Quick insertion type stop valve

InactiveCN112747133AEasy to installEasy to disassembleSleeve/socket jointsOperating means/releasing devices for valvesSurgeryBiomedical engineering

The invention relates to a quick insertion type stop valve. The valve comprises a valve body, a clamping device, a sealing device and a cut-off device, the clamping device is arranged at the left end of the interior of the valve body, the sealing device is arranged on the right side of the clamping device, the cut-off device is installed on the right side of the sealing device, and the cut-off device is arranged in the middle of the valve body. The valve can solve the following problems that may be met in the using process of an existing stop valve, a, the mounting and dismounting processes are tedious, the operation speciality is high, time and labor are consumed, and thus the practicability of the existing stop valve is poor; and b, it is often required to apply a large force to control the opening and closing of the existing stop valve, the use resistance to a user is prone to be increased, the stop valve is very inconvenient to use, and the use effect of the stop valve is reduced.

Owner:周圳慧

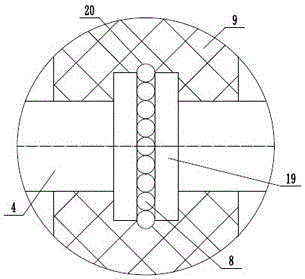

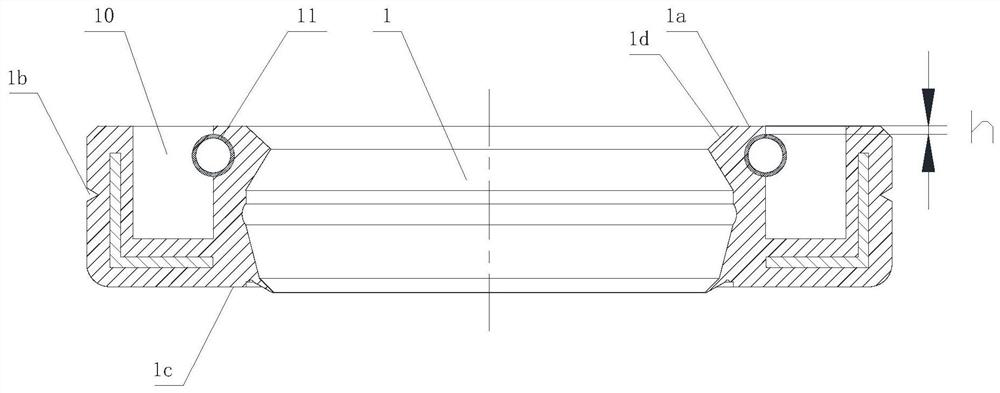

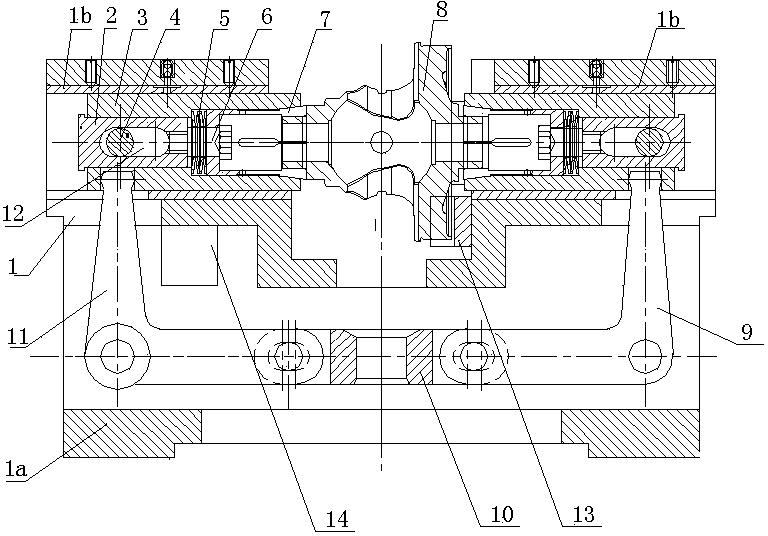

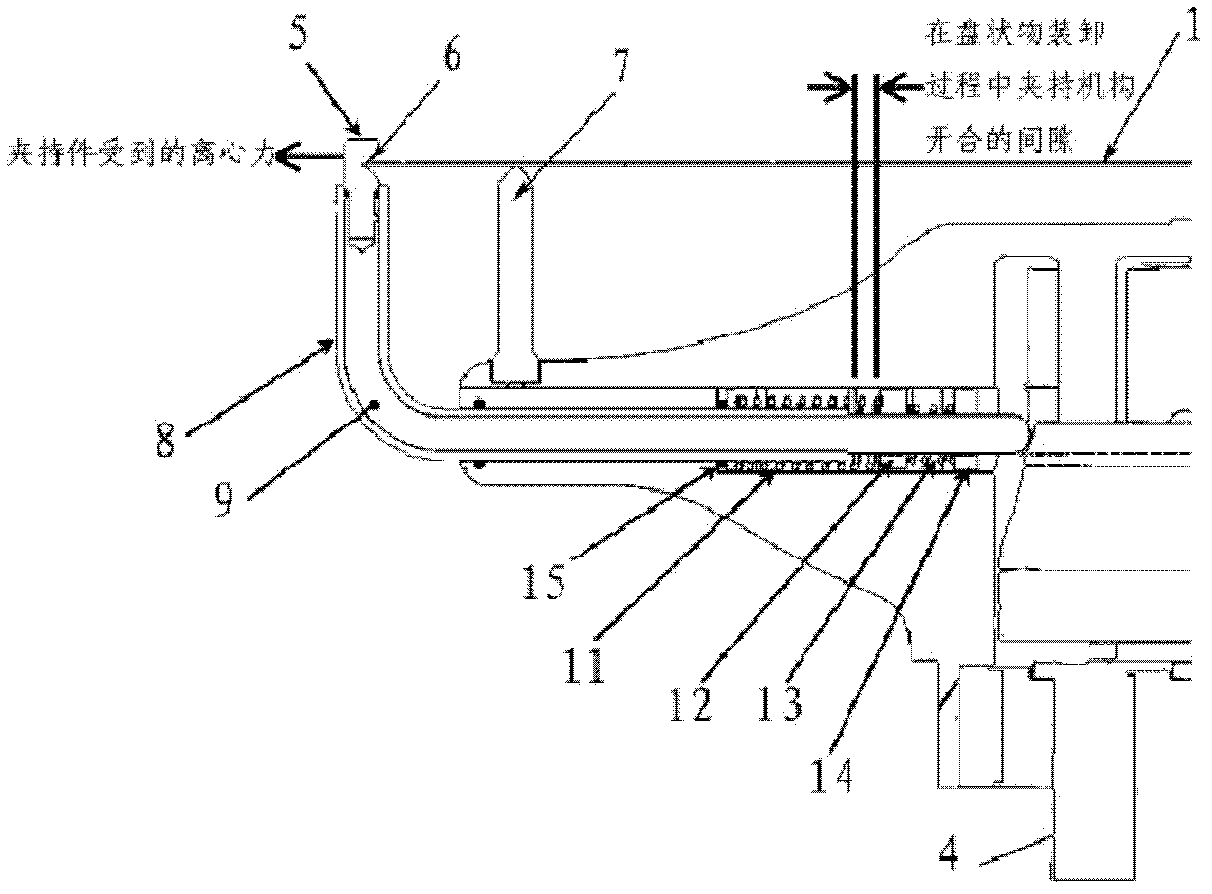

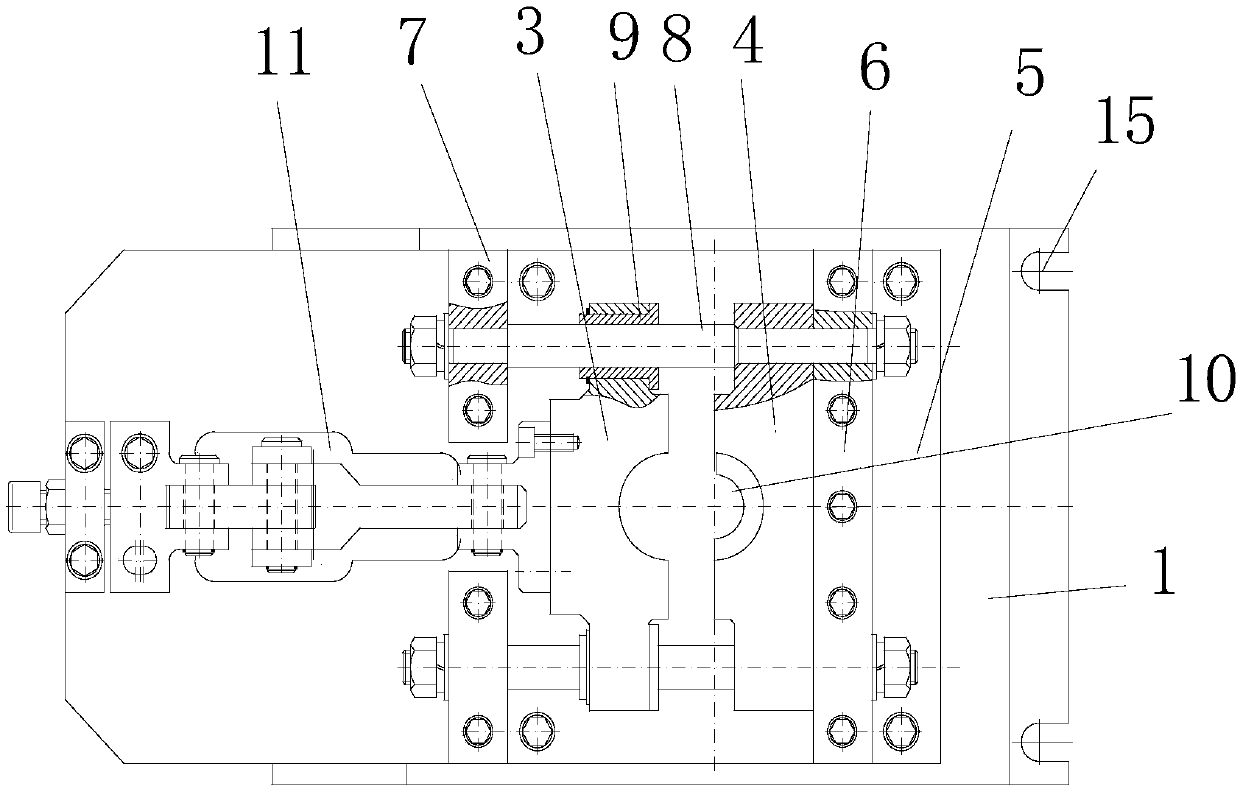

Differential case vehicle inner spherical surface two-side pressing clamp

InactiveCN104043998AAvoid too much centrifugal forceFast clampingWork clamping meansPositioning apparatusEngineeringDynamic balance

The invention provides a differential case vehicle inner spherical surface two-side pressing clamp. The differential case vehicle inner spherical surface two-side pressing clamp comprises a clamp body, wherein a connecting flange portion is arranged at the rear end of the clamp body; bosses are symmetrically arranged at the front end of the clamp body, and elastic sleeve clamping mechanisms are symmetrically arranged on the bosses. When the clamp is in use, the clamp body is connected to a lathe spindle, tightening nuts are connected with a pull rod in the lathe spindle, and the tightening nuts move to drive the two elastic sleeve clamping mechanisms to simultaneously carry out centering and clamping through a first swing arm and a second swing arm. A rotation-preventing positioning block and a balance weight are further arranged on the clamp body. According to the differential case vehicle inner spherical surface two-side pressing clamp, the clamp body is of an integrated structure, synchronous swing arms on the two sides carry out self-centering clamping and pressing, and disc springs at the two ends carry out pre-adjustment pressing; due to the fact that the balance weight is arranged, the phenomenon that centrifugal force is overlarge can be avoided, dynamic balance is achieved, and it is ensured that clamping is quick, and positioning is accurate.

Owner:SHIYAN HEJUN IND

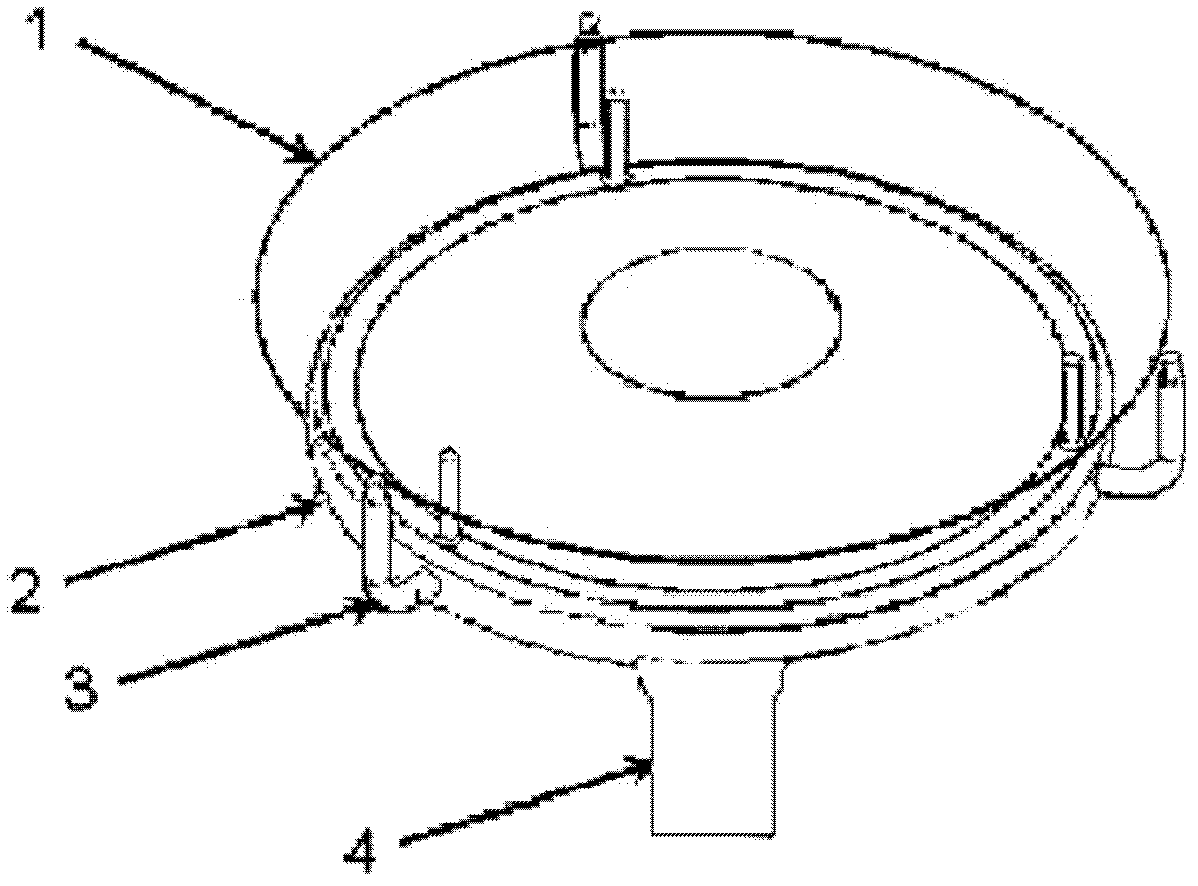

Cam-type disc clamping device

InactiveCN102593033ARealize opening and closingFast clampingSemiconductor/solid-state device manufacturingCamBiomedical engineering

The invention relates to the technical field of integrated circuits, and in particular discloses a cam-type disc clamping device. The cam-type disc clamping device comprises a cam, a clamp disc and clamping mechanisms, wherein the centre on the lower part of the clamping disc is connected with the cam; the clamping mechanisms are all arranged on the clamping disc; and each clamping mechanism comprises an extension rod, wherein one end of the extension rod is extended into the clamping disc and is contacted with the circumference of the cam, and the other end of the extension rod is upward and is provided with a clamping piece used for clamping a disc object. By using the device, the disc object can be clamped conveniently and rapidly; and moreover, the device is simple in structure, low in cost and easy to implement.

Owner:北京硅元科电微电子技术有限责任公司

Wire clamp clamping and fixing device

InactiveCN107649911ACompact structurePlay the role of clamping and fixingWork clamping meansPositioning apparatusPower cableEngineering

The invention belongs to the technical field of power cable clamping devices, and particularly relates to a wire clamp clamping and fixing device. The device comprises a base, an air cylinder, a leftclamping plate, a right clamping plate and a bottom plate, wherein the bottom plate is fixed on the base; the right clamping plate is fixed to the right side of the bottom plate through a right fixingseat; two left fixing seats are fixed on the left side of the bottom plate; two guide columns are connected between the left fixing seats and the right fixing seat; guide sleeves are arranged at thetwo ends of the left clamping plate; the left end of the left clamping plate is hinged to one end of a right connecting arm; a connecting seat is arranged on the bottom plate on the left side of a through hole; the connecting seat is hinged to one end of the left connecting arm; the other end of the left connecting arm and the other end of the right connecting arm penetrate through the through hole to be hinged to a piston rod of the air cylinder; and the bottom of the air cylinder is hinged to the base. The wire clamp clamping and fixing device is compact in structure and can be mounted at any position as a whole, so that the effect of clamping and fixing is achieved, the wire clamp can be clamped through the wire clamp clamping and fixing device, and the clamping is rapid and stable.

Owner:徐州宇飞电力科技有限公司

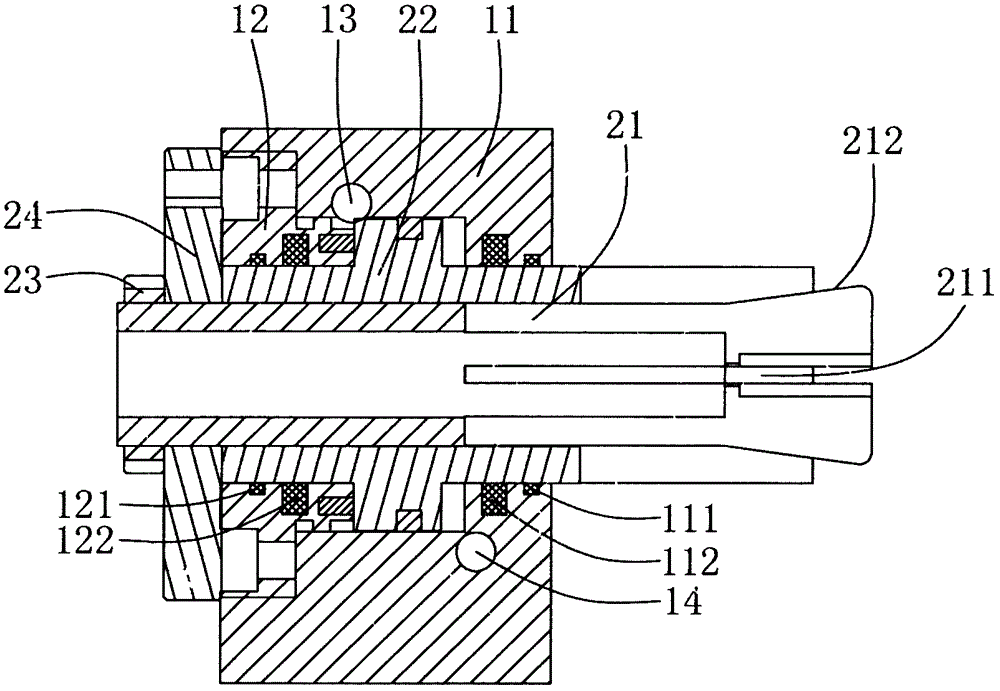

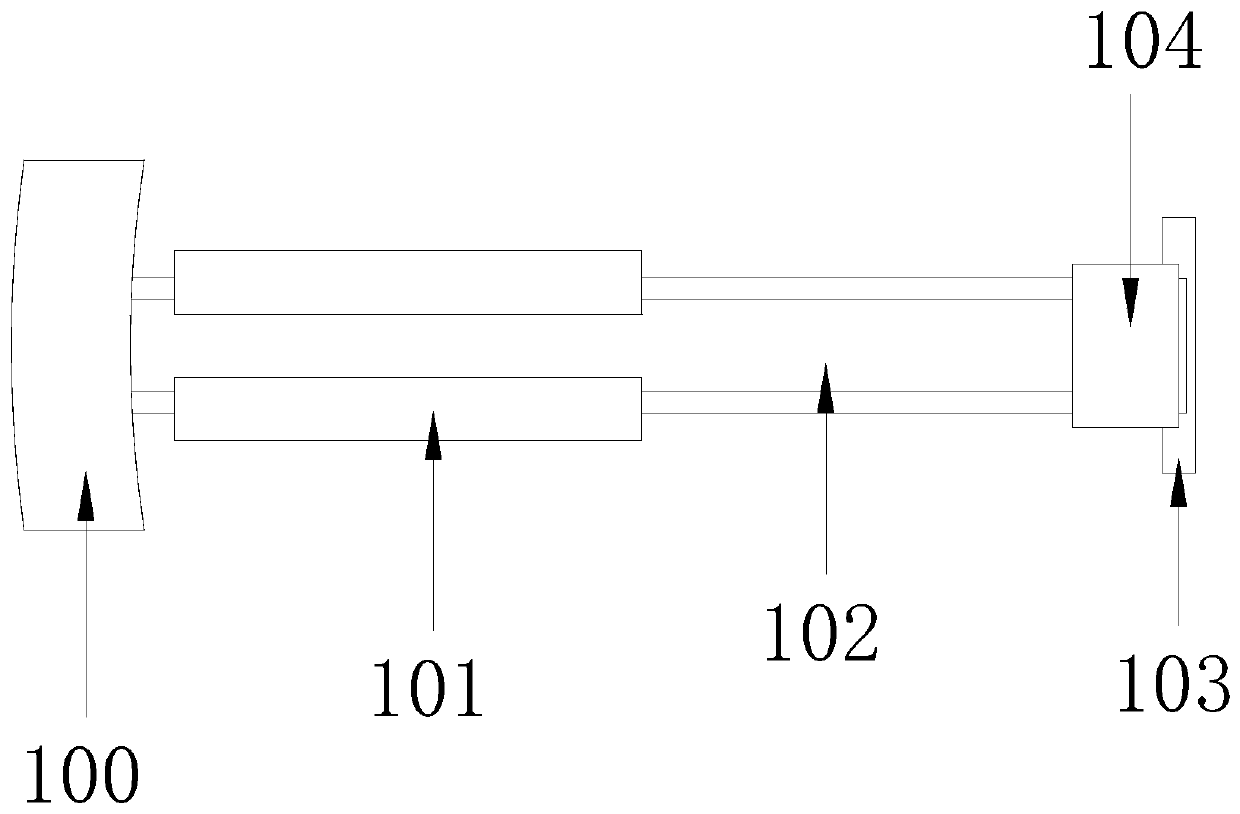

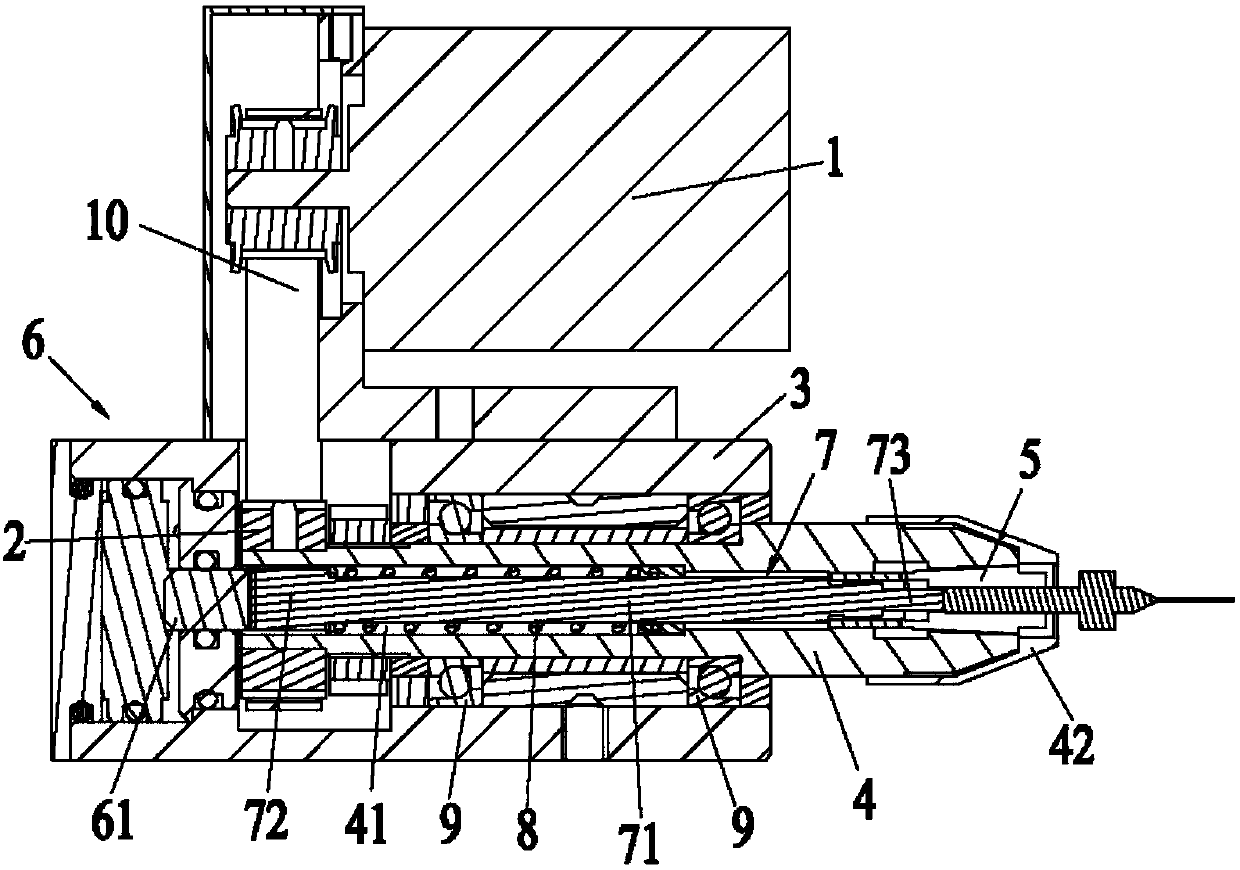

Precision chuck for clamping PCB micro drill bit

The invention relates to the technical field of mechanical chucks, in particular to a precision chuck for clamping a PCB micro drill bit. The precision chuck comprises a stepping motor, a synchronouspulley, a chuck base, a working head core, a chuck body, an air cylinder, a chuck pull rod and a compression spring. The working head core is installed inside the chuck base through a bearing. The synchronous pulley is arranged on the working head core in a sleeving mode and is further connected with the stepping motor. The working head core is provided with a through cavity. The chuck body and the chuck pull rod are both installed in the through cavity and are further matched to be connected. The compression spring is arranged on the chuck pull rod in a sleeving mode. A piston of the air cylinder corresponds to the end of the chuck pull rod. According to the precision chuck for clamping the PCB micro drill bit, the air cylinder is used for driving the chuck pull rod to move, the PCB microdrill bit can be clamped or loosened quickly through the chuck body, and machining of the PCB micro drill bit is facilitated; and the production efficiency is improved, labor cost is reduced, and unsafe factors like needle breaking and hand injuries caused by manual material collection traditionally are avoided.

Owner:GUANGDONG UCAN ROBOT TECH CO LTD

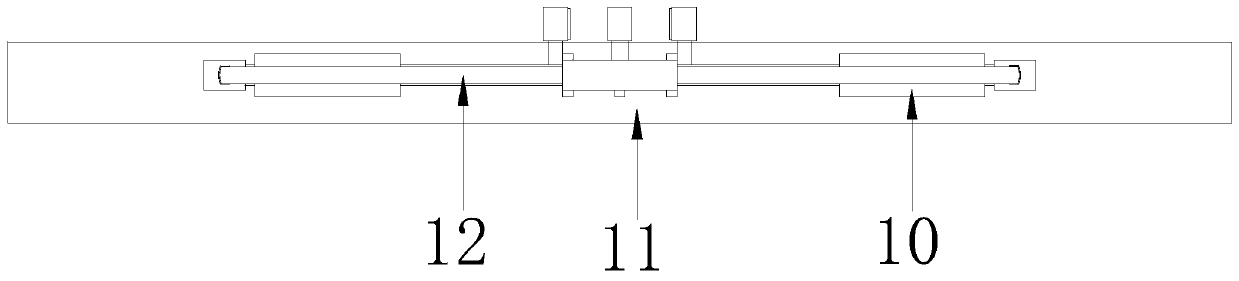

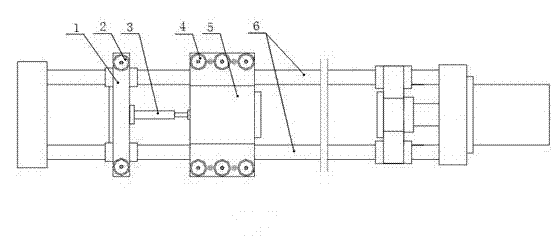

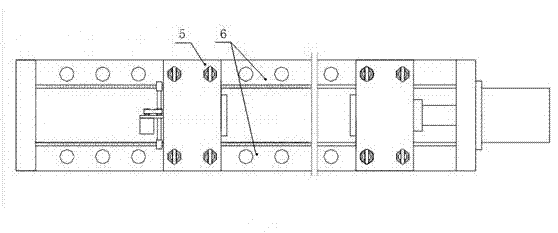

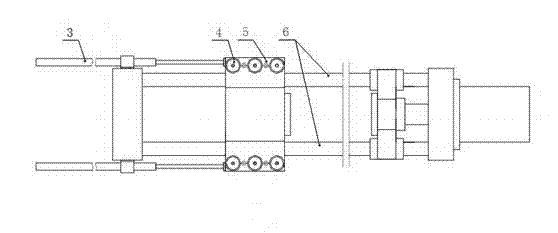

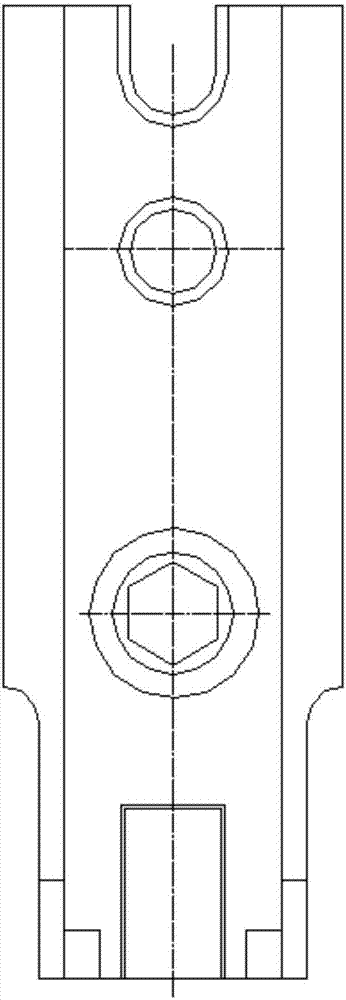

Clamping and moving device and method of cross beam of horizontal type tensile and compression testing machine

InactiveCN102967503AFast clampingMake full use of the site spaceStrength propertiesHydraulic cylinderEngineering

The invention discloses a clamping and moving device and method of a cross beam of a horizontal type tensile and compression testing machine. The device comprises a column, the cross beam and cross beam clamping cylinders, wherein the cross beam clamping cylinders are installed on the four corners of the cross bean; and the cross beam is clamped or released from the column through the cross beam clamping cylinders. The device further comprises a push-pull oil cylinder, a fixing plate and fixing plate clamping cylinders, wherein the fixing plate is arranged in parallel to the cross beam; the fixing plate is clamped or released from the column through the fixing plate clamping cylinders; the push-pull oil cylinder is arranged inside a frame and positioned between the cross beam and the fixing plate; the push-pull oil cylinder is a double action hydraulic cylinder; the piston and the cylinder barrel of the push-pull oil cylinder are respectively linked with the cross beam and the fixing plate; and hydraulic oil paths of the fixing plate clamping cylinders, the push-pull oil cylinder and the cross beam clamping cylinders are switched under electric control so as to clamp, release and move along the column in a stepless adjustment mode. By combining cross beam hydraulic clamping and hydraulic pushing, the resource of a testing machine is sufficiently utilized, occupied field is small and operation is convenient.

Owner:JINAN SHIDAI SHIJIN TESTING MACHINE GRP

Special inserting tool for fuses of automobile electrical box

InactiveCN106981405AImprove placement efficiencyEasy to holdEmergency protective devicesMetal sheetEngineering

The invention relates to a special inserting tool for fuses of an automobile electrical box, which comprises a clamping base and an elastic clamping metal piece, and is characterized in that the clamping base is made of an organic material with certain flexibility; the clamping base and the elastic clamping metal piece are laminated and are fixedly connected through at least one bolt; the bottom of the elastic clamping metal piece is provided with a long rectangular gap at the central part, the bottom of the elastic clamping metal piece is enabled to form two clamping strips, and the end part of each clamping strip is provided with a flange; the bottom of the clamping base is provided with a short rectangular gap with the width corresponding to that of the long rectangular gap; and when the special inserting tool is used, the flanges are embedded into grooves on a fuse shell, the clamping base and the elastic clamping metal piece are matched so as to clamp the fuse shell, and the short rectangular gap is used for limiting the clamping depth of the fuse shell. The special inserting tool clamps the fuse shell by matching the elastic clamping metal piece and the clamping base made of an organic material with certain flexibility, the clamping process is easy and quick, the stability is high, and the fuse inserting efficiency is improved.

Owner:SHANGHAI HUGONG AUTO ELECTRIC

Air cylinder pressing clamp for numerical control machine tool

PendingCN112692617ARapid positioningQuick clampingPositioning apparatusMetal-working holdersNumerical controlEngineering

The invention provides an air cylinder pressing clamp for a numerical control machine tool, and relates to the technical field of numerical control machining. The air cylinder pressing clamp for the numerical control machine tool comprises a base, a rotating platform is rotationally connected to the top of the base, a center base is fixedly connected to the center of the top of the rotating platform, a supporting plate is fixedly connected to the top of the center base, and clamping mechanisms are fixedly installed at the front ends and the rear ends of the two sides of the top of the rotating platform; and openings corresponding to the clamping mechanisms are formed in the corners of the supporting plate, a limiting mechanism is installed at the rear end of the top of the supporting plate, and a pushing mechanism is installed between fixing blocks. By designing the clamping mechanisms, the limiting mechanism and the pushing mechanism, various to-be-machined workpieces of different shapes and sizes can be rapidly clamped and fixed, and after the workpieces are placed on the supporting plate, the pushing mechanism can automatically push the workpieces to move to the designated position, so that the overall working efficiency is greatly improved, and the clamp is worthy of vigorous popularization.

Owner:江苏艾克赛勒金属科技有限公司

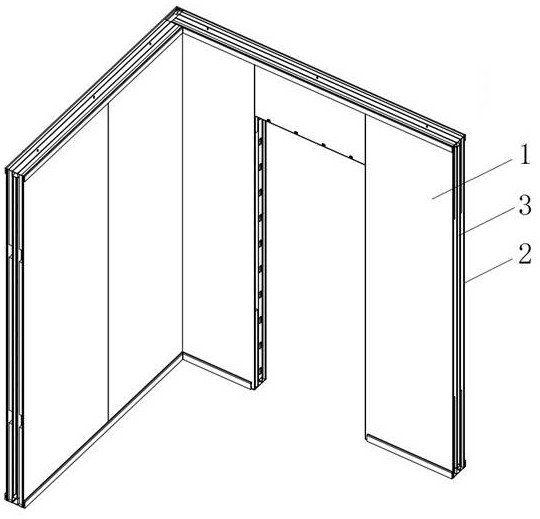

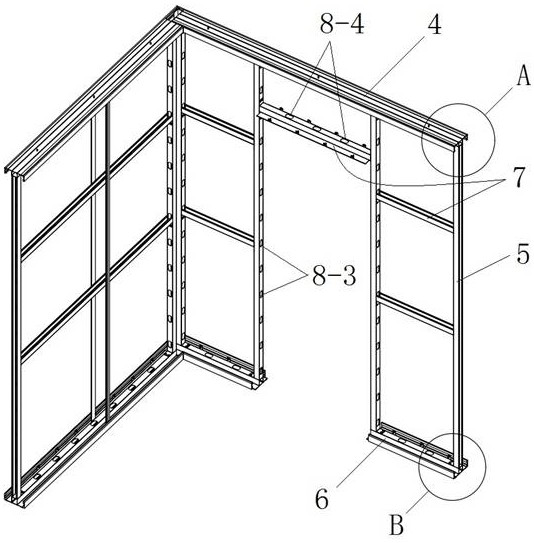

Assembly type partition wall and installation method thereof

InactiveCN113187128AGuaranteed sound insulation efficiencyImprove sound insulationWallsLine tubingKeel

The invention provides an assembly type partition wall and an installation method thereof, and belongs to the technical field of construction. The assembly type partition wall comprises a keel frame and a composite board, the keel frame comprises a top keel, a vertical keel and a bottom keel, the top keel, the vertical keel and the bottom keel are combined to form a frame structure, a sound insulation material is arranged on the inner side of the composite board in a compounded mode, the composite board comprises a first side wall board connected to one side of the keel frame in an attached mode and further comprises a second side wall board connected to the other side of the keel frame in an attached mode, an interlayer is arranged on a position, between the first side wall board and the second side wall board, on the keel frame, and a channel suitable for providing a reserved pipeline is formed in the interlayer. According to the assembly type partition wall, the composite board is attached to the two sides of the keel frame for installation, and therefore sound insulation filler arranged in the keel frame is omitted, when the reserved pipeline is arranged in the keel frame, the integrity of the sound insulation material in the composite board cannot be damaged, and the sound insulation efficiency of the partition wall is guaranteed.

Owner:北京和能人居科技有限公司

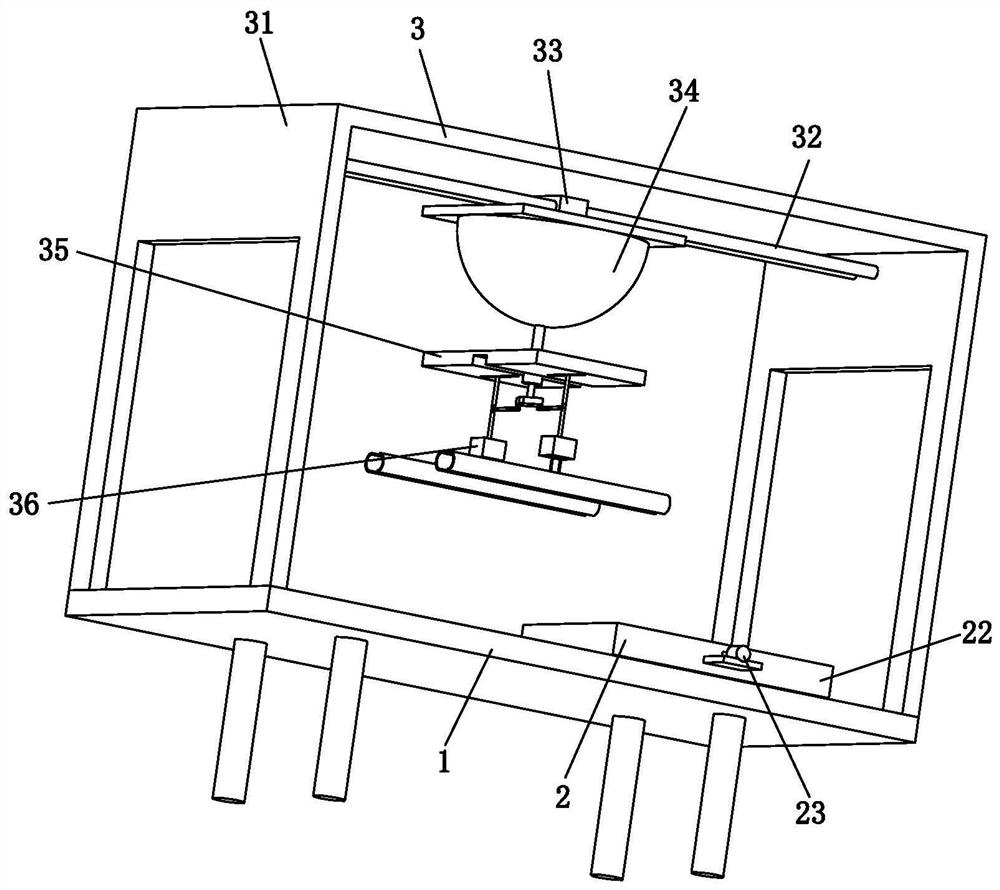

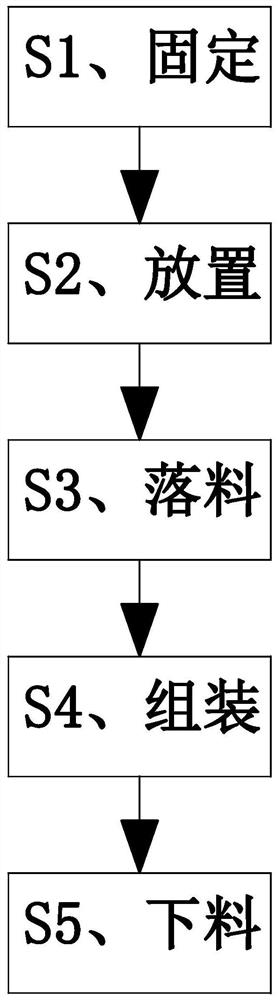

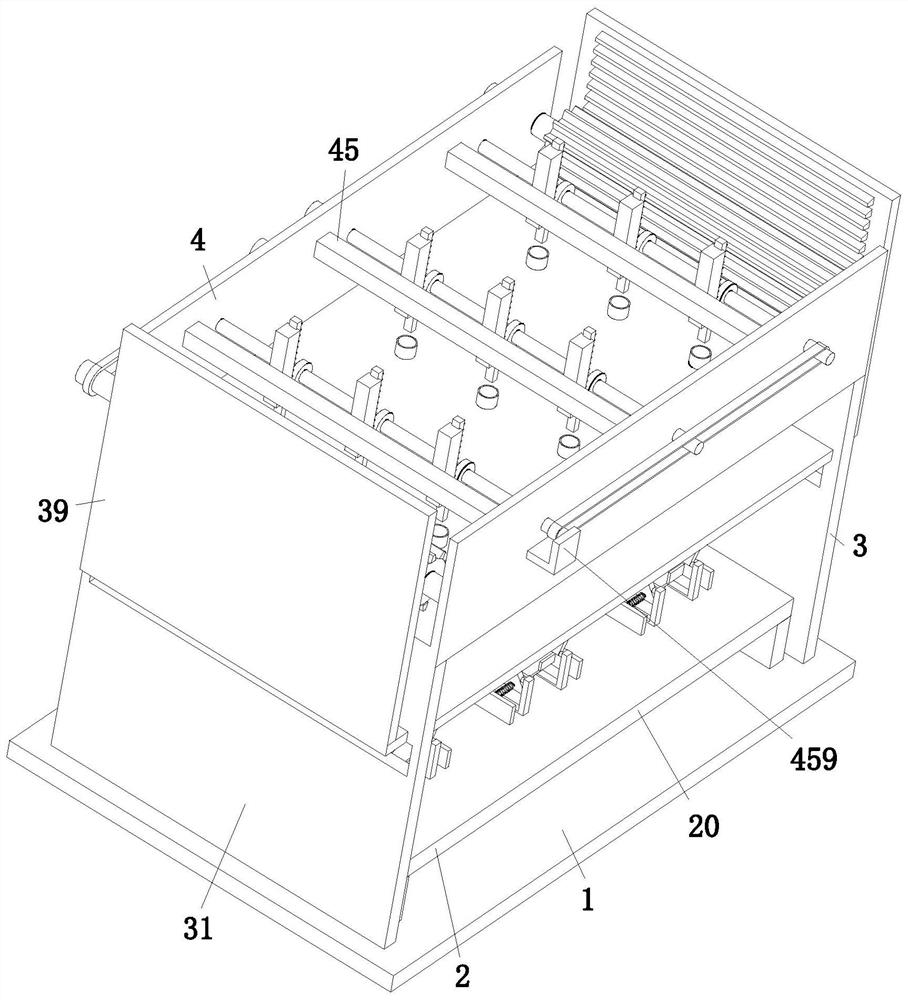

Production and assembly method for electric power splicing fitting

ActiveCN113102985AImprove applicabilityImprove work efficiencyMetal working apparatusMachineElectric power

The invention relates to a production and assembly method for electric power splicing fitting, which comprises a workbench, a fixed device, a moving device and a blanking device. Through cooperation of the workbench, the fixed device, the moving device and the blanking device, according to different numbers of bolts in a group of electric power splicing fittings needing to be assembled, the bolts are placed on the fixed device in batches, so that the applicability is improved when the electric power splicing fittings are assembled, the electric power splicing fittings are clamped and fixed through the fixed device, at the moment, a lower die base and an upper die base are assembled, and after assembling, nuts are blanked onto the nuts through the blanking device, and finally, the nuts and the bolts are quickly assembled through the arranged moving device, so that the situation that the nuts and the bolts are too tight or too loose when being assembled is avoided, and the working efficiency is improved when the electric power splicing fittings are assembled by a machine.

Owner:新昌县新明实业有限公司 +1

Color box processing system and color box processing method thereof

ActiveCN112172334AEasy to pass through symmetricallyFast clampingBox making operationsPaper-makingProcess engineeringIndustrial engineering

The invention discloses a color box processing system and a color box processing method thereof. The color box processing system comprises a cutting device, a printing system, a surface treatment system, a corrugation mounting device, a box rolling device, an inspection device and a packaging device. The processing process of the color box processing method sequentially comprises the steps of cutting, printing, printing inspection, surface treatment, corrugation mounting, box rolling, forming, full inspection, packaging and warehousing. The printing step comprise the steps of S1, paper tube installation, S2, printing paper positioning, S3, stable paper feeding and S4, printing operation. According to the system and the method, it can be ensured that the printed content is complete, and waste caused by the situation that content is missing or large-area paper is adopted is avoided.

Owner:厦门市环岛包装科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com