Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

109results about How to "Quick Retrieval" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material delivery transfer device

The invention relates to a material delivery transfer device, and the device comprises a storage and delivery trolley with wheels, wherein a buffering cushion is arranged on the storage and delivery trolley; the buffering cushion is provided with a plurality of delivery containers which are in one-to-one correspondence with materials prepared for stations of produced or repaired products; the delivery containers are counter bores formed in the upper surface of the buffering cushion and matched with the corresponding materials in appearance; the inner wall of each counter bore or the buffering cushion near to the counter hole is adhered with a first label matched with the type of the corresponding material; the first labels can be managed by color codes; a plurality of colors can be configured to respectively represent a plurality of models of the products. The material delivery transfer device disclosed by the invention is designed according to standardization, modularization, flexibility and visualization; the delivery containers have constant volume and are fixed according to the characteristics of the materials needed by stations of the produced or repaired products, and are designed by using the station as unit; the buffering cushion can protect the materials; the materials need not to be packed and no dismounting of the packing is needed, so waste of the resources is reduced and the work efficiency is improved as well.

Owner:NANJING NANCHE PUZHEN IND LOGISTICS CO LTD

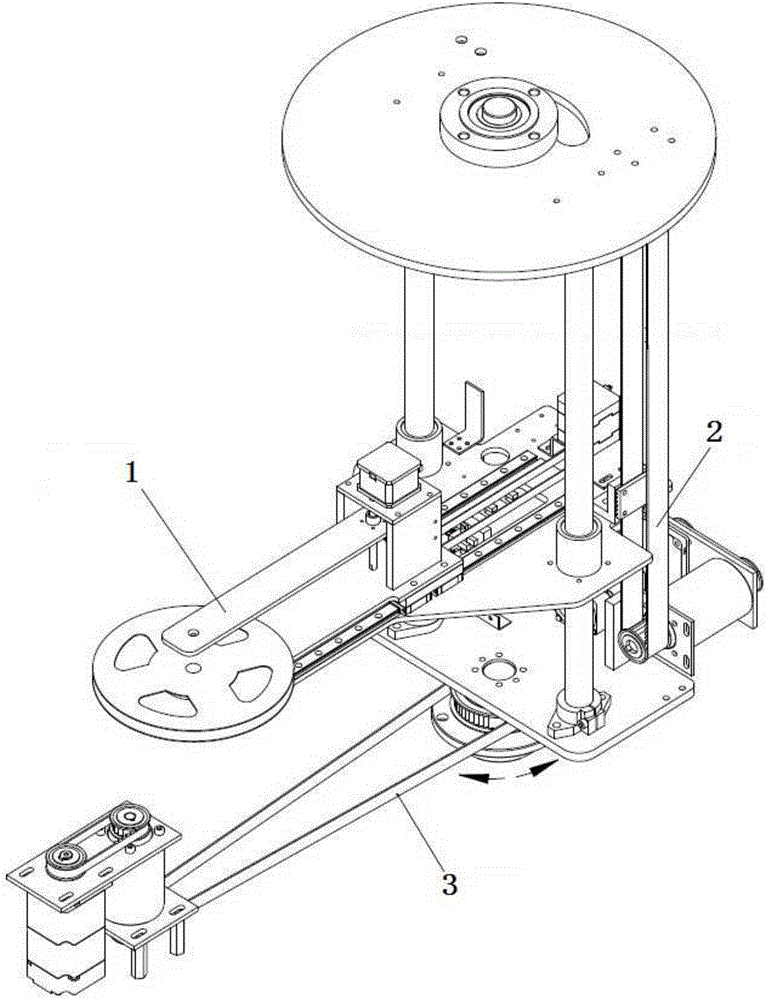

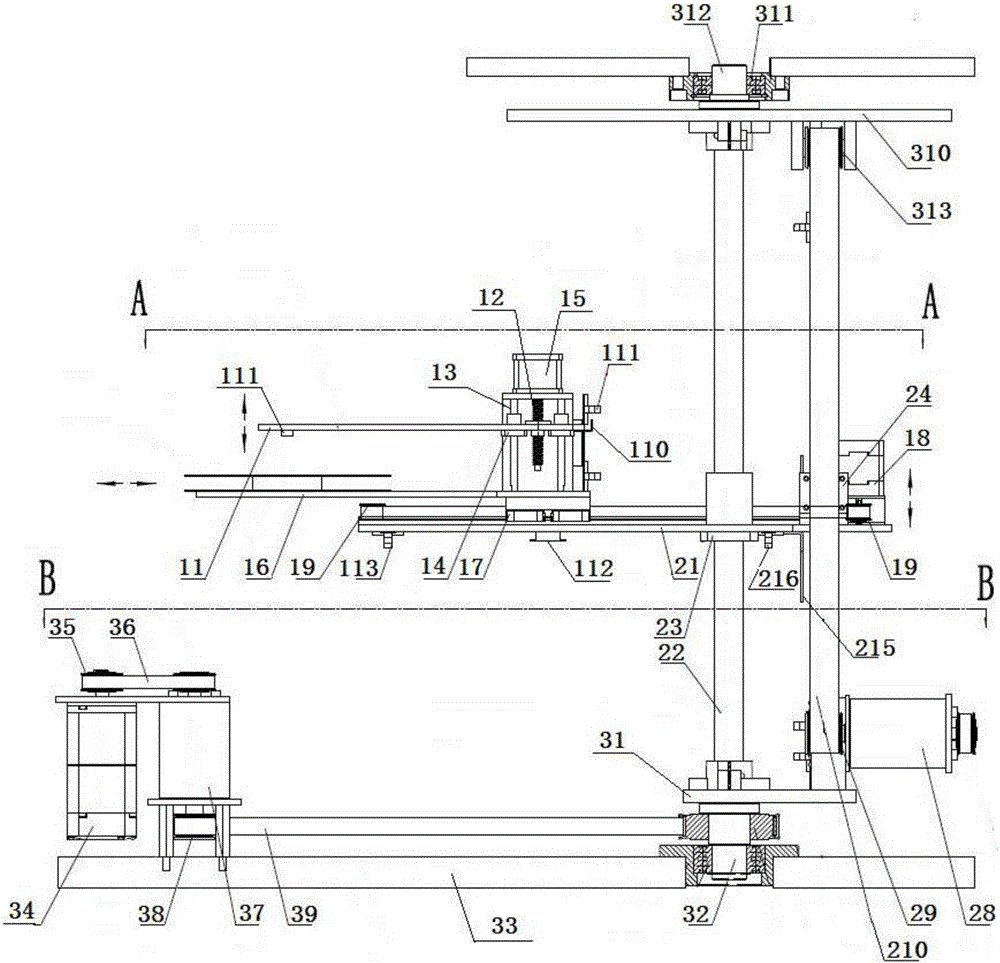

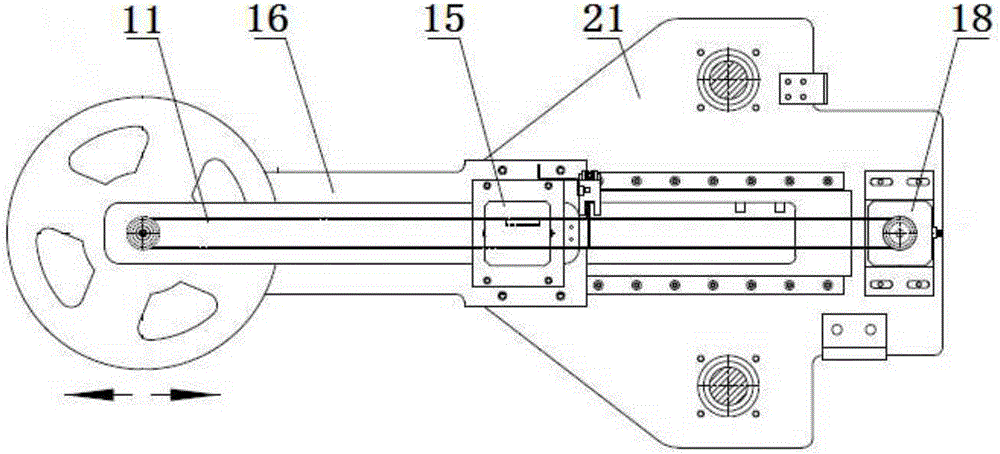

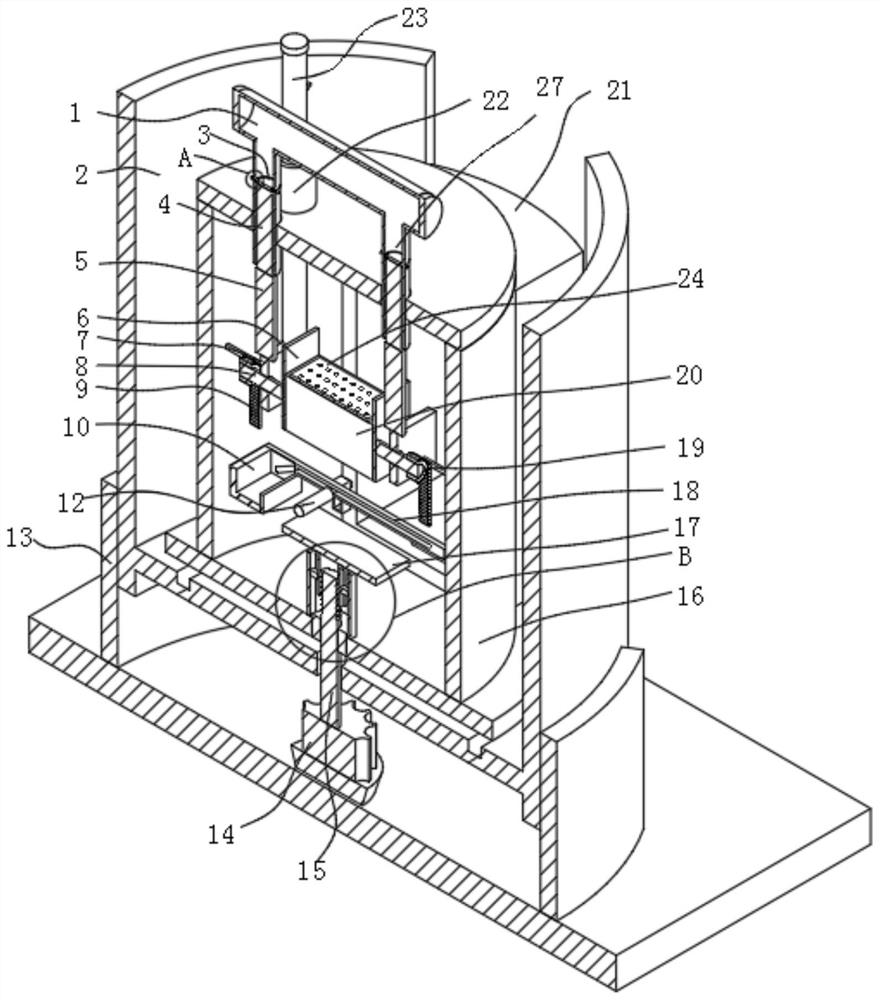

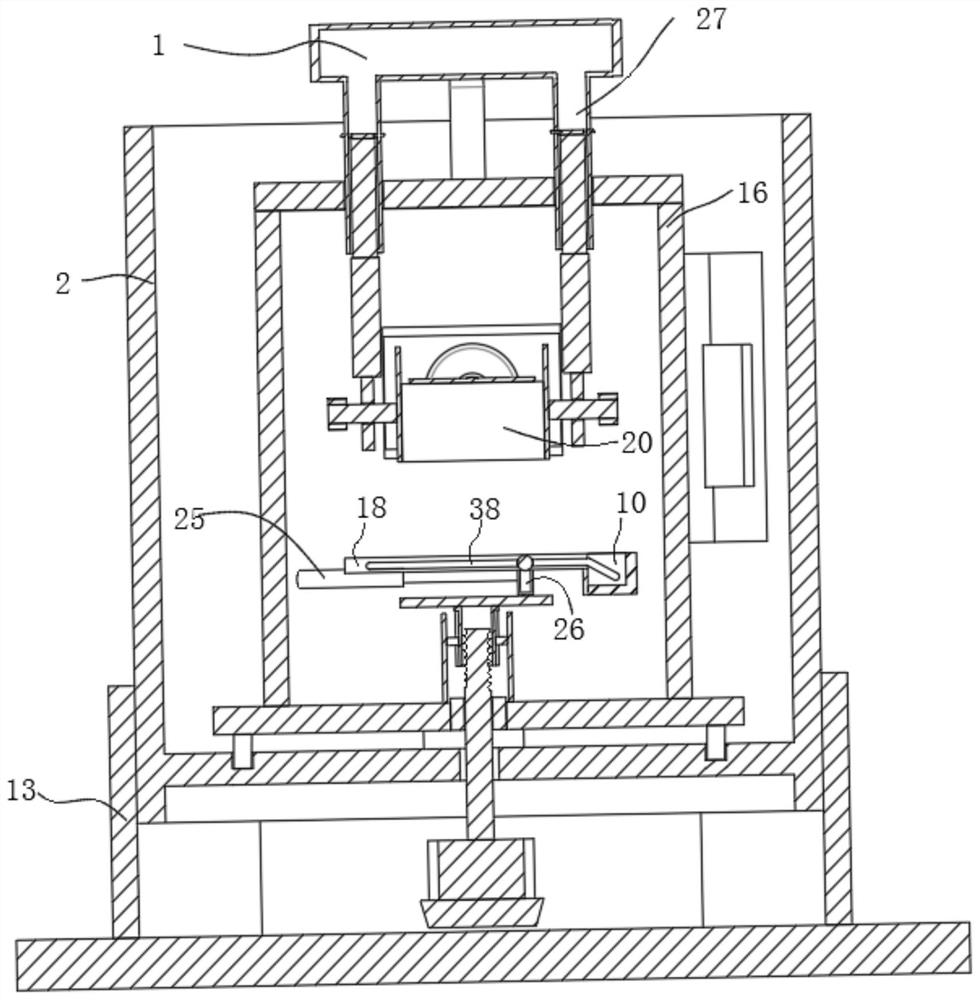

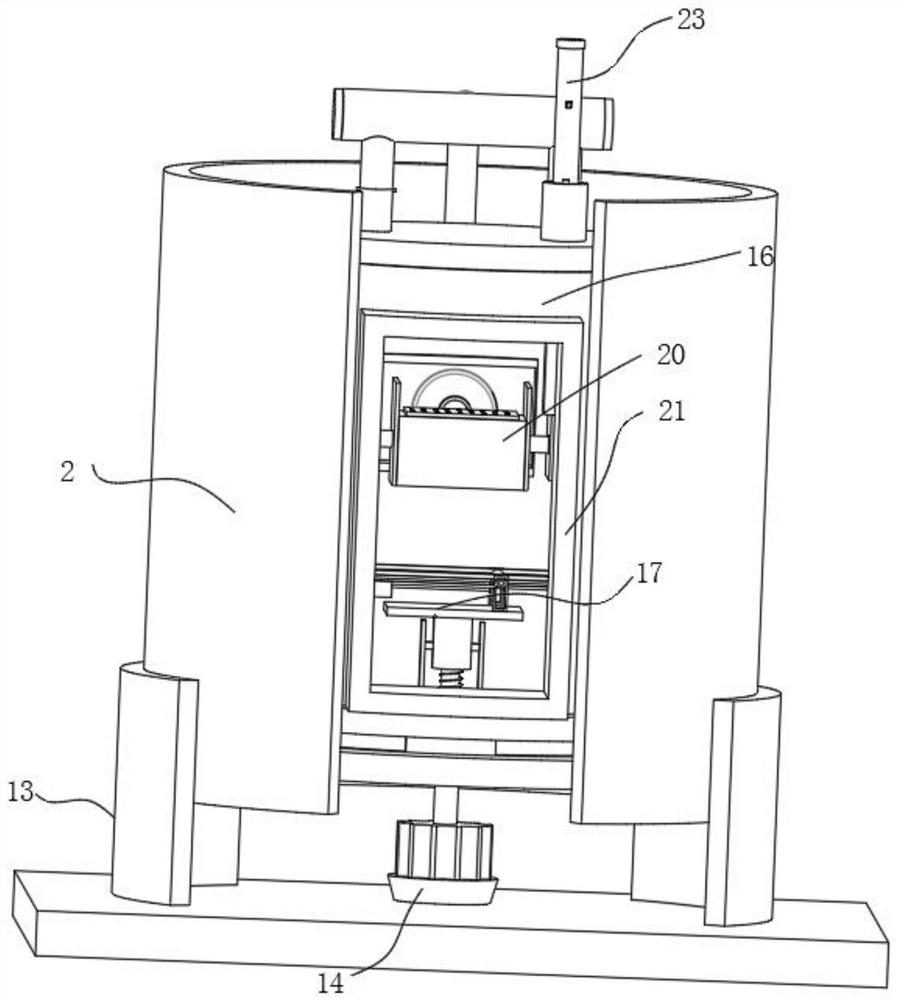

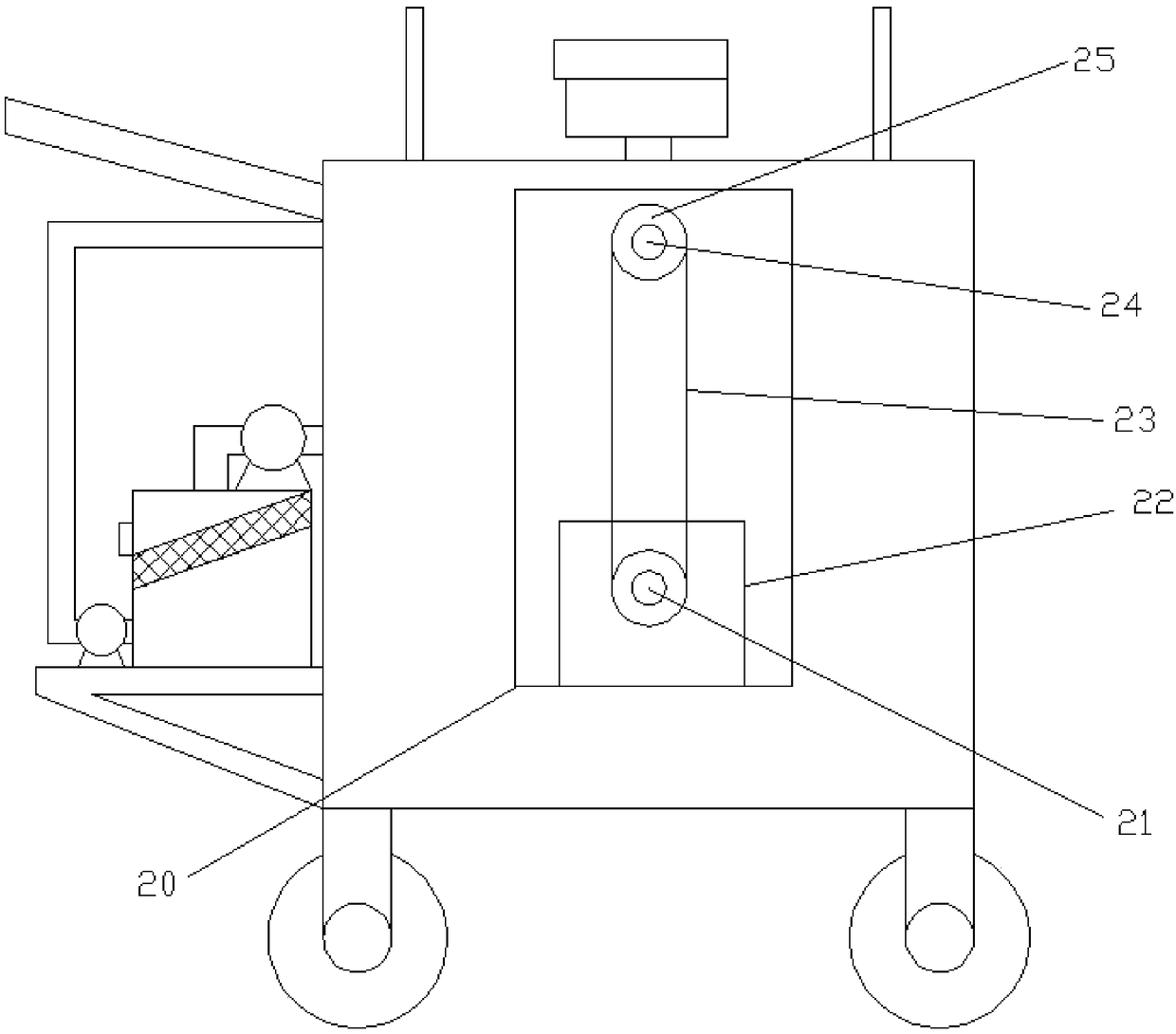

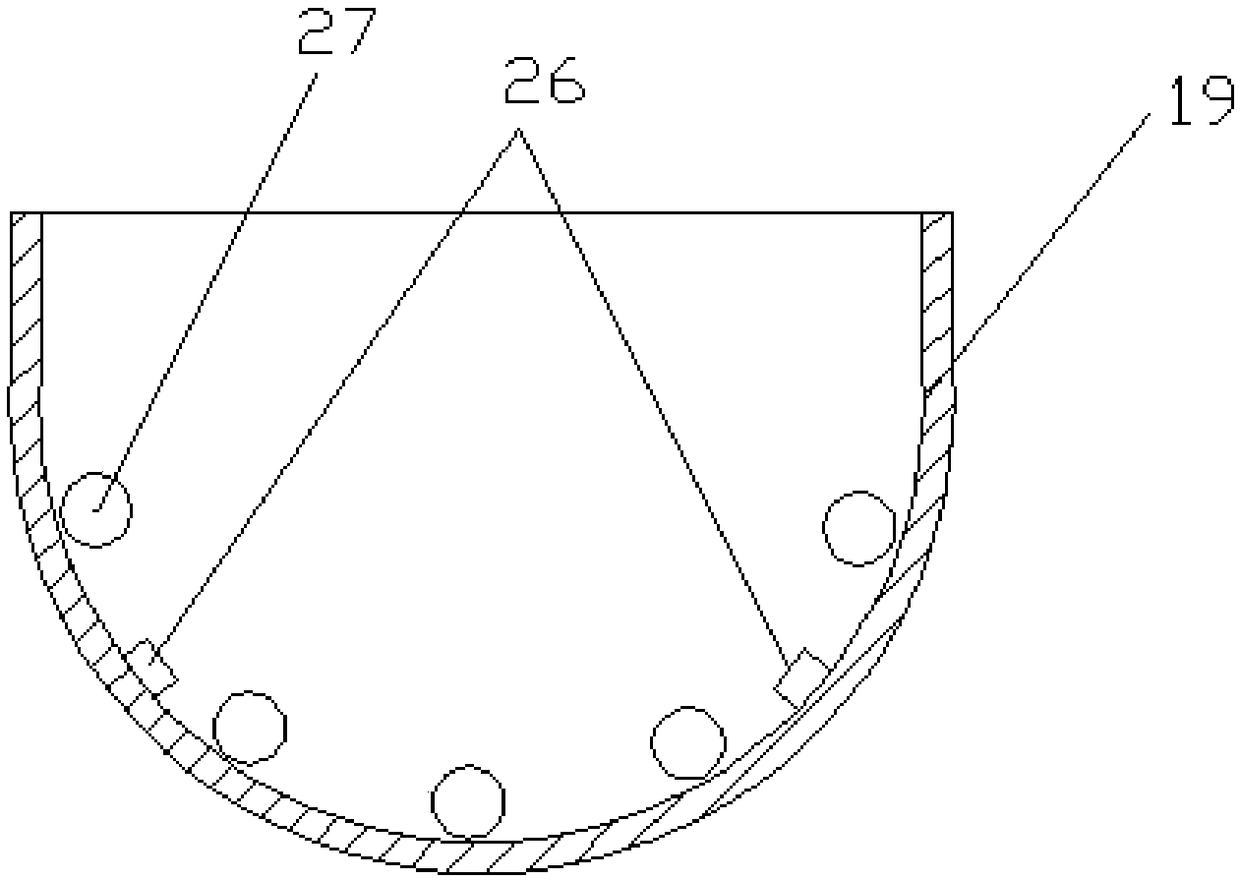

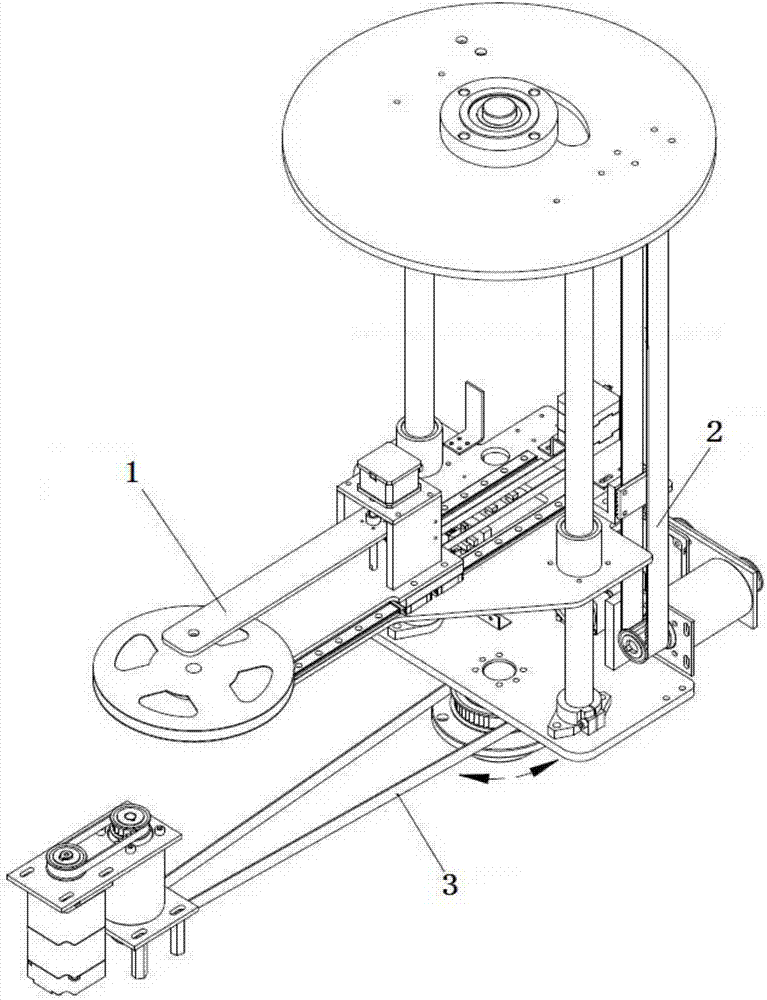

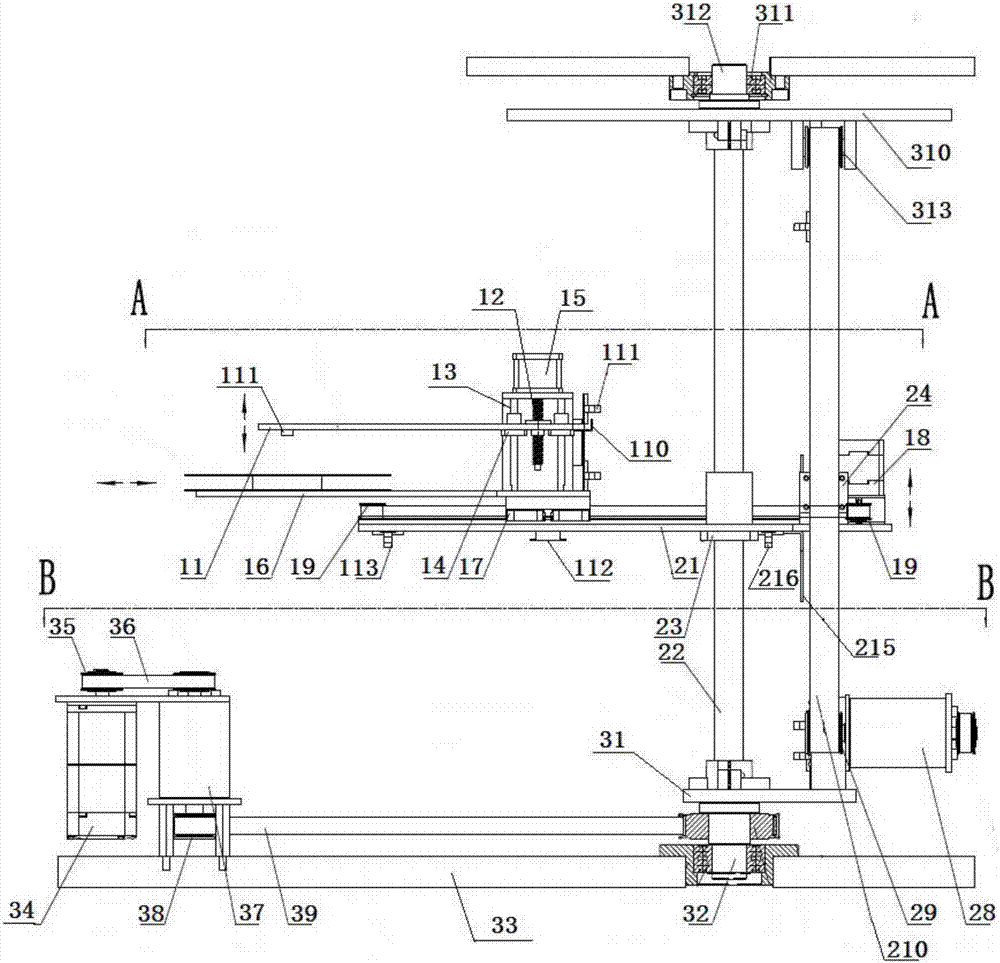

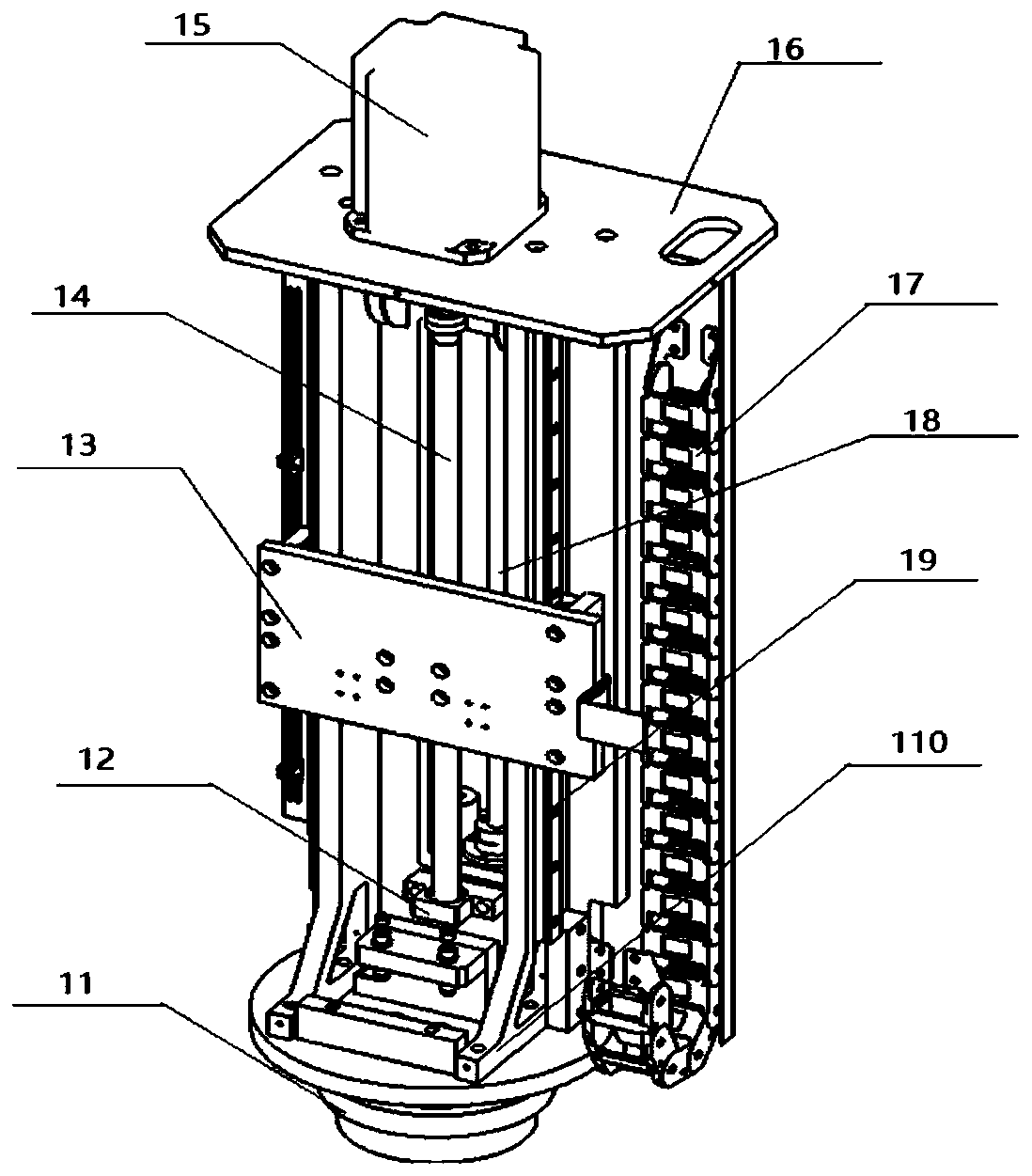

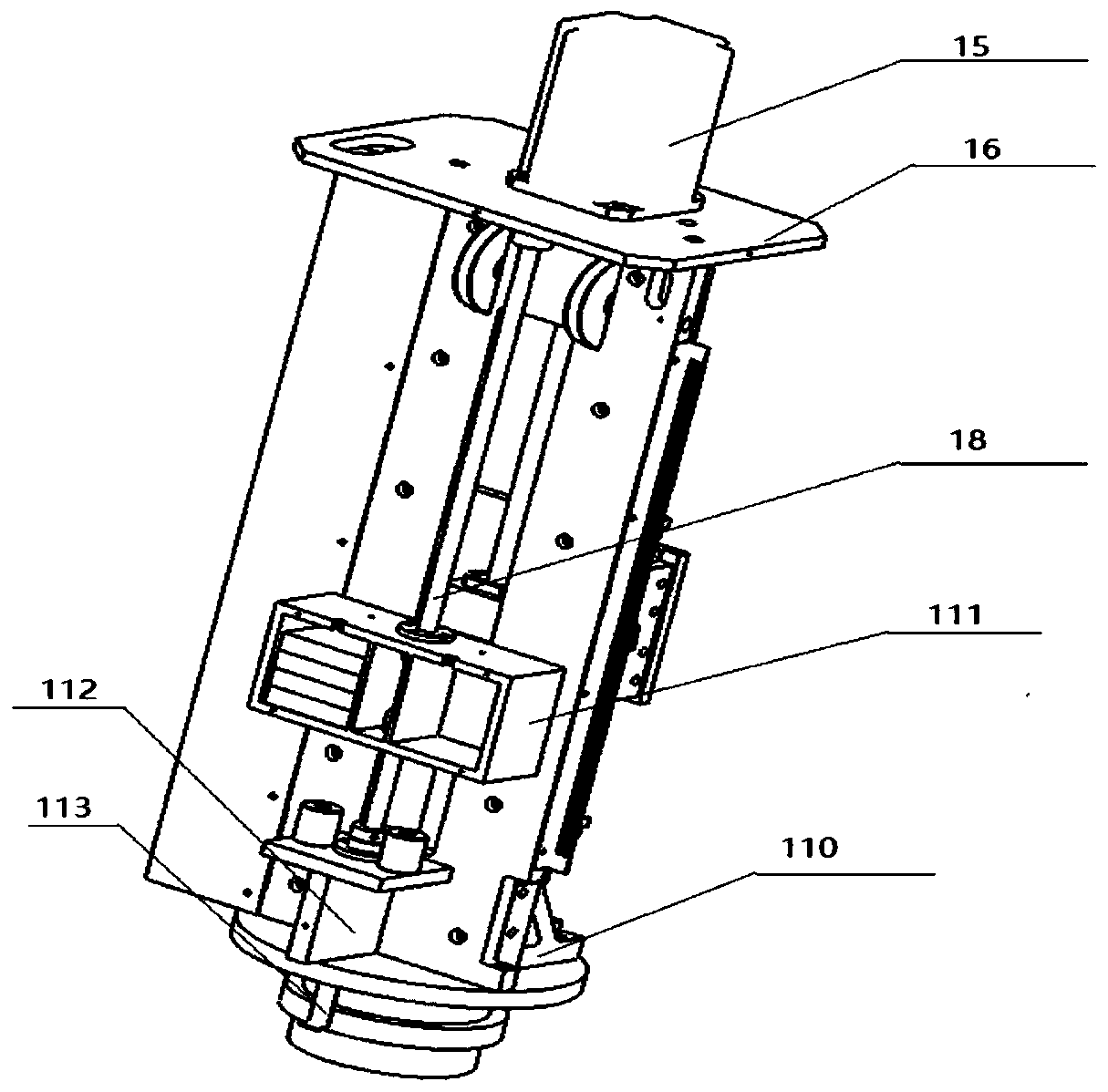

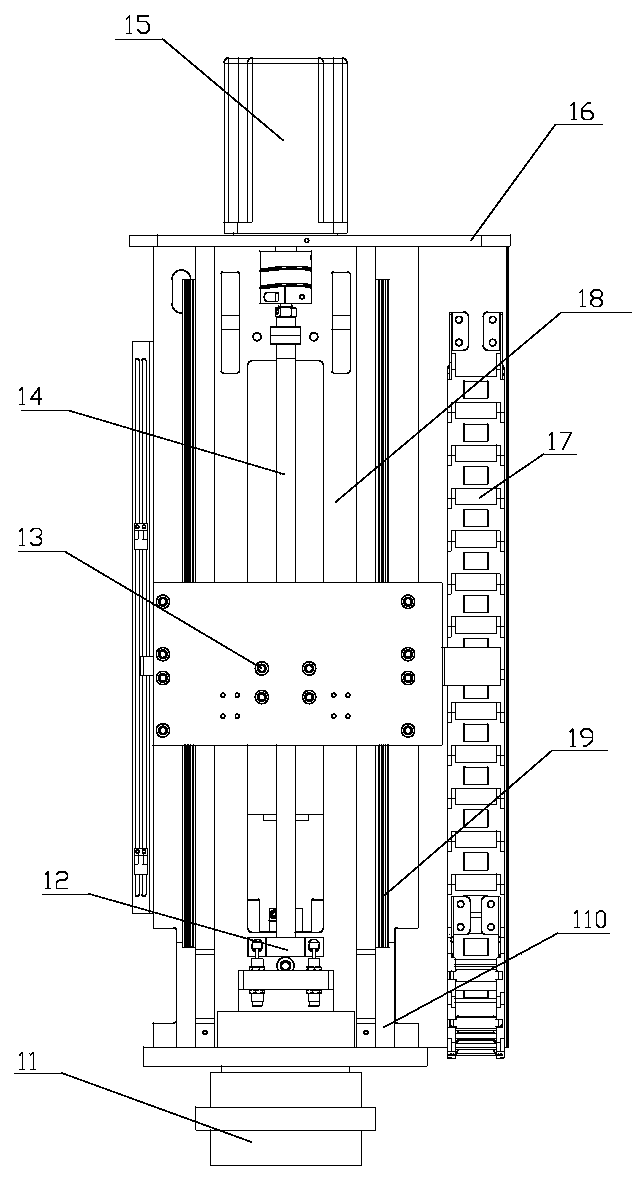

Material handling robot

ActiveCN105752640AAccurate placementAvoid collisionConveyorsControl devices for conveyorsControl systemThree-dimensional space

The invention relates to the technical field of handling and particularly relates to a material handling robot.The robot comprises a clamping device, a lifting device and a rotating device, the lifting device is mounted on the rotating device, the clamping device is mounted on the lifting device, the material handling robot further comprises a PLC control system, and the PLC control system controls the lifting device to be ascended and descended, the rotating device to rotate within a three-dimensional space and the clamping device to clamp materials and move back and forth.According to the material handling robot, the clamping device, the lifting device and the rotating device are controlled by the PLC control system , and therefore materials can be placed at the right position rapidly and accurately; photoelectric induction plates and mini-size photoelectric switches are used to detect the limit position of motion, and the service life is prolonged; the robot can rotate in the space freely, operate flexibly and meanwhile place materials to a high position, and manpower and material resources are saved.

Owner:南京优倍自动化系统有限公司

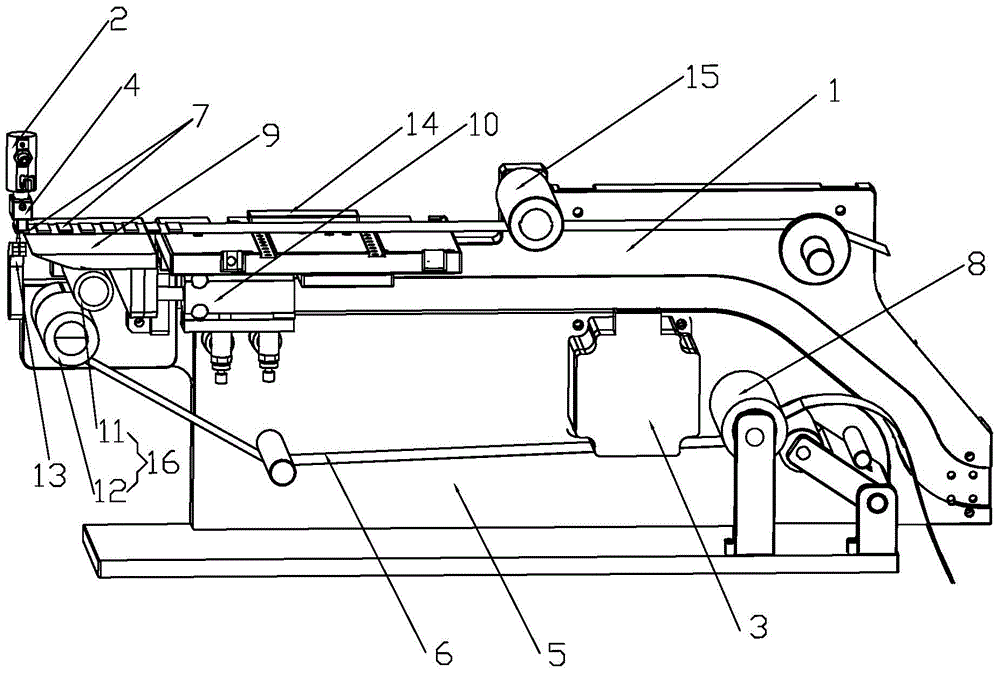

Automatic striping and taking device and method

InactiveCN104944153AQuick RetrievalEffective combinationArticle unpackingConveyor partsEngineeringAutomatic testing

The invention discloses an automatic striping and taking device and method. The automatic striping and taking device comprises a striping mechanism and a taking mechanism arranged above the stripping mechanism. The taking mechanism comprises a movable material suction nozzle. The stripping mechanism comprises as a stripping table and a material belt, and a stripping knife is arranged on the stripping table. After materials arrive at the cutting edge of the stripping knife, part of the materials are stripped from the material belt, the material suction nozzle sucks the materials, the stripping knife moves by a distance in the reverse direction of the advancing direction of the materials, the material belt is kept in a tensioned state all the time before and after the movement of the stripping knife, in this way, the materials are separated from the material belt, and the material suction nozzle takes away the materials. According to the automatic striping and taking device and method, the stripping process and the taking process are effectively combined, so that the material stripping effect is improved, and the stripping and taking efficiency is improved.

Owner:ZHUHAI CITY GUANGHAOJIE PRECISION MACHINERY

Numerical control double-end lathe

ActiveCN105665749AFix as soon as possiblePut into production as soon as possibleAutomatic workpiece supply/removalMetal working apparatusNumerical controlMechanical engineering

The invention discloses a numerical control double-end lathe, and solves the problems of slow loading and unloading speed and low efficiency of a lathe. The numerical control double-end lathe comprises a base plate provided with chucks, and is characterized in that the chucks are provided with loading mechanisms for feeding the chucks one by one and unloading mechanisms for unloading the chucks one by one; the loading mechanisms include wide air jaws and ejector rods; the wide air jaws are provided with rollers for clamping and guiding materials; the ejector rods push the materials to the chucks along the rollers; the unloading mechanisms include conveying belts for outputting the materials, and clamping air jaws for unloading the chucks; the clamping air jaws feed the materials to the conveying belts; power sources for driving the conveying belts are mounted on the lower belt surfaces of the conveying belts; and the power sources slide in the belt directions to achieve the effect of effectively improving the lathe loading and unloading efficiency.

Owner:WENLING KEYU AUTOMATION EQUIP CO LTD

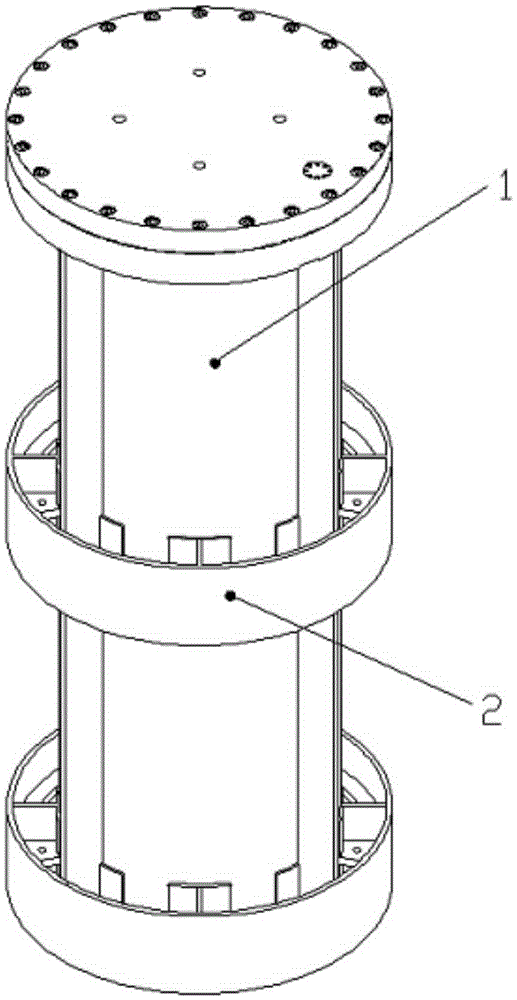

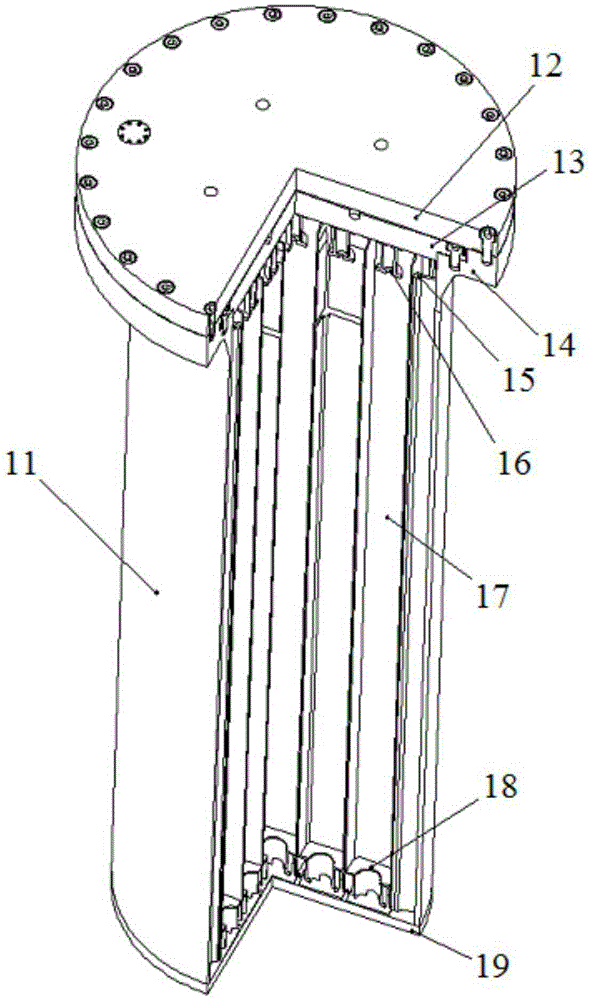

Fuel storage tank for nuclear power plant spent fuel dry-type storage

ActiveCN105261402AAchieve reuseFast loadingNuclear energy generationReactor fuel elementsNuclear powerEngineering

The invention discloses a fuel storage tank for nuclear power plant spent fuel dry-type storage. The fuel storage tank comprises a storage tank body and a storage tank support structure fixed at the periphery of the storage tank body. The storage tank body comprises a cylinder, an outer top cover, an inner top cover, a flange and a base plate. The base plate is fixedly connected at the bottom of the cylinder. The flange is fixedly connected at the top of the cylinder. The top of the flange is equipped with a step sealing surface. The inner top cover and the outer top cover are connected with different steps of the step sealing surface of the flange through bolts. Compared with the prior art, the fuel storage tank employs a flange-type top cover structure, thus the fuel storage tank top cover sealing performance is ensured, and the sealing operation difficulty is lowered. A spent fuel assembly can be loaded and taken out and recycle of the fuel storage tank can be achieved.

Owner:CHINA NUCLEAR POWER DESIGN COMPANY +3

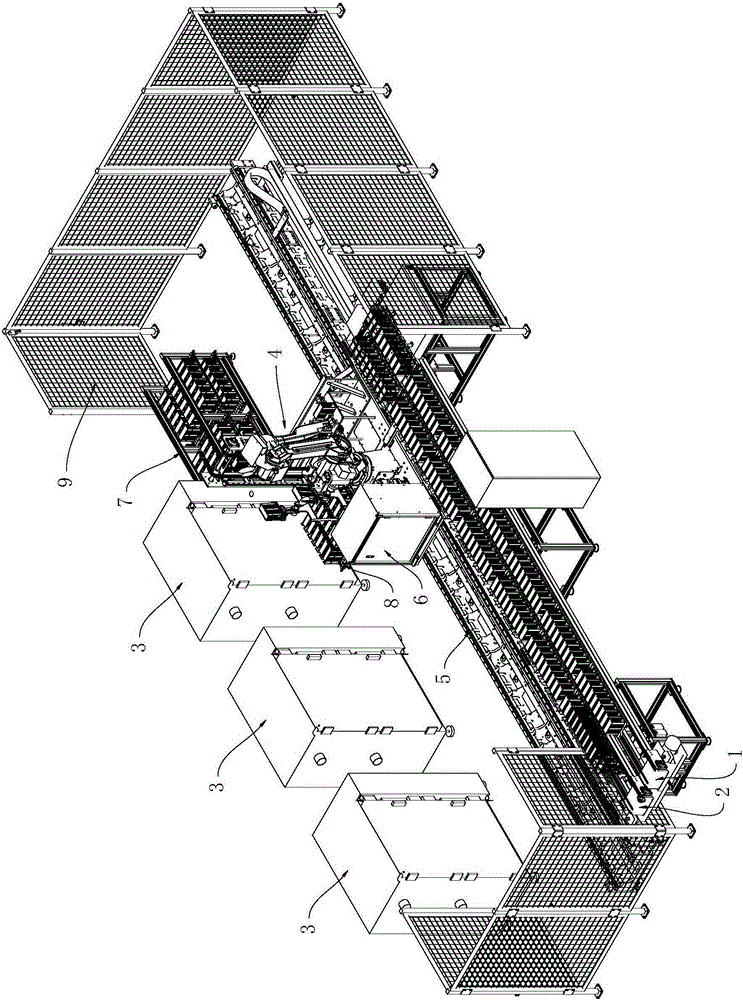

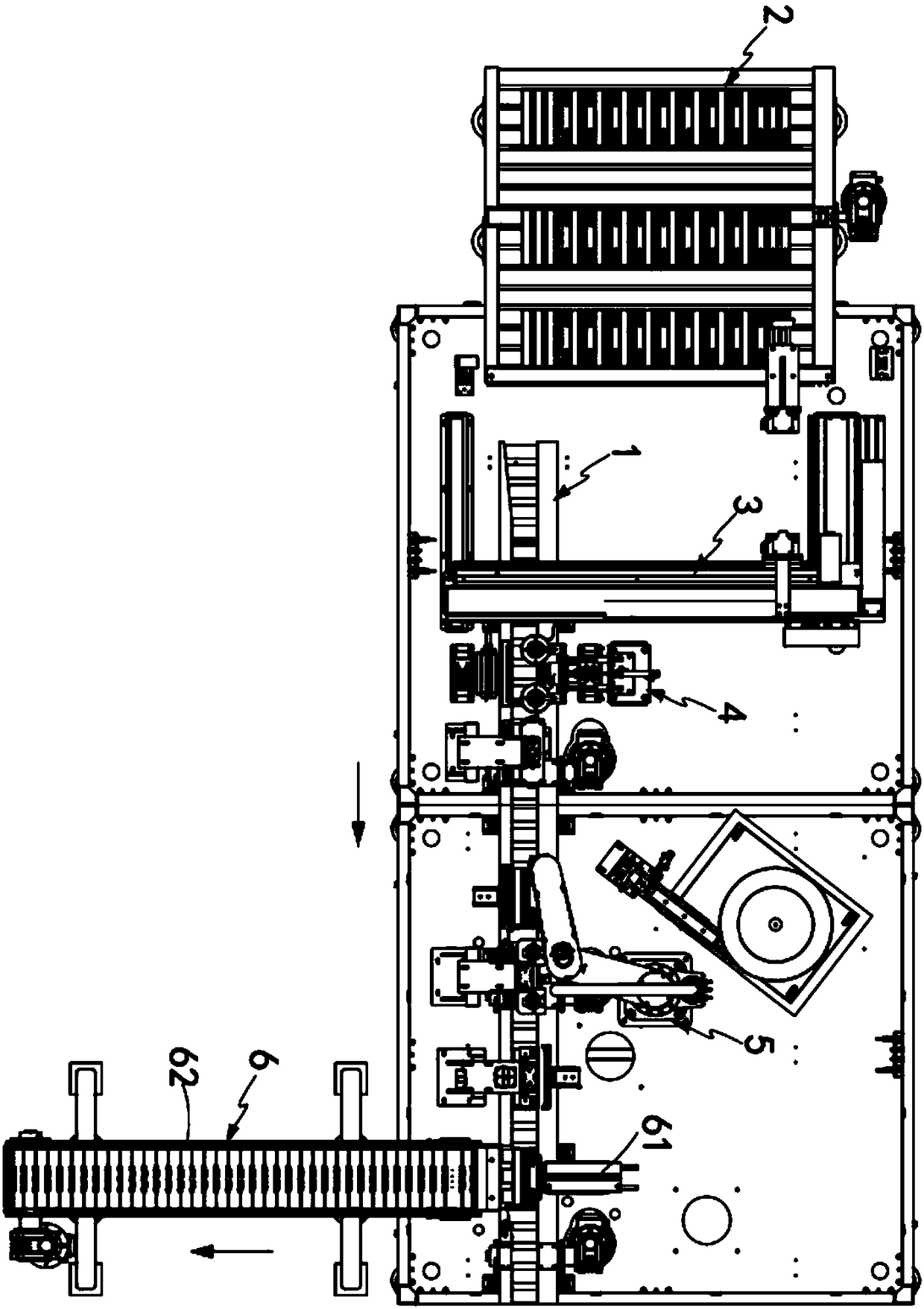

Baking oven automatic material loading and unloading system based on robot and method thereof

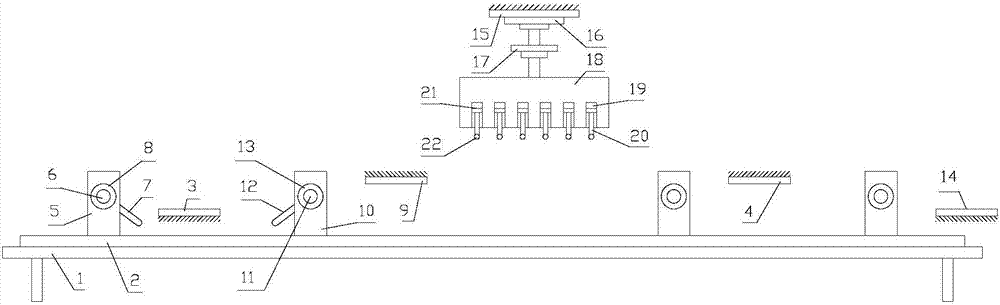

InactiveCN105206556AEasy dischargeQuick RetrievalSemiconductor/solid-state device manufacturingConveyor partsEngineeringAssembly line

The invention discloses a baking oven automatic material loading and unloading system based on a robot. The baking oven automatic material loading and unloading system based on the robot comprises a material inlet assembly line which is used for conveying products to be baked; a material outlet assembly line which is arranged to be side-by-side with the material inlet assembly line and used for conveying the baked products; multiple baking ovens which are used for baking the products; the robot which is arranged on a traveling mechanism and can move along the traveling mechanism; and a master control unit which is used for controlling operation of the material inlet assembly line and the material outlet assembly line and also used for controlling the robot to open and close the baking oven doors, controlling the robot to move the products to be baked on the material inlet assembly line to the baking ovens, controlling the robot to move the products baked by the baking ovens to the material outlet assembly line and controlling baking time of the baking ovens. The baking oven automatic material loading and unloading system based on the robot has characteristics of being high in production efficiency, low in labor cost, great in accuracy, high in product percent of pass, intelligent and humanized. Besides, the baking oven automatic material loading and unloading system based on the robot can also be used for technical preparation of importing of an information management system and real-time tracking of material production.

Owner:SHENZHEN HIKER TECH CO LTD

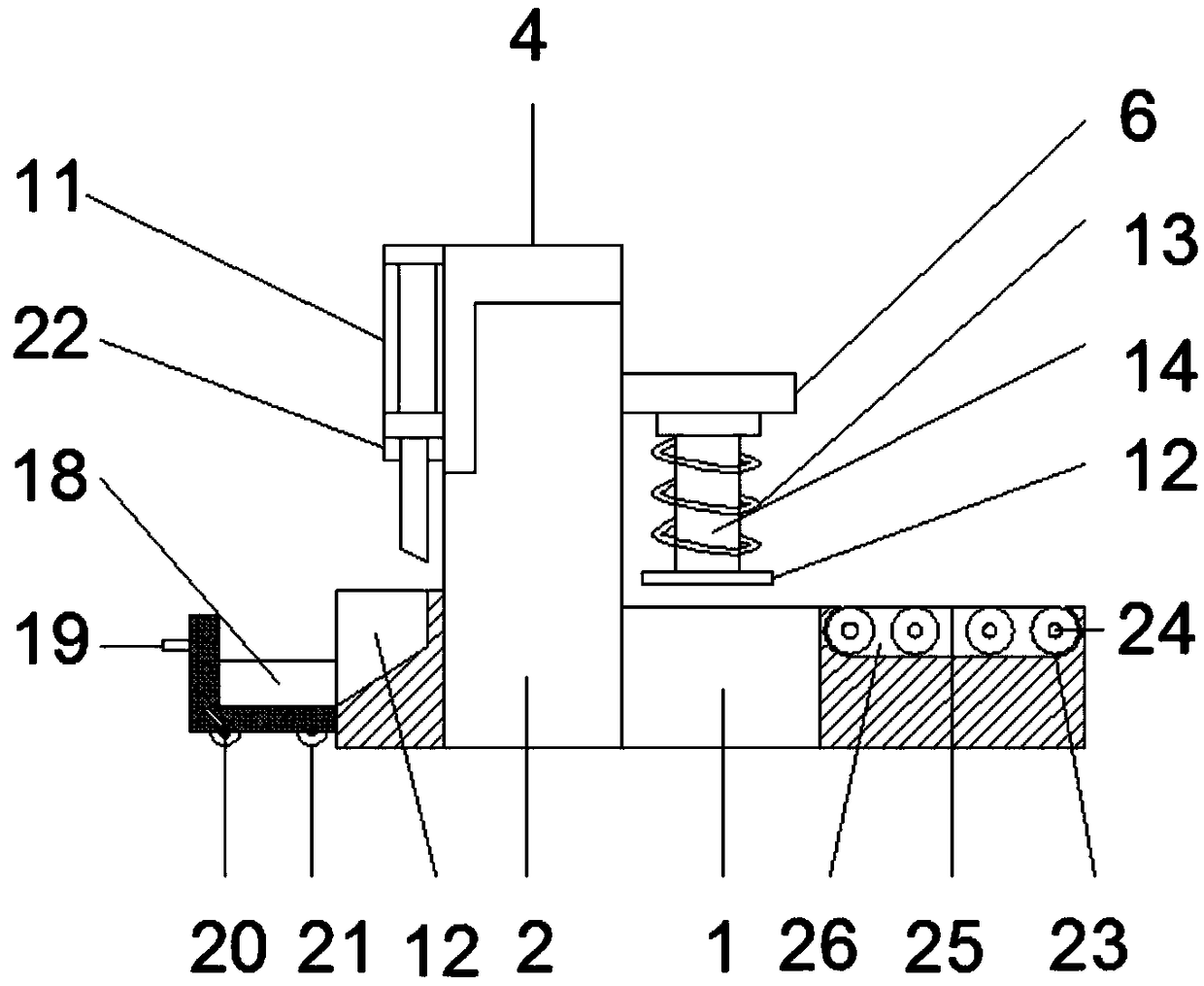

Automatic seal ring loading system for lead-acid battery after cover closure

ActiveCN108511782ASolve the technical problem of poor loading accuracySolve technical problems with poor accuracyAssembling battery machinesFinal product manufactureEngineeringMechanical engineering

The invention provides an automatic seal ring loading system for a lead-acid battery after cover closure. The automatic seal ring loading system comprises a conveying mechanism, a material pile arranged at an input end of the conveying mechanism, a feeding device located on the rear side of the material pile, a detection and correction device located on the rear side of the feeding device as wellas a seal ring loading device located on the rear side of the detection and correction device. Perpendicularity of a pole of the lead-acid battery is corrected by the detection and correction device,then the seal ring is loaded to the pole by the seal ring loading device, the seal ring is rotationally pressed by a pressing mechanism in a loading process, the technical problem of low seal ring loading precision for the pole of the lead-acid battery is solved, sealing performance of the seal ring is improved, seal ring loading speed is increased, and poor sealing effect caused by twist in the seal ring loading process is prevented.

Owner:浙江金麦特自动化系统有限公司

Refrigerator drawer injection mold

The invention discloses a refrigerator drawer injection mold, and relates to the technical field of refrigerator drawer production. According to the following scheme aiming at the problems that an existing injection mold cannot be quickly filled after injection molding, gaps easily exist, the production quality of products is influenced, and materials are inconvenient to take quickly: the refrigerator drawer injection mold comprises a placing plate, transmission mechanisms are arranged on the two sides of the top of the placing plate, the tops of the transmission mechanisms are rotationally connected with fixing plates, a lower mold is fixedly connected between the two fixing plates, the bottom of the lower mold is movably sleeved with an ejection mechanism, the top of the lower mold is provided with an upper mold, the two sides of the upper mold are provided with lifting mechanisms, and the a push rod motor is fixedly sleeved with the interior of the placing plate. Closing and openingof the upper mold and the lower mold are conveniently and automatically controlled, vibration during injection molding is convenient, sufficient injection molding is facilitated, the production quality of products is guaranteed, meanwhile, after injection molding, the products are conveniently and rapidly taken out, operation is simple and fast, and the automation degree is high.

Owner:CHUZHOU DIMENGDE MOLD MFG

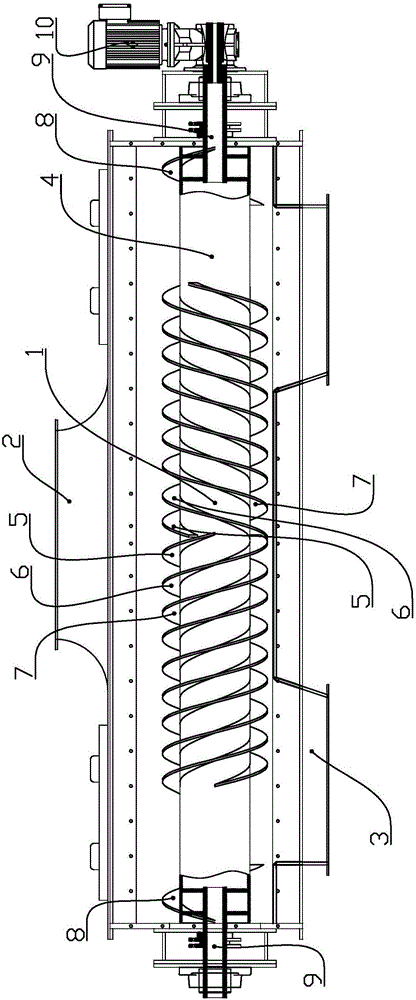

Garbage stokehole separator

The invention discloses a material separator in front of a waste furnace, which comprises a horizontally arranged shafted screw conveyor, a feeding port is provided in the middle of the top of the shell of the shafted screw conveyor, and the bottom of the shell of the shafted screw conveyor is provided with a feeding port. A discharge port is respectively opened at both ends of the screw conveyor, and a screw blade is fixed on the rotating shaft of the shafted screw conveyor. On the outer surface of the rotating shaft, one end of the rotating shaft is provided with a driving mechanism for driving the rotating shaft to rotate. The spiral blades on the outer surface of the rotating shaft of the present invention transport the garbage entering from the feeding port to both ends of the rotating shaft when rotating. When the garbage is transported to the position of the discharging port, the garbage is discharged from the discharging port by gravity. , After being conveyed by the shaft screw conveyor, the garbage can be discharged evenly from the discharge port, which is beneficial to the combustion of the incinerator and improves the combustion efficiency.

Owner:ZHEJIANG ZOKSEN ENVIRO ENERGY EQUIP

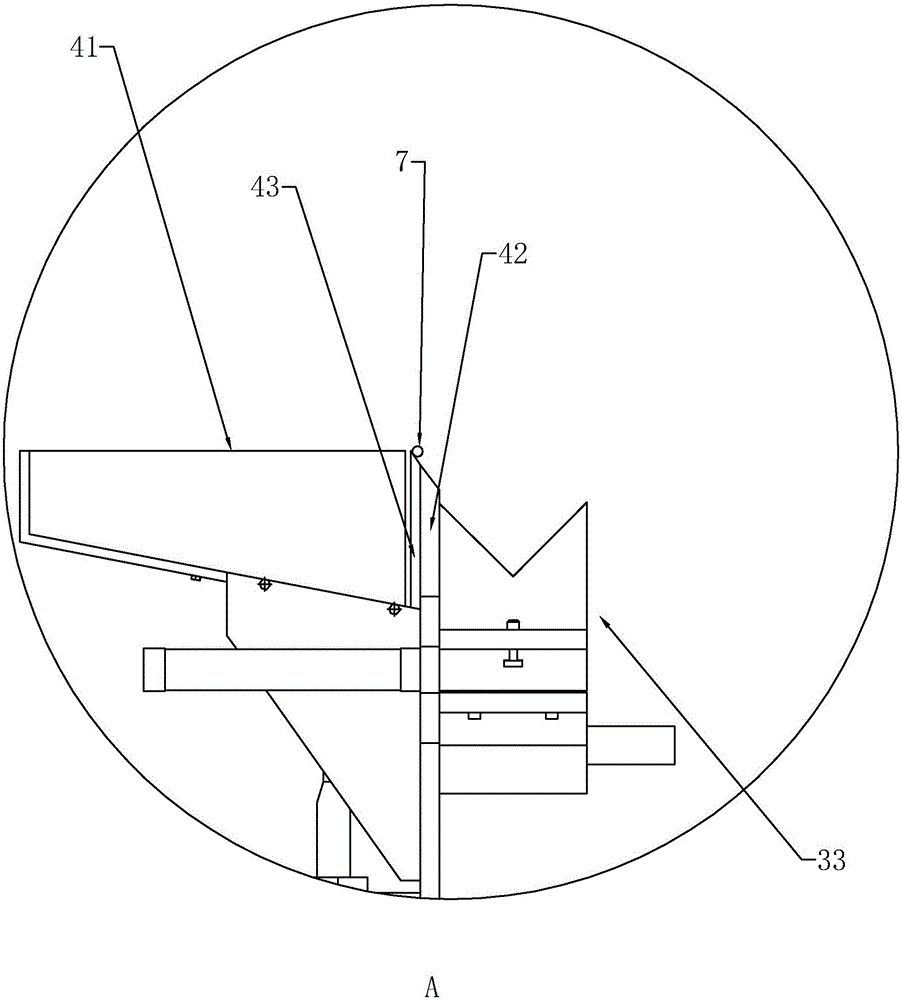

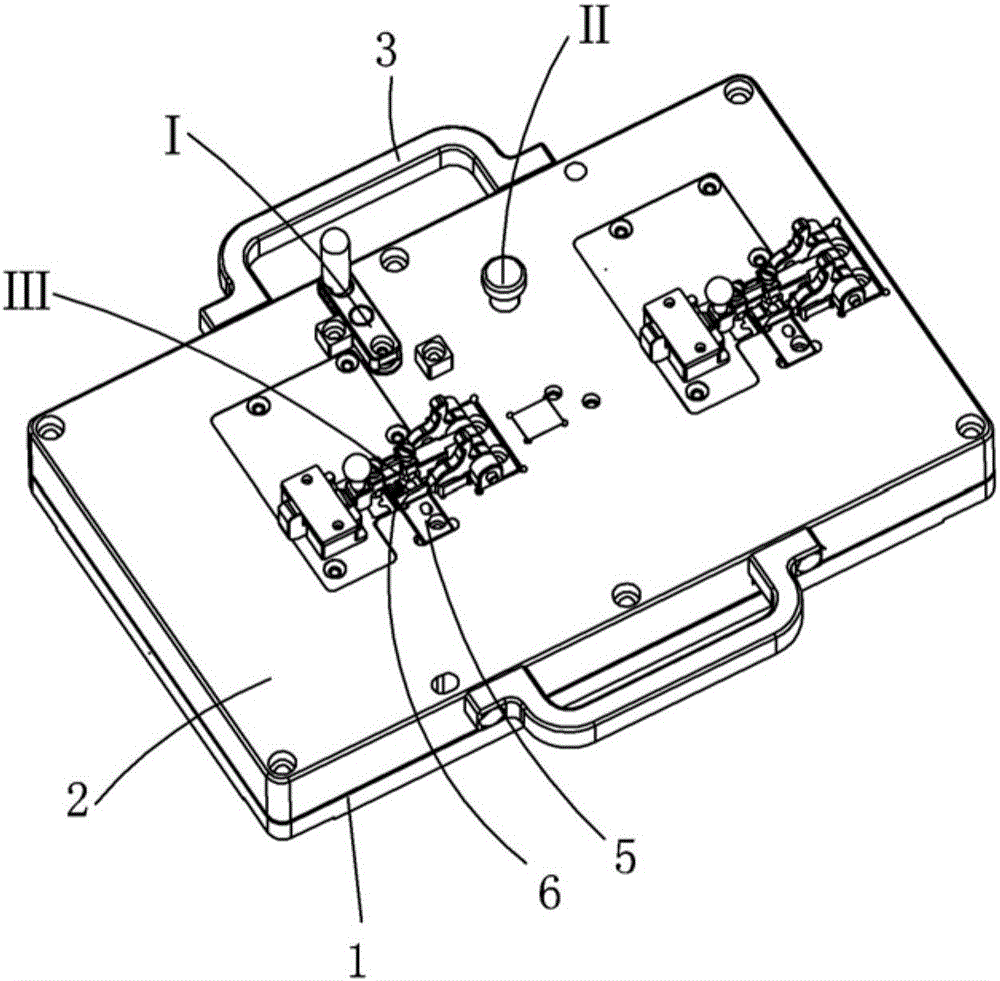

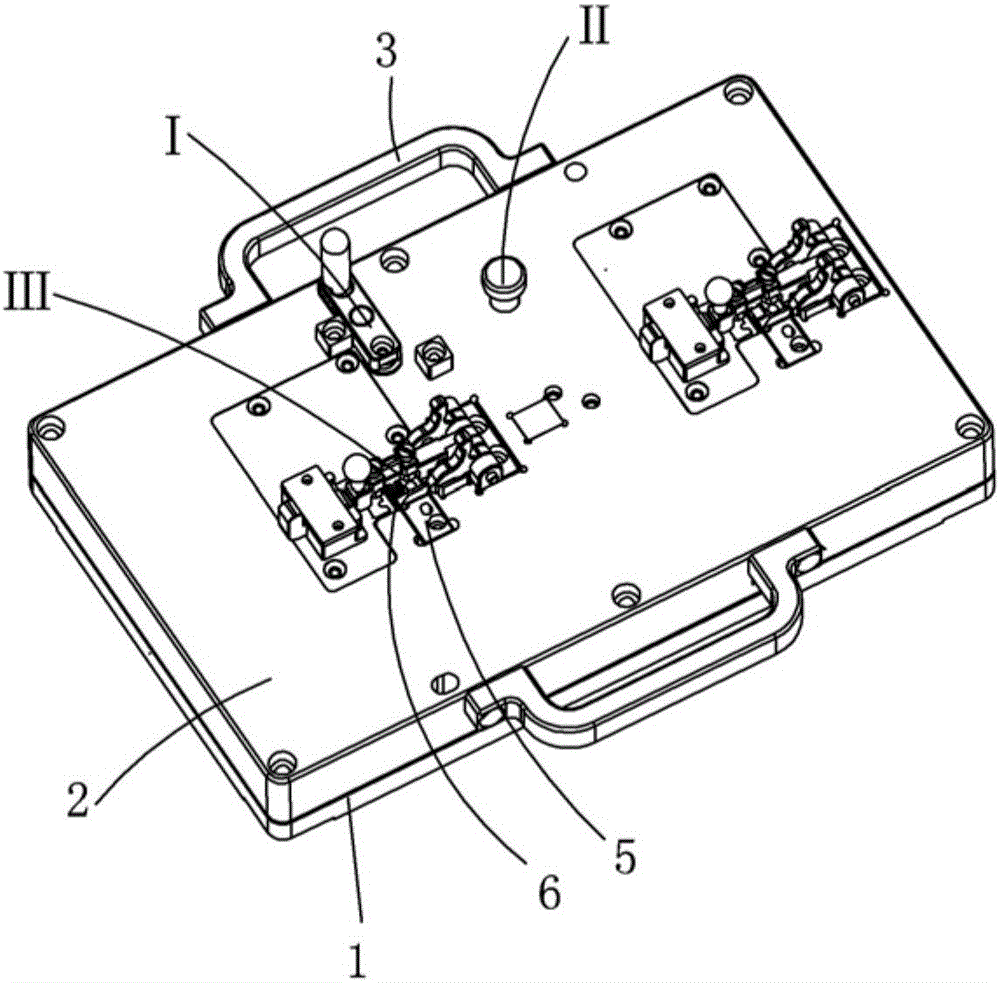

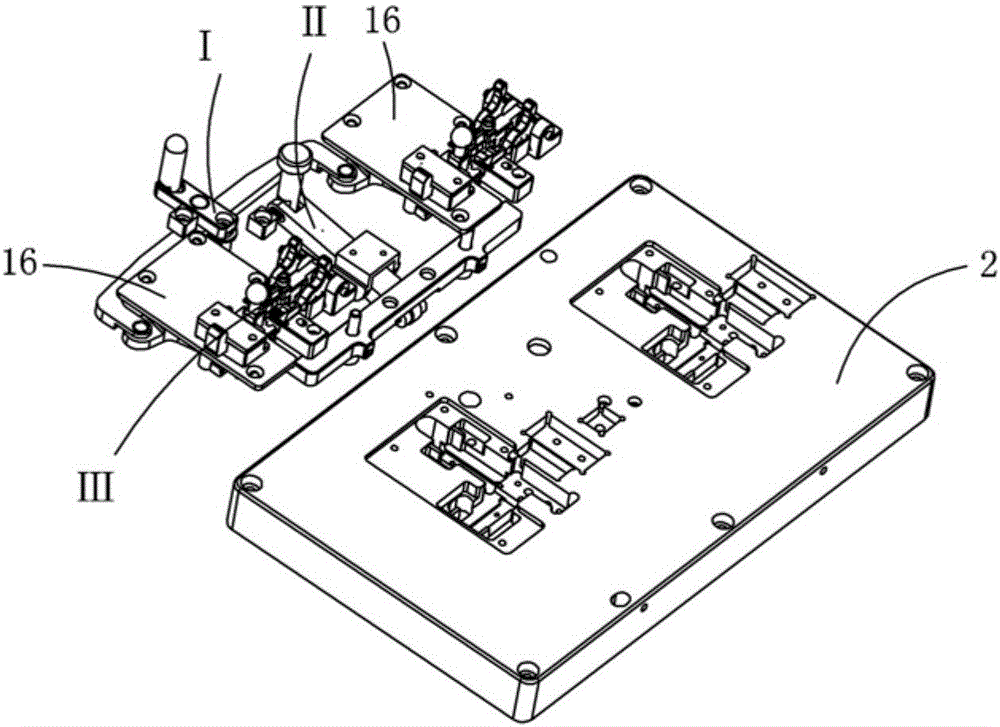

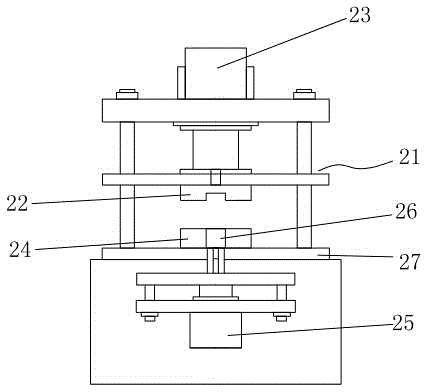

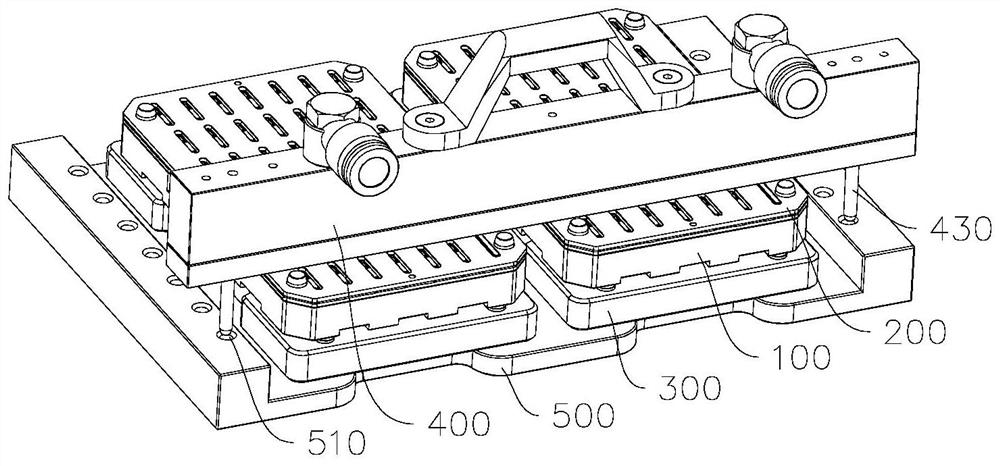

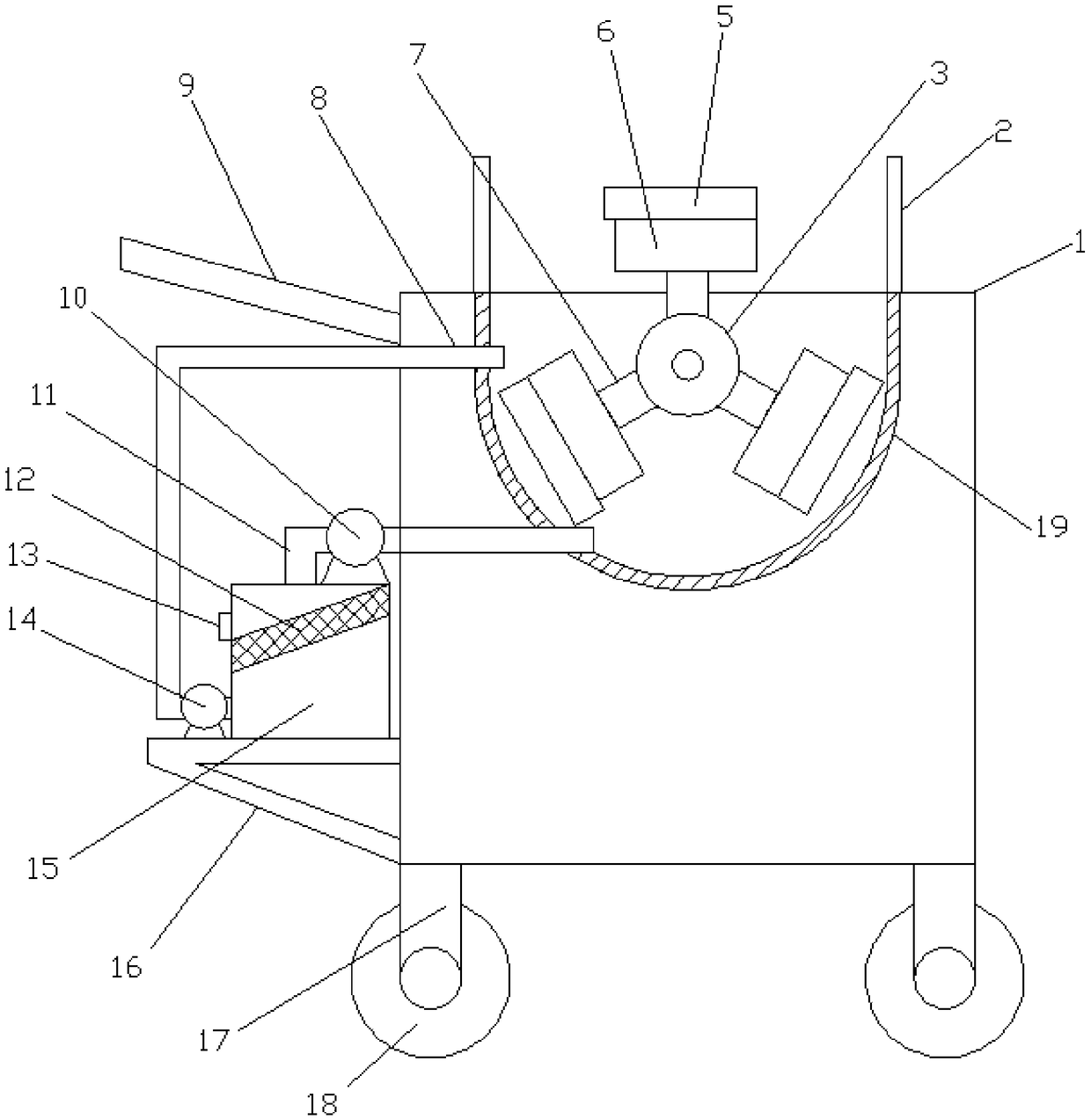

Double-station linkage positioning device capable of rapidly taking materials

ActiveCN105773049ASolve the problem of too small and difficult to removeShorten the timeWelding/cutting auxillary devicesWork holdersEngineeringCam

The invention relates to a double-station linkage positioning device capable of rapidly taking materials. An upper box body is arranged on the upper portion of a lower bottom plate and provided with product positioning blocks which can contain products. A linkage clamping assembly which can clamp the products is installed between the lower bottom plate and the upper box body and comprises a cam connecting rod assembly, linkage blocks connected with the cam connecting rod assembly, a first drive rod and a second drive rod, wherein the first drive rod and the second drive rod abut against the linkage blocks. A first clamping block is installed on the first drive rod. A second clamping block is installed on the second drive rod. A rapid material taking assembly is installed between the lower bottom plate and the upper box body and comprises a connecting rod drive assembly, ejector rod installation bases used in cooperation with the connecting rod drive assembly, and ejector rods installed on the ejector rod installation bases. Through holes for the ejector rods to penetrate are formed in product positioning blocks. Pressing assemblies are installed on the upper portion of the upper box body. By means of the linkage design, two products can be positioned at a time, materials can be rapidly taken, and the problems that mini-type parts are too small and difficult to take out are solved.

Owner:BOZHON PRECISION IND TECH CO LTD

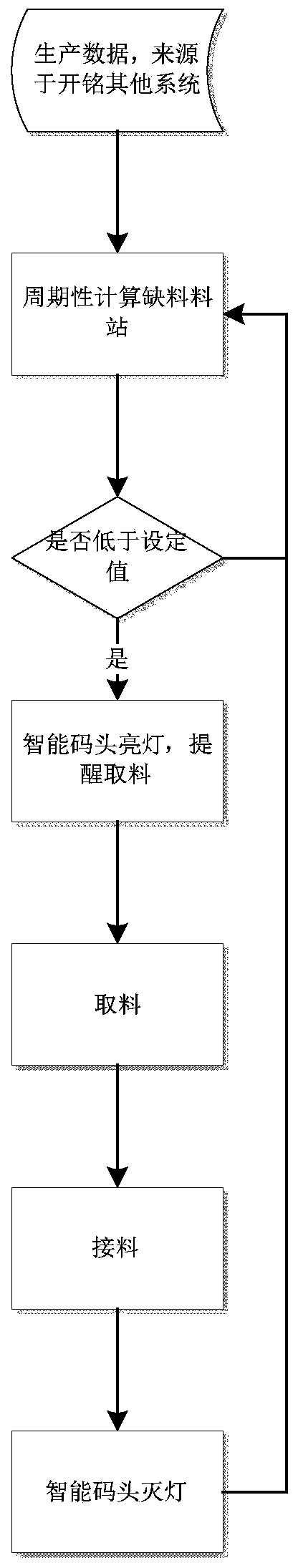

Material shortage warning method

PendingCN110312377AQuick RetrievalReduce labor intensityPrinted circuit assemblingCo-operative working arrangementsProduction lineMetallurgy

The invention discloses a material shortage warning method and is applied to an SMT production line. The material shortage warning method comprises steps that production line data in real time is obtained; according to the production line data, whether material shortage occurs in a material station is determined; if yes, a material terminal prompt corresponding to the material station is triggered; materials are taken from a prompted material terminal and replenished to the material shortage station; after material receiving scanning is performed to confirm material receiving, the material terminal prompt is closed. The method is advantaged in that the corresponding material terminal prompt is automatically triggered, an operator removes the materials from a prompt location, material receiving scanning is performed normally, after the materials are received, the corresponding material terminal prompt is closed, the material shortage prompt can be performed in real time, manually focusing and viewing in real time are not required, labor intensity of workers is reduced, accuracy is further improved, the operator is convenient to obtain the materials quickly without seeking here and there, improvement of work efficiency is facilitated, the production quality is improved, and quality problems are not easy to occur.

Owner:COMING INTELLIGENCE TECH CO LTD

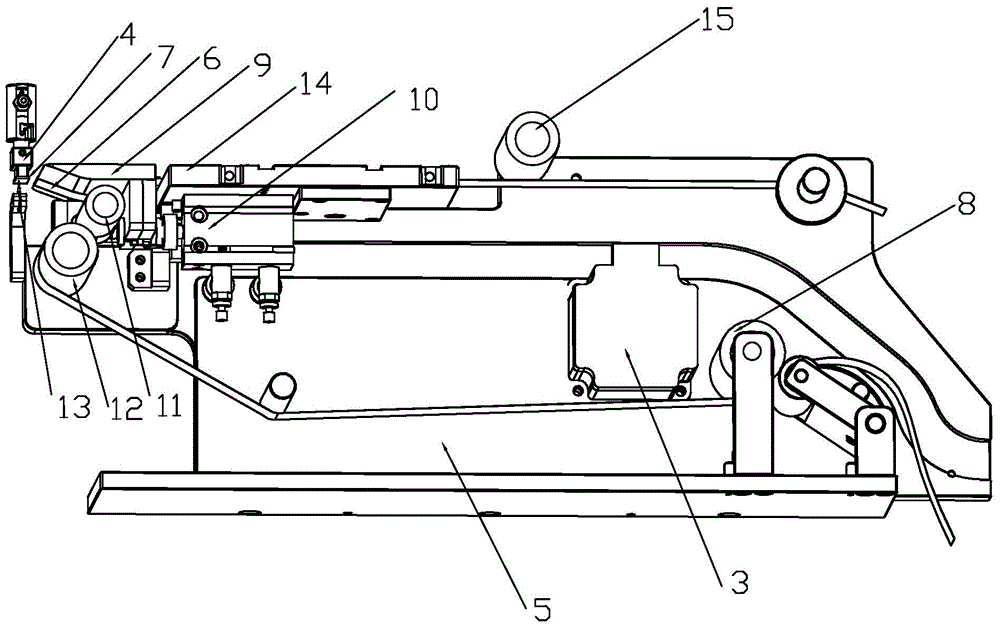

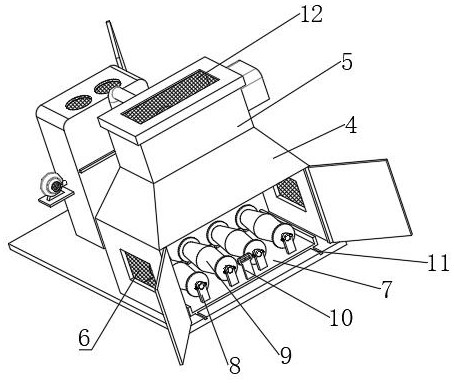

Automatic shearing machine

InactiveCN1721147AImprove qualityQuick RetrievalMetal working apparatusElectrical controlWork in process

This invention discloses auto shearer and comprises main body, receiving mechanism, shearing mechanism, taking mechanism, power device and electrical control part; wherein, set taking mechanism on base of main body, near to receiving mechanism and comprised frame set on base and len receiving device assembled on frame; the latter comprises multiple-layer tube lantern rings to receive len; when starting work, the lantern ring takes len of semi-product inside; when finishing shear, the len keeps in receiving device. it realizes the integration of shearing and package of auto shearer.

Owner:ASIA OPTICAL CO INC

Large plate cutting machine

InactiveCN109014363AEffectively fixedQuick cutShearing machinesShearing machine accessoriesCompression deviceArchitectural engineering

The invention discloses a large plate cutting machine, and relates to the technical field of plate cutting. The large plate cutting machine comprises a base, a support seat, a support plate and an upper bracket, wherein the support seat is arranged on the side edge of the base, the support plate is fixed on the middle of the support seat, the upper bracket is fixed on the upper portion of the support seat, sliding rails are arranged on the support seat, a sliding block are slidably connected with the sliding rails, fixing rods are fixed between the upper bracket and the support plate, the upper bracket is provided with a motor, an output shaft of the motor is connected with a screw rod which is rotatably connected to the support plate, the middle of the sliding block is provided with a threaded hole, the sliding block is connected to the screw rod through the threaded hole, compression devices are arranged on the sliding block, a cutting device is fixed on the side edge of the upper bracket, and a cutting table is arranged below the cutting devices. According to the large plate cutting machine, the structure is simple, operation is convenient, plates can be effectively fixed by arranging a clamping device, and the plates can be cut quickly by arranging the cutting device.

Owner:芜湖龙鳞汽车部件有限公司

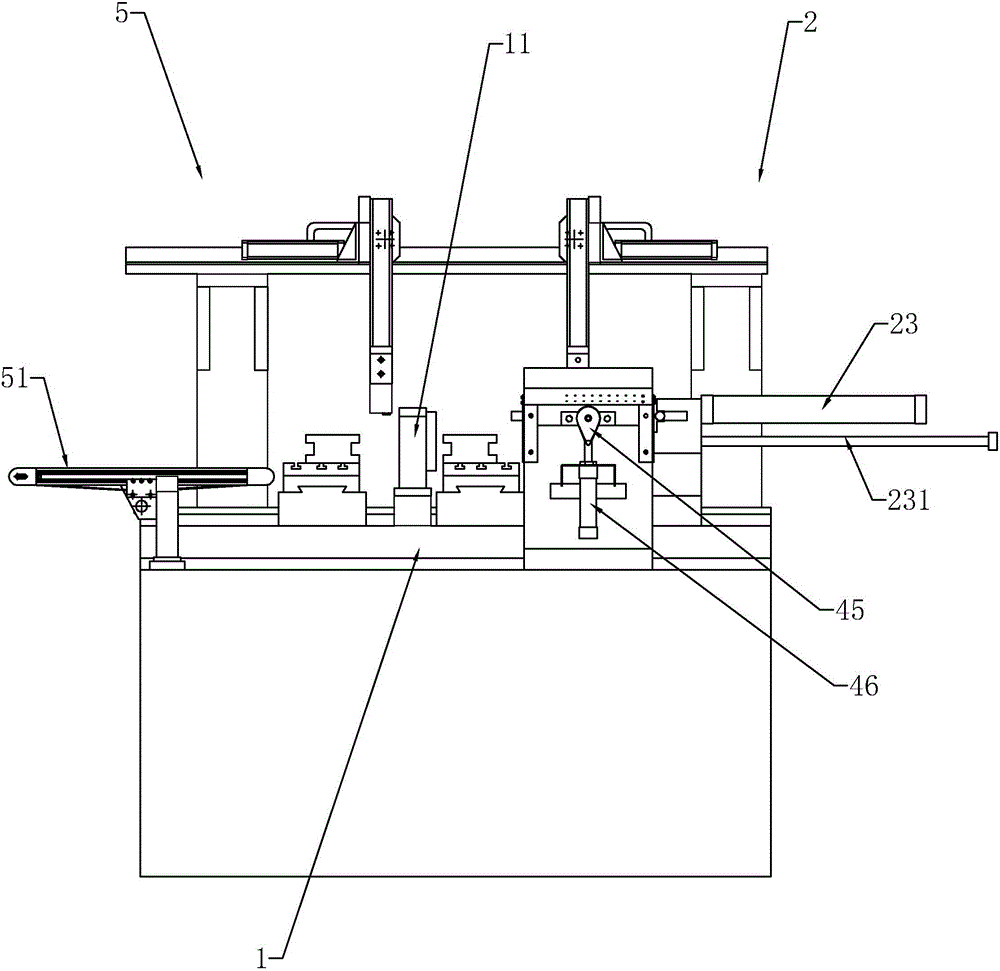

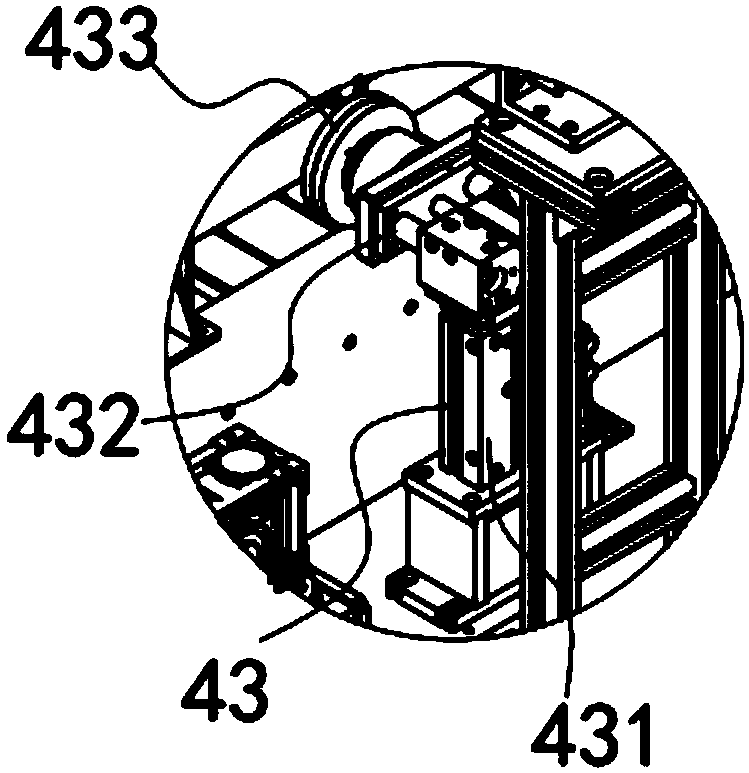

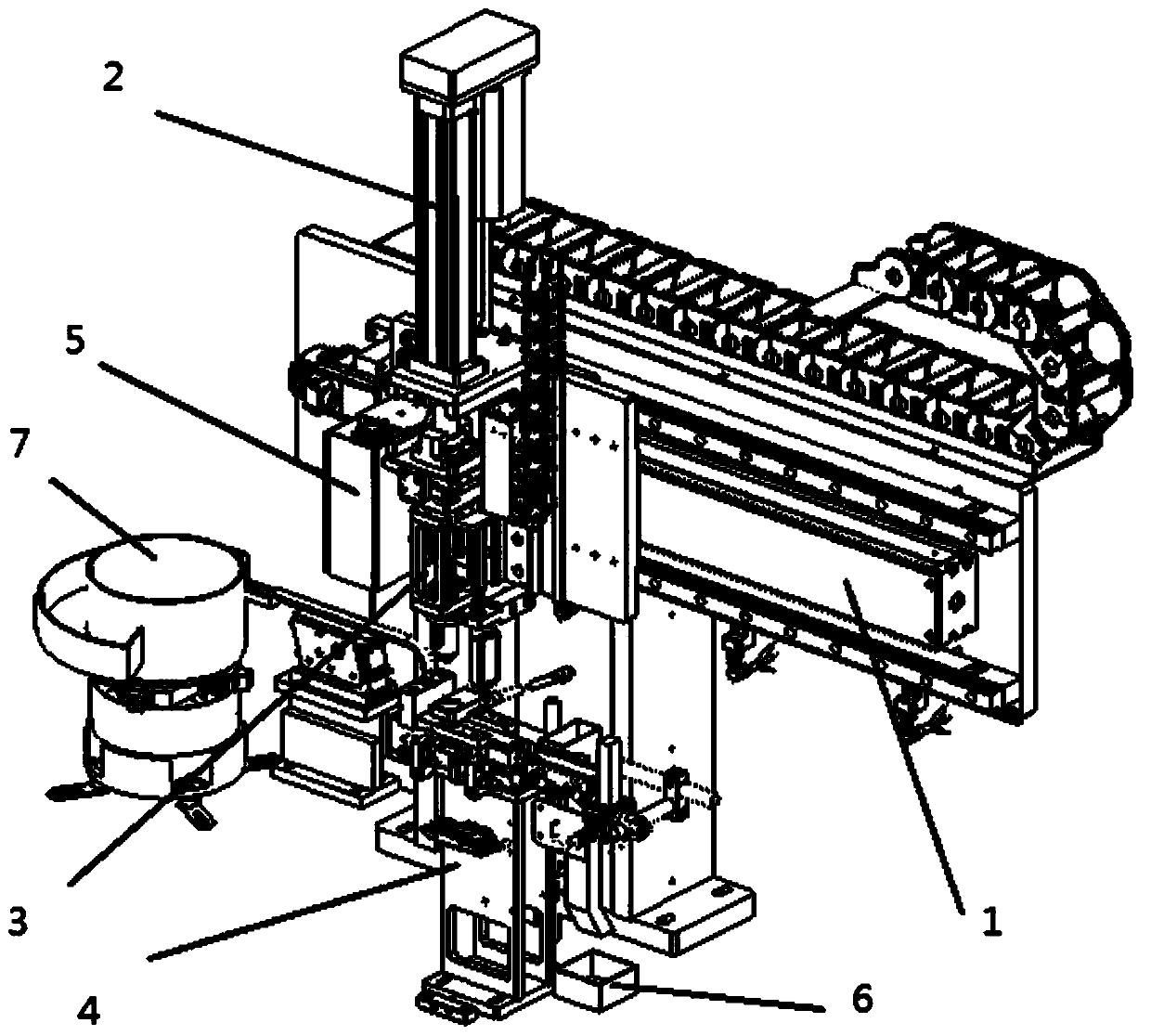

Adjustable intelligent charging and discharging mechanism of punch press

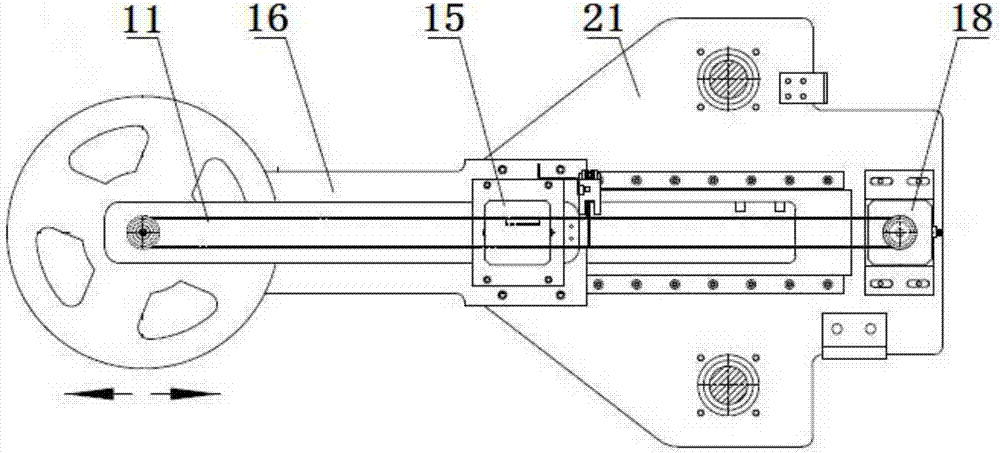

ActiveCN106001305AHigh precisionQuick RetrievalMetal-working feeding devicesPositioning devicesPunch pressEngineering

The invention provides an adjustable intelligent charging and discharging mechanism of a punch press. The adjustable intelligent charging and discharging mechanism is mounted at a charging position of a machine tool, and comprises a charging mechanism, a feeding mechanism, an X-axis left-and-right movement liner die set, and a Z-axis up-and-down movement liner die set, wherein the charging mechanism is mounted on one side of the machine tool; the feeding mechanism is erected on the charging mechanism, and the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set are mounted on the feeding mechanism. The adjustable intelligent charging and discharging mechanism of the punch press comprises the charging mechanism, the feeding mechanism, the X-axis left-and-right movement liner die set, and the Z-axis up-and-down movement liner die set, and through the X-axis left-and-right two-dimensional movement liner die set, and the Z-axis up-and-down two-dimensional movement liner die set, rapid and intelligent material taking can be realized. The adjustable intelligent charging and discharging mechanism is simple in structure and high in operating stability, the precision of a manipulator is high, and the consistency of products is notably improved; besides, normal time for charging and discharging needs to be four hours or above, and the normal processing time of the adjustable intelligent charging and discharging mechanism disclosed by the invention is within 2 hours, so that the efficiency is doubled.

Owner:江苏迈步智能装备科技有限公司

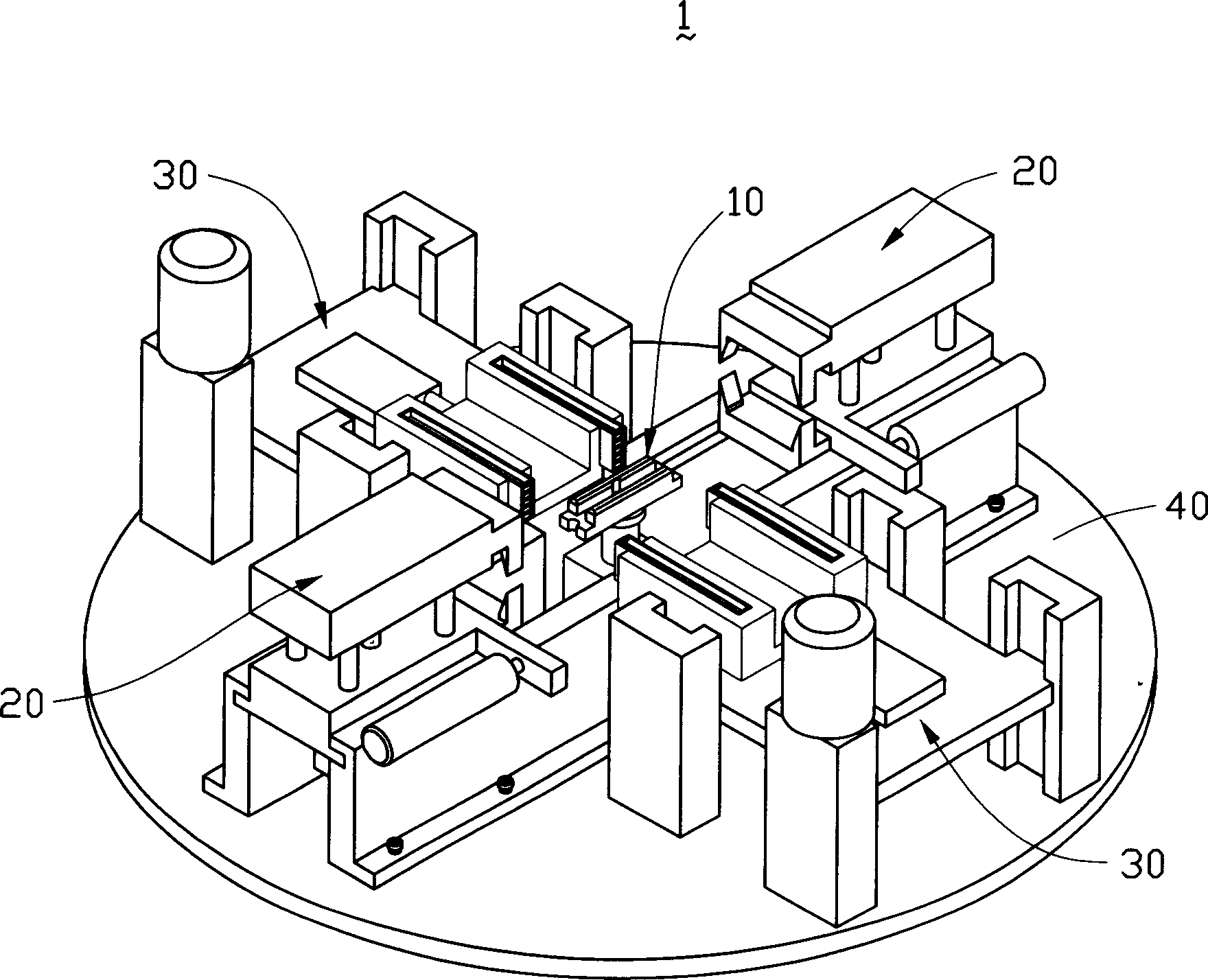

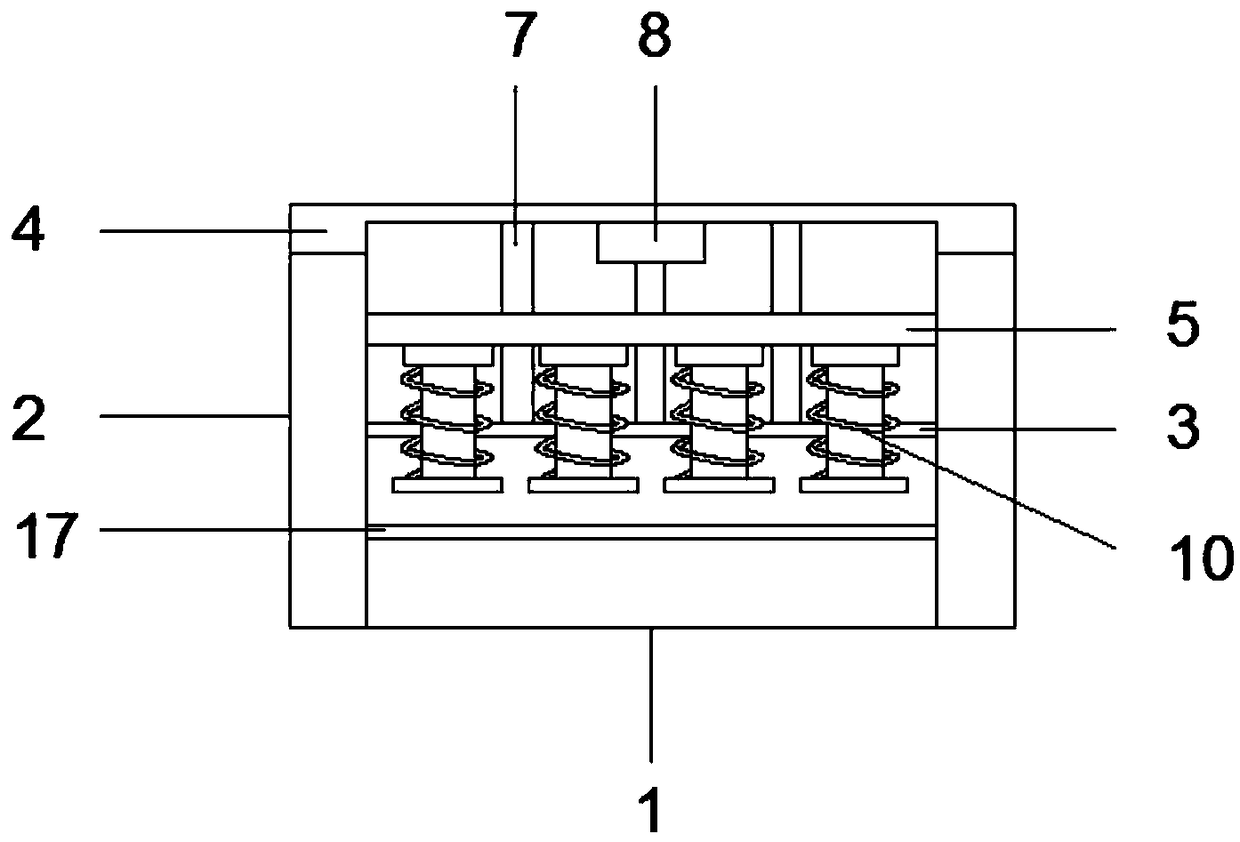

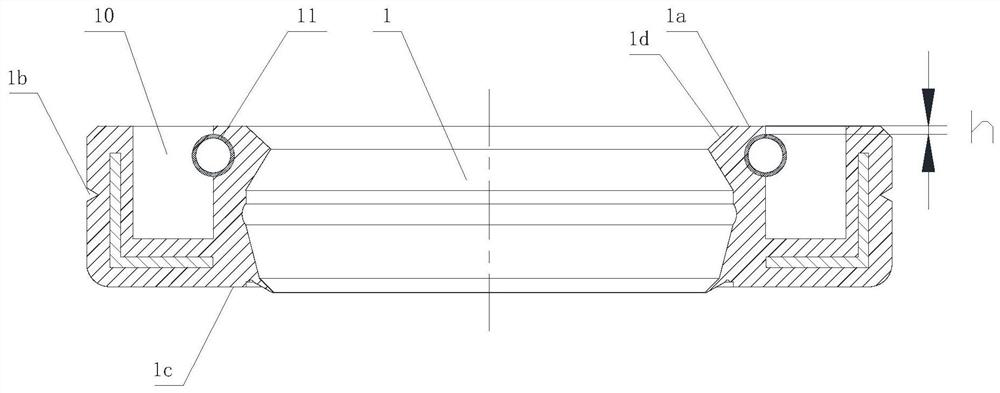

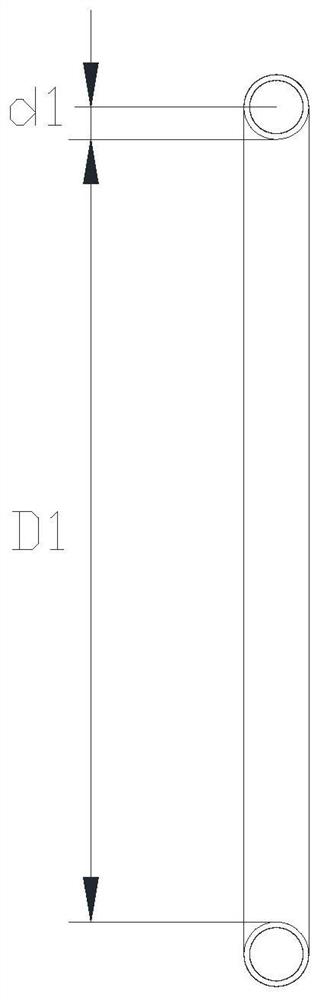

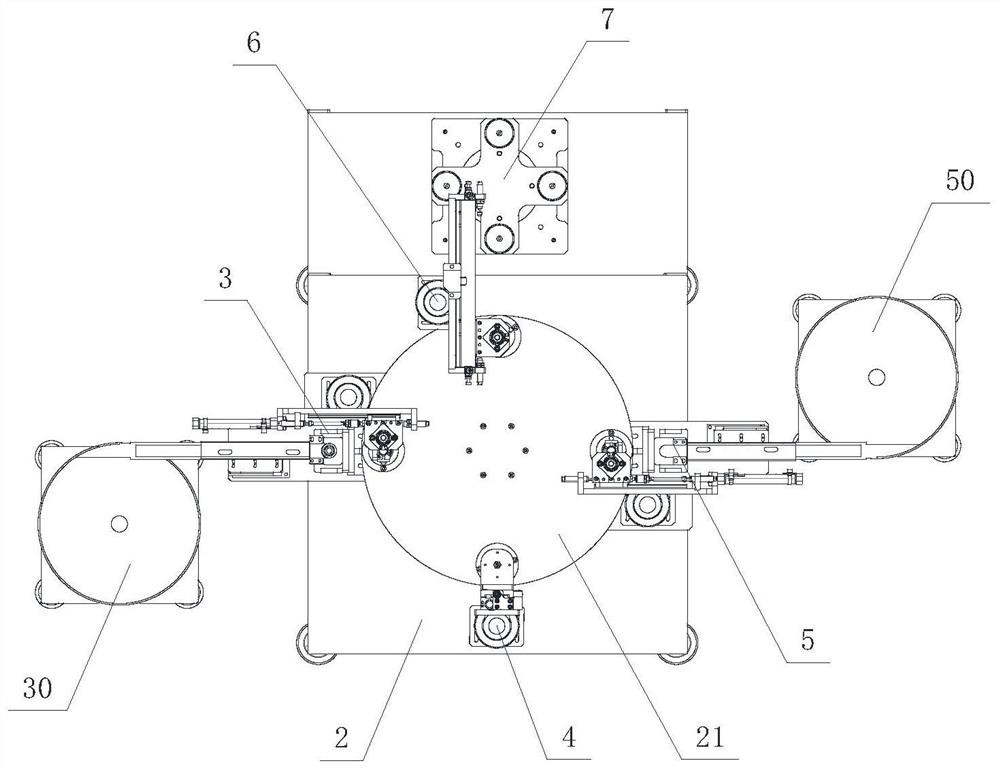

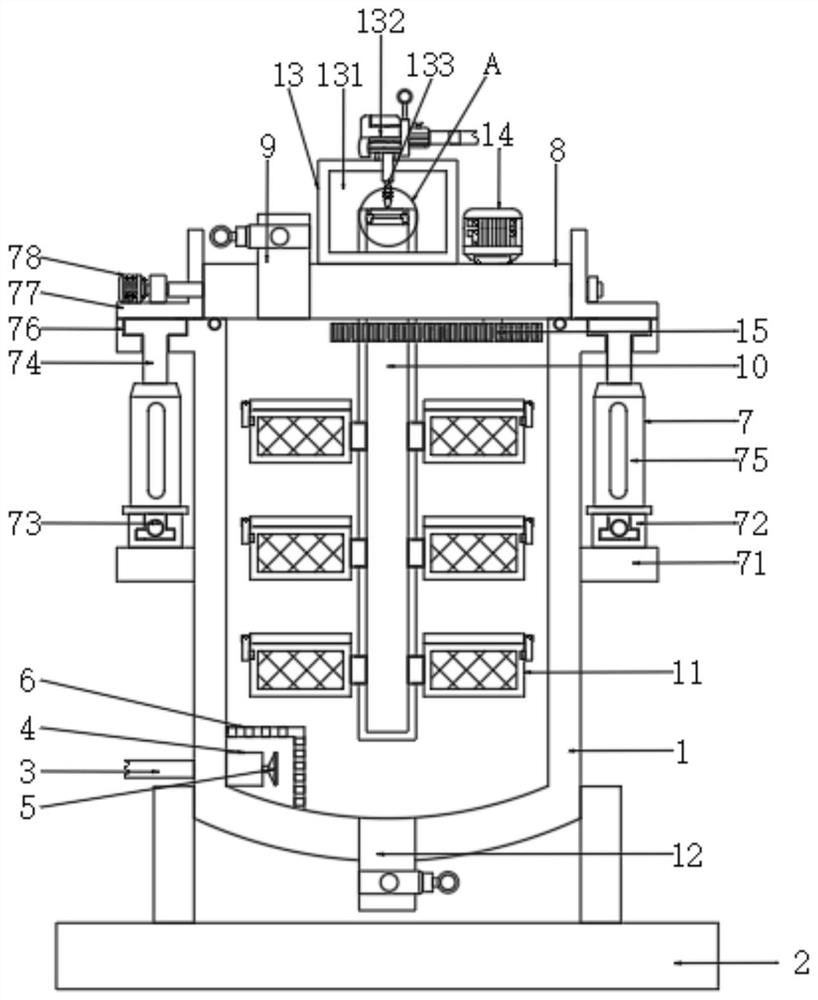

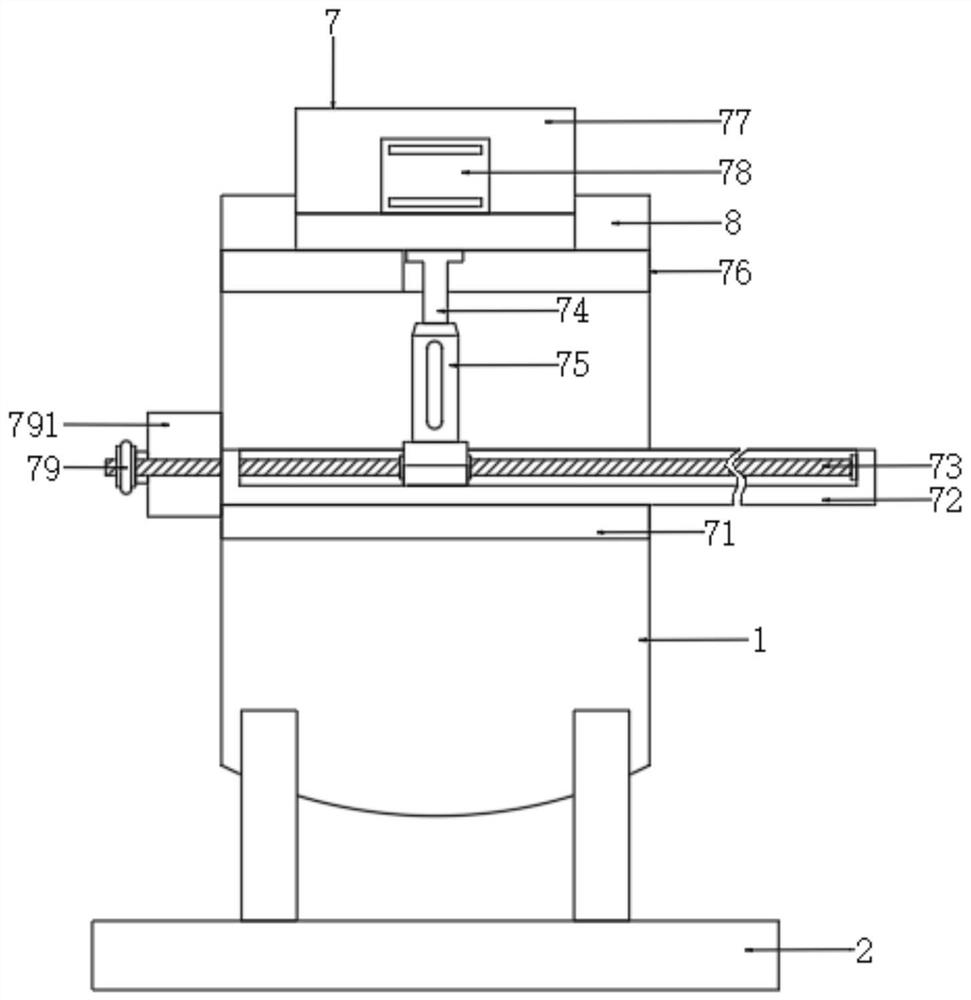

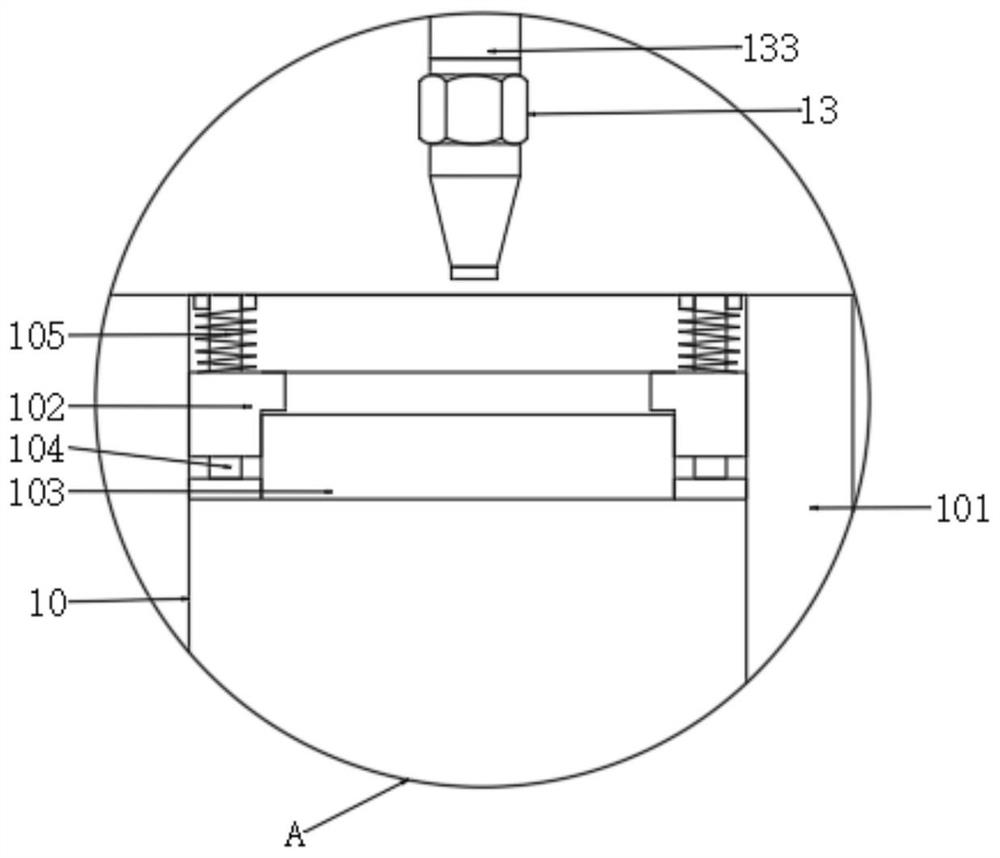

Full-automatic slurry pump framework oil seal four-station assembling system

ActiveCN111890019AEasy to adjustQuick RetrievalMetal working apparatusControl engineeringProcess engineering

The invention provides a full-automatic slurry pump framework oil seal four-station assembling system which comprises a mounting table, an oil seal feeding device, a pressing device 4 and a discharging device; a rotary disc is mounted on the mounting table; four clamps are uniformly distributed on the rotary disc in the circumferential direction; four stations are arranged on the mounting table; the oil seal feeding device is used for feeding a framework oil seal body into the clamp on the first station; the pressing device is used for completely pressing the framework oil seal body in the clamp on the second station into the clamp to realize precise positioning; a spring feeding device is used for grabbing a spring at the discharging end of a second vibrating disc and mounting the springon the framework oil seal body in the clamp on the third station; and the discharging device comprises a third walking mechanism and a discharging manipulator. The full-automatic slurry pump frameworkoil seal four-station assembling system can realize automatic feeding, pressing, assembling and discharging, is high in degree of automation, greatly lowers the production cost and improves the production efficiency.

Owner:LONGKOU FLYING WHEEL CAR ACCESSORIES

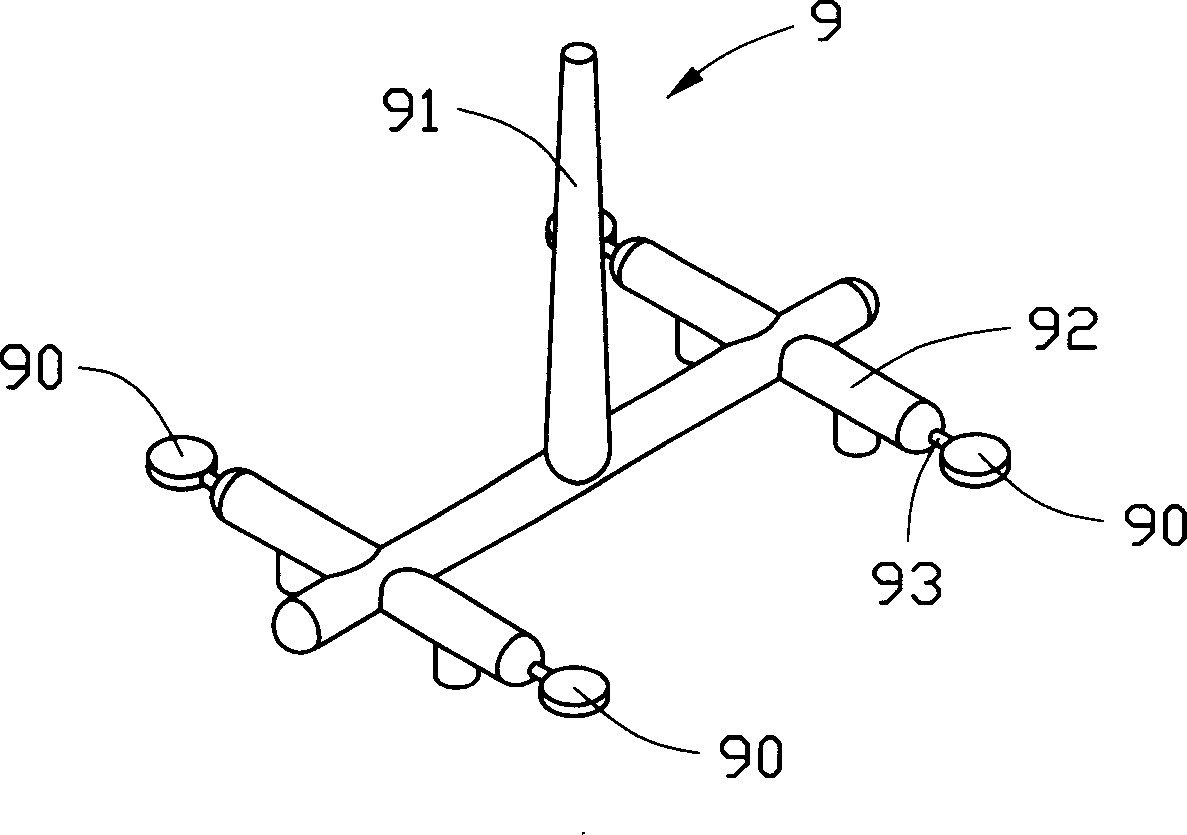

An automatic device for sleeving O-shaped ring

The invention relates to an automatic device for sleeving an O-shaped ring. The device comprises a fixed main body, a shell, a O-shaped ring sleeving mechanism and a driving mechanism; the O-shaped ring sleeving mechanism comprise a material stripping sleeve, an elastic returning part, a moving rod, a plurality of material taking claws which are positioned in the material stripping sleeve and arein linkage fit with the moving rod and a material stripping rod which corresponds to the position above the material stripping sleeve and is in linkage with the moving rod; and a through hole allowingone ends of the plurality of material taking claws to penetrate through is formed in the material stripping sleeve, the plurality of material taking claws are distributed in an annular array and aremovably arranged on the moving rod, returning components are arranged between the moving rod and the plurality of material taking claws, one ends of the plurality of material taking claws act along with the moving rod and can penetrate through the through hole of the material stripping sleeve and are mutually supported to be opened, and the material stripping rod moves along with the moving rod and can be used for driving one end of the material stripping sleeve to extend out of the shell. The device has the advantages of being simple in structure, stable and reliable in performance, high in efficiency and capable of saving manpower.

Owner:ZHEJIANG BLCH PNEUMATIC SCI & TECH

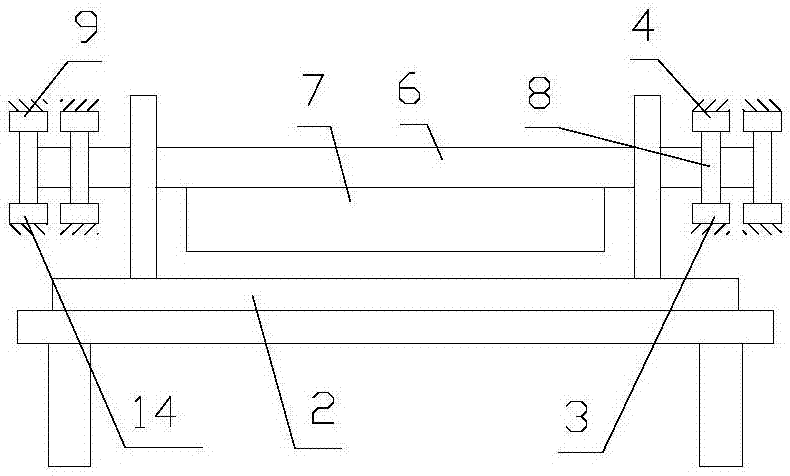

Machining device capable of achieving continuous production

ActiveCN107309790AEffective clamping and fixingEffectively removedEdge grinding machinesGrinding carriagesEngineeringMachining

The invention discloses a machining device capable of achieving continuous production. The device is used for metal plate machining and at least comprises a machining table, a guiding rail, a machining plate, a driving mechanism and a clamping part. The guiding rail is horizontally mounted on the machining table, the machining plate is slidably mounted on the guiding rail, and the driving mechanism is used for driving the machining plate to move in the length direction of the guiding rail. The clamping part comprises a plurality of clamping mechanisms, a first rack and a second rack. The multiple clamping mechanisms are sequentially arranged in the length direction of the guiding rail and comprise first clamping units. The first clamping units comprise first supporting plates, first rotary shafts, first pressing plate and first gears, and the first supporting plates are mounted on the machining plate. The first rotary shafts are horizontally and rotatably mounted on the first supporting plates, the length direction of the first rotary shaft is perpendicular to that of the guiding rail, and the first pressing plates are mounted on the first rotary shafts.

Owner:TONGLING MINGCHENG FOUNDRY

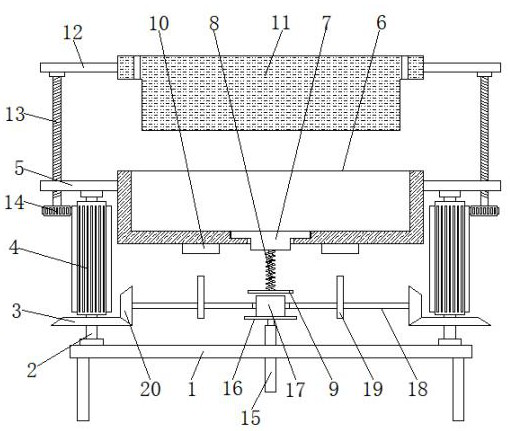

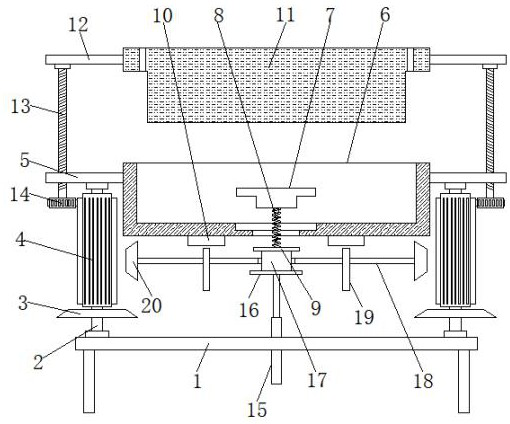

Vibration method cleaning device

InactiveCN110125078AQuick washAvoid bumpingDrying gas arrangementsCleaning using liquidsWater resourcesEngineering

The invention discloses a vibration method cleaning device. The vibration method cleaning device comprises a main machine shell, the right side of the upper end wall of a moving space is provided witha driving device in power connection with a moving plate, a lifting plate and the moving plate are connected through a connection device, four corners of the lower end face of the lifting plate and asliding groove are each correspondingly provided with one lifting device extending downwards, a cleaning space is internally provided with a concentric-square-shaped frame, the rear side of the mainmachine shell is provided with a flushing device, the upper side of the right end wall of the cleaning space is provided with an air blowing device, and the lower side of the right end face of the main machine shell is fixedly provided with a water adding device. According to the vibration method cleaning device, in working of the vibration method cleaning device, one plastic soft pad is installedbetween gears, bumping of the gears is prevented, the product quality is guaranteed, the concentric-square-shaped frame performs vibration up and down, so that cleaning of the gears is made to be faster and more efficient, clean water for flushing workpieces falls into the cleaning space to be used for compensating loss of the water due to steam generated by heating, and water resources are saved.

Owner:温州博华纸张有限公司

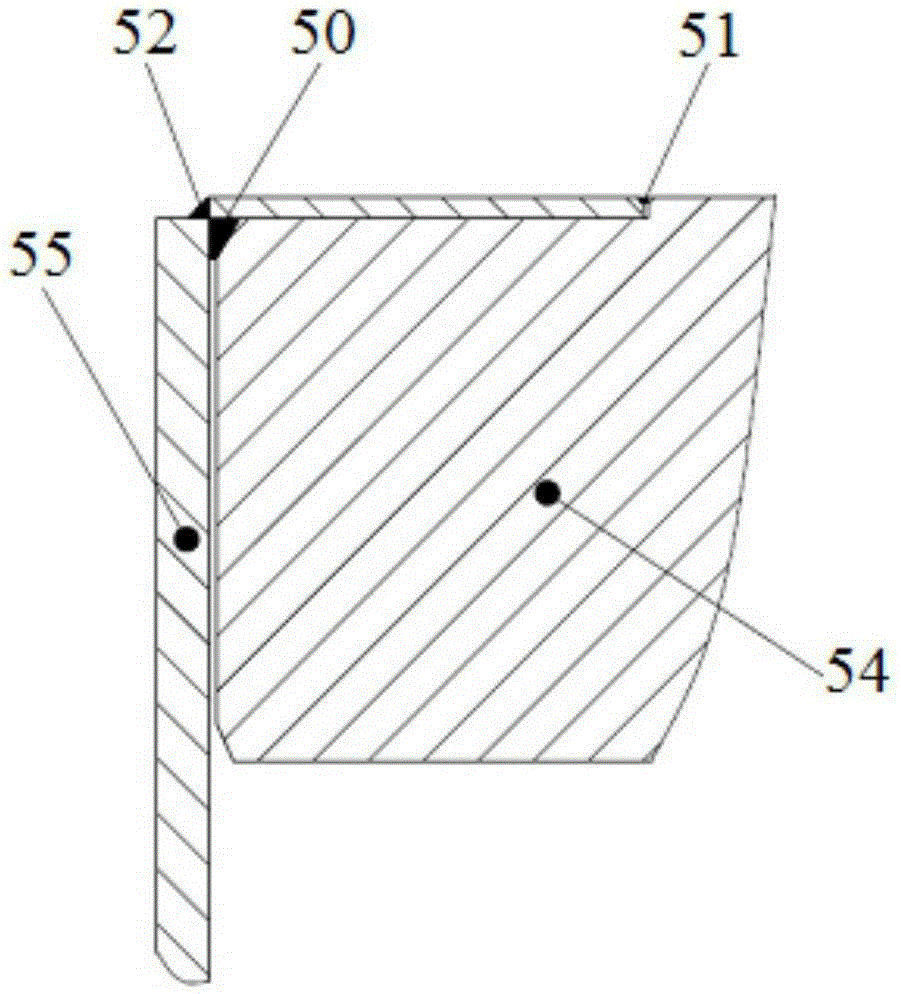

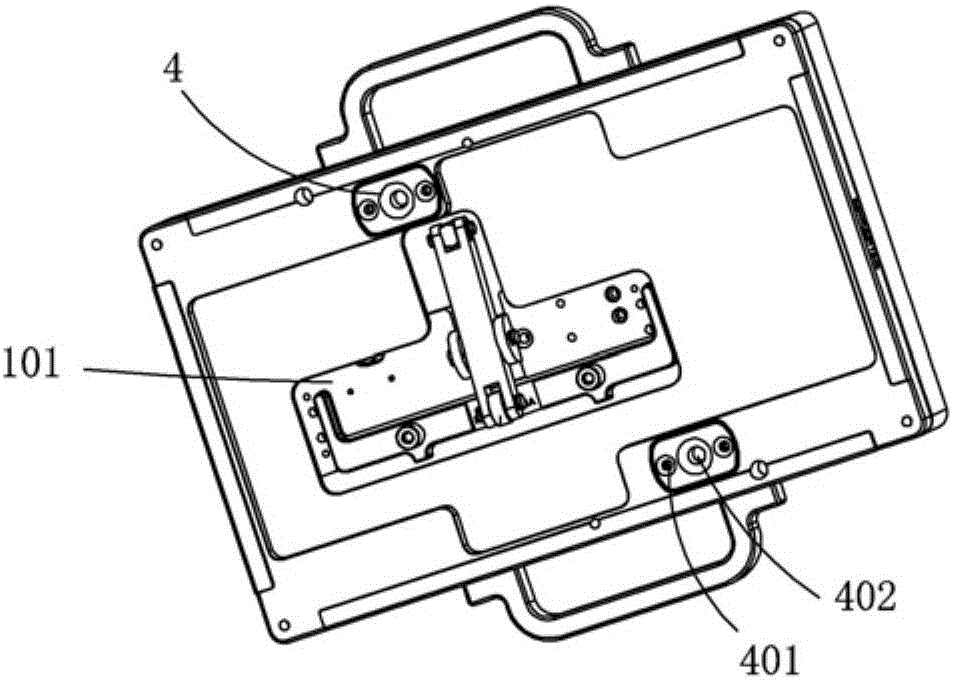

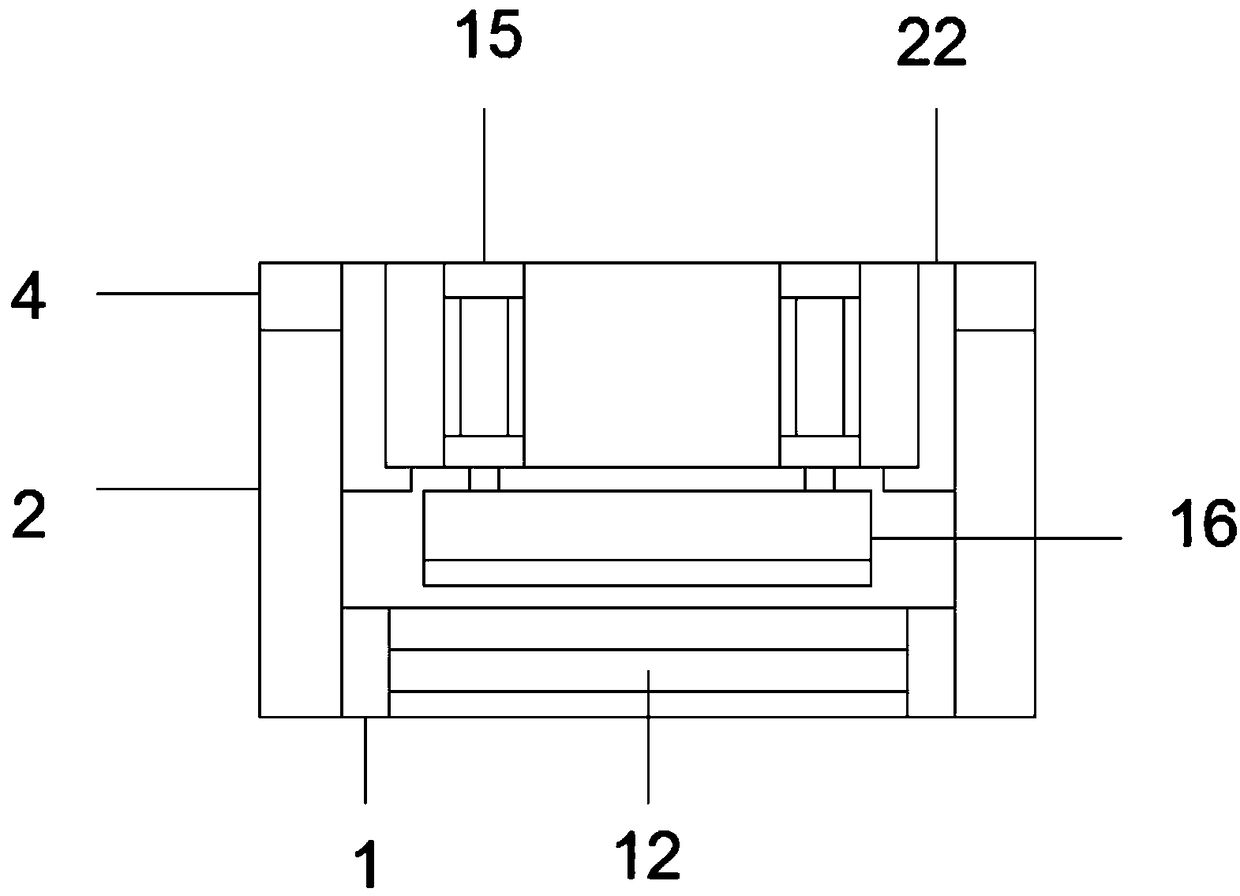

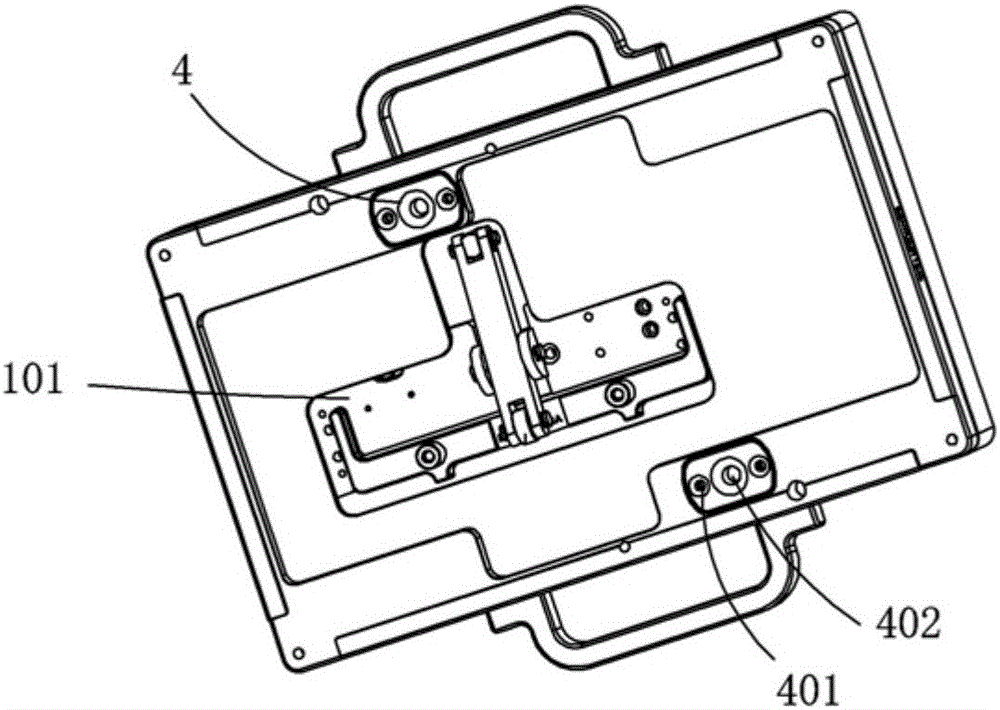

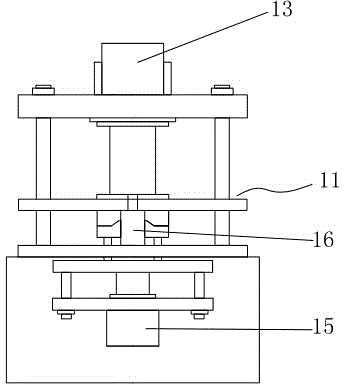

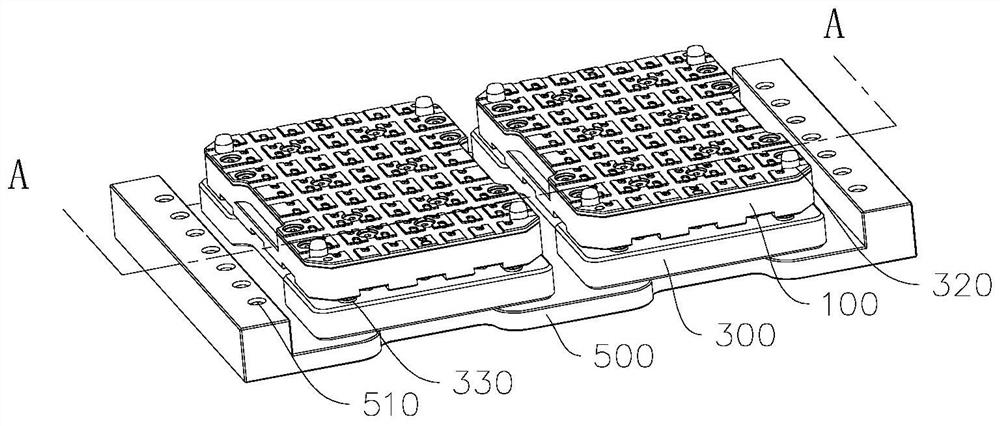

Double-station linking positioning and material pressing device

ActiveCN105798518ASolve the problem of too small and difficult to removeShorten the timeWelding/cutting auxillary devicesWork holdersBlock matchMechanical engineering

The invention relates to a double-station linking positioning and material pressing device. The upper portion of a lower bottom plate is provided with an upper box body. The upper box body is provided with a product positioning block. A linking clamping assembly capable of clamping a product is arranged between the lower bottom plate and the upper box body. A pressing assembly comprises a pressing head seat, a left pressing head and a right pressing head, wherein the left pressing head and the right pressing head are connected to the two sides of the pressing head seat through a connecting rod, and the lower end of the pressing head seat is connected with a pressing head. The front end of the left pressing head, the front end of the right pressing head and the front end of the pressing head seat are connected with a rotating seat through a rotating shaft. The rotating seat is arranged on the upper box body. The upper portion of the pressing head seat is provided with a pressing hand. Each connecting plate is provided with a buckle fixing seat, wherein the buckle fixing seat is movably connected with a buckle in a clamping manner, a clamping block matched with the pressing head seat is arranged on the buckle fixing seat; the pressing hand is downwards pressed to push the clamping block to move, the clamping block can move to be connected with the buckle in a clamping manner, the clamping block is provided with a pin, and the displacement of the pin is determined through photographing positioning so that whether clamping connecting is completed or not can be judged. By means of linking design, two products can be positioned at a time; and the products and micro parts on the products can be pressed, and accurate positioning is facilitated.

Owner:BOZHON PRECISION IND TECH CO LTD

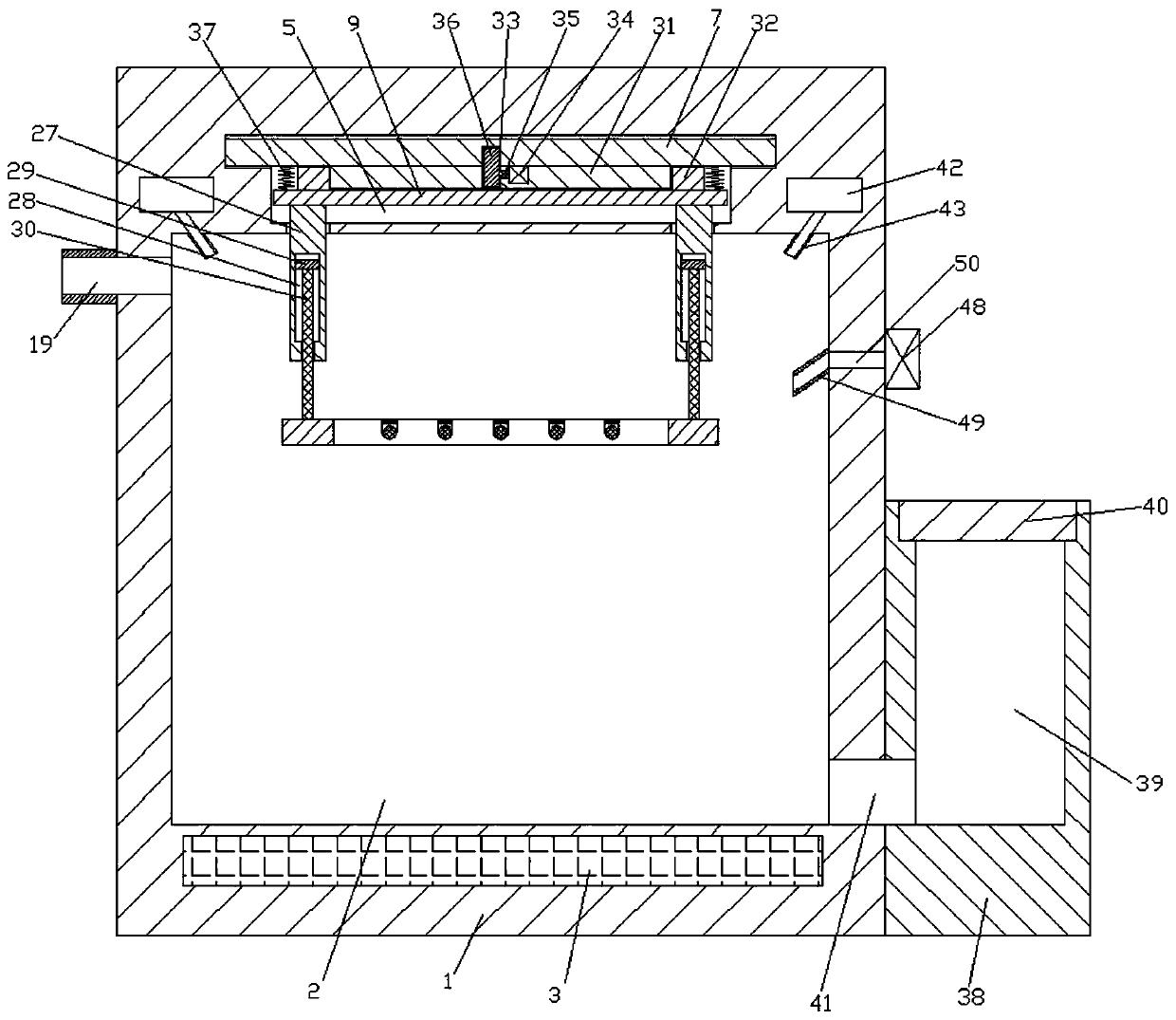

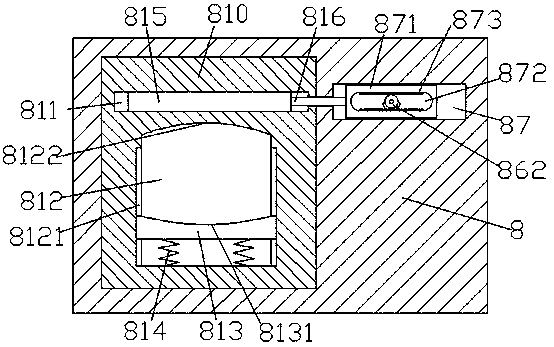

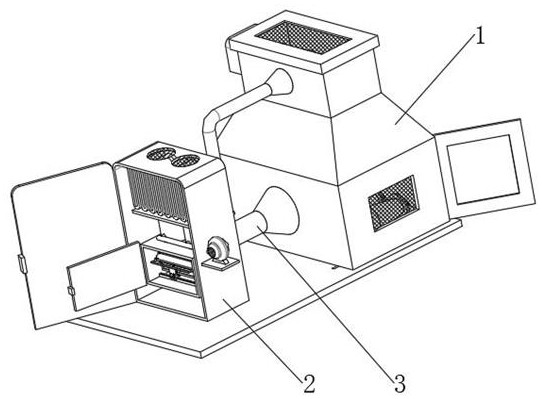

Automobile part ultrasonic washing machine

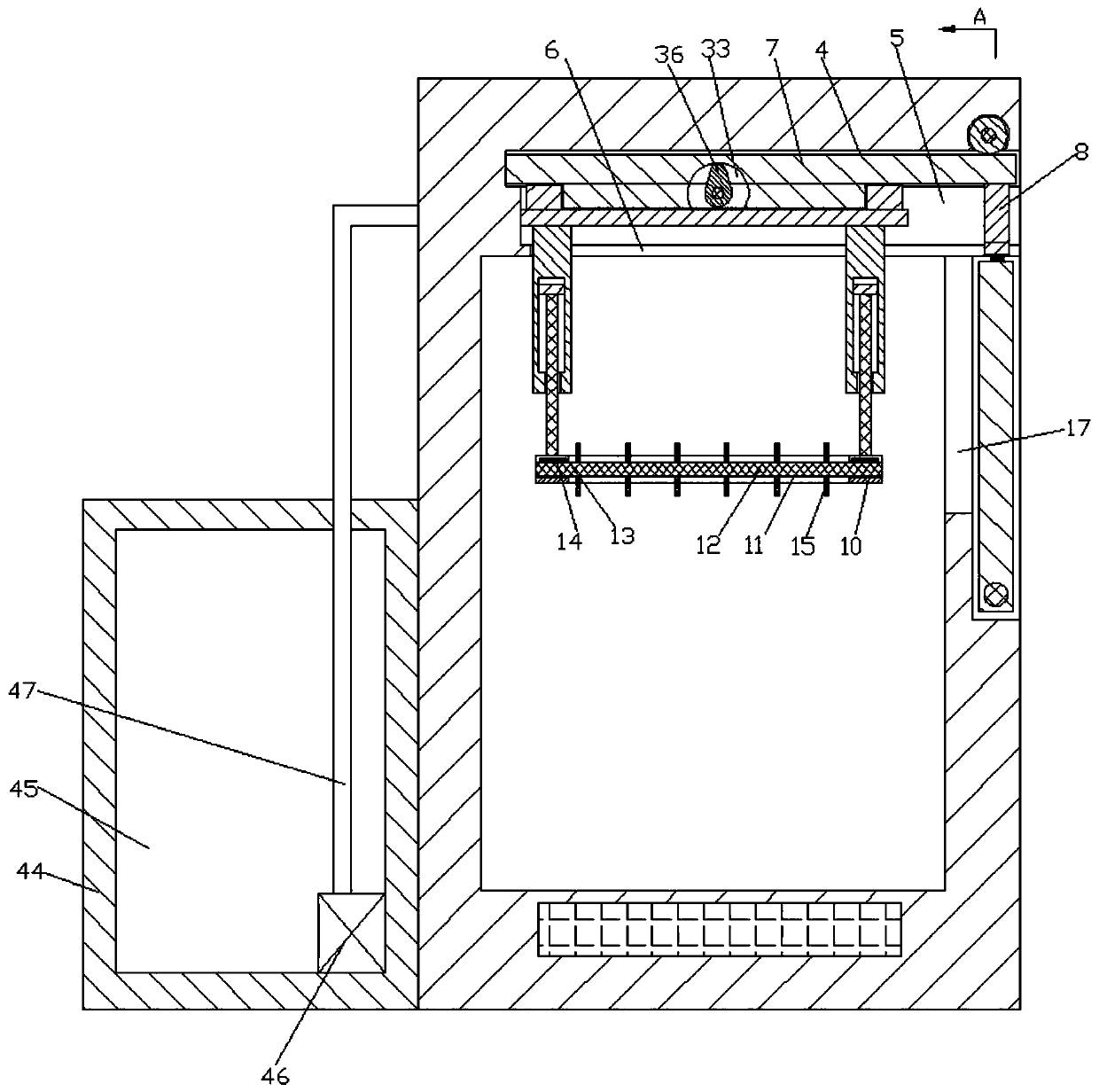

ActiveCN110586570AQuick storageControlled reciprocating drive for cleaning workCleaning using toolsCleaning using liquidsMegasonic cleaningUltrasonic generator

The invention discloses an automobile part ultrasonic washing machine. The automobile part ultrasonic washing machine comprises a washing main body, wherein a washing groove with an opening arranged upwards is formed in the washing main body, an ultrasonic focus cavity is formed in the lower side of the washing groove, an ultrasonic transducer is fixedly arranged on the top wall of the ultrasonicfocus cavity, an ultrasonic generator is fixedly arranged on the bottom wall of the ultrasonic focus cavity, a liquid storage cavity is formed in the left side of the ultrasonic focus cavity, a pistonslide block is connected in the liquid storage cavity in a sliding fit mode, a communication pipe communicating with the washing groove is arranged in the top wall of the liquid storage cavity, multiple groups of washing hairbrushes arranged at equal intervals are arranged in the washing groove, and a hairbrush control mechanism used for controlling the washing hairbrushes to work in a left-rightmovement mode is further arranged in the washing groove. The automobile part ultrasonic washing machine is simple in structure and convenient to operate, and improves overall work efficiency of washing.

Owner:爱阔特(上海)清洗设备制造有限公司

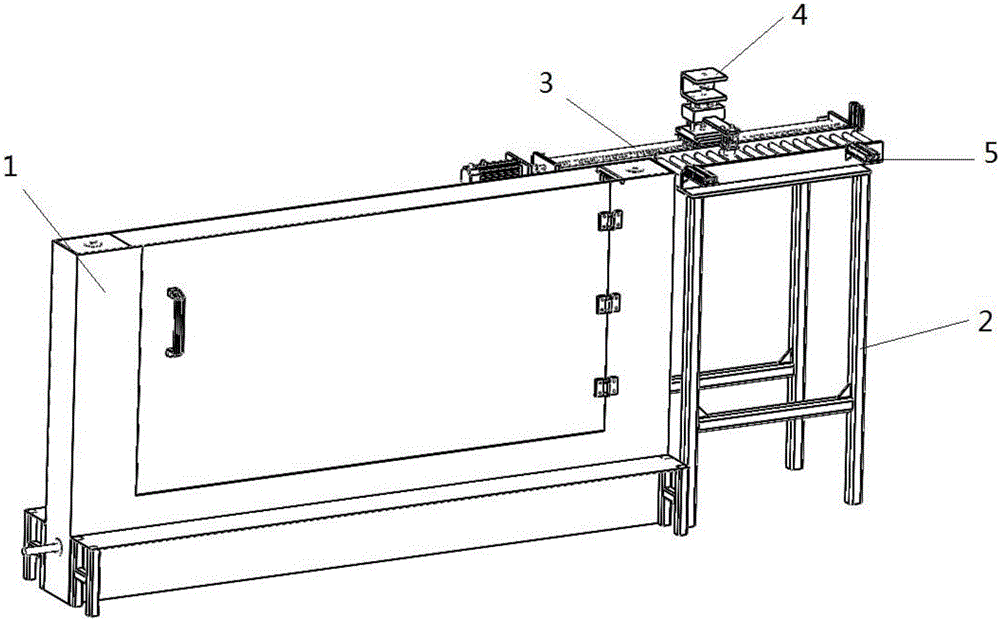

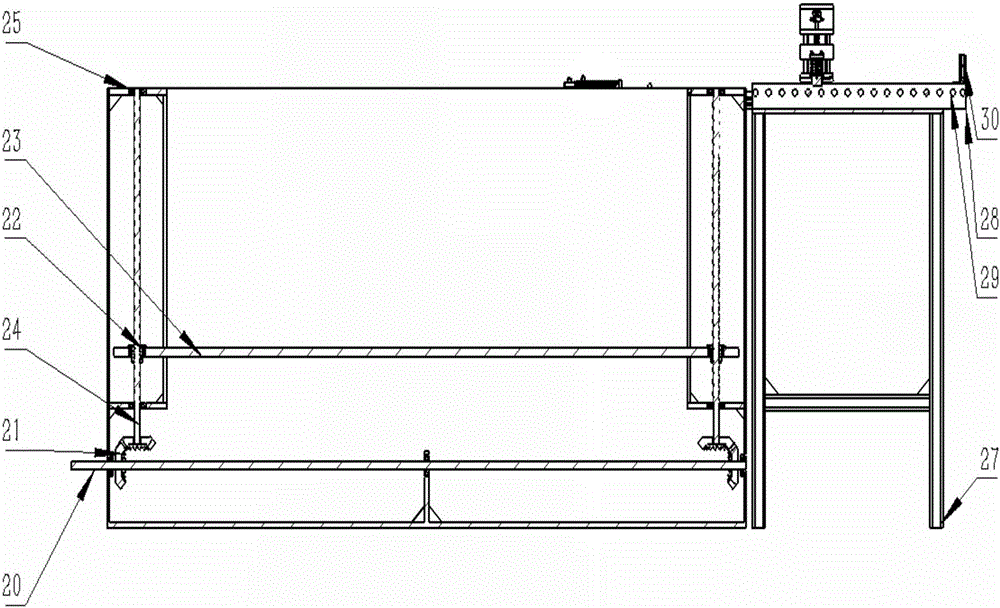

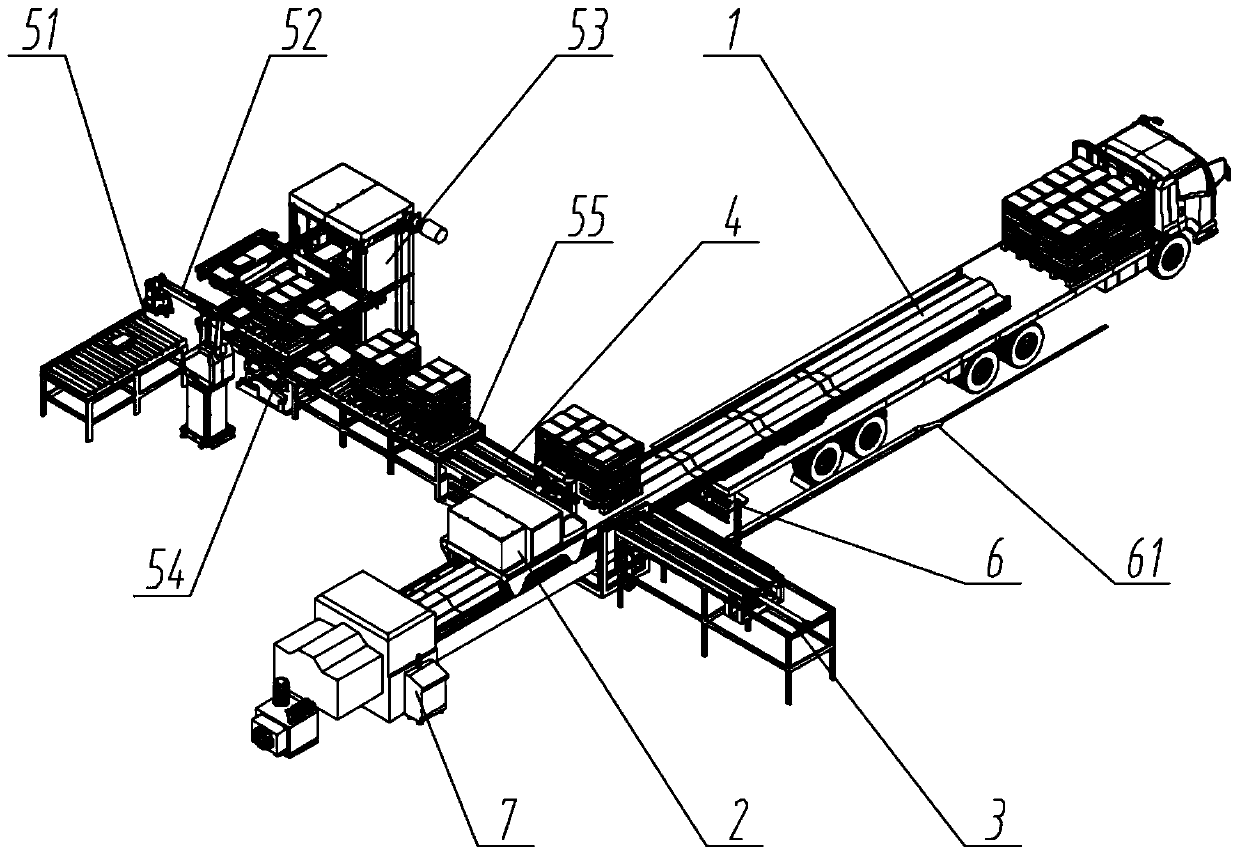

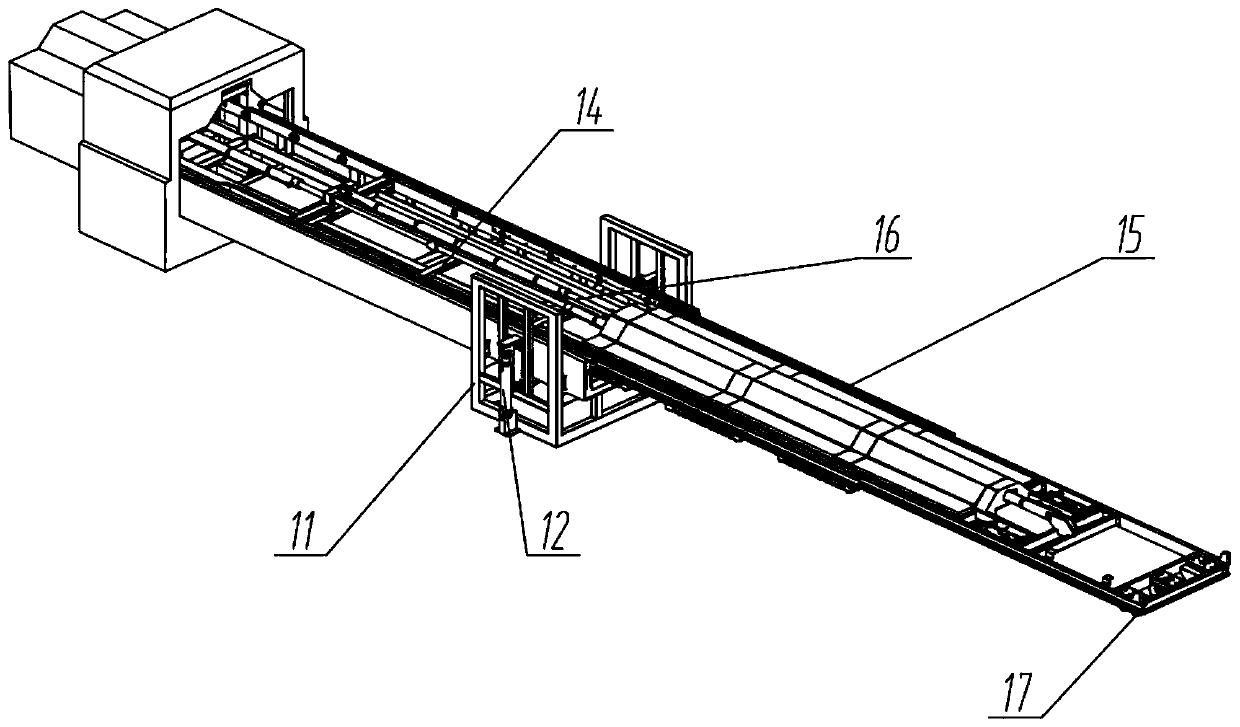

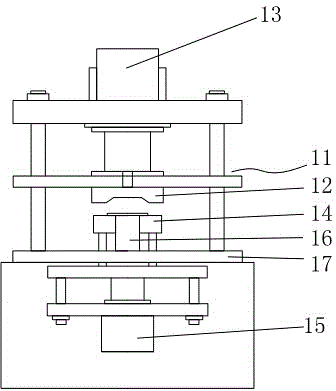

Rapid automatic truck loading system and control method thereof

InactiveCN111453468AFast loadingLoad accuratelyStacking articlesLoading/unloadingEngineeringControl theory

The invention discloses a rapid automatic truck loading system. The rapid automatic truck loading system comprises a truck loading device and a material fetching component located at one end of the truck loading device, wherein the truck loading device comprises a stretching and contracting component, a supporting component and a material feeding forklift, the stretching and contracting componentcomprises a plurality of sliding rails performing stretching-contracting moving among the sliding rails, the adjacent sliding rails are stacked inside and outside and are driven by a first stretchingand contracting rod, the sliding rail on the outermost side is installed on supporting racks, and the lower portions of the sides, close to a truck-loading vehicle, of the other inner-side sliding rails are all provided with a plurality of different supporting idler wheels, the different supporting idler wheels can be in supporting contact with a carriage, the stretching and contracting componentcan perform stretching and contracting into the carriage in the length direction of the carriage, the material feeding forklift performs linear movement through one sliding rail with a guiding position-limiting strip and performs truck loading on cargoes, and the material fetching component is located at the tail portion of the truck-loading vehicle and can perform material fetching on the conveyed cargoes. By means of the rapid automatic loading system, the cargoes is fed into the carriage, manual carrying is saved, furthermore, rapid truck loading is realized through the linear movement of the material feeding forklift, the rapid automatic loading system is more efficient and rapid, and the truck loading is conveniently performed.

Owner:HEFEI EAGLE AUTOMATION ENG TECH

Metal sheet stretching energy-saving method

The invention discloses a metal sheet stretching energy-saving method. The metal sheet stretching energy-saving method is applied to a stretching machine with a fixed blank holder and a vertically-moving male die core. The method includes the following steps that firstly emptying and blank pressing are conducted, wherein a metal sheet is coated with lubricating fluid and is placed on the blank holder, a female die moves downwards under drive of a blank pressing oil cylinder, and blanks are pressed; secondly, stretching forming is conducted, wherein the male die core moves upwards relative to the blank holder under drive of a stretching oil cylinder, the male die core and the female die are matched to finish integral stretching forming work; in the process, a servo hydraulic closed-loop control system linearly adjusts blank pressing force and stretching force in real time according to the requirements of produced products; thirdly, discharging is conducted, wherein the female die and the male die core simultaneously act, the female die is moved upwards and reset, the male die core is moved downwards and reset, and the products which are acquired after stretching forming are exposed and placed on the blank holder. The method has the following advantages that energy is saved, and production cost is reduced; the speed is high, and production efficiency is improved; equipment operation and maintenance cost is reduced; the defective rate of the products is reduced.

Owner:广东贤辰节能科技有限公司

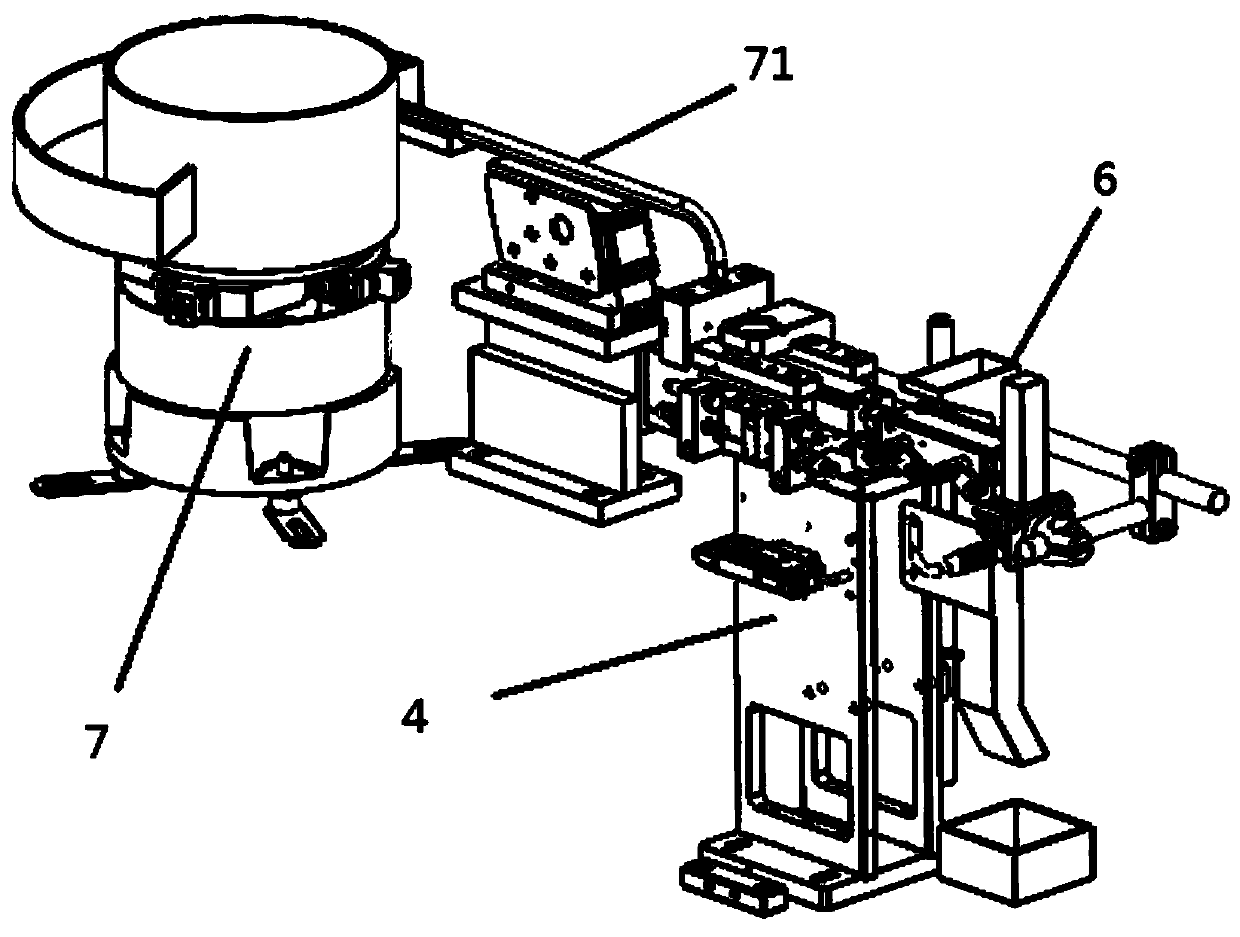

Automatic assembly device for clamping spring

ActiveCN110640418AGuaranteed installation effectQuick RetrievalMetal working apparatusControl engineeringControl theory

The invention discloses an automatic assembly device for a clamping spring. The automatic assembly device for the clamping spring comprises an X-axis moving module, a Z-axis moving module and a material taking module, the Z-axis moving module is connected to the X-axis moving module, and the material taking module is connected to the Z-axis moving module; the material taking module includes a power unit, a material taking shaft and a guide sleeve, the material taking shaft is connected to the output end of the power unit, the guide sleeve is connected with the power unit, and the power unit works to drive the material taking shaft to extend and retract in the guide sleeve; and the X-axis moving module and the Z-axis moving module move to drive the material taking module to move to a material taking position, the material taking shaft is extended to take the clamping spring, and the X-axis moving module and the Z-axis moving module move, so that the material taking module moves to a mounting position, the material taking shaft retracts, and the Z-axis moving module is descended to mount the clamping spring. According to the automatic assembly device for the clamping spring, materialtaking can be quickly performed, during mounting, the clamping spring is mounted by the combined action of the retracting of the material taking shaft and the descending of the Z-axis moving module,the mounting effect of the clamping spring is ensured, and the efficiency is improved.

Owner:卓越(昆山)自动化技术有限公司

Convenient-to-pickup spinning cooking device and application method

ActiveCN111826838AQuick RetrievalEasy dischargeTextile/flexible product manufactureTextile treatment by spraying/projectingHydraulic cylinderYarn

The invention discloses a convenient-to-pickup spinning cooking device in the technical field of spinning cooking. The spinning cooking device comprises a cooking shell; a pickup adjusting mechanism matched with a shell cover is arranged at a position, close to the upper side, of the outer wall of the cooking shell; a cooling mechanism is fixedly arranged in the center of the top of the shell cover; an assembly column mechanism is movably inserted into the center of the bottom of the cooling mechanism; and a plurality of groups of yarn placing mechanisms with the same structure are arranged onthe outer wall of the assembly column mechanism in an annular array manner. According to the convenient-to-pickup spinning cooking device, the pickup adjusting mechanism is arranged, two groups of hydraulic cylinders are driven, two groups of L-shaped blocks are driven by push rods to move upwards to designated positions; a servo motor is driven, therefore, two groups of T-shaped sliding blocks are enabled to drive the hydraulic cylinders to move towards the front side in a T-shaped sliding groove; and after the shell cover and the assembly column mechanism move towards the front side to thedesignated positions, the servo motor is turned off, a stepping motor is driven to drive a rotating rod II till a hollow column rotates to a longitudinal state, a user can conveniently and rapidly pick up and place materials, and the safety of picking up and placing the materials is greatly improved.

Owner:湖州领先丝带有限公司

Cotton spinning fine spinning system

InactiveCN111691024AEase of pay-off and take-up processImprove filtering effectTransportation and packagingTextiles and paperYarnSpinning

The invention discloses a cotton spinning fine spinning system and belongs to the technical field of spinning equipment. The cotton spinning fine spinning system comprises a spinning and winding component and a dust removal component. The spinning and winding component and the dust removal component are connected through an air flow delivery pipe. The dust removal component comprises a dust collection box. A dust removal box is arranged in the dust collection box. The dust removal box is internally provided with a dust removing and sweeping mechanism. The cotton spinning fine spinning system facilitates yarn unwinding and winding during cotton spinning, filters and collects tiny cotton fluff floating in the spinning and winding component during yarn unwinding and winding and completes therapid yarn winding process. The dust removal component adsorbs cotton fluff generated by the spinning and winding component through negative pressure, and the generate negative pressure takes cotton fluff into the dust removal box. Dust removal stop frames and filter screens are used in cooperation with a suction cover to adsorb the cotton fluff onto the filter screens. The cotton spinning fine spinning system intermittently drives a rotary roller to rotate through an intermittent mechanism. The four dust removal stop frames complete operation of filtering cotton fluff in sequence.

Owner:刘玉会

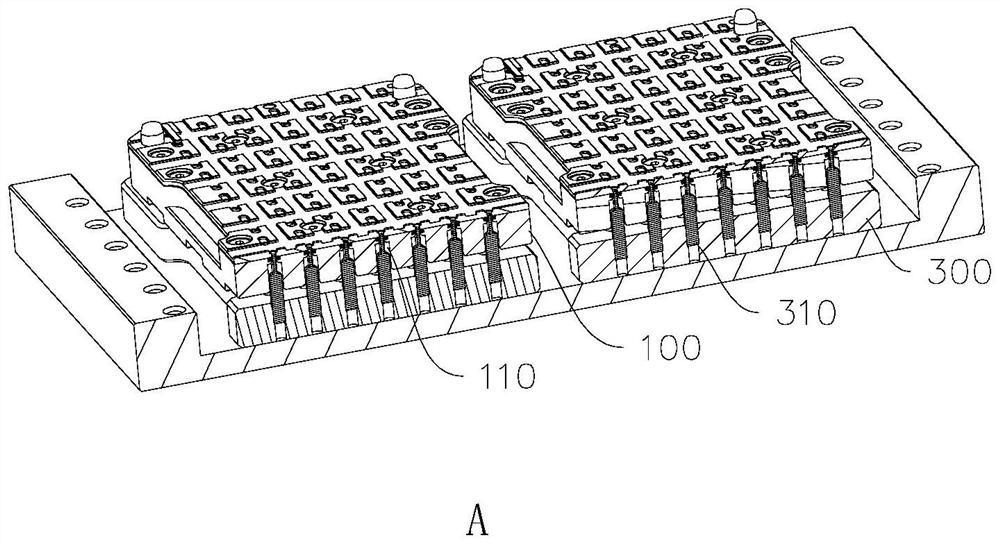

Flat grinding and material taking jig set

PendingCN114012598AWon't hurtQuick RetrievalGrinding feedersGrinding work supportsEngineeringGrinding

The invention discloses a flat grinding and material taking jig set which comprises a flat grinding jig, a material ejecting jig, a product positioning plate and a material taking device. A plurality of fixing positions are arranged at the top of the flat grinding jig and used for fixing workpieces, and an ejecting hole extending to the bottom face of the flat grinding jig is formed below each fixing position; the product positioning plate is detachably connected to the flat grinding jig, and through holes are formed in the positions, corresponding to the fixing positions, of the product positioning plate; a plurality of ejector pins are arranged at the top of the material ejecting jig, are matched with the ejection holes one by one and are used for ejecting the workpieces in the fixing positions and enabling the workpieces to enter the through holes; the material taking device is used for sucking the workpieces in the through holes. After flat grinding is finished, the product positioning plate is installed on the face, where the flat grinding jig conducts flat grinding on the workpiece, of the flat grinding jig, the ejector pin penetrates through the ejection hole, the workpiece protrudes out of the flat grinding jig and is contained in the through hole of the product positioning plate, the material taking device sucks the workpiece in the through hole, and therefore the small workpiece is rapidly taken.

Owner:DONGGUAN LINGJIE PRECISION MACHINING TECH CO LTD

Surface protection film packaging machine for LED display screen production

ActiveCN113363372AQuick unloading and unloadingEasy dischargeIdentification meansSemiconductor devicesPhysicsInternal connection

The invention relates to the technical field of LED display screens, and concretely relates to a surface protection film packaging machine for LED display screen production. The machine comprises a base and an outer barrel fixedly mounted on the base, an inner barrel is rotatably mounted at the inner bottom of the outer barrel, the front side of the inner barrel is connected with a discharge port for feeding, the bottom of the inner barrel is connected with a support plate for placing an LED substrate, the bottom of the base is connected with a driving mechanism used for rotating the outer barrel and lifting the supporting plate, the inner part of the inner barrel above the supporting plate is connected with a gluing mechanism used for gluing the surface of the supporting plate, and the upper part of the inner barrel is connected with a supporting mechanism used for placing a protection film. Through the arrangement of the structure, a sealed environment is conveniently provided for the packaging process while rapid discharging and taking are achieved.

Owner:林华敏

Deep-frying device with function of easily taking out materials

InactiveCN108835142AEasy to take outQuick RetrievalBaking cavity cleaningOil/fat bakingDeep fryingEngineering

The invention discloses a deep-frying device with a function of easily taking out materials. The deep-frying device comprises a shell, a deep fryer is arranged on the top in the shell, and a baffle isarranged at the position, corresponding to the top of the deep fryer, of the top of the shell. The deep fryer is of a semi-circular arc-shaped shell structure, a rotary roller is sleeved in the center of the deep fryer, and roller shafts at the two ends of the rotary roller are sleeved with bearings which are arranged at the corresponding positions of the side wall of the shell. According to thedeep-frying device with the function of easily taking out the materials, the structure is ingenious, arrangement is reasonable, quick deep frying is achieved, and the materials are conveniently takenout. During work, materials are placed in net containers, net covers are closed and fixedly locked, the rotary roller is driven to drive the net containers to enter the deep fryer, and the materials are deep-fried in the deep fryer. Electric heating pipes are arranged in the deep fryer, temperature sensors are arranged, the oil temperature is convenient to control, after deep frying of the materials is finished, the rotary roller is driven to lift the net container out of the deep fryer, after cooling, the net cover is opened, and the materials are easily taken out; multiple kinds of materialscan be placed into different net containers for separation, and tainting of odor is prevented.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

A material handling robot

ActiveCN105752640BAccurate placementAvoid collisionConveyorsControl devices for conveyorsControl systemThree-dimensional space

Owner:南京优倍自动化系统有限公司

Wine jar opening sealing material automatic material taking and material supplementing device and material supplementing method

PendingCN111516945AAdsorption stroke reductionQuick RetrievalWrapper twisting/gatheringPackaging automatic controlPhotoswitchControl cell

The invention provides a wine jar opening sealing material automatic material taking and material supplementing device and a material supplementing method. The material supplementing device comprisesa transfer unit, a material supplementing unit and a control unit. The transfer unit comprises a lifting mechanism, a telescopic mechanism and a rotation mechanism. The lifting mechanism is used for driving the telescopic mechanism to move so as to adjust the position of the telescopic mechanism. The telescopic mechanism is used for sucking and transferring opening sealing materials. The rotationmechanism is used for driving the lifting mechanism to synchronously rotate in the circumferential direction. The material supplementing unit is used for containing the opening sealing materials and drying the opening sealing materials to rise and fall. The control unit comprises a control cabinet and a photoelectric switch. The material supplementing method includes the following steps that the control cabinet conducts material taking according to the setting, and after a material sucking part sucks the opening sealing materials the set times, an electric push rod receives a rising signal andpushes a lifting table to rise to conduct material supplementing, and the sucking stroke of the material sucking part is reduced so that rapid material taking can be achieved. The wine jar opening sealing material automatic material taking and material supplementing device and the material supplementing method have the beneficial effects that a large number of materials are stacked on the material supplementing unit at a time, there is no need to conduct material supplementing at any time, and manual operation is not needed.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com