Full-automatic bearing spherical surface drilling, chamfering, tapping all-in-one machine and use method thereof

A fully automatic, all-in-one technology, applied in the field of bearing processing, can solve the problems of long cycle, low efficiency, and easy errors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

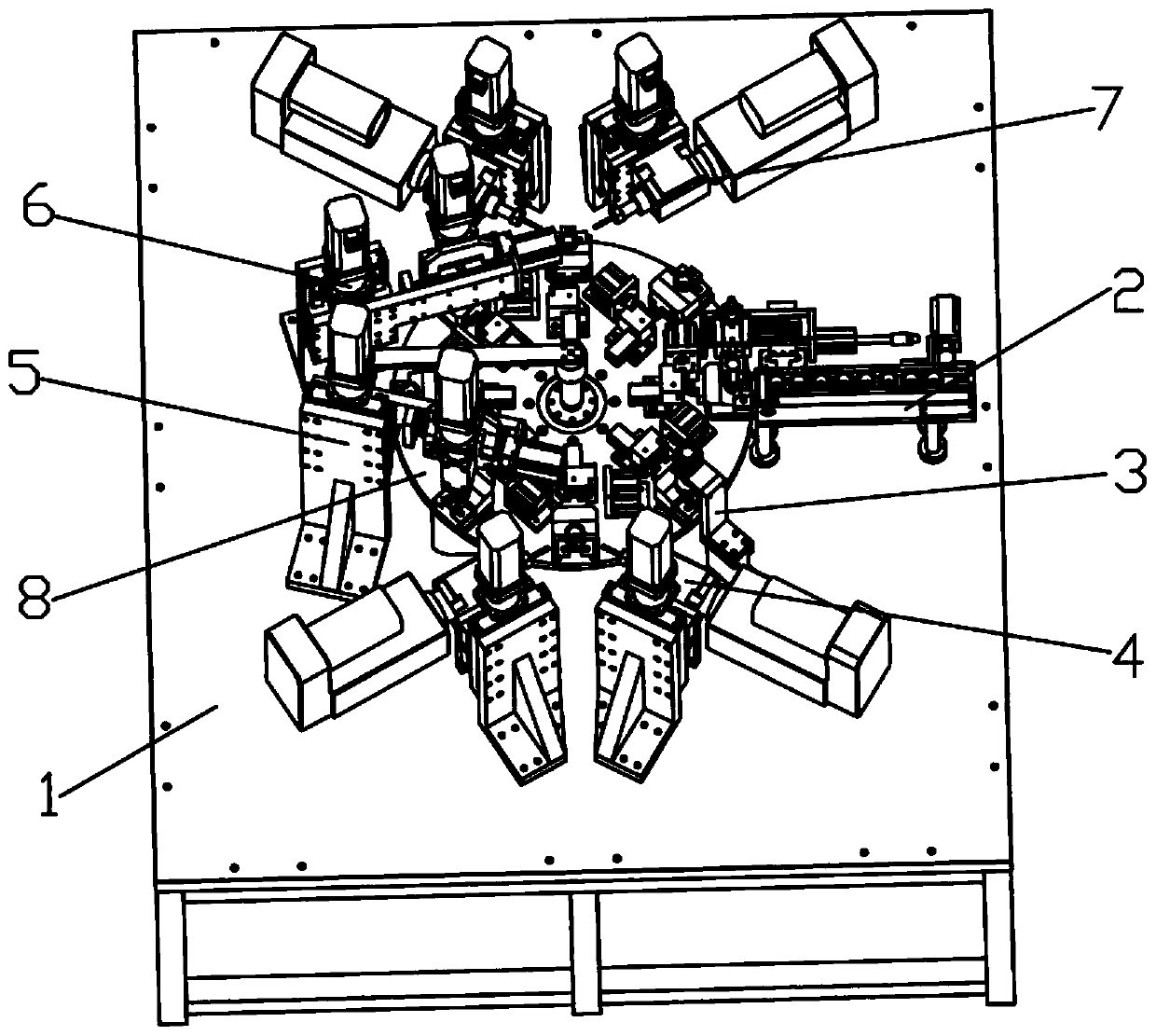

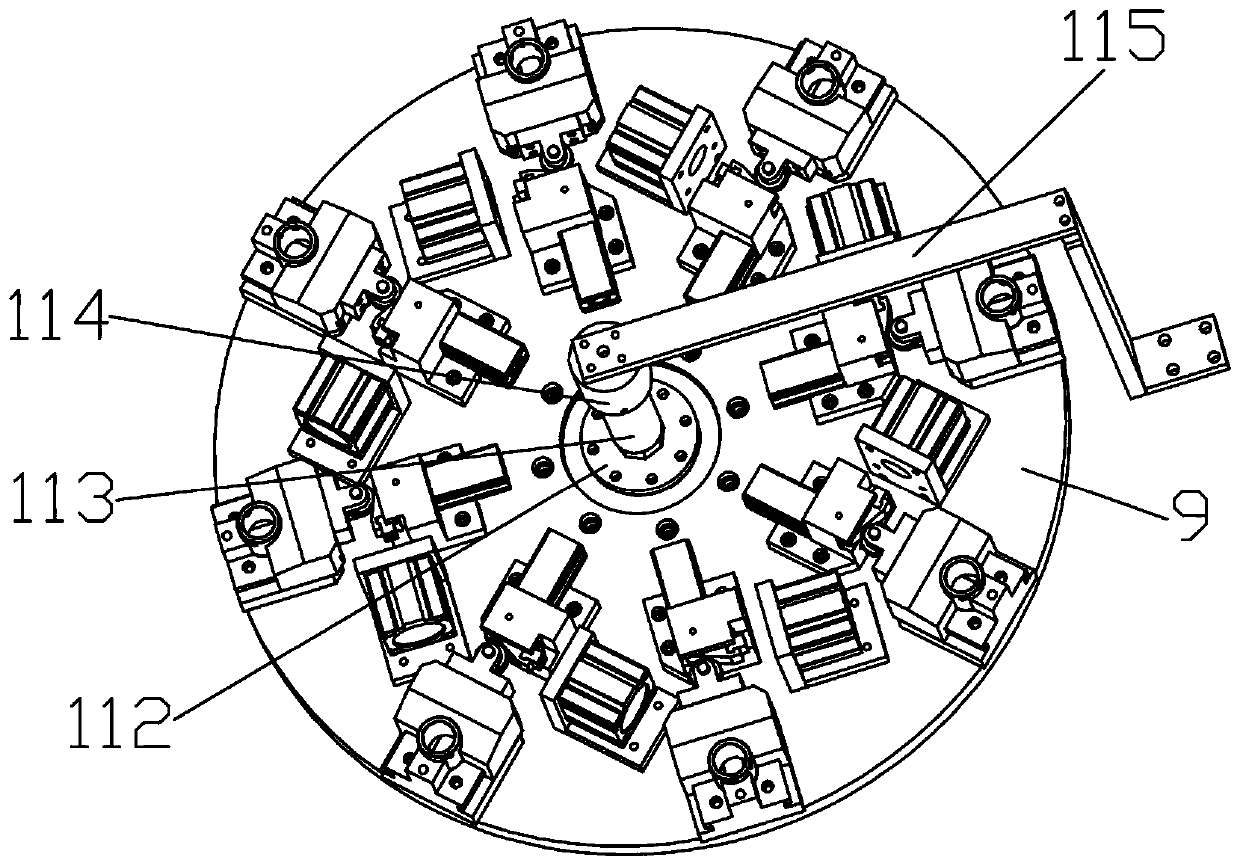

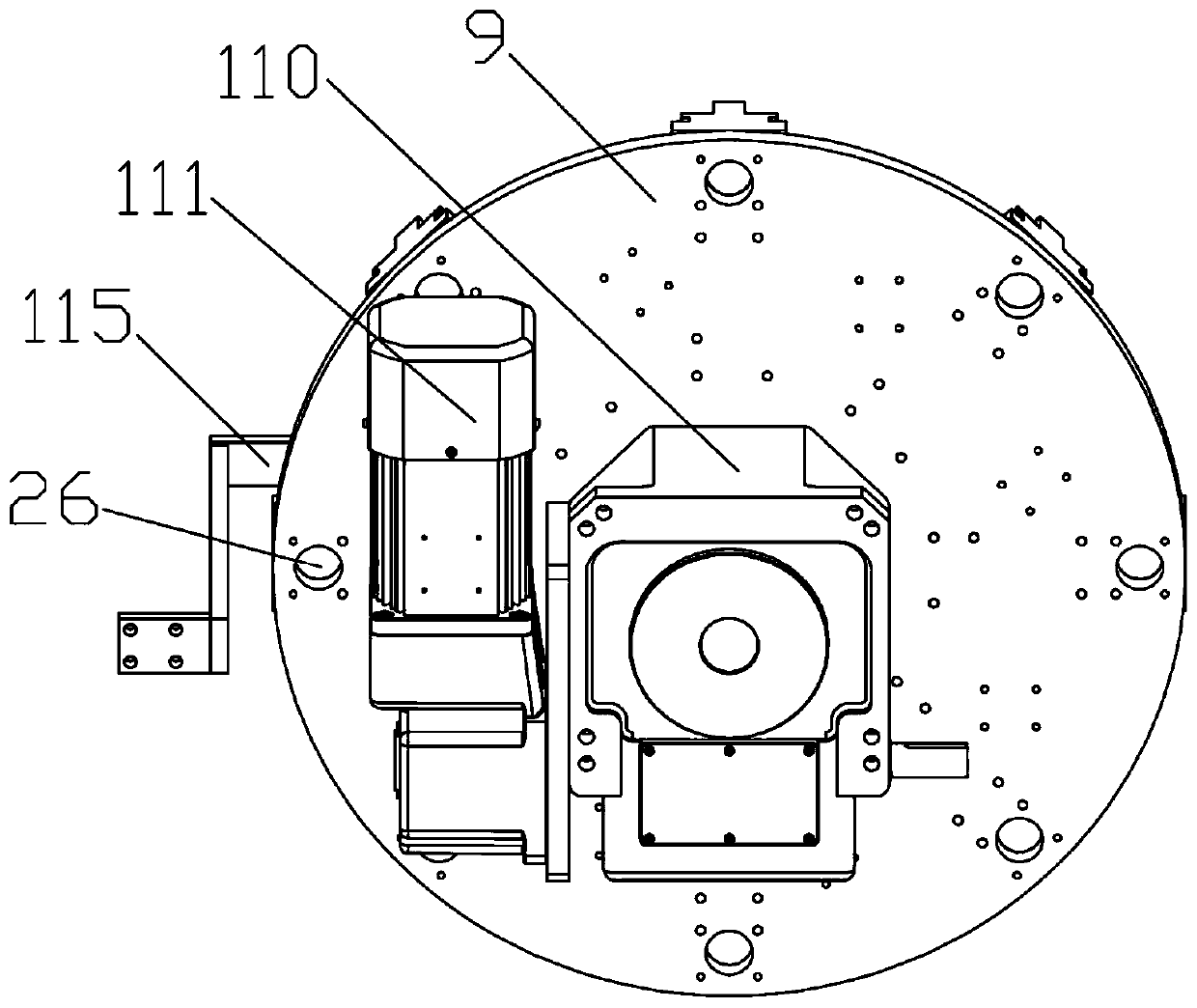

[0060] Example: A fully automatic bearing spherical surface drilling, chamfering and tapping machine, such as Figure 1-Figure 15 As shown, it includes a frame, a feeding mechanism, a pressing mechanism, a drilling mechanism, a first inner chamfering mechanism, a second inner chamfering mechanism, a tapping mechanism, and a turntable mechanism. The feeding mechanism, the pressing mechanism, The drilling mechanism, the first internal chamfering mechanism, the second internal chamfering mechanism, the tapping mechanism and the turntable mechanism are all fixedly installed on the frame. The turntable mechanism includes a turntable and eight clamping modules, and the eight clamps The tight module is arrayed in a circumferential direction with the center of the turntable as the center. The feeding mechanism, the pressing mechanism, the drilling mechanism, the first inner chamfering mechanism, the second inner chamfering mechanism and the tapping mechanism are located on the periphery...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com