Wine jar opening sealing material automatic material taking and material supplementing device and material supplementing method

A sealing material and automatic retrieving technology, which is applied in the directions of automatic packaging control, packaging, transportation packaging, etc., can solve the problems of shortage of skilled workers, decreased production efficiency, high labor intensity, etc., to improve the working environment, increase production efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1 An automatic feeding and refilling device for wine jar sealing materials, comprising:

[0037] The transfer unit includes a lifting mechanism, a telescopic mechanism and a rotating mechanism, wherein the rotating mechanism has a rotating part that can rotate around its own vertical central axis, and the rotating part is fixedly connected with the fixed part of the lifting mechanism to drive the lifting mechanism to synchronize the circumferential direction. Rotation; the lifting part of the lifting mechanism is connected with the installation end of the telescopic mechanism, which is used to drive the movement of the telescopic mechanism to adjust the position of the telescopic mechanism; the telescopic end of the telescopic mechanism is provided with a suction part, which is used to absorb the sealing material and transfer it ;

[0038] The feeding unit is set under the telescopic mechanism and has a lifting platform for placing the sealing material and dr...

Embodiment 2

[0047] Embodiment 2 The wine jar sealing material automatic refilling device according to the present invention includes a refilling unit, a transfer unit and a control unit, wherein the transfer unit includes a lifting mechanism, a telescopic mechanism and a rotating mechanism. Workers can place the required materials on the lifting platform, and when the suction cup is finished picking up the material, the feeding unit will automatically rise a certain distance to ensure that the material can be quickly picked up at the same position next time.

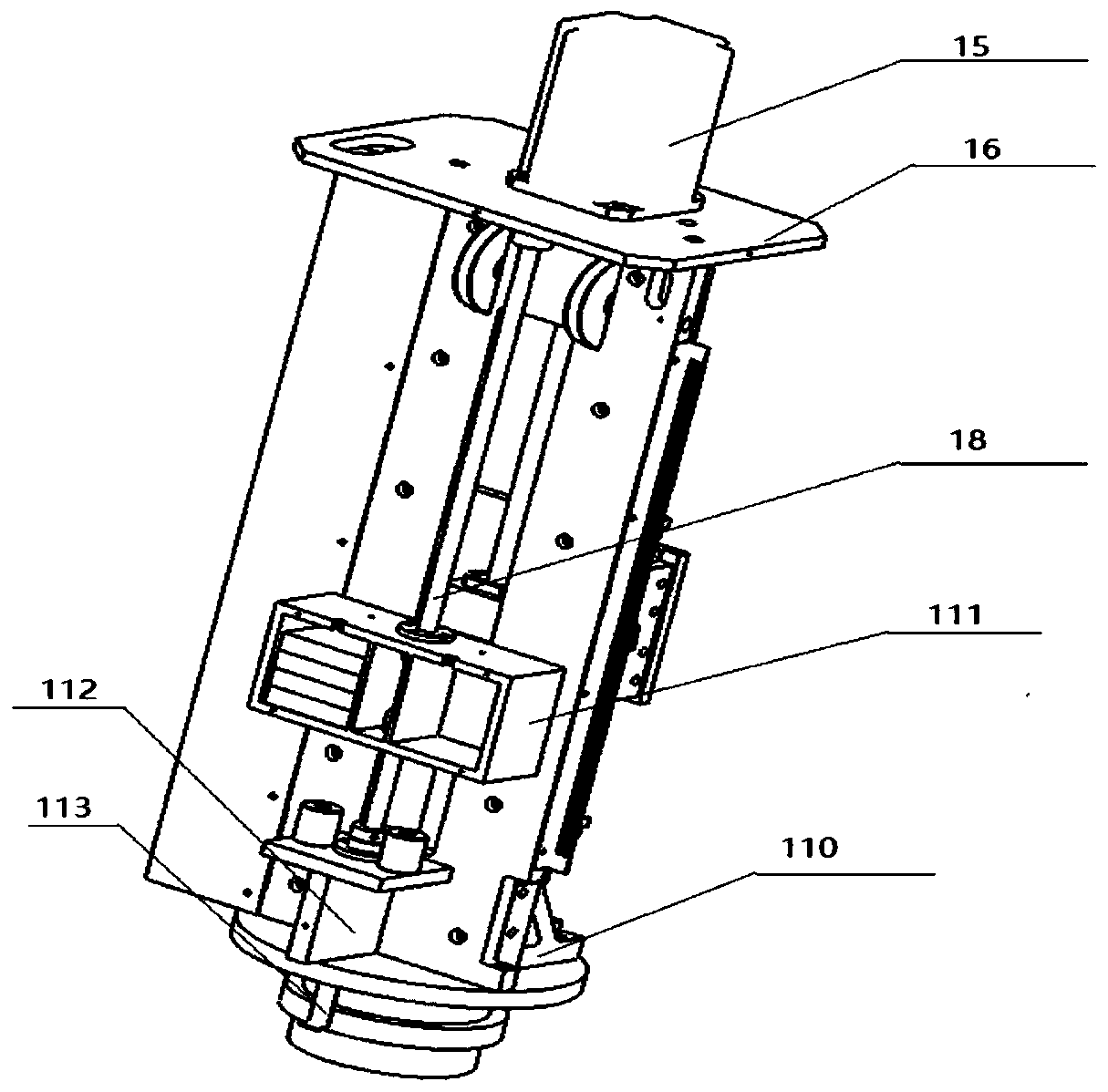

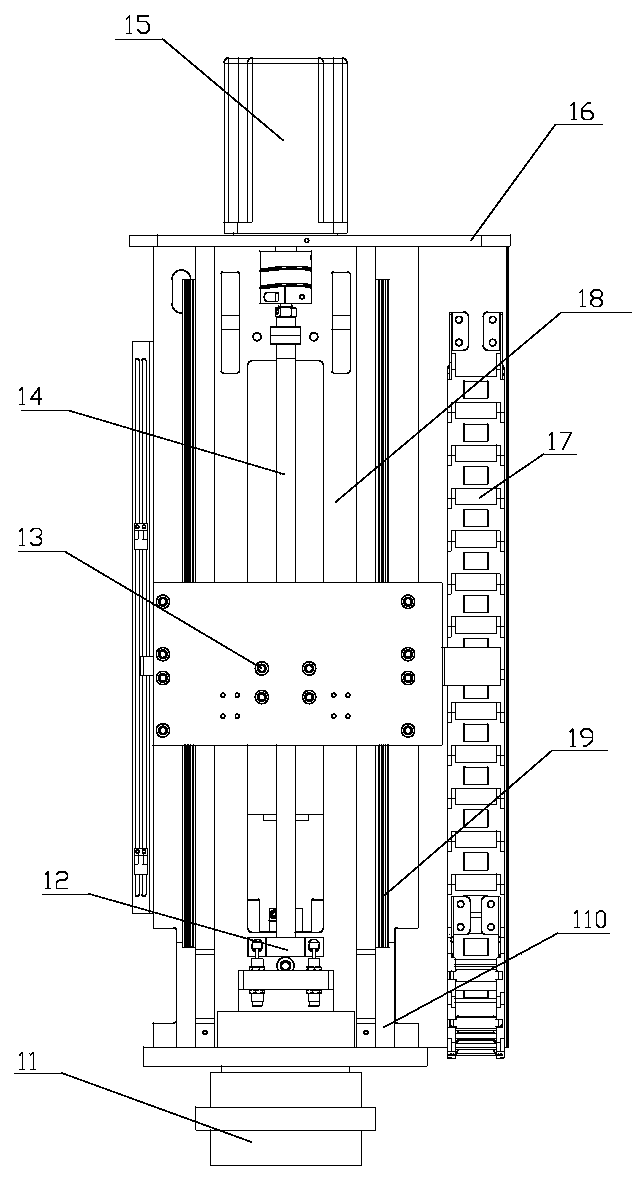

[0048] In the lifting mechanism: the fixed support base is fixed on the turntable 11, the screw rod holder 12 is arranged on the fixed support base 110, the vertical linear slide rail 19 is arranged on the side of the fixed support base, and the lifting slider on the linear slide rail 19 is fixed. Below the lifting plate 13, the screw mandrel 14 is connected with the motor 15 by a screw coupling, the lifting drive motor is fixed on t...

Embodiment 3

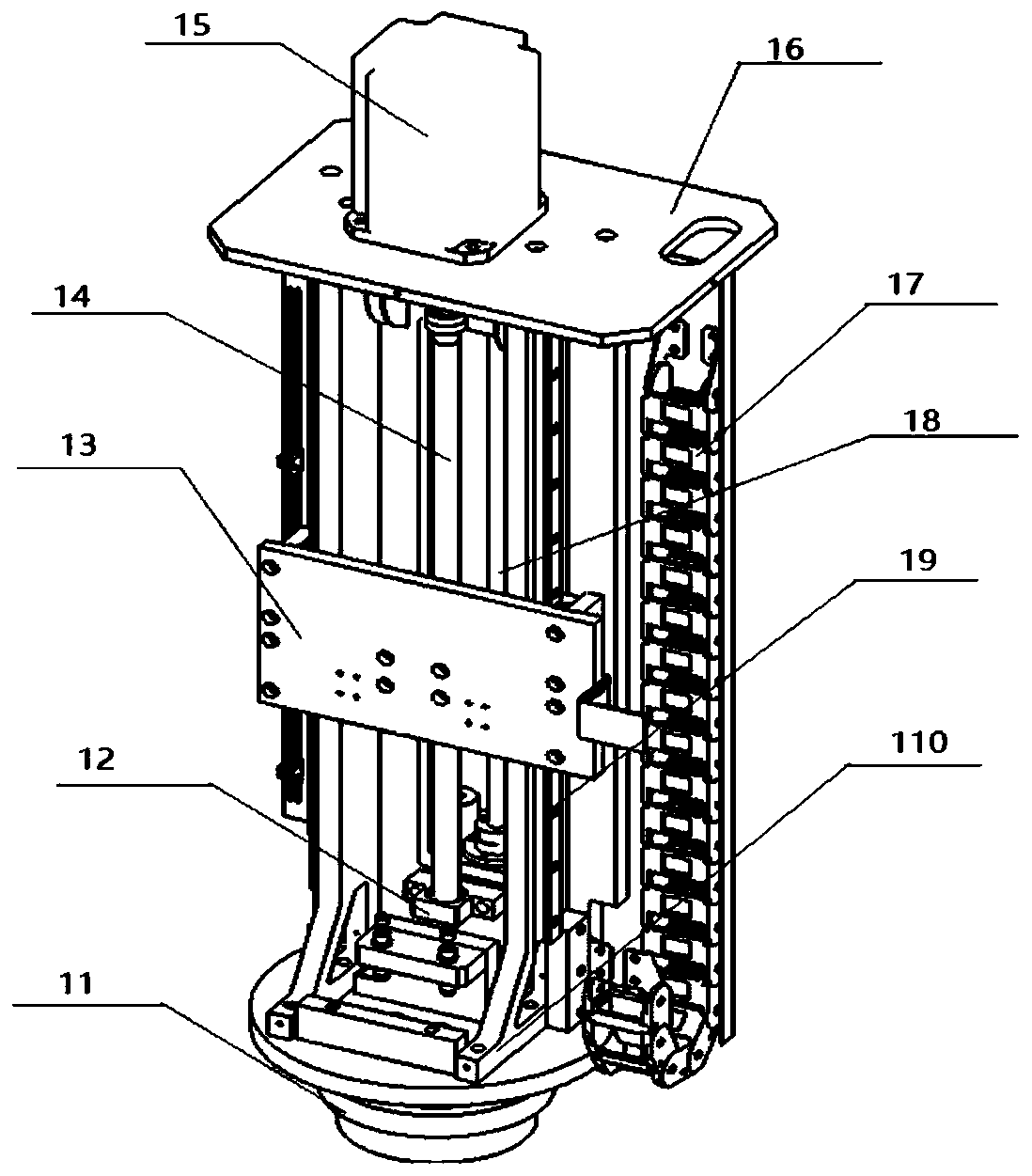

[0051] Embodiment 3 The device for automatically retrieving and refilling wine jar sealing materials according to the present invention, with reference to accompanying drawings 1-5b, the lifting mechanism 1 includes a turntable 11, a screw fixing seat 12, a lifting plate 13, a lifting screw 14, and a lifting drive motor 15 , upper base plate 16, crawler belt 17, polished rod fixing rod 18, linear slide rail 19, fixed support seat 110, guide rod support plate 111, crawler belt fixing plate 112, photoelectric switch 113; Synchronous wheel 23, connecting plate 24, telescopic motor 25, horizontal slider 26, bottom plate 27, horizontal slide rail 28, bearing fixing seat 29; material continuing unit 3 includes lifting frame 31, material discharging plate 32, linear bearing 33, outer frame 34, guide rod 35, electric push rod 36, guide fixed plate 37; Control unit comprises control box 4 and photoelectric switch 5.

[0052] The overall structure is that the lifting mechanism is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com