Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Baking cavity cleaning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

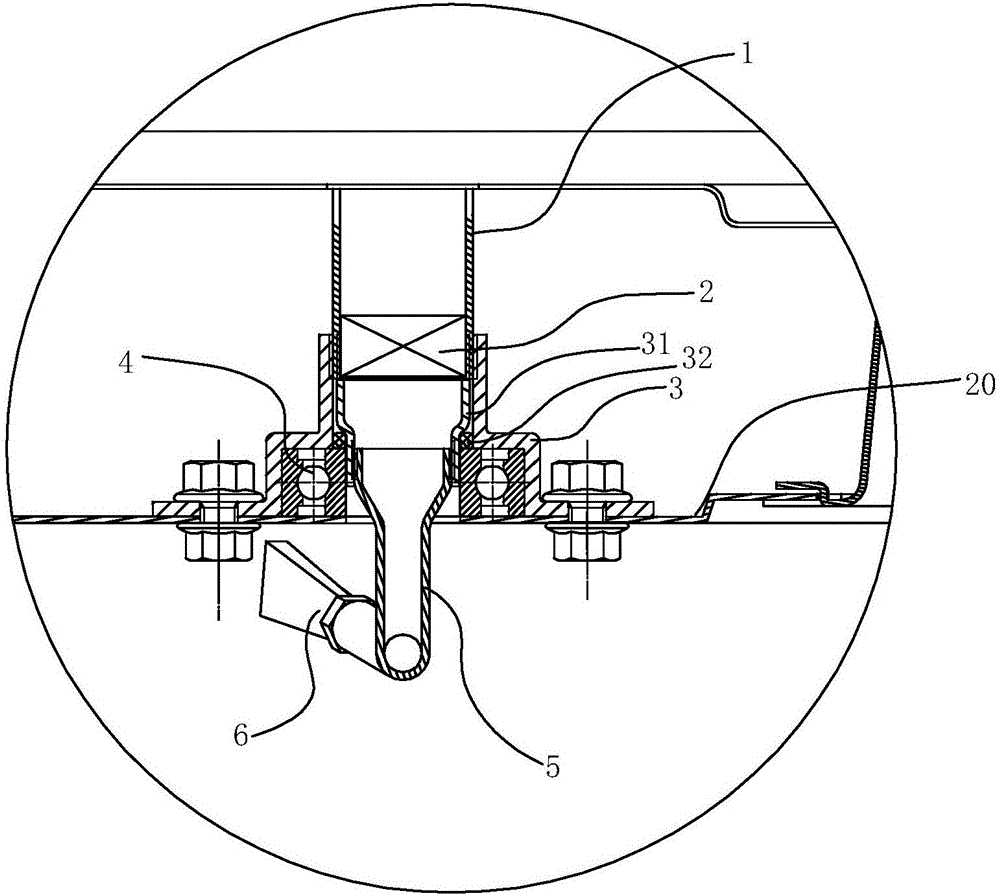

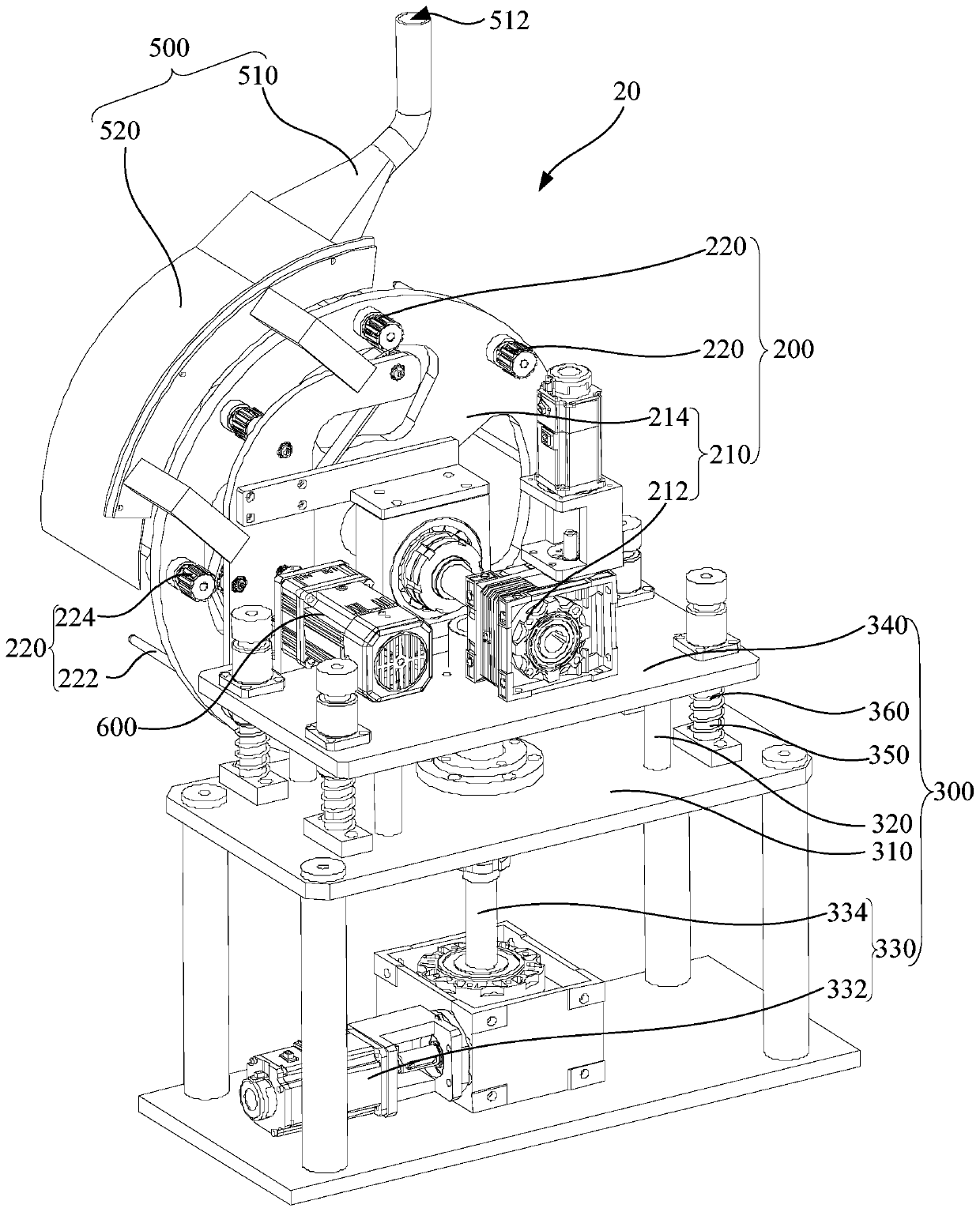

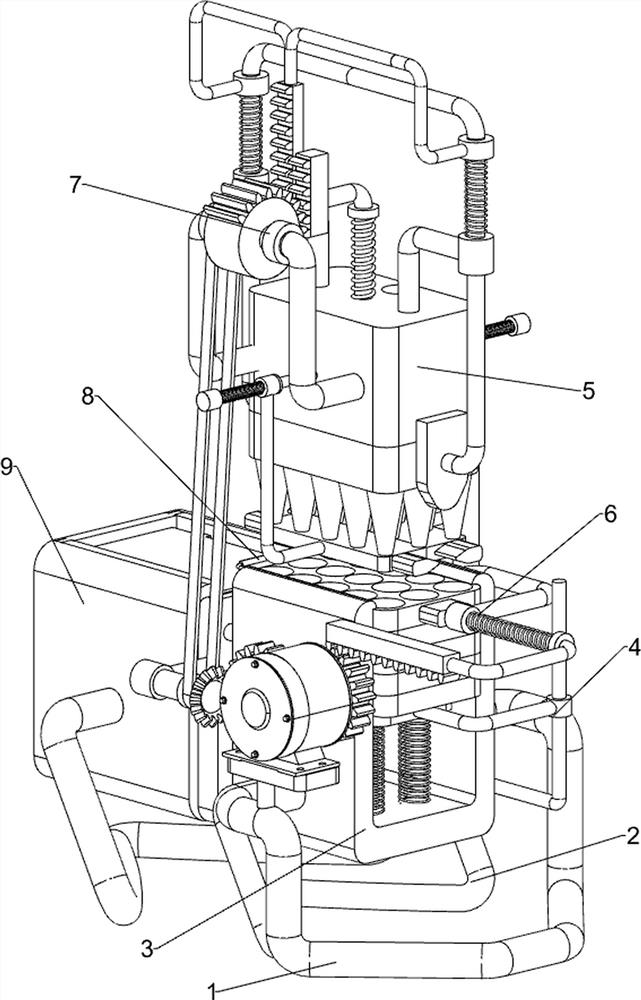

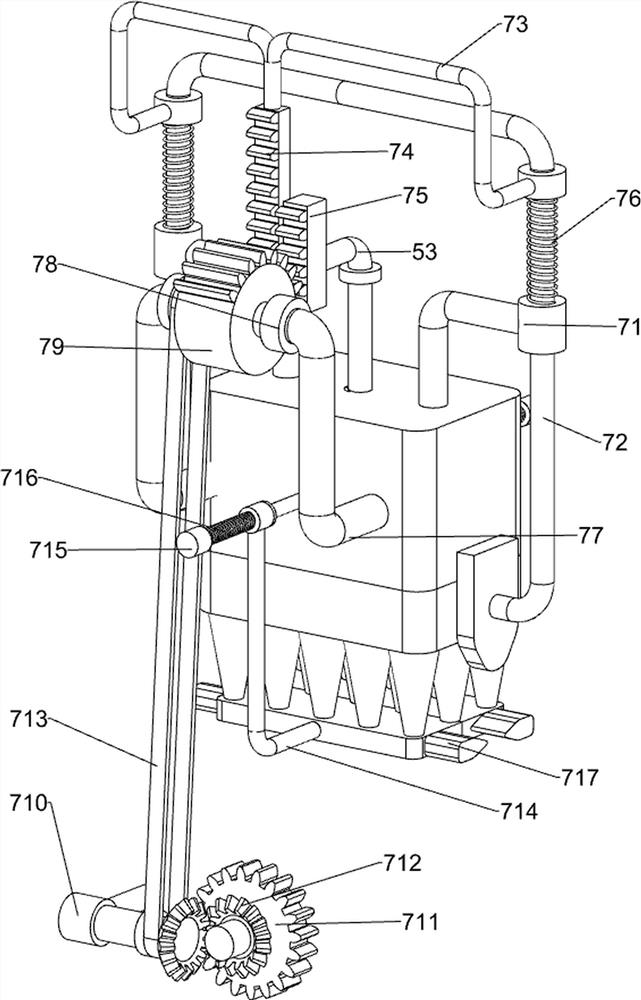

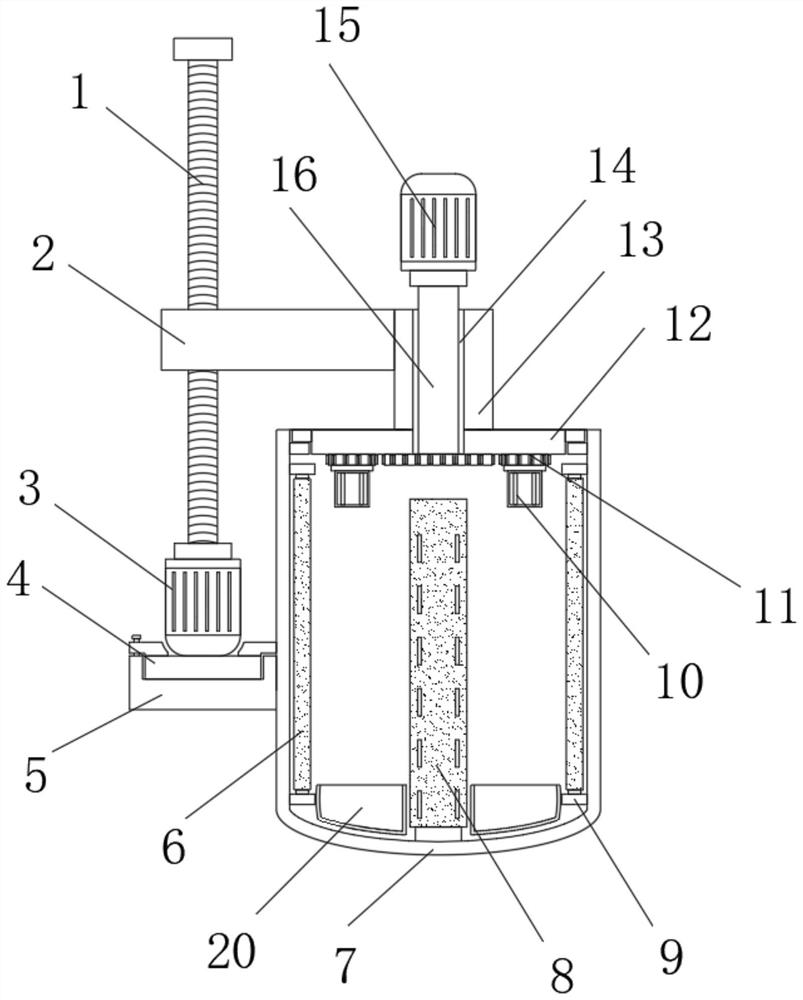

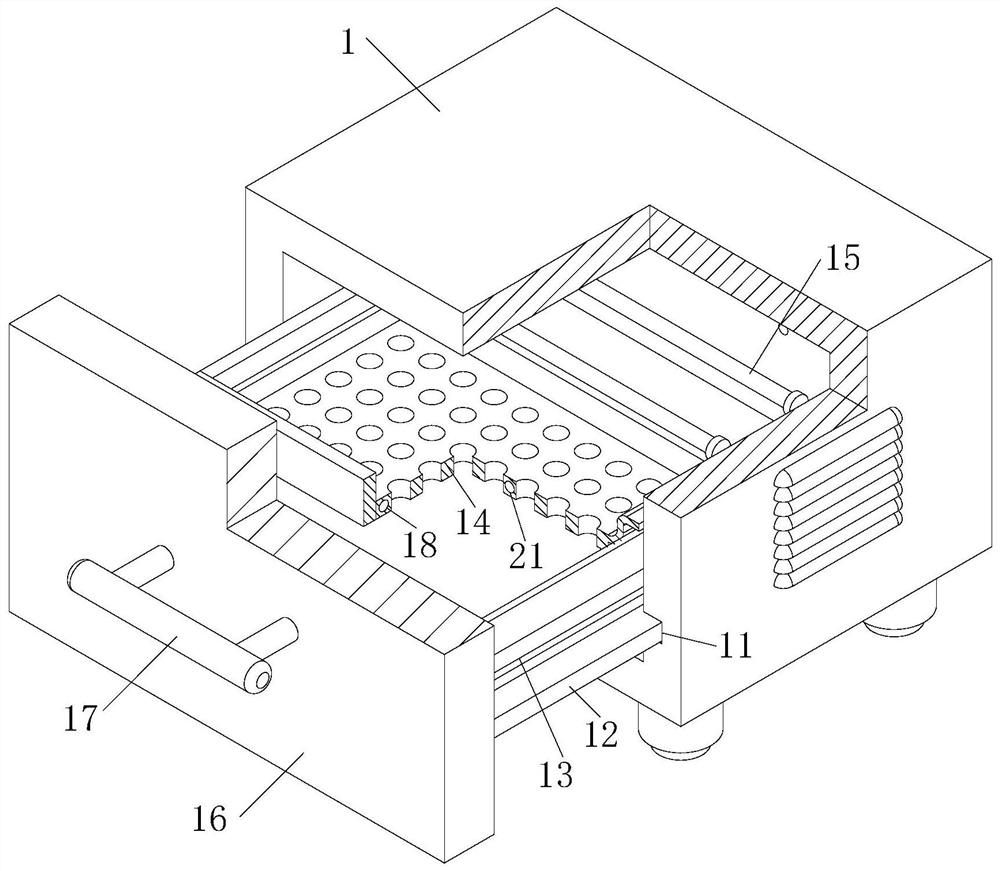

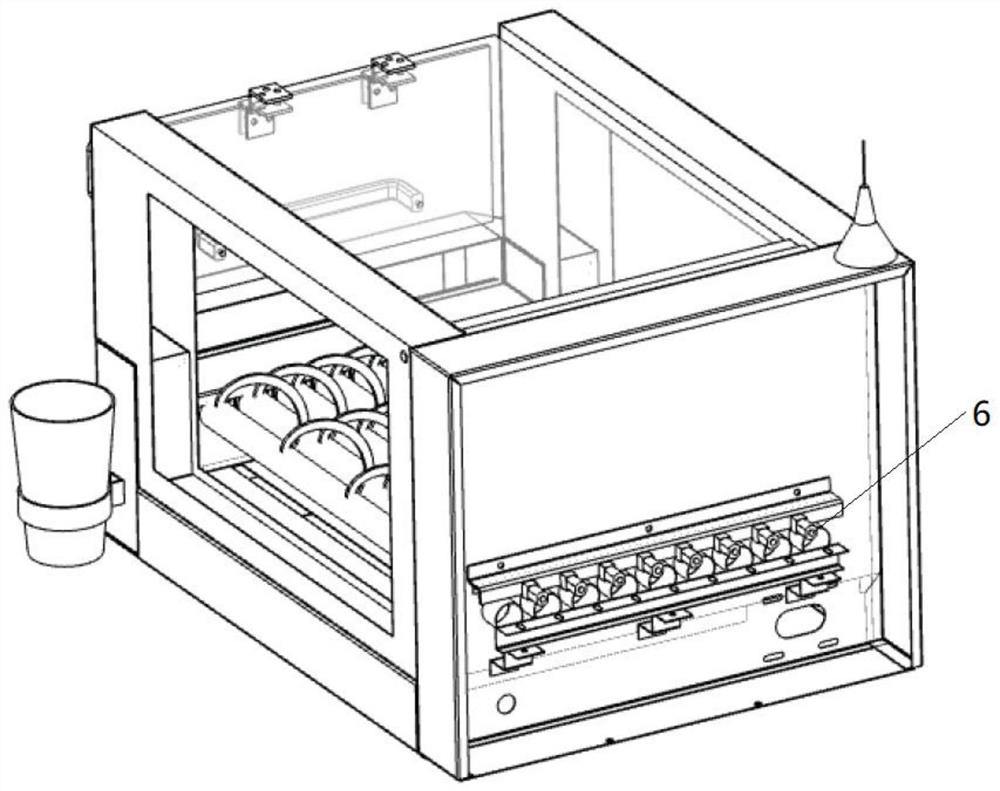

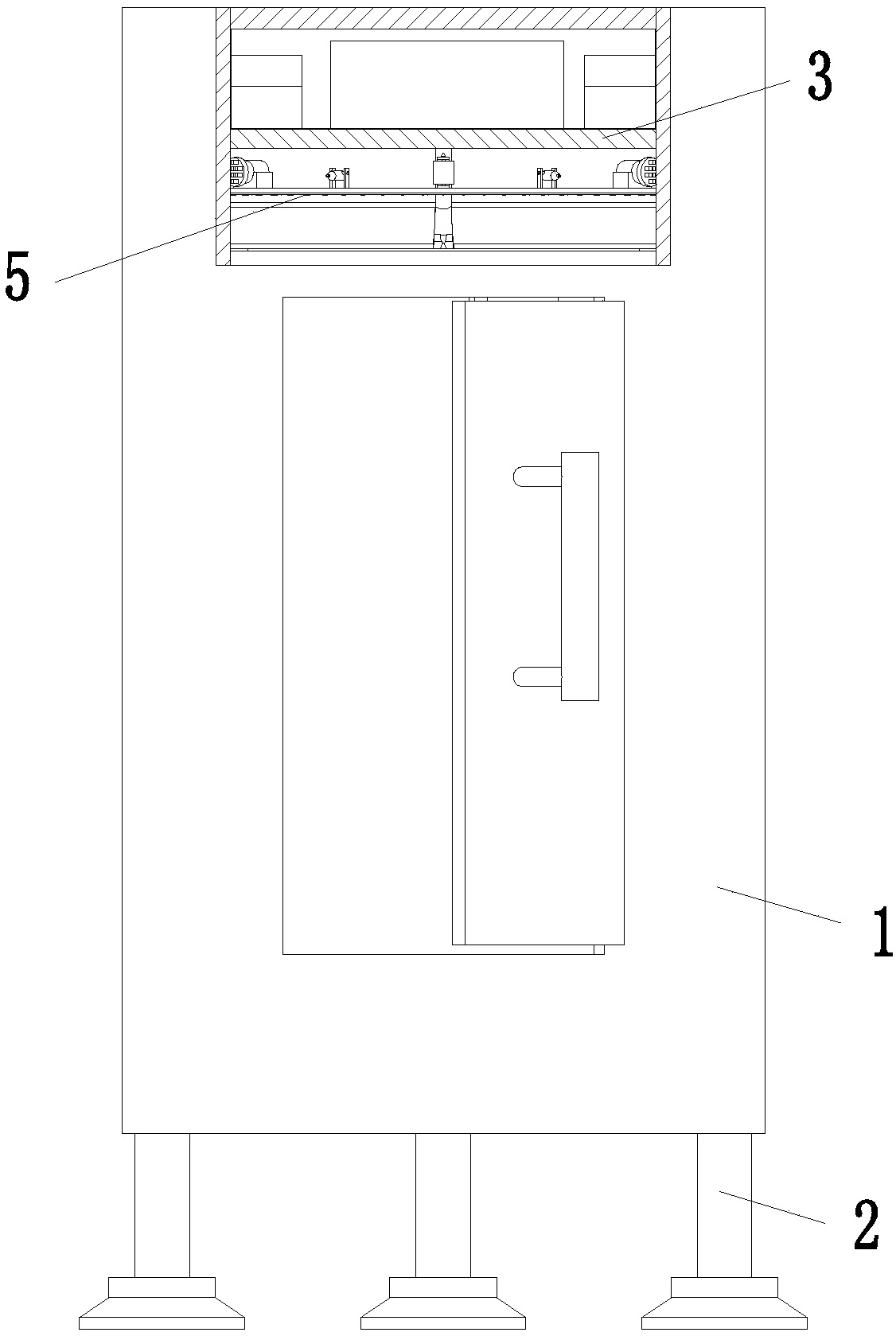

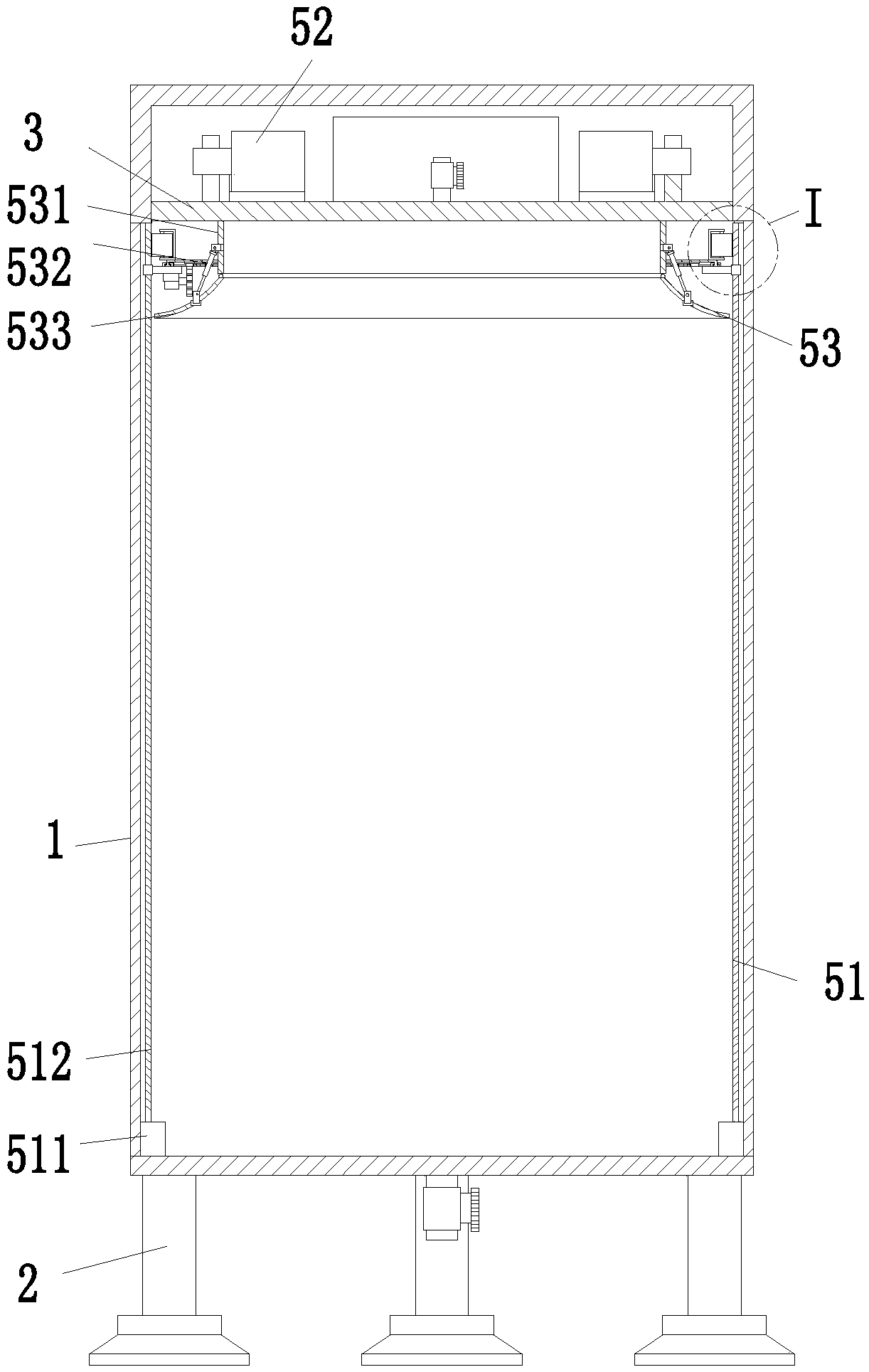

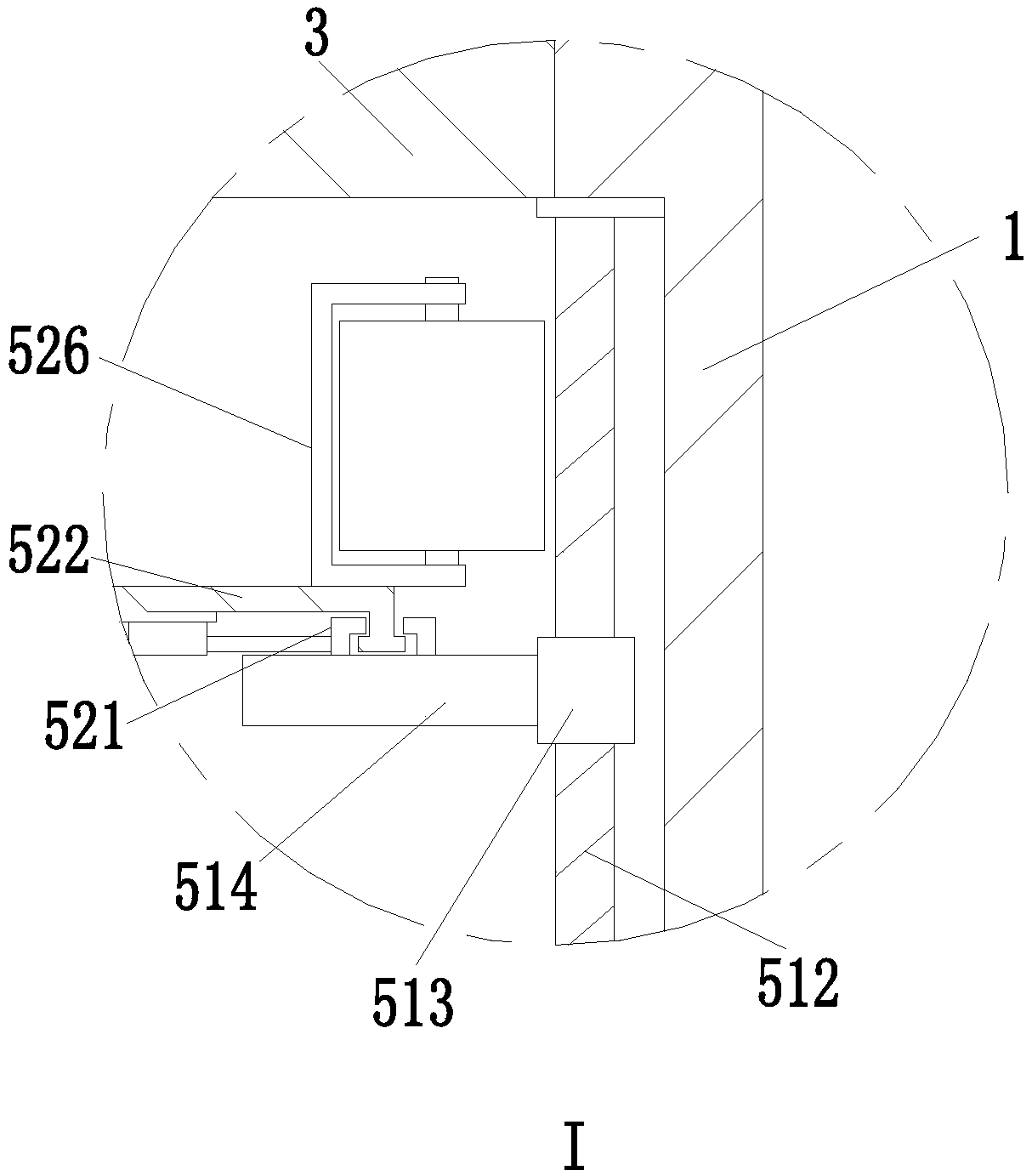

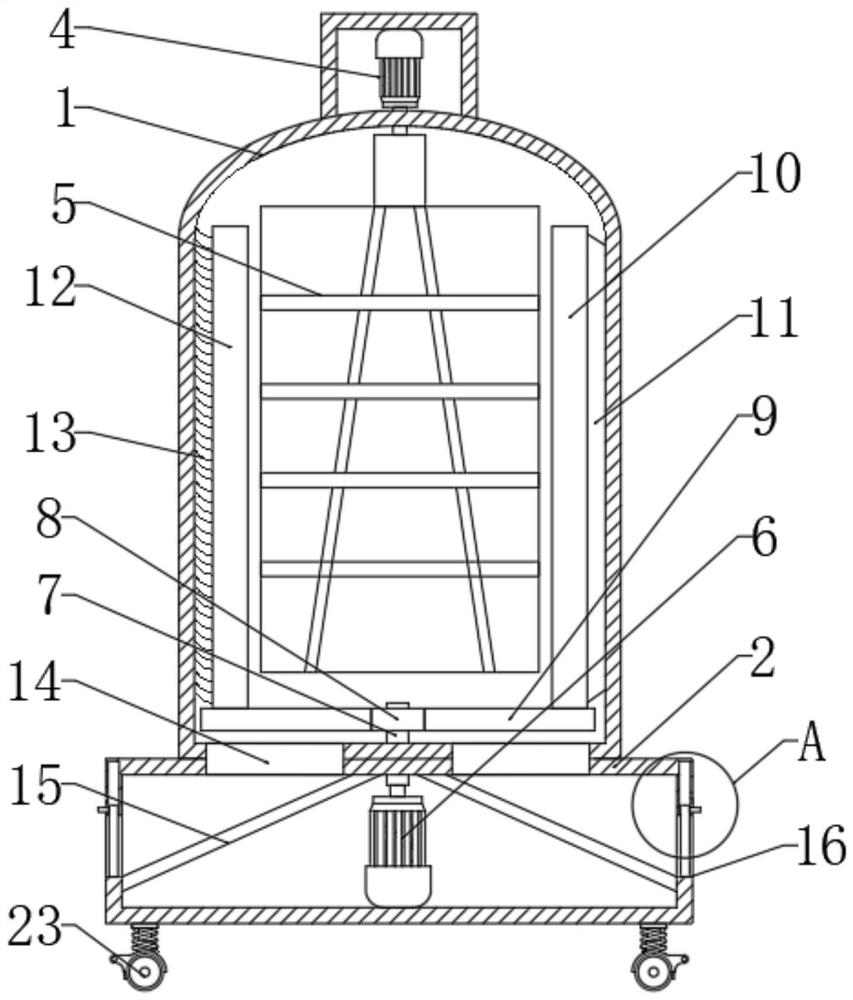

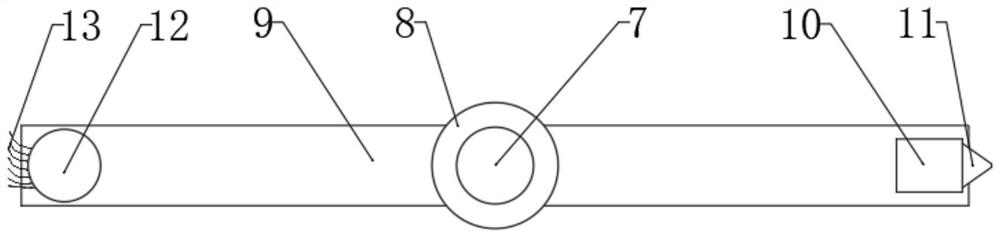

Intelligent food baking oven

ActiveCN109392968AImprove baking efficiencyEvenly bakedBaking cavity cleaningCooking & bakingEngineering

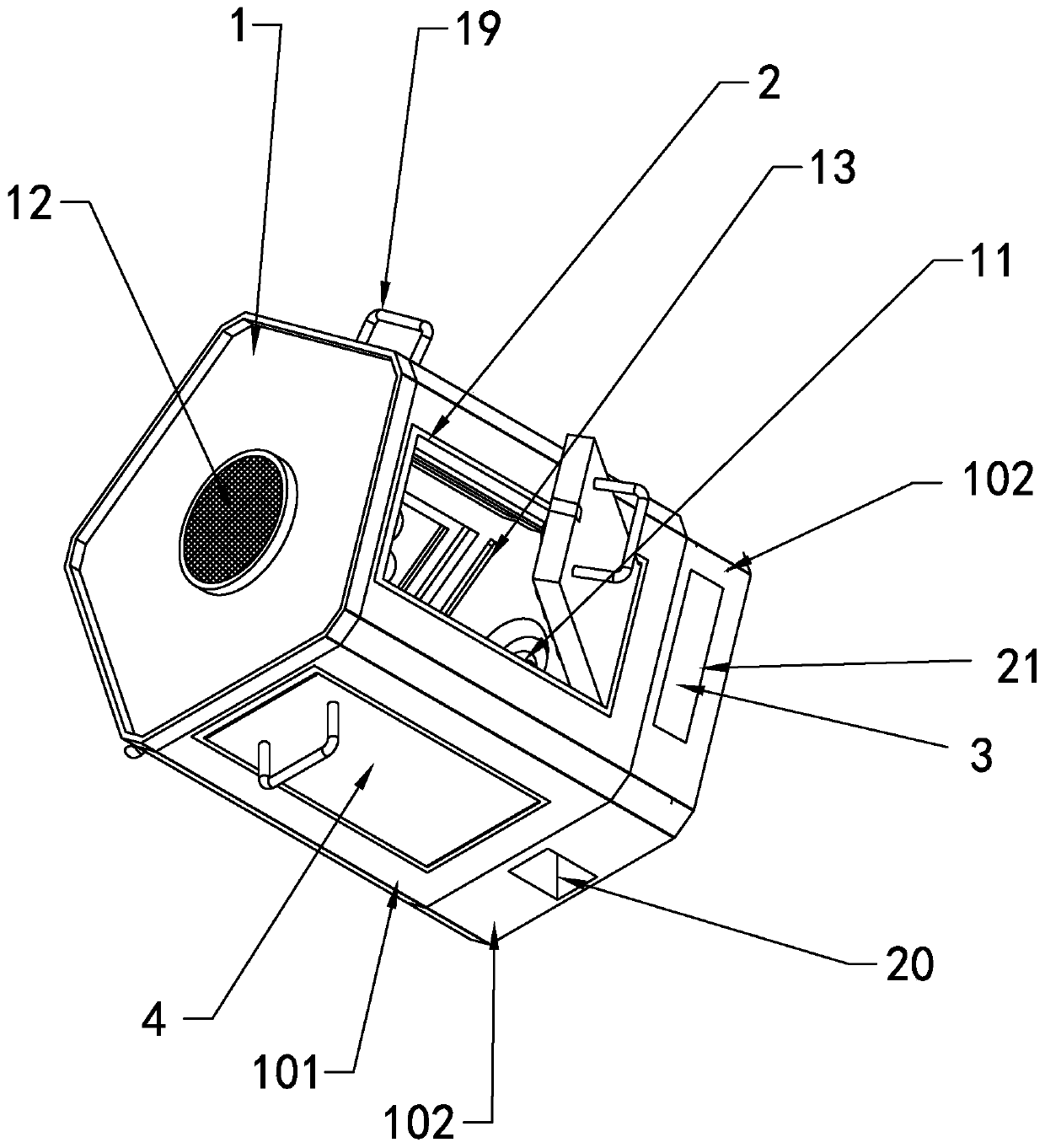

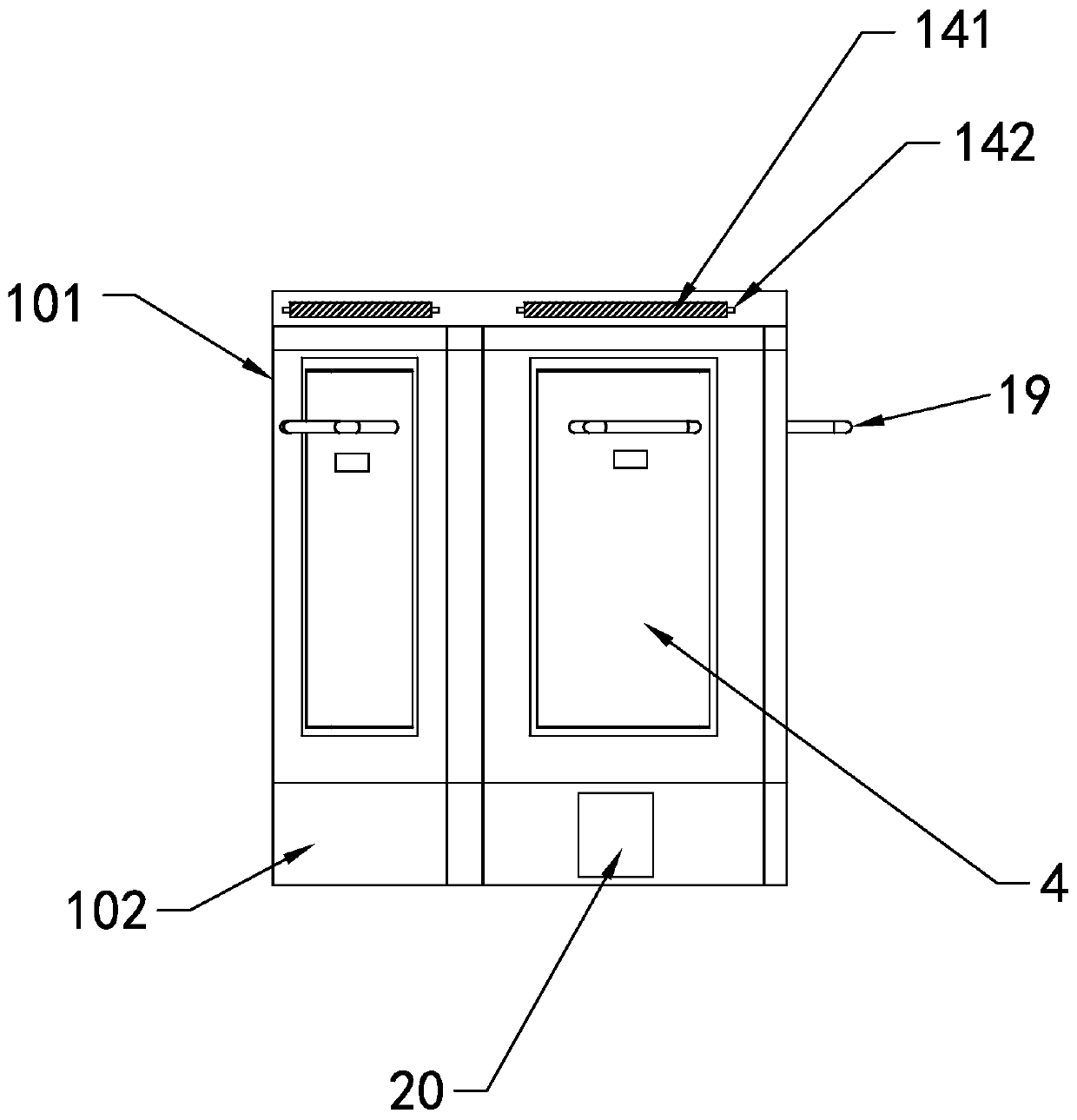

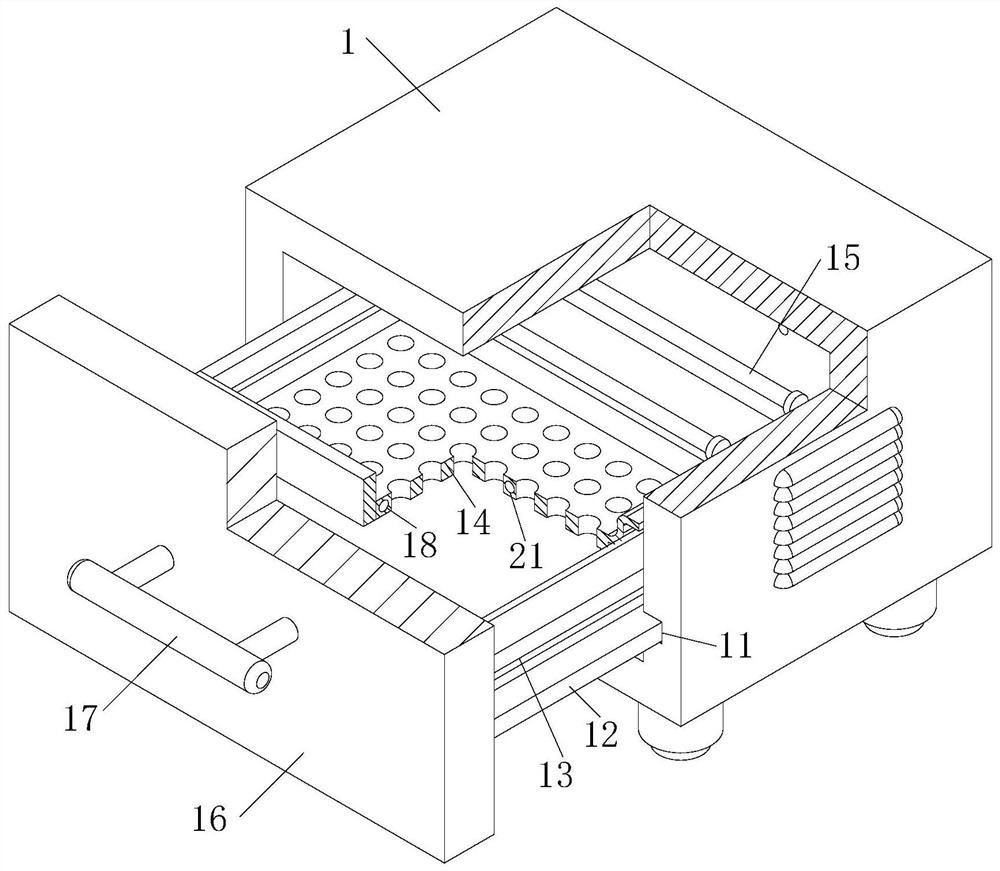

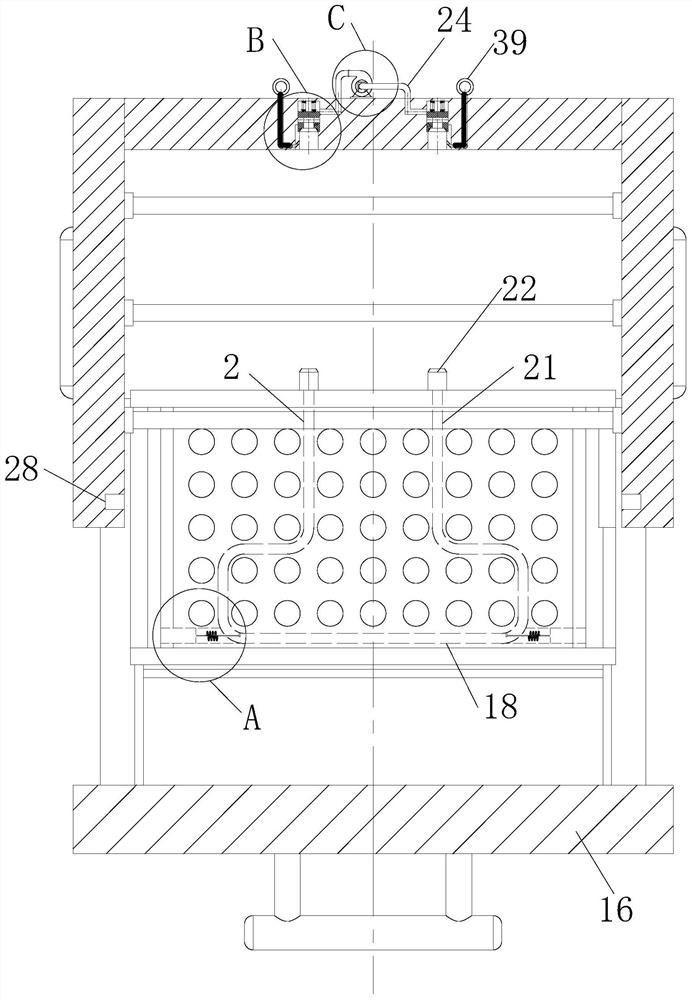

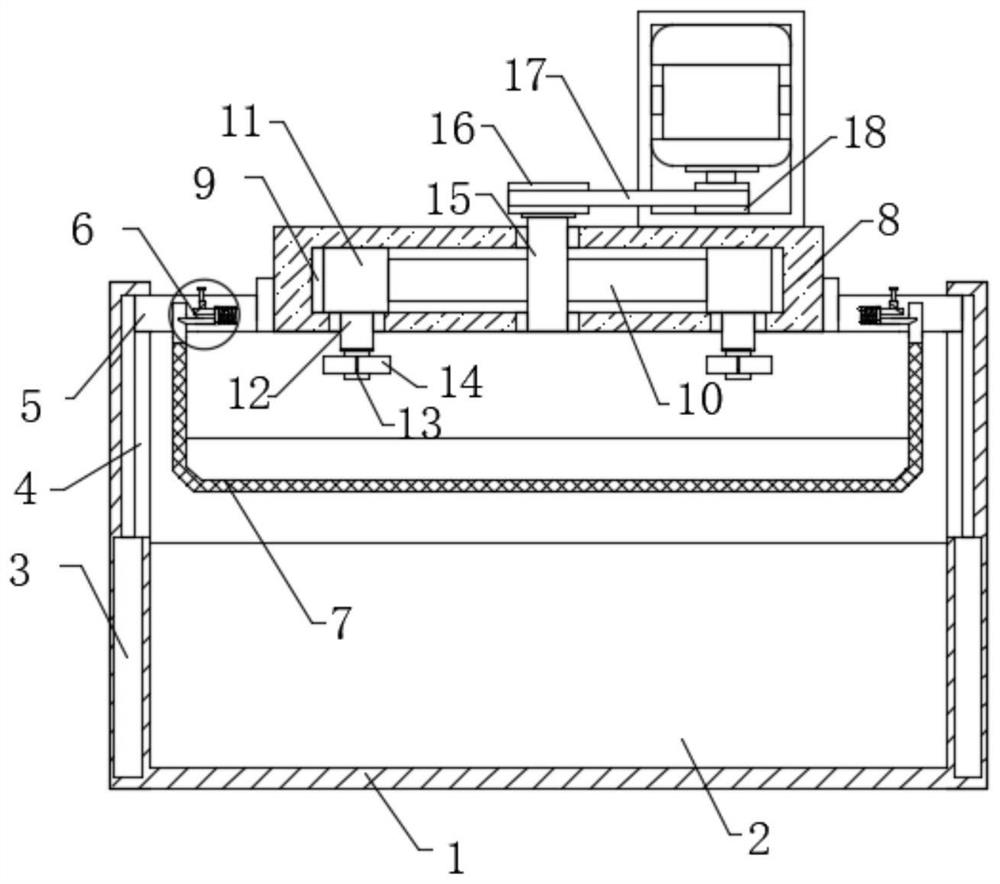

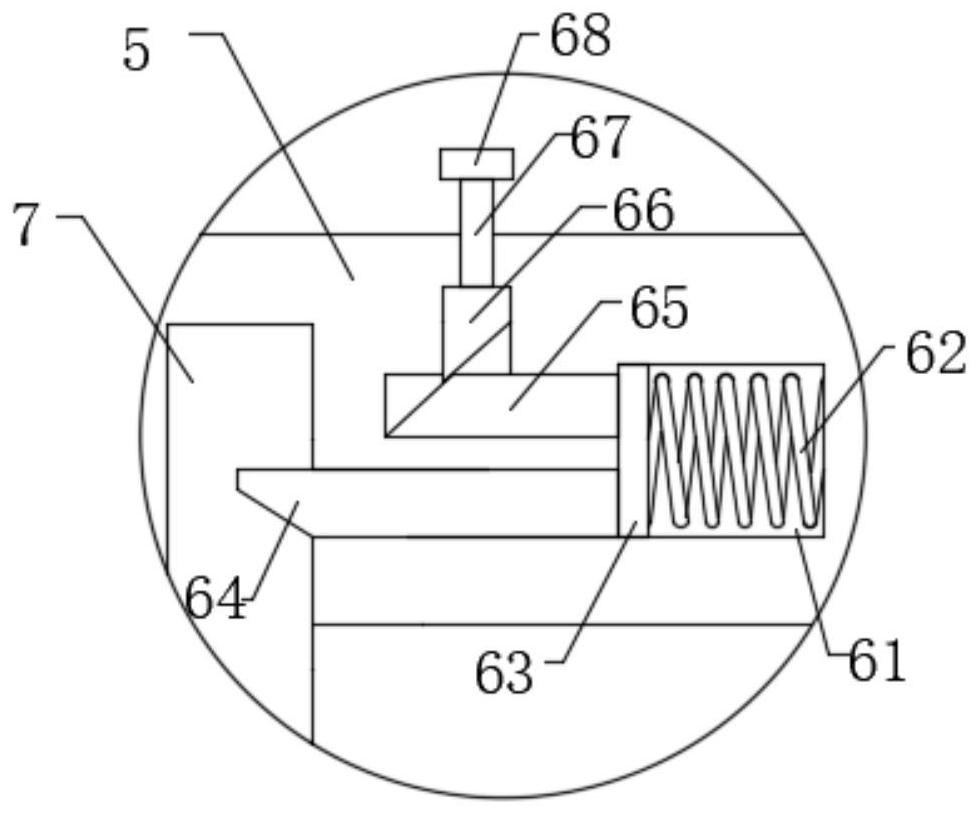

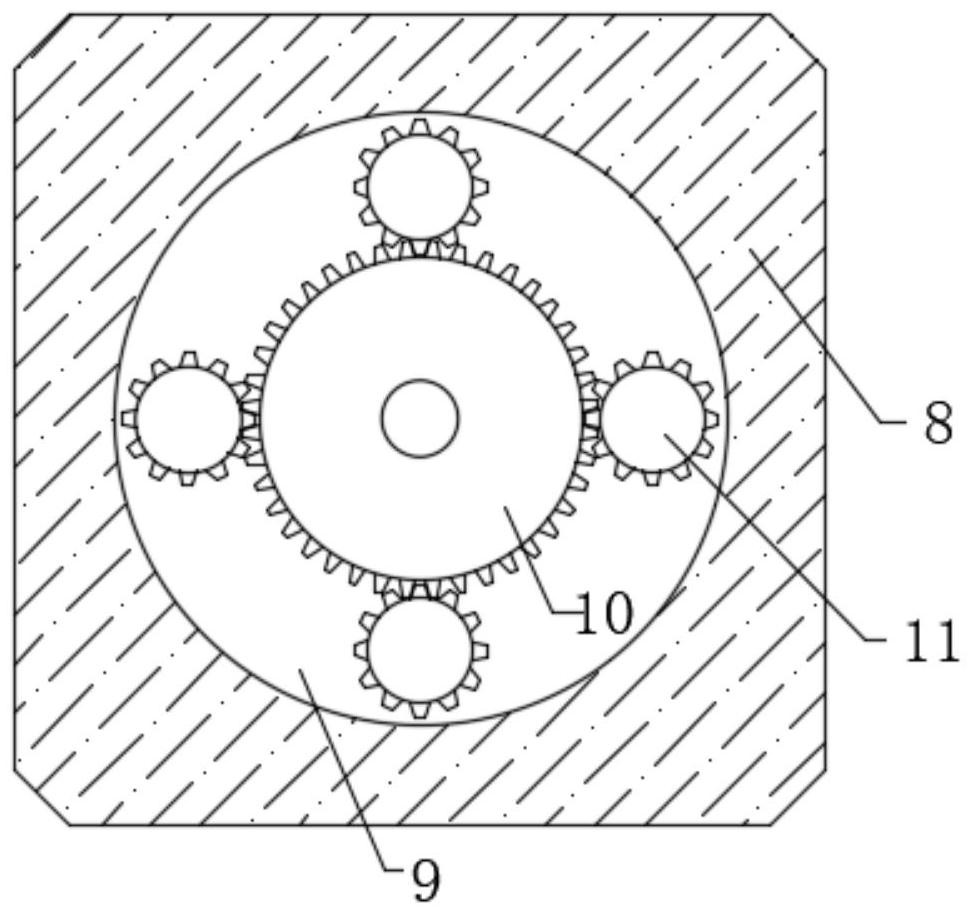

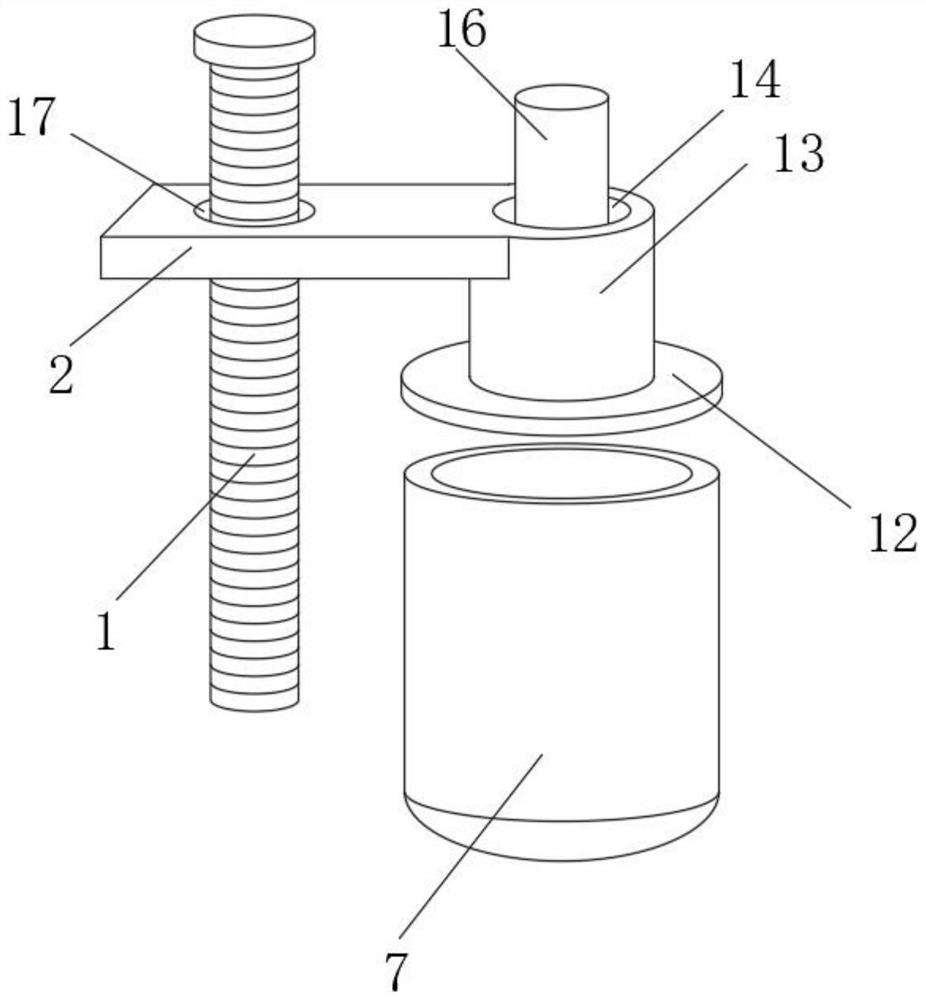

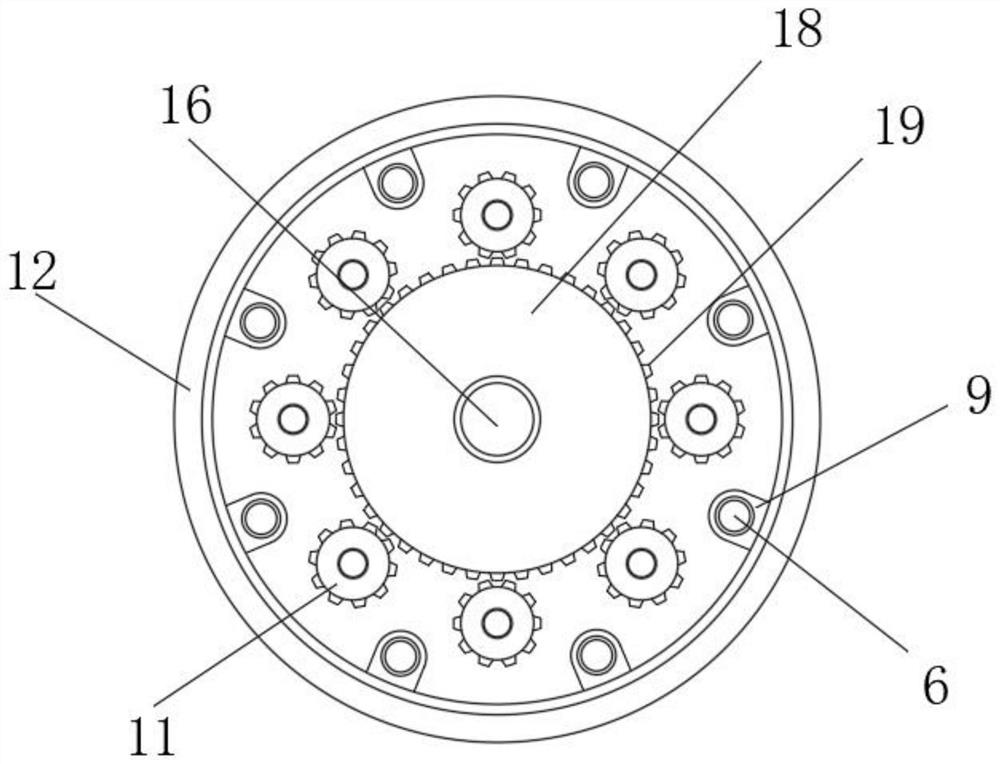

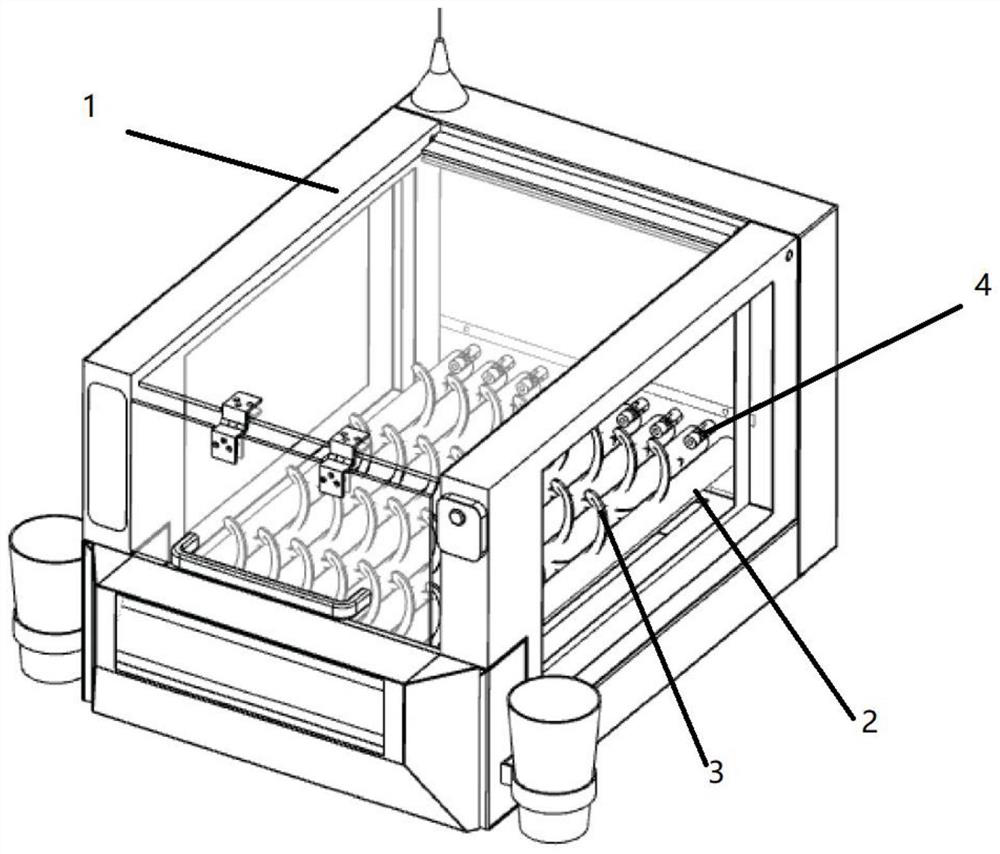

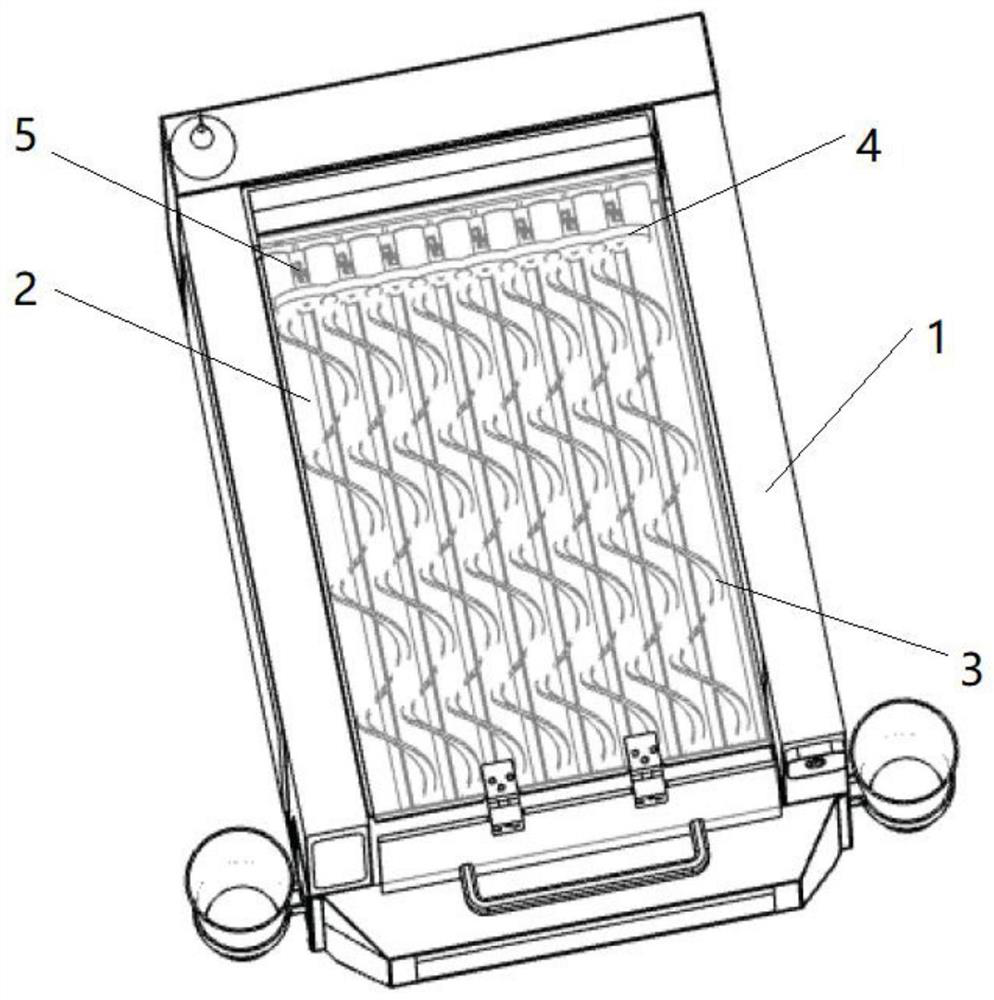

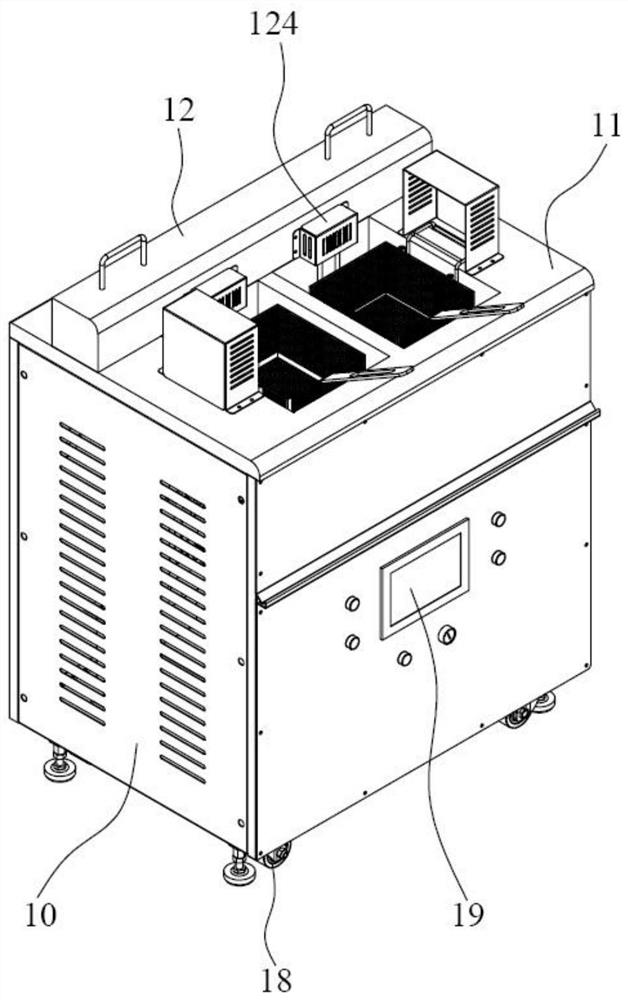

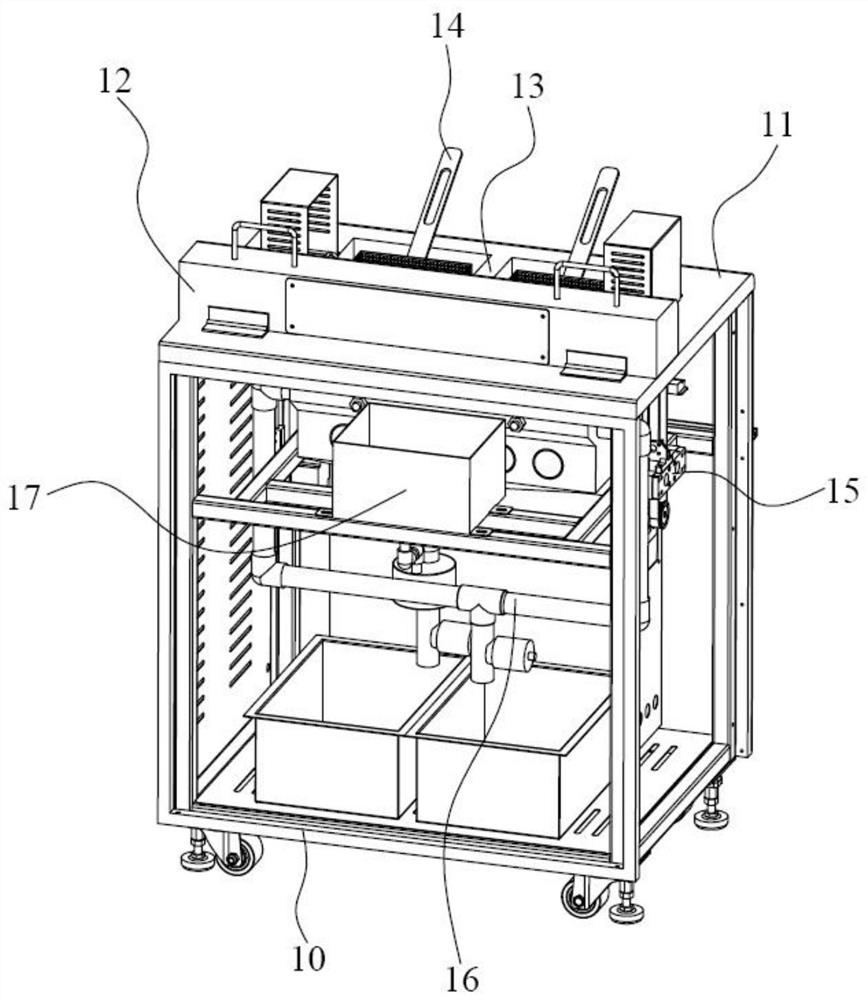

The invention relates to an intelligent food baking oven. The intelligent food baking oven comprises a food baking oven body, support legs, a clapboard, a heating and rotating device, and a cleaning device; the support legs are evenly mounted at the lower end of the outer side of the food baking oven body; the clapboard is mounted at the upper end of the interior of the food baking oven body; theheating and rotating device is mounted at the middle of the lower end of the clapboard; and the cleaning device is mounted outside the lower end of the clapboard. The intelligent food baking oven is capable of solving the problems of uneven baking, poor baking effect and liable coking during baking processes of existing food baking ovens; moreover, common manual washing caused by unable washing ofinner walls of baking ovens during baking processes of existing food baking ovens; moreover, the intelligent food baking oven also solves the problems of low automation level, poor manual washing effect, low washing efficiency, complex operation, poor stability, high labor intensity and the like due to common manual washing caused by unable washing of inner walls of the existing baking ovens after completion of baking. Thus, automatic washing function on the inner walls of the food baking oven is realized; moreover, the intelligent food baking oven has the advantages of being simple in operation, good in stability, low in labor intensity and so on.

Owner:BOAO ZONGHENG NETWORK TECH CO LTD

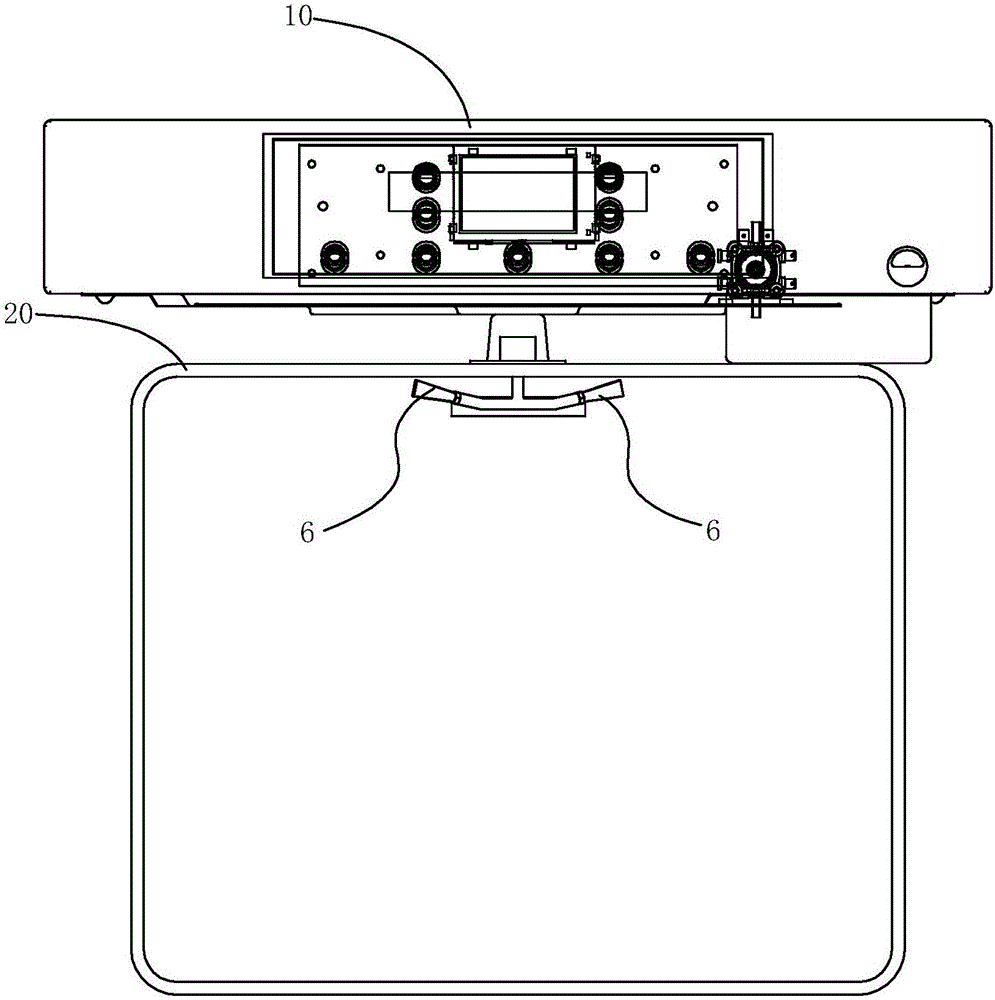

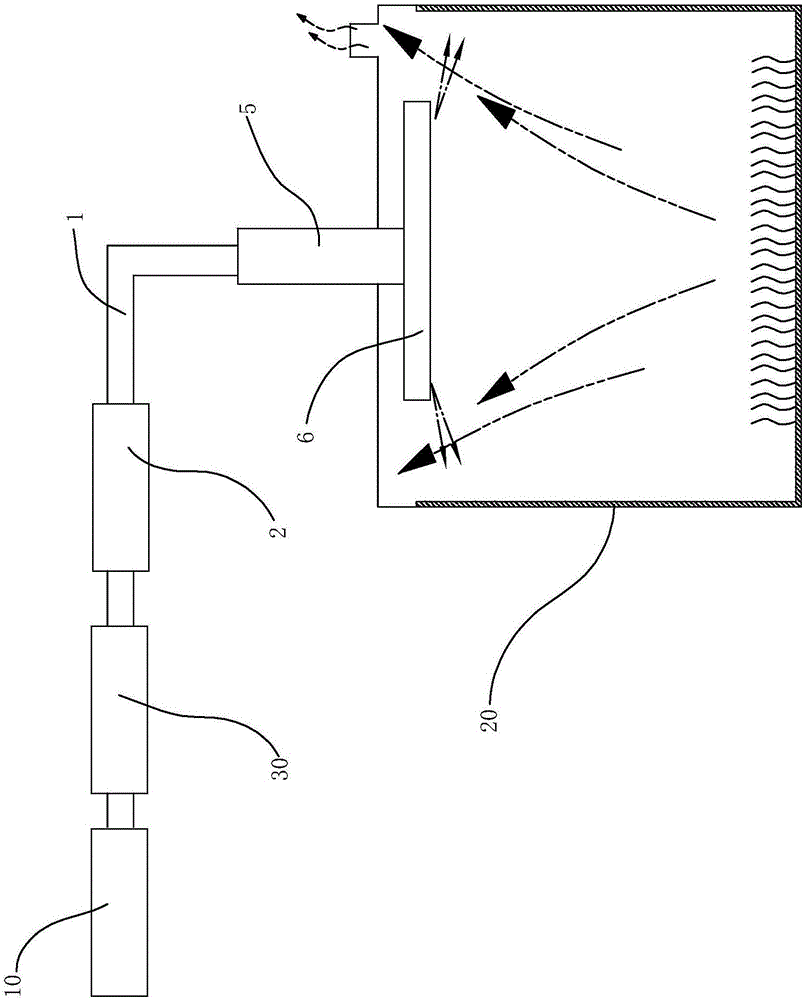

Oven self-cleaning device and cleaning method thereof

The present invention discloses an oven self-cleaning device. The oven self-cleaning device consists of a pipeline connecting a water box. The oven self-cleaning device is characterized in that the pipeline is connected with a vertically arranged rotary pipeline. One end of the rotary pipeline passes through a liner and extends to the interior of the liner, the rotary pipeline winds around an own vertically arranged shaft to rotate, the end of the rotary pipeline located in the interior of the liner tank communicates with a laterally arranged water outlet pipe, and a nozzle is arranged at a free end of the water outlet pipe. The oven self-cleaning device is simple in structure, easy to be loaded into the oven, convenient for disassembly and installation, and does not require additional power for cleaning. In addition, a self-cleaning method using the self-cleaning device uses heating to produce steam, which can better wash the oven liner clean. Besides, water steam is dispelled from the top part, the bottom of the oven only needs wiping after cleaning, and the oven self-cleaning device is easy to operate and high in cleaning efficiency.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

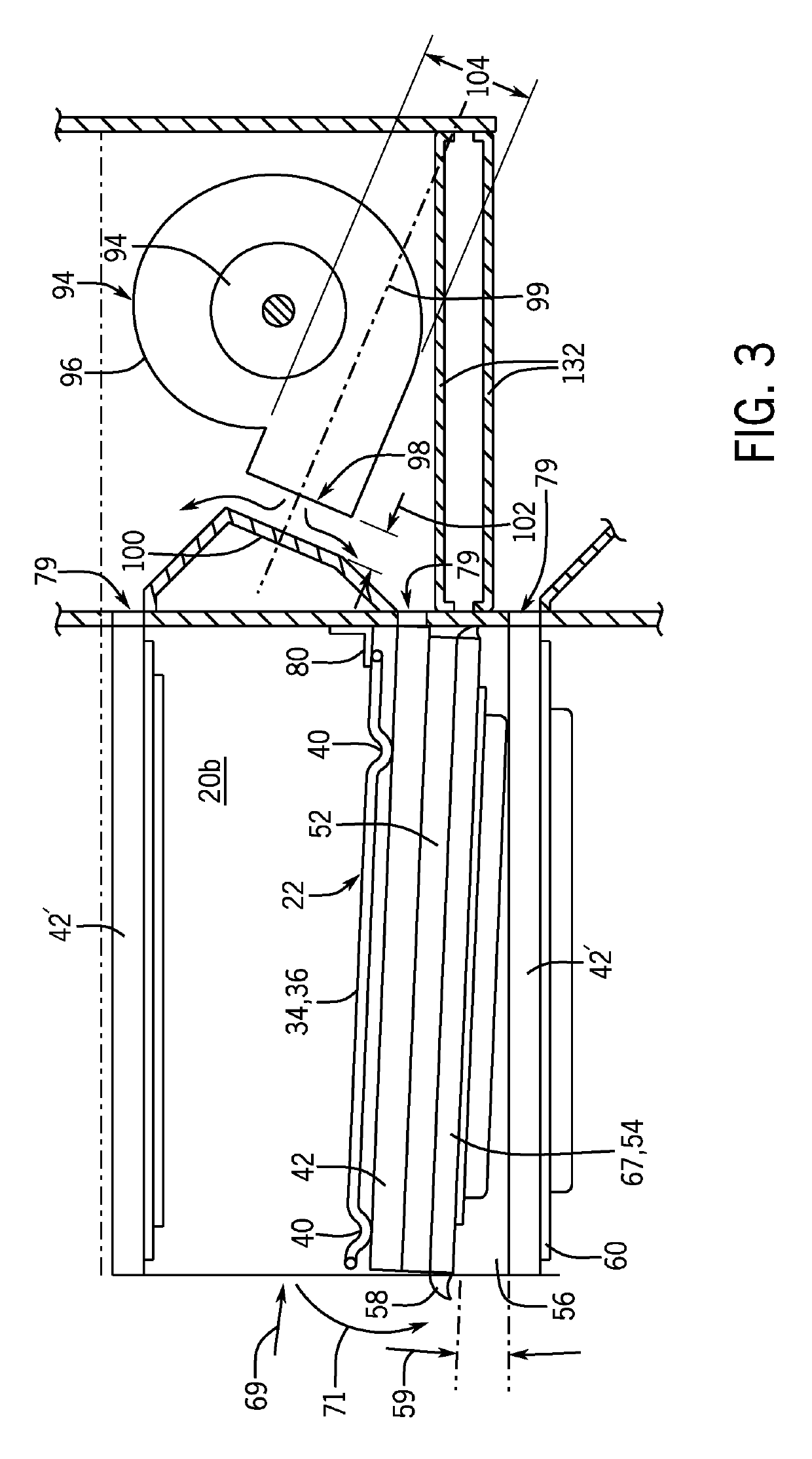

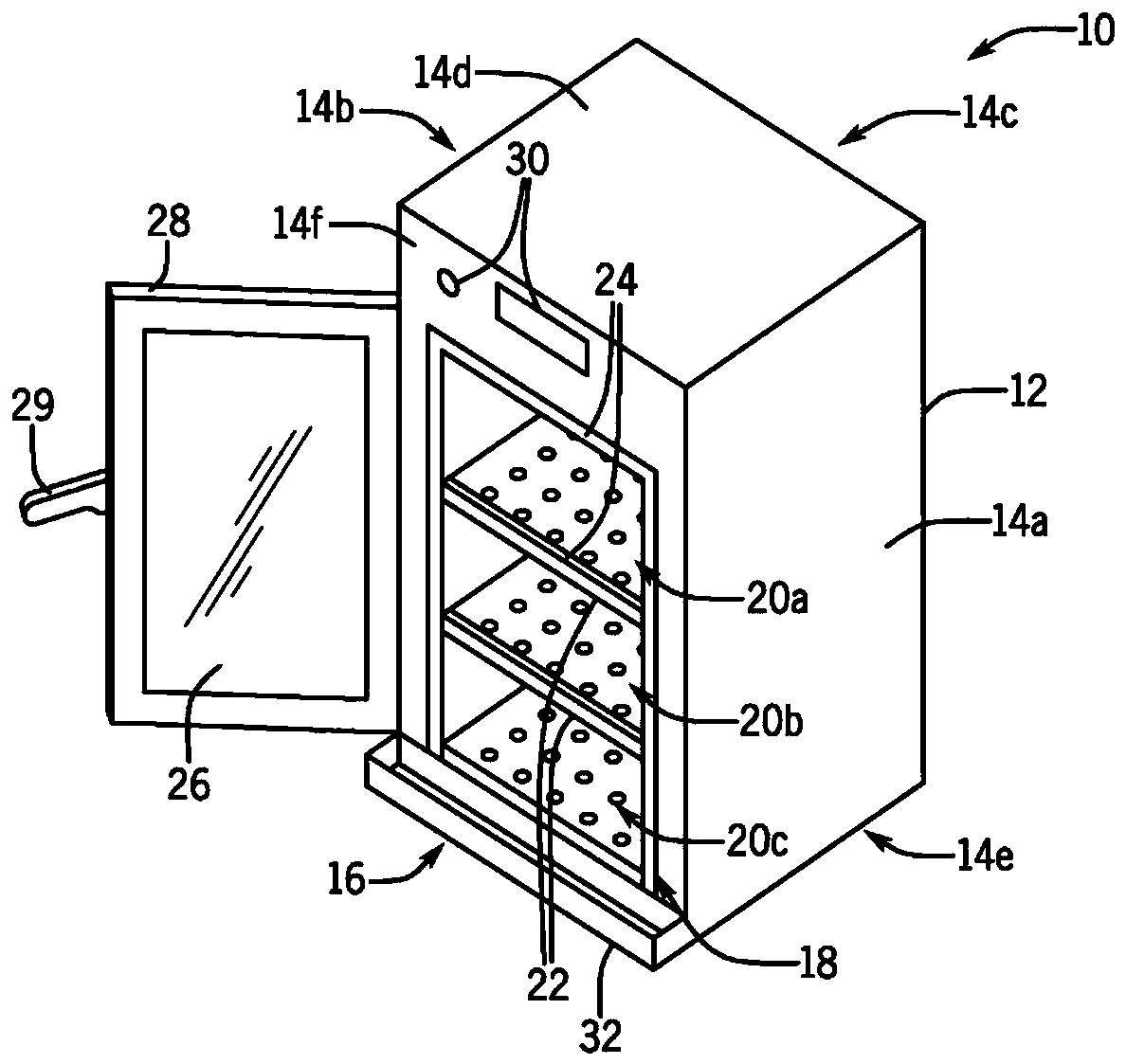

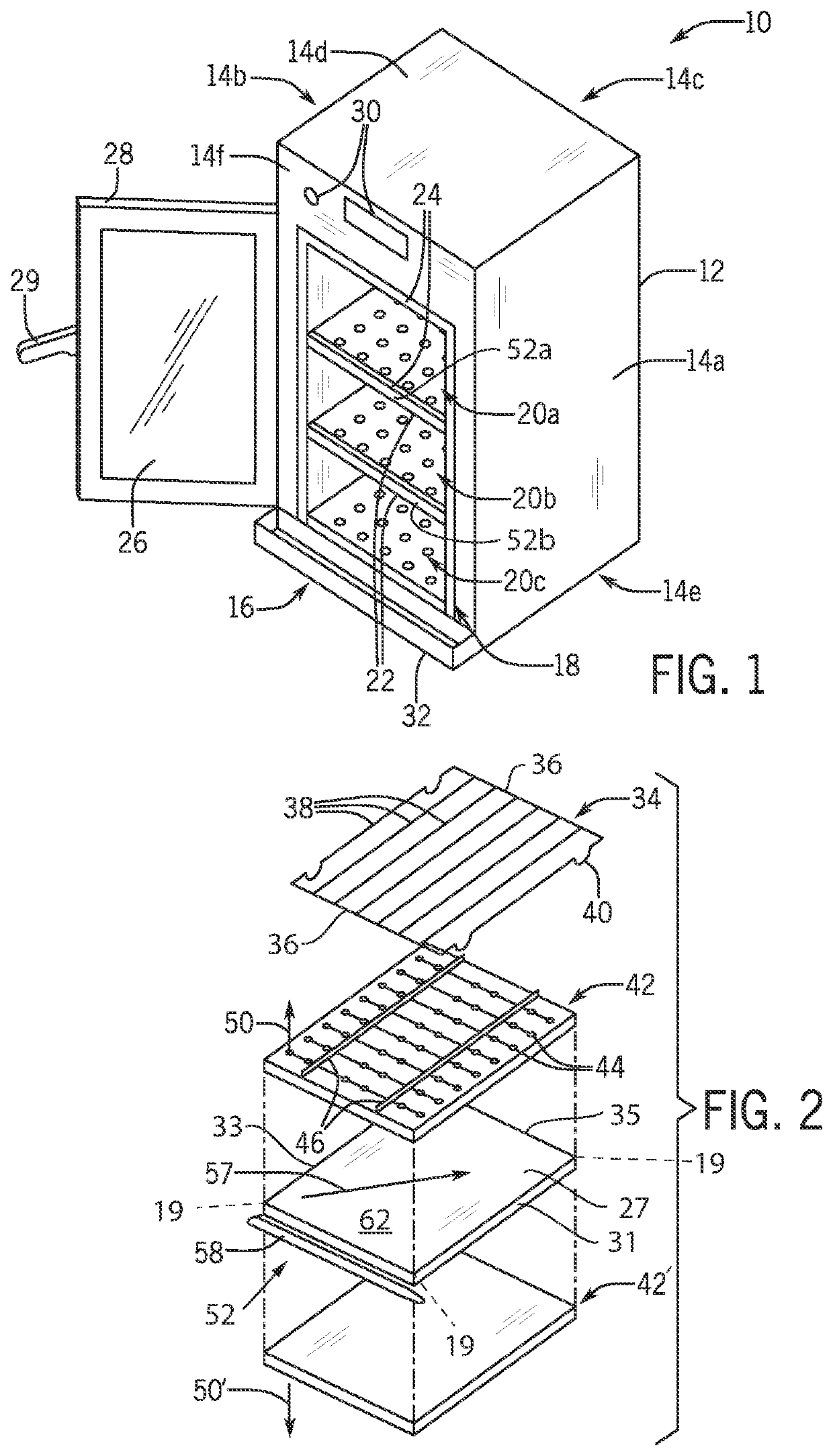

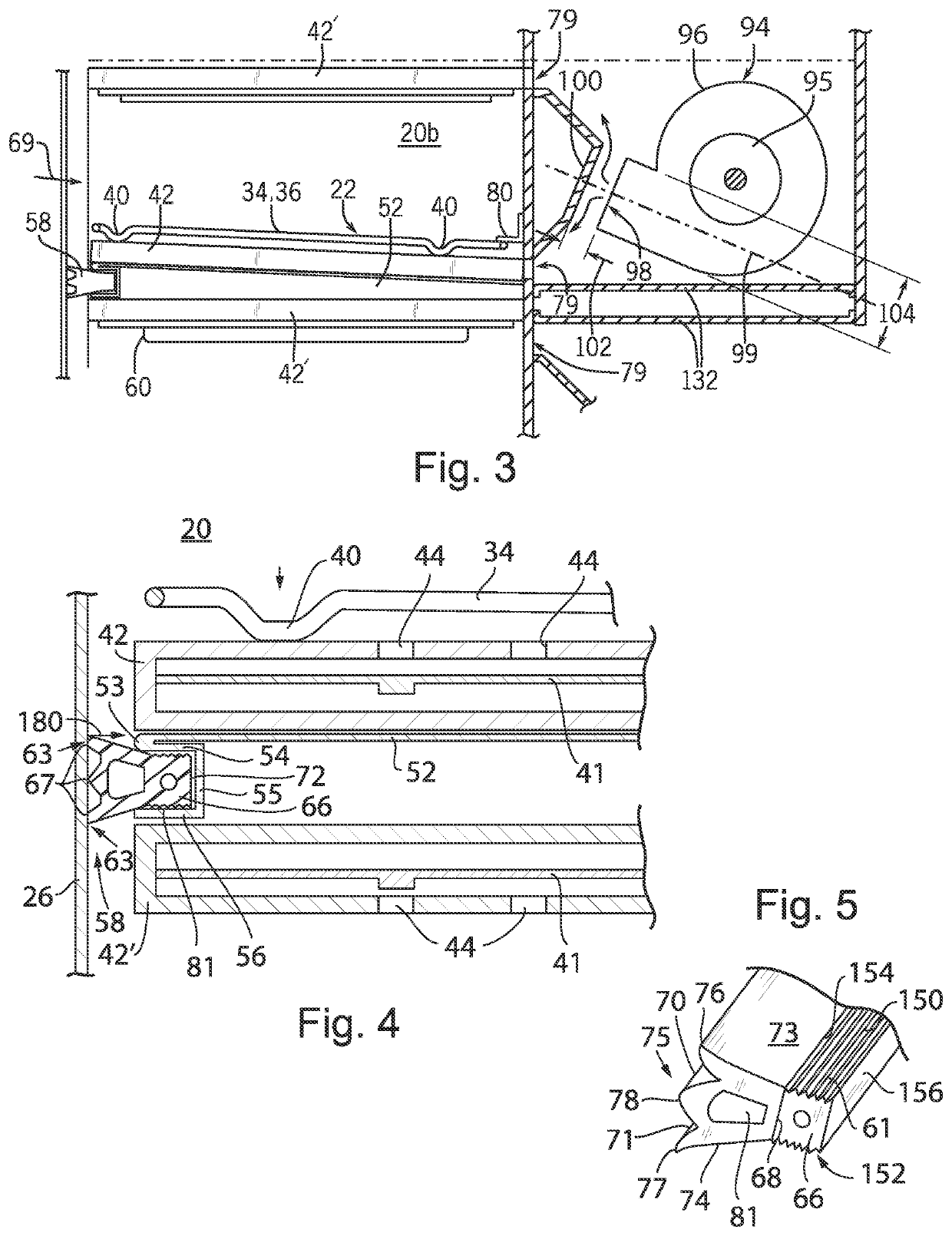

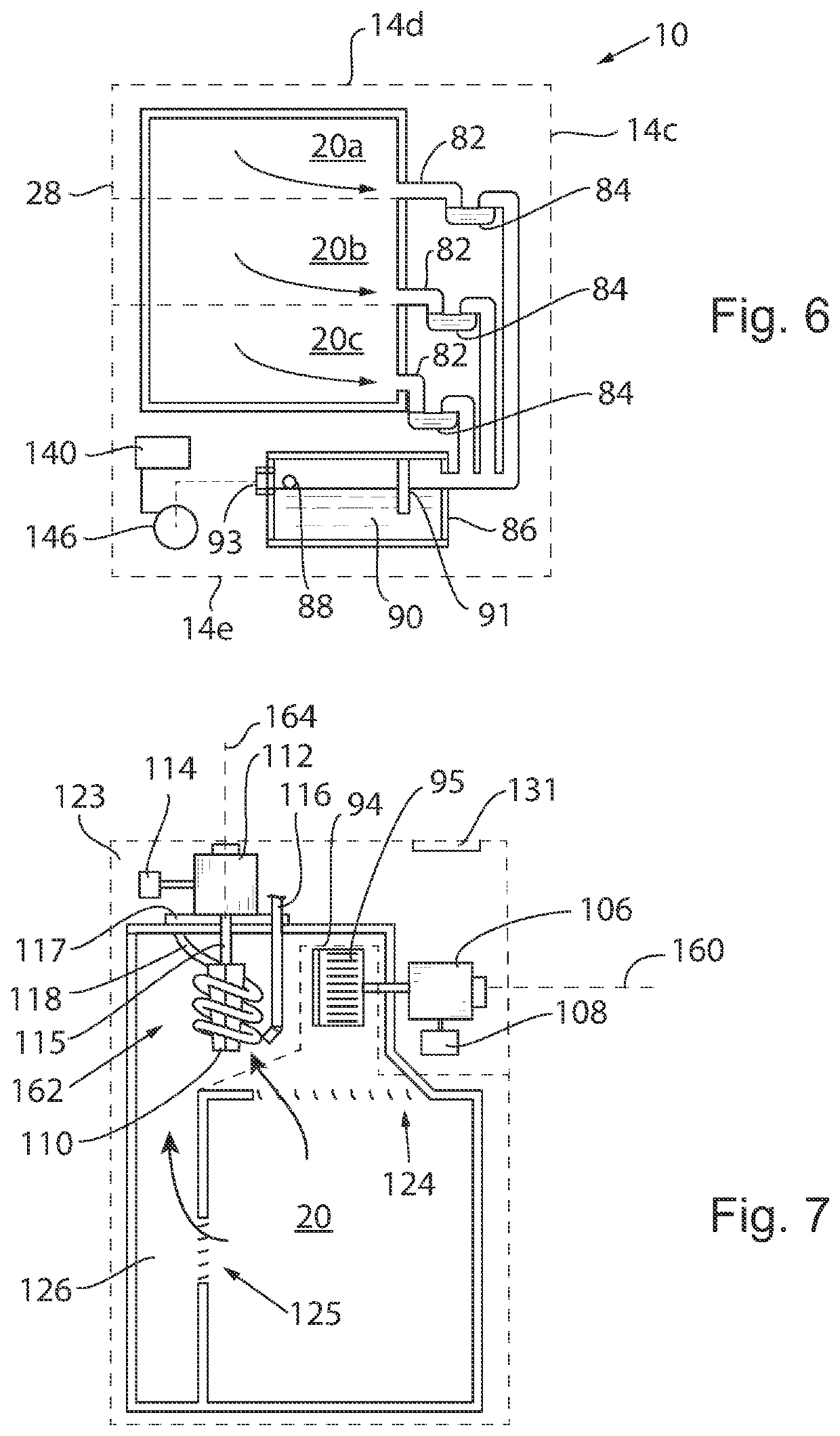

Combination Drain System for Multizone Oven

ActiveUS20190239517A1Excessive heatingSimple methodBaking cavity cleaningDomestic stoves or rangesEngineeringMoisture

Owner:APPLIANCE INNOVATION INC

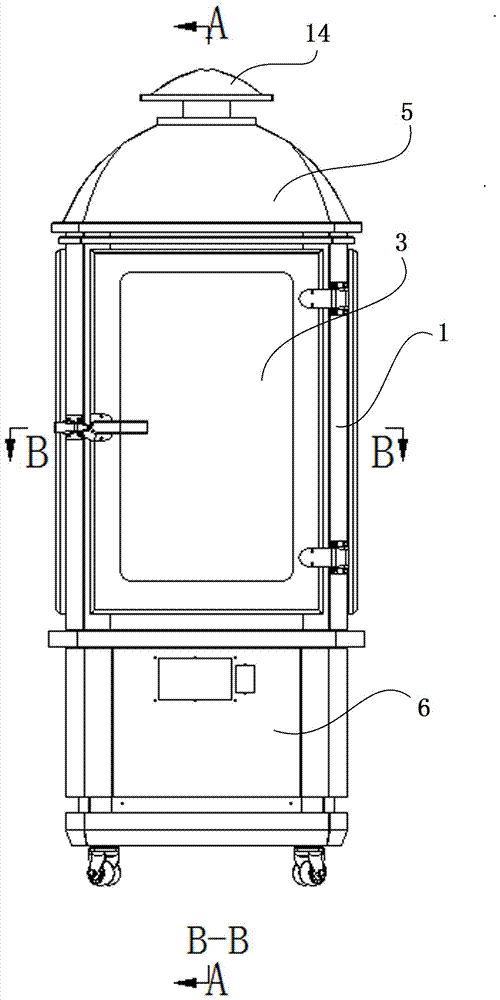

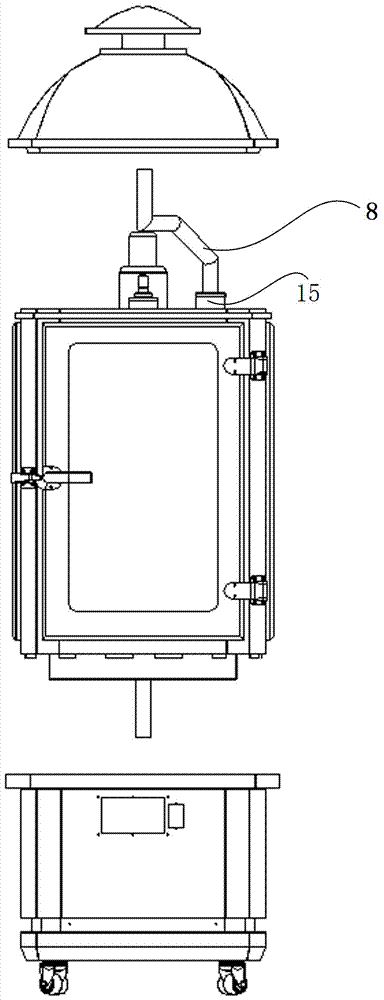

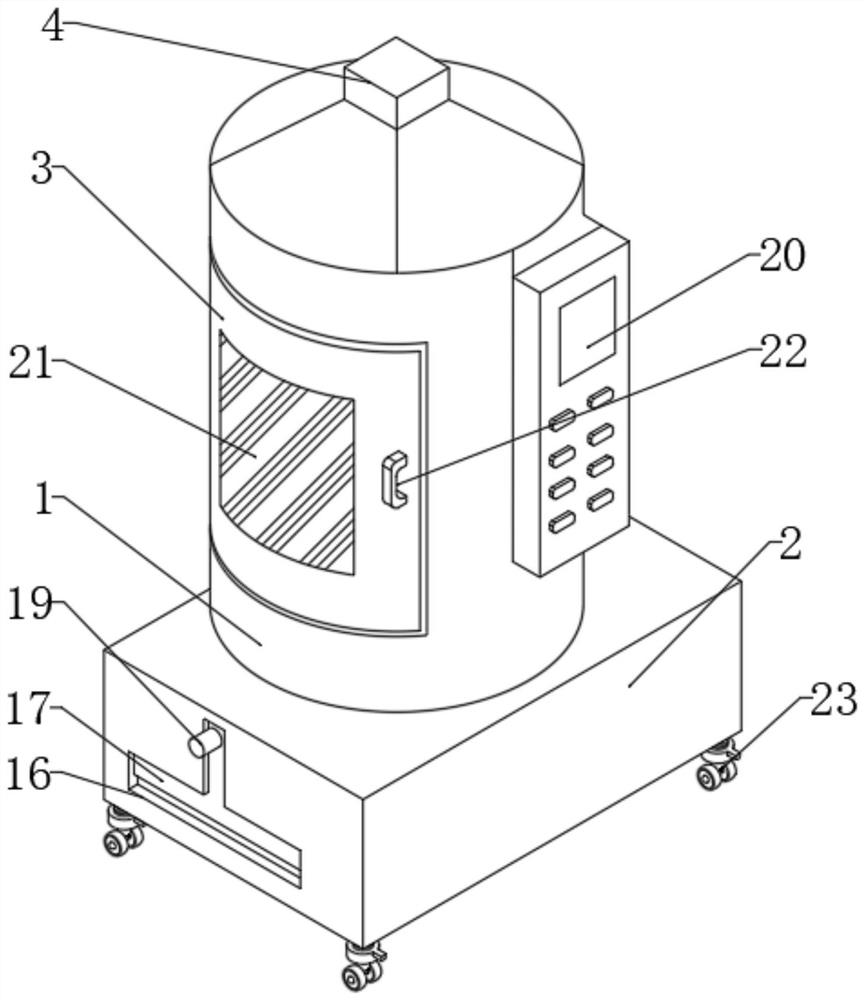

Transparent lamb roasting furnace

The invention discloses a transparent lamb oven. The side panel of the furnace body is a glass panel, the front of the furnace body is provided with a glass door, the back side of the furnace body is provided with a heat source box, the upper part of the furnace body is provided with a furnace cover, and the lower part of the furnace body is provided with a There is a base, and the furnace body is provided with a speed-regulating motor and a smoke exhaust pipe connected with the inner cavity of the furnace body. At least one group of electric heating tubes and the first water tank are distributed in the heat source box. The bottom of the furnace body is provided with a second water tank. The second water tank The drain port of the furnace is connected with the cleaning port of the furnace body through the pipeline through the water pump, and the furnace body is provided with a sewage discharge pipeline. The furnace body is rectangular or polygonal, and the other sides except the back of the furnace body are embedded with high-temperature-resistant glass materials (including the furnace door). There are two water tanks in the furnace body, which are used for the steam heating system and the circulation cleaning system respectively.

Owner:SHANGHAI CHUANGLYU CATERING EQUIP CO LTD

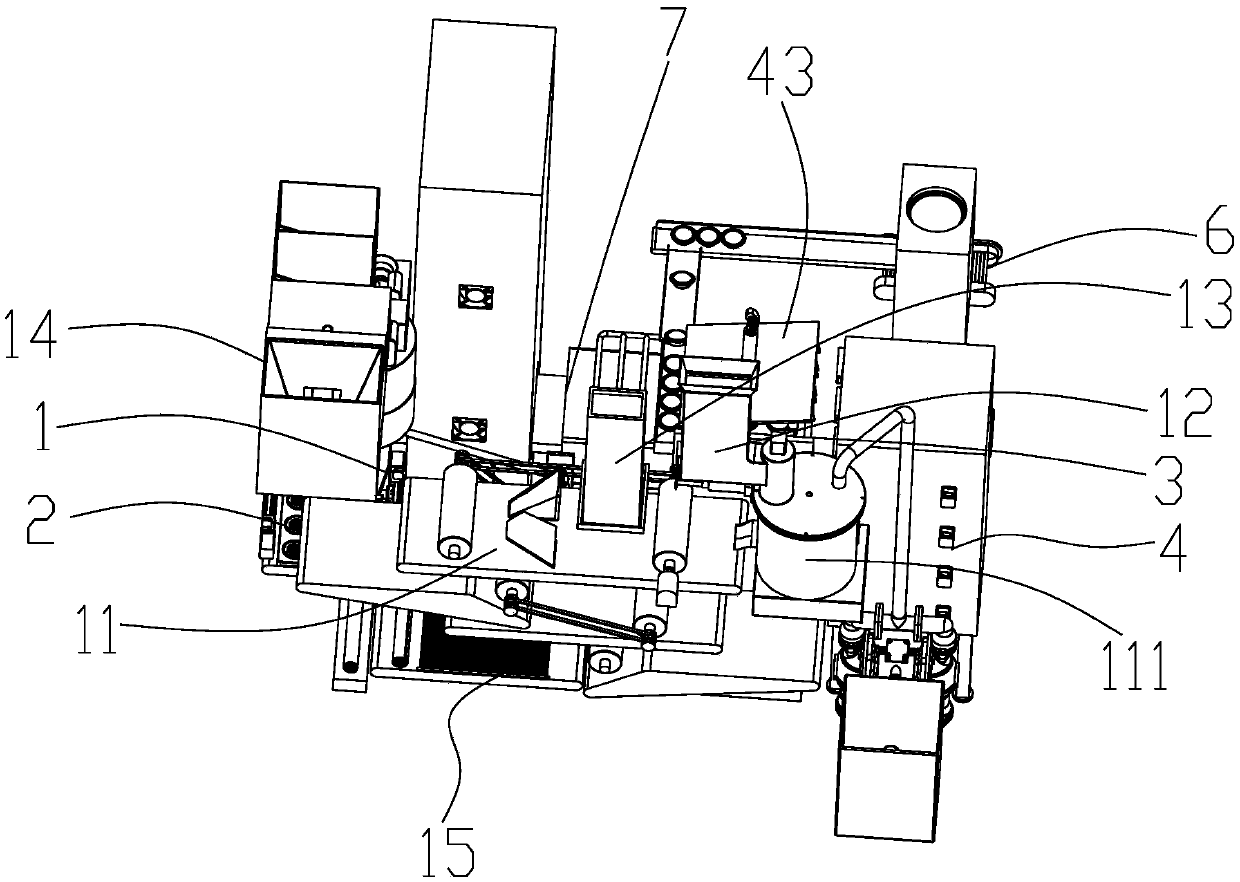

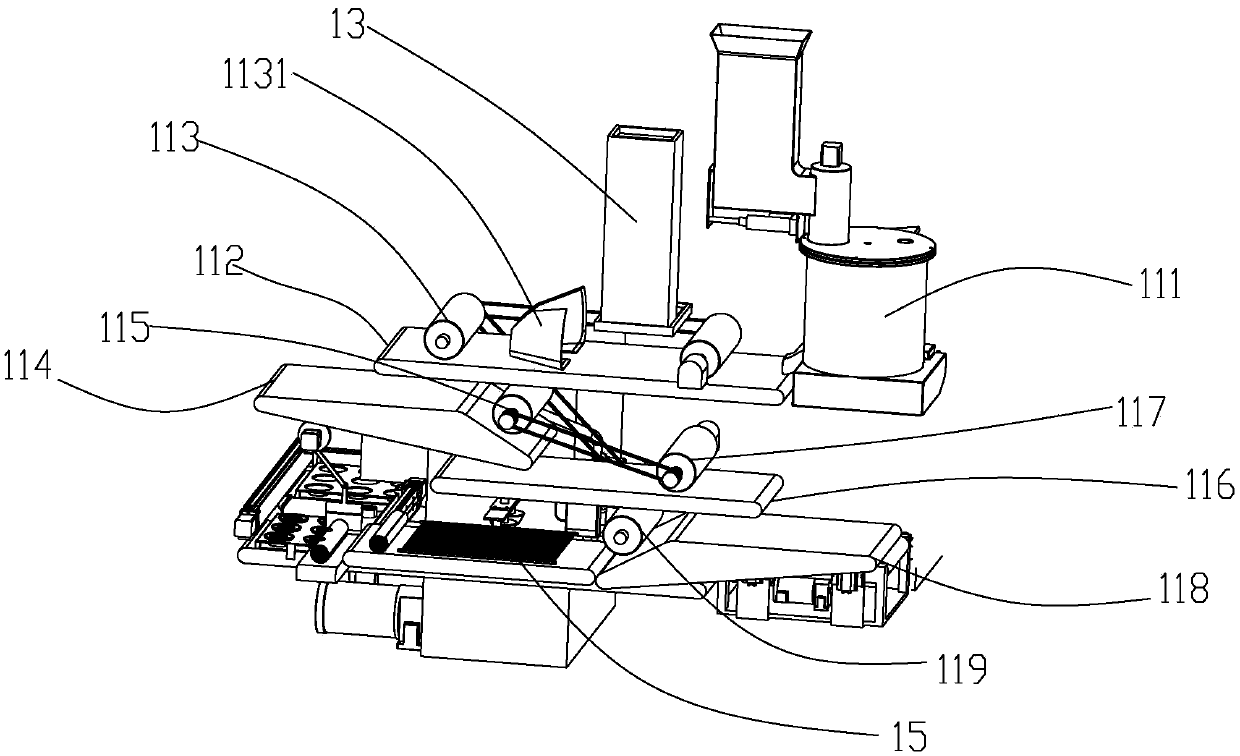

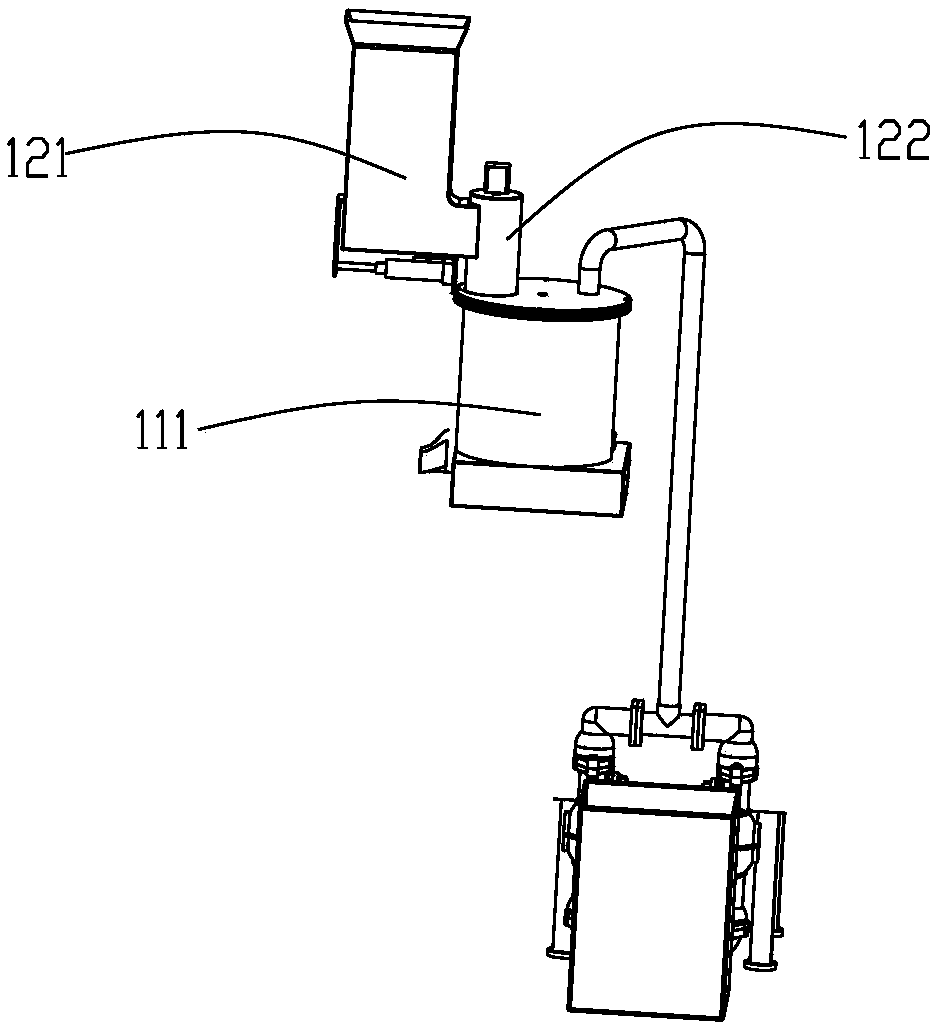

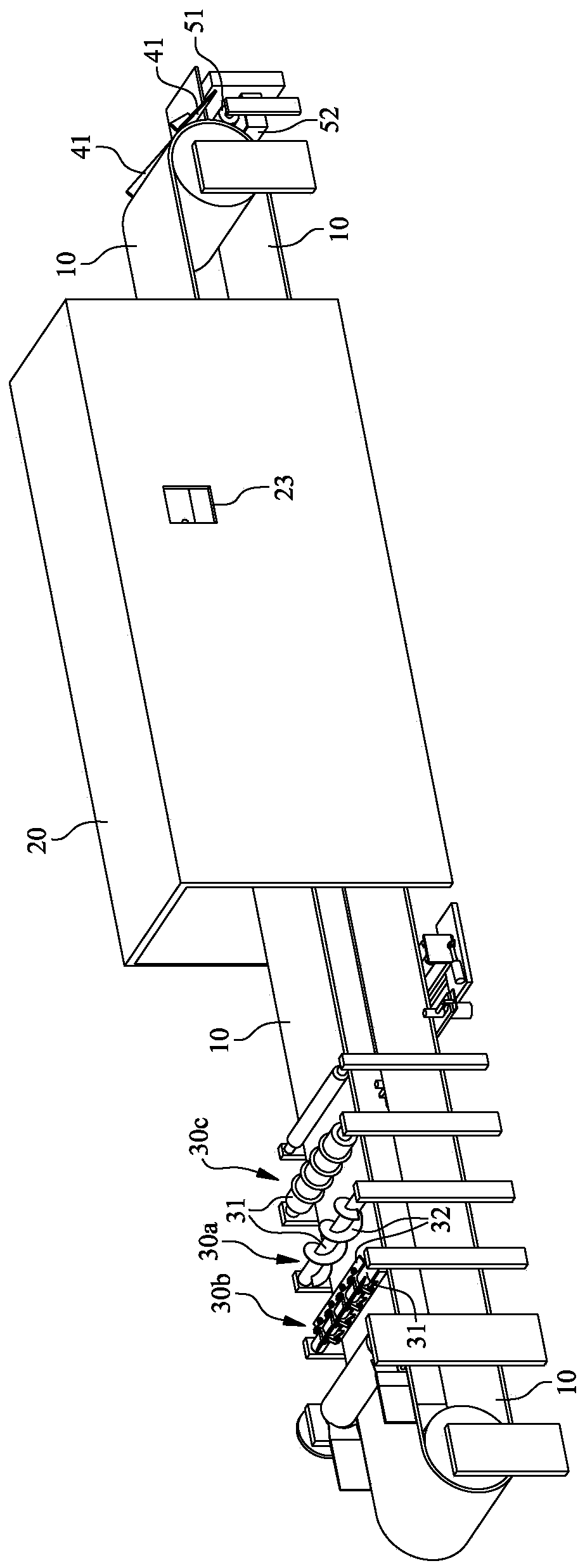

Roll-shaped food processing device and forming mechanism

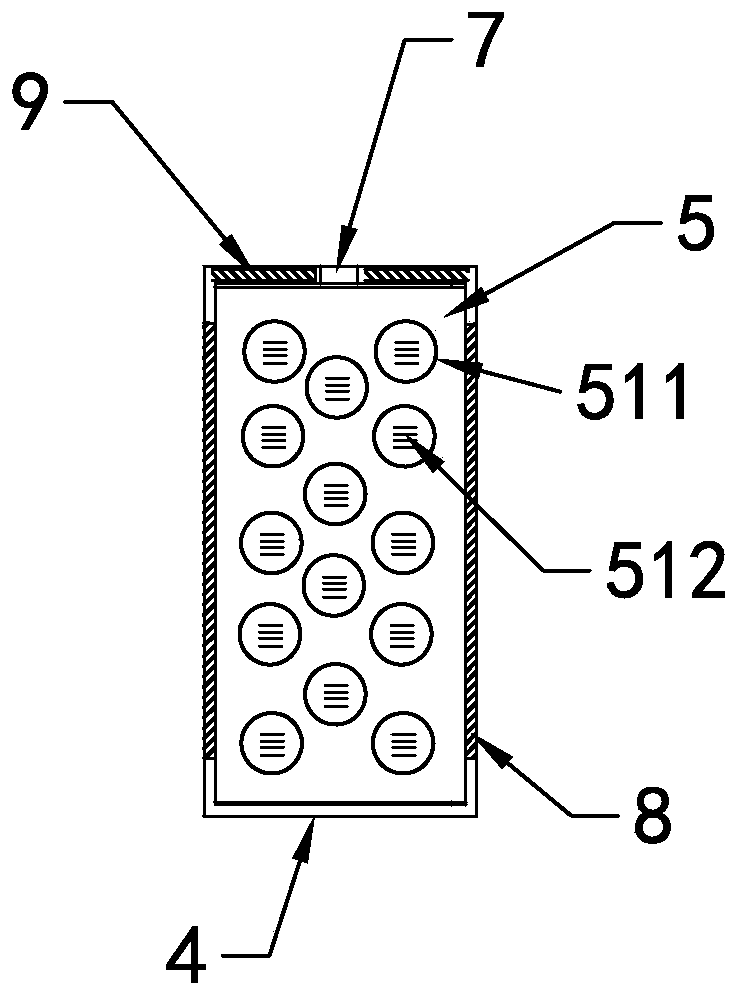

The invention relates to a roll-shaped food processing device and a forming mechanism. The forming mechanism comprises a baking tray assembly, a rolling assembly and a supporting assembly. A to-be-formed egg liquid is placed on a baking platform in the baking tray assembly for baking to form egg skin, and the supporting assembly drives a rolling part of the rolling assembly to move towards the baking platform, so that rolling rollers on the rolling part make contact with the egg skin on the baking platform. As the rolling rollers can rotate relative to the rolling part, the rolling rollers canrotate to roll the egg skin on the baking platform on the rolling rollers to form egg rolls. According to the roll-shaped food processing device, the rolling rollers and the egg skin on the baking platform make contact effectively, the stability of rolling of the egg skin on the rolling rollers is improved, the egg forming stability is improved, and the forming effect on the egg rolls is guaranteed.

Owner:ZHUHAI GREE INTELLIGENT EQUIP CO LTD +1

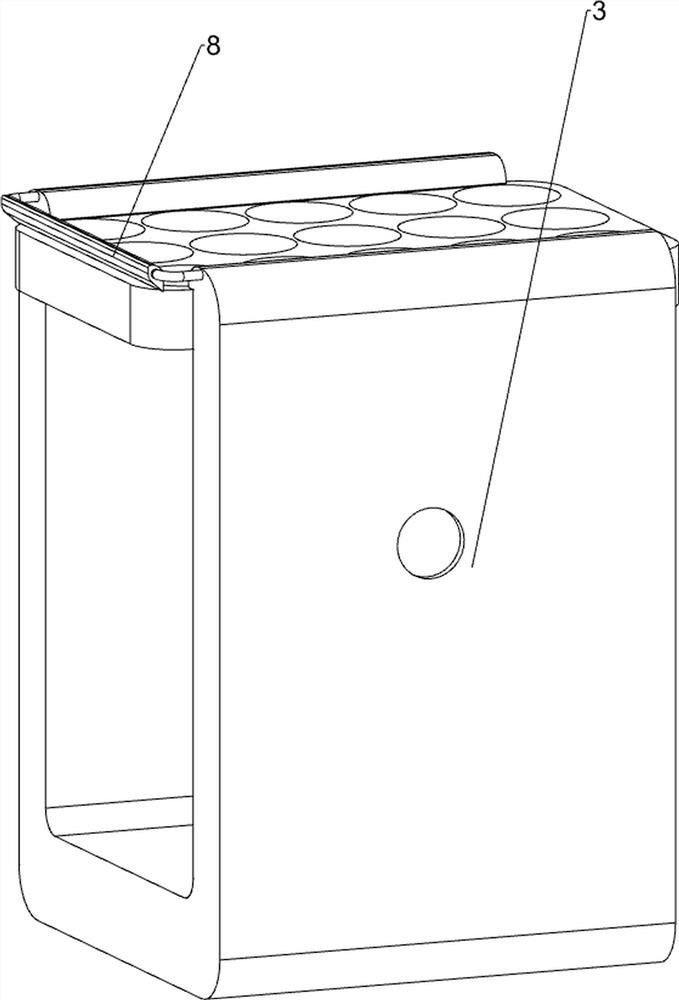

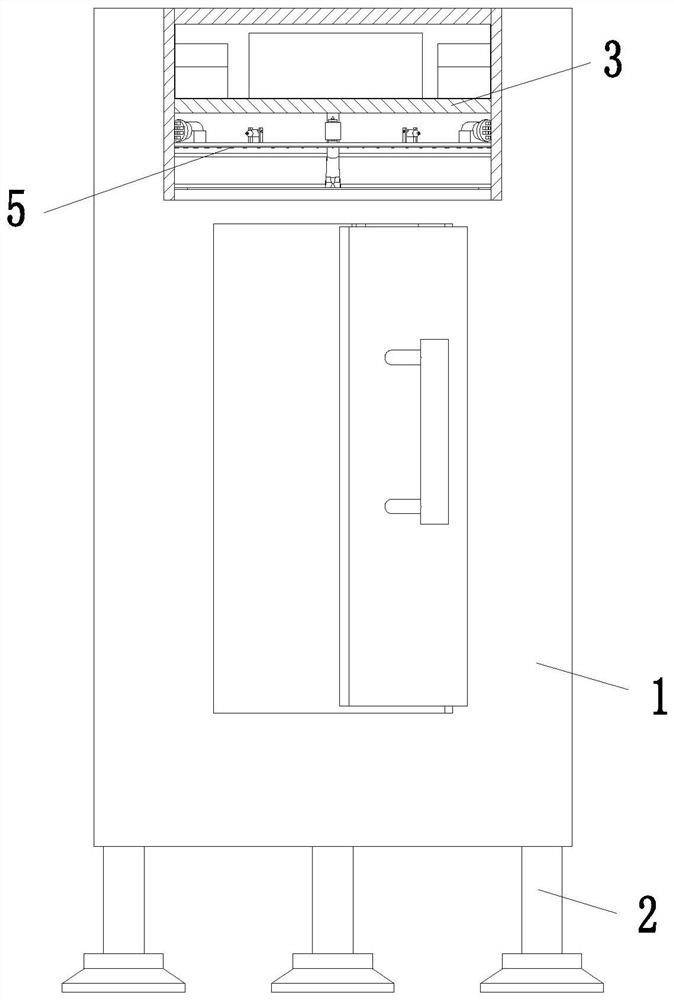

Automatic making device for egg tarts

PendingCN109645048ACrispy tasteGood crisping effectBaking cavity cleaningDough-sheeters/rolling-machines/rolling-pinsAdditive ingredientEngineering

The invention relates to automatic making equipment for egg tarts, in particular to an automatic making device for egg tarts. The automatic making device for egg tarts is high in automation degree, and comprises an ingredient making device, a baking tray conveying device, a transferring platform, an oven, a discharging dish-up device, an egg tart transporting device and a baking tray recovering device which are arranged on a rack; through a crispy crust making device, dough is repeatedly kneaded and pressed, egg tart crusts can be automatically folded multiple times, and the crispy taste of the egg tart finished products is guaranteed. The automation degree is high.

Owner:GUANGZHOU FUGANG WANJIA INTELLIGENT TECH CO LTD

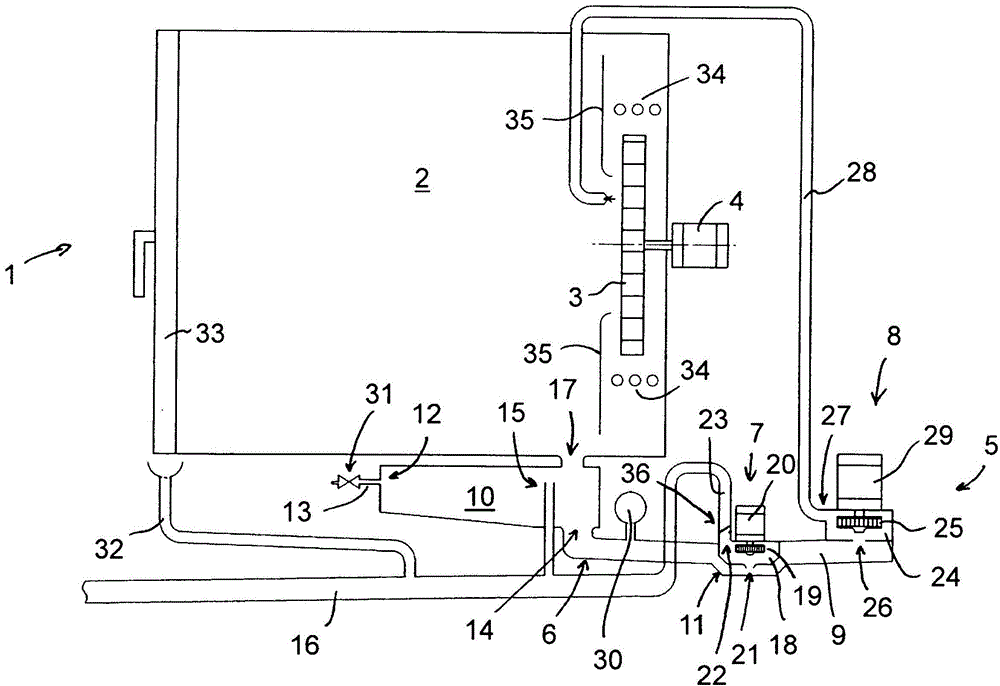

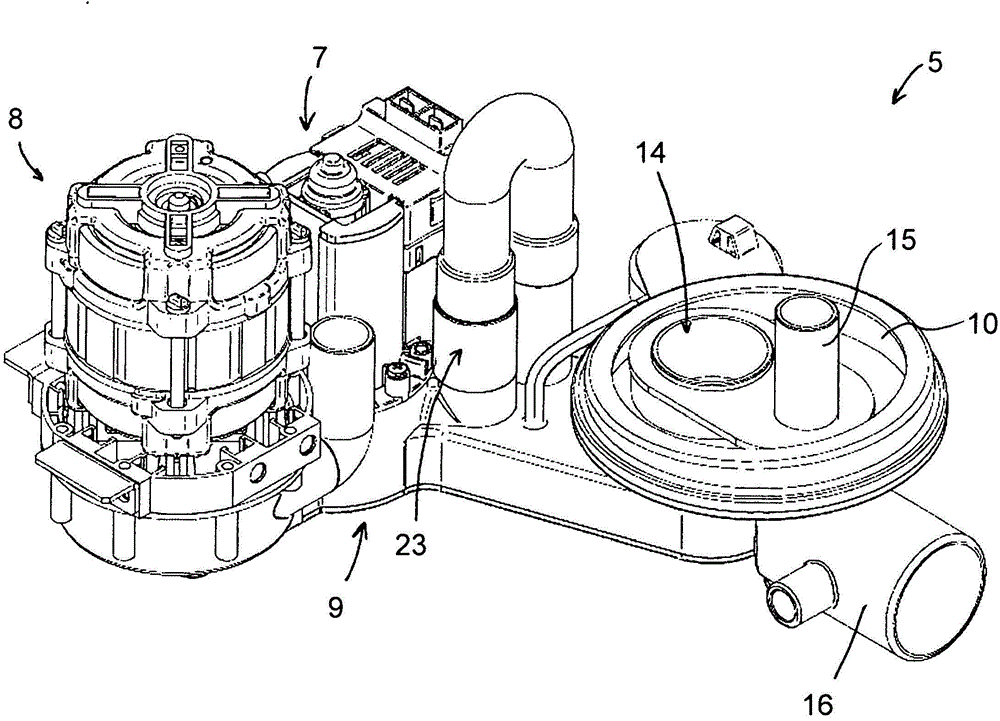

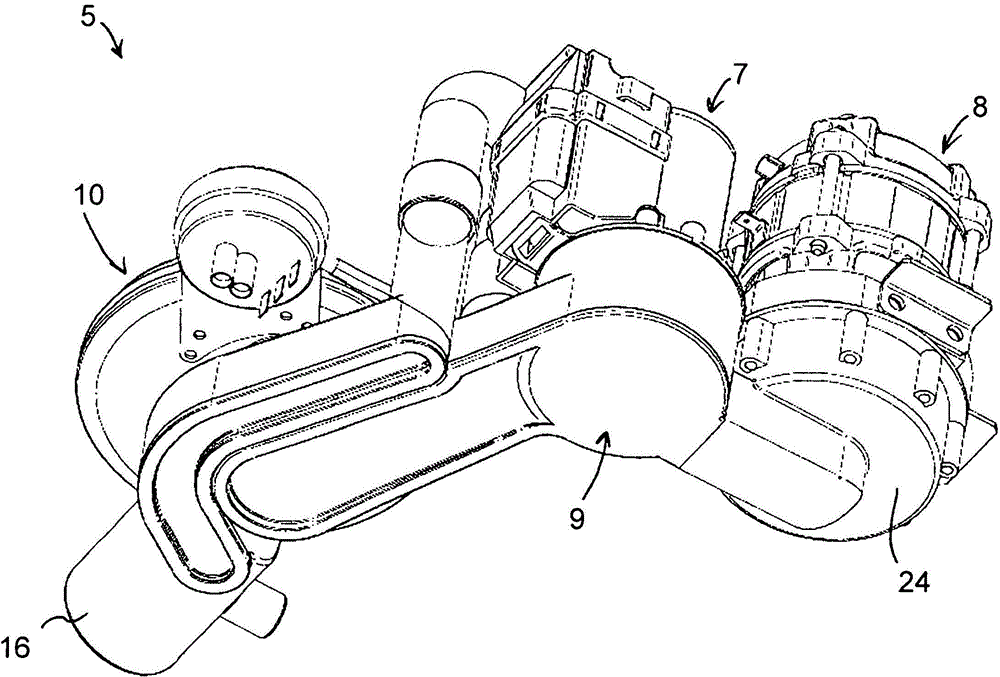

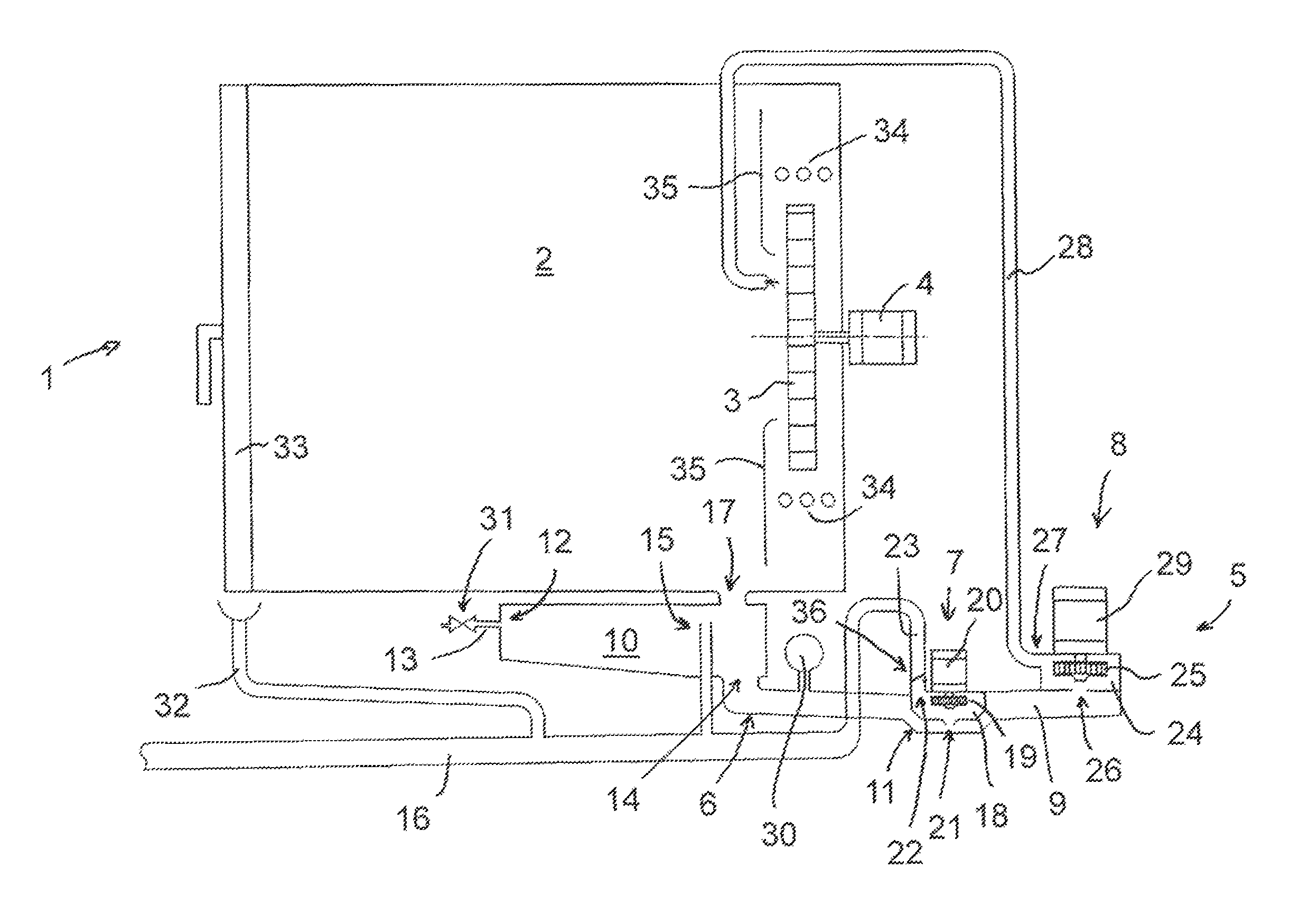

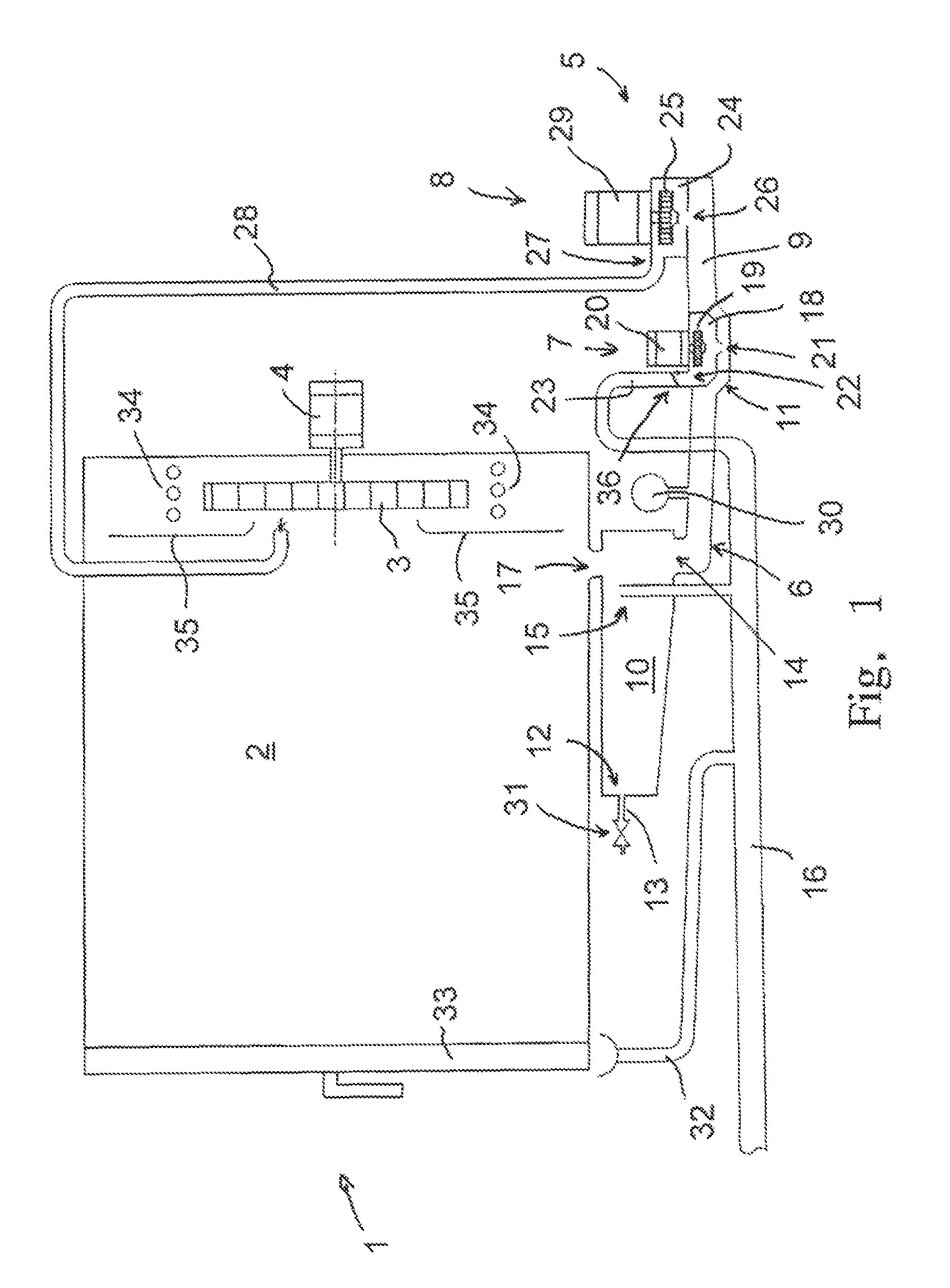

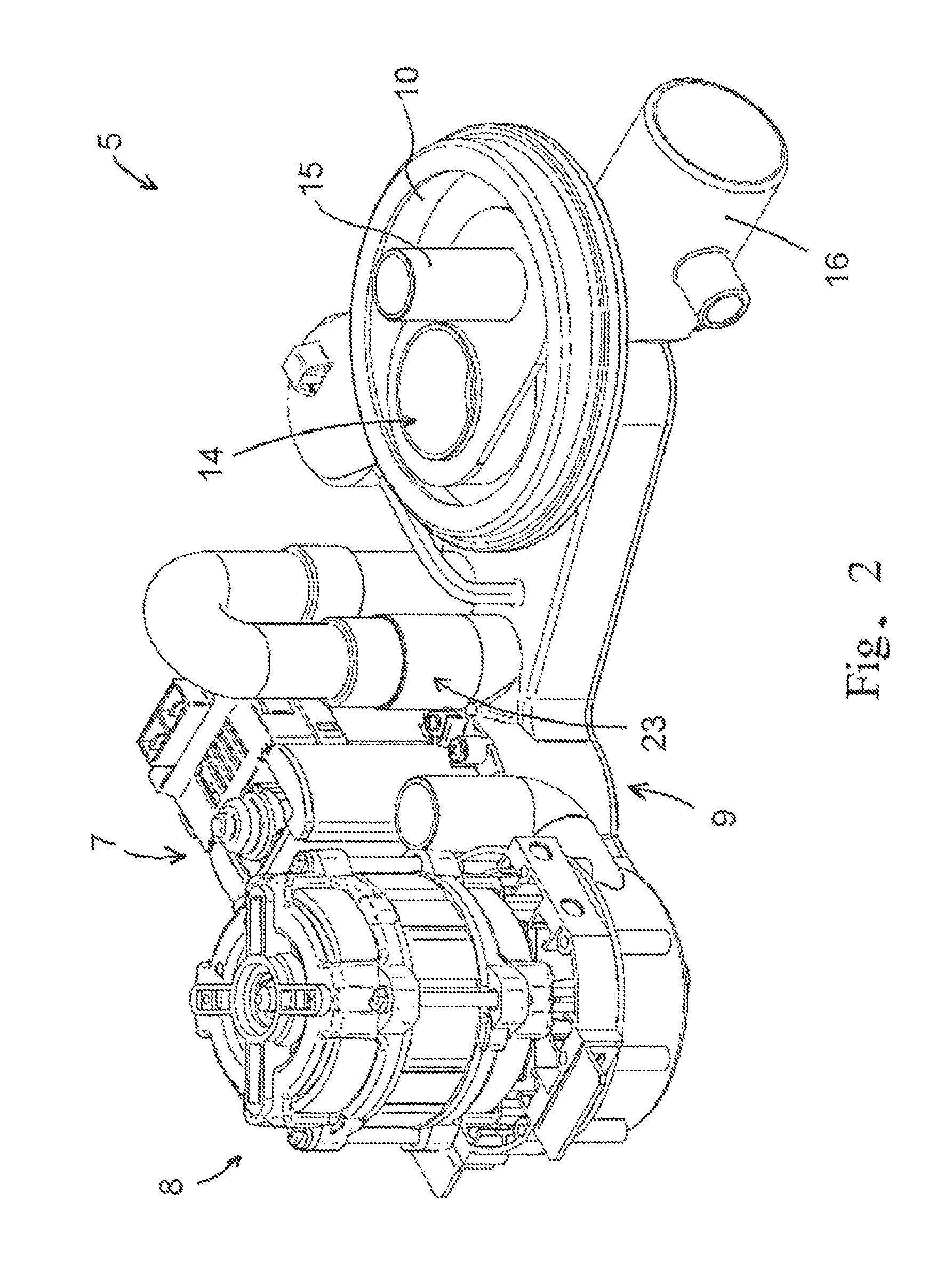

Cleaning device for kitchen devices and pump system

ActiveCN104055472AImprove efficiencyHelp to separateBaking cavity cleaningSelf-cleaning stoves/rangesFresh waterDrive motor

The invention relates to a cleaning device for kitchen devices, especially combined steaming devices, baking or cooking appliances. The device comprises a to-be-cleaned cooking space, a ventilation wheel distributed for the cooking device, a driving motor for the ventilation wheel, a collecting container, an inlet pipeline through which fresh water and / or cleaning liquid can be supplied, a circulating pump arranged on the collecting container and used for setting the liquid, a circulating pipeline through which the liquid arranged in the collecting container and conveyed by the circulating pump can be conveyed to the cooking space, and a discharge line for discharging the liquid from the cooking space, and the feeding of the fresh water and / or the cleaning fluid can be controlled by a valve arranged in the inlet pipeline. An emptying pump is provided at the collecting container. The liquid arranged in the collecting container and solid materials probably arranged in the container are conveyed into the discharge line through the emptying pump. The invention also relates to a pumping system for the cleaning device.

Owner:HANNING ELECTRO WERKE GMBH & CO KG

Stirrer capable of laterally turning over and discharging for beef processing

InactiveCN112516906AQuick clean upReduce churnBaking cavity cleaningTransportation and packagingForeign matterElectric machine

The invention discloses a stirrer capable of laterally turning over and discharging for beef processing. The stirrer comprises a frying boiler, a supporting bottom frame is fixedly installed on the lower surface of the frying boiler, a power motor is fixedly installed on the inner side face of the supporting bottom frame, a filtering pot is movably installed on the inner side of the frying boiler;a stirring motor is fixedly mounted above the end opening of the filtering pot, and a heat preservation cover plate is movably mounted on the upper surface of the filtering pot. According to the stirrer capable of laterally turning over and discharging for beef processing disclosed by the invention, tiny substances can be separated from beef granules with qualified sizes through a microporous steel wire filter screen, and meanwhile, the tiny substances are prevented from entering a heated frying boiler to be contacted with a heating block for heating, and being burnt and adhered to the surface of a heating device and difficult to clean; heat loss can be reduced, the heating speed can be increased, external foreign matter or dust can be prevented from falling into the stirrer, the movablecover plate can be collected into the heat preservation cover plate when not used, and therefore the occupied space of the cover body structure is reduced.

Owner:山东鲁拓畜产品有限公司

Deep-frying device with function of easily taking out materials

InactiveCN108835142AEasy to take outQuick RetrievalBaking cavity cleaningOil/fat bakingDeep fryingEngineering

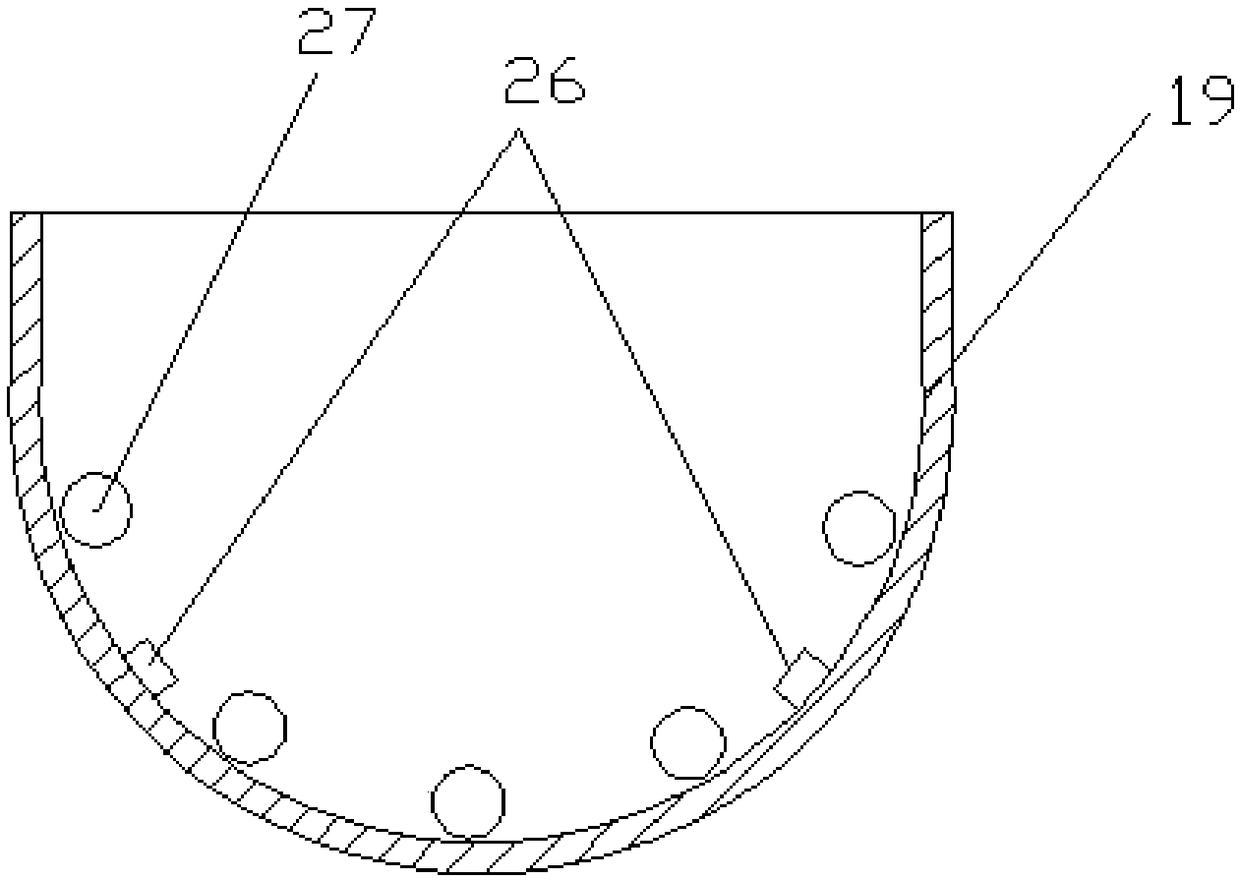

The invention discloses a deep-frying device with a function of easily taking out materials. The deep-frying device comprises a shell, a deep fryer is arranged on the top in the shell, and a baffle isarranged at the position, corresponding to the top of the deep fryer, of the top of the shell. The deep fryer is of a semi-circular arc-shaped shell structure, a rotary roller is sleeved in the center of the deep fryer, and roller shafts at the two ends of the rotary roller are sleeved with bearings which are arranged at the corresponding positions of the side wall of the shell. According to thedeep-frying device with the function of easily taking out the materials, the structure is ingenious, arrangement is reasonable, quick deep frying is achieved, and the materials are conveniently takenout. During work, materials are placed in net containers, net covers are closed and fixedly locked, the rotary roller is driven to drive the net containers to enter the deep fryer, and the materials are deep-fried in the deep fryer. Electric heating pipes are arranged in the deep fryer, temperature sensors are arranged, the oil temperature is convenient to control, after deep frying of the materials is finished, the rotary roller is driven to lift the net container out of the deep fryer, after cooling, the net cover is opened, and the materials are easily taken out; multiple kinds of materialscan be placed into different net containers for separation, and tainting of odor is prevented.

Owner:CHANGSHA FENGYING MACHINERY TECH CO LTD

Oven

PendingCN110959641AGuaranteed comfortPrevent penetrationBaking cavity cleaningFood processingFood qualityProcess engineering

The invention discloses an oven. An oven body comprises an inner cavity and a heating unit used for supplying heat in the inner cavity. The oven is characterized in that the side wall of the oven bodyis provided with at least one door opening and an oven door capable of opening or closing the door opening; and the inner side surface of the oven door can bear food to be processed. When food is putin or taken out, workers are not prone to being scalded, and the quality of the baked food is improved. The oven is suitable for baking food on a large scale, is energy saving and environmentally friendly, and is safe to use.

Owner:浙江寻炉记餐饮管理有限公司

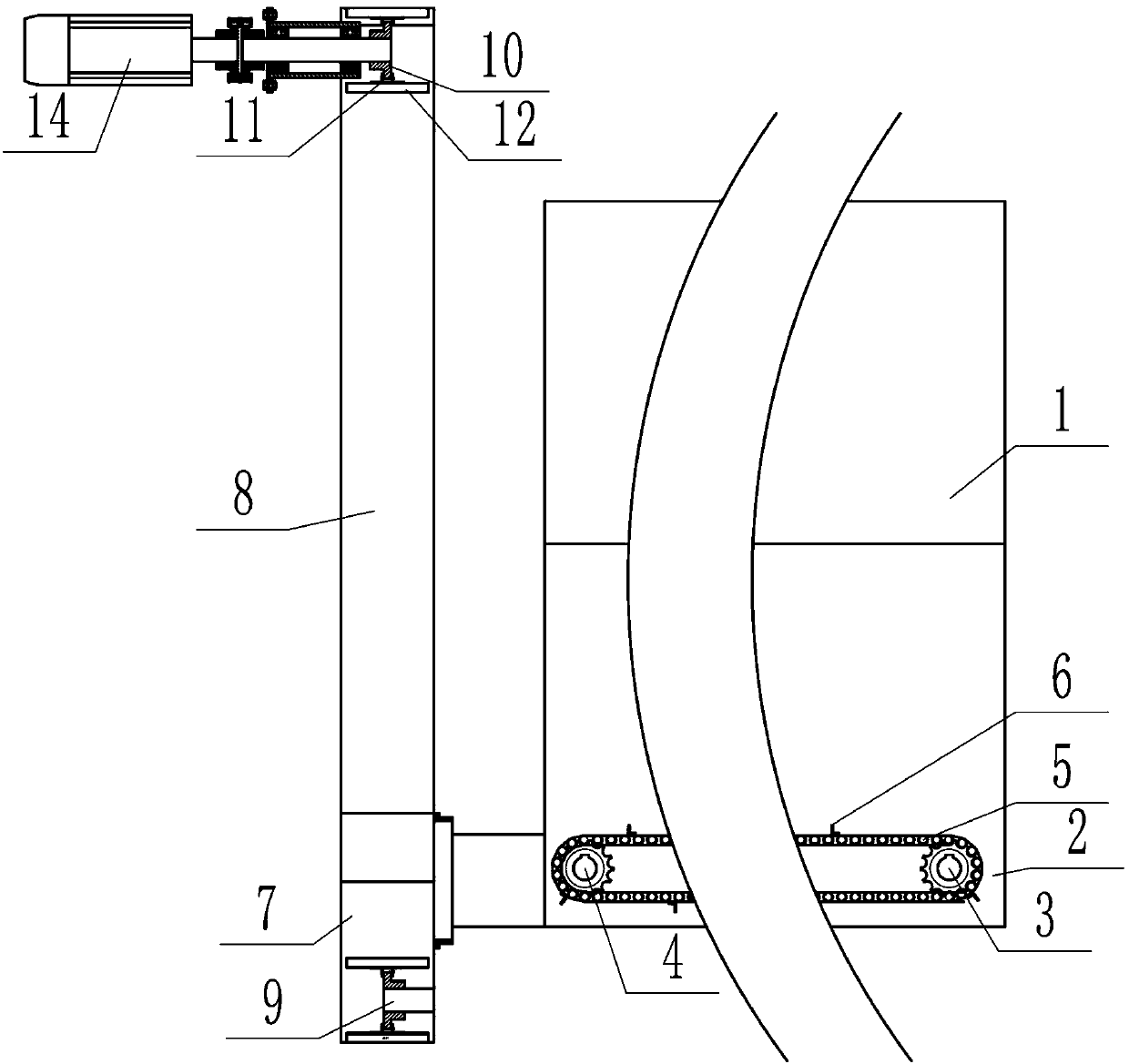

Round biscuit making machine

ActiveCN112352800AImprove securityImprove product qualityBaking cavity cleaningCharging/discharging ovensProcess engineeringMechanical engineering

The invention relates to a making machine, particularly to a round biscuit making machine, and provides a round biscuit making machine, which can achieve automatic feeding and automatic discharging, and is accurate and safe in feeding. The round biscuit making machine comprises: a first supporting rod, a second supporting rod and a material placing frame, wherein the first supporting rod and the second supporting rod are provided with the material placing frame used for containing round biscuit molds; a charging mechanism arranged on the material placing frame; and a feeding mechanism arrangedon the material placing frame. Through efficient cooperation of the discharging mechanism, the feeding mechanism and the automatic intermittent material placing mechanism, the effects of automatic intermittent feeding and automatic discharging are achieved; and by means of the charging mechanism, the round biscuit molds needing to be loaded with the materials are automatically replaced, and the round biscuit molds loaded with the materials are collected in time by means of the receiving mechanism.

Owner:FUJIAN XINXING FOOD

Multizone oven comprising a combination drain system

PendingCN110115517AAvoid transmissionBaking cavity cleaningDomestic stoves or rangesEnvironmental engineeringMechanical engineering

Owner:ALTO SHAAM

Cake baking equipment

ActiveCN112616864AReduce the temperatureImprove operational safetyBaking cavity cleaningOven air-treatment devicesEngineeringMechanical engineering

The invention belongs to the technical field of cake processing, and particularly relates to cake baking equipment. The cake baking equipment comprises an oven body, wherein sliding rods are slidably connected to the inner parts of sliding grooves formed in two sides of the inner wall of the oven body, collecting discs are fixedly connected to the adjacent sides of the sliding rods, trays are arranged on the sliding rods at the tops of the collecting discs, and heating pipes are evenly distributed in the oven body on the upper sides and the lower sides of the trays; a water inlet and a water outlet are symmetrically formed in one side, away from a box door, of each tray, a first hole is formed in one side, close to the box door, of each tray, and the two ends of each first hole communicate with the corresponding water inlet and the corresponding water outlet; a butt joint unit communicates with a first pipe and a second pipe; a water tank and a water pump communicate between the first pipe and the second pipe; and the water pump works when the heating pipes are powered off. Cooling water is injected into the first hole through the water pump and then flows back through the water outlet, so that the temperature of the trays is rapidly reduced, and scalding in the tray taking process is reduced.

Owner:咸宁市圆满电子商务有限责任公司

Electromagnetic-heating fryer

PendingCN112314651AEasy to viewIncrease the number ofBaking cavity cleaningOil/fat bakingEconomic benefitsEngineering

Owner:漳州众瑞达食品机械有限公司

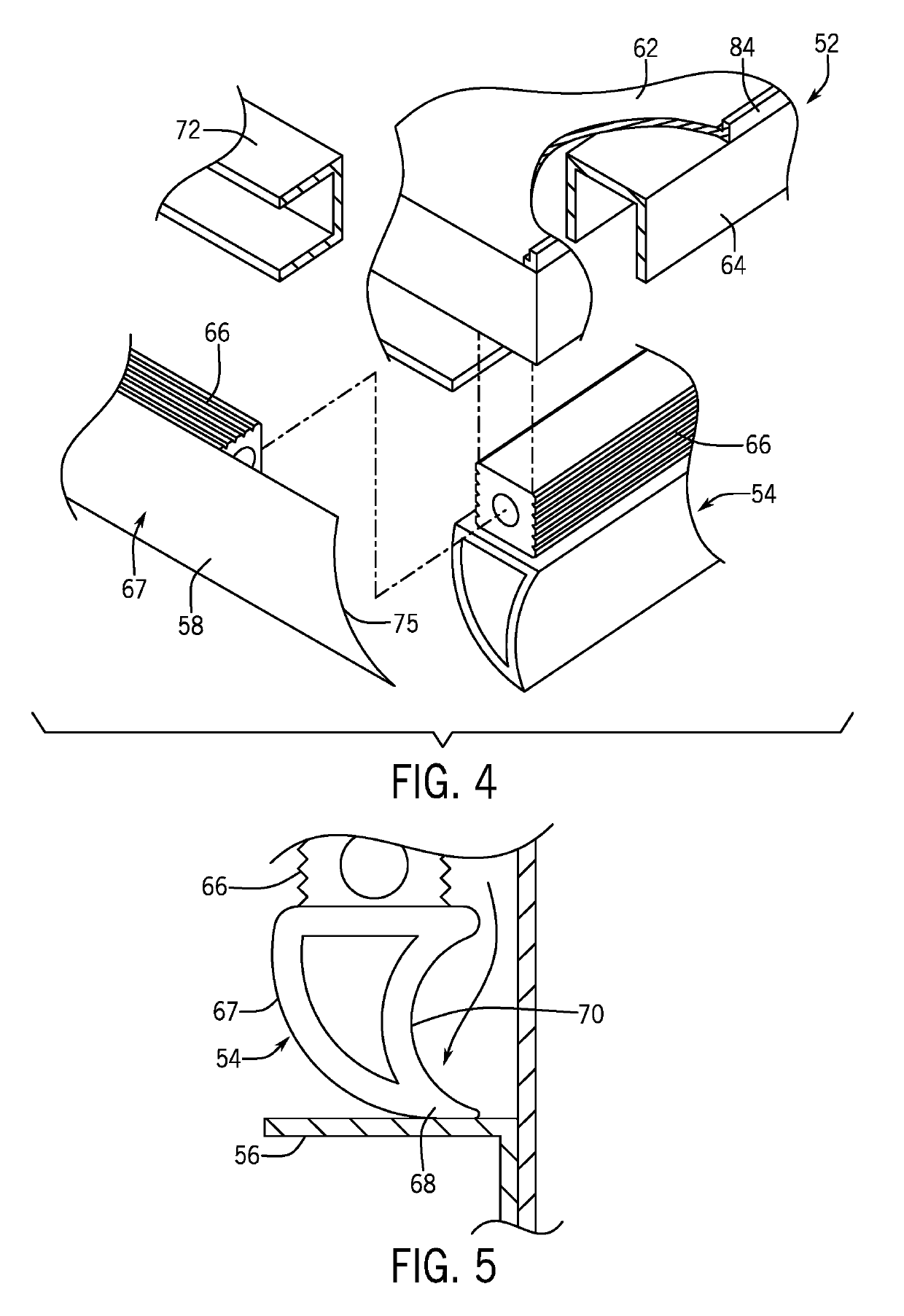

Cleaning device for kitchen appliances and pump systems

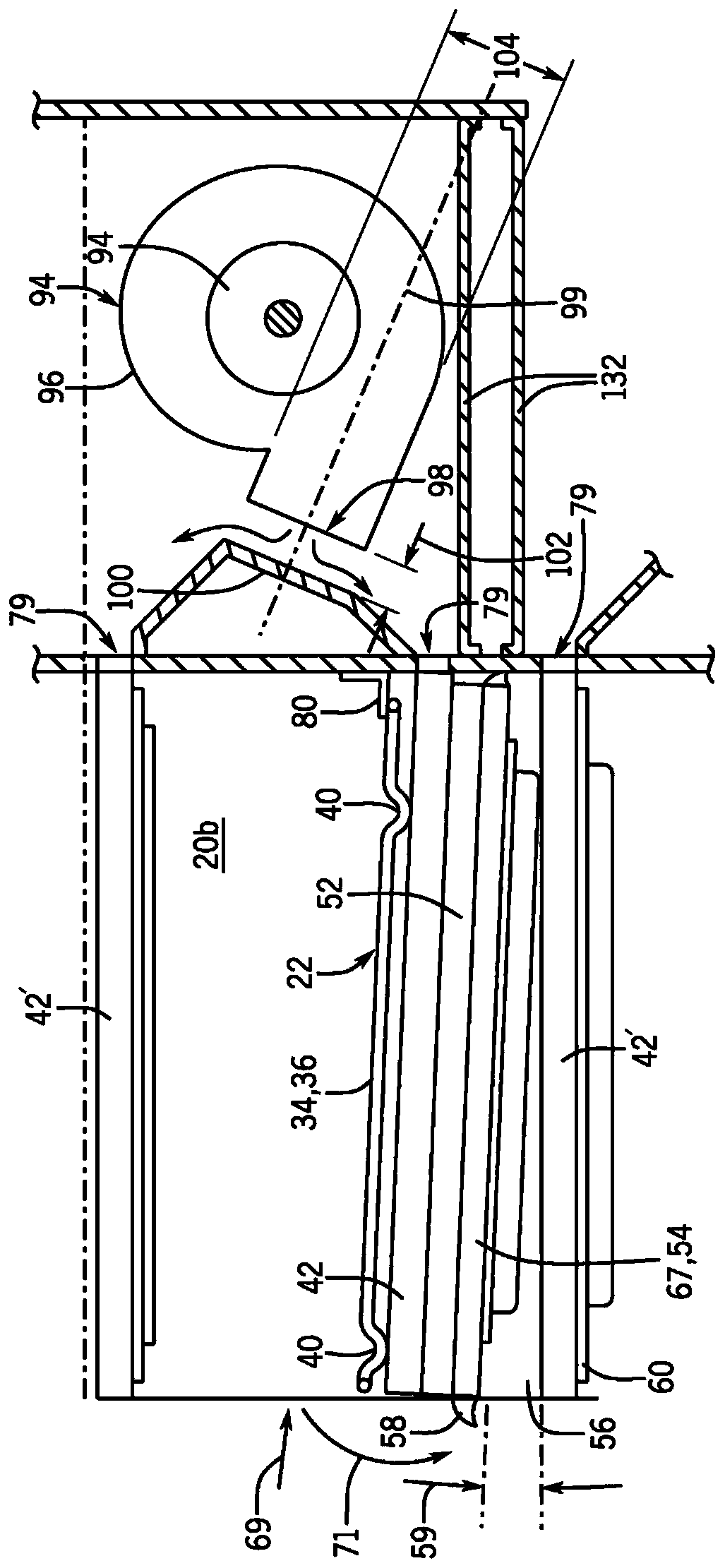

ActiveUS9464814B2Prevent backflowBaking cavity cleaningSelf-cleaning stoves/rangesDrive motorFresh water

Cleaning apparatus for kitchen equipment, in particular combination streaming, baking and cooking equipment has a cooking space that is to be cleaned which is delimited by at least one wall and includes at least one outlet opening for a liquid. The apparatus comprises a ventilation fan associated with the cooking space having a drive motor; a collecting tank which at least temporarily collects the liquid that exits the cooking space via the outlet opening; a supply line that can be used to supply fresh water and / or a cleaning fluid that can be controlled through a valve in the line; a circulating pump provided at the collecting tank for the liquid sitting in the collecting tank; a circulation line by which the liquid sitting in the collecting tank and conveyed by the circulating pump can be supplied to the cooking space and a drain line for discharging the liquid that exits the cooking space. A drain pump is provided at the circulation container in addition to the circulating pump which is able to actively convey the liquid sitting in the collecting tank, together with solids that may be present therein, into the drain line.

Owner:HANNING ELECTRO WERKE GMBH & CO KG

Steam clean booster powder

InactiveUS20170313961A1PleasantPleasant aromaBaking cavity cleaningSelf-cleaning stoves/rangesEngineeringEffervescence

In accordance with one aspect of the present invention, a method for cleaning a cooking chamber is provided. The method comprises applying a cleanser composition and water to the cooking chamber followed by incubating the cooking chamber. The cleanser composition comprises components that aid in loosening soil and debris during the steam cleaning and also provides a pleasant aroma. The cleanser composition aids in loosening soil and debris by effervescence.

Owner:ELECTROLUX HOME PROD CORP NV

Making technology of scallion-flavor sesame seed cakes

InactiveCN107347961AEnsure food hygieneClear dosageBaking cavity cleaningNon-ionic surface-active compoundsFlavorCooking & baking

The invention discloses a making technology of scallion-flavor sesame seed cakes, and relates to the technical field of food processing. The making technology comprises the following steps of (1) preparing materials; (2) performing dough leavening; (3) making cakes; and (4) performing baking. The scallion-flavor sesame seed cakes are made by the making method, and the making method has the characteristics of being simple to operate, easy to operate and explicit in consumption of raw materials and operation steps, and is suitable for beginners without any making experience, and the beginners can make the scallion-flavor sesame seed cakes being rich in chewiness, crispness and fragrance according to the making technology, so that the scallion-flavor sesame seed cakes become domestic snacks, and the edible hygiene of the sesame seed cakes can be guaranteed by making the sesame seed cakes by oneself.

Owner:安徽芈八子食品科技有限公司

Energy-saving and environment-friendly baking device

InactiveCN112471184AImprove functionalityReduce burnt etc.Baking cavity cleaningCharging/discharging ovensGear wheelElectric machinery

Owner:合肥一诺机械配件有限公司

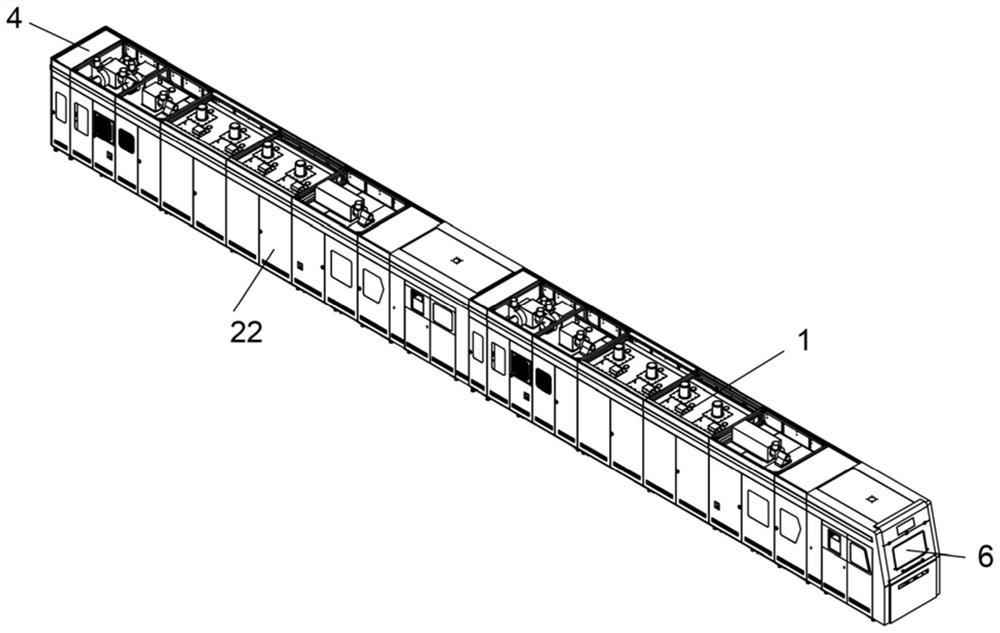

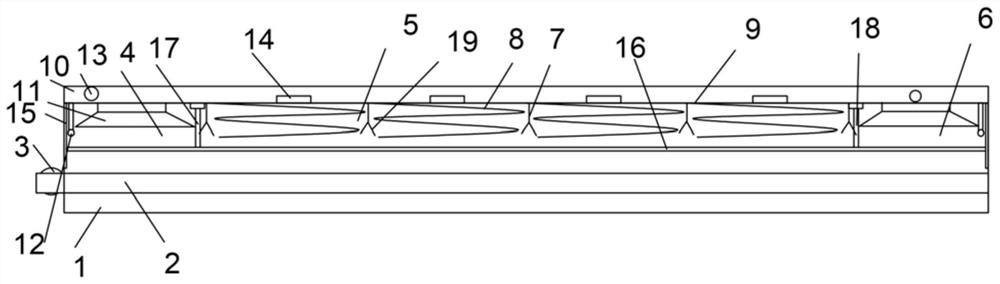

Tunnel furnace

PendingCN112056331AIncrease temperatureImprove the heating effectBaking cavity cleaningOven air-treatment devicesThermodynamicsElectric machine

The present invention discloses a tunnel furnace. The tunnel furnace comprises a tunnel furnace body, a conveying pipeline and a first motor, the tunnel furnace body comprises a feeding area, a heating area and a discharging area, the heating area comprises one or more heating boxes, heating wires are arranged in the heating boxes, a first partition plate for isolating the tunnel furnace body up and down is arranged at an upper portion in the tunnel furnace body, an upper cavity of the tunnel furnace body serves as a waste heat absorption pipeline, air outlet channels and high-pressure air blowers are arranged in the feeding area and the discharging area, suction devices are arranged on two sides of the waste heat absorption pipeline respectively, a conveying pipe communicating with the waste heat absorption pipeline is arranged above each heating box, a vertically-arranged sliding strip is arranged on each of a left side and a right side in the tunnel furnace body, a mesh belt locatedon the conveying pipeline is connected between the two sliding strips in a sliding mode, first air cylinders for driving the mesh belt to move up and down are arranged in the tunnel furnace body, andguide rods penetrating through the mesh belt are further arranged in the tunnel furnace body. The structure can adjust distances between the mesh belt and the conveying pipeline according to a heightof a product.

Owner:志合装备技术(惠州)有限公司

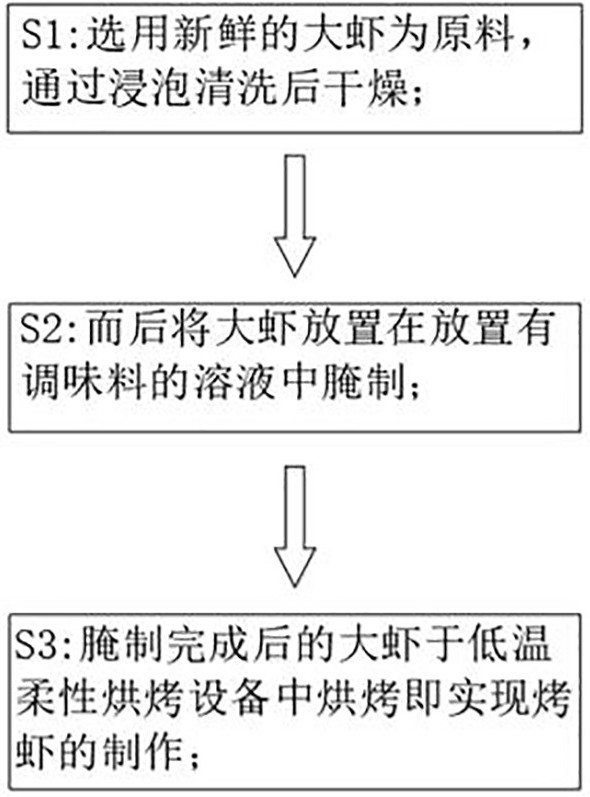

Low-temperature flexible roasted prawn production process

The invention relates to the technical field of roasted prawn production, in particular to a low-temperature flexible roasted prawn production process. The low-temperature flexible roasted prawn production process comprises the following steps that S1, fresh prawns are selected as raw materials, and soaking, cleaning and drying are carried out; S2, then the prawns are put into a solution in which seasonings are placed, and the prawns are pickled; and S3, the pickled prawns are baked in low-temperature flexible baking equipment to realize the preparation of the baked prawns. In the low-temperature baking stage of the pickled prawns, a scraping assembly is arranged in a baking oven, so that dripped seasonings in the baking stage can be effectively collected, and the situation that the taste of the prawns is affected due to the fact that the baking environment in the baking oven is affected by evaporation of the seasonings in the baking process is avoided; and meanwhile, a vibration assembly arranged in an oven is combined, so that the prawns placed on a conveying belt are effectively prevented from being burnt, and the baking quality is improved.

Owner:WENZHOU XIANGHAI FOOD CO LTD

A kind of cake baking equipment

ActiveCN112616864BReduce the temperatureImprove operational safetyBaking cavity cleaningOven air-treatment devicesEngineeringMechanical engineering

The invention belongs to the technical field of pastry processing, and specifically relates to cake baking equipment, which includes an oven body; slide bars are slidably connected to slide grooves provided on both sides of the inner wall of the oven body; There is a tray on the slider on the top of the collection tray, and heating pipes are evenly distributed in the oven body on the upper and lower sides of the tray; the side of the tray away from the door is symmetrically provided with water inlet and outlet holes, and the side of the tray near the door There is a No. 1 hole inside the side, and the two ends of the No. 1 hole are respectively connected with the water inlet and the water outlet; the docking unit is respectively connected with the No. 1 pipe and the No. 2 pipe, and the water tank and the water pump are connected between the No. 1 pipe and the No. 2 pipe; The water pump works when the tube is powered off; the invention injects cooling water into the No. 1 hole through the water pump and then flows back through the outlet hole, thereby rapidly reducing the temperature of the tray and reducing burns during the tray picking process.

Owner:咸宁市圆满电子商务有限责任公司

Heating pot with residue discharge function

InactiveCN108669112AAchieve cleanupNovel ideaBaking cavity cleaningOil/fat bakingEdge surfaceEngineering

The invention relates to a heating pot with a residue discharge function and aims to effectively solve the problem that residues cannot be discharged when a conventional heating pot is used. Accordingto the solving technical scheme, the heating pot comprises a heating pot, wherein a settling tank is arranged at the bottom of the heating pot; one end of the settling tank is arranged inside the heating pot; the other end of the settling tank penetrates through and extends outside the left end surface of the heating pot; a first chain wheel is arranged at one end inside the heating pot, of the settling tank; a second chain wheel is arranged at the other end of the settling tank; the first chain wheel is connected with the second chain wheel through a first chain; a first scraper plate is fixed on the outer edge surface of the first chain; a collecting box is arranged at one end outside the heating pot, of the settling tank; a conveying tube of which one end is inclined upwards is arranged at the bottom of the collecting box; a third chain wheel is arranged at one end inside the collecting box, of the conveying tube; a fourth chain wheel is arranged at the other end of the conveying tube; the third chain wheel and the fourth chain wheel are connected through a second chain; a second scarper plate is arranged on the outer edge surface of the second chain. The heating pot is novel in structure, smart in structure and good in practicability.

Owner:LUOHE XINRUI MACHINERY CO LTD

Control method and cooperative control method for automatic baking machine

PendingCN112889852AEnsure food safetySmall footprintBaking cavity cleaningApparatus for meter-controlled dispensingFood safetyElectric machinery

The invention discloses an automatic baking machine and a control method thereof. The automatic baking machine comprises a box body, a plurality of heating rollers, a plurality of spiral pieces, a connecting piece and a coupler, wherein one end of each spiral piece is fixed on the connecting piece, the other end of each spiral piece is in a free state, and the axis of each spiral piece is located above the middle position of two adjacent heating rollers; and the connecting piece is connected with a motor through the coupler and is driven by the motor to rotate, and the box body is provided with an opening in one side of the free state in the axial direction of the spiral pieces for baked food to enter and exit. According to the automatic baking machine and the control method thereof, the sold baked food can be directly pushed out from the heating rollers, the transfer path is shortened, and the food safety of the baked food can be guaranteed; the food baking equipment is simplified, and the space occupied by the baking machine is greatly shortened; and the automatic baking machine is convenient to clean.

Owner:北京亦香云科技有限公司

Rice crust production equipment

PendingCN111436466ASpread evenlyGreat tasteBaking cavity cleaningBaked articles handlingFood industryEngineering

The invention belongs to the technical field of food industry, and particularly relates to rice crust production equipment. A displacement path of a conveying belt is sequentially provided with a cloth section, a cutting section, a baking section and a cleaning section; the baking section is provided with a furnace body extending in the conveying direction of the conveying belt; the furnace body is internally provided with a heating unit in the extending direction of the furnace body; and the middle section of the furnace body is internally provided with a spraying unit. The combined arrangement of various functional units in the equipment changes baking processes and conditions of materials, so that a product greatly improved in shape and taste is obtained.

Owner:安徽云岭星火旅游发展有限公司

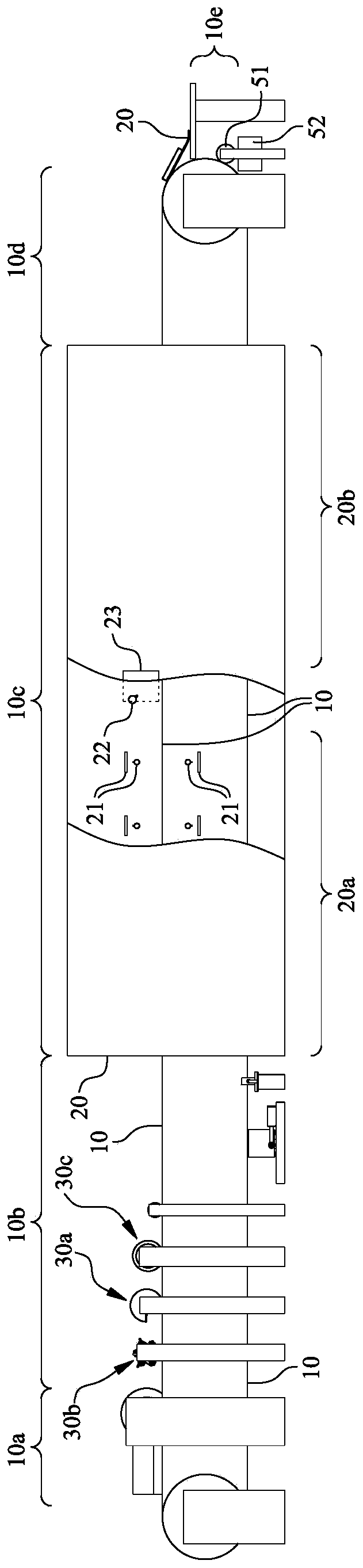

Automatic processing equipment for food baking oven and automatic processing method for baking oven

ActiveCN109392967BLow degree of automationGood degree of automationBaking cavity cleaningProcess engineeringIndustrial engineering

Owner:青岛高恩机械有限公司

Double-station oil-water separation fryer and using method thereof

ActiveCN112425614AIncrease diversityImprove adaptabilityBaking cavity cleaningFood processingThermodynamicsOil water

The invention discloses a double-station oil-water separation fryer and a using method thereof. The double-station oil-water separation fryer comprises a main rack and a double-station fryer body, a turnover heating mechanism is arranged at the top of the double-station fryer body, the double-station fryer body comprises an upper-layer oil storage cavity and a lower-layer water storage cavity, andthe upper-layer oil storage cavity forms two frying chambers; a frying basket is arranged in the frying chambers and connected with a lifting mechanism penetrating through the top of the double-station fryer. The side edge of the frying chambers is connected with an oil discharging mechanism through an oil discharging hole, and the conical bottom of the lower-layer water storage cavity is connected with a slag discharging and flushing mechanism through a water discharging hole. Through the double-station design, different foods can be cooked at the same time, the oil temperature is independently controlled in a partitioned mode, the lifting mechanism can control the cooking time at different oil temperatures, and the diversification and taste adaptability of the foods are greatly improved; oil-water separation is achieved through the oil discharge mechanism and the residue discharge cleaning mechanism, automatic residue discharge can be conducted, and the reusability of edible oil andthe sanitation degree of food are greatly improved.

Owner:JIUJIANG UNIVERSITY

Multizone Oven with Improved Cleaning Distribution

PendingUS20210120825A1Enlarged cavityEasy to cleanBaking cavity cleaningSelf-cleaning stoves/rangesThermodynamicsMechanical engineering

Owner:ALTO SHAAM

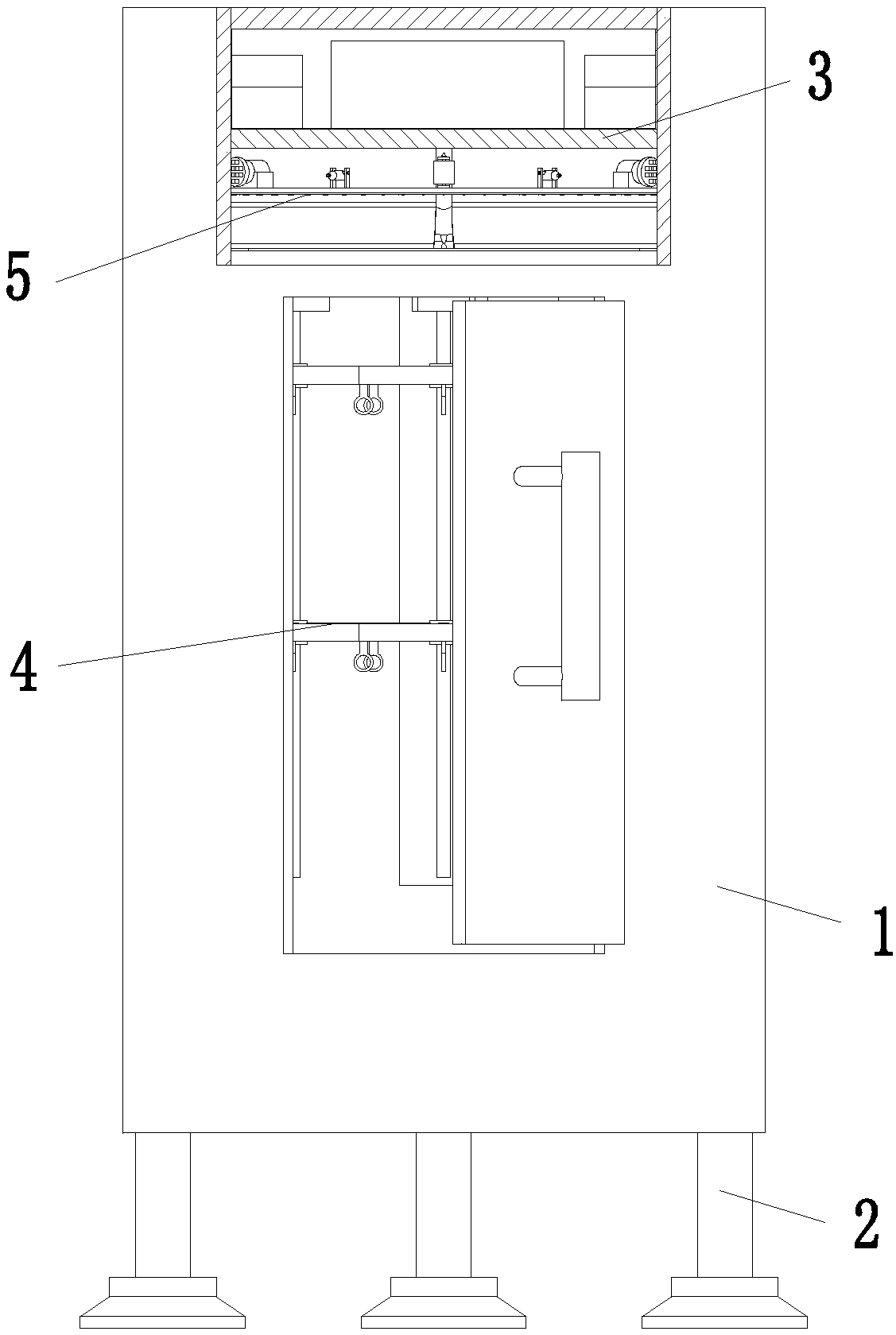

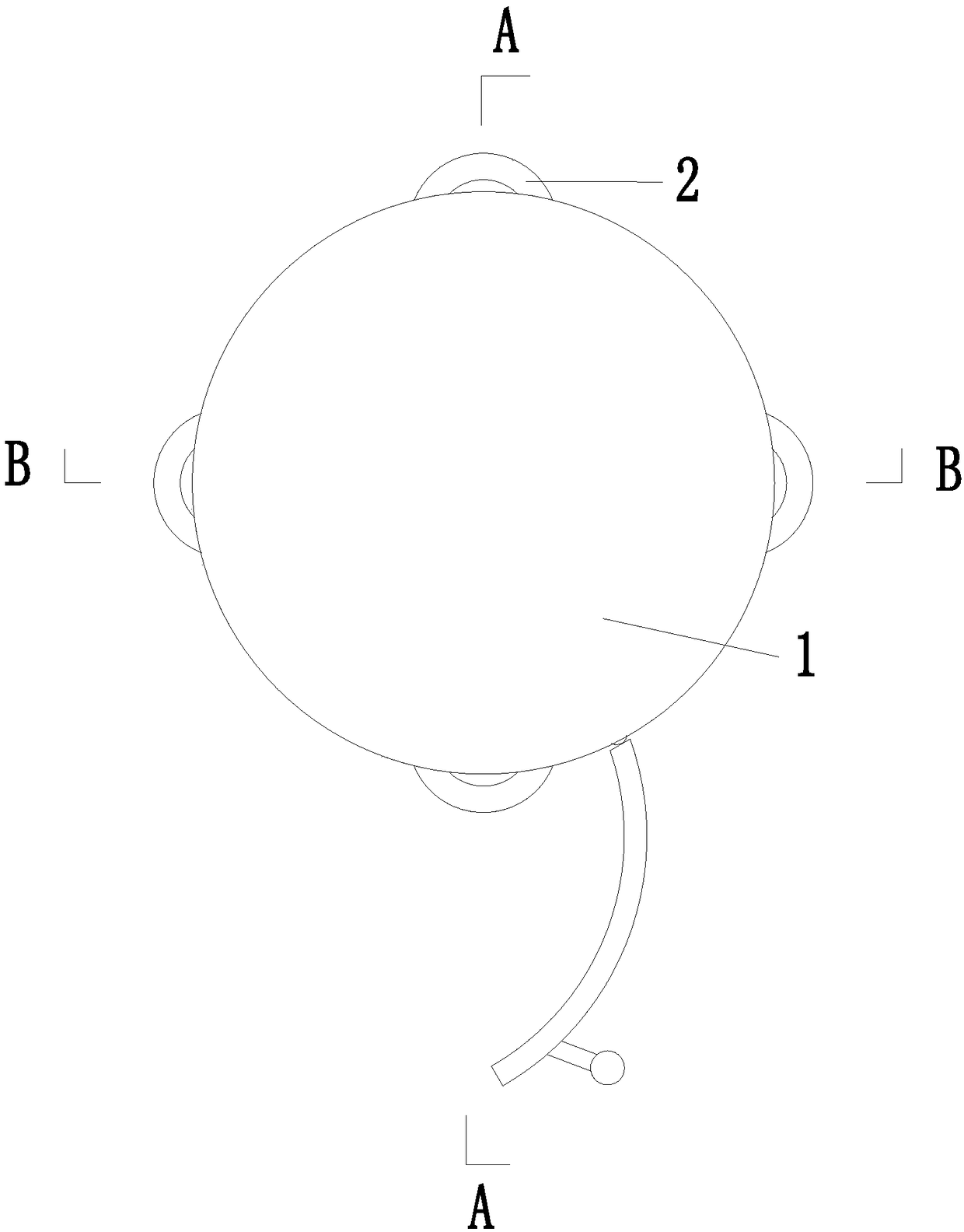

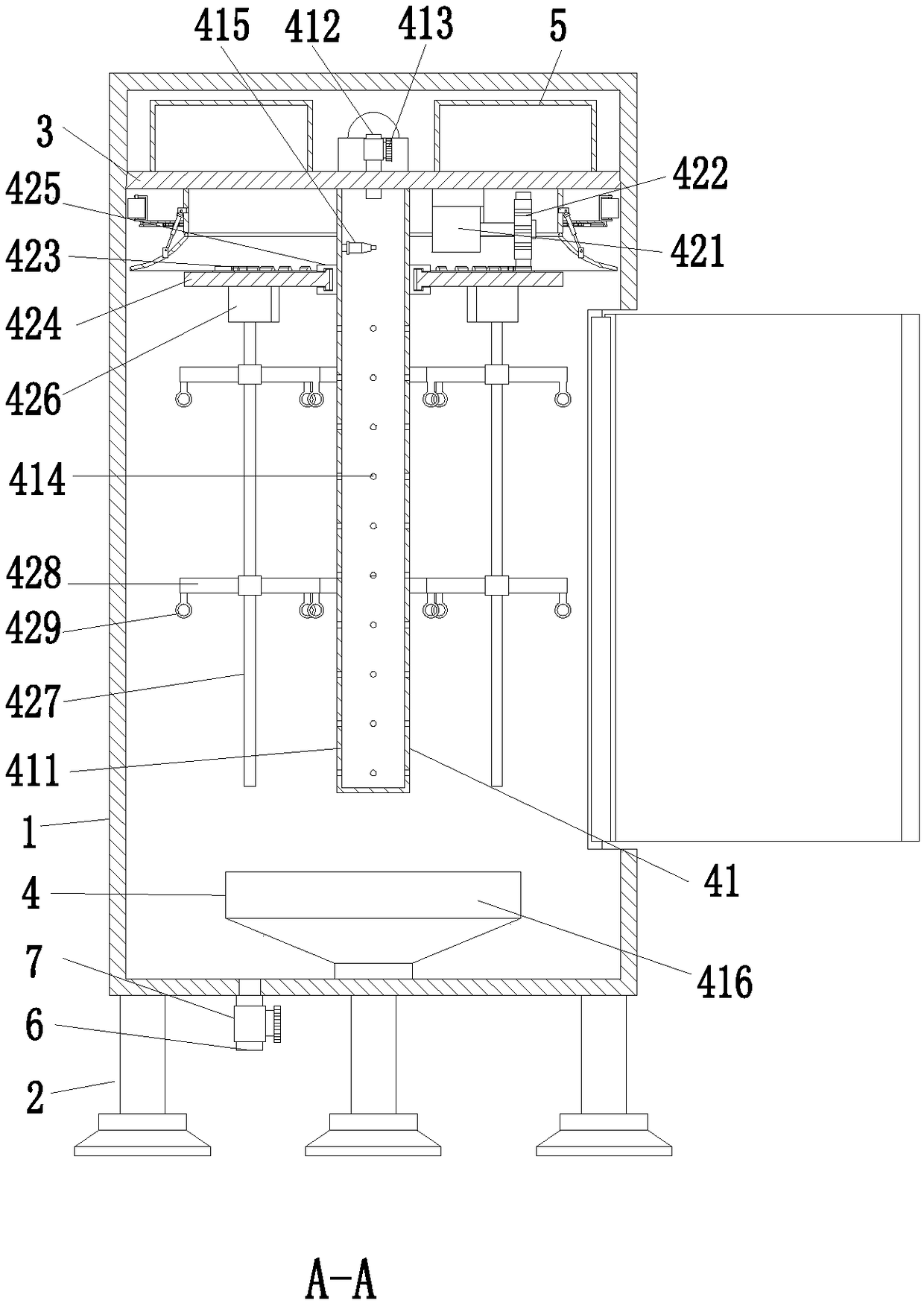

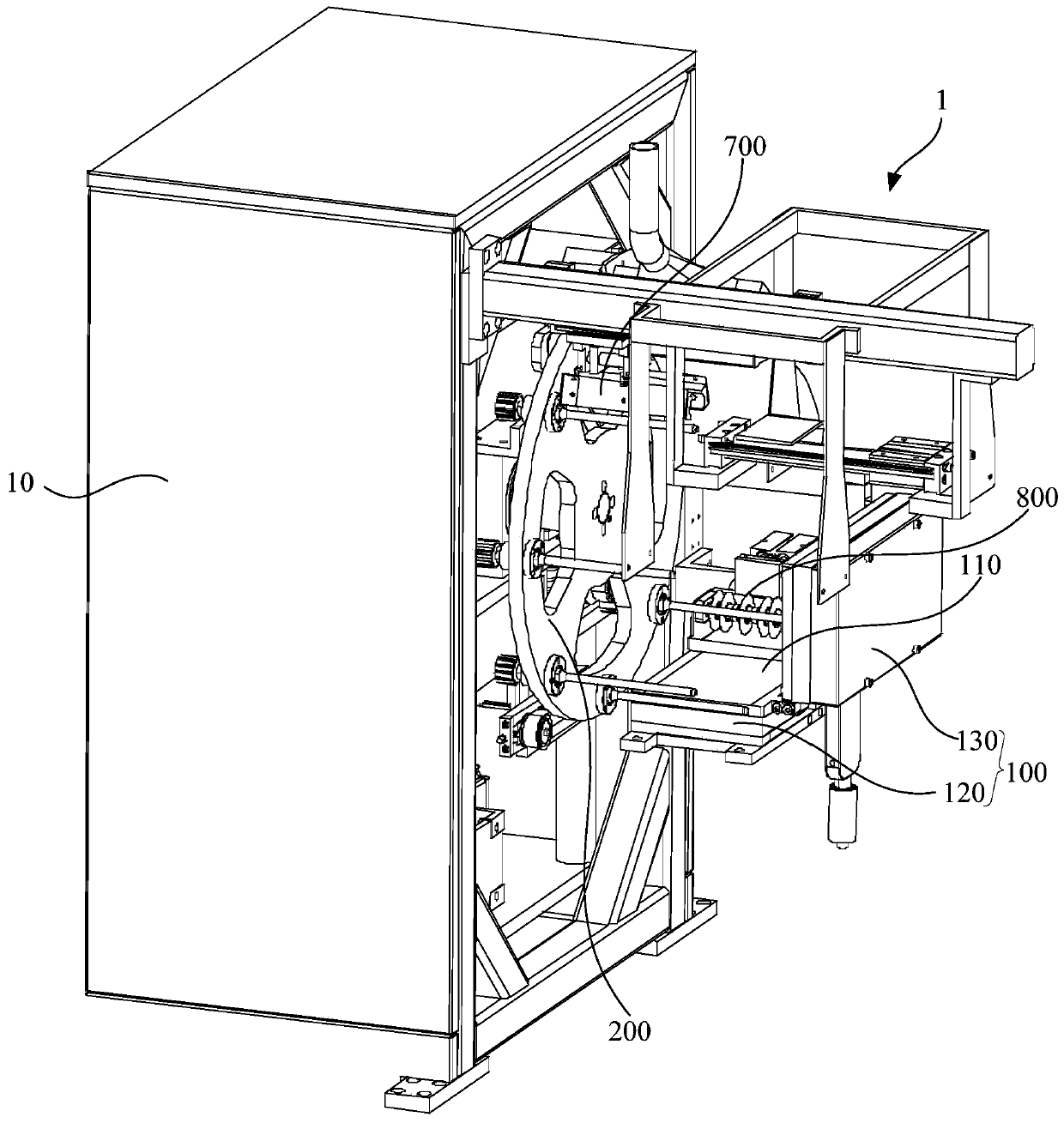

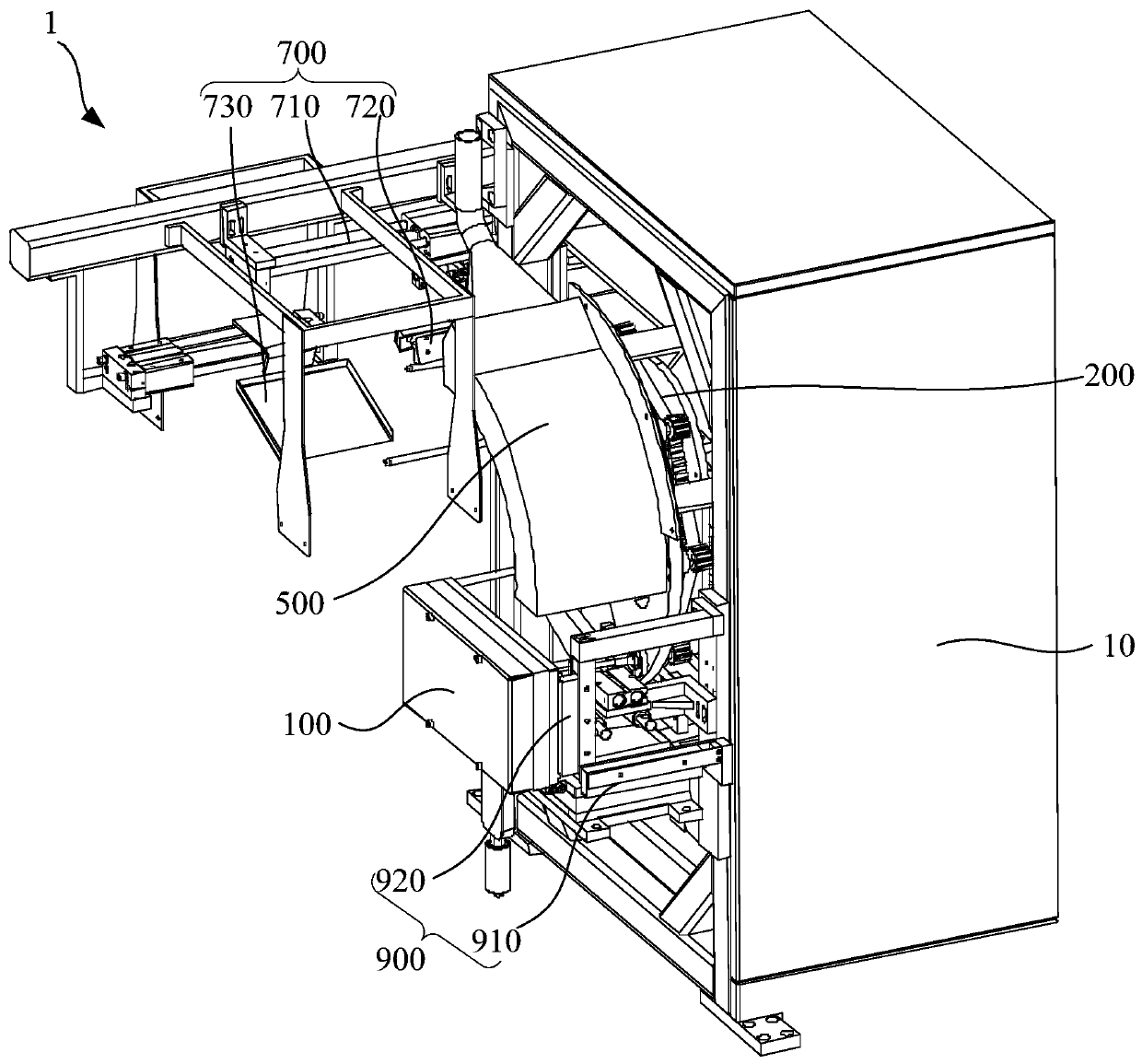

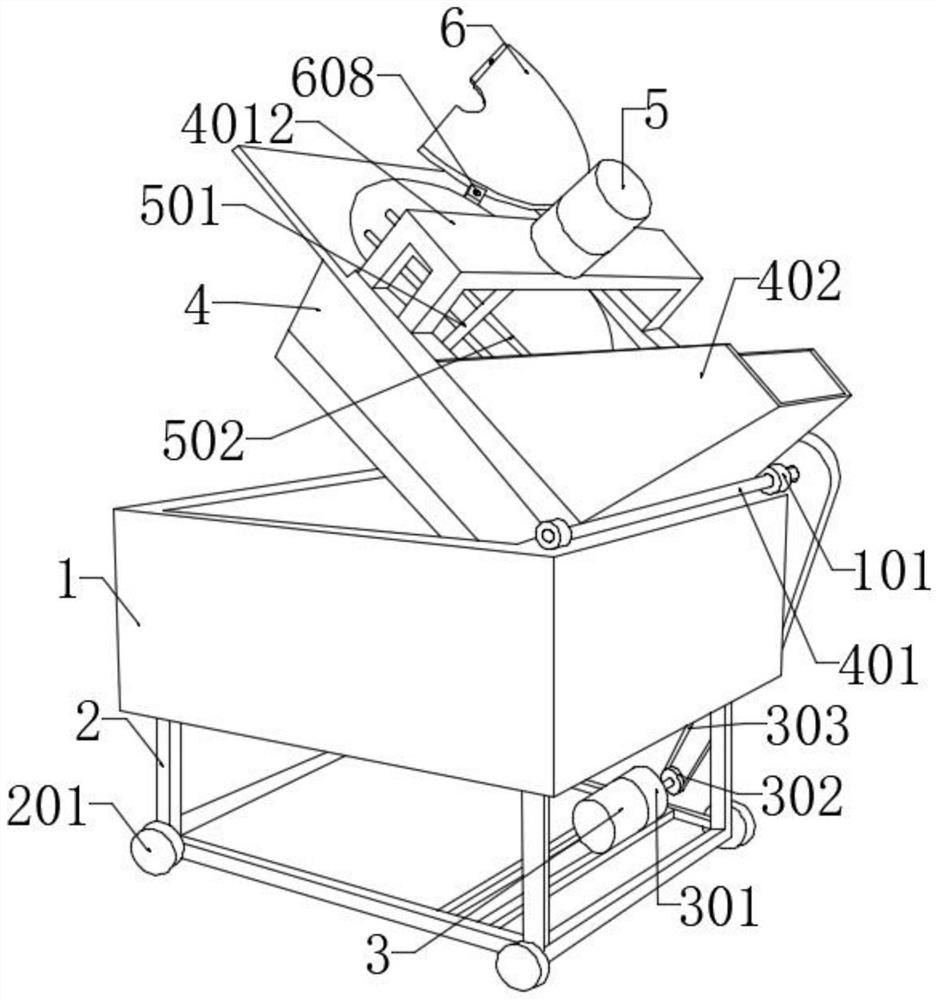

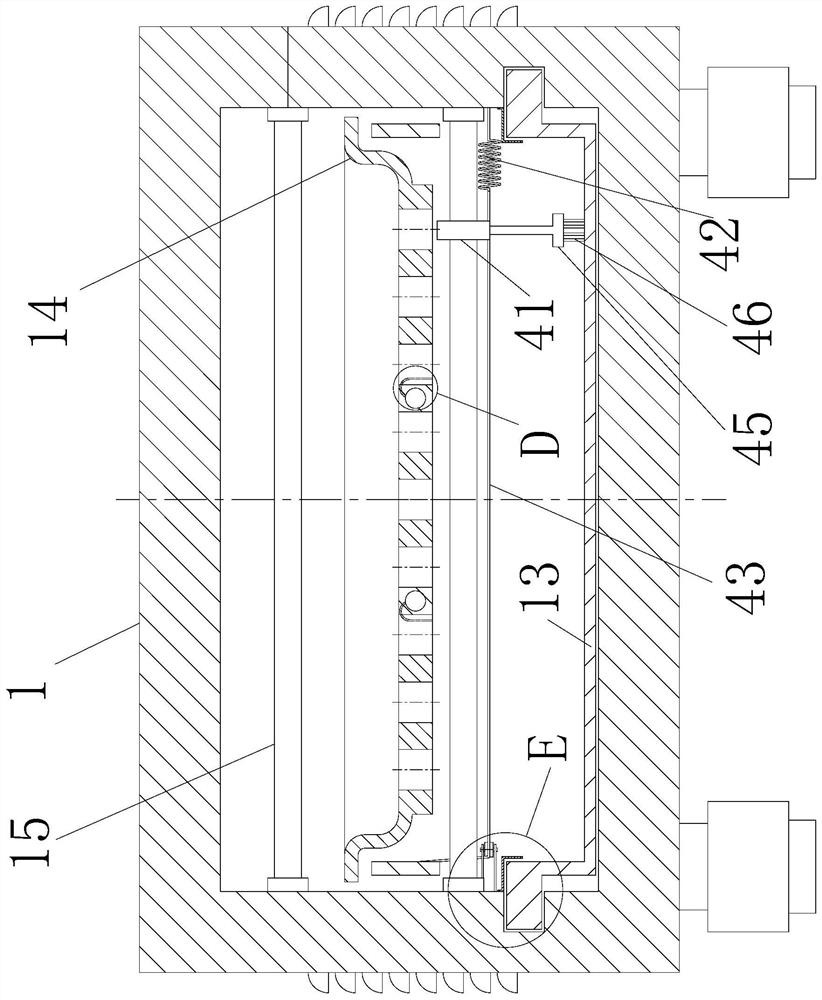

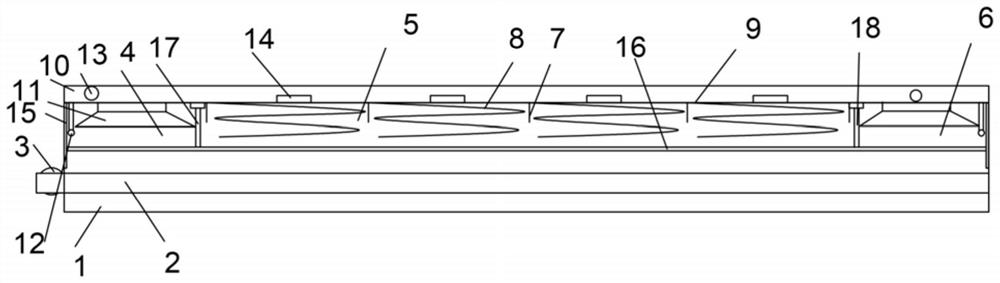

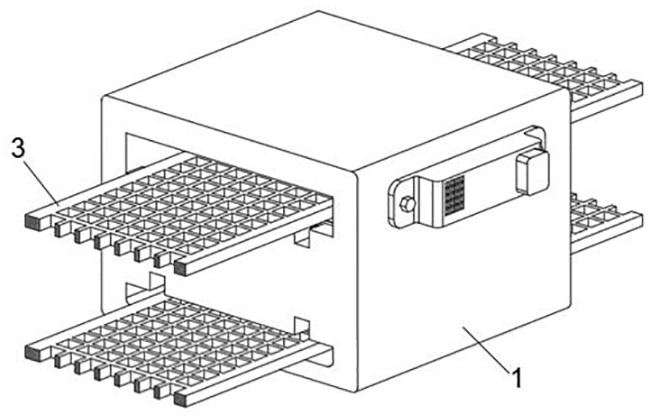

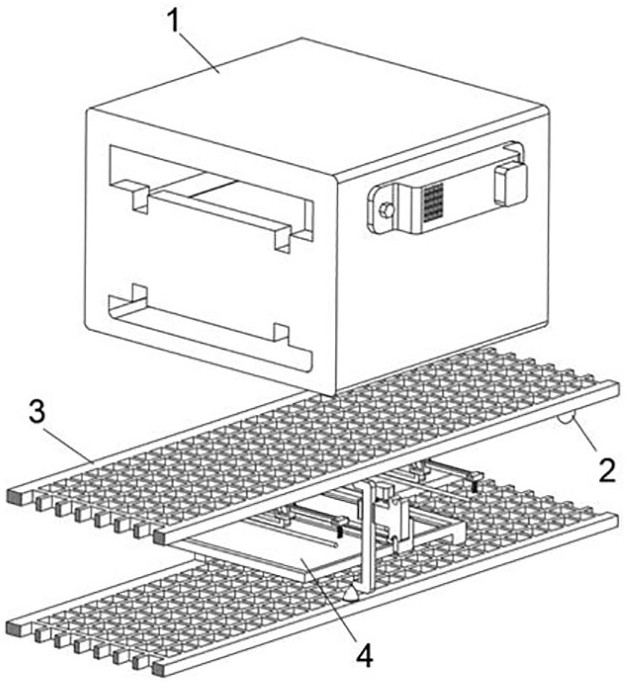

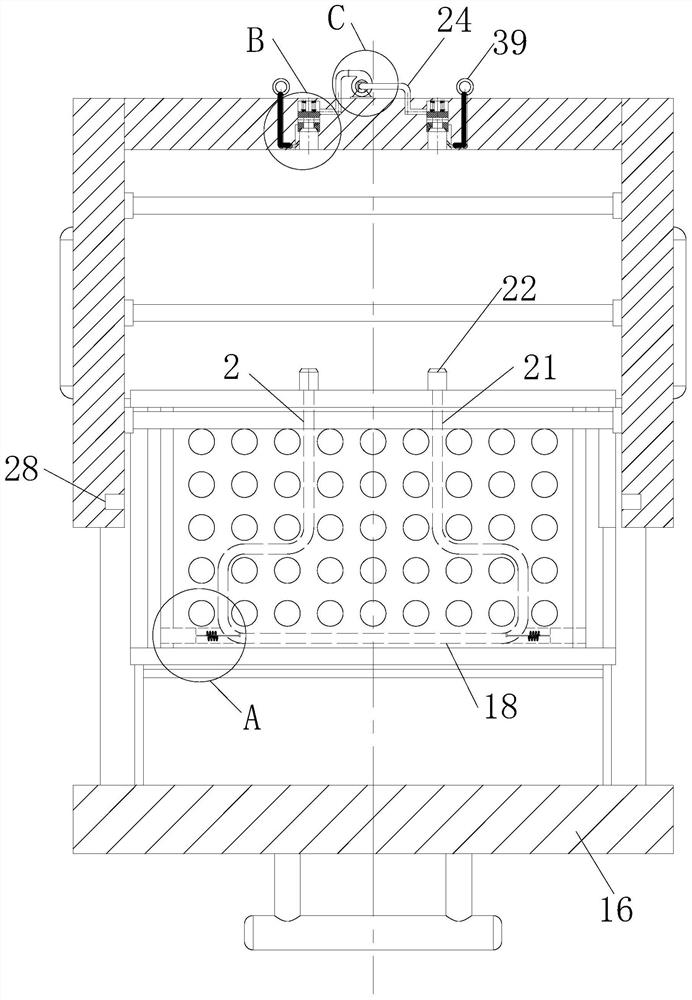

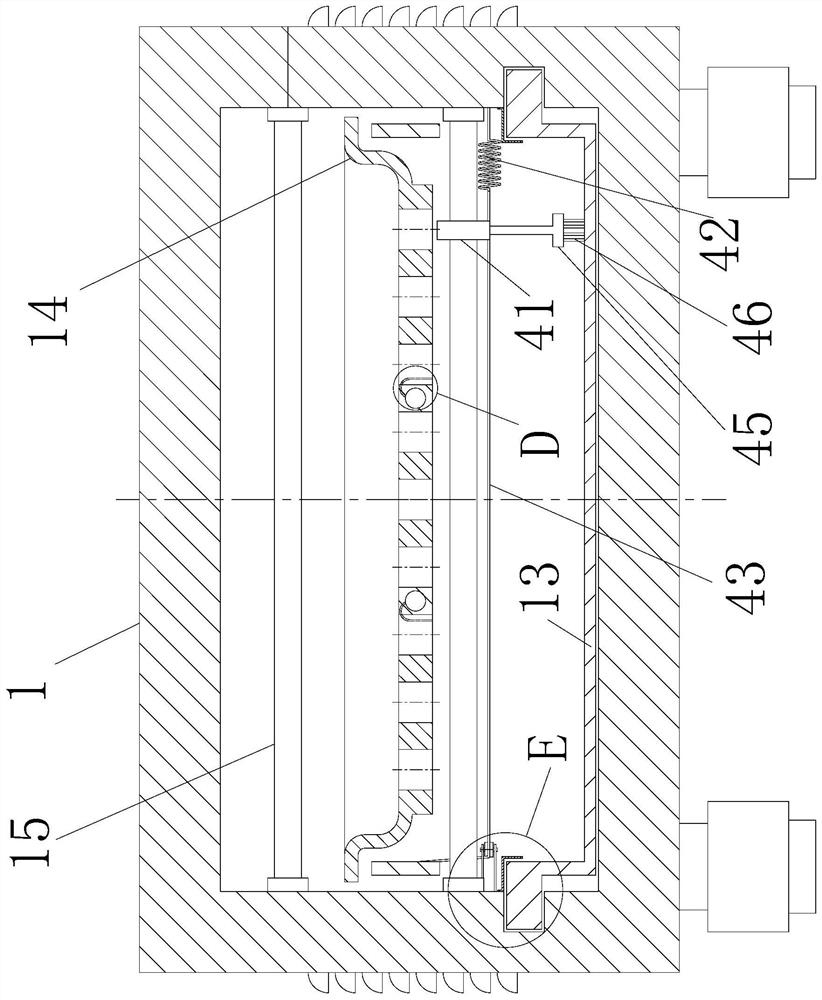

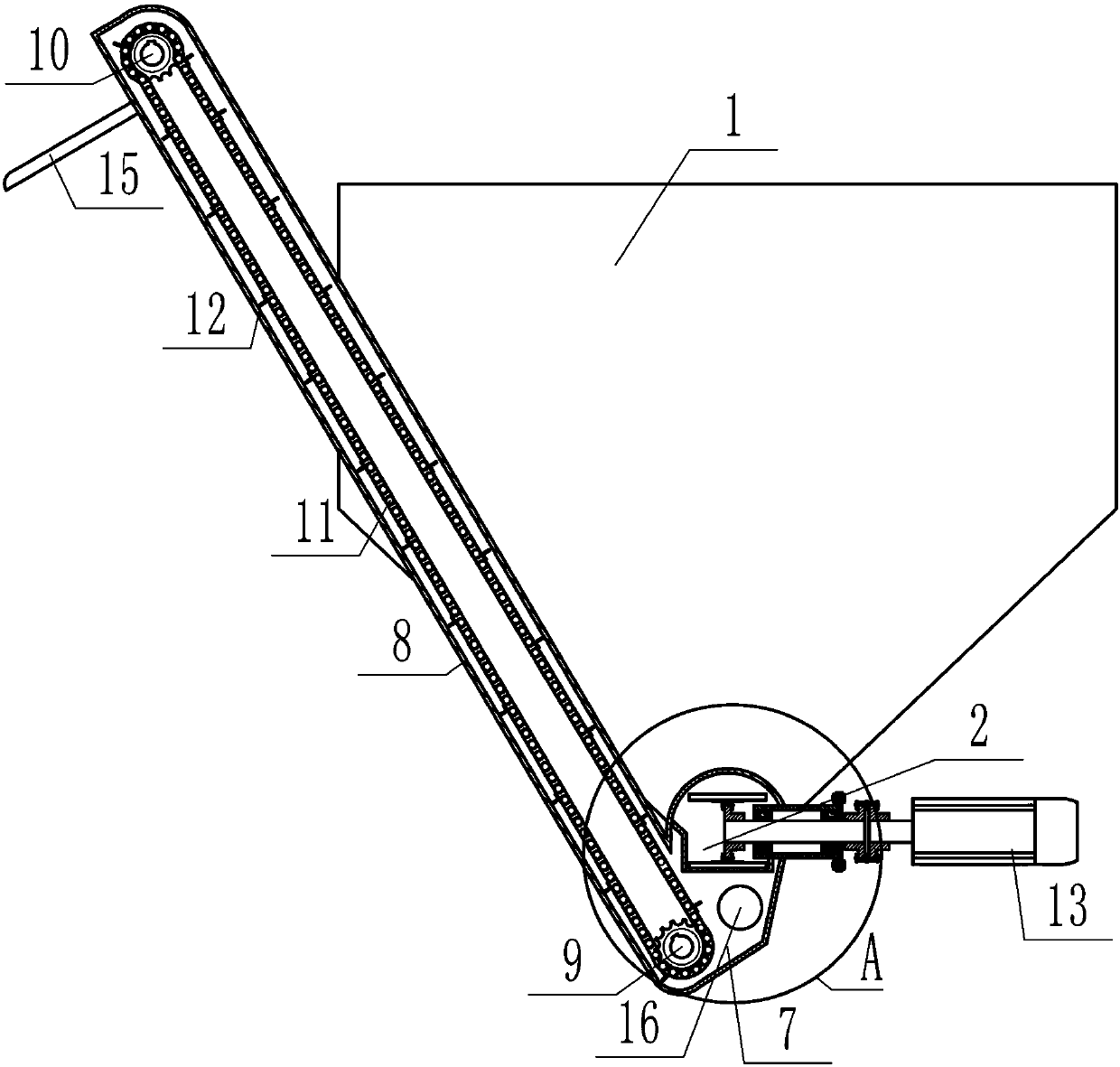

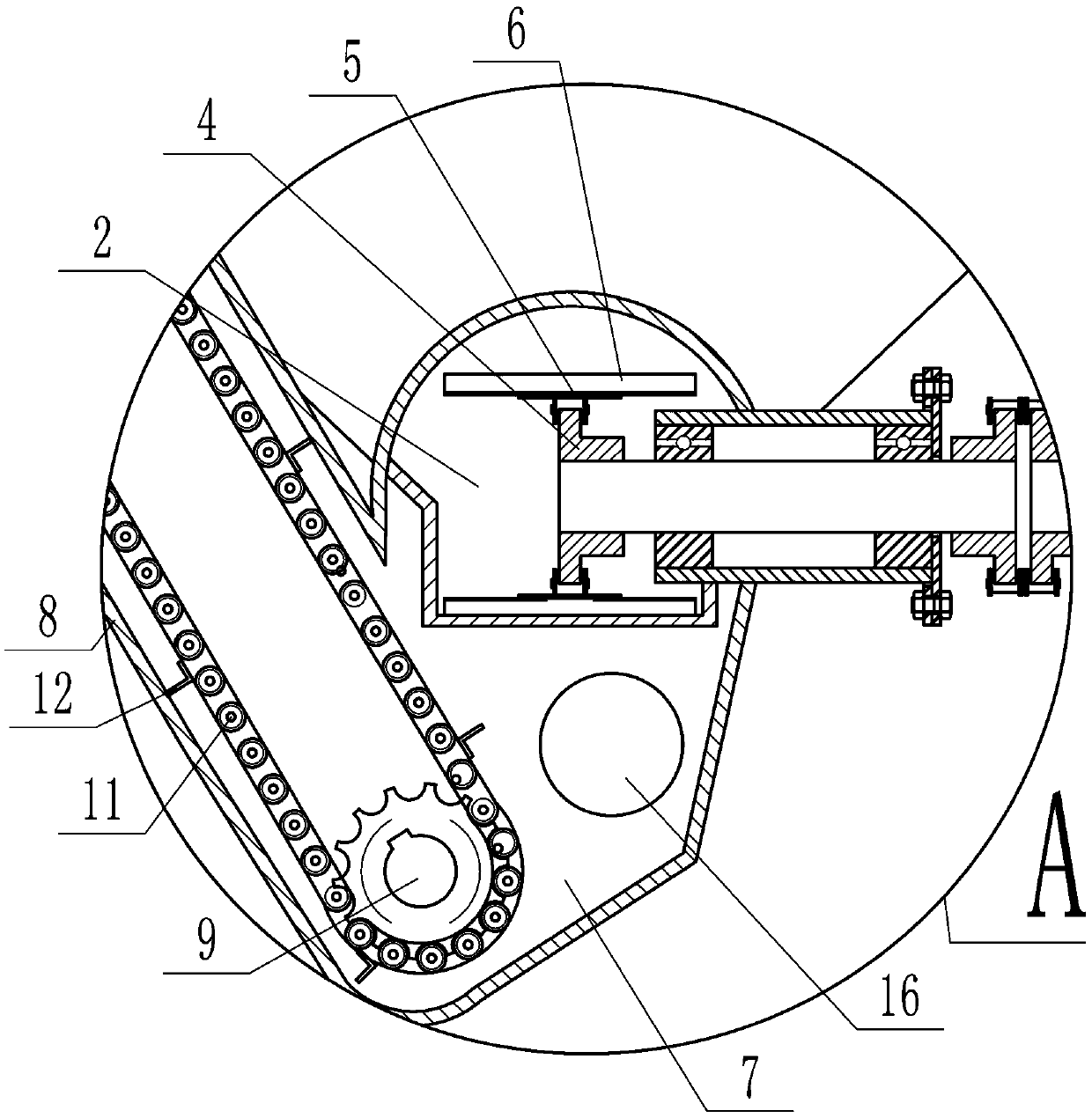

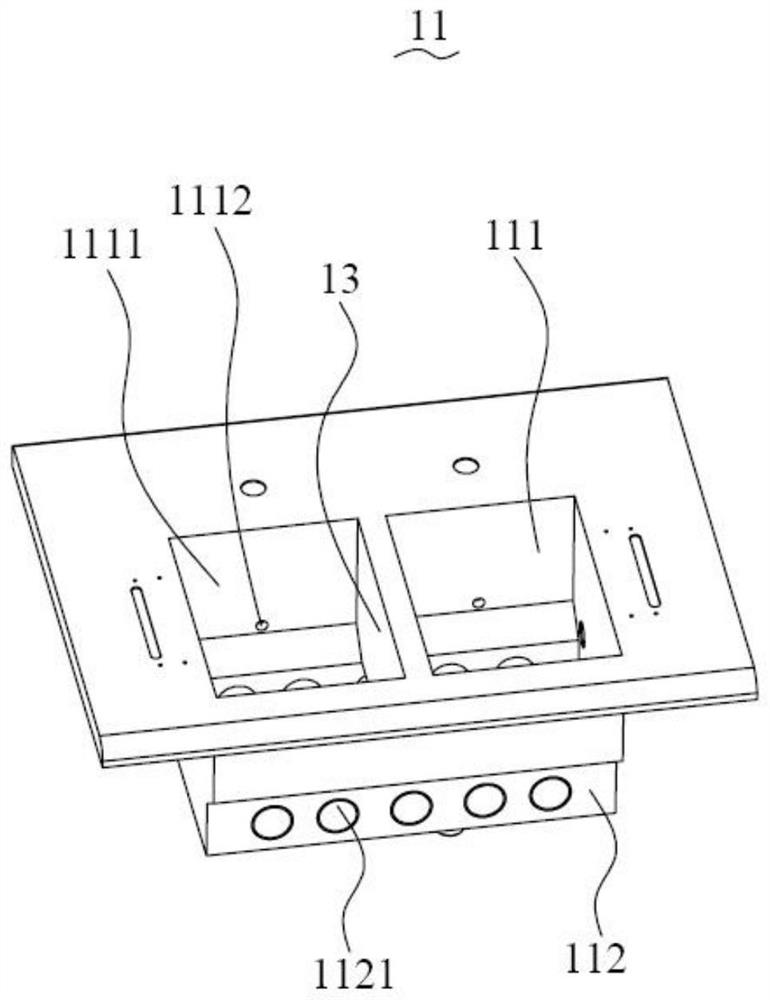

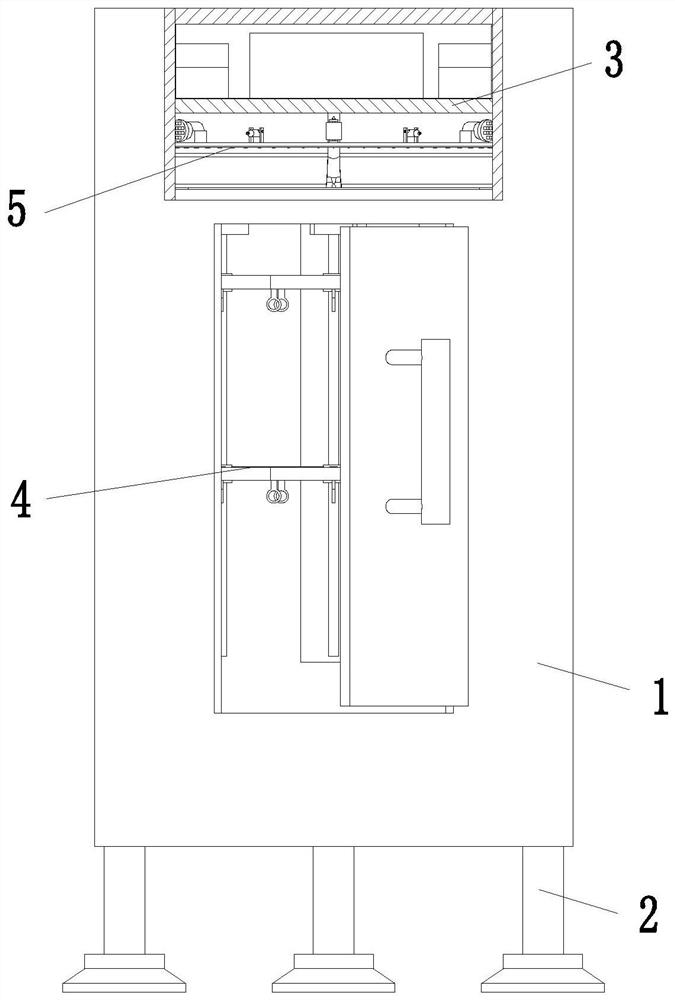

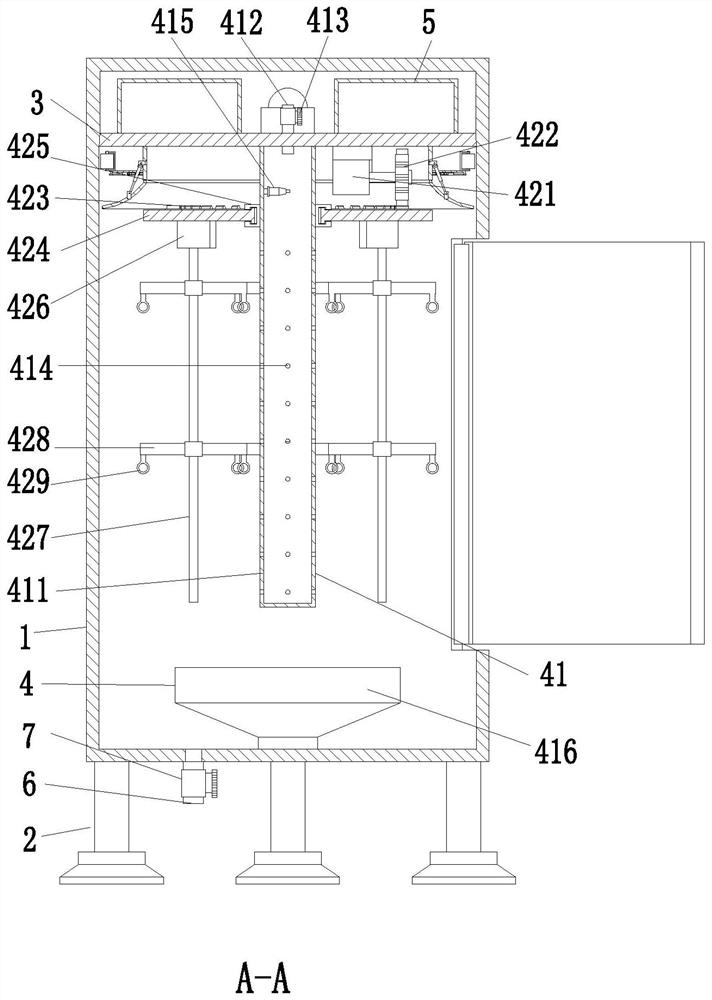

Automated processing equipment used for food baking oven and automatic processing method of baking oven

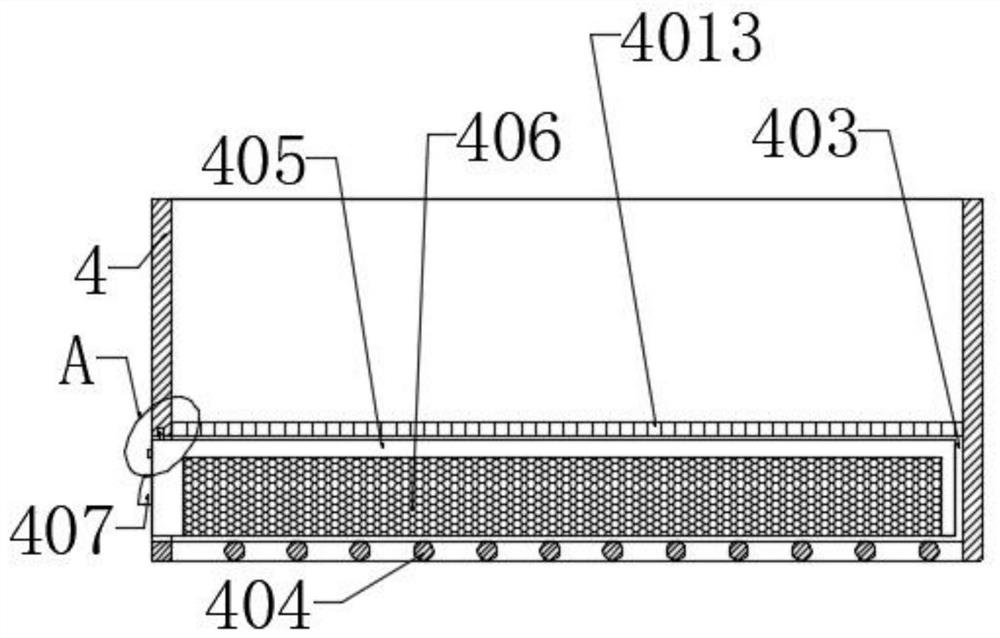

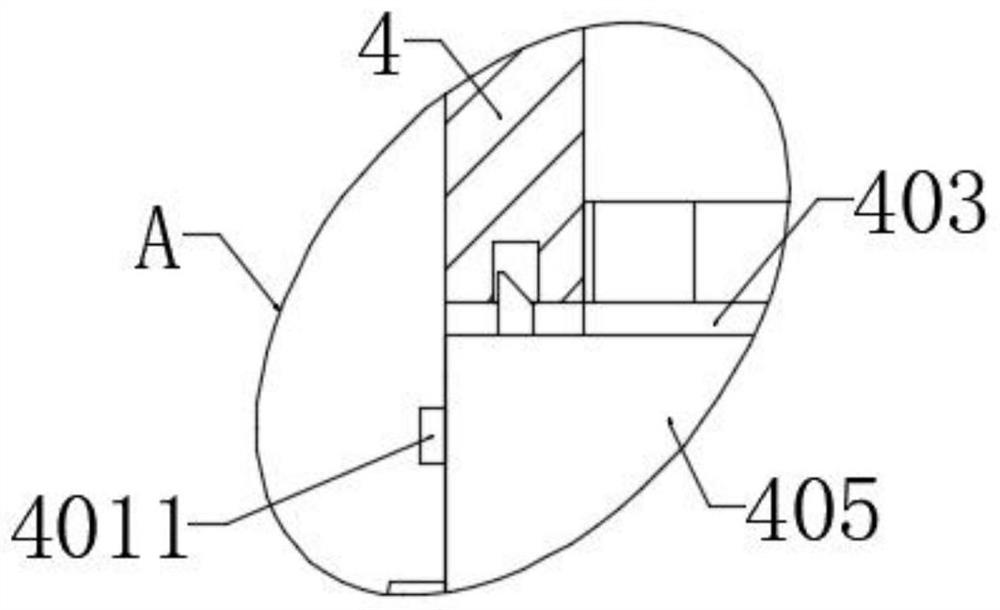

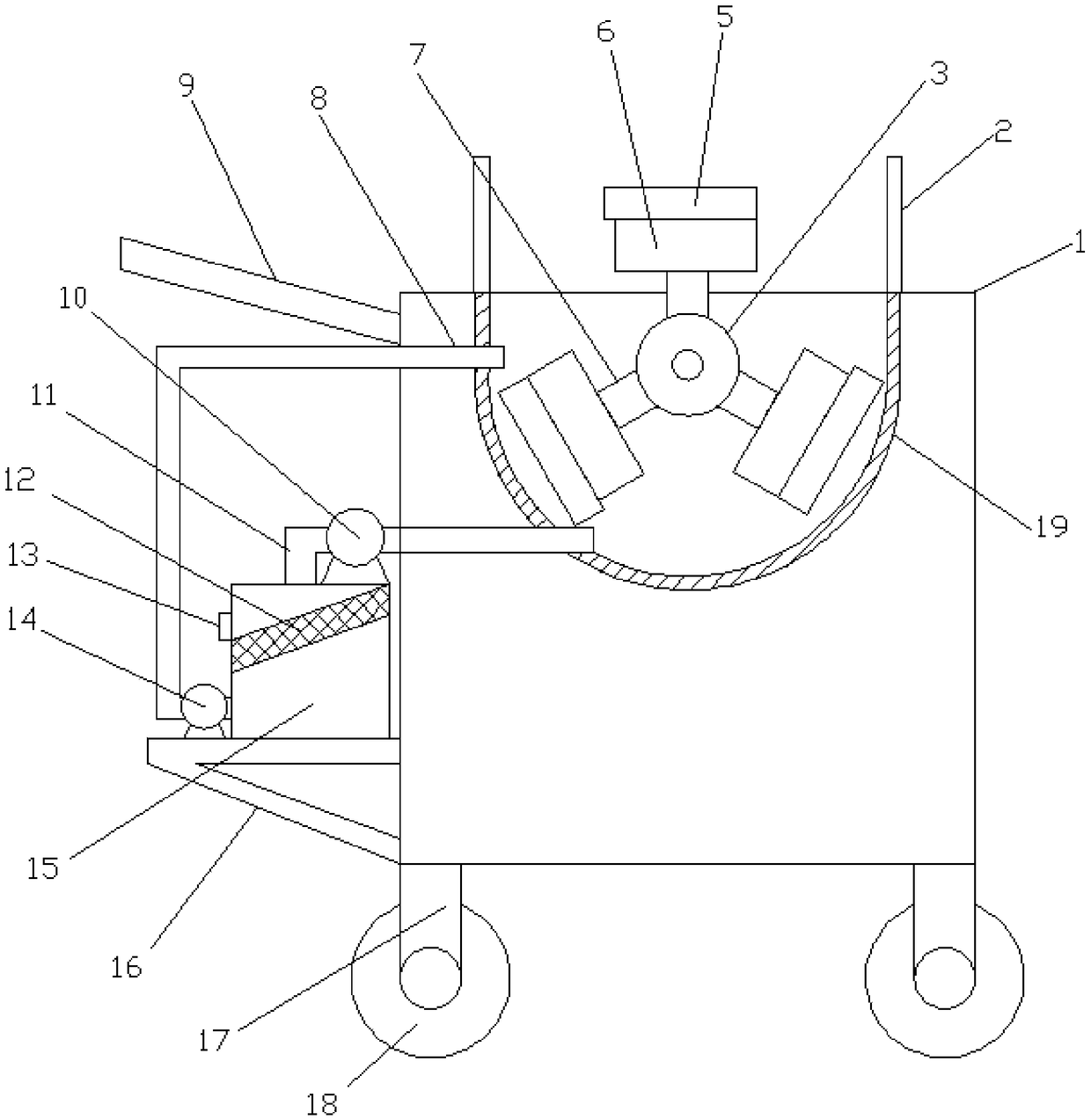

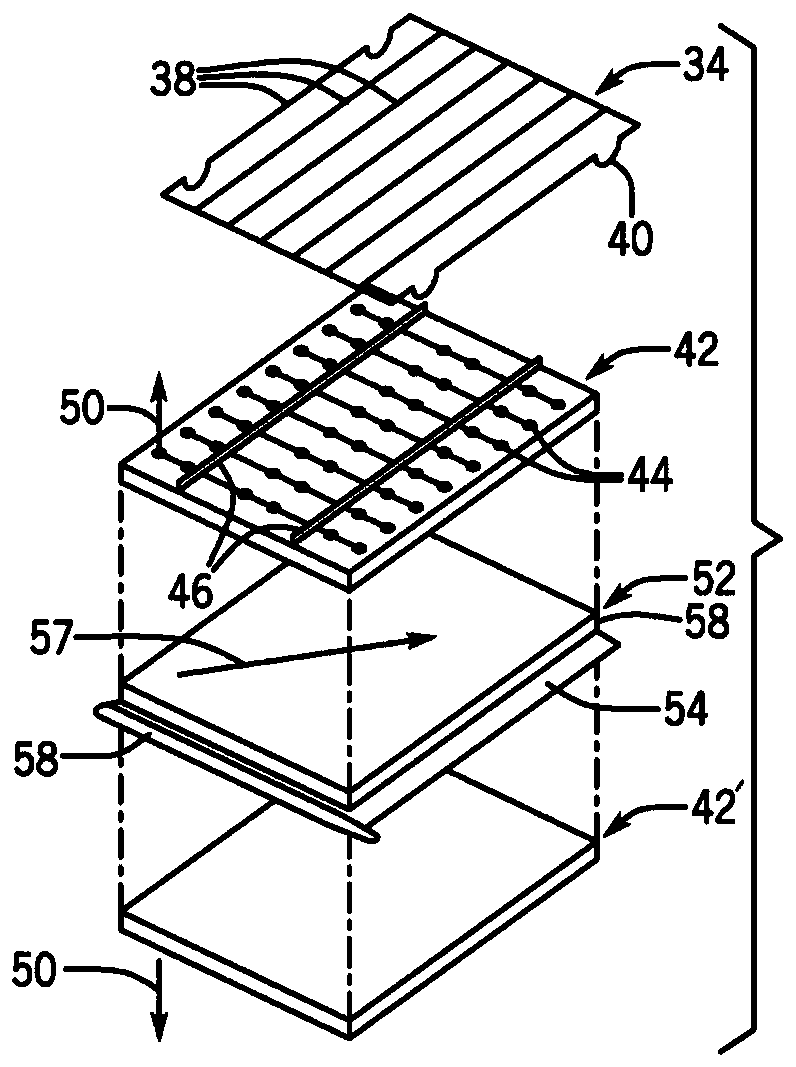

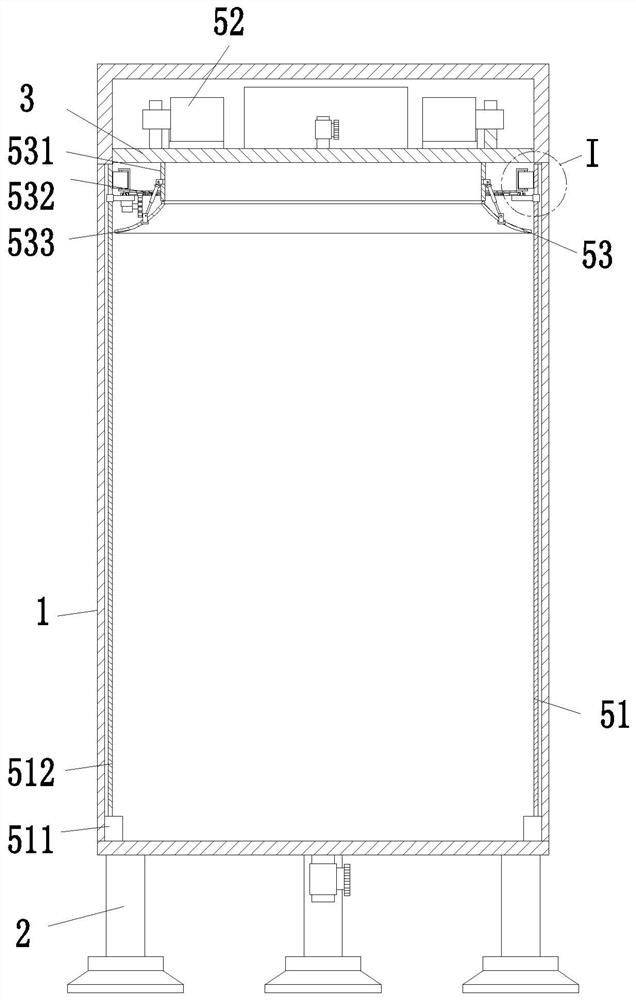

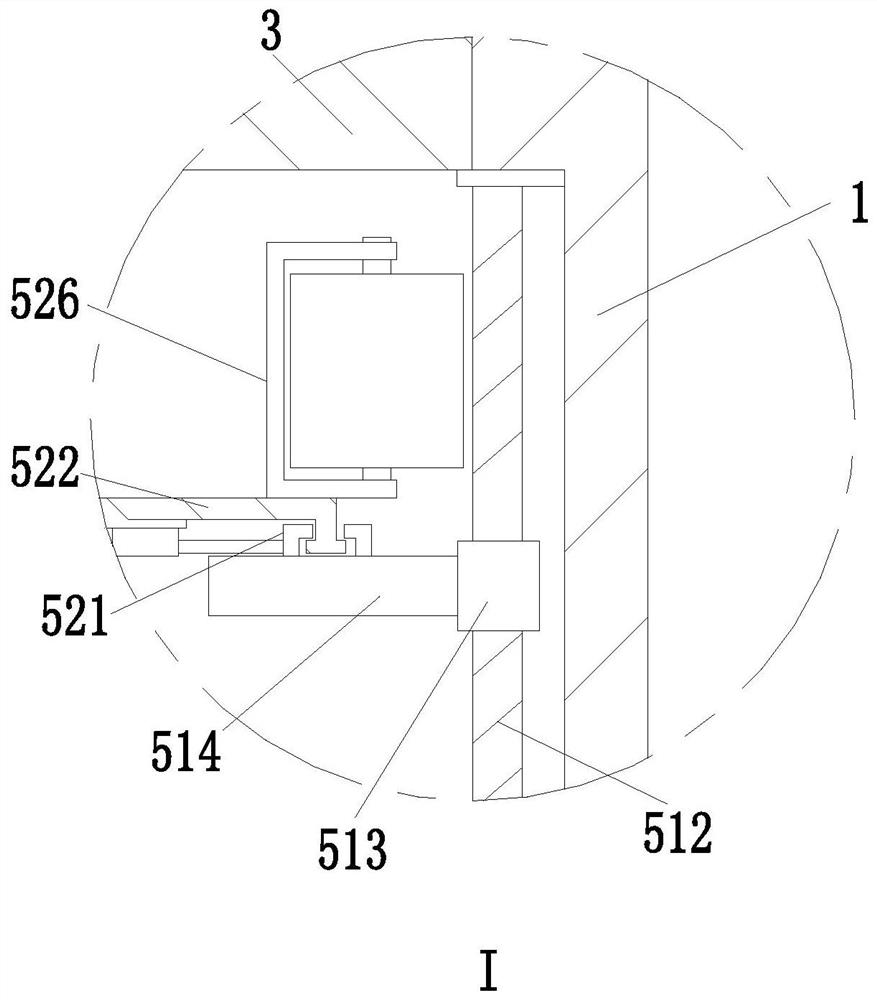

ActiveCN109392967AEfficient removalAvoid damageBaking cavity cleaningAutomatic processingProcess engineering

The invention relates to automated processing equipment used for food baking oven and an automatic processing method of baking oven. The automated processing equipment used for the food baking oven comprises a baking oven body, support legs, a clapboard and a cleaning device; the support legs are evenly mounted at the lower end of the outer side of the baking oven body; the clapboard is mounted atthe upper end of the interior of the baking oven body; and the cleaning device is mounted at the lower end of the clapboard. The automated processing equipment used for the food baking oven is capable of solving the problems of low automation level, poor manual washing effect, low washing efficiency, poor protection effect, complex operation, poor stability, high labor intensity and the like dueto common manual washing caused by unable washing of inner walls of baking ovens during baking processes of existing food baking ovens; namely, automatic washing function on the inner walls of the baking oven is realized. The automated processing equipment used for the food baking oven is capable of automatically performing washing on the inner walls of the baking oven, so that, high automation level is realized with good washing effect and high washing efficiency achieved; moreover, good protection effect is also achieved so as to have service life prolonged. The automated processing equipment used for the food baking oven has the advantages of being simple in operation, good in stability, low in labor intensity and so on.

Owner:青岛高恩机械有限公司

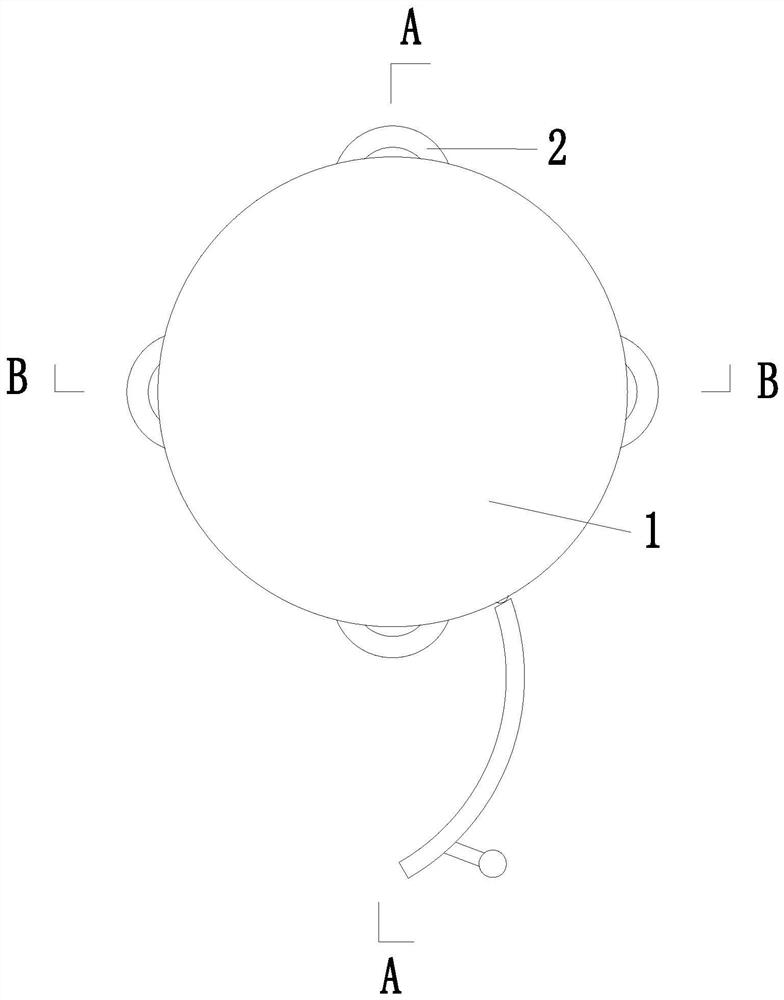

Rotary furnace convenient for cleaning slag

PendingCN112715583AEasy to cleanEasy to concentrate and dropBaking cavity cleaningSlagElectric machine

The invention discloses a rotary furnace convenient for cleaning slag. The rotary furnace comprises a rotary furnace body, a fixed box body is fixedly connected to the lower surface of the rotary furnace body, rotating rods are fixedly connected to the two sides of a fixed part, a fixed vertical rod is fixedly connected to one end of each rotating rod, and a slag scraper is fixedly connected to one side of each fixed vertical rod; and a slag falling hole is formed between the rotary furnace body and the fixed box body, and a slag guide plate is fixedly connected to the interior of the fixed box body. Through the arrangement of the scraping plates and the cleaning brushs, when slag on the inner wall of the rotary furnace body needs to be cleaned, the second driving motor is started, and the second driving motor drives the rotating rods on the two sides of the fixed vertical rods to rotate, so that the slag scraper on one side of the fixed vertical rod rotationally scrapes the slag on the inner wall of the rotary furnace body; the supporting rod drives the cleaning brushs to clean the inner wall obtained after slag scraping, the inner wall of the rotary furnace body is further cleaned, and the cleaning effect is better and more thorough.

Owner:内蒙古东岳金峰氟化工有限公司

An intelligent food oven

ActiveCN109392968BEvenly bakedGood degree of automationBaking cavity cleaningProcess engineeringMechanical engineering

The invention relates to an intelligent food baking oven, which includes a food baking oven body, legs, partitions, a heating and rotating device and a cleaning device. Outriggers are evenly installed on the lower end of the food baking oven body. A partition is installed at the upper end of the furnace body, a heating and rotating device is installed in the middle of the lower end of the partition, and a cleaning device is installed outside the lower end of the partition. The present invention can solve the problems of uneven baking, poor baking effect and prone to scorching in the existing food baking oven, and the inability to clean the inner wall of the food baking oven after baking. Usually manual cleaning, low degree of automation, poor manual cleaning effect, slow cleaning efficiency, complicated operation, poor stability, high labor intensity, etc., can realize the automatic cleaning function of the inner wall of the food baking oven, with simple operation and stable performance Good, low labor intensity and other advantages.

Owner:BOAO ZONGHENG NETWORK TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com