Intelligent polishing machine for manufacturing inner ring and outer ring of bearing

A technology for inner and outer rings and polishing machines, which is applied in the field of bearings, can solve the problems of increased workload and low efficiency of workers, and achieve the effects of increasing service life, improving polishing effects, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

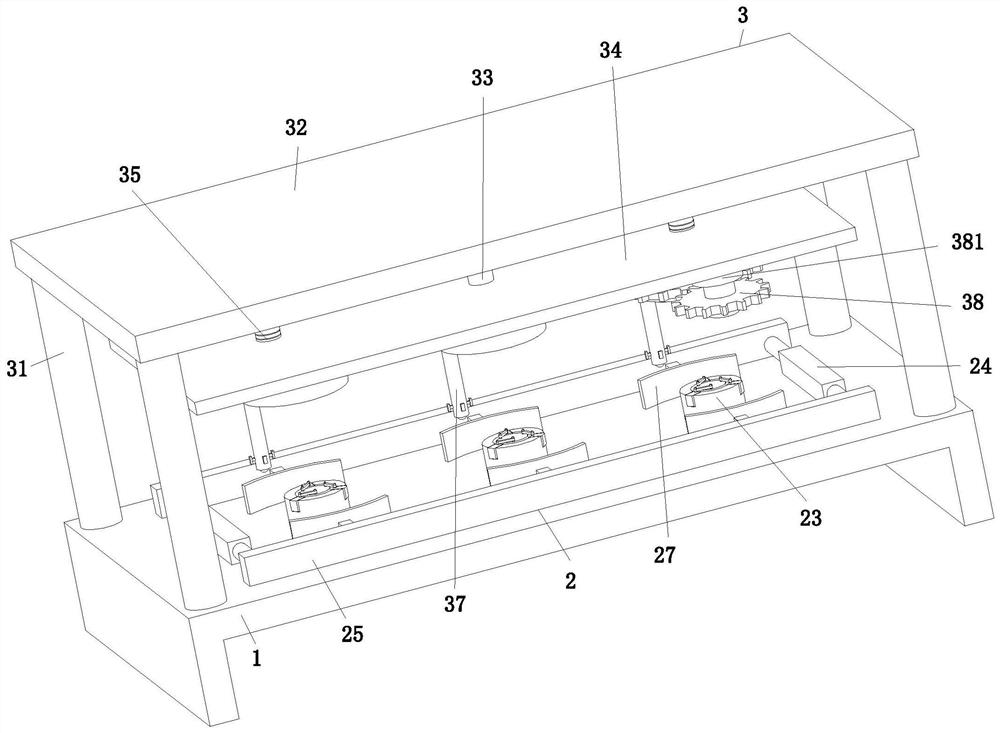

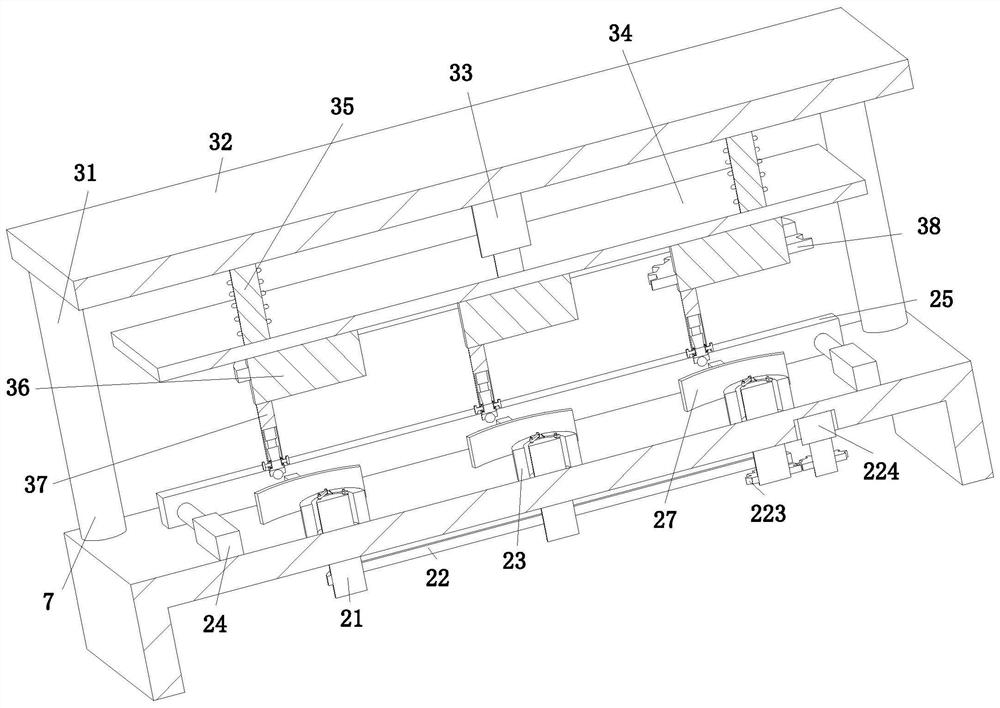

[0030] refer to figure 1 and figure 2 , an intelligent polishing machine for manufacturing inner and outer rings of bearings, including a workbench 1, a fixing device 2 and a moving device 3, the workbench 1 is a U-shaped plate with an opening downward, and the upper end surface of the workbench 1 is provided with Stationary device 2 and mobile device 3;

[0031] refer to figure 2 , image 3 and Figure 4 , the fixing device 2 includes a cylindrical rod 21, a moving frame 22, a clamping frame 23, a two-way electric push rod 24, a square plate 25, an extension rod 26 and a No. 1 arc plate 27. The workbench 1 The center position of the upper end face is uniformly rotated from left to right and a cylindrical rod 21 is installed. The lower end face of the cylindrical rod 21 runs thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com