Cam-type disc clamping device

A clamping device and disc-shaped technology, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effects of avoiding flying out, easy to implement, and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

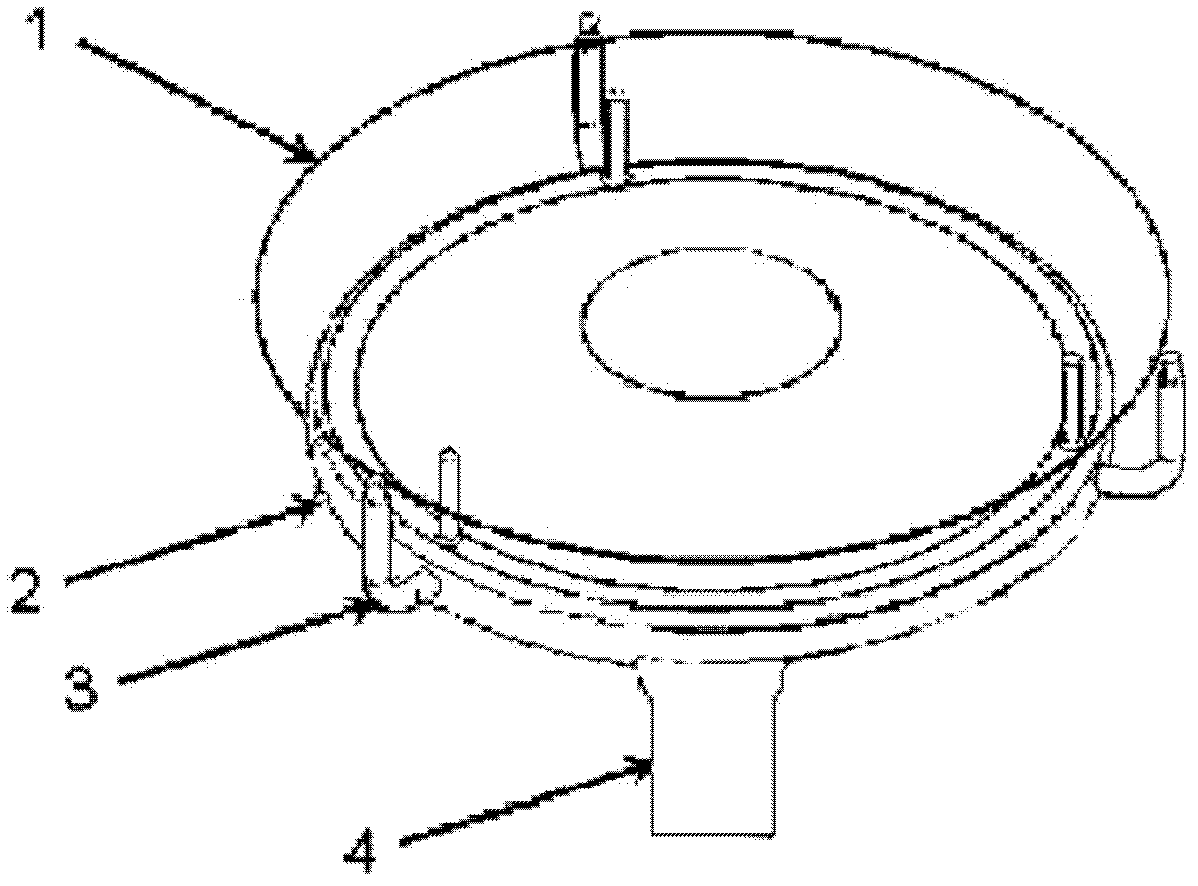

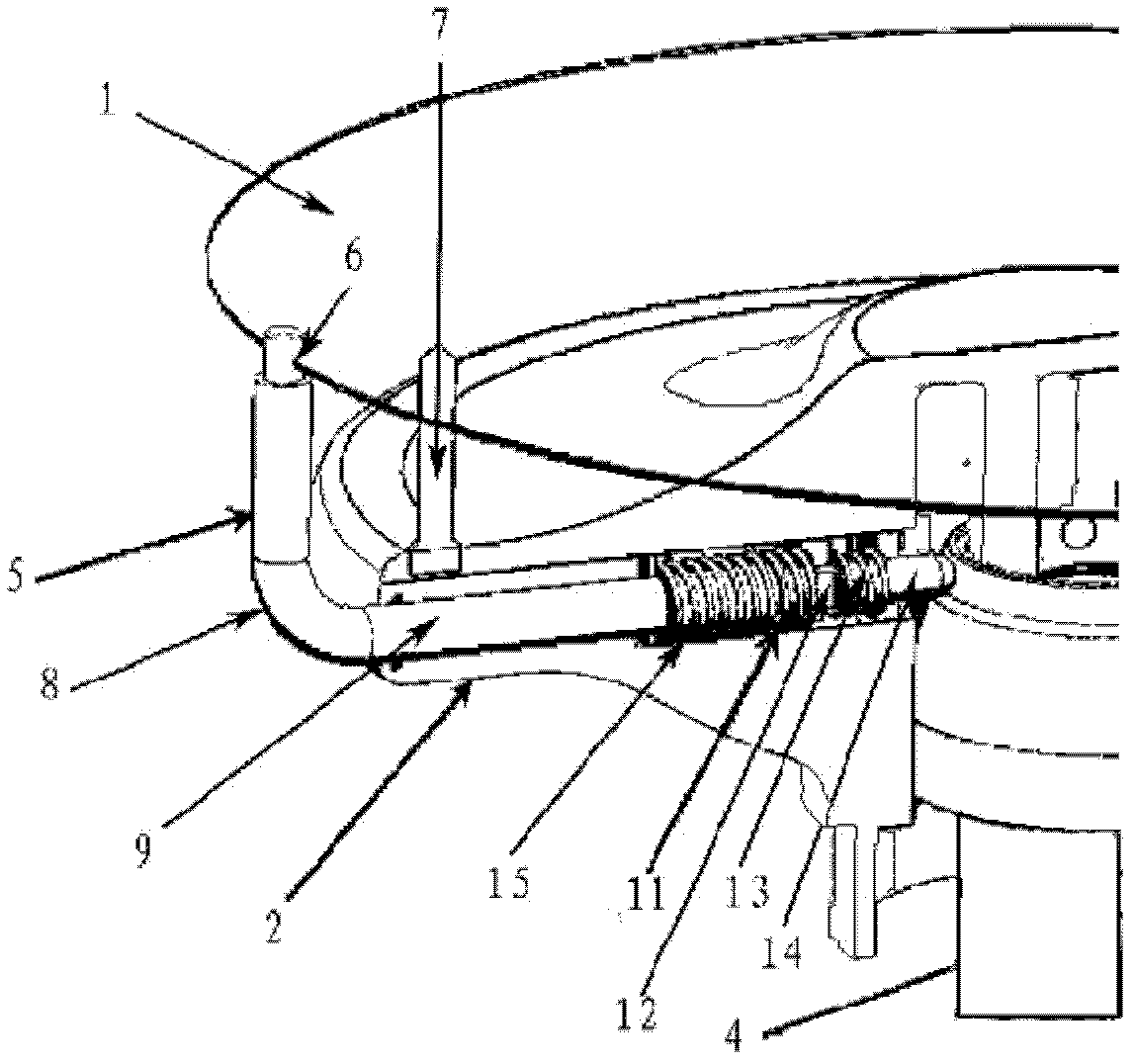

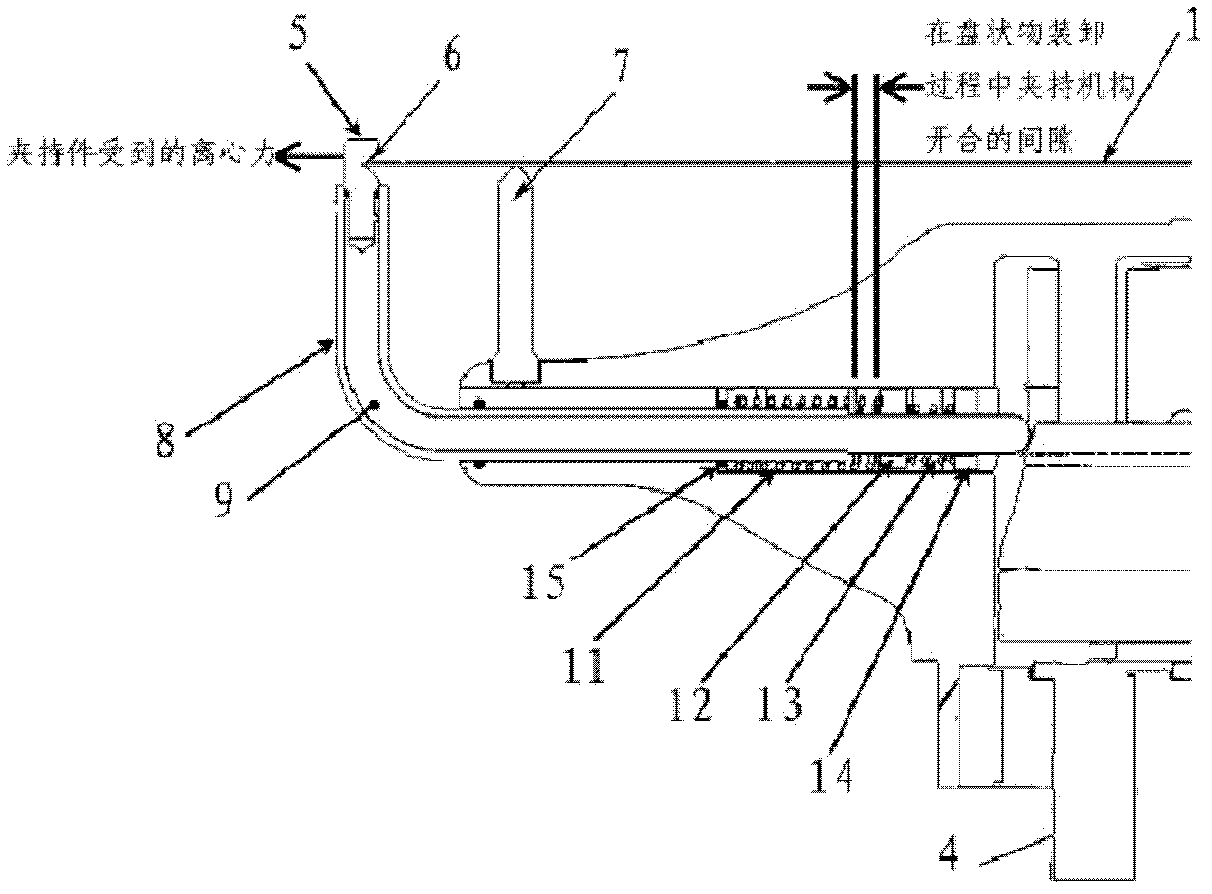

[0035] Such as Figure 1-Figure 6 As shown, it is a schematic structural diagram of a cam-type disk clamping device provided by an embodiment of the present invention, which includes a chuck 2 , a clamping mechanism 3 and a cam 4 .

[0036] Wherein the chuck 2 is a circular disc, which can rotate under the drive of a driving device such as a motor, and a cam 4 is installed at the center of the lower part thereof.

[0037] The clamping mechanism 3 includes a clamping piece 5 and an extension rod 9 . The extension rod 9 is L-shaped, one end of which is detachably connected with the clamping member 5, and faces upwards, and the other end extends into the interior of the chu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com