Clamping and moving device and method of cross beam of horizontal type tensile and compression testing machine

A technology of mobile devices and testing machines, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of large adjustment test space, large push-pull cylinder stroke, and increased manufacturing cost of testing machines, so as to achieve convenient operation and occupy space on the site small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings and embodiments.

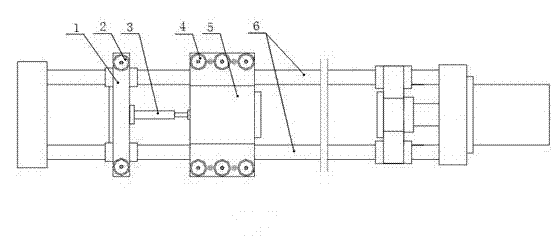

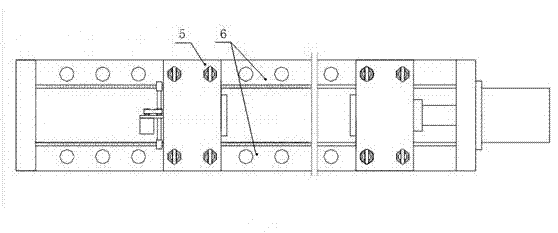

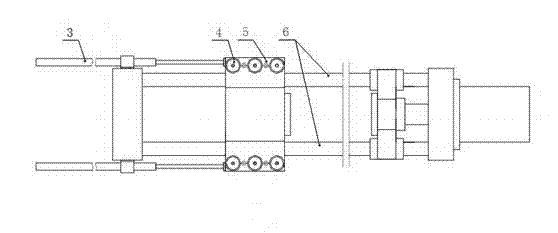

[0016] figure 1 It is a structural schematic diagram of the present invention.

[0017] In order to realize the clamping and fixing of the crossbeam 5, the present invention includes a column 6, a crossbeam 5 and a crossbeam clamping cylinder 4, and multiple sets of crossbeam clamping cylinders 4 are installed on the four corners of the crossbeam 5, and the crossbeam clamping cylinder on each corner 4 is responsible for the fixing of this position and the column 6. When the beam clamping cylinder 4 is clamped, the beam 5 is fixed on the column 6. When the beam clamping cylinder 4 is loosened, the beam 5 is loosened by its own elasticity. At this time, the beam 5 can move along the column 6 after being acted by external force.

[0018] In order to realize the movement of the beam 5 , the present invention also includes a fixed plate 1 , a clampin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com